Page 1

ElliCalc

Manual

Version 3.5.23 8.2.2011

Ocean Optics Germany GmbH Thin Film Metrology

Page 2

CONTENTS

CONTENTS ....................................................................................................................................................................... 1

1 Introduction .................................................................................................................................................................... 3

1.1 Measurement setup ............................................................................................................................................. 4

1.2 Measurement signal ............................................................................................................................................ 4

1.3 Physical principle ................................................................................................................................................ 5

2 Installation .................................................................................................................................................................. 6

3 Product support ........................................................................................................................................................... 6

4 Getting started ............................................................................................................................................................. 7

5 User modes of ElliCalc ............................................................................................................................................... 9

5.1 SCOUT mode ..................................................................................................................................................... 9

5.2 Internal mode ...................................................................................................................................................... 9

5.3 Combiversion with NanoCalc ........................................................................................................................... 10

5.4 List of all menus and buttons ............................................................................................................................ 12

6 Basic features of ElliCalc ......................................................................................................................................... 13

6.1 Init ..................................................................................................................................................................... 13

6.2 Auto intensity .................................................................................................................................................... 13

6.3 Simulate ............................................................................................................................................................ 13

6.4 Measure............................................................................................................................................................. 14

6.5 Analyze ............................................................................................................................................................. 14

6.6 Continuous mode .............................................................................................................................................. 15

6.7 Fitness ............................................................................................................................................................... 15

7 Detailed features of ElliCalc .................................................................................................................................... 16

7.1 Main menu “File” ............................................................................................................................................. 16

7.1.1 Load layer recipe ...................................................................................................................................... 16

7.1.2 Import raw data ......................................................................................................................................... 17

7.1.3 Export raw data ......................................................................................................................................... 17

7.1.4 Print report ................................................................................................................................................ 18

7.1.5 Show all results ......................................................................................................................................... 18

7.1.6 Exit ............................................................................................................................................................ 18

7.1.7 Function keys ............................................................................................................................................ 18

7.2 Main menu “Screen” ......................................................................................................................................... 19

7.2.1 Spectrometer data ..................................................................................................................................... 19

7.2.2 Limits ........................................................................................................................................................ 21

7.2.3 Dispersion ................................................................................................................................................. 23

7.3 Main menu “Externals”..................................................................................................................................... 25

7.3.1 Mapping .................................................................................................................................................... 25

7.3.2 Result List ................................................................................................................................................. 31

7.3.3 Analyze mapped data ................................................................................................................................ 32

7.3.4 Structure of .map-file ................................................................................................................................ 32

7.3.5 Online/multipoint measurements .............................................................................................................. 32

7.3.6 Analyze online/multipoint data ................................................................................................................. 36

7.3.7 Structure of .onl-file .................................................................................................................................. 36

7.3.8 RS232 ....................................................................................................................................................... 36

7.3.9 Vision system ............................................................................................................................................ 37

7.4 Main menu “Options” ....................................................................................................................................... 38

7.4.1 Change buttons ......................................................................................................................................... 38

7.4.2 Fit parameters ........................................................................................................................................... 39

7.4.3 Some setups .............................................................................................................................................. 39

7.4.4 Operator mode .......................................................................................................................................... 40

7.4.5 Remote control .......................................................................................................................................... 41

7.5 Main menu “Version” ....................................................................................................................................... 42

7.6 Chart and chartdesigner .................................................................................................................................... 42

8 Special features for “SCOUT mode” ........................................................................................................................ 43

8.1 Main menu “File” ............................................................................................................................................. 43

1

Ocean Optics Germany GmbH Thin Film Metrology

Page 3

8.1.1 Change layer recipe................................................................................................................................... 43

8.2 Main menu “Screen” ......................................................................................................................................... 44

8.2.1 Psi/Delta or tan(Psi)/cos(Delta) ................................................................................................................ 44

8.3 Main menu “Options” ....................................................................................................................................... 44

8.3.1 Some setups .............................................................................................................................................. 44

9 Special features for “internal mode” ......................................................................................................................... 45

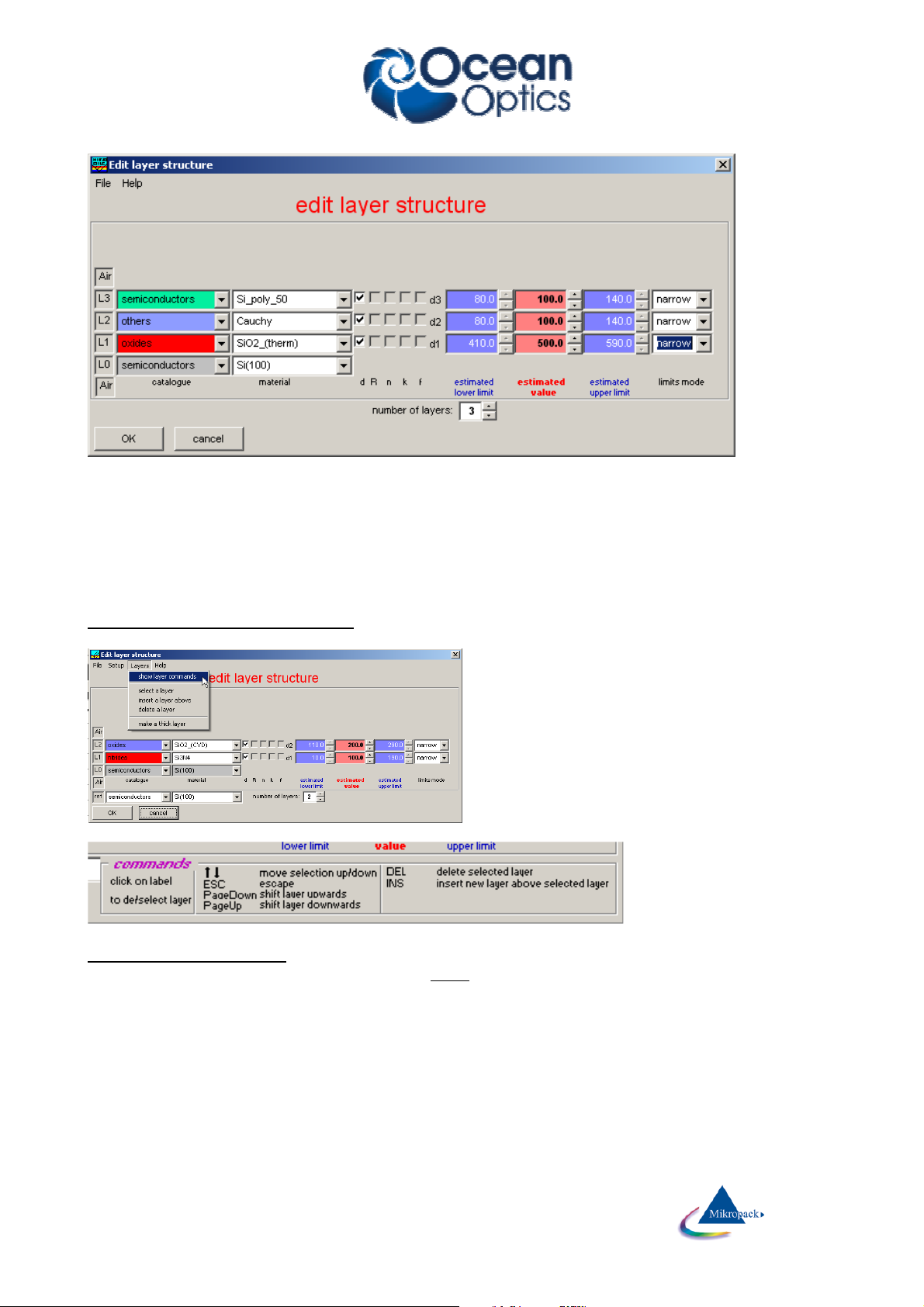

9.1 EditStructure button .......................................................................................................................................... 45

9.1.1 General ...................................................................................................................................................... 46

9.1.2 Catalogues ................................................................................................................................................. 47

9.1.3 Materials ................................................................................................................................................... 47

9.1.4 Thickness .................................................................................................................................................. 47

9.1.5 Estimates ................................................................................................................................................... 47

9.1.6 Fixed limits ............................................................................................................................................... 48

9.1.7 Narrow Limits ........................................................................................................................................... 48

9.1.8 Wide Limits .............................................................................................................................................. 48

9.1.9 User limits ................................................................................................................................................. 48

9.1.10 Number of layers ...................................................................................................................................... 48

9.1.11 Layer commands ....................................................................................................................................... 49

9.2 Main menu “Options” ....................................................................................................................................... 51

9.2.1 Roughness ................................................................................................................................................. 51

10 Experimental setups and problems ....................................................................................................................... 52

10.1 General .............................................................................................................................................................. 52

10.1.1 Experimental setup ................................................................................................................................... 52

10.1.2 Maximum intensity ................................................................................................................................... 52

10.1.3 Polarization ............................................................................................................................................... 52

10.1.4 Signal to noise ratio .................................................................................................................................. 52

10.1.5 Stray light .................................................................................................................................................. 52

10.1.6 Fiber .......................................................................................................................................................... 52

10.1.7 Absorbing media ....................................................................................................................................... 52

10.1.8 Passwords ................................................................................................................................................. 53

10.1.9 Function buttons ....................................................................................................................................... 53

11 Physical explanations ............................................................................................................................................ 54

11.1 Refraction index and absorption indices ........................................................................................................... 54

11.2 Cauchy coefficients ........................................................................................................................................... 54

11.3 Interference ....................................................................................................................................................... 55

12 Thinfilm.ini ........................................................................................................................................................... 56

13 APPENDIX........................................................................................................................................................... 58

13.1 ElliCalc-Quick-Setup ........................................................................................................................................ 58

2

Ocean Optics Germany GmbH Thin Film Metrology

Page 4

1 Introduction

ElliCalc is an ellipsometric software to extract thickness and optical data from thin, transparent layers on

different substrates. ElliCalc uses Ocean Optics microspectrometers.

ElliCalc offers a lot of different options like:

• Simulation and measurement of multilayer systems (weakly absorbing or transparent)

• A powerful software engine in the background (“SCOUT”)

• Additionally: an easy-to-use “internal “ mode for thickness extraction and/or Cauchy dispersion

• A graphical user interface that is very easy to use (recipes)

• Simulation of up to 10 layers (weakly absorbing or transparent)

• Highly accurate thickness measurements between some nanometers up to about 25 µm.

• Extraction of dispersion n(λ) and k(λ), roughness, EMA-fractions and other layer parameters, if

using SCOUT add-on (and Cauchy models in internal mode)

• 3D - mapping mode with a motor driven xy(z)-stage (=function of position)

• Online/multipoint measurements (=function of time)

• Remote control via OLE-commands from external software

• Video

• Combination with reflectometry (“NanoCalc”)

Measurement principle

A thin layer is illuminated with white light via a collimating optics and a spectrometer measures the change

of polarization (that occurs after reflection) as a function of wavelength. ElliCalc software determines

thickness (and optical parameters) of the layer.

The mathematics to extract useful data about the film is quite ambitious, but the user is separated from

these problems. The internally measured properties are called “Psi” and “Delta” (in degrees) or sometimes

tan(Psi) and cos(Delta). Of course in spectroscopic ellipsometry these 2 properties are measured as a

function of wavelength (in contrast to single wavelength ellipsometry)

ElliCalc has 2 different modes of operation:

1. data extraction via an optional software tool called “SCOUT”. This SCOUT software is very powerful

and works more or less in the background. SCOUT is able to handle very complicated dispersion

curves, but needs some experience with optical modeling. ElliCalc acts as a user interface to simplify

the data extraction process. Even without deep understanding of the underlying physics it is possible to

measure complex layer systems by using a recipe concept. A layer recipe has to be loaded and the

rest is a “one-button-solution” (of course there must be an expert in the beginning to establish this

recipe. Ask your software supplier…)

2. data extraction by ElliCalc itself (without SCOUT). In this “internal mode” it is very easy to extract

thicknesses and –to some extent- dispersion values without optical modeling. Recipes may be used,

but even without recipes it is extremely simple to get results. This “internal mode” does not need an

expert, but it is not as powerful as the “SCOUT mode”.

3

Ocean Optics Germany GmbH Thin Film Metrology

Page 5

1.1

Measurement setup

white light

source

spectrometer

polarizer

analyzer

A broadband white light source is focused on a thin layer under oblique incidence. The incoming light is

polarized by a “polarizer”, the reflected light is analyzed by an other polarizer, the so called “analyzer”. The

intensity as a function of wavelength is measured by a spectrometer, a PC extracts the wanted information.

1.2

Measurement signal

The typical modulated signal of such a spectroscopic thin film measurement might look like this (after some

data manipulations):

On the screen you see two different curves (Ψ/∆or tan(Ψ) and cos(∆) as a function of wavelength. ElliCalc

uses these signals to extract thicknesses and optical data for this (SiO2 ) layer on Si.

Ocean Optics Germany GmbH Thin Film Metrology

4

Page 6

1.3

Physical principle

The measurement principle of ElliCalc is the well-known fact of oblique reflection and interference of light

in thin layers. Light is reflected (and normally transmitted), resulting in different phase shifts and different

intensities for different wavelengths. Ellipsometry measures the change of phases and intensities between

vertically and horizontally oriented light and calculates different layer parameters like dispersion or

thickness.

70°

After some calculations ElliCalc will show a result (here: 998 nm) nm as the best fit to the experimental

data (blue and magenta curves=measured signals, black curves = theoretical curves):

layer

substrate

70°

transmitted (and

absorbed) intensity

reflected intensity

Ocean Optics Germany GmbH Thin Film Metrology

5

Page 7

2

Installation

ElliCalc (and SCOUT) is delivered on a CD-ROM.

Insert the CD-ROM in your CD-ROM drive, use Microsoft Explorer to run „ElliCalc-Setup.exe “. Do not call

“ElliCalc.exe” at this level, if you happen to find it in some subdirectory.

ElliCalc will ask you for a directory (and propose a directory „c:\programs\ElliCalc“).

If you prefer other names, change this to "c:\MyPrograms\ElliCalc” or any convenient directory name).

Reboot the PC after installation.

Deinstallation:

If you want to deinstall ElliCalc from your computer, go to „system control“, „software“ and deinstall ElliCalc.

Do NOT just delete it because ElliCalc adds some files to your windows\system directory !! Always deinstall the software properly.

3

Product support

Please contact your local distributor for product support. Here you can find additional information:

www.OceanOptics.de

6

Ocean Optics Germany GmbH Thin Film Metrology

Page 8

4

Getting started

After installation of your hardware and software you should be ready to make your first measurements.

An example:

1. For the first steps it is a good idea to use a special “step wafer” with different oxide thicknesses. You

can use this wafer to check the correct functionality of the ellipsometer. Please ask your hardware

supplier for information about step wafers.

Otherwise use a really well known sample with good optical properties (not rough, homogenous,

simple layer structure, like SiO2 on Si). Put the wafer on the stage.

2. Choose a room without too much light, avoid full sunlight and reflections (you might run into problems

with stray light).

3. Load a layer recipe (via “files/load layer recipe”) corresponding to your sample, e.g. “SiO2 on Si.lrc”.

Then the structure in Setup picture shows a correct layer system

4. Then put your wafer in the middle of the chuck and switch on your power supply and lamps

5. Start ElliCalc.exe (there should be no warnings or error messages) and wait unil all messages “please

wait” have disappeared.

6. click on the button „init“and wait unil all wait and progress messages have disappeared.

7. Now the ellipsometer motors are initialized. There is no absolute need to press the button “auto

intensity”, as this action has been performed by “init” (but are allowed to do it….)

8. Now press the button “continuous”, you should see a live signal. Try to maximize this signal by using

the height adjustment and the tilt adjustment of your stage. In case that these 2 adjustments were

considerable: press “auto intensity” to optimize the integration time again.

9. Now click on the button “init” and wait for some seconds. The motors of the ellipsometer will move to

their starting positions.

10. Click on the black button “continuous”. The button turns to red and you should see an intensity signal

on the screen. Manually adjust the height of your stage to maximize this signal. Click on the (red)

button “continuous” again to stop this mode.

11. Click on the button “auto intensity”. The integrations times are chosen automatically so that the

maximum signal height is about 75% of the maximum to avoid saturation. If you change your sample

now or later and the new sample has a different reflectivity you have to press the button “auto

intensity” again. If the new sample is of the same type as before this is not necessary but advisable.

12. Now click the button “measure”. The measurement will take some seconds.

13. Now you see the measured data with the typical interference wiggles.

14. Then click on the button „analyze“ and wait for the result. You should get meaningful results.

7

Ocean Optics Germany GmbH Thin Film Metrology

Page 9

8

Ocean Optics Germany GmbH Thin Film Metrology

Page 10

ElliCalc:

SpecEl

SCOUT

ElliCalc:

SpecEl

5

User modes of ElliCalc

ElliCalc has two different user modes, the “SCOUT-mode” and the “ElliCalc internal mode”. At the moment

the “SCOUT-mode” is the normal mode, the “internal mode” can only extract thicknesses and Cauchy

dispersion

The “SCOUT-mode” requires that another software, called “SCOUT” is installed on this PC, the “internal

mode” only uses ElliCalc.

5.1

SCOUT mode

ElliCalc works as a graphical user interface for a sophisticated film software “SCOUT” working in the

background.

The whole process is necessarily driven by recipes.

• within ElliCalc you have to load a “recipe”, e.g. “SiO2 on Si.lrc”. This ASCII-readable recipe

contains a link to a SCOUT recipe like “SiO2 on Si.sc2”. All necessary layer informations are

contained in this SCOUT recipe and are read by ElliCalc, but only for display purposes.

• ElliCalc now controls the hardware, measures the sample and sends the measured Psi/Delta-values

to SCOUT (via a file EC_Data.xy in directory “ElliCalc\Internal_Files”).

• SCOUT does the calculation of all parameters

• the results are given back to ElliCalc via OLE-connection. The main fit parameters (thickness,

refraction, absorption, roughness and EMA-fractions) are displayed by ElliCalc, as well as all other

SCOUT fit parameters.

This SCOUT mode relies totally on good SCOUT recipes. So there must be someone (you or the

administrator or OceanOptics) in the background being familiar with the details and the physics of SCOUT.

The advantage is a “one-button-ellipsometry” for the user and an enormous calculation power !

calculation

SCOUT sc2-recipe ElliCalc lrc--recipe

measure spectrum

display results

ellipsometer

5.2

Internal mode

In this internal mode the user can create own layer stacks and does not need the external SCOUT software

at all. There is no need to work with recipes, but is is recommended. BUT: At the moment only thickness

values and a Cauchy dispersion can be extracted.

Ocean Optics Germany GmbH Thin Film Metrology

ElliCalc lrc-recipe

define layer stack

measure spectrum

calculate thickness

display thickness

ellipsometer

9

Page 11

5.3

Combiversion with NanoCalc

If you bought a combiversion ElliCalc + NanoCalc (= ellipsometry and reflectometry) you will see an extra

menu “version”. Here you can switch from one application to the other.

10

Ocean Optics Germany GmbH Thin Film Metrology

Page 12

Ocean Optics Germany GmbH Thin Film Metrology

11

Page 13

5.4

List of all menus and buttons

Main menu Sub-menu SCOUT

mode

FILES menu Load Scout layer recipe x x

Load ElliCalc layer recipe

Save as layer recipe x

Change layer recipe x

Export raw data x x

Import raw data x x

Show all results x

Exit x x

SCREEN menu Spectrometer data x X

Limits x x

Dispersion x x

Psi/Delta or tan(Psi)/cos(Delta) x

EXTERNALS Mapping x x

Analyze mapped data x x

Online/multipoint x x

Analyze online data x x

RS232 x x

Video camera x x

Show plot x x

OPTIONS Change buttons x x

Roughness (x) x

Special modes x

Fit parameters x

Some setups ElliCalc (motor steps) x x

Some setups SCOUT (stoptime) x

Some setups (change colors) x x

VERSION NanoCalc_1 x x

NanoCalc_10nk x x

HELP Contents x x

About x x

EDITSTRUCTURE x

Internal

mode

Ocean Optics Germany GmbH Thin Film Metrology

12

Page 14

6

Basic features of ElliCalc

6.1

Init

This button performs 2 tasks:

• initialize the motors for polarizer and analyzer (e.g. end positions)

• automatically set the integration times to good values (so there is no need to press “auto intensity”

directly after an init procedure). But: If you change the stage height you should apply “auto intensity”

hint:

If you change your sample you may run into saturation of the spectrometer = a (nearly) horizontal part in

some of the measured curves near to the upper limit of the plot.

6.2

Auto intensity

This option automatically adjusts integration times.

This button has to be pressed if you use a completely different sample (each sample has a different reflectivity, so a different integration time). Normaly the “init button” already has performed such an auto intensity

procedure.

If your sample is of the same type as your last sample (=has nearly the same reflectivity) it is not necessary

to press this button.

AutoIntensity tries to get 75% of the maximum allowed value. You can change this value by manually editing

the file “thinfilm.ini”

6.3

Simulate

This routine simulates a spectrum.

• in SCOUT-mode: from the .sc2-layer recipe data within SCOUT

• in ElliCalc internal mode: from the data in EditStructure (identical to the data in Thinfilm.ini-file)

Ocean Optics Germany GmbH Thin Film Metrology

13

Page 15

Hint:

If you want to have a short check which structure is simulated at the moment, put the mouse cursor over

the appropriate layer for some seconds and you see the layer thickness.

OR:

Leave your mouse cursor for some seconds over the button SIMULATE and look at the text in the status

bar.

6.4

Measure

This routine measures the ellipsometric spectra of your test device.

If you use a double spectrometer, you had to adjust the crossover wavelength. Below this wavelength the

data are collected from channel A ("master spectrometer"), above this wavelength they are collected from

channel B ("slave spectrometer").

6.5

Analyze

This routine analyzes a spectrum (either simulated or measured) within the data extraction limits.

• In SCOUT-mode: SCOUT is doing the calculations. The structure that is simulated may only be

changed within SCOUT.

• In ElliCalc’s internal mode: ElliCalc is doing the calculations (only thickness and Cauchy parameters at

the moment)

Hint:

To have a short check which structure is simulated at the moment, put the mouse cursor over the

appropriate layer for some seconds and you see the layer thickness.

OR:

Leave your mouse cursor for some seconds over the button SIMULATE and look at the text in the status

bar.

Ocean Optics Germany GmbH Thin Film Metrology

14

Page 16

6.6

Continuous mode

The continuous button switches between continuous mode (=red button) and “stop continuous” (button

=black). Then there will be a continuous measurement of the signal (necessary to adjust the height and tilt

of your stage !!)

All others buttons of ElliCalc are disabled until you finish the continuous mode.

6.7

Fitness

Any extraction of parameters is accompanied by a value of "fitness". This is the sum of the mean square

deviations between measured and simulated curve (normalized to the range of extraction). The fitness is a

rough guide whether your thickness value is "good" or not.

In the file “Thinfilm.ini” you will find 3 entries in section [fit]:

Failure_RedLevel=1

Failure_YellowLevel=0.1

RYG_LevelsAreDisplayed=False

If you change the variable RYG_LevelsAreDisplayed from “False” to “True” (in main menu “Fitparameters”),

the usual rainbow pattern on the screen will disappear and a simple color will show up.

• If the fitness is below Failure_YellowLevel=0.1 you will see a GREEN color.

• If the fitness is between Failure_YellowLevel=0.1 and Failure_RedLevel=1 you will see a

YELLOW color.

• If the fitness is above Failure_RedLevel=0.1 you will see a RED color

Attention:

If you measure very thick layers (with a good correlation between maxima positions, but bad correlation

between signal heights) you may end up with high values of fitness, but nevertheless the thickness results

may be o.k.

Ocean Optics Germany GmbH Thin Film Metrology

15

Page 17

7

Detailed features of ElliCalc

In this chapter the most common commands and menus of ElliCalc are decribed.

Special commands and menus for “SCOUT mode” and for ElliCalc’s “internal mode” are decribed in later

chapters.

7.1

Main menu “File”

Internal mode

SCOUT mode

7.1.1

This routine loads a layer recipe that has been saved earlier (extension: .lrc). Do not change the extension

.lrc.

In SCOUT mode you may either load another SCOUT recipe (“load Scout layer recipe”) or you may switch

to ElliCalcs internal mode (“Load Ellicalc layer recipe”). See the screenshots above.

In SCOUT mode all buttons captions are in italic, otherwise in normal.

It is assumed that all .lrc-files are in the default directory “ElliCalc\recipes\layer_recipes”, but you can

change the directory path to any other directory on your PC (provided that you did not use "UseLastFilenames_EC=False" in section [Filenames_EC] in Thinfilm.ini).

Load layer recipe

Ocean Optics Germany GmbH Thin Film Metrology

16

Page 18

There is a section [Scout] in this layer recipe with an entry for "Scout_Recipename_EC". This entry is a link

to the corresponding SCOUT .sc2-recipe in the directory "c:\programs\scout\scout_sc2_recipes" (or similar

directory name).

If this linked .sc2-recipe is existent, SCOUT will be used for calculations = “SCOUT mode”. If this link is

empty, ElliCalc will calculate without SCOUT = “internal mode” (at the moment only for thicknesses and

Cauchy parameters!)

Example for SCOUT-mode (in ellipsometry):

[Scout]

Scout_DirPath=c:\programs\scout

ScoutStopTime=15

Scout_RecipeName_NC=

Scout_RecipeName_EC=SiO2 (table) on Si.sc2

Example for ElliCalc internal mode:

[Scout]

Scout_DirPath=c:\programs\scout

ScoutStopTime=15

Scout_RecipeName_NC=

Scout_RecipeName_EC=

The *.lrc-file is an ASCII file that contains most parameters of the software, but NO measured or simulated

values of psi/delta (or tan(psi) /cos(delta)) as a function of the wavelength.

If you load a recipe you will not see any curve on the screen, but a change in the setup or the limits.

7.1.2

(internal mode and SCOUT mode)

You are asked for an import- directory. The imported values are displayed in blue (=similar to measured

values). The scale of the screen is not adjusted.

7.1.3

(internal mode and SCOUT mode)

If a curve was produced by simulation or measurement it may be exported as ASCC-file (“raw data”). This

file has a very simple structure: (lambda, tan(Psi), cos(Delta)

350,0.796,0.064

351,0.780,0.050

352,0.764,0.034

353,0.749,0.014

354,0.736,-0.009

355,0.722,-0.035

356,0.710,-0.064

357,0.697,-0.096

You are asked for a directory to save this file. Please use the default directory \RawData_Files\Ellipsometry

Import raw data

Export raw data

Ocean Optics Germany GmbH Thin Film Metrology

17

Page 19

7.1.4

This routine allows you to enter some user data (names of operator, of sample and so on), shows a

preview and prints on the Windows standard printer. Changing the printer is possible only within Windows

itself.

Entering of user data: you may also change the names of the labels (empty labels: this line is not shown on

the final print). In the preview window you may zoom in and out. After pressing the print button you have

the chance to change some printer options.

If you want to get a printout of the complete screen or parts of it:

It is recommended to use a hardcopy program to print the different parts of the software with enough

options to change colors, resolution etc.

We recommend a shareware ”HC.EXE” (http://www.sw4you.de and on the CD-ROM in : tools\general),

which will include a small button in every (!) window of your system near to the close button.

For online-users: we recommend to buy the OPTION ElliCalc-Online for printouts of Multipoint

Measurement, Result-Windows with Statistic Data’s and Excel-Connection.

7.1.5

See chapter “Special features for SCOUT mode”

7.1.6

This routine exits ElliCalc and SCOUT and closes all windows. All important data have been written to the

Thinfilm.ini -file before and will be reloaded in the next run.

Important warning:

Do NOT close SCOUT separately !!! This would break the OLE-connection between SCOUT and ElliCalc.

The only way to restore this connection is to exit ElliCalc and restart the software !

Print report

Show all results

Exit

7.1.7

If you click on the button F1, you get access to help functions.

Ocean Optics Germany GmbH Thin Film Metrology

Function keys

18

Page 20

7.2

Main menu “Screen”

7.2.1

physical meaning:

These 4 numbers are the coefficients in a formula that shows the dependence between wavelength (in

nanometers) and pixel number of your spectrometer according to the following formula:

λ

with:

I = intercept

C

1

C2 = second coefficient

C

3

P = pixel number

Hint: Ask your hardware supplier if you have the impression that it might be necessary to recalibrate the

spectrometer (a red HeNe-laser should show 632.8 nm)

Spectrometer data

21

= first coefficient

= third coefficient

The 4 spectrometer coefficients are

displayed for information purposes. They

are automatically set by the Thinfilm.ini file

which is specific for each single system.

Changing these values will screw up the

system and is therefore password

protected and only accessible for technical

service.

For calibration purposes you may change

these values (with a password and only

within several percent deviation from your

original values).

2

3

PCPCPCI ⋅+⋅+⋅+=

3

7.2.1.1 Integration time

Whenever you change this value, it is written to disk (in file “Thinfilm.ini”) and will be used as a startup

value.

How to change integration time:

1. method = “auto intensity” button (or “init” button !): This method starts with the lowest available integration times for different positions of the polarizer and checks the resulting spectra (every 10 nm) to find

an optimum integration time. The software will try to achieve a maximum signal of 75 % of the total

range and will try to avoid saturation. The absolute value of the integration time will depend very much

on the reflectivities of your reference materials, your substrate material and your layer material.

2. method = use the menu "options/spectrometer data" and and enter a value. Be careful: this may lead to

bad results ...

Ocean Optics Germany GmbH Thin Film Metrology

19

Page 21

You may check the value of integration time at any time without entering the menu OPTIONS: Put your

mouse cursor over the button MEASURE and wait for about 2 seconds: a small window will pop up to inform you about integration time, samples to average and boxcar width.

These values correspond to the channel A ("master spectrometer") if you use a double spectrometer.

7.2.1.2 Boxcar width

physical meaning:

The OceanOptics spectrometer is able to average over some pixels to increase signal/noise-ratio.

A boxcar width of 1 pixel means no averaging at all (which is an ideal situation and would correspond to a

very narrow fiber). This has to be used if you want to measure very thick layers (like 50 micrometers of resist)

A boxcar width of 5 pixels means an averaging over 2 pixels on the left side and 2 pixels on the right side

(= 5 pixels altogether). This averaging routine is shifted from the left side of the simulated spectrum to the

right side with a step size of 1 pixel only. Values of 5-9 are recommended if you want to measure films in

the range of 1 micrometer or less as you get a better signal-to-noise ratio.

hint:

You may check boxcar width at any instance without entering the menu OPTIONS: Put your mouse cursor

over the button REFERENCE or MEASURE and wait for about 2 seconds: a small window will pop up to

inform you about integration time, samples to average and boxcar width.

These values correspond to the channel A spectrometer if you use a double spectrometer.

7.2.1.3 Samples to average

Whenever you change this value, it is written to disk (in file “Thinfilm.ini”) and will be used as a startup

value.

physical meaning:

The Ocean Optics /spectrometer is able to average over some runs to increase signal/noise-ratio.

Tips:

Try to use small values for Samples To Average while keeping the lamp intensity as high as possible (to

get short measuring times). This is especially important in mapping mode.

You may check Samples To Average at any instance without entering the menu OPTIONS: Put your

mouse cursor over the button MEASURE and wait for about 2 seconds: a small window will pop up to

inform you about integration time, samples to average and boxcar width.

7.2.1.4 Internal correct for dark

If you choose this option, dark current is corrected automatically (see button “measure”).

The Ocean Optics Spectrometer is able to measure the dynamic dark current internally within a couple of

pixels that are NOT irradiated by external light, and is correcting dynamically.

7.2.1.5 Dark button

Ocean Optics Germany GmbH Thin Film Metrology

20

Page 22

If you choose this option, dark current is corrected mathematically. This is only necessary if you can’t

protect your system against ambient light or stray light.

7.2.1.6 Maximum intensity

This value describes the maximum intensity in the spectrum of your (halogen ?) lamp.

This value helps ElliCalc to achieve an automatic adjustment of the integration time within the limits of the

screen (=without saturation)

If you use a double spectrometer there are TWO such wavelengths corresponding to the different lamps

and the different sensitivities of the two spectrometers.

If you use a double spectrometer with different sensitivity regions, e.g. 200-600 nm for channel A ("master

spectrometer") and 500-1100 nm for channel B ("slave spectrometer"), ElliCalc

single spectrum (200-1100 nm). The wavelength where the two overlapping spectra are joined is called

"crossover wavelength". (any value is possible, 550 nm would be a good choice in this case).

7.2.1.7 Crossover wavelength

If you use a double spectrometer with different sensitivity regions, e.g. 200-600 nm for channel A ("master

spectrometer") and 500-1100 nm for channel B ("slave spectrometer"), ElliCalc joins the 2 spectra to get a

single spectrum (200-1100 nm). The wavelength where the two overlapping spectra are joined is called

"crossover wavelength". (any value is possible, 550 nm would be a good choice in this case).

joins the 2 spectra to get a

7.2.2

The spectrometer limits in magenta colors are showing the maximum range of your specific system.

7.2.2.1 Plot limits

The plot limits are the left and right side of the plot on your screen and coincide with limits of measurement.

The adjustable values of the plot limits depend on the grating in your Ocean Optics spectrometer and are

noted in the calibration sheet of your system.

Limits

Ocean Optics Germany GmbH Thin Film Metrology

21

Page 23

The plot limits may be changed within ElliCalc in steps of 1 nm.

1. normal mode to change the limits:

open the menu “spectrometer data \ limits” and enter numbers or use the up-down arrows

2. fast and rough method to change the limits:

If you click in the field near the

LOWER numbers you may change the plot limits without entering the

menu option/limits:

If you click in the LEFT half with your LEFT mouse button you will decrease the lower plot limit.

If you click in the LEFT half with your RIGHT mouse button you will increase the lower plot limit.

If you click in the RIGHT half with your LEFT mouse button you will decrease the lower plot limit.

If you click in the RIGHT half with your RIGHT mouse button you will increase the lower plot limit.

The same feature applies to plot limits and reflectivity limits.

3. fast and precise method to change the limits:

If you move your mouse very near to the lower part of the plot window (but still in the grey part) you will

see a little vertical arrow and the value of the wavelength is displayed. If you now click with the left

mouse button, you are able to change the lower plot limit (right mouse button=upper plot limit). The

same applies to the other 2 grey zones = extraction and reflectivity limits (see picture)

4. Zoom

You may zoom by dragging the

mouse from one point to

another within the plot area.

If you click with the right mouse

button a small popup window

will appear with the chance to

undo this zoom.

You can also change the plot

limits back to the full range

(according to your spectrometer

limitations).

You can also set the current plot

limits as a standard or return to

a previously set standard.

ATTENTION:

Tto be consistent with data handling, ALL materials files contain n and k data between 150 nm and

1100 nm. Usually only parts of these data are measured data (e.g. between 206 nm and 840 nm or

between 300 nm and 1100 nm). If you simulate, the valid part of the curve is shown in black while the

rest is shown in grey (and you get a message).

Extraction limits are restricted to the range of valid n and k data.

7.2.2.2 Extraction limits

These limits cannot be larger than the plot limits. Try to use a large extraction range as long as your signal

is “good”.

1. normal mode to change the limits:

open the menu “spectrometer data \ limits” and enter numbers or use the up-down arrows

2. fast and rough method to change the limits:

If you click in the field near the UPPER numbers you may change the extraction limits without entering

the menu “spectrometer data \ limits”.

If you click in the LEFT half with your LEFT mouse button you will decrease the lower extraction limit.

If you click in the LEFT half with your RIGHT mouse button you will decrease the lower extraction limit.

If you click in the RIGHT half with your LEFT mouse button you will decrease the lower extraction limit.

Ocean Optics Germany GmbH Thin Film Metrology

22

Page 24

If you click in the

The same feature applies to plot limits and reflectivity limits.

3. Fast and precise method to change the limits:

If you move your mouse very near to the upper part of the plot window (but still in the grey part) you will

see a little vertical arrow and the value of the wavelength is displayed. If you now click with the left

mouse button, you are able to change the lower extraction limit (right mouse button=upper extraction

limit)

ATTENTION:

To be consistent with data handling, ALL materials files contain n and k data between 150 nm and 1100

nm. Usually only parts of these data are measured data (e.g. between 206 nm and 840 nm or between 300

nm and 1100 nm).

If you simulate, the valid part of the curve is shown in black while the rest is shown in grey (and you get a

message).

Extraction limits are restricted to the range of valid n and k data.

7.2.2.3 Y limits

To zoom in the plot and to see some more details you may change the Y limits. In most cases you will not

need this option.

1. normal mode to change the limits:

open the menu “spectrometer data \ limits” and enter numbers or use the up-down arrows

2. fast and rough method to change the limits:

If you click in the field near the LEFT numbers you may change the reflectivity limits without entering

the menu option \ limits:

If you click in the LOWER half with your LEFT mouse button you will decrease the lower reflectivity limit.

If you click in the LOWER half with your RIGHT mouse button you will decrease the lower reflectivity

limit.

If you click in the UPPER half with your LEFT mouse button you will decrease the lower reflectivity limit.

If you click in the UPPER half with your RIGHT mouse button you will decrease the lower reflectivity

limit.

The same feature applies to plot limits and reflectivity limits.

2. Fast and precise method to change the limits:

If you move your mouse very near to the left part of the plot window (but still in the grey area) you will

see a little horizontal arrow and the value of the wavelength is displayed. If you now click with the left

mouse button, you are able to change the lower reflectivity limit (right mouse button=upper reflectivity

limit)

RIGHT half with your RIGHT mouse button you will decrease the lower extraction limit.

7.2.3

This form shows the refraction index n and the absorption index k (within the plot limits) for different layers.

This form is just a tool to control your data, nothing can be really changed in this form.

There are two cursors available for n and k (press the cursor symbol and drag them with the mouse, atrthe

beginning they are on top of oneanother)

Ocean Optics Germany GmbH Thin Film Metrology

Dispersion

• You may use 2 cursors (symbol #4). At start time of the cursors both cursors are painted on top of

one another, move them with the mouse. The cursor values are shown in blue (= k(λ)) and red (=n(λ))

• You may also zoom in and out and in an area (symbols #1 - #3)

23

Page 25

You may also save these dispersion values

as a dat-file, but be very careful about the

target directory !!

ATTENTION:

To be consistent with data handling, ALL materials files contain n and k data between 150 nm and 1100

nm. Usually only parts of these data are measured data (e.g. between 206 nm and 842 nm or between 300

nm and 1100 nm).

If you simulate, the valid part of the curve is shown in black while the rest is shown in grey (and you get a

message).

Extraction limits are restricted to the range of valid n and k data.

Ocean Optics Germany GmbH Thin Film Metrology

24

Page 26

7.3

Main menu “Externals”

7.3.1

Mapping

You need a mapping-xy-stage and a special mapping

add-on software for ElliCalc to measure in mapping

mode. In this mode it is possible to measure and

display your film parameters as a function of x and y.

Ocean Optics Germany GmbH Thin Film Metrology

25

Page 27

Scan mode:

main menus of mapping mode

1. menu “Recipes”

• Save as map recipe

• Load map recipe

Here you may save or load ALL the settings you have done in all the various possibilities. It is

recommended to save your usual settings in a recipe. It is possible to use a special recipe name like

“myownRecipe”. Recipes for mapping will receive the extension “.mrc” and will be saved in menu

“Recipes\Map_Recipes”

2. menu “Teach in”

This will be explained later in the following section

3.menu “help”

this is the usual access to help functions

main buttons (lower right side)

init stage

you can initialize your ellipsometer (right mouse button=time adjustments possible)

auto intensity

you can adjust the nintegration times automatically (right mouse button=time adjustments possible)

measure

you can take a real (test) measurement with your sample. Thus you can control all settings before you

start the mapping

clear

clears the screen

conti

this will make a continuous mode for measurement

analyze

you can analyze the layer parameters your sample. Thus you can control all settings before you start

the mapping

initialize stage:

After starting mapping mode you have to initialize the xy-mapping stage first.

Until the xy-mapping stage is initialized the function start mapping is deactivated.

start mapping

this will start the mapping sequence

cancel

leave mapping mode

a. shape of the wafers:

1. You may use square or round wafers.

2. To use your own design as a background you need to edit the file

OwnDesign.bmp within the ElliCalc directory (this is possible with

lots of drawing programs, or ask your software supplier for help).

b. wafer size

Wafer size may be changed between 50 mm and 300 mm (= 8''). A

grid is shown with a constant grid distance (e.g. 10 mm).

c. scan region

It is possible to change:

-

the x and y coordinates of the origin in steps of 0.1 mm

-

the number of rows and the number of columns of the scanning

grid

(from 1 to 100)

-

the size of the x and y steps (in multiples of 0.1 mm)

The wafer plot shows what you are doing.

d. rotation

Ocean Optics Germany GmbH Thin Film Metrology

26

Page 28

e. mapping positions

Wafer:

here you can rotate the scan region

measuring position:

If you press one of the position buttons, the mapping stage will immediately go to this point and a red circle

is displayed on the screen. Additionally the coordinates of this point are displayed. If option "measure on

each click" in Tab2 is activated, a measurement will be performed.

You may reach any point by clicking with the LEFT mouse button or by entering the coordinates and

pressing the xy-button.

You may move up and down or left and right by pressing the appropriate arrow buttons. If you press the

arrow buttons with the left mouse button the cursor will move in increments of xSteps. If you press the arrow

buttons with the right mouse button the cursor will move in smaller increments of xSteps/10

f. position buttons:

1. home position

Typically this is in the right lower corner of the xy-stage. The hardware of the stage will define this point

at the beginning of the mapping experiment (and it can be changed manually in the ini-File in section

[mapping], HomepositionX/Y=.... The numbers mean the percentage compared to wafersize (0.05 =5%

of wafersize)

2. scan position

this is the origin of the scanning coordinate system

3. center position

this is the center of the (round) wafer stage

The wafer plot shows what you are doing.

The shape of the substrate may be:

a. circular (between 50 and 300mm)

b. square (between 50 and 300 mm)

c. your own design (change file "OwnDesign.bmp" with any drawing

software)

example:

Wafer size may be changed between 50 mm (= 2'') and 300 mm

(=8””).

Ocean Optics Germany GmbH Thin Film Metrology

27

Page 29

Stage:

Data extract:

Ocean Optics can deliver an xy-stage for 8'' (=300mm).

a. serial port:

The port is used for communication with the mapping-stage. Ask your

hardware supplier for details..

To drive the mapping-stage you need one COM-port for xy-stages (or

a USB port and a converter).

b. wait interval:

After each measurement the scanning may be interrupted for a

certain interval of time

c. single step:

If you activate this option each single measurement is waiting for a

trigger signal (a keystroke with ENTER key or an external TTL trigger

signal which is applied to the spectrometer. Ask your hardware

supplier…)

a. plot during map

With this option you choose the layer you want to "extract" = to

display.

You cannot choose more than one parameter as only one

parameter can be displayed at a time. If you use ElliCalc_10nk you

may calculate up to 10 layers (but display ONE of these)

b. analyzing options

Analyze parameters on each left mouse click. This is a very useful

feature to make a quick check on film parameter distributions on

your wafer (do not forget to activate option "plot value during

mapping").

Fitness limit: if your results are completely wrong for some

reasons, all measured values with a fitness greater than this fitness

limit here will be set to zero. This feature is useful, if dust causes a

measurement error during mapping. Without this feature you might

get enormous spikes.

c. visible during map

You have the choice between 1D-plots for line scans, 2D-plots

and/or 3D-plots.

The 2D-plot and the 3D-plot contain the same data.

A 1D-plot is possible only if you measure along ONE row or

column (and not a two-dimensional field.)

d. number of runs

You have the choice between a single run (for real measurement

purposes) and a nearly infinite number of runs (=30000) for

demonstration purposes.

Ocean Optics Germany GmbH Thin Film Metrology

28

Page 30

Data exp

ort:

Scan data:

You may choose the following options during a mapping experiment:

1. plot the simulated curve

2. plot parameter value

It is more informative to see the analyzed curve and the calculated

parameter value during the simulation, but this is time-consuming. If

the mapping takes a longer time it is recommended to switch off

these 2 features.

You may choose the following options after a mapping experiment:

1. write data as map-file

2. insert comments in map or Excel-files

3. show results window

1. Write data as map-file

All parameter and fitness data together with some coordinate

information are written to a ASCII-file in directory

“ElliCalc\data\map_files”.

examples can be found in the directory “ElliCalc\data\map_files”

2. insert comments in map or Excel-files

you may enter text like “sample #1, “Paul McCartney” or

“myfirsttest”.

This text will be a header for your map-files and also for all

exported Excel_files

3. show result window

If you accept this option a results window with possibility for Excel

export will open after the mapping process.

This feature is used in microscope arrangement (e.g. for measuring

structured wafers) if you want to hit the xy-positions with higher

accuracy.

Usually the wafer or sample will be positioned on the chuck with

some mechanical adjustments (like pins on 2 sides of the wafer and

adjustment to the wafer flat). This will result in a medium accuracy,

but not comparable to fine positioning like in semiconductor

photolithography.

How to get a higher accuracy:

1. click on “marker 1”:

The stage will move to this position. If you now look through the

microscope you will see a slight deviation between the illuminated

spot and the real marker on your wafer.

2. Correct this deviation by moving the stage (use the keyboard

arrows: clicking or pressing once = 10 micrometer, SHIFT +

clicking or pressing once = 1 millimeter). The red circle on the

screen will move slightly off the marker.

3. Repeat step 1 and 2 for marker 2

4. Now the software knows both deviations and is able to calculate

what to do: shifting the origin and rotating the scan pattern a little

bit. Press the button: “accept teach-in”

5. Control the values of rotation angle and xy-origin

6. Start mapping as usual

Ocean Optics Germany GmbH Thin Film Metrology

29

Page 31

Teach in:

Teach in is an interactive tool to write new map-recipes without using text editors to edit the map recipe file.

Now the method with teach-in-mode:

1. Open the mapping window (main menu “map data”) and then the menu “TeachIn”

2. You will see this window:

3. To set the first marker position, click on “marker 1”, then move the measuring position

with the arrow keys on the keyboard

or by clicking somewhere in the wafer area

or by typing values in the text box

4. To set the second marker position, click on “marker 2”, then move the measuring position as before

5. To set the first data point, click on “data”, then move the measuring position as before

6. To set the next data point, click on the up down counter (now it should show the value 2 instead of 1)

and then move to the measuring position as before

7. Save the new recipe (like test.mrc) with the extension .mrc

Ocean Optics Germany GmbH Thin Film Metrology

30

Page 32

It is possible to change any or these values by clicking on the first columns in the appropriate row. Then the

stage moves to that position and you are able to change it.

It is NOT possible to interchange or delete rows

.

7.3.2

As soon as the mapping is finished you will see a result list:

Result List

On the first page you see the measured thickness values for each layer. In the picture above there was just

one layer and 3 x 3 = 9 measured data points. In the last page you can see the associated fitness values for

each coordinate. In the text windows below the data window you see mean values, maximum and minimum

values and standard deviation σ, the 3σ-value and the number of failures (according to the measured fitness

and your fitness limit).

If you did not choose a regular scan pattern, you will see a one-dimensional list.

If you click on the buttons with the numbers in a row or a column you will highlight a certain number of data

points (in the picture above column 3 was highlighted). Now you can control these selected values in a oneor two-dimensional plot by pressing the appropriate button in the last row. You may also choose a smaller

amount of data by dragging with the mouse (e.g. 2 x 2 = 4 points).

Ocean Optics Germany GmbH Thin Film Metrology

31

Page 33

If you press “write data to EXCEL-file” EXCEL will be opened (if installed on your PC) and the data will be

transferred to a spreadsheet.

With “close all windows” you will return to NanoCalc main window and all mapping windows will be closed.

If you enter a value for “fitness limit” and press ENTER, the screen will be updated and all cells with a higher

fitness than your limit will be plotted in red (cells in grey show that this point was outside the wafer).

7.3.3

This feature helps to analyze mapped data that have been measured earlier.

You are asked for a file name (extension .map) in directory ElliCalc\data\map_files. Then the results window is opened and you may inspect your data, plot the data or export them to Microsoft Excel.

7.3.4

The first 2 lines are comments, the file format is very strict.

Analyze mapped data

Structure of .map-file

test4

user4

***

xy-ScanMode

1 Layer(s)

1 Layer(s)ToExtract

2 Row(s)

2 Col(s)

4 total points

5 xStep

5 yStep

***

IndexNo, row, col, x, y, fitness, d1

1, 1, 1, 30.000, 30.000, 0.048, 132.880717

2, 1, 2, 35.000, 30.000, 0.048, 132.806642

3, 2, 1, 35.000, 35.000, 0.048, 132.918102

4, 2, 2, 30.000, 35.000, 0.048, 132.858514

7.3.5

Ocean Optics Germany GmbH Thin Film Metrology

Online/multipoint measurements

32

Page 34

load online recipe:

The online setup window contains lots of input data, so

usually you will want to use an online recipe to do that job

for you.

You will be asked for a file name (usually in directory

“ElliCalc\recipes\online_recipes”). After loading this file

nothing happens except new parameters in setup, like

different y-axis or other trigger parameters.

save as online/multipoint recipe:

The online setup window contains lots of input data, so usually you will want to use an online recipe to do

that job for you.

If you changed some setup parameters you can save them as a new online recipe.

You will be asked for a new file name (usually in directory “ElliCalc\recipes\online_recipes”).

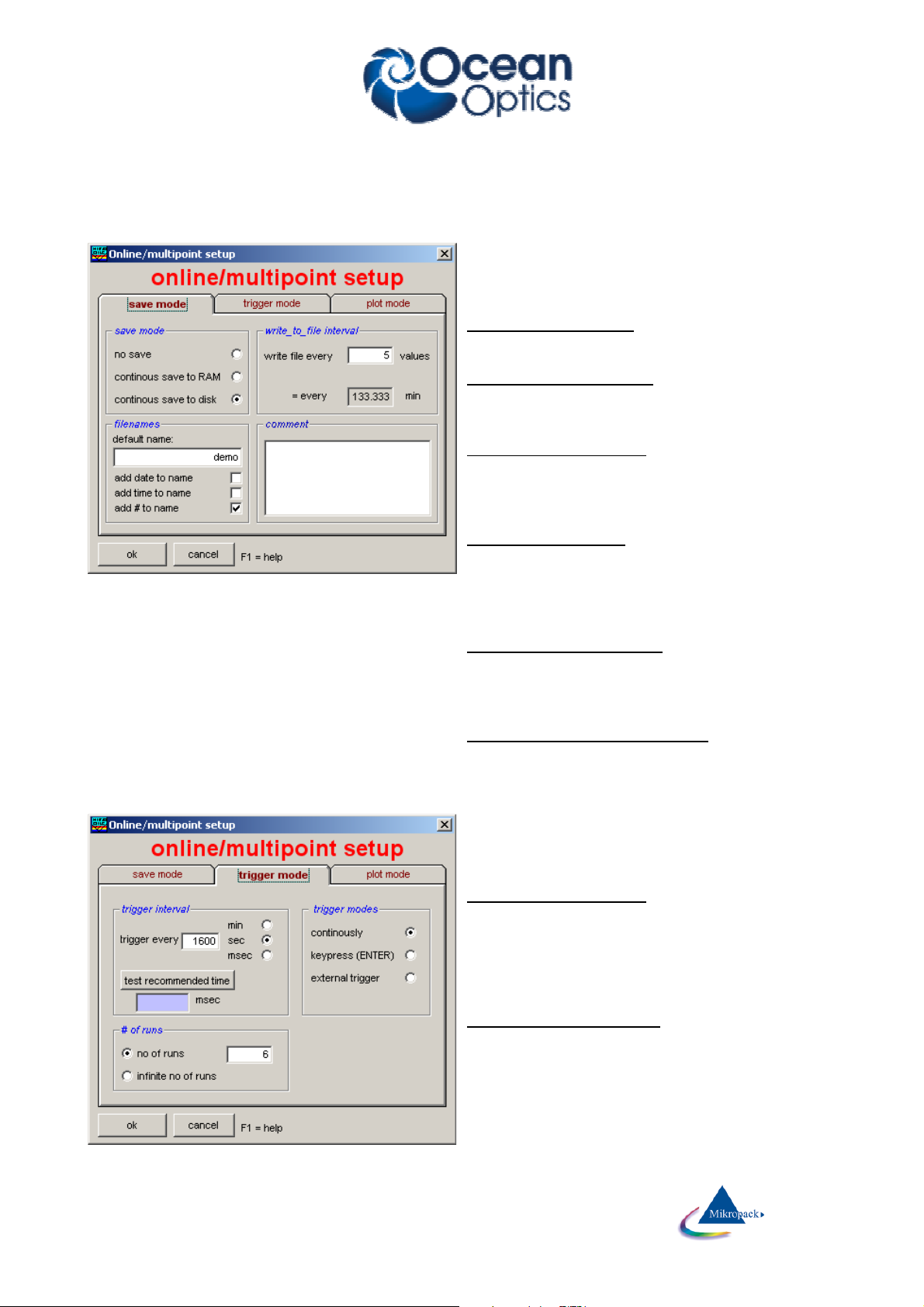

online/multipoint setup:

Depending on the switch “show setup first” in menu “online\setup” the setup window for online

measurements is shown at first or not. If you want to rename your files at the beginning of each

measurement cycle it is recommended to open the setup window first.

Ocean Optics Germany GmbH Thin Film Metrology

33

Page 35

Trigger:

The setup window contains lots of input data, so usually you will want to use an online recipe to do that job

for you.

Save mode:

In this first part of online setup you can

choose:

a. Option “save mode“

1. Do not save the online data

all data are lost and only visible on screen

2. save online data to RAM

At the end of the run you may observe

and analyze your data in the results

window

3. save online data to disk

according to option “write_to_file_interval”

all data are written to file in smaller

portions with filenames that are

determined in option “filenames”

b. Option “filenames“

1. Choose a name like “series 1“ or “test4” or

alike

2. Choose one or more options “add…..”

example: a filename might look like:

test156.onl

c. Option “trigger interval”

You might want to save the value (not the

file !) every trigger, but for some reasons

you might want to save only every third

trigger.

d. Option “write_to_file_interval”

You might want to save the file (not the

value !) every trigger, but for some

reasons you might want to save only

every third trigger.

In this second part of online setup you can

choose:

a. option “trigger mode“

You can trigger continuously by adjusting

the appropriate software parameters like

trigger interval.

you can trigger externally with a TTLsignal to your spectrometer. Please

consult your hardware supplier…

b. option “trigger interval”

Here you choose the time interval between two

software triggers. Pay attention on the correct

unit.

You may test the trigger interval empirically with

“test recommended time”. Add some safety

margins.

Ocean Optics Germany GmbH Thin Film Metrology

34

Page 36

c. option “number of runs”

You might want to run a certain number of

data points only or (nearly) infinitely.

Attention: “infinite” means about 999999

data points.

Result list for online/multipoint mode

On the first page you see the measured thickness values for each layer. In the picture above there 5

measured data points. In the last page you can see the associated fitness values for each measurement. In

35

Ocean Optics Germany GmbH Thin Film Metrology

Page 37

the text windows below the data window you see mean values, maximum and minimum values and

standard deviation σ, the 3σ-value and the number of failures (according to the measured fitness and your

fitness limit).

If you press “write data to EXCEL-file” the data are transferred to an .xls-file (Excel need not be installed on

this PC).

If you press this Excel-button together with the SHIFT-key the text will switch to “write data as csv-file” and

such a csv-file will be generated instead of an .xls-file.

With “close all windows” you will return to ElliCalc main window and all online windows will be closed.

7.3.6

This feature helps to analyze online/ multipoint data that have been measured earlier.

You are asked for a file name (extension: .onl) in directory ElliCalc\data\online_files. Then the results window is opened and you may inspect your data, plot the data or export them to Microsoft Excel.

7.3.7

The first line is a comment, the file format is very strict.

7.3.8

Analyze online/multipoint data

Structure of .onl-file

test1

***

55 total points

***

triggercounter, time, fitness, d1

1, 10:35:19, 0.010, 128.3

2, 10:35:19, 0.010, 128.1

3, 10:35:20, 0.014, 128.1

4, 10:35:20, 0.009, 128.3

5, 10:35:21, 0.008, 128.2

RS232

If you own an xy-stage or any other arrangement with Faulhaber motors you may use this menu to drive

the motors and to test their behaviour. You find a list of commands on the left side, for more information

please consult the motor manuals.

Ocean Optics Germany GmbH Thin Film Metrology

36

Page 38

You may open and close each virtual port separately. If you send the signal "ver" the motors of the xystage should answer (more precise: this command is "1ver" for motor1 and "2ver" for motor2). Ask your

hardware supplier for the motor numbers.

7.3.9

If you own a vision system with an IDS uEye-camera you may turn on the camera with this menu

Vision system

Ocean Optics Germany GmbH Thin Film Metrology

37

Page 39

7.4

Main menu “Options”

7.4.1

with SCOUT

In this window you can make visible or invisible:

- The startup image:

The picture will disappear after some seconds or you might “click it away”

- measure and analyze-button:

to combine the functions to the measure and the analyze button

- show fit checkboxes (in internal mode of ElliCalc only):

in the menu Edit Structure there are some fit checkboxes that can be made visible or not. In the

current software version only thickness and n and k (for Cauchy models) are activated

- show fit sliders (in internal mode of ElliCalc only):

you may use fit sliders to check for variations of thickness, n or k

- show dark button:

to measure any dark current separately

- show SCOUT recipe button:

it is not necessary to see the SCOUT window, but for experienced users this might be helpful

Change buttons

witout SCOUT = internal mode

38

Ocean Optics Germany GmbH Thin Film Metrology

Page 40

- show ElliCalc recipe button:

to make it easier to load recipes

- show mapping button:

to make it easier to use mapping

- quality slider is allowed

With this feature it is possible to set the speed (or the precision of the fit) for each individual

measurement

7.4.2

In the 1st Tab “General” you may change the time for simulation = the number of Simplex fits. A longer time

usually means more precise data (up to some limit…)

In the 2nd Tab “Traffic lights” you may change the fitness values for the trafficlight = good/medium/bad

Fit parameters

7.4.3

7.4.3.1 ElliCalc setups

Here you can change:

• Number of polarizer steps

• Analyzer angle

7.4.3.2 Change colors

In this menu you may change the colors of your layers in the layer stack. It is just an optical effect and has

nothing to do with calculations.

Ocean Optics Germany GmbH Thin Film Metrology

Some setups

Typically ElliCalc uses 18 steps per revolution of the polarizer = a measurement every 20°. This is

good for most purposes. If you use less steps (e.g. only 9 steps) you might loose presicion (but you

may try, it’s faster…)

Normally this value is 45°. BUT: if you have measured your signal and see that the mean value of Psi

is totally different from 45° (e.g. around 15°) then reset the analyzer angle to this mean Psi-value (15°)

and repeat the whole mesurement. This will increase the quality of your data and is especially useful

for thin layers

39

Page 41

First click on the layer area on the left side. Then move the mouse over the large colored area and click if

the color pleases you. Then press OK

7.4.4

NanoCalc can be used in administrator or operator mode.

7.4.4.1 administrator mode

In user mode certain restrictions apply: e.g. the user is not allowed to edit the structure or to change the

parameters of the spectrometer.

The default password to come back to administrator mode is: ”admin”. This password can be changed

arbitrarily, there are no severe restrictions concerning passwords. Please use letters and numbers only.

7.4.4.2 administrator mode

In administrator mode no restrictions apply.

This mode is reserved for the administrator of the system.

The default password to come back to administrator mode is: ”admin”. This password can be changed

arbitrarily, there are no severe restrictions concerning passwords. Please use letters and numbers only.

The administrator may define the options that will work for a standard user. To get this Rights of User window just click ”administrator mode”.

7.4.4.3 Rights of user

The administrator may set the rights for the user for nearly every single feature of the software.

Operator mode

Ocean Optics Germany GmbH Thin Film Metrology

40

Page 42

7.4.5

There is a very powerful OLE remote control as well.

Ask your software supplier...

Ocean Optics Germany GmbH Thin Film Metrology

Remote control

41

Page 43

7.5

Main menu “Version”

This menu is visible only if you own a “combiversion” = a combined version of NanoCalc and ElliCalc. You

may switch to the other application

7.6

Chart and chartdesigner

help directory of your ElliCalc installation.

1D-plot

2D-plot

If you produced a 1Dplot or 2Dplot or 3D-plot

you may change nearly

ALL parameters of the

plot by clicking with the

RIGHT mouse button

Hint:

To change the view

position: keep CTRL

button pressed and

move the mouse at the

same time.

For further information

see VCFI5.hlp in the

3D-plot

During mapping it is possible to produce 1D-plots, 2D-plots and 3D-plots.

These plot types can be changed interactively after the mapping was finished. Click on the plot with right

mouse button to get access to the "chart designer“.

42

Ocean Optics Germany GmbH Thin Film Metrology

Page 44

8

Special features for “SCOUT mode”

8.1

Main menu “File”

8.1.1

Change layer recipe

If you load a (.lrc)-recipe containing a link to a SCOUT .sc2-recipe and measure your sample, SCOUT will

analyze in the background and the results will be displayed in the graphical user interface of ElliCalc.

The layer stack and all layer parameters are defined within SCOUT and are extracted by SCOUT. ElliCalc

is only a user interface. There are lots of data in ElliCalc's internal .lrc-recipe, but most of them are not important in this context: SCOUT is the "master".

With "change layer recipe" you may change some of the layer and fit parameters of SCOUT (but not all).

Your changes are NOT permanently saved to the SCOUT recipe on the harddisk, only to the running

SCOUT instance. If you are convinced that your changes are good enough you may also save them permanently (at the moment only via Scout itself).

To switch to a completely new recipe you have to load another .lrc-recipe with a different SCOUT .sc2recipe (do NOT use SCOUT directly !). With "change layer recipe" it is not possible to change the layer

structure, only values of the recipe.

SCOUT fit parameters: Changing a value

SCOUT fit parameters: Changing a range for parameters

Ocean Optics Germany GmbH Thin Film Metrology

43

Page 45

SCOUT fit parameters: Changing an extraction method

8.2

Main menu “Screen”

8.2.1

Here you may switch between a display in Psi/Delta or in tan(Psi)/cos(Delta), whichever you prefer. The

data transfer to SCOUT (via a file EC_data.xy in Internal_Files) is done in tan(Psi)/cos(Delta)

8.3

8.3.1

Scout stoptime in seconds.

You may enter a number (in sec) to stop SCOUT calculations independent of the quality of the data. This is

equivalent to the above mentioned slider in menu “Fit parameters” / Tab1

Psi/Delta or tan(Psi)/cos(Delta)

Main menu “Options”

Some setups

Ocean Optics Germany GmbH Thin Film Metrology

44

Page 46

9

Special features for “internal mode”

This internal mode can only extract thicknesses in layer stacks, so this is much more restricted than

“SCOUT mode”. You do not need the SCOUT software and it may be faster than SCOUT in simple cases.

To reach this mode you have to use a lrc-recipe without an internal link to a SCOUT .sc2-recipe. There are

different possibilities to do do this:

• Press SHIFT+CTRL+F12