Page 1

Installation Instructions

TUBULAR

SKYLIGHT

CALL US FIRST

Do not return to the store!

For assistance with your Tubular Skylight installation,

or for additional product information, call our

toll-free customer service number:

1-866-635-4968, or visit us online at www.odl.com.

Important

Be sure to first read through and then follow

completely all step-by-step instructions.

This will help to insure proper installation

and functionality. Expect installation to take

from 1 to 3 hours.

Page 2

3

Section-i

What You Need To Know

REVIEW THIS INFORMATION PRIOR TO BEGINNING INSTALLATION

These instructions have been designed to help install your ODL® Tubular Skylight easily and safely. We’ve included a parts

list, list of tools required, installation instructions for a variety of ceiling types, handy tips, and safety precautions. Please

read these instructions thoroughly before installing your ODL® Tubular Skylight. Pay particular attention to the assembly

diagrams, assembly order, and part names. Identify and organize all parts before assembly. Make a list of the tools and

components you will need for each installation location. Following these instructions carefully will greatly enhance your

ability to install your tubular skylight and enjoy flawless performance for many years.

Caution

The tubular skylight is not designed to hold your

weight or the weight of tools or other objects.

Walking/placing objects on the skylight could cause

personal injury and property damage. A damaged

skylight should be repaired immediately.

For safe installation and use, do not deviate from

these installation instructions.

Warning:

Working on a roof is potentially dangerous but

you can significantly reduce the risk by following

these precautions:

• Never work in wet, windy or cold conditions.

Roofing materials can be slippery when wet;

asphalt shingles are brittle when cold and may

crumble underfoot. Plan your installation for

a calm, dry day.

• Wear shoes with slip-resistant soles.

WARNING

POTENTIAL FIRE HAZARD. After removing

the film lining from the interior of tube shaft,

a reflective inner surface is created. DO NOT

leave tube shaft components unattended or

exposed to direct sunlight prior to full installation.

Exposed surfaces may catch fire or incur heat

damage as a result of focused sunlight until the

tube shaft is fully installed with diffuser in place.

Pre Installation Checklist:

Tube Installation/Location

• Your tubular skylight kit comes with enough

tubing for a 48" installation – if you require

more tubing, you can purchase additional

extension tubes through your retailer.

• For best results always attempt to install the tube

as straight as possible (this would locate the

dome/flashing directly above the ceiling diffuser).

• Make sure that the location you pick on your roof

for your dome/flashing is exposed to direct sunlight

throughout the day. You will not want any trees,

chimneys, etc. to cast a shadow on your tube.

• Before installation, carefully survey the attic area

of your desired location. Make sure your tube can

avoid any wiring, plumbing, roof valleys, ceiling

mounted registers/fans, etc.

For cathedral ceiling, see Section 10.

For long tube shaft installation, see Section 11.

For metal roof installations, see Section 12.

For tile roof installations, see Section 13.

For 14” skylight with 16” on-center rafter spacing

see Section 4.

Building Codes:

• Consult your local building official about local

construction ordinances before starting your installation.

• Consult your community covenants. Some subdivisions may

not allow tubes on the street side of home.

Determining roof pitch:

• “Roof Pitch” is how far the roof drops vertically

for every 12” of horizontal run.

• ODL Tubular Skylights are for roof slopes of 3:12 to 12:12.

Safety information:

• Wear safety glasses and work gloves when

using power tools.

• Use protective work gloves while handling tube

sections to protect hands from sharp edges.

2

Page 3

Section-ii

Limited Warranty for ODL Tubular Skylights

Visit odl.com/warranty_SKY.htm,

for warranty registration.

To validate your warranty,

please register online within 10 days.

Tell us more...

Rate your new ODL product at odl.com

Effective 02/04

2. The Customer must use reasonable diligence to include

in the written claim all of the following:

a. An adequate description of the claimed defect(s);

b. Identification of Product (size, design, type and model

number).; c. Date of the Customer’s purchase, place of purchase,

and the date of delivery to the Customer.

3. The Consumer must, if requested by ODL, permit ODL

or its representative to inspect the Product either in person

or via appropriate photographs of said Product.

Warranty Coverage

Subject to the conditions, exclusions and limitations herein,

ODL Incorporated (“ODL”) warrants that its Tubular Skylight

Product (“Product”) is free from defects in material and

workmanship that would render the Product unfit for its

normal and recommended use.

THIS LIMITED LIFETIME WARRANTY APPLIES AND EXTENDS

ONLY TO THE ORIGINAL CONSUMER PURCHASING THIS

PRODUCT. THE DURATION OF THIS WARRANTY BEGINS

ON THE DATE OF PURCHASE BY THE CONSUMER.

Exclusions from Coverage

This warranty does not cover:

• Defects or damages arising out of shipment by common

carriers, private transportation or other means of

transportation.

• Defects or damages arising out of improper handling or

cleaning, defective or improper installation (including

installation not in accordance with ODL’s installation

instructions), accident, act of God, intentional human act,

misuse or abuse, or any other circumstances beyond the

control of ODL.

• Products installed in or submitted to high heat, high moisture,

high vibration, or extreme temperature changes.

• Products subjected to stress resulting from (i) localized

application of heat, (ii) movement of building and /or building

components, or (iii) expansion or contraction of framing

members.

• Replacement products beyond the balance of the remaining

warranty period applicable to the original Product or

accessory which is replaced.

• Labor, shipping or other charges incurred or claimed

by the Customer.

• Accessories, flashing or other installation materials

manufactured or sold by persons other than ODL.

Warranty Claim Procedures

If the Customer discovers a defect in the Product or an

accessory which is covered by this warranty, the Customer must

follow this procedure:

1. The Customer must promptly call Customer Service at

1-866-635-4968, or present a written claim to the Customer

Service Manager, ODL Incorporated, 215 East Roosevelt Avenue,

Zeeland, Michigan 49464.

Remedies

After receiving a valid claim, ODL will, at its option, provide

a replacement Product (or part, as appropriate) of like kind

and design.

If ODL elects to provide a replacement Product, the limited

warranty on the replacement will last only for the balance of

the original Product warranty period. If the Customer fails to

provide satisfactory proof of the date of purchase, the date of

manufacture shall be used instead.

ODL’S LIABILITY UNDER THIS WARRANTY IS LIMITED TO

THE ABOVE, AND ODL WILL IN NO EVENT BE RESPONSIBLE

FOR SHIPPING, LABOR, REMOVAL OF ORIGINAL PRODUCT,

INSTALLATION OF REPLACEMENT PRODUCT, FINISHING

EXPENSES, OR OTHER CHARGES, COSTS OR CLAIMS

INCURRED BY THE CONSUMER.

Disclaimer of Warranty

NO IMPLIED WARRANTY, INCLUDING WARRANTY OF

MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

PURPOSE, SHALL APPLY TO THE PRODUCT (OR ANY

REPLACEMENT) BEYOND THE DURATION OF THIS WRITTEN

WARRANTY. (Some states or provinces do not allow limitations

on how long an implied warranty lasts, so the above limitation

may not apply to you.)

Limitation of Remedies

THE REMEDIES SET FORTH ABOVE ARE THE CONSUMER’S

EXCLUSIVE REMEDIES FOR BREACH OF WARRANTY OR

NEGLIGENCE. IN NO CASE SHALL ODL BE LIABLE TO THE

CONSUMER OR ANY OTHER PERSON FOR ANY GENERAL,

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.

(Some states or provinces do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitations

or exclusions may not apply to you.)

Unless modified in a later writing signed by both ODL and

Consumer, this warranty is the complete and exclusive warranty

related to the Product, and it supersedes all earlier agreements

and other communications relating to the Product. No employee

of ODL or any other party is authorized to make any warranty in

addition to this warranty. Invalidation of any one or more of the

other provisions of this warranty shall not invalidate or affect one

of the other provisions. This warranty is not transferable.

This warranty gives the Consumer specific legal rights, and the

Consumer may also have other legal rights which may vary from

state to state.

3

Page 4

5

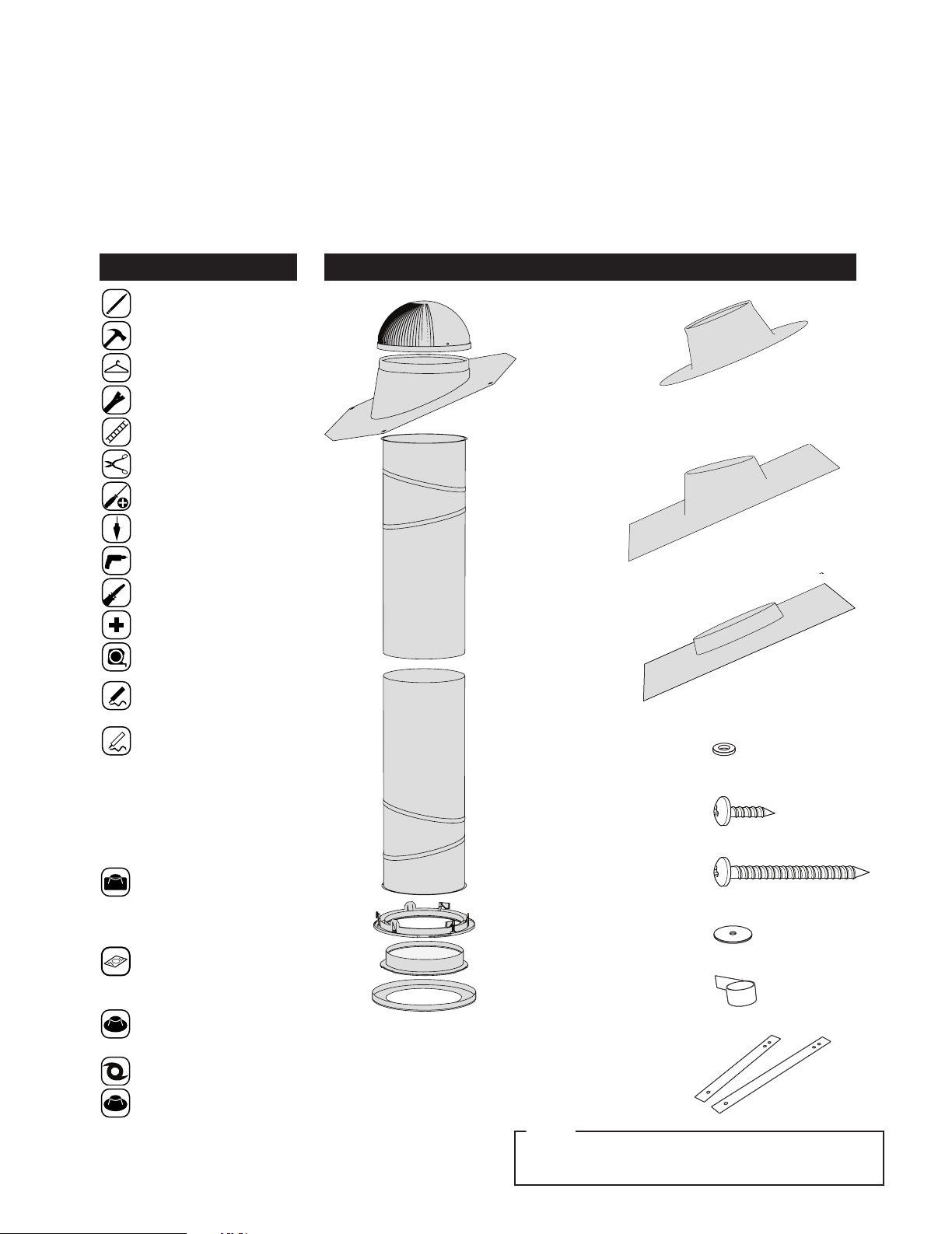

Section-iii

Tools & Parts Identification

TOOLS

Carpenter Pencil

Claw Hammer

Coat Hanger Wire

Flat Pry Bar

Ladder

Metal Shears

Phillips Screwdriver

Plumb Line

Power Drill

Power Saw

Safety Equipment

Measuring Tape

Non-Curing/Non-Hardening

Roof Sealant (Not provided in kit)

Exterior Silicone

(Not provided in kit)

PARTS

Solar Lens® Dome

(10” Dome shown)

Roof Flashing

(Composite flashing shown)

Adjustable Tubes

Optional Spun Aluminum

Roof Flashing

(Non Formable)

Optional Formable

Aluminum Roof Flashing

Underlayment

(4) dome washers

Other Roofing

Applications

Formable Aluminum Flashing

(All pitched roof types - including

Metal, Tile, and Shingled

Applications)

Secondary Underlayment Flashing

(Required for use w/ Formable

Flashing)

Seamless Aluminum Flashing

(Flat Roof Applications)

Severe Weather Tube

w/ Seamless Aluminum Flashing

(Severe Weather Regions / Dade

County & Texas Gulf Coast

approved)

Ceiling Ring with Flip Tabs

Low-Profile Insulated

Diffuser Lens Assembly

NOTE

Read through the section specific to your roof for

additional parts and tools.

4

(4) 3/4” dome screws

(9) 2” flashing screws

(9) flashing washers

(1) roll of foil tape

(2) hole cutting templates

Page 5

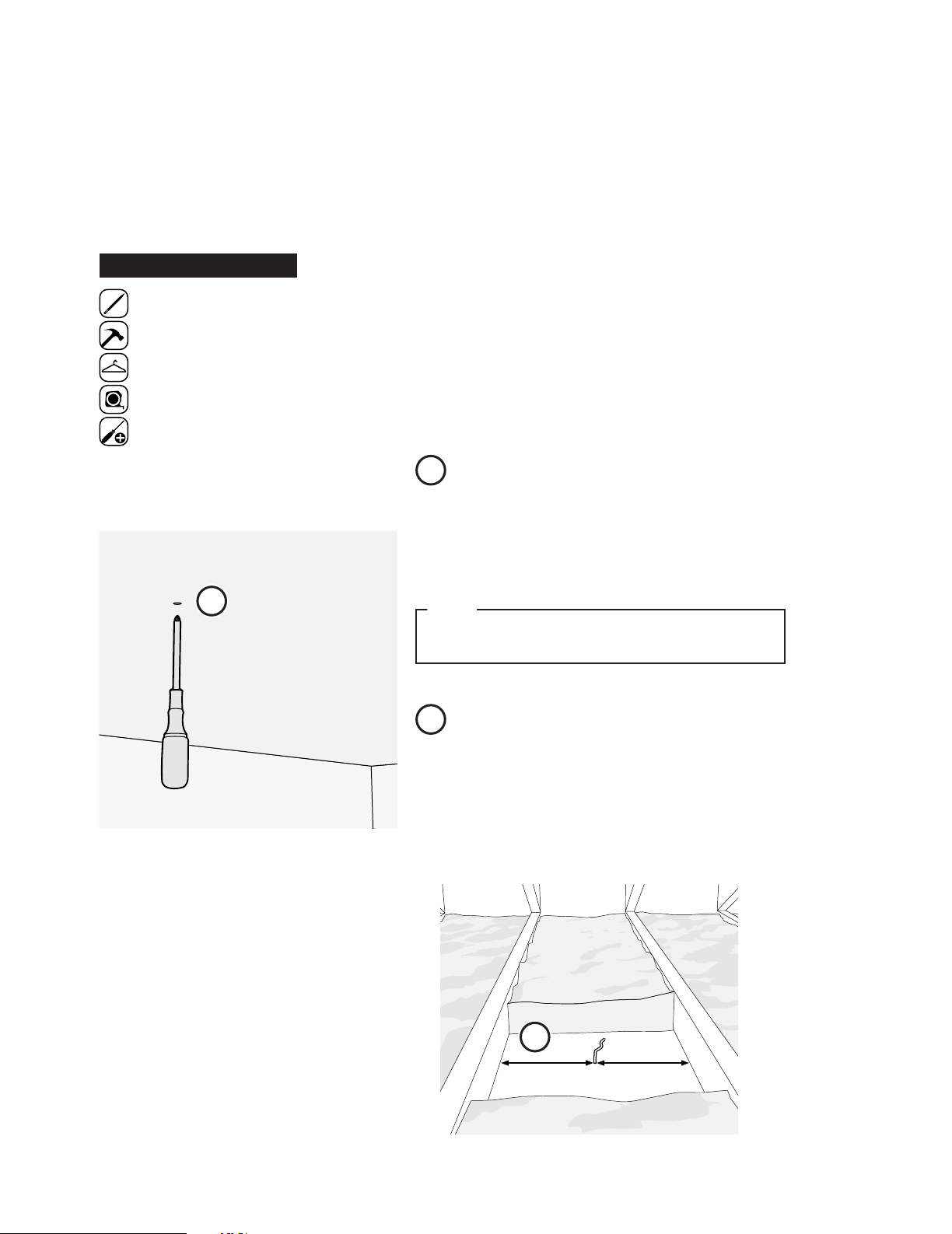

Section-1

Determine The Desired Position

Of The Tubular Skylight In The Ceiling

TOOLS & PARTS

Carpenter Pencil

Claw Hammer

Coat Hanger Wire

Measuring Tape

Phillips Screwdriver

1

These instructions outline the step-by-step process to install an

ODL Tubular Skylight. Before starting, review all instructions and

become familiar with the parts shown on the previous page.

SPECIAL NOTES

• Always use safe procedures.

• Wear safety glasses when working with tools.

• Check all measurements before cutting or drilling.

• It is helpful to have a second person assist during installation.

Using a stud finder or hammer, find a location

1

between the ceiling joists. Push a screwdriver or nail

through the desired position.

Cut and insert a section of coat hanger wire through

the hole. This will make it easier to identify the hole

location in the attic.

NOTE

Refer to Pre-installation Checklist for tube location tips

in section i.

In the attic, locate the coat hanger wire. Adjust its

2

location, centering the opening for the tube between

the framing members. Check wire visibility in the

ceiling below as well as from the hole that will be cut

in the roof.

2

5

Page 6

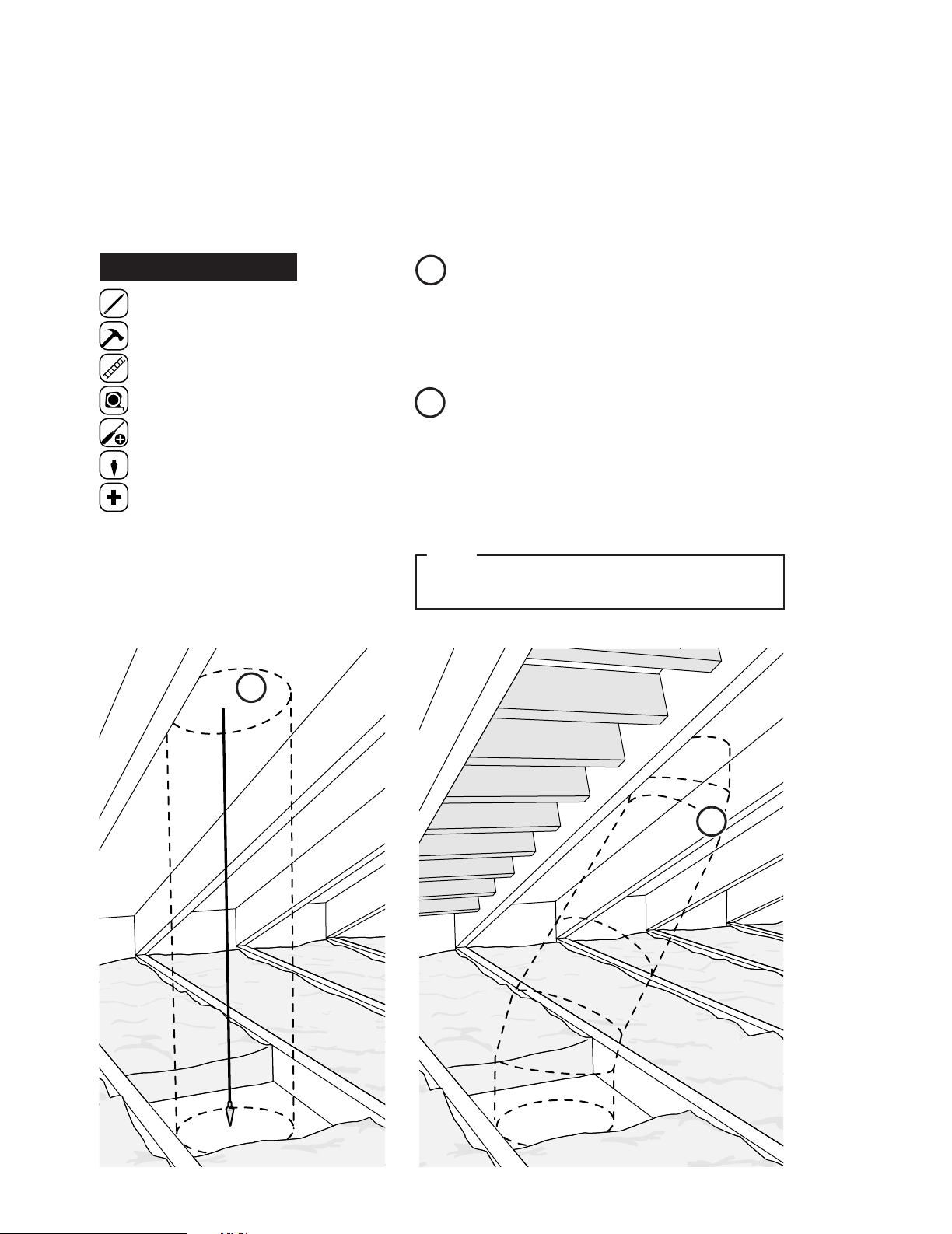

7

Section-2

Locating The Roof Position

TOOLS & PARTS

Carpenter Pencil

Claw Hammer

Ladder

Measuring Tape

Phillips Screwdriver

Plumb Line

Safety Equipment

Straight Tube Installation

1

In the attic, use a plumb line to find a straight

location from the ceiling hole to the roof location.

Center the opening for the tube between the framing

members. Drive a nail up into the roof deck and

through the shingles.

2

Angled Tube Installation

In the attic, if there are obstructions at the roof

location (valleys, wires, pipes, ducts, framing, etc.),

adjust tubes up to a combined 45° angle to find a

path that avoids interference. Center the opening for

the tube between the framing members. Drive a nail

up into the roof deck and through the shingles.

NOTE

Trial-fitting your tubing will help in determining

adjustablilty and need for additional extensions.

Straight Tube Installation Angled Tube Installation

1

2

6

Page 7

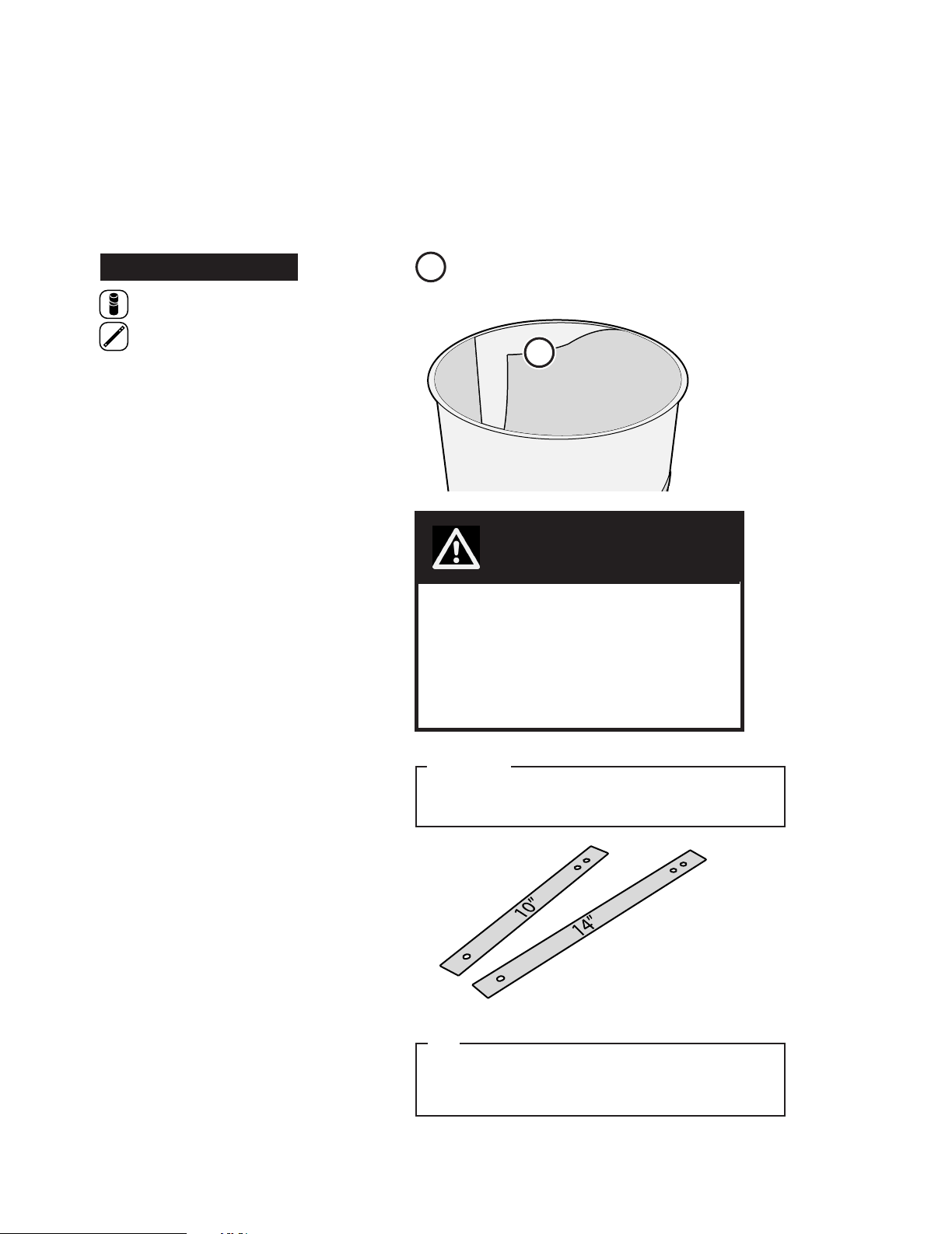

Section-3

Prepare The Components

TOOLS & PARTS

Adjustable Tubes

Hole Cutting Template

Remove protective film from inside all tubes.

1

1

11

WARNING

POTENTIAL FIRE HAZARD. After removing

the film lining from the interior of tube shaft,

a reflective inner surface is created. DO NOT

leave tube shaft components unattended or

exposed to direct sunlight prior to full installation.

Exposed surfaces may catch fire or incur heat

damage as a result of focused sunlight until the

tube shaft is fully installed with diffuser in place.

CAUTION

From the hardware pack, be sure to use the correct

hole cutting template for the selected tube size.

10” Template

14” Template

TIP

It is recommended that you put all of your tools and

rooftop components in a box or bag for easy transfer

to the roof. See Section 4.

7

Page 8

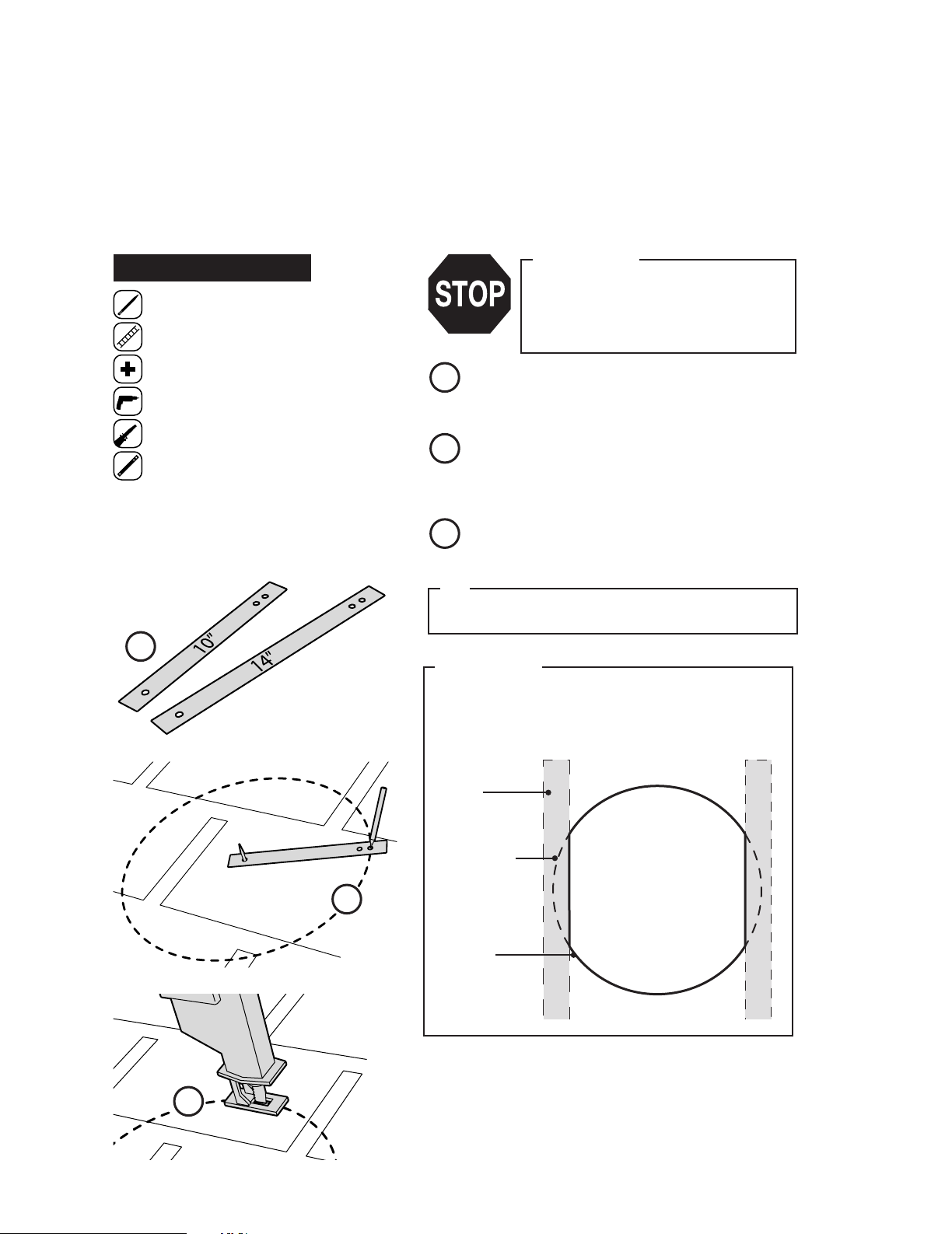

9

Section-4a

On The Roof

TOOLS & PARTS

Carpenter Pencil

Ladder

Safety Equipment

Power Drill

Power Saw

Hole Cutting Template

10” Template

1

14” Template

IMPORTANT

For 14” skylight with 16” on-center

rafter spacing, see below.

See Section 12 for metal roof installation.

See Section 13 for tile roof installation.

Select the correct hole cutting template for the tube

1

(10” or 14”).

Locate the protruding nail. Use the correct hole-

2

cutting template to trace the diameter of the outer

template hole.

Use a reciprocating/sabre saw to cut the roof hole.

3

TIP

Drill a hole inside the traced circle to insert saw blade.

IMPORTANT

For 14” skylight with 16” on-center rafter spacing, the

14” template will draw a line that overlaps the rafters.

Be sure to adjust your cutting angle to avoid cutting into

the rafters. (See illustration)

Rafter

Traced Line

2

Cut Line

3

8

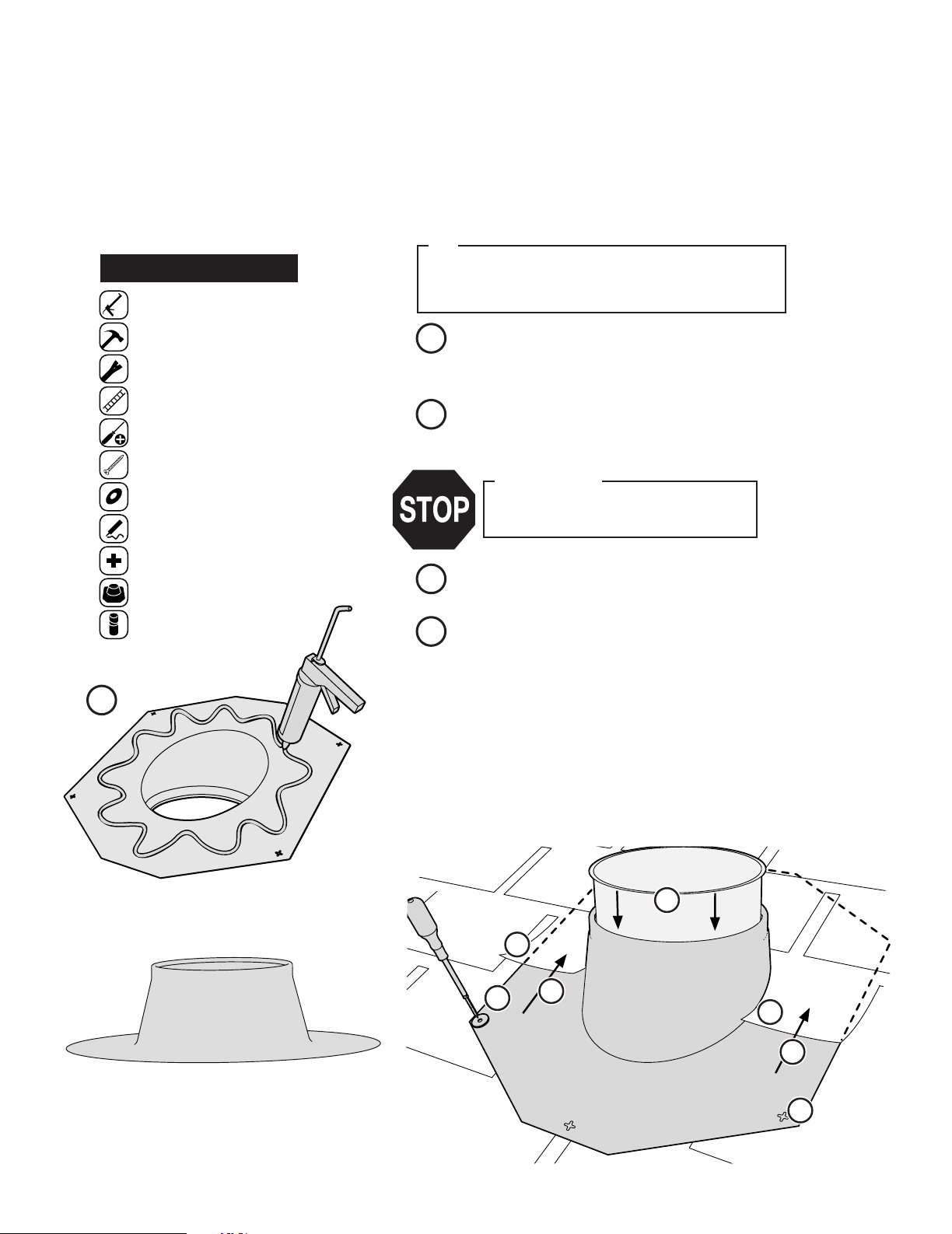

Page 9

Section-4b

On The Roof

TOOLS & PARTS

Caulk Gun

TIP

The vertical seam of the reflective tube should point to

the East or West to avoid irregular light patterns in your

room.

Claw Hammer

Flat Pry Bar

Ladder

Phillips Screwdriver

2” Screws

3/4” Washers

Roofing Sealant

Safety Equipment

Roof Flashing

Top Adjustable Tube

2

Sealant

Use a flat pry bar to carefully break the seals on

1

the shingles upslope above the cuthole. Use a claw

hammer to remove nails on the shingles above the

cut hole.

Generously apply roof sealant around bottom of

2

flashing. Slide top and sides of roof flashing under

top shingles.

IMPORTANT

For short shaft cathedral style installation

see Section 10. Do not install dome yet.

Slide Top Adjustable Tube (pink label) into the flashing

3

to check for proper alignment.

Secure flashing to roof with 2” Flashing Screws and

4

Washers. For aluminum flashing (Both Spun Severe

Weather & Formable. See images on pg. 4), use 9 screws

& washers in an evenly spaced, circular pattern around

the 10” or 14” hole. The circular pattern should be

a 21” diameter for the 10” unit and a 24” diameter

pattern on the 14” unit.

For injection molded flashing, use 8 screws and washers

in the preformed holes for the 10” and 14” unit.

Seal screw heads with roof sealant.

Spun aluminum flashing does not have pre-drilled holes.

Optional Spun Aluminum Roof Flashing

(Non Formable)

3

1

4

2

1

2

4

9

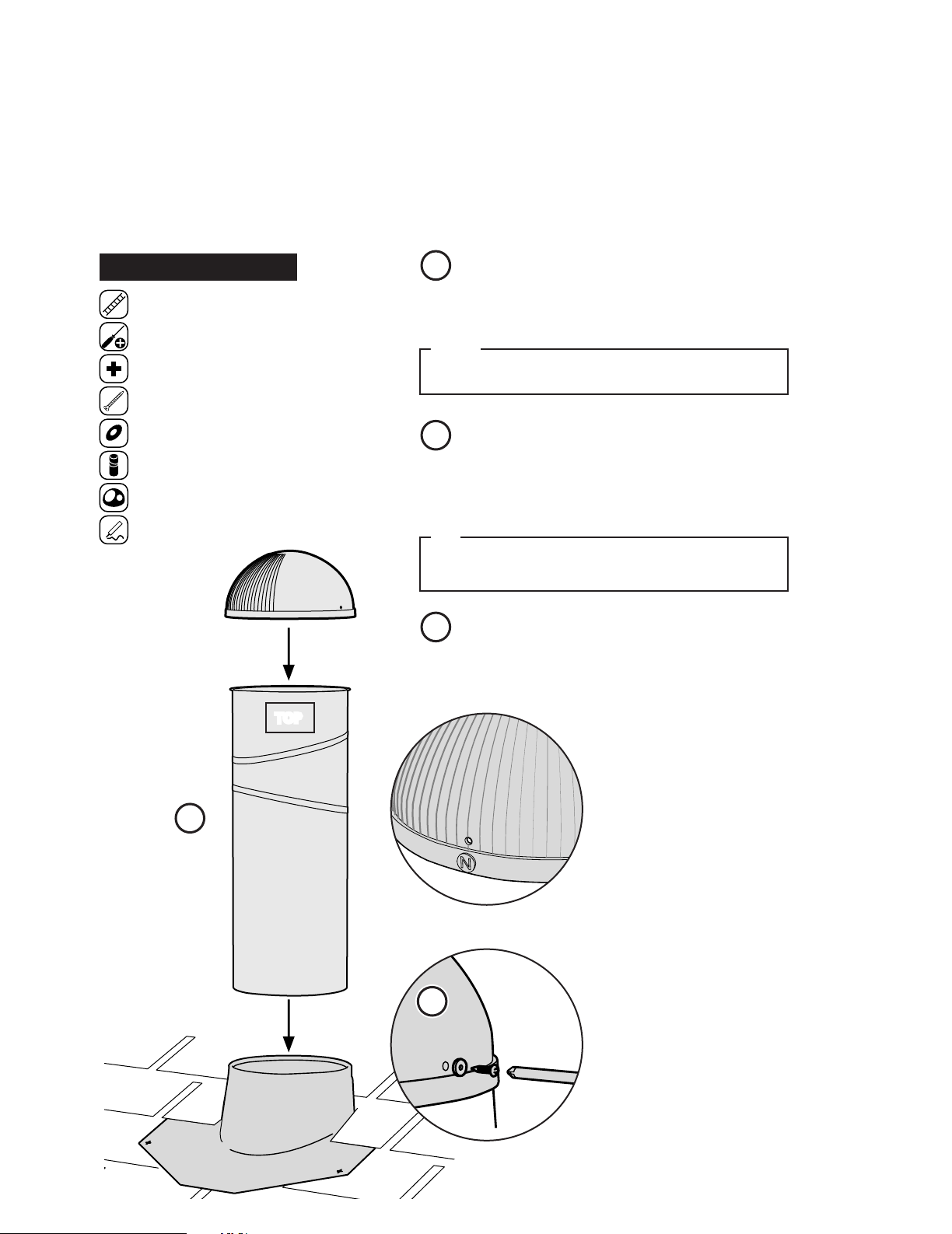

Page 10

Section-4c

On The Roof

TOOLS & PARTS

Ladder

Phillips Screwdriver

Safety Equipment

3/4” Dome Screws

For angled tube installation, reach and adjust the

1

Adjustable Tube so it points to the wire in the ceiling,

or adjust the angle of the tube and then insert tube

into flashing.

NOTE

Adjust tubes by lightly turning, using one hand on each end.

Dome Washers

Top Adjustable Tube

Solar Dome

Exterior Clear Pure Silicone

TOP

1

Using the 3/4”dome screws and dome washers

2

(dome washers have the rubber backing – rubber

backing should face the dome), mount the dome on

the flashing aligning the “N” (molded into outer edge

of the dome) towards the North.

TIP

Dome screws should be snug but do not over tighten

creating pressure against the dome.

Cover dome screw heads and washers with an

3

exterior silicone .

Align Toward North

Mount Dome

2

10

Page 11

Section-5

Inside The Room

TOOLS & PARTS

Pencil

Phillips Screwdriver

Power Saw

Hole Cutting Template

Ceiling Trim Ring

2

IMPORTANT

For 14” skylight with 16” on-center rafter

spacing, see below.

Using the correct (10" or 14") Hole Cutting Guide

1

for your size tube, and a pencil, locate protruding

wire in the ceiling and trace the diameter of the

ceiling inner hole using the template marked “A”.

TIP

You may have to drill a hole inside the traced diameter

circle to insert saw blade.

Use a keyhole/drywall saw to cut the hole.

2

1

Slide the Trim Ring up into your ceiling hole. Make

3

sure the flip tabs are turned in. Reach through hole

and turn flip tabs out to hold ring in place.

Secure the ceiling trim ring by tightening the screws.

4

IMPORTANT

For 14” skylight with 16” on-center rafter spacing, the

14” template will draw a line that overlaps the rafters.

Be sure to adjust your cutting angle to avoid cutting into

the rafters. (See illustration)

Rafter

3

Traced Line

Cut Line

Trim Ring

Flip Tab

4

11

Page 12

Section-6

In The Attic

TOOLS & PARTS

Measuring Tape

TIP

The vertical seam of the reflective tube should point to

the East or West to avoid irregular light patterns in your

room.

Bottom Adjustable Tube

Foil Tape

Flip Tab Lock Tab

IMPORTANT

At this point, if you purchased a dimmer or

combo kit, this is where you reference the

dimmer instructions, packaged with the

dimmer unit.

Gently set the Bottom Adjustable Tube flange down

on the trim ring. Do not snap in place at this time.

1

If you have an angled installation you will need to

2

twist your Bottom Adjustable Tube (blue label) so it

lines up with the Top Adjustable Tube above. (Be sure

you have removed the protective film.)

NOTE

Adjust tubes by lightly turning, using one hand on each end.

1

Measure distance from the top of Roof Flashing to

ceiling (See illustration) to determine proper trimming

3

of length of tubes. Refer to “Tube Length Chart” in

Section 8 for cutting recommendations if you need to

shorten the tubes.

Slide Bottom Adjustable Tube over the outside of Top

Adjustable Tube.

4

Now you can push down to lock the Bottom

Adjustable Tube securely into the lock tabs of the

5

ceiling trim ring.

3

Distance from top of flashing

to face of ceiling (take longest

measurement)

Tape ALL seams securely with Foil Tape to keep dust,

moisture, and insects out of the tube.

6

6

12

Page 13

Section-7

When Cutting Your Tube...

TOOLS & PARTS

Carpenter Pencil

Metal Shears

Safety Equipment

Safety Glasses

Extension Tubes

Gloves

Trimmed Extension Tube

IMPORTANT

Once contact is made with adhesive strip on an Extension

Tube, parts cannot be repositioned.

Be sure to measure and cut if necessary, before

1

1

removing adhesive strip and assembling the Extension

Tube. Wear gloves when working with sharp edges.

TIP

When trimming Extension Tubes, always measure and

start from the wide end where tube end diameter =

10” or 14”.

After referring to “Tube Length Chart” in Section 8,

1

2

use metal shears to shorten the Extension Tube. Allow

for a 1” overlap at each end where you will connect

each tube to another.

Once Extension Tubes are sized to the proper length,

1

3

remove tan backing paper from adhesive strip on

edge of Extension Tube. Beginning at one end of

the Extension Tube, over-lap the edges of the tube/s,

aligning the edge of the tube along the crimp on the

other side.

Adhesive Strip

(Once contact is made with adhesive strip, parts

cannot be repositioned.)

13

Page 14

Section-8

Tube Length Chart

adjustable tube only )

More Than 48”26” Through 48”Less Than 25”

(Must use bottom

Tube Extension

(Sold separately )

14

Page 15

Section-9

Inside The Room

TOOLS & PARTS

Diffuser Lens Assembly

Install the Diffuser Assembly by aligning the Diffuser

1

with the three tabs on the Trim Ring. Turn clockwise

until snug in place on the ceiling.

TIP

Diffuser should be rotated at least through two

“clicks”. (Full rotation is four “clicks”) to attach

to Trim Ring.

Installation Complete!

1

Ceiling Trim Ring

Lens Diffuser & Insulator

15

Page 16

Section-10a

Cathedral Ceiling/Short Shaft Installation

TOOLS & PARTS

Ladder

Pencil/Marker

Safety Equipment

Shim

Bottom Adjustable Tube

1

Start with regular installation instructions beginning in Section 1.

NOTE

The solar powered dimmer will not work with a cathedral

ceiling or some short installations due to space restrictions.

Place bottom adjustable tube (blue label) (with the

1

flanged end down) through the rough-cut hole in

the ceiling.

Guide the top portion of the tube up through the

2

roof flashing so it protrudes upward through the

flashing collar on the roof.

Place a temporary shim or ruler across the ceiling opening.

3

(Approx 1/8” thick)

Center the tube over the ceiling cut-out, resting the

4

tube down onto the shim. (The shim will keep the

tube from falling through the ceiling.)

On the roof, mark the protruding tube at the top of the

5

flashing collar with a felt pen. This will indicate where

the extra length of tubing must be trimmed off for a

short shaft install.

16

2

5

3

4

Page 17

Section-10b

Cathedral Ceiling/Short Shaft Installation

TOOLS & PARTS

Gloves

ladder

Metal Shears

Safety Equipment

Bottom Adjustable Tube

Ceiling Ring

6

7

At the ceiling, slide the temporary shim out of your

6

way and pull tube section back out of the ceiling

Wearing protective gloves, carefully trim away the

7

excess aluminum tubing using your felt pen marks as

a guide.

Remove the protective film from the inside of the

8

tubing.

Place the tube section back into the ceiling making

9

sure to align and center it inside the roof flashing

collar. Place shim back across the cut-out.

Open the diffuser assembly box and separate the

6

10

ceiling ring from the diffuser. Install only the Ceiling

Ring into the cut-out.

You can now remove the shim from the ceiling and

11

allow the tube to rest centered over the ceiling ring.

10

18

9

11

17

Page 18

Section-10c

Cathedral Ceiling/Short Shaft Installation – On The Roof

Use gloves! The trimmed edge of the tube will be

TOOLS & PARTS

Ladder

Phillips Screwdriver

Safety Equipment

12

sharp! Carefully press downward on the trimmed

end of the tube. It will lock down into the 3 plastic

locking tabs located in the Ceiling Trim Ring, securing

the tube into the rubber gasket in the ceiling trim

ring.

3/4 Dome Screws

Dome Washers

Bottom Adjustable Tube

Diffuser

Solar Lens Dome

Install the Solar Lens Dome onto the flashing collar.

13

See dome install instructions Section 4c, then return

to this page for further instructions.

Rotate the Insulated Ceiling Diffuser onto the Ceiling

14

Trim Ring. See Section 9.

Installation Complete!

13

12

14

18

Page 19

Section-11

Long Shaft Installation

TOOLS & PARTS

(2) 2-1/2” Pan Head Sheet

Metal Screws (Not Included)

3/32” Bit

Drill

Phillips Drill Bit

3

(2) 2-1/2”

Sheet Metal

Screws

1

Top Adjustable

Tube

5

Long Shaft Installation

For long shaft installation, use steps listed below, referring to

those listed on previous pages for more specific install details.

On roof, locate and install Top Adjustable Tube (pink

1

label) into roof flashing. Install Ceiling Ring at ceiling.

Install Bottom Adjustable Tube (blue label) in attic as

seen in diagram.

Frame 2 x 4 support between joists. Span from roof

2

to ceiling with a length of 2 x 4 flat to outside of each

Adjustable Tube creating a “spine”.

Put a (2) 2-1/2” pan-head, sheet metal screw (not

3

included) in each connecting extension.

Slide next tube section in and attach with screw/s.

4

Continue until all but one extension is connected. Cut

and install last section of extension tube.

Tape ALL joints. Go to Section 9 to continue standard install.

5

2

2 x 4 Support

Extension Tube(s)

5

1

Bottom

Adjustable Tube

Optional Long Shaft Installation,

showing Adjustable Tubes at an angle.

19

Page 20

Section-12a

Metal Roofing InstallationUsing Formable Aluminum Flashing

TOOLS & PARTS

Drill

Drill Bit (For Metal)

Gloves

Hole Cutting Template

Power Saw

2

Cut Hole In Roof

Start with regular installation instructions beginning in Section 1.

After finding your roof location, drill up through the

1

roof until it pushes carefully through the panel, on the

roof side. (An assistant on the roof is recommended

during this step.)

Select the correct Hole Cutting Template for the tube

2

(10” or 14”).

Locate the drilled hole. Use the correct Hole Cutting

3

Template to trace the diameter using the outer

template hole. A nail inserted into the hole will help

guide the template.

Use a reciprocating/sabre saw to cut the roof hole.

4

Use a blade specifically for metal cutting. Use gloves

for safety.

Hole Cutting Template

3

TIP

Drill a hole inside the traced circle to insert saw blade.

4

20

Page 21

Section-12b

Metal Roofing InstallationUsing Formable Aluminum Flashing

TOOLS & PARTS

Caulk Gun

Measuring Tape

Metal Shears

Roofing Sealant

Safety Equipment

Plastic Underlayment

Flashing

2

Cut Slit In Roof Panel

Draw a horizontal line across the center of the hole in

1

the roof, running side to side the entire width of the

Formable Flashing.

Cut a slit through the METAL ROOF PANEL ONLY

2

across the horizontal line. Use gloves for safety.

With your safety gloves on, be sure your cut is

3

smooth and free of sharp edges.

Slide the Plastic Underlayment Flashing through the

4

slit under the upper metal panel and felt paper.

Then down under the lower metal panel. Be sure the

opening is aligned with the cut hole.

Run a continuous bead of sealant between the

5

Underlament Flashing and the next layer of roofing

around the opening.

5

4

4

Plastic Underlayment Flashing fully

inserted underneath metal roof

21

Page 22

Section-12c

Metal Roofing InstallationUsing Formable Aluminum Flashing

TOOLS & PARTS

Drill

Phillips Screwdriver

Gloves

Roofing Sealant

Hole Cutting Template

Formable Main Flashing

(9) 2” Screws

(9) 3/4 Washers

1

Position & Secure Flashing

Slide the UPPER portion of the main flashing under

1

the metal panel through the slit. Be sure to align the

flashing directly over the hole.

“Dry-fit form” the lower side of the flashing to

2

conform to the panel ridges.

Once flashing is formed over the panel ridges to your

3

satisfaction, apply a generous bead of sealant to the

underside of the LOWER flashing section.

Press formed flashing down around roofing material.

4

Attach with (9) 2” screws and 3/4 diameter washers

5

in an evenly spaced circular pattern around the 10” or

14” hole. The circular pattern should be 21” diameter

on the 10” unit and 24” diameter on the 14” unit.

Add additional 2” pan head screws as needed to

secure edge of flashing.

Refer back to Section 4c for complete installation.

IMPORTANT

Be sure to dab sealant on all screw heads to ensure a

leak-free installation.

2

5

3

4

22

Page 23

Section-13a

Tile Roof Intallation

Using Formable Aluminum Flashing

TOOLS & PARTS

Drill

Drill Bit

Formable Aluminum Flashing

Pencil

Spike/Rod

Find Hole Location On Roof

Start with regular installation instructions beginning in Section 1.

After finding your roof location, drill up through the

1

roof. Then drive a 4”-6” rod or spike up through

the roof sheathing until it pushes the tile/shingles

upward on the roof side. (An assistant on the roof is

recommended during this step.)

Carefully remove the lifted tile and remove the rod/

2

spike from it’s hole.

Position the Formable Aluminum Flashing piece

3

perfectly centered over the punctured hole.

3

Trace the opening of the formable collar base so that

4

your tiles are marked. This will assist in trimming the

roofing materials to properly fit the flashing once in

place.

Flash Piece Centered over

Puncture Hole

4

The Opening Of The Flashing’s Collar

Base Is Traced Onto The Tiles

23

Page 24

Section-13b

Tile Roof Intallation

Using Formable Aluminum Flashing

TOOLS & PARTS

Gloves

Hole Cutting Template

Power Saw

1

Remove Tiles & Cut Hole

Carefully remove the tiles or shingles from the “work

1

area”. Set them aside in the same order or pattern as

when attached to the roof.

Select the correct hole cutting template for the tube

2

(10” or 14”).

Use the correct Hole Cutting Template to trace the

3

diameter of the outer template hole. A nail inserted

into the hole will help guide the template.

Use a reciprocating/sabre saw to cut the roof hole. .

4

Use gloves for safety.

TIP

Drill a hole inside the traced circle to insert saw blade.

2

Hole Cutting Template

3

4

Hole Cut in Roof Deck

24

Page 25

Section-13c

Tile Roof Intallation

Using Formable Aluminum Flashing

TOOLS & PARTS

Metal Shears

Safety Equipment

Clear Plastic

Underlayment

Slit Cut In

Felt Paper

1

Position The Clear Plastic Underlayment

Cut a slit through the felt paper at the “3:00 and

1

9:00” positions. Be sure the slit is as wide as the

Clear Plastic Underlayment.

Slide the Clear Plastic Underlayment up through the

2

slit under the upper felt paper. Be sure the opening is

aligned with the cut hole. Remove any fasteners/nails

that obstruct the Clear Plastic Underlayment.

Be sure opening is

2

aligned with the cut hole

Slide Plastic Flashing

2

Up Through Slit

25

Page 26

Section-13d

Tile Roof Intallation

Using Formable Aluminum Flashing

TOOLS & PARTS

Gloves

Power Saw

Formable Formable Flashing

Clear Plastic Underlayment

Top Adjustable Tube

Dry-Fit All The Parts

Do a practice run of installing the Clear Plastic

1

Underlayment, Formable Aluminum Flashing, and the

reflective tube

Remember to use protective gloves when handling metal.

Position the components in place. If the hole cut in

the roof deck is too small to allow proper position of

components, enlarge the hole with power saw.

Top Adjustable

Tube

26

Formable Aluminum

Flashing

Clear Plastic Underlayment

Page 27

Section-13e

Tile Roof Intallation

Using Formable Aluminum Flashing

TOOLS & PARTS

Caulk Gun

Roofing Sealant

Safety Equipment

Clear Plastic

Underlayment

1

Seal The Clear Plastic Underlayment

Secure the Clear Plastic Underlayment to the roof

1

deck by applying a generous, continuous bead of

sealant on the underside of the flashing.

Sealant

27

Page 28

Section-13f

Tile Roof Intallation

Using Formable Aluminum Flashing

TOOLS & PARTS

Gloves

Formable Aluminum

Flashing

Clear Plastic

Underlayment

Top Adjustable Tube

2

Top Adjustable

Tube

1

Formable Aluminum

Flashing

Position & Shape The Formable

Aluminum Flashing

Position the Formable Aluminum Flashing in place by

1

centering it’s opening with the hole cut into the roof

deck.

Centering is best achieved by inserting the reflective

2

tube into the opening of the aluminum flashing letting

the fit of the tube-to-roof hole serve as a guide.

The uphill half of the Formable Aluminum Flashing

3

should be laying on top of the felt roofing paper,

while the downhill half of the flashing should be

laying on top of the downhill tiles.

Manually shape the downhill edge of the Formable

4

Aluminum Flashing to match the surface of the tiles.

3

TIP

You might find it difficult contouring the Formable

Aluminum Flashing to fit the downhill tiles. Try shifting

those tiles further downhill to allow more aluminum to

work with. Or add a 2” shim to the roof deck so the

Formable Aluminum Flashing is angled to the roof rather

than parallel to it.

Clear Plastic

Underlayment

4

2” Shim To Help

Shape Flashing

(Not Included)

28

Page 29

Section-13g

Tile Roof Intallation

Using Formable Aluminum Flashing

TOOLS & PARTS

Gloves

Formable Aluminum Flashing

(9) 2” Metal Flashing Screws

Washers

Phillips Screwdriver

Roofing Sealant

1

Sealant

Secure The Formable Aluminum Flashing

Once the Formable Aluminum Flashing is shaped to

1

match the downhill tiles, clean and dry the surfaces of

aluminum, felt paper, and tile. Apply roofing sealant

to all adjoining surfaces.

Secure the Formable Aluminum Flashing with the

2

Metal Flashing Screws and Washers.

The 9 screws provided should be installed in a circular,

equally spaced pattern around the aluminum collar

to improve water sealing. Dab roof sealant on each

screw to create a water-tight seal.

The 10” unit has a 21” diameter screw pattern;

the 14” unit has a 24” diameter screw pattern

TIP

The optional wooden shim can be used as a screw

anchor as well.

Screws In

2

Circular Pattern

3

Screws Anchored

Into Optional Shim

29

Page 30

Section-13h

Tile Roof Intallation

Using Formable Aluminum Flashing

TOOLS & PARTS

Gloves

Safety Equipment

Exterior Clear

Pure Silicone

Reinstall Tiles

Reinstall the trimmed tiles at the sides of the roof

1

cutout, making sure to install them in the same

pattern as they were removed, from bottom to top.

These tiles need to be installed on top of the Formable

Aluminum Flashing.

Make any required adjustments in trimming the tiles

or shingles for a proper fit around the side of the

formable flashing collar. A “proper fit” is one that is

within 1”-2” of the aluminum vertical wall.

Attach these tiles with nails, caulk the heads of the

nails with Exterior Silicone.

Reinstall the final tiles along the uphill edge of the

2

formable flashing. This requires the row of tiles to

be lifted slightly and may be necessary to loosen their

attachments.

Secure the tiles with nails, caulk the heads of the nails

with sealant.

Quick setting mortar may be used to fill in the gaps

3

2

between the tile and aluminum collar to provide

proper run-off of water.

Check all areas for proper sealing and water run-off.

1

3

TIP

Paint the Formable Aluminum Flashing to match the

color of the tiles or shingles, if desired.

Install remaining components of the tubular skylight

4

as instructed in standard installation starting in

Section 4c.

30

Page 31

For new homes and projects requiring building permits cut out

1

NFRC label once product installation is complete.

Affix to diffuser ring as shown and secure with tape.

2

Label to remain in place until final inspection to qualify project

3

for Energy Star.

31

Loading...

Loading...