OEM-ALI FA/181/M, OMFA181MS, FA/181/T, OMFA181S, FA/182/T Brochure

...

FA spiral mixers

FX RB RVE spiral mixers

dough dividers and rounders

hot presses

preparation

equipment

spiral mixers

FA

8

spiral mixers

FX-RB-RVE

15

dough dividers and rounders

25

hot

presses

35

baking

solutions

40

Pizza Hub

42

spiral mixers

dough dividers and rounders

hot presses

2

Mixing, rounding, rolling out the bases: the art of pizza does

not just lie in the baking, but also and above all in the care and

quality you invest in every stage of the preparation.

It is important to choose reliable aids that can simplify and

facilitate the various stages of your work, helping you to

enhance the taste and quality of your pizza.

We therefore offer you a fully comprehensive range of

innovative pizza-preparation products. With our mixers,

rounders and presses you can always count on reduced times,

uniform processes and excellent results.

At the same time, we care about your health because our

products allow you to work in comfort without stress or strain.

a must for

TRADITIONAL

PIZZA HOUSES

ARTISAN PIZZA

MANUFACTURING

UNITS

MODERN FOOD

OUTLETS

BY-THE-SLICE AND TAKEAWAY

PIZZERIAS, PIZZA-CORNERS IN

SHOPPING CENTRES, ETC.

preparation equipment

3

4

Your own working aid

We offer state-of-the-art equipment to help you through

the various stages of preparation.

NO STRESS OR STRAIN

Our equipment makes your work easier. It saves your

time and effort and also protects your health as it avoids

developing occupational diseases such as arthritis of the

shoulder and carpal tunnel syndrome.

ROOM FOR YOUR CREATIVITY

Our auxiliary equipment is the best aid for the art of pizza.

Let the equipment do all the donkey work and devote your

time and attention to creativity.

IMPROVED SPEED

Efcient and reliable, our equipment speeds up every single

process. You therefore save time and money.

LARGE QUANTITIES

Our equipment can handle large amounts of dough and

allows you to organise your work in the best possible way.

UNIFORM AND EXCELLENT RESULTS

You can always rely on perfect results. Precise dough

balls, pizza bases of uniform size and thickness.

HIGH QUALITY

Whatever our types, recipes and methods you use, with

our products you will always achieve high quality levels.

SIMPLICITY AND SAFETY

Using and cleaning requires just a few simple actions.

You can work comfortably and carefreely because all of

our equipment is tted with the safety devices needed to

provide full protection whilst you work.

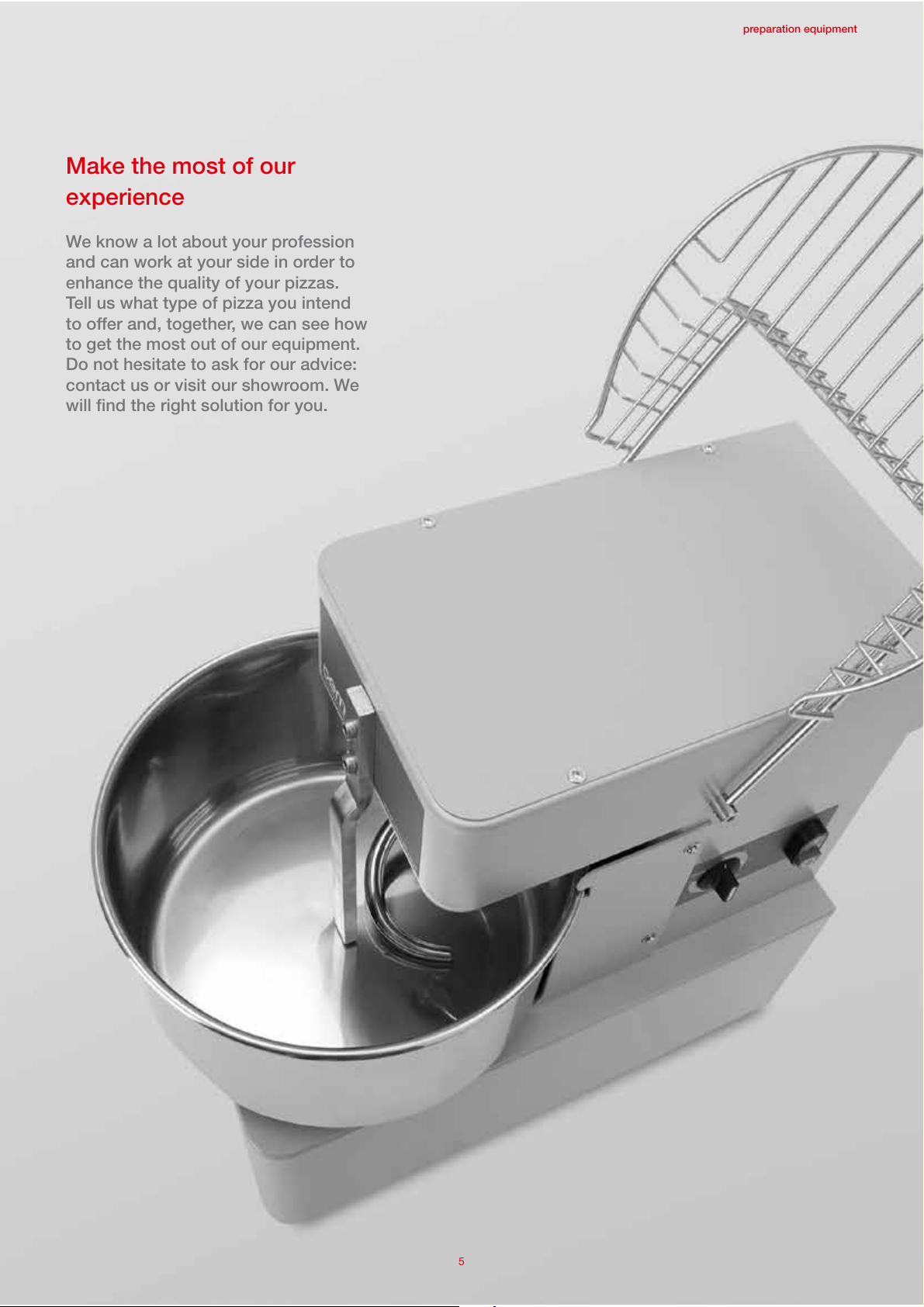

Make the most of our

experience

We know a lot about your profession

and can work at your side in order to

enhance the quality of your pizzas.

Tell us what type of pizza you intend

to offer and, together, we can see how

to get the most out of our equipment.

Do not hesitate to ask for our advice:

contact us or visit our showroom. We

will find the right solution for you.

preparation equipment

5

6

7

Spiral mixers

spiral mixers

8

A GREAT WORKER

AT A GREAT PRICE

Over the same period,

you can produce 6 times as much dough

as you can by hand mixing.

CONSTANT TEMPERATURE

Each machine runs at low rpm to

avoid overheating the dough

(max. temperature 24 °C).

IDEAL OXYGEN LEVELS

It will produce a smooth dough

according to your own recipe

and proportions.

QUICK

Obtain the dough you want in just 15-20

minutes.

STRETCHY DOUGH

The dough obtains the right consistency without

sticking to the bowl.

REDUCED FOOTPRINT

It provides a space saving solution because it

can be placed beneath worktops or ovens.

By tting castors, it can be moved wherever

you want, ready for use at all times.

FA spiral mixers

Simplicity in action

7 FIXED-HEAD MODELS: 18, 25, 38 KG

Practical range with an essential design.

Quality-and price wise remarkable.

Silver colour version with black panels.

Why choose a fixed head mixer?

9

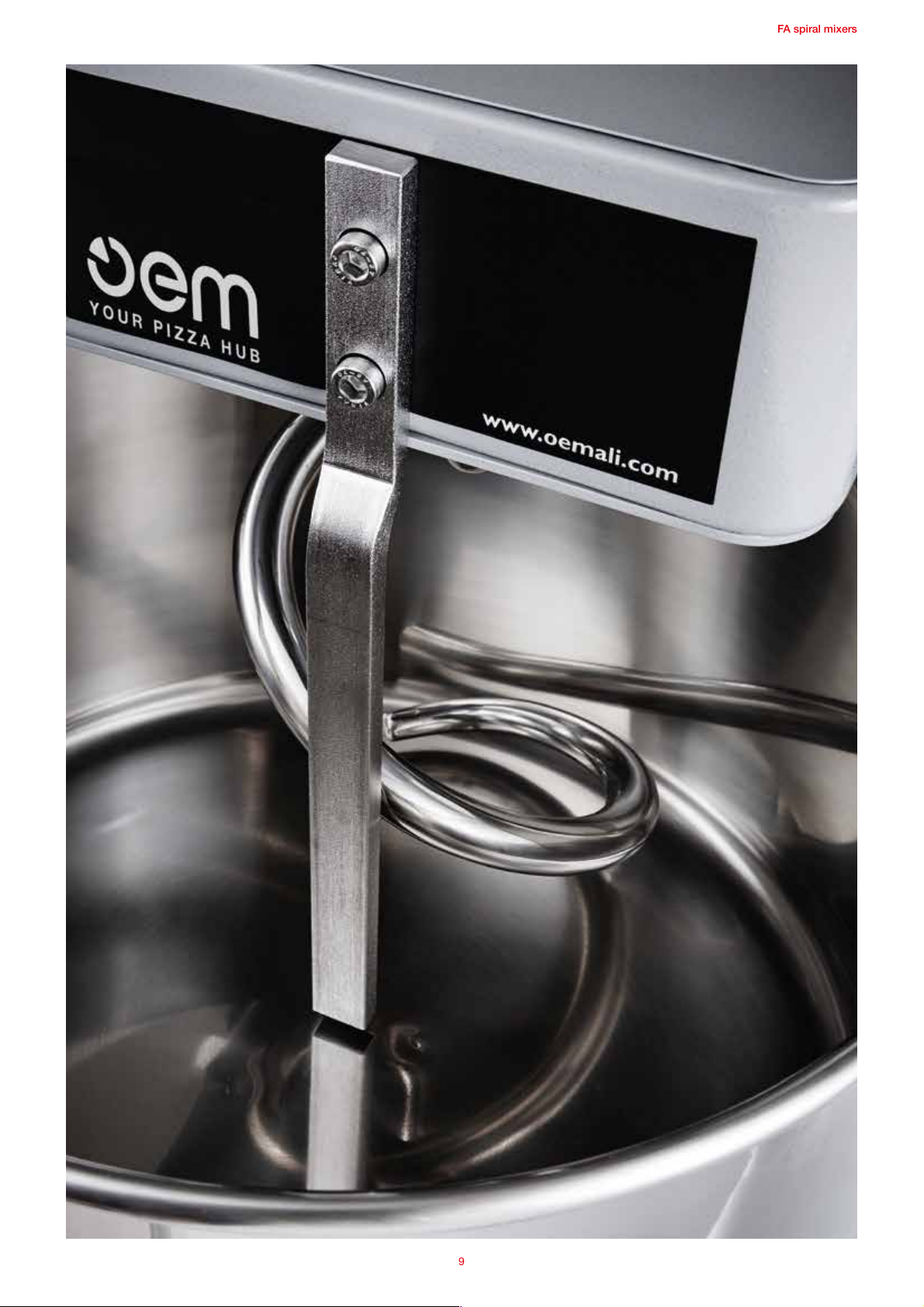

FA spiral mixers

10

FA spiral mixers

Technical specifications

• Painted steel frame.

• Stainless-steel bowl.

• Adjustable timer (up to 30 minutes).

• Active and passive safety devices (micro switch tted as

standard outt).

• Machine body fully sealed

for improved hygiene.

• Transmission through oil-bathed gear motor.

• Optimal RPM of the spiral arm and bowl for improved

mixing without overheating the dough.

• Thrust bearing to maintain an optimal distance between the

spiral arm and bowl edge even at a full machine load.

• Dough breaker pierce supplied as standard outt.

• 1 or 2 operating speeds.

• 400 V 3-phase/neutral o 230 V single-phase power supply

(only mod. 18 kg).

• Optional castors (front ones with brakes).

• An interesting feature: the special “open” bowl safety guard

lets you add all the various ingredients with the mixer in

operation, thus giving you full control over the dough at all

times.

11

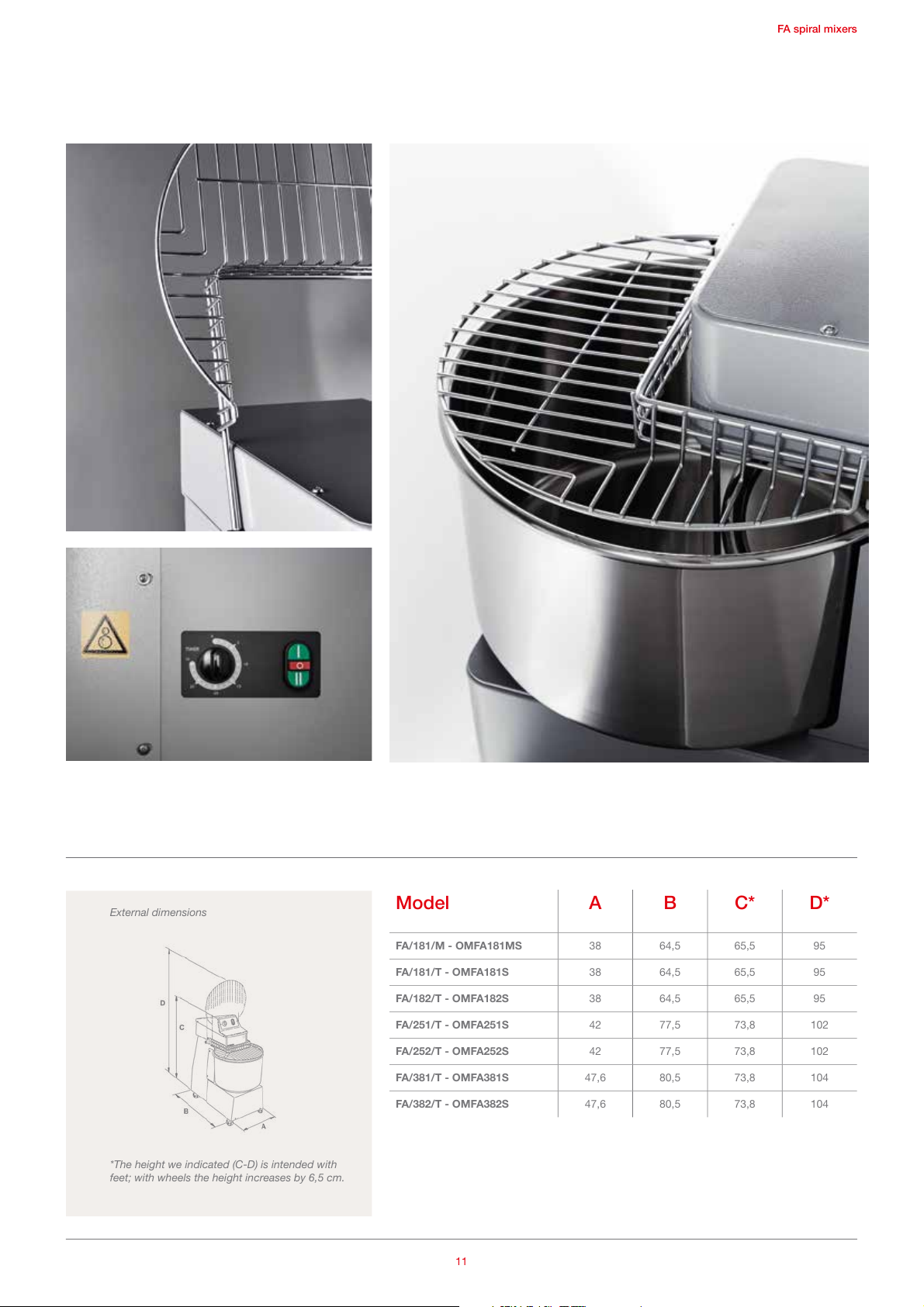

Model A B C* D*

FA/181/M - OMFA181MS 38 64,5 65,5 95

FA/181/T - OMFA181S 38 64,5 65,5 95

FA/182/T - OMFA182S 38 64,5 65,5 95

FA/251/T - OMFA251S 42 77,5 73,8 102

FA/252/T - OMFA252S 42 77,5 73,8 102

FA/381/T - OMFA381S 47,6 80,5 73,8 104

FA/382/T - OMFA382S 47,6 80,5 73,8 104

*The height we indicated (C-D) is intended with

feet; with wheels the height increases by 6,5 cm.

FA spiral mixers

External dimensions

FA spiral mixers

Models

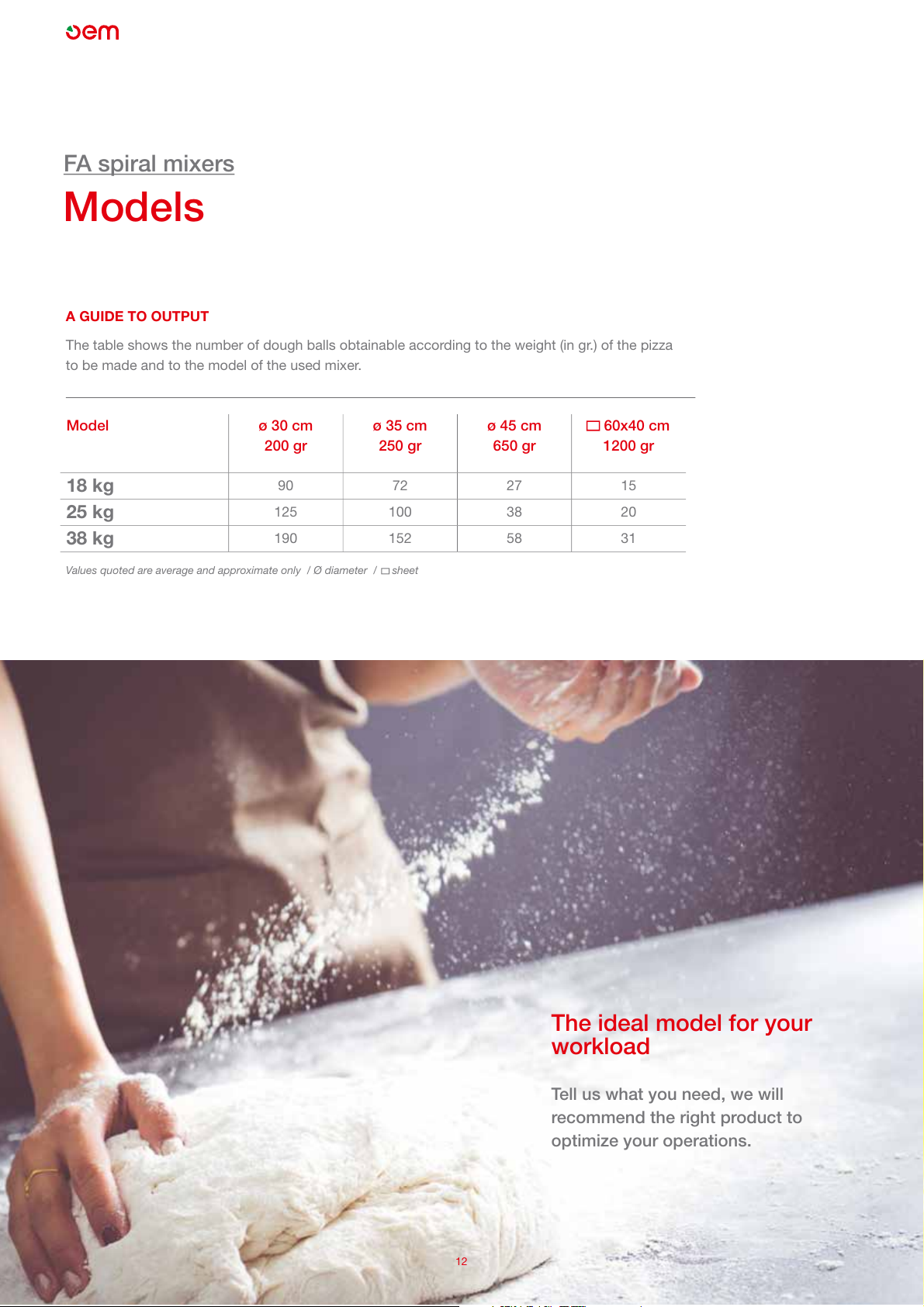

A GUIDE TO OUTPUT

The table shows the number of dough balls obtainable according to the weight (in gr.) of the pizza

to be made and to the model of the used mixer.

Model ø 30 cm

200 gr

ø 35 cm

250 gr

ø 45 cm

650 gr

60x40 cm

1200 gr

18 kg

90 72 27 15

25 kg

125 100 38 20

38 kg

190 152 58 31

Values quoted are average and approximate only / Ø diameter / sheet

The ideal model for your

workload

Tell us what you need, we will

recommend the right product to

optimize your operations.

12

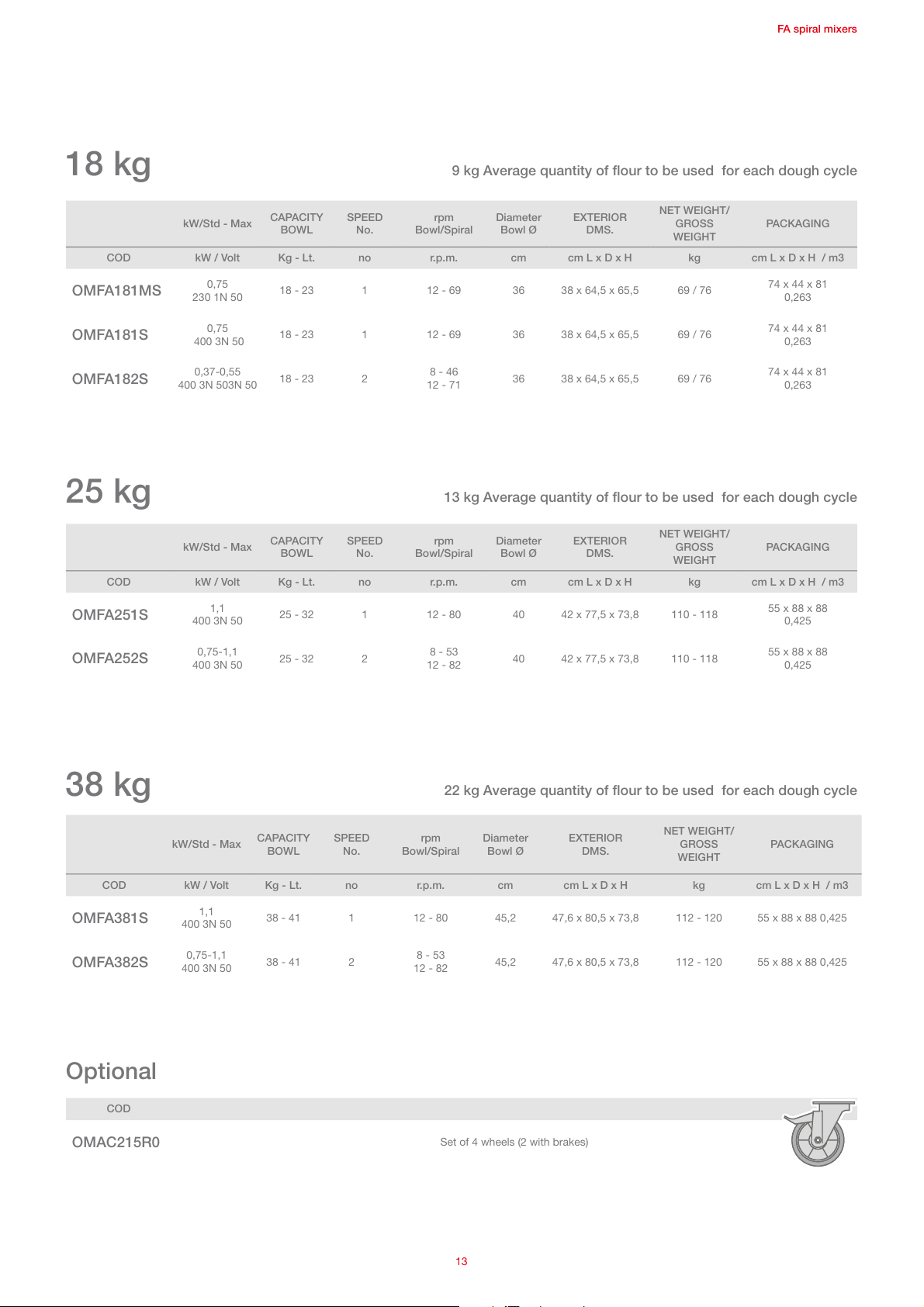

13

FA spiral mixers

kW/Std - Max

CAPACITY

BOWL

SPEED

No.

rpm

Bowl/Spiral

Diameter

Bowl Ø

EXTERIOR

DMS.

NET WEIGHT/

GROSS

WEIGHT

PACKAGING

COD kW / Volt Kg - Lt. no r.p.m. cm cm L x D x H kg cm L x D x H / m3

OMFA181MS

0,75

230 1N 50

18 - 23 1 12 - 69 36 38 x 64,5 x 65,5 69 / 76

74 x 44 x 81

0,263

OMFA181S

0,75

400 3N 50

18 - 23 1 12 - 69 36 38 x 64,5 x 65,5 69 / 76

74 x 44 x 81

0,263

OMFA182S

0,37-0,55

400 3N 503N 50

18 - 23 2

8 - 46

12 - 71

36 38 x 64,5 x 65,5 69 / 76

74 x 44 x 81

0,263

18 kg

9 kg Average quantity of flour to be used for each dough cycle

kW/Std - Max

CAPACITY

BOWL

SPEED

No.

rpm

Bowl/Spiral

Diameter

Bowl Ø

EXTERIOR

DMS.

NET WEIGHT/

GROSS

WEIGHT

PACKAGING

COD kW / Volt Kg - Lt. no r.p.m. cm cm L x D x H kg cm L x D x H / m3

OMFA251S

1,1

400 3N 50

25 - 32 1 12 - 80 40 42 x 77,5 x 73,8 110 - 118

55 x 88 x 88

0,425

OMFA252S

0,75-1,1

400 3N 50

25 - 32 2

8 - 53

12 - 82

40 42 x 77,5 x 73,8 110 - 118

55 x 88 x 88

0,425

25 kg

13 kg Average quantity of flour to be used for each dough cycle

kW/Std - Max

CAPACITY

BOWL

SPEED

No.

rpm

Bowl/Spiral

Diameter

Bowl Ø

EXTERIOR

DMS.

NET WEIGHT/

GROSS

WEIGHT

PACKAGING

COD kW / Volt Kg - Lt. no r.p.m. cm cm L x D x H kg cm L x D x H / m3

OMFA381S

1,1

400 3N 50

38 - 41 1 12 - 80 45,2 47,6 x 80,5 x 73,8 112 - 120 55 x 88 x 88 0,425

OMFA382S

0,75-1,1

400 3N 50

38 - 41 2

8 - 53

12 - 82

45,2 47,6 x 80,5 x 73,8 112 - 120 55 x 88 x 88 0,425

38 kg

22 kg Average quantity of flour to be used for each dough cycle

COD

OMAC215R0

Set of 4 wheels (2 with brakes)

Optional

Loading...

Loading...