Page 1

Flame Miniature Spectrometer

User Manual

Amy to r

For Products: FLAME-S, FLAME-T

Document: 225-00000-000-11-201604

Page 2

Ocean Optics, Inc.

830 Douglas Ave.

Dunedin, FL 34698

USA

Manufacturing & Logistics

4301 Metric Dr.

Winter Park, FL 32792

USA

Ocean Optics Asia

666 Gubei Road

Kirin Tower Suite 601B

Changning District

Shanghai

PRC, 200336

Sales & Support

Geograaf 24

6921 EW Duiven

The Netherlands

Manufacturing & Logistics

Maybachstrasse 11

73760 Ostfildern

Germany

AMERICAS & WORLD HEADQUARTERS

Phone: +1 727-733-2447

Fax: +1 727-733-3962

Sales: info@oceanoptics.com

Orders: orders@oceanoptics.com

Support: techsupport@oceanoptics.com

EUROPE, MIDDLE EAST & AFRICA

Phone: +31 26-319-0500

Fax: +31 26-319-0505

Email: info@oceanoptics.eu

Germany : +49 711-341696-0

UK : +44 1865-811118

France : +33 442-386-588

ASIA

Phone: +86 21-6295-6600

Fax: +86 21-6295-6708

Email: asiasales@oceanoptics.com

Japan & Korea: +82 10-8514-3797

Copyright © 2015 Ocean Optics, Inc.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, by any means,

electronic, mechanical, photocopying, recording, or otherwise, without written permission from Ocean Optics, Inc.

Trademarks

All products and services herein are the trademarks, service marks, registered trademarks or registered service marks of their

respective owners.

Limit of Liability

Every effort has been made to make this manual as complete and as accurate as possible, but no warranty or fitness is implied. The

information provided is on an “as is” basis. Ocean Optics, Inc. shall have neither liability nor responsibility to any person or entity

with respect to any loss or damages arising from the information contained in this manual.

www.oceanoptics.com

Page 3

Table of Contents

About This Manual ......................................................................................................... v

Document Purpose and Intended Audience .............................................................................. v

Document Summary .................................................................................................................. v

Product-Related Documentation ............................................................................................... vi

Document Version ..................................................................................................................... vi

Patent Pending Notice ................................................................................................... vi

Warranty ........................................................................................................................ vii

ISO Certification ............................................................................................................ vii

Compliance ................................................................................................................... vii

Chapter 1: Introduction ..................................................................... 1

Product Introduction ...................................................................................................... 1

Product Features ....................................................................................................................... 2

Typical Applications ................................................................................................................... 3

Product Versions ....................................................................................................................... 6

Chapter 2: Installation and Setup ..................................................... 9

What’s In the Box ................................................................................................ .......... 9

Flame Installation ................................................................................................ .......... 9

Software Installation .................................................................................................................. 10

About OceanView ...................................................................................................................... 11

Hardware Setup ......................................................................................................................... 11

Hardware Features .................................................................................................................... 13

Flame LEDs .......................................................................................................................... 13

Change the Slit ...................................................................................................................... 13

Accessories ................................................................................................................... 14

Cables and Connectors ............................................................................................................. 14

DB15 Connector Cable (FLAME-CBL-DD4P-DB15P) .......................................................... 15

PAK50 Connector Cable (FLAME-CBL-DD4P-PAK50P) ..................................................... 16

Breakout Box (HR4-BREAKOUT) ............................................................................................. 16

Interchangeable Slits ................................................................................................................. 16

Light Sources, Cuvette Holders and Other Accessories ........................................................... 17

Measurement Techniques – Typical Set-ups ................................................................. 17

Absorbance ............................................................................................................................... 17

225-00000-000-11-201604 i

Page 4

Table of Contents

Common UV-Vis Applications ............................................................................................... 18

Reflectance & Transmission ...................................................................................................... 18

Common UV-Vis Reflectance Applications ........................................................................... 18

Common UV-Vis Transmission Applications ........................................................................ 18

Fluorescence ............................................................................................................................. 19

Common Fluorescence Applications .................................................................................... 19

Irradiance ................................................................................................................................... 20

Common Irradiance Applications .......................................................................................... 21

Chapter 3: Flame Operation with OceanView .................................. 23

Overview ....................................................................................................................... 23

Launch OceanView ....................................................................................................... 23

OceanView Main Screen ............................................................................................... 24

Connect the Flame in OceanView ............................................................................................. 25

Set Acquisition Parameters ....................................................................................................... 25

Quick View and Device Response ............................................................................................ 26

Continuous and Single Acquisitions .......................................................................................... 26

Save Data .................................................................................................................................. 27

Saved Data Panel ...................................................................................................................... 27

Projects and Methods ................................................................................................................ 28

Spectroscopy Application Wizards ............................................................................................ 29

Dark and Reference Measurements ......................................................................................... 29

Schematic View ......................................................................................................................... 30

Chapter 4: Troubleshooting .............................................................. 31

Overview ....................................................................................................................... 31

Microsoft Windows Operating Systems ................................................................................ 32

Apple Mac OSX Operating Systems ..................................................................................... 33

Linux Operating Systems ...................................................................................................... 33

Chapter 5: How the Flame Spectrometer Works ............................. 37

Overview ....................................................................................................................... 37

Chapter 6: Technical Specifications ................................................. 45

Mechanical Diagram ...................................................................................................... 48

Electrical Pinout ............................................................................................................. 49

DD4 Accessory Connector Pinout Diagram .............................................................................. 49

SPI ......................................................................................................................................... 52

I2C ......................................................................................................................................... 52

ii 225-00000-000-11-201604

Page 5

Table of Contents

CCD Overview ............................................................................................................... 52

CCD Detector ............................................................................................................................ 52

CCD Well Depth ........................................................................................................................ 53

Signal Averaging ....................................................................................................................... 53

Internal Operation ...................................................................................................................... 54

Pixel Definition ...................................................................................................................... 54

CCD Detector Reset Operation ................................................................................................. 55

Timing Signals ............................................................................................................... 55

Strobe Signals ........................................................................................................................... 55

Single Strobe ......................................................................................................................... 55

Continuous Strobe ................................................................................................................ 56

Synchronous Continuous Strobe .......................................................................................... 56

External Triggering ........................................................................................................ 56

Triggering Modes ....................................................................................................................... 57

Normal ................................................................................................................................... 57

External Synchronous Trigger Mode .................................................................................... 57

External Hardware Level Trigger Mode ................................................................................ 57

External Hardware Edge Trigger Mode ................................................................................ 57

Chapter 7: Calibration ....................................................................... 59

Overview ....................................................................................................................... 59

Wavelength Calibration.................................................................................................. 59

About Wavelength Calibration ................................................................................................... 59

Calibrating the Spectrometer Wavelength ................................................................................. 60

Preparing for Calibration ....................................................................................................... 60

Calibrating the Wavelength of the Spectrometer .................................................................. 60

Irradiance Calibrations ................................................................................................... 63

Chapter 8: Firmware and Advanced Communications ................... 65

FLAME-S Firmware ....................................................................................................... 65

Hardware Description ................................................................................................................ 65

USB Information ........................................................................................................................ 65

Instruction Set ............................................................................................................................ 65

Command Syntax .................................................................................................................. 65

USB Command Summary ......................................................................................................... 66

USB Command Descriptions ................................................................................................ 67

Flame –S Serial Port Interface Communications and Control Information ............................... 81

Hardware Description ............................................................................................................ 81

Instruction Set ....................................................................................................................... 82

Command Descriptions ......................................................................................................... 84

FLAME-T Firmware ....................................................................................................... 91

Hardware Description ................................................................................................................ 91

225-00000-000-11-201604 iii

Page 6

Table of Contents

Spectral Memory Storage ..................................................................................................... 91

USB Information ........................................................................................................................ 91

Instruction Set ............................................................................................................................ 91

Command Syntax .................................................................................................................. 91

USB Command Summary ......................................................................................................... 92

USB Command Descriptions ................................................................................................ 93

Flame –T Serial Port Interface Communications and Control Information ................................ 106

Hardware Description ............................................................................................................ 106

Spectral Memory Storage ..................................................................................................... 106

Instruction Set ....................................................................................................................... 106

Command Summary ............................................................................................................. 106

Command Descriptions ......................................................................................................... 108

Examples .............................................................................................................................. 116

Index ................................................................................................... 117

iv 225-00000-000-11-201604

Page 7

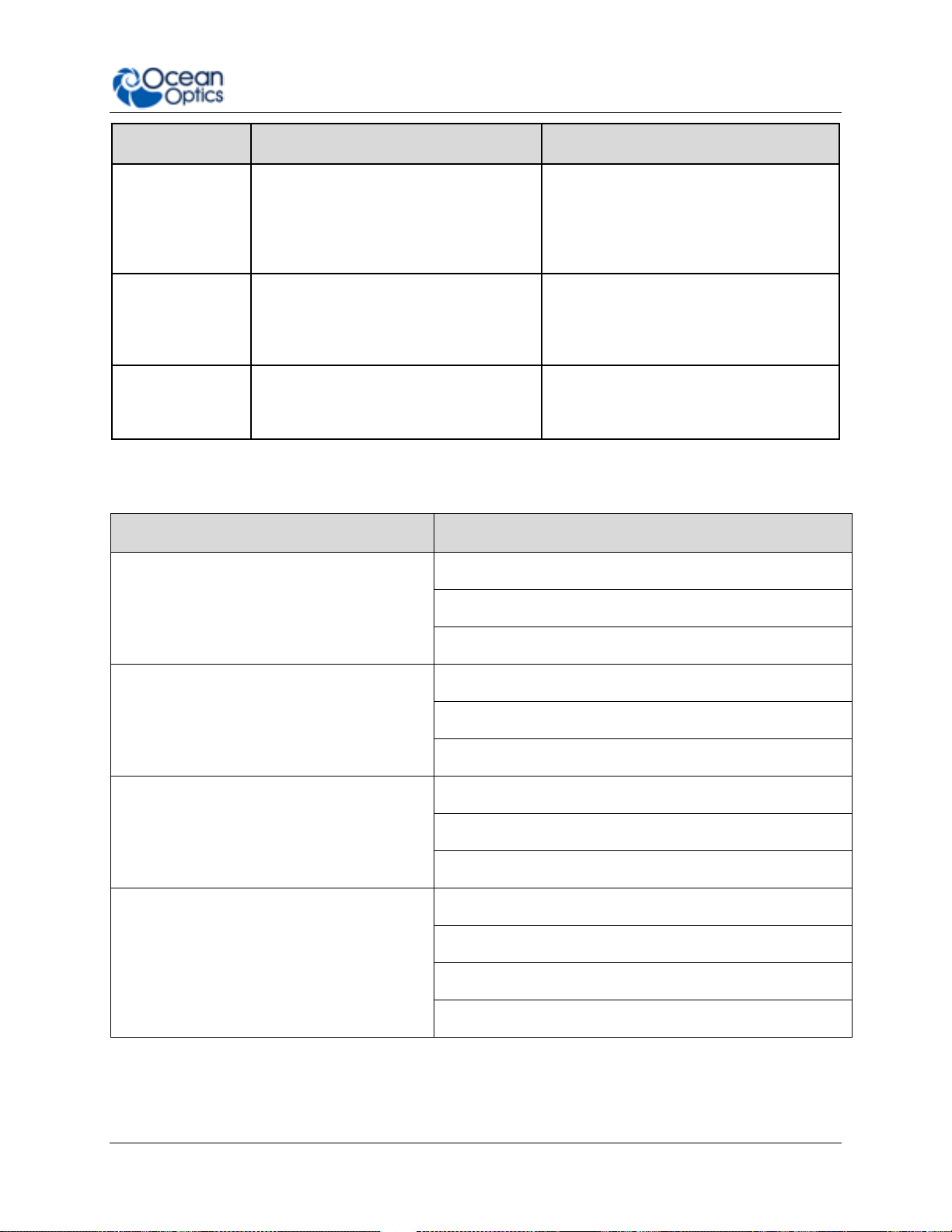

Chapter

Description

Chapter 1: Introduction

Introduces the product features. Contains descriptive

information about the Flame Spectrometer. It also provides a

list of system requirements, typical applications, and product

versions.

Chapter 2: Installation and Setup

Provides installation instructions, including how to set up the

Flame with OceanView. Also includes package contents and

typical set-ups for different measurement techniques.

Chapter 3: Flame Operation with

OceanView

Describes how to use the Flame with OceanView software,

including how to connect, acquire, save and other basic

features.

Chapter 4: Troubleshooting

Contains recommended steps to isolate and correct common

problems.

Chapter 5: How the Flame

Spectrometer Works

Describes how the Flame operates, illustrating the various

parts and functions.

Chapter 6: Technical

Specifications

Contains technical specifications and connector pinouts for the

Flame Spectrometer.

Chapter 7: Calibration

Provides instructions for calibrating the Flame Spectrometer.

Chapter 8: Firmware and

Advanced Communications

Contains a description of firmware commands.

About This Manual

Document Purpose and Intended Audience

Thank you for choosing Ocean Optics! We hope that you’ll be delighted with your decision. This

document provides the users of Flame Spectrometers with instructions for setting up,

calibrating and performing experiments with their spectrometer. It also contains detailed

technical specifications and information about firmware and hardware integration. If you can’t

find what you’re looking for in this document, please do not hesitate to contact us at

techsupport@oceanoptics.com or via www.oceanoptics.com.

Document Summary

225-00000-000-11-201604 v

Page 8

About This Manual

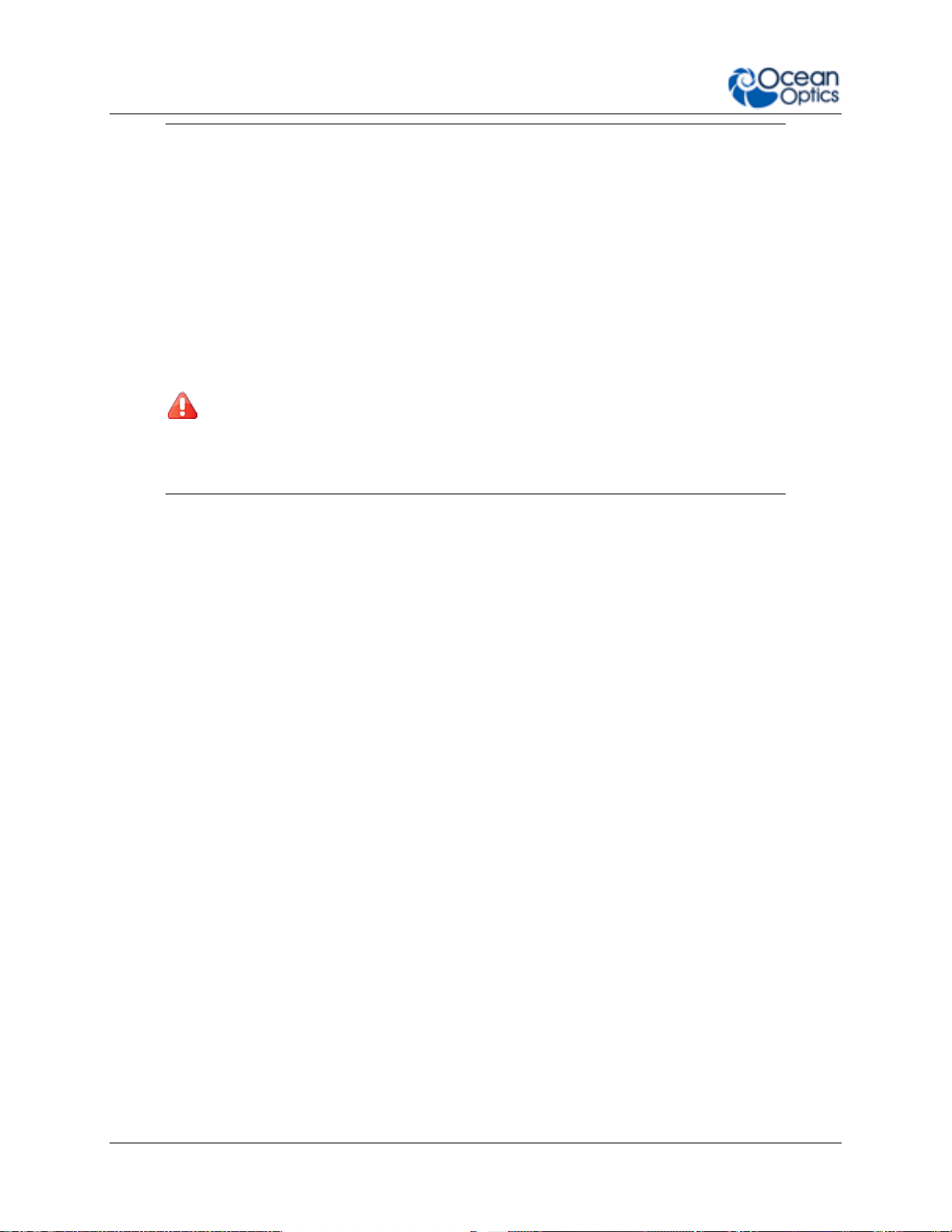

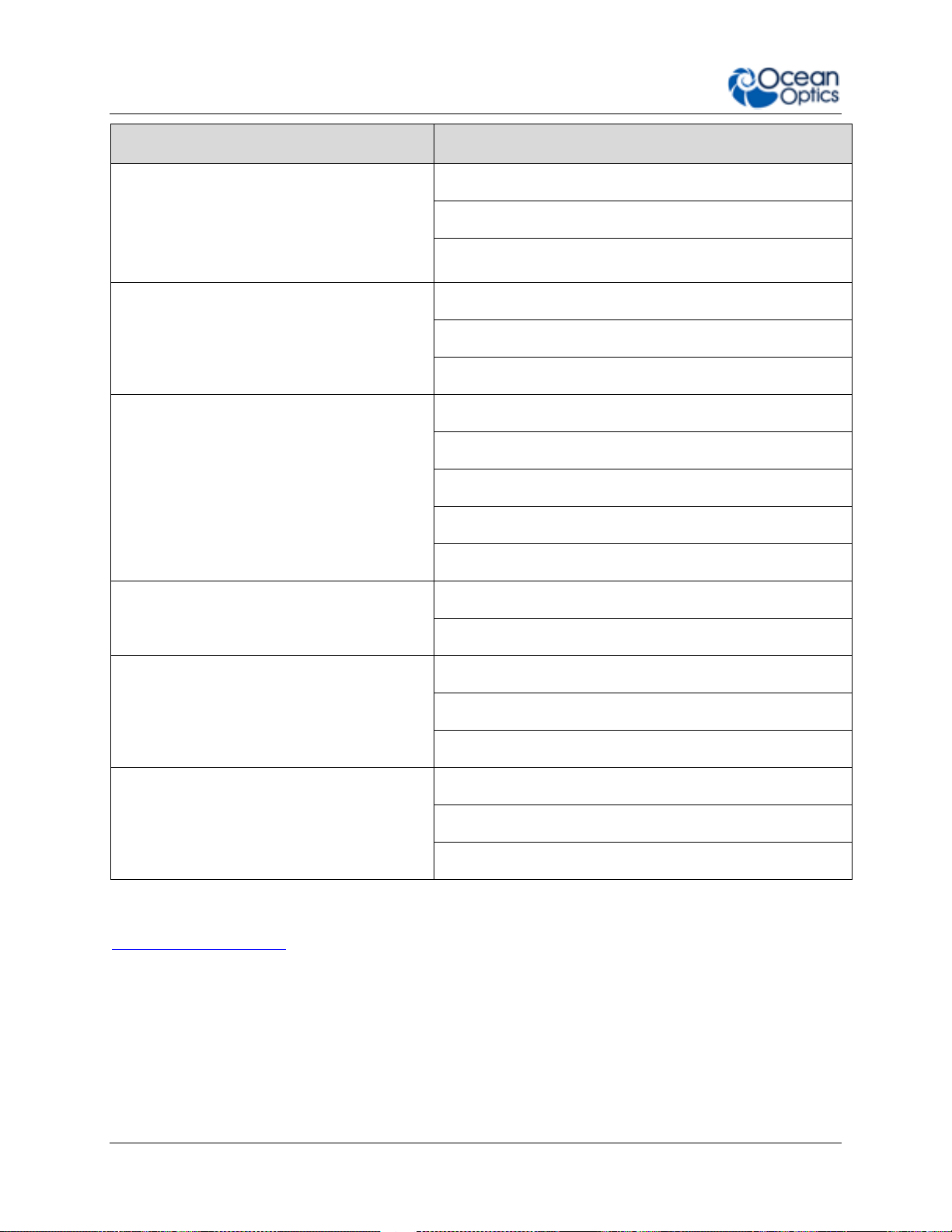

Document for…

Document Location

OceanView software

http://oceanoptics.com/wp-content/uploads/OceanViewIO.pdf

SpectraSuite software

http://oceanoptics.com///wp-content/uploads/SpectraSuite.pdf

HR-4 Breakout Box

http://oceanoptics.com/wp-content/uploads/HR-4-Breakout-Box.pdf

External triggering

http://oceanoptics.com/wp-content/uploads/External-TriggeringOptions_Firmware3.0andAbove.pdf

Replacing the slit

http://oceanoptics.com/wp-content/uploads/INTSMA-Slit.pdf

Device driver issues

http://oceanoptics.com///wp-content/uploads/Correcting-Device-Driver-Issues.pdf

Document Number

Version

225-00000-000-11-201503

First release

225-00000-000-11-201503b

Updates technical specifications, troubleshooting instructions, and

other minor issues.

225-00000-000-11-201504

Updates the Electrical pinout information

225-00000-000-11-201505

Adds information for the Performance Charts.

225-00000-000-11-201505

Updates the specificaitons.

225-00000-000-11-201604

Updates the specifications and triggering information

Product-Related Documentation

You can access documentation for Ocean Optics products by visiting our website at

http://www.oceanoptics.com. Select Support Technical Documents, then choose the

appropriate document from the available drop-down lists.

Ocean Optics offers a Glossary of spectroscopy terms to help you further understand your

state-of-the-art products and how they function, located at: http://oceanoptics.com/glossary/.

Document Version

Patent Pending Notice

The Flame spectrometer is covered by Patents Pending. Any violation of Ocean Optics

intellectual property will be prosecuted.

vi 225-00000-000-11-201604

Page 9

About This Manual

Warranty

Our 3-Year Warranty covers Ocean Optics miniature fiber-optic spectrometers, spectral sensors,

light sources and sampling accessories – regardless of the application – from manufacturing

defects. It also covers fibers and probes for a full 12 months:

http://oceanoptics.com/services/exclusive-3-year-warranty/.

This comprehensive warranty ensures you of the highest level of craftsmanship and reliability

for years to come. No other manufacturer offers such a solid guarantee of quality and reliability.

The Ocean Optics 3-Year Warranty applies to Ocean Optics equipment (excluding OEM

configurations) purchased on or after July 1, 2010. The warranty covers parts and labor needed

to repair manufacturing defects that occur during the warranty period. We also will cover the

costs of shipping warranty-related repairs from our customers to Ocean Optics and from us to

our customers.

ISO Certification

Ocean Optics, the industry leader in miniature photonics, has been certified for ISO 9001:2008

certification applicable to the design and manufacture of electro-optical equipment since 2009.

Compliance

This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

WARNING

225-00000-000-11-201604 vii

Page 10

About This Manual

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which the user will be required

to correct the interference at his own expense.

WARNING: The authority to operate this equipment is conditioned

by the requirement that no modifications will be made to the

equipment unless the changes or modifications are expressly approved

by the manufacturer.

viii 225-00000-000-11-201604

Page 11

Chapter 1

Introduction

Product Introduction

The Flame Spectrometer is the latest generation of Ocean Optics’ ubiquitous Czerny-Turner

design. With the release of the world’s first miniature spectrometer in 1993, Ocean Optics

helped to make spectroscopy portable, inexpensive and flexible in a way that was never before

possible. Researchers, educators and OEM manufacturers embraced the technology and have

used it in ways we never thought possible.

Flame Spectrometer

Now, fueled by our passion for solving problems, and inspired by the feedback of our customers

we have reinvented our core miniature spectrometer platform to meet the most demanding

challenges of today’s applications. Flame combines our heritage, creativity and insight in a way

that delivers the power of miniature, modular spectroscopy without compromise.

Flame is built using industry leading manufacturing techniques that help deliver high thermal

stability and low unit to unit variation without compromising the flexibility and configurability

that are the hallmark of the design. New features such as interchangeable slits, indicator LEDs

and simpler device connectors deliver more freedom and less frustration.

Whether you are an educator looking for an instrument to teach students the basic principles of

spectroscopy, a research lab looking to make a breakthrough, a scientist working in the field to

study the world around us or an engineer working to integrate a spectrometer into an OEM

system, the Flame will provide you with the performance and features you need to make your

UV-Vis spectroscopy application successful.

225-00000-000-11-201604 1

Page 12

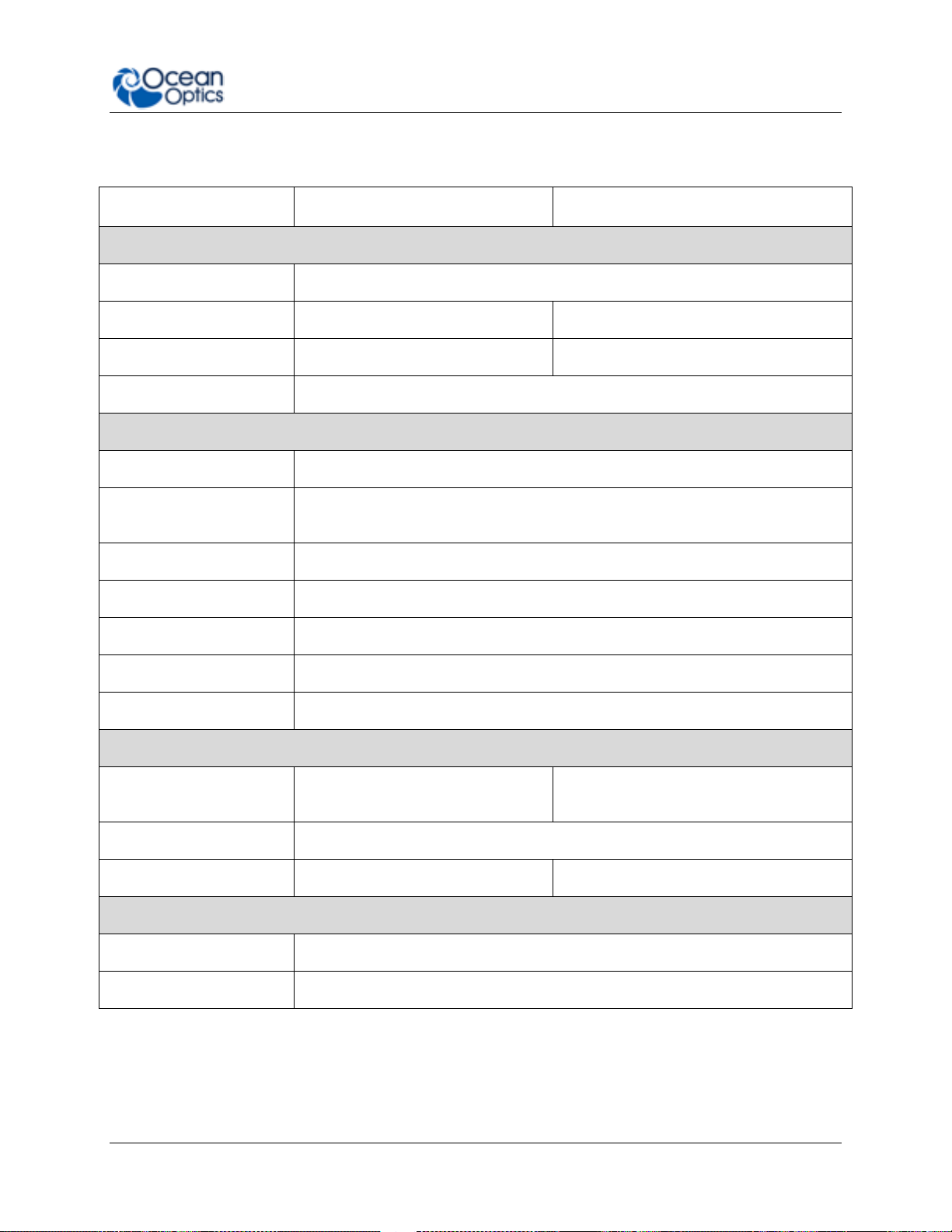

1: Introduction

Key Feature

Best For…

Example Applications

UserInterchangeable

Slits

Users who wish to vary resolution and

throughput during measurements, or

switch from absorbance to

fluorescence in minutes

Life science and other labs using a wide

variety of biological samples

Indicator LEDs

Convenient visual reference for

spectrometer operation and status

Teaching and general lab use

Thermal Stability

Applications that require repeatable

results in industrial and other

environments with varying

temperatures and conditions

LED binning and light metrology,

process monitoring

Reduced Unit to

Unit Variation

OEM applications such as uncalibrated

sensitivity and other measurement

needs where users benefit from low

variance

OEM manufacturers of analytical

instrumentation

Product Features

Incredibly configurable, with over 1 billion possible off-the-shelf configurations across

the wavelength range 190-1100nm. Balanced throughput, resolution and range to

optimize the spectrometer for your application.

Works seamlessly with Ocean Optics’ large range of light sources, accessories and

software

Easy to use. Plug and play via the micro-USB connection.

User-interchangeable slit allows you to vary the resolution and throughput of the

spectrometer on demand. In seconds, go from high resolution to high throughput using

the same spectrometer.

Indicator LEDs show the power and data transfer status of the spectrometer at all times.

Compact and lightweight. The “go anywhere” spectrometer for the lab and in the field.

The introduction of new, high-tech manufacturing methods has dramatically improved

optical alignment accuracy resulting in improved unit-to-unit performance and

reproducibility.

High thermal stability allows for accurate and repeatable measurements in demanding

environments.

Choice of USB or RS-232 serial communications supported by drivers and software that

make it easy to integrate into almost any system.

8 GPIO pins and the ability to provide power to external devices through the 40-pin

connector.

2 225-00000-000-11-201604

Page 13

1: Introduction

Key Feature

Best For…

Example Applications

Configurability

Optimizing your spectrometer for

application-specific requirements;

adjusting range, throughput and

resolution and adding features such as

filters as required

Laser characterization, low signal

fluorescence and optimizing for specific

absorbance bands

Plug & Play

Operation

Users that want the convenience of

simple, fast operation via the micro

USB connection; lets users take the

measurement to the sample

Remote sensing measurements in the

field, including air and water quality

monitoring and solar irradiance

Ease of

Integration

OEMs and developers who need to

integrate a spectrometer as part of a

system via USB or RS-232

Engineering labs, developers, OEM

manufacturers; works with LabVIEW

and other design platforms

Application Area

Examples

Light Laser LED

Laser Characterization

LED Measurement

Light Metrology Measurement

Research and Education

Applied Research

Basic Research

Teaching Labs for Physics, Chemistry, Biomed

Life Sciences

Biotechnology

Medical Diagnostics

Protein and Nucleic Acid Analysis

Materials Identification

Biomaterial Analysis

Metallurgical Analysis

Polymer Analysis

Semiconductor Materials Analysis

Typical Applications

225-00000-000-11-201604 3

Page 14

1: Introduction

Application Area

Examples

Semiconductors Processing and Thin Film

Metrology

Plasma Monitoring

Process Endpoint Detection

Thickness Measurement

Farm to Table Technologies

Agricultural Measurements and Monitoring

Food and Beverage Quality Control

Food Safety

Energy Technologies

Biofuels Analysis

Mining and Exploration

Oil and Petroleum Analysis

Photovoltaic Analysis

Solar Simulators

Anti-Counterfeit

Testing and Qualification

Product Identification and Authentication

Quality Control and Process Monitoring

Defect Identification

Raw Material Inspection

Verification Testing

Environmental Monitoring

Air and Water Quality Analysis

Remote Sensing

Volcanic Research

You can find more information about applications of UV-Vis spectroscopy and the Flame at

www.oceanoptics.com.

4 225-00000-000-11-201604

Page 15

1: Introduction

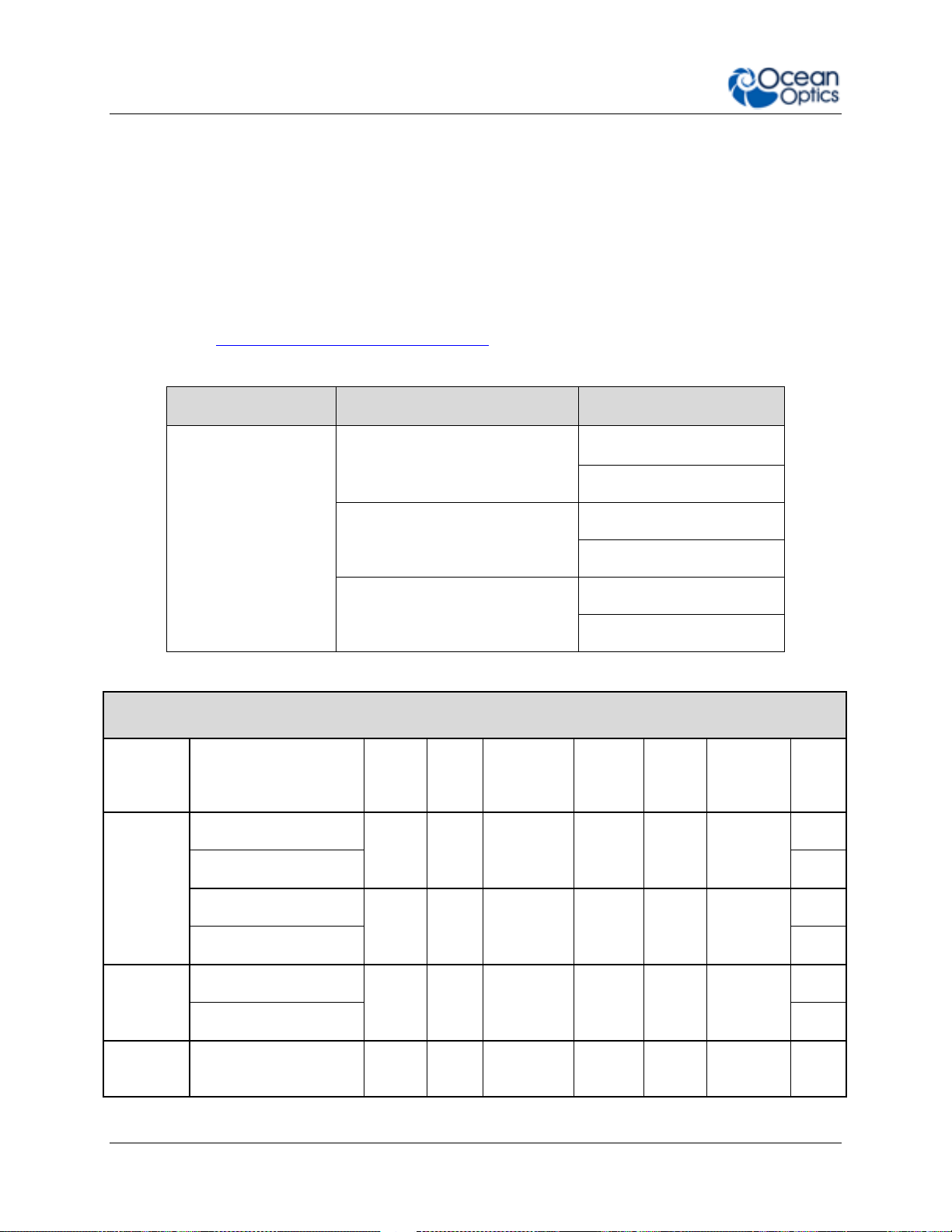

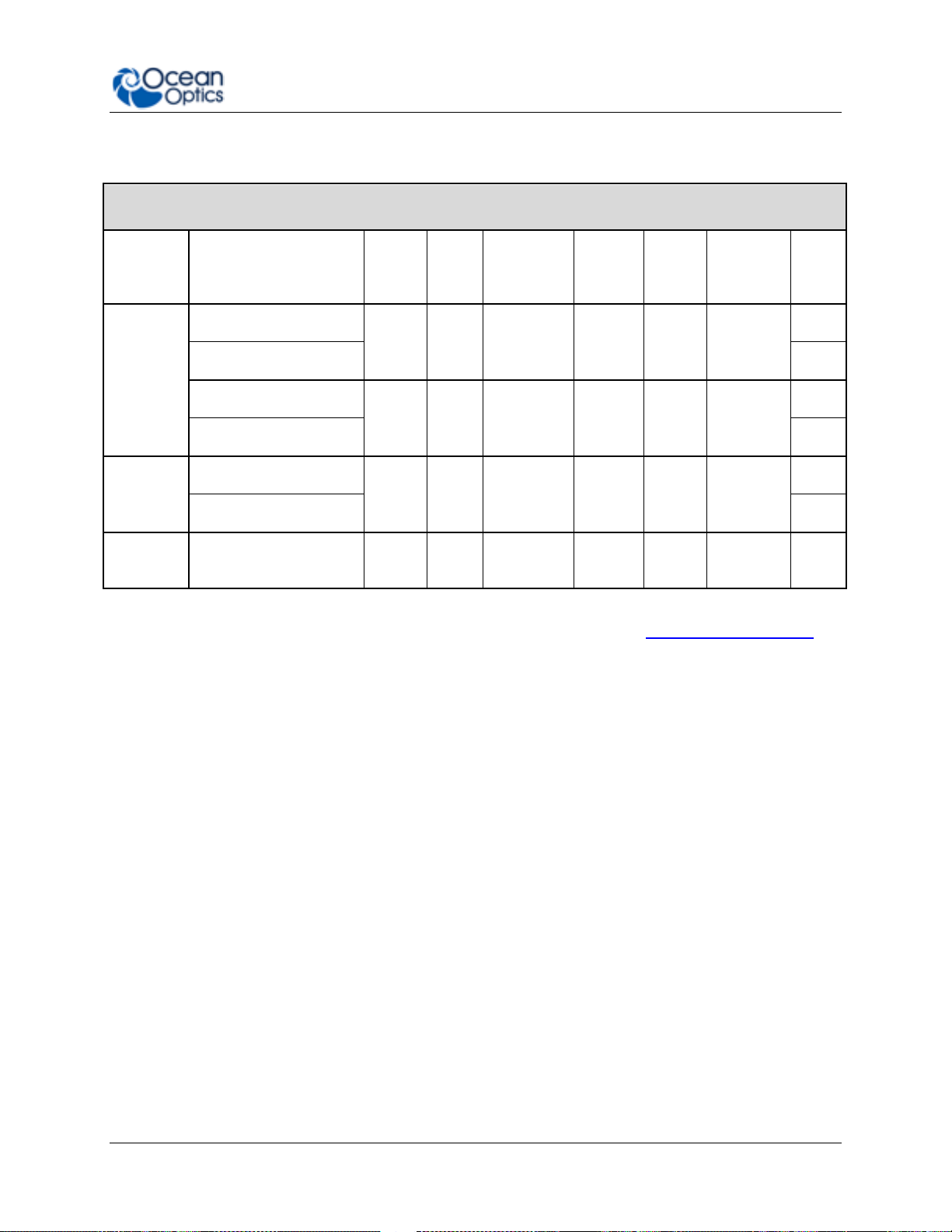

Specification

FLAME-S

FLAME-T

SPECTROSCOPIC

Optical resolution

~0.1-10.0 nm FWHM (configuration dependent)

Signal-to-noise ratio

250:1

300:1

Integration time

10 µs – 65 seconds

3.8 ms – 10 seconds

Corrected linearity

>99.8%

ELECTRONIC

A/D resolution

16 bit

Power requirement

(spectrometer functions)

250 mA @ +5 VDC

Inputs/Outputs

8 x digital user programmable GPIOs

Trigger modes

4 modes

Strobe functions

Yes

Gated delay feature

Yes

Connectors

Micro-USB and JAE DD4 40-pin connector

DETECTOR

Detector

Sony ILX511B linear silicon CCD

array

Toshiba TCD1304AP linear CCD array

Detector range

190–1100 nm

Pixels

2048 pixels

3648 pixels

PHYSICAL

Dimensions

88.9 mm x 63.5 mm x 31.9 mm

Weight

265 g

Specifications Summary

225-00000-000-11-201604 5

Page 16

1: Introduction

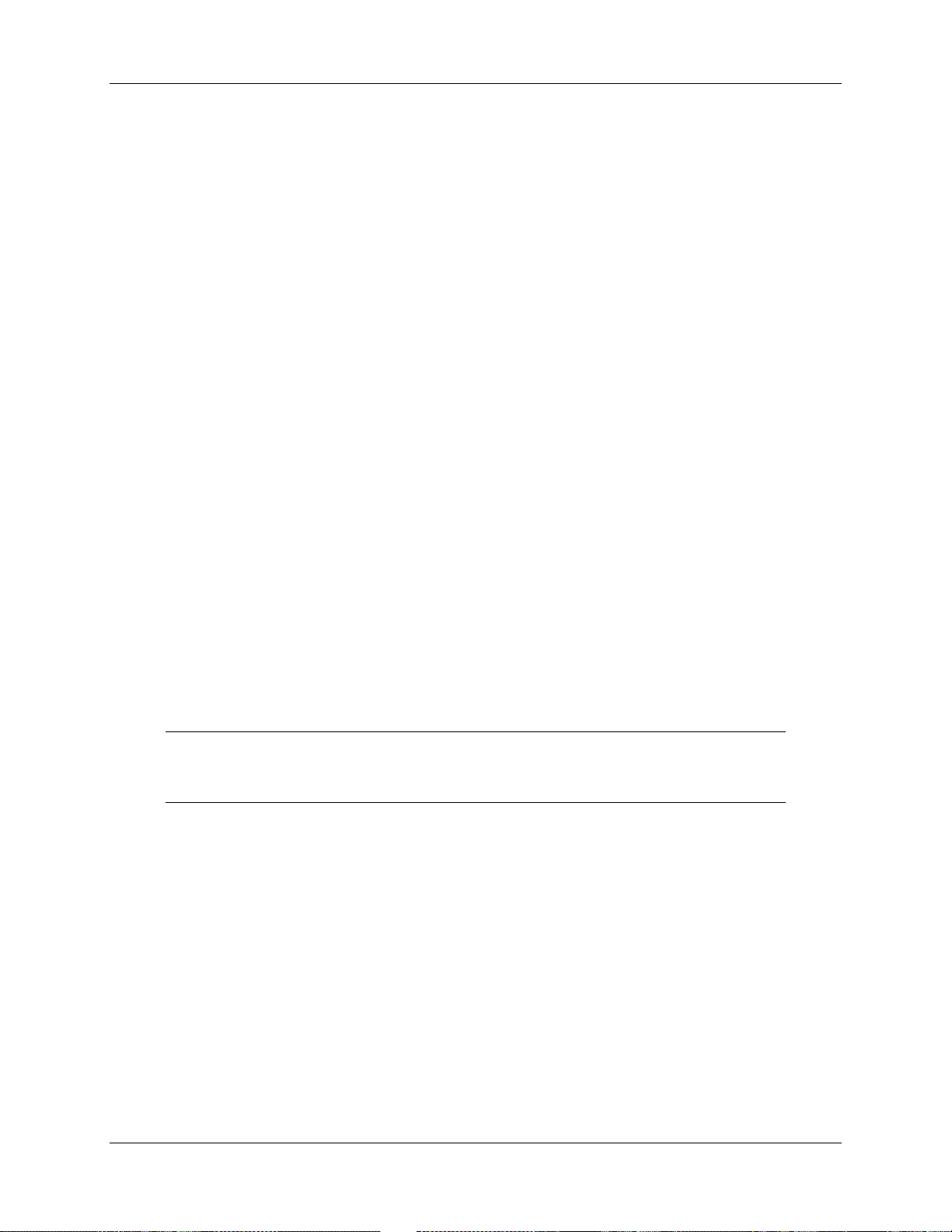

Spectrometer Family?

Detector Type?

Preconfigured or Custom?

FLAME-

S- (Sony ILX511B)

UV-VIS, VIS-NIR, XR

CUSTOM

T- (Toshiba TCD1304AP)

UV-VIS, VIS-NIR, XR

CUSTOM

F- (Hamamatsu S11639)

UV-VIS, VIS-NIR, XR

CUSTOM

FLAME-S Preconfigured Models (Sony ILX511B Detector)

Model

Range

(nm)

Std

Slit

(μm)

Resolution

std slit

(nm)

Grating

#

Mirror

Type

Filters &

Detector

Options*

Lens

General

Purpose

FLAME-S-UV-VIS

200850

25

~1.5

1

Al

OSF

200-850

no

FLAME-S-UV-VIS-ES

L2

FLAME-S-VIS-NIR

3501000

25

~1.5

3

Al

OSF

350-1000

no

FLAME-S-VIS-NIR-ES

L2

Extended

Range

FLAME-S-XR1

2001025

25

~2

31

Al

OSF

200-1100

no

FLAME-S-XR1-ES

L2

Irradiance

FLAME-S-RAD

3601000

50

~3 2 Al

UV

Window

no

Product Versions

Many variants of the Flame Spectrometer exist. Ocean Optics offers both preconfigured units as

well as custom-configured units, enabling you to order a customized spectrometer optimized for

your application. You can tell which kind of spectrometer you have by looking at the product

code, located on the bottom of your spectrometer.

You can find more information about the various components and possible configuration options

in Chapter 5: How the Flame Spectrometer Works.

Product Code Taxonomy

Preconfigured Models

6 225-00000-000-11-201604

Page 17

1: Introduction

FLAME-T Preconfigured Models (Toshiba TCD1304TP Detector)

Model

Range

(nm)

Std

Slit

(μm)

Resolution

std slit

(nm)

Grating

#

Mirror

Type

Filters &

Detector

Options*

Lens

General

Purpose

FLAME-T-UV-VIS

200850

25

~1.5

1

Al

OSF

200-850

no

FLAME-T-UV-VIS-ES

L2

FLAME-T-VIS-NIR

3501000

25

~1.5

3

Al

OSF

350-1000

no

FLAME-T-VIS-NIR-ES

L2

Extended

Range

FLAME-T-XR1

2001025

25

~2

31

Al

OSF

200-1100

no

FLAME-T-XR1-ES

L2

Irradiance

FLAME-T-RAD

3601000

50

~3 2 Al

UV

Window

no

For more information and specifications on preconfigured models, see www.oceanoptics.com.

225-00000-000-11-201604 7

Page 18

1: Introduction

8 225-00000-000-11-201604

Page 19

Installation and Setup

What’s In the Box

Packing List

The packing list is inside a plastic bag attached to the outside of the shipment box (the

invoice arrives separately). It lists all items in the order, including customized

components in the spectrometer (such as the grating, detector collection lens, and slit).

The packing list also includes the shipping and billing addresses, as well as any items on

back order.

Flame Spectrometer

Your Flame spectrometer arrives pre-calibrated and ready to plug and play.

Chapter 2

Micro USB Cable

Use this cable (CBL-MICROTOA-USB) to connect your spectrometer to a computer

running on a Windows, Mac or Linux operating system.

Wavelength Calibration Data Sheet

Each spectrometer is shipped with a Wavelength Calibration Data Sheet that contains

information unique to your spectrometer. OceanView reads this calibration data from

your spectrometer when it interfaces to a computer via the USB port.

Note

Please save the Wavelength Calibration Data Sheet for future reference.

Flame Installation

The following procedure provides general instructions for getting your new Flame spectrometer

up and running.

225-00000-000-11-201604 9

Page 20

2: Installation and Setup

Caution

Be sure to install the software BEFORE connecting the spectrometer to your PC.

The software installs the drivers required for spectrometer installation. If you do

not install the software first, the system will not properly recognize the

spectrometer.

If you have already connected the Flame to a computer running on a Windows

platform prior to installing the operating software, consult Chapter 4:

Troubleshooting for information on correcting a corrupt Flame installation.

► Procedure

Use the following procedure to get your system up and running quickly. See Hardware

Setup for more detailed information.

1. Install your spectroscopy operating software by following the installation wizard

prompts. See Software Installation for more in-depth information.

2. Locate the micro USB cable provided with the spectrometer. Connect the spectrometer

to the USB port on your computer using this cable.

3. Take measurements. Refer to your spectrometer operating software manual for

information on the software user interface.

Software Installation

Use OceanView version 1.5 and above for Flame. Flame can be used with SpectraSuite, but will

appear as a USB2000+ Spectrometer in the software. You can use OceanView or SpectraSuite

on the following operating systems.

Caution

Be sure that you download the correct software package for your computer

version (32 or 64-bit). See the Frequently Asked Questions in Chapter 4:

Troubleshooting for more information on determining your computer version.

10 225-00000-000-11-201604

Page 21

2: Installation and Setup

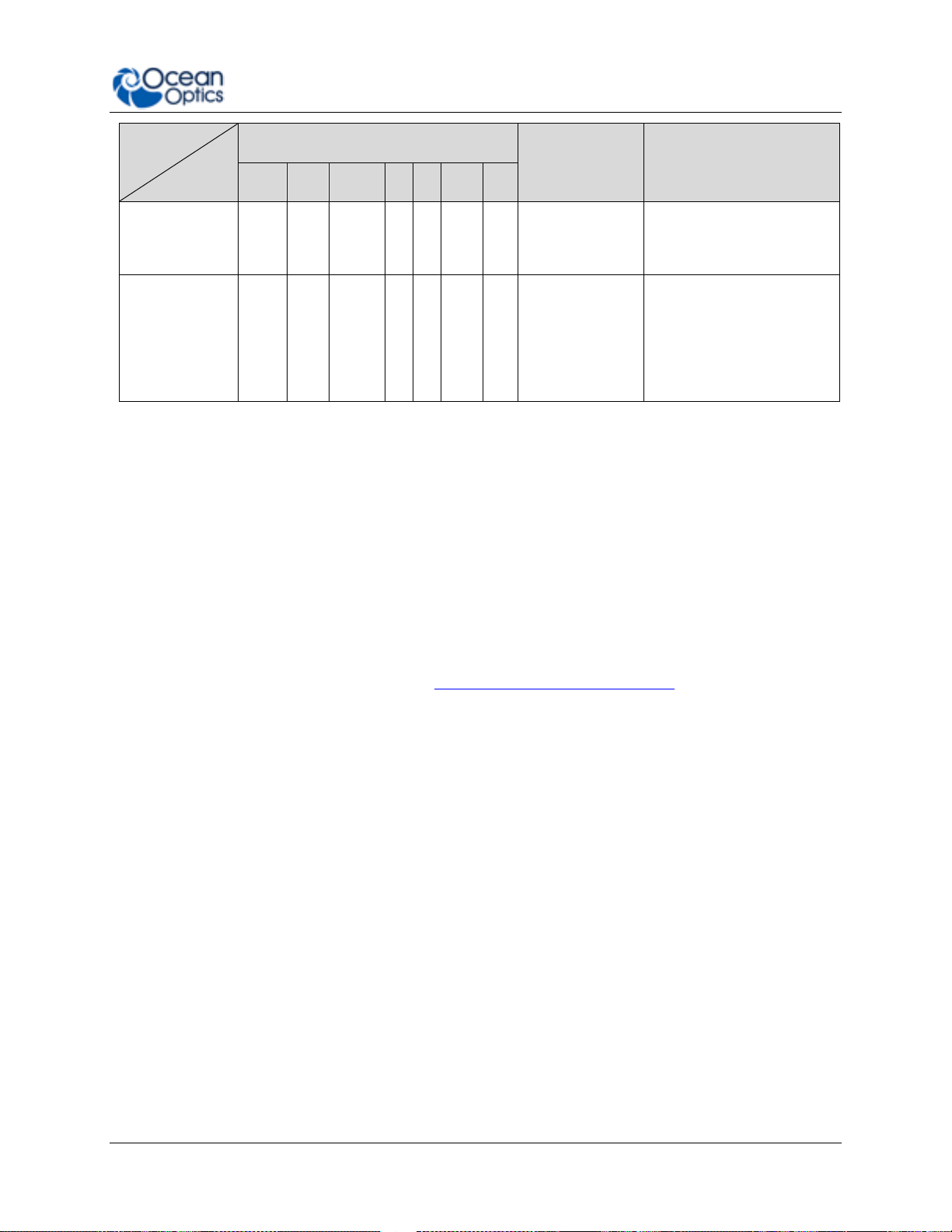

Software

OS

Windows

Apple

Linux

2000

XP

Vista

7 8 8.1

10

OceanView

√ √ √ √ √

√

OS X Version

10.5 or later on

Intel processor

Any version released for

an x86 or amd64 platform

since 2010

SpectraSuite

√ √ √

√

OS X Version

10.0 or later

Red Hat 9 or later,

Fedora (any version),

Debian 3.1 or later

(Sarge), SUSE (9.0 or

later), Centos (any

version), and Ubuntu

About OceanView

OceanView is the latest generation of operating software for all Ocean Optics spectral devices.

It is a Java-based spectroscopy software platform that operates on Windows, Macintosh and

Linux operating systems. The software can control any Ocean Optics USB device.

OceanView is a user-customizable, advanced acquisition and display program that provides a

real-time interface to a variety of signal-processing functions. With OceanView, you have the

ability to perform spectroscopic measurements (such as absorbance, reflectance, and emission),

control all system parameters, collect and display data in real time, and perform reference

monitoring and time acquisition experiments. Consult the OceanView manual for hardware

requirements when using OceanView (see Product-Related Documentation).

Hardware Setup

The Flame Spectrometer connects to a computer via the USB port or serial port. When

connected through a USB 2.0 or 1.1 port, the spectrometer draws power from the host

computer, eliminating the need for an external power supply. The Flame, like all Ocean Optics

USB devices, can be controlled by our OceanView software (see Product-Related

Documentation).

225-00000-000-11-201604 11

Page 22

2: Installation and Setup

Ocean Optics Flame Fiber Optic Spectrometer Typical Set-up

Follow the steps below to connect the Flame to a computer via the USB port:

1. Install the spectrometer operating software on the destination computer.

2. Locate the USB cable (CBL-MICROTOA-USB) provided with the Flame.

3. Insert the micro connector end of the cable into the side of the Flame and the larger

end of the cable into the USB port of the computer.

4. Connect any spectroscopy accessories. To find operating instructions for Flame-

compatible products (such as light sources, sampling chambers, and probes), consult

the Ocean Optics website at http://oceanoptics.com/support/technical-documents/.

5. Attach the fiber to the fiber optic connector on the spectrometer.

If you installed the spectrometer operating software prior to connecting the Flame, the software

automatically installs the Flame drivers. If the drivers do not successfully install (or if you

connected the Flame to the computer before installing the software), consult Chapter 4:

Troubleshooting.

Note

The Flame driver appears as USB2000+ to your computer since a common driver

is used to ensure backwards and forwards compatibility. This does not affect

functionality.

12 225-00000-000-11-201604

Page 23

2: Installation and Setup

LED

Steady

Flashing

red

Unit is on

N/A

green

Unit is ready

Unit is acquiring data

Hardware Features

Flame LEDs

The Flame features two indicator lights that operate as shown below:

Note that LEDs can be turned off in OceanView or by using a firmware command.

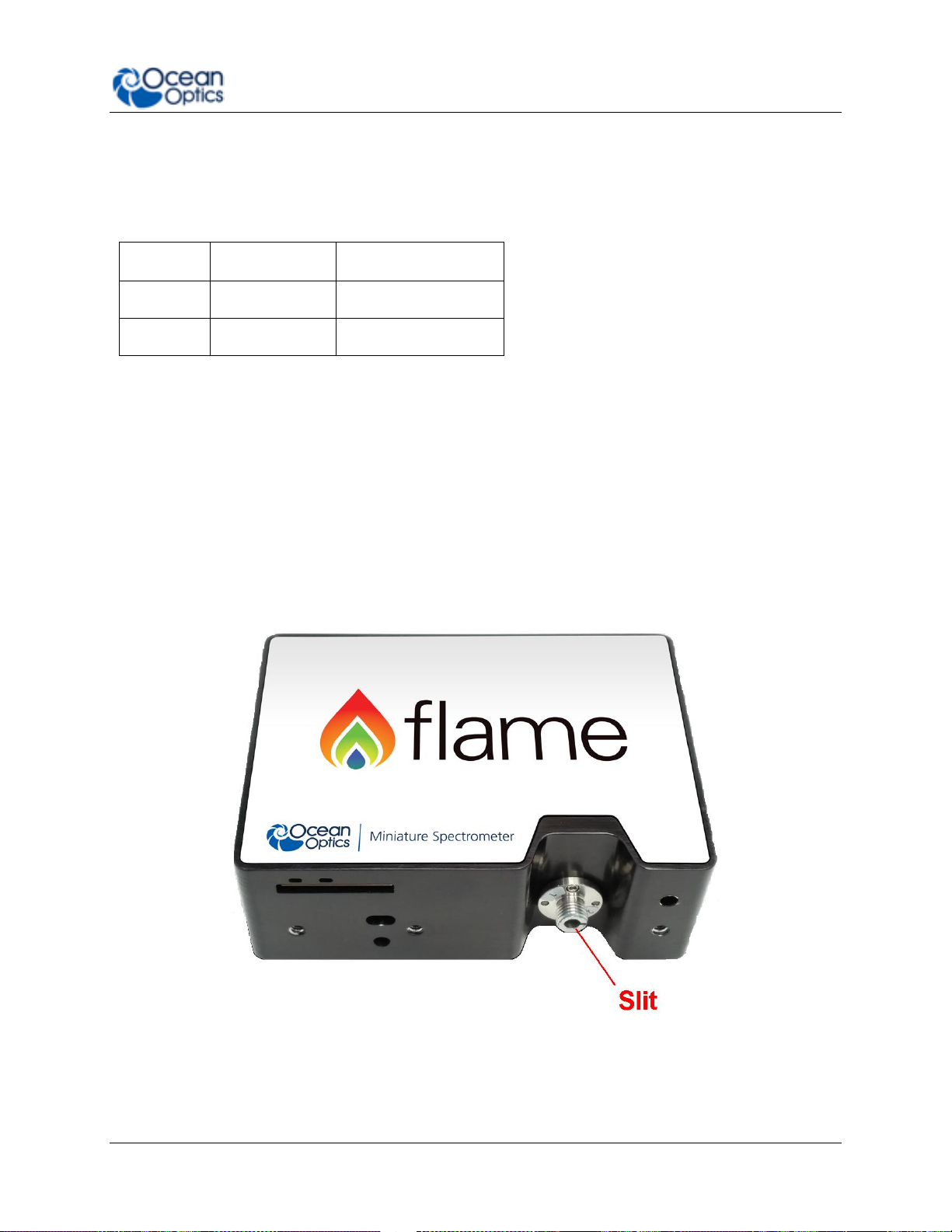

Change the Slit

The Flame allows you to change your spectrometer’s slit to match your application

requirements. Note that a filter must be ordered for each slit (if your application requires a

filter). There’s no need to calibrate your spectrometer when changing the slit, just install and

start measuring!

► Procedure

1. Find the SMA connector. If a fiber is attached, remove it.

2. Use the Allen key to remove the 2 the screws attaching the slit to the spectrometer.

3. Pull the slit out of the spectrometer.

225-00000-000-11-201604 13

Page 24

2: Installation and Setup

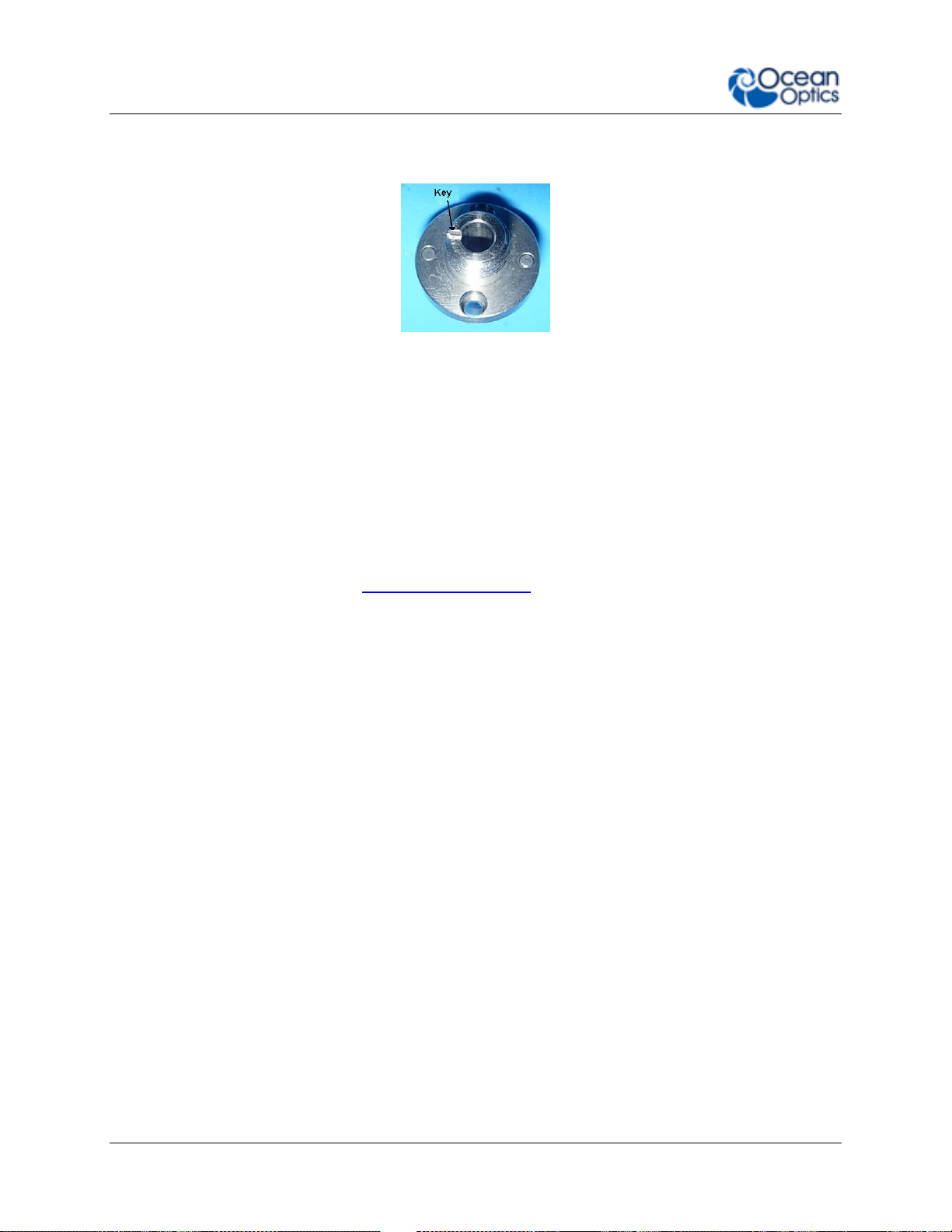

4. Put the new INTSMA slit connector into the spectrometer; with the key of the connector

on the left side.

5. Install the 2 screws again. Use the Allen key to tighten the screws carefully (do not

over-tighten).

6. If necessary, connect the fiber again.

Accessories

Ocean Optics provides a range of standard cables and accessories that connect the Flame to

our large range of sampling and light source accessories. Items specifically designed for the

Flame are described here; they are not provided with the Flame spectrometer and must be

purchased separately. Visit us at www.oceanoptics.com for a complete list of products available

for all of your spectroscopy needs.

Cables and Connectors

Cables are available to connect your Flame Spectrometer to accessories:

Accessory cable for light sources and other accessories (DB15 Connector Cable)

Accessory cable for HR-type connector (PAK50 Connector Cable)

Breakout board (DD4 -BREAKOUT-BOARD ) This breaks out the 40 pin DD4 connector to

a set of header pins that can be used to wire each pin, as required.

14 225-00000-000-11-201604

Page 25

2: Installation and Setup

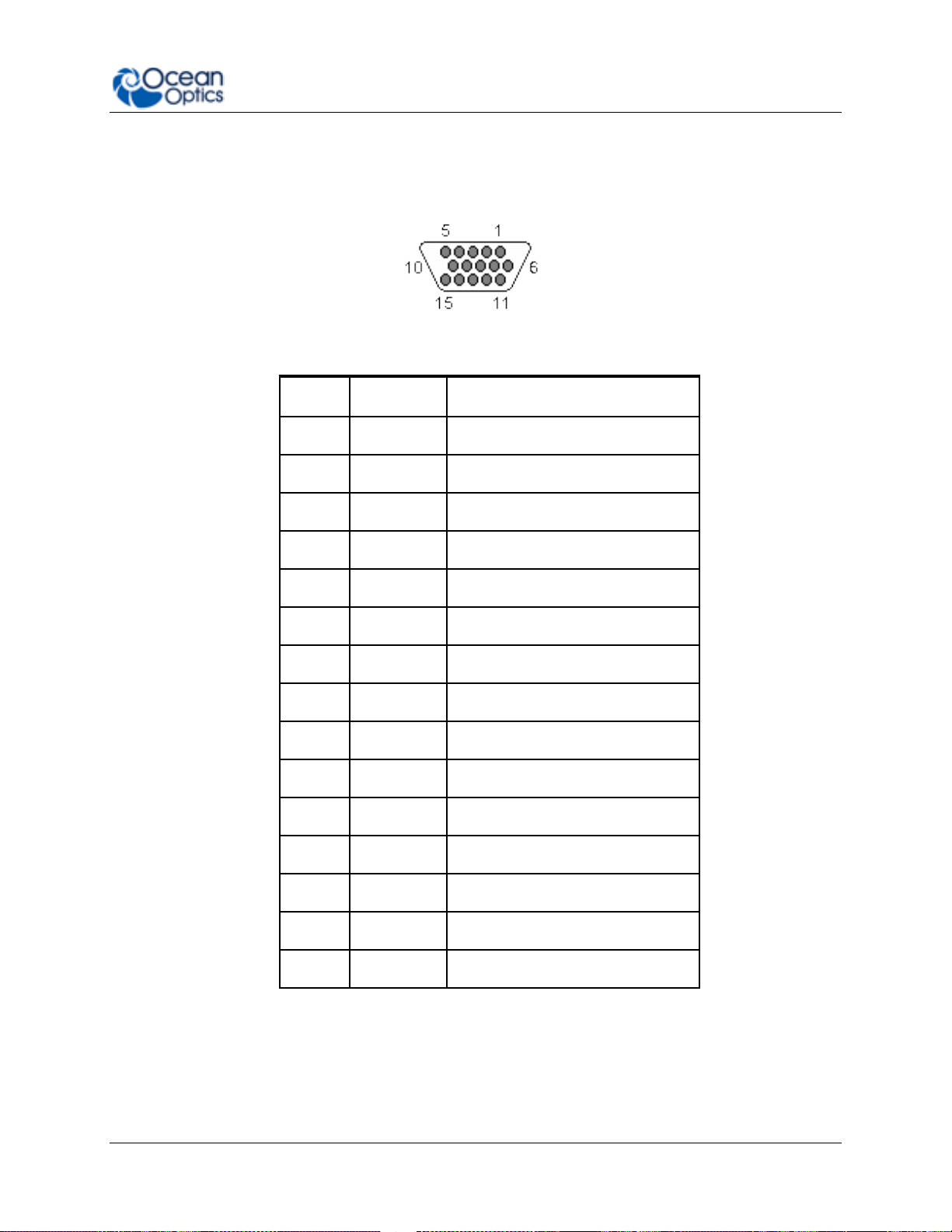

15 PIN

DD4

Name

1 4 Single Strobe

2 3 Continuous Strobe

3

40

Vusb

4 2 External Trigger In

5 2 External Trigger In

6 7 GPIO 1

7

NC

Reserved (NC)

8 2 External Trigger In

9 8 GPIO 2

10 1 Ground

11

22

I2C SDA

12

21

I2C SCL

13 5 Lamp Enable

14

NC

Reserved (NC)

15

11

GPIO 4

DB15 Connector Cable (FLAME-CBL-DD4P-DB15P)

This cable connects the Flame to existing Ocean Optics accessories that use a DB-15HD

connector. These include the PX-2, LLS and HL-2000-FHSA light sources.

DD4-DB15 Pin Connections

225-00000-000-11-201604 15

Page 26

2: Installation and Setup

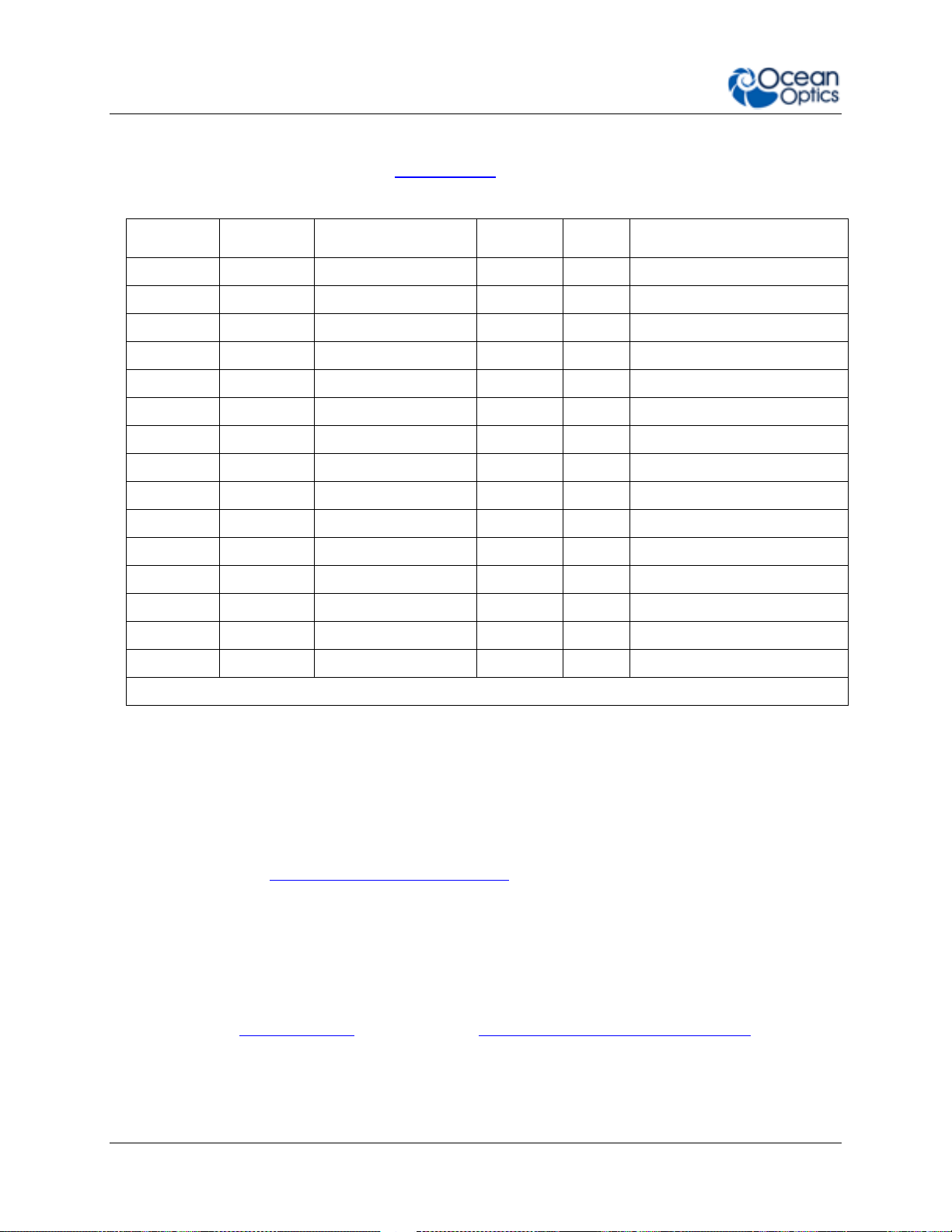

PAK50P

DD4

Name

PAK50P

DD4

Name

1

25

RS232 Rx

16

11

GPIO 4

2

24

RS232 Tx

17 4 Single Strobe

3 8 GPIO 2

18

12

GPIO 5

4

40

VUSB

19

16

SPI CLK

5 1 GND

20 3 Continuous Strobe

6

21

I2C SCL

21

18

SPI CS

7 6 GPIO 0

22

13

GPIO 6

8

22

I2C SDA

23

28

Reserved (do not connect)

9 7 GPIO 1

24

NC

Reserved (NC)

10 2 External Trigger In

25 5 Lamp Enable

11 9 GPIO 3

26

14

GPIO 7

12

40

VUSB

27

10

GND

13

17

SPI MOSI

28

NC

Reserved (NC)

14

40

VUSB

29

15

GND

15

19

SPI MISO

30

NC

Reserved (NC)

For the DD4, connect shield to connector case, if shield is included.

PAK50 Connector Cable (FLAME-CBL-DD4P-PAK50P)

This cable connects the Flame to the Breakout Box.

DD4P to PAK50P 30-Pin Connections

Breakout Box (HR4-BREAKOUT)

The Breakout Box is a passive module that separates the signals from the Flame’s DD4 40-pin

connector to an array of standard connectors and headers, enabling functionality with a wide

range of accessories. In addition to the accessory connector, the breakout box features a circuit

board based on a neutral breadboard pattern that allows custom circuitry to be prototyped on

the board itself. See Product-Related Documentation to access the manual for the Breakout

Box.

Interchangeable Slits

The Flame offers the capability of changing the slit size to match your measurement needs. You

can order additional replacement slits either individually or as a kit (in various widths from 5 µm

to 200 µm). See Change the Slit and Chapter 5: How the Flame Spectrometer Works for more

information.

16 225-00000-000-11-201604

Page 27

2: Installation and Setup

Light Sources, Cuvette Holders and Other Accessories

Ocean Optics supplies a large range of accessories for use with our spectrometers. Visit us at

www.oceanoptics.com for a complete list of products available for all of your spectroscopy

needs.

Fibers

Light Sources

Integrated Sampling Systems

Cuvettes, including microfluidic cuvettes

Filter Holders & Filters including Low Pass, Band Pass and High Pass

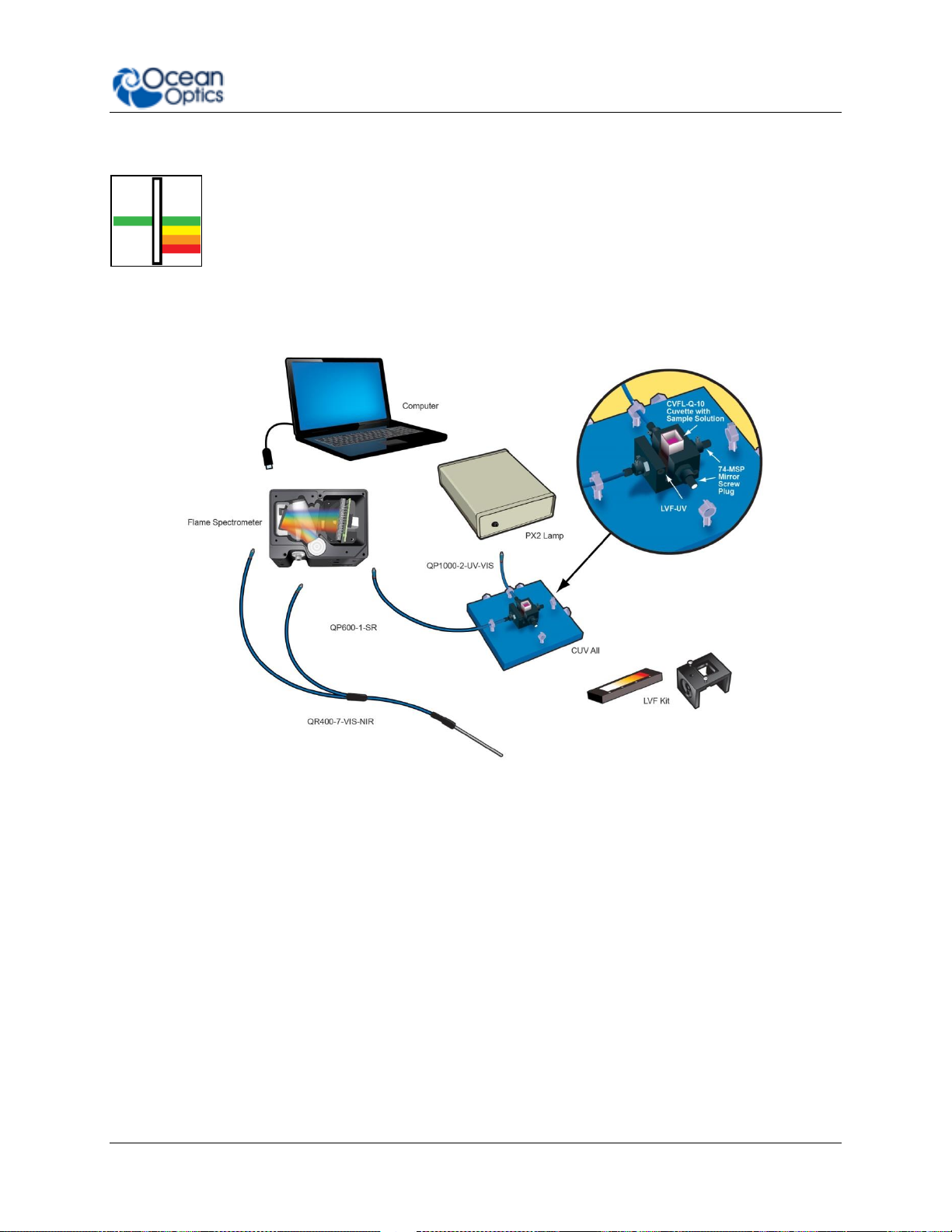

Measurement Techniques – Typical Set-ups

The Flame, in conjunction with Ocean Optics light sources and sampling accessories, can be

used for many different measurement techniques. One of the key advantages of modular fiber

optic spectroscopy is that you can change components of the system without having to buy a

whole new system. Here, we show a range of typical UV-Vis set ups for basic spectroscopy

techniques. You’ll find lots more information about measurement techniques at

www.oceanoptics.com/measurementtechnique.

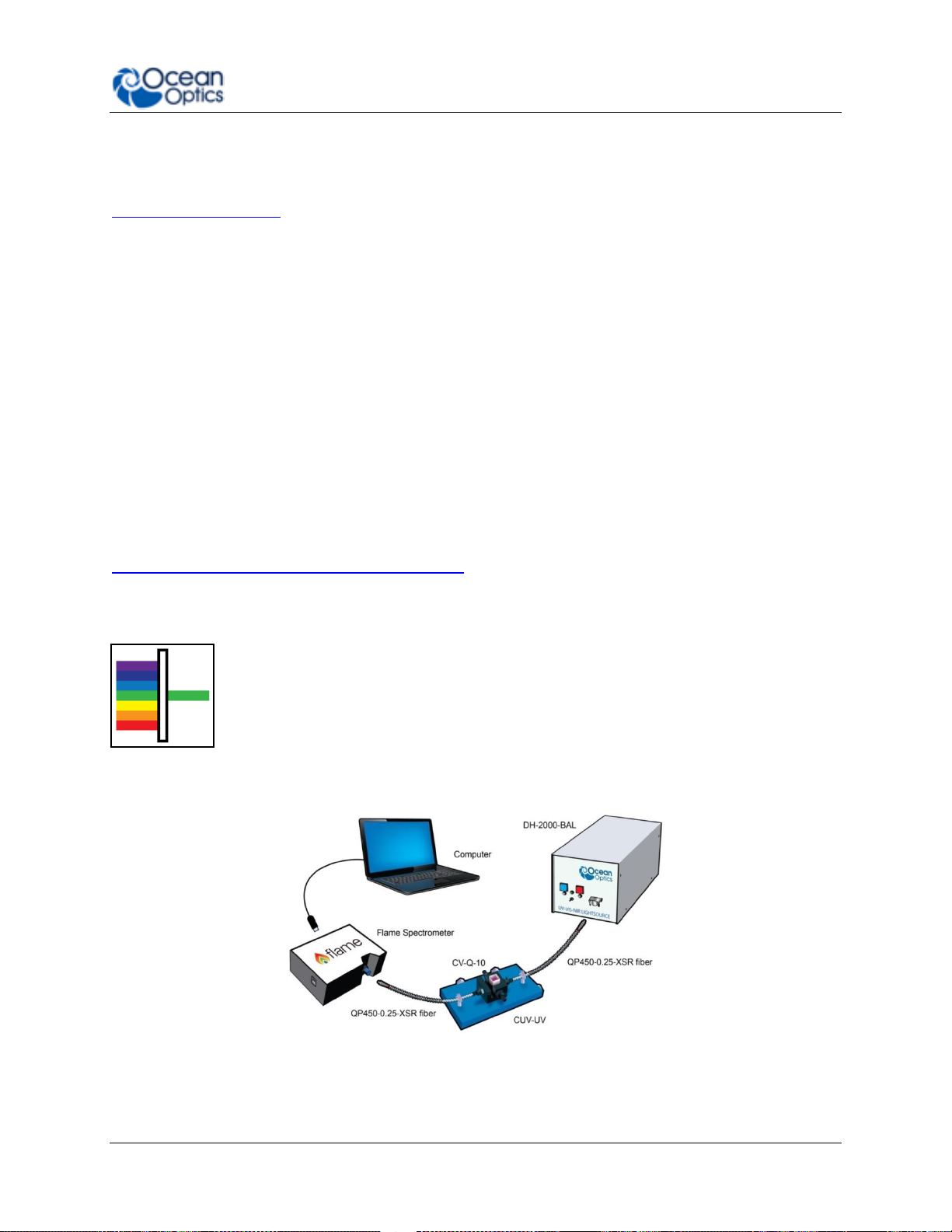

Absorbance

Absorbance is typically a relative measurement, comparing the spectrum from

the sample to that of a reference. Absorbance is commonly used for

concentration measurements and for identifying components in mixtures. The

absorbance measurement scales the response logarithmically. Connect the Flame

to our cuvette accessories via the SMA Adaptor accessory to take a liquid sample

Absorbance measurement, or mount it directly against the sample with a light

source on the opposite side for solid sampling.

Typical Absorbance Set Up

225-00000-000-11-201604 17

Page 28

2: Installation and Setup

Common UV-Vis Applications

Quantification of DNA & proteins in life science samples

Concentration of solutions & gaseous samples

Identification of trace gases in a mixture

Reflectance & Transmission

Reflectance spectroscopy compares the relative level of light reflected off a

sample compared with a reference (given as a percentage of the reference

spectrum at each wavelength). A reflectance standard is used to set the

reference level of 100%. Transmission is similar but compares the light

transmitted through a sample, relative to a reference, rather than reflected off it.

Typically Reflectance uses a fiber optic probe attached to a light source and a

spectrometer, but measurements can be done easily with the Flame, both in

free-space or with the SMA Adaptor accessory. Transmission setups are usually

the same as Absorbance setups.

A Reflectance Set Up with Probe, Reflectance Standard and Probe Holder

Common UV-Vis Reflectance Applications

Diffuse and Specular Color Measurements

Process control for Surface quality of metals

Thin film and semiconductor metrology

Common UV-Vis Transmission Applications

Turbidity measurements of chemical solutions

Measuring the transmission efficiency of optics and glass

18 225-00000-000-11-201604

Page 29

2: Installation and Setup

Fluorescence

Fluorescence is a technique where a sample is excited with a light source and

fluorescent light emitted from the sample at a higher wavelength is measured by

the spectrometer. Typically the excitation source is applied at 90º to the sample

to minimize light from the excitation source reaching the spectrometer. Similarly

filters are used to block lower wavelength light from reaching the detector.

Spectrometers used for fluorescence typically have a large slit, sacrificing

resolution for throughput sensitivity.

Typical Fluorescence Set Up with an LED Excitation Source at 90º

Common Fluorescence Applications

Identifying proteins using fluorophores

NADH fluorescence

Remote sensing of chlorophyll

Medical diagnosis of tumors and tissue types

Detection of anti-counterfeiting tags

225-00000-000-11-201604 19

Page 30

2: Installation and Setup

Irradiance

Irradiance is the technique of measuring the total energy of light at a

given wavelength, either relative to the spectral output of a known source

(relative irradiance) or in absolute units of power or energy (absolute

irradiance). This is used widely in light metrology, color measurement and

environmental science. Absolute irradiance measurements require an

irradiance-calibrated spectral device. This can be done in the factory for

some configurations or by using a calibration lamp in the lab or field.

Every time a set-up is changed, the device used must be recalibrated.

For a more detailed explanation of how to calibrate a device see Chapter 6:

Calibration, or contact Ocean Optics. Use the front-mounted diffuser and SMA

adapter accessories for irradiance measurements with the Flame.

Typical Relative Irradiance Set-up for Measuring Light Power Output of an LED

Using and Integrating Sphere

20 225-00000-000-11-201604

Page 31

2: Installation and Setup

Typical Set-up for an Absolute Irradiance Measurement Using Field Calibration with

a Calibrated Light Source

Common Irradiance Applications

Measuring the radiant output of lamps and LEDs

Measuring color using relative irradiance

Measuring the color rendering index (CRI)

Measuring UV exposure for health and safety

225-00000-000-11-201604 21

Page 32

2: Installation and Setup

22 225-00000-000-11-201604

Page 33

Chapter 3

Flame Operation with OceanView

Overview

The following information enables you to perform the basics of acquiring and saving data with

your Flame Spectrometer and OceanView software. More detailed information about OceanView

is in the OceanView Manual (see Product-Related Documentation).

Launch OceanView

Once you have installed your software and connected your spectrometer, you are ready to

display your measurement data using OceanView. Launching OceanView differs, depending on

your operating system and where you have placed your OceanView program files.

For PCs running Microsoft Windows, the default location is Start | Programs | Ocean Optics |

OceanView | OceanView.

For Mac computers, the default location is the Applications folder.

When you first start OceanView, the Welcome Screen appears.

The OceanView Welcome Screen (Version 1.5)

225-00000-000-11-201604 23

Page 34

3: Operation

1. Acquisition Group Window

Use to set acquisition parameters such as integration time. Controls

the spectrometer acquisition.

2. Schematic View

Schematic view graphically displays the flow of information from the

spectrometer to the view. Use nodes to mathematically modify the

data to create processed measurements (methods). This function is

extremely flexible and incredibly powerful.

3. View Display

Display your data, view, save and display controls, as well as other

features such as peak finder and quick dark & reference.

4. Global Controls

Control all spectrometers synchronously, save projects, and start a

new application wizard.

5. Saved Data

Displays data saved in the active save file path. Preview data, store

notes and load overlays directly to the active view. Click to open.

Quick View - Displays the spectrum in Quick View mode showing raw, unprocessed data.

This is uncorrected for instrument response vs. wavelength. Quick View shows you a live

shot of what the Flame is “seeing.” From Quick View you can launch application wizards or

construct your own method.

Load a Saved Project - Loads a previously saved project. Click Restore Last Session to

reload the schematic and views as they were when the software was last closed.

Spectroscopy Application Wizards – Use this function to set up a measurement using

simple step-by-step wizards. A large range of applications is available.

OceanView Main Screen

No matter what route you take on start up, you will soon end up on the OceanView main

screen. This is where you can set and view acquisitions, save and load data and save projects.

24 225-00000-000-11-201604

Page 35

3: Operation

Connect the Flame in OceanView

The Flame should automatically appear when you start OceanView and should be acquiring with

the default acquisition parameters. If you do not see a signal or the Flame icon on the

schematic you may need to rescan for spectrometers.

► Procedure

To rescan for attached devices,

1. Click on the Device Manager icon ( ).

2. Click Rescan. The spectrometer should automatically connect.

Set Acquisition Parameters

Set Acquisition parameters in the Acquisition Group Window to control the spectrometer. This

window may be minimized when you first start OceanView. You can either expand or open a

new window from the menu (Window | Acquisition Group). An active acquisition is required for

the Acquisition window to appear. Functions available to control in the Acquisition window

include the following:

Integration Time – Sets the integration time, the time over which the detector

captures incident light. At the end of the integration time the accumulated signal is read

from the detector by the electronics.

Averaging – Signal, especially at low levels, is often significantly impacted by noise.

Averaging several spectra together reduces the impact of noise and provides a cleaner

result. However, at long integration times, averaging can increase the total time of a

measurement significantly.

225-00000-000-11-201604 25

Page 36

3: Operation

Boxcar – Boxcar is a form of averaging across pixels. It applies a rolling average to

multiple adjacent pixels to help smooth the spectral response and reduce the impact of

noise.

Electric Dark Correction (on/off) – There are pixels on the detector that are kept

deliberately dark. Dark correction subtracts the signal from these dark pixels to reduce

the impact of thermal noise, which produces a baseline signal from the detector.

Non Linearity Correction (on/off) – Detectors do not have a completely linear

response. As they approach saturation, typically their efficiency reduces.

Stray Light Correction – An advanced user option that allows you to set a 1 or 2-term

polynomial correction for stray light correction.

Trigger Modes – Sets triggering mode. For more information on triggering see External

Triggering.

Strobe/ Lamp (on/off) – Use this function to turn an attached light source on or off.

GPIO Controls – Can be used to control compatible accessories or custom hardware.

Can be set to three states, on, off and alternate.

Controls that appear in this window depend on the spectrometer model. You can add and

remove acquisition controls from this window.

Quick View and Device Response

In Quick View mode (formerly Scope mode) the spectra that are displayed have an arbitrary

y-axis given in counts. This is the raw signal from the detector and is proportional to the

voltage induced by the light falling on the detector.

It is very important to realize that this is uncalibrated data and that a counts signal

does not represent a particular power or energy from one wavelength to the next.

Because the response of the detector is linear, twice the counts at a particular

wavelength do indicate that the amount of light at that wavelength has “doubled”

(relative to another wavelength). However, a small peak relative to a big peak does not

indicate that there is less or more light at a particular wavelength relative to another in

absolute terms. To understand the true relationship you need to do a relative

measurement (including relative irradiance), or if you want a quantified result, an

absolute irradiance measurement.

The relative efficiency of converting light to detector signal varies significantly across the range

of a spectrometer. Many things impact this including the responsiveness of the detector

(quantum efficiency) and the efficiency of optical components. Each configuration of a spectral

device has a unique response curve, referred to as the instrument response.

Continuous and Single Acquisitions

There are two sets of controls for taking or pausing acquisitions. The set on the Acquisition

group window allows you to control each device individually. The set on the top bar is a global

control that will allow you to start and pause all devices currently attached.

26 225-00000-000-11-201604

Page 37

3: Operation

Aquire data continuously

Take a single acquisition and then pause

Pause all acquisitions.

Configure Saving, set saving parameters and file type, file directory and file naming convention.

Once selected, the file directory will persist until changed.

Start saving data. Turns red when save is active. If saving data continuously, click when red to

stop saving. Will only activate saving for acquisitions attached to that particular view.

Global Save. Activates all configured saves across all views. Use to save data from multiple

devices at the same time.

Save Data

By default OceanView will save data as a single “snapshot” acquisition. By configuring the save

you can set the save behavior to fit your measurement needs, from single snap shots to a

continuous stream of data over time.

Saved Data Panel

The saved data panel lets you see your data as it is saved and preview data. It also makes it

simple to add overlays of saved data to your screen.

225-00000-000-11-201604 27

Page 38

3: Operation

1. Saved Files

List of saved files currently in the saved directory. Arrange by name or date.

2. Preview

Shows a preview of the saved spectra, time series or appended series saved data

can be stepped through acquisition by acquisition using the controls above the

saved files list.

3. File Path

Set the file directory.

4. Overlay

Set the previewed spectra as an overlay on the active view.

5. Notes

Enter notes about the saved spectra. Notes are saved with the same file name as

a separate .tsv file. These can be viewed or edited with any text viewer such as

notepad.

Click to save a project. Alternatively select File | Save Project from the menu. Saves all view

and schematic parameters to a single ASCII file.

Load a project or method.

Saved Data Panel

Projects and Methods

OceanView makes it easy to save and load projects and methods. We define a project as a

measurement set up made with a particular spectral device. If the software cannot find the

device, it will load this as a method and prompt the user to select a substitute device from

those selected.

28 225-00000-000-11-201604

Page 39

3: Operation

Click this button to set up a measurement using simple step by step wizards. A large range

of applications is available.

Quick Reference – click to take a reference and set up a new view. After clicking it will prompt

the user to take a dark.

Quick Dark – click to take a dark measurement and sets up a new Quick View minus dark view.

Spectroscopy Application Wizards

Application Wizard Window

Dark and Reference Measurements

Dark and reference measurements are commonly used in spectroscopy.

Dark Measurements – subtract a background signal from the spectrum. This can be

considered the removal of a constant error. Typically this is done when the light source

is off to remove any background from the ambient environment, hence the name dark.

Reference Measurements – make the signal relative to the reference. Consider this a

normalization of the signal against a reference. Typically this is taken with a reference

sample and the light source turned on. This lets you look at the relative spectral change

compared to a reference sample.

Most often you will set up your measurement with the reference and dark through the

application wizards. The wizards will prompt you to take your reference and darks. Alternatively

you can use the quick dark and quick reference features. Once a dark and/or reference

measurement has been set, you can update it with the controls on the top bar of the view.

225-00000-000-11-201604 29

Page 40

3: Operation

Reference – click to update the stored reference measurement.

Dark – click to update the stored dark measurement.

Devices – Each spectrometer will appear as a separate device. Right click to open a

menu that can generate an acquisition, control a TEC (if applicable) and add other

device controls.

Acquisitions – A spectrometer can output one acquisition per detector channel. Right

click to open menu.

Nodes – These are the building blocks of the schematic view. They are all various

functions that take data in and provide an output. To make a node, right click on the

schematic background. Each node can be configured by double clicking on the node.

To join nodes press ctrl, click and drag (windows).

Views – Are a type of window that displays data. To generate a new view right click on

the schematic background.

Schematic View

The schematic view is a graphical interface that allows you to move from device through to

processed data. There are a few basic components to consider.

More information about schematic view including detailed descriptions of the available nodes

can be found in the

OceanView Installation and Operation Manual

(see Product-Related

Documentation and in the help section of the OceanView software.

30 225-00000-000-11-201604

Page 41

Chapter 4

Troubleshooting

Overview

Sometimes things don’t quite go to plan; hopefully you’ll find some answers below. If not, don’t

hesitate to contact us and our Tech Support team will leap into action. Some typical questions

are answered here. For more information, consult the FAQs on the Ocean Optics website at

http://oceanoptics.com/faq/.

I connected the USB cable and started OceanView but I don’t see

my spectrometer attached.

Use the Rescan button in the Device Manager to rescan for attached devices.

I am having trouble installing the drivers, what should I do?

Hardware device driver installation is usually seamless on Microsoft Windows operating systems

and should happen in the background when you connect your spectrometer to a computer with

the software installed. However, some Windows systems require a bit more care when

connecting your spectrometer for the first time.

225-00000-000-11-201604 31

Page 42

4: Troubleshooting

If your spectrometer is not recognized by OceanView on your computer, you need to manually

install the spectrometer drivers. See your OceanView manual for this procedure. Also consult

the

Correcting Device Driver Issues

document (see Product-Related Documentation).

How do I know my spectrometer has power?

The red LED on the spectrometer should be on steadily if the unit is receiving power.

How do I know my spectrometer is transmitting data?

The green LED on the spectrometer flashes when transmitting data.

I’m installing OceanView but I need a product key; where can I find

this?

The product key was sent to the contact e-mail on the sales order when you purchased your

OceanView license. Contact info@oceanoptics.com for more information. You’ll need your sales

order number, quotation number, the serial number of the spectrometer that was purchased

with the software, and, if known, the e-mail address under which your product key was created

to recover your key.

I connected the Flame to the computer before installing my

spectroscopy operating software to install the drivers. What do I

do now?

The steps to take to resolve this issue differ, depending on your computer’s operating system.

Microsoft Windows Operating Systems

If you connected your Ocean Optics Flame device to the computer prior to installing your Ocean

Optics software application on a Windows platform, you may encounter installation issues that

you must correct before your Ocean Optics device will operate properly.

Follow the applicable steps below to remove the incorrectly installed device, device driver, and

installation files.

Note

If these procedures do not correct your device driver problem, you must obtain

the

Correcting Device Driver Issues

http://oceanoptics.com/wp-content/uploads/Correcting-Device-Driver-Issues.pdf.

document from the Ocean Optics website:

32 225-00000-000-11-201604

Page 43

4: Troubleshooting

Remove the Unknown Device from Windows Device Manager

► Procedure

1. Open Windows Device Manager. Consult the Windows operating instructions for your

computer for directions, if needed.

2. Locate the Universal Serial Bus Devices option and expand the Universal Serial

Bus Devices selection by clicking on the "+" sign to the immediate left.

Note

Improperly installed USB devices can also appear under the Universal Serial Bus

Controller option. Be sure to check this location if you cannot locate the unknown

device.

3. Locate the unknown device (marked with a large question mark). Right-click on the

Unknown Device listing and select the Uninstall or Remove option.

4. Click the OK button to continue. A warning box appears confirming the removal of the

Unknown Device. Click the OK button to confirm the device removal.

5. Disconnect the Flame from your computer.

6. Replug the spectrometer into your computer.

The system should now able to locate and install the correct drivers for the USB device.

Apple Mac OSX Operating Systems

Since there are no device files for the Flame Spectrometer in a Mac operating system, you

should not encounter any problems if you installed the spectrometer before the spectrometer

operating software.

Linux Operating Systems

For Linux operating systems, all you need to do is install the spectrometer operating software,

then unplug and replug in the spectrometer. Technically, the driver files for Linux simply give

nonprivileged users permission to use newly connected hardware. There isn’t any long-term

harm to plugging in the device before installing the software.

I have both SpectraSuite and OceanView installed. Will my

spectrometer work with both?

Yes. There should be no driver issues with Windows 64-bit, Mac, and Linux operating systems

since they all use the winusb driver. For Windows 32-bit systems, you will need to swap the

drivers when switching software since OceanView uses the winusb driver, while SpectraSuite

uses the ezusb driver.

225-00000-000-11-201604 33

Page 44

4: Troubleshooting

How do I determine whether my Windows computer is 32-bit or 64bit?

Errors can occur if you download the wrong version of software (for 32-bit or 64-bit

computers). To verify your computer version for most Windows computers, go to the

Properties window (under Computer or My Computer). If no version is listed, then your system

is a 32-bit. For more information see the Microsoft Frequently Asked Questions at

http://windows.microsoft.com/en-us/windows/32-bit-and-64-bit-windows#1TC=windows-7.

How do I check the configuration of my spectrometer?

Check the label on the bottom of your spectrometer. You can also check your configuration

using your spectrometer operating software.

For OceanView: Open the Schematic window and double click the spectrometer icon.

For SpectraSuite: Click the plus (+) icon next to the spectrometer to open properties and

configuration.

Product Upgrades, Repairs and Servicing

Occasionally, you may find that you need Ocean Optics to make a change or an upgrade to

your system. To facilitate these changes, you must first contact Customer Support and obtain a

Return Merchandise Authorization (RMA) number. Please contact Ocean Optics for specific

instructions when returning a product.

Repairs

Sometimes accidents happen! If you need to return your Ocean Optics Product for repair, here

is what to do:

► Procedure

1. Contact us to speak to an Ocean Optics representative about the problem. If it is

determined that the product must be returned, the representative will issue an RMA

number.

2. Package your product, ideally in the original packaging, and return it to Ocean Optics,

along with the RMA number that you received.

Note

For RMA returns under warranty we will organize and pay for shipping both

ways. For accidental damage, you only pay to have the product delivered to your

closest Ocean Optics or OOI Distributor Office.

34 225-00000-000-11-201604

Page 45

4: Troubleshooting

Upon careful examination, we’ll advise you with an estimate. When your product is ready, it will

be returned to you.

Servicing

To keep your instrument in tip top shape we recommend yearly wavelength recalibration. You

can do this yourself if you have appropriate tools or we can do this for you. Contact your local

representative to find out more about service availability and cost. We offer the following

services:

Wavelength Calibration

Absolute Irradiance Calibrations

225-00000-000-11-201604 35

Page 46

4: Troubleshooting

36 225-00000-000-11-201604

Page 47

Chapter 5

How the Flame Spectrometer

Works

Overview

This section provides an overview of the Flame spectrometer and how it works from light

entering the slit through to the transmission of the spectrum over USB. It also provides an

overview of all the different possible configurations that are possible, designed to help you

optimize your spectrometer for specific applications.

You’ll find more useful information, including a glossary of spectroscopy and spectrometer

terms, on our website at www.oceanoptics.com.

Flame Open Bench

225-00000-000-11-201604 37

Page 48

5: How the Flame Spectrometer Works

Slit

Description

Pixel Resolution

INTSMA-5

5-µm wide x 1-mm high

~3.0 pixels

INTSMA-10

10-µm wide x 1-mm high

~3.2 pixels

INTSMA-25

25-µm wide x 1-mm high

~4.2 pixels

INTSMA-50

50-µm wide x 1-mm high

~6.5 pixels

INTSMA-100

100-µm wide x 1-mm high

~12 pixels

INTSMA-200

200-µm wide x 1-mm high

~24 pixels

INTSMA-000

Interchangeable bulkhead with no slit

NA

INTSMA-KIT

Interchangeable SMA Kit connectors; 5µm; 10µm; 25µm;

50µm; 100µm and 200µm

NA

1. Fiber Optic Connector: Light from a fiber enters the optical bench through the SMA

905 Connector. The SMA 905 bulkhead provides a precise location for the end of the

optical fiber, slit, absorbing filter and fiber clad mode aperture. While we supply SMA

connectors as standard, FC connectors are also available. See #2 for available options.

2. Interchangeable Slit: Light passes through the installed slit, which acts

as the entrance aperture. Slits come in various widths from 5 µm to 200

µm. The slit is fixed in the SMA 905 bulkhead to sit against the end of

a fiber. Smaller slit sizes achieve the best optical resolution while larger

slits have higher light throughput. Slit size is labeled as shown.

Ocean Optics also offers a range of FC connector slits in the same wavelengths, with the

product code INTFC-XXX. An INTFC-KIT is also available. Note that these items are

made to order and have a longer lead time. Contact an Ocean Optics Application Sales

Engineer for more details.

► Procedure

To calculate the optical resolution for your spectrometer,

1. Find the number of pixels for your detector.

2. Divide the range of the spectrometer by the number of pixels.

3. Multiply this number by the pixel resolution from the table above.

For example: Resolution of the Flame-S with a 50 µm slit and 650 nm range

650/2048 x 6.5 = 2.1 nm

38 225-00000-000-11-201604

Page 49

5: How the Flame Spectrometer Works

Item Code

Description

Dot 1

Dot 2

OF1-BG28

Bandpass filter, transmits >325 and <500 nm

blue

red

OF1-WG305

Longpass filter; transmits light >305 nm

black

white

OF1-U325C

Bandpass filter, transmits >245 and <390 nm

white

green

OF1-GG375

Longpass filter; transmits light >375 nm

red

black

OF1-GG395

Longpass filter; transmits light >395 nm

white

red

OF1-CGA420

Longpass filter; transmits light >420 nm

orange

white

OF1-GG475

Longpass filter; transmits light >475 nm

green

green

OF1-OG515

Longpass filter; transmits light >515 nm

pink

yellow

OF1-OG550

Longpass filter; transmits light >550 nm

orange

orange

OF1-OG590

Longpass filter; transmits light >590 nm

red

pink

OF1-RG695

Longpass filter; transmits light >695 nm

white

blue

OF1-RG830

Longpass filter; transmits light >830 nm

black

blue

OF1-CGA1000

Nonfluorescing longpass filter, transmits >1000 nm

red

green

OF1-CGA760

Nonfluorescing longpass filter, transmits >760 nm

blue

black

OF1-CGA780

Nonfluorescing longpass filter, transmits >780 nm

white

yellow

OF1-CGA830

Nonfluorescing longpass filter, transmits >830 nm

green

orange

OF1-CGA475

Nonfluorescing longpass filter, transmits >475 nm

yellow

pink

3. LongPass Absorbing Filter (optional): If selected, an absorbing filter

is installed between the slit and the aperture in the SMA 905 bulkhead.

The filter is used to limit bandwidth of light entering spectrometer or to

balance color. Filters are installed permanently. A filter is for a specific slit.

If you anticipate needing the filter with multiple slit sizes, then you must

specify this at the time you order. You will know which filter is installed in each slit

because of the color-coded dots on the outside as shown in the figure and described in

the table below.

4. Collimating Mirror (specify Standard or SAG+): The collimating mirror is matched

to the 0.22 numerical aperture of our standard optical fibers. Light reflects from this

mirror, as a collimated beam, toward the grating. You can opt to install a standard

mirror or a NIR-enhancing but UV absorbing SAG+ mirror.

SAG+ mirrors are often specified for fluorescence. These mirrors absorb nearly all UV

light, which reduces the effects of excitation scattering in fluorescence measurements.