Page 1

DTS

TM

Near Infrared Spectrometers

Operator’s Manual

30 Upton Drive

Wilmington MA 01887

Telephone (978) 284-6000

Fax (978) 284-6060

www.polychromix.com

Document Number 04-91-0201-00 Rev. A

Page 2

Notices:

This product is covered by a limited warranty. A copy of the warranty is

included in this manual.

Using the equipment in a manner not specified by this manual may impair the

protection provided by the equipment.

Information in this document is subject to change without notice and does not

represent a commitment on the part of Polychromix Inc. No responsibility is

assumed by Polychromix Inc. for the use of this software, hardware or other

rights of third parties resulting from its use.

The software described in this document is furnished under a license

agreement and may be used or copied only in accordance with the terms of

the agreement. The user may make a single copy of the software for archival

purposes.

Polychromix products are covered by the following US patents: 5,757,536;

6,329,738; 6,664,406; 6,724,125. Additional patents pending.

DTSTM, DTS-1700TM, DTS-2500TM, DTS-NBTM and SpectralCodeTM are

trademarks of Polychromix, Inc. Spectralon is a registered trademark of

Labsphere, Inc.

All other brands and products mentioned are trademarks or registered

trademarks of their respective holders.

Copyright, 2005 by Polychromix, Inc. All rights reserved. No part of this

document may be reproduced in any form or by any means, electronic or

mechanical, including photocopying without written permission from

Polychromix, Inc.

Page 3

Warranty

Polychromix, Inc. (Polychromix or Seller) warrants that its products will be free from

defects in materials and workmanship under normal use and service in general

process conditions for the effective period set out below. This warranty and its

remedies are in lieu of all other warranties expressed or implied, oral or written, either

in fact or by operation of law, statutory or otherwise, including warranties of

merchantability and fitness for a particular purpose, which Polychromix specifically

disclaims. Polychromix shall have no liability for incidental or consequential damages

of any kind arising out of the sale, installation, or use of its products.

Polychromix’s obligation under this warranty shall not arise until Buyer notifies

Polychromix of the defect. Polychromix’s sole responsibility under this warranty is, at

its option, to replace or repair any defective component part of the product within the

warranty period.

Except in the case of an authorized distributor or seller, authorized in writing by Seller

to extend this warranty to the distributor’s customers, the warranty herein applies only

to Buyer as the original purchaser from Seller and may not be assigned, sold, or

otherwise transferred to a third party.

No warranty is made with respect to used, reconstructed, refurbished, or previously

owned Products, which will be so marked on the sales order and will be sold “As Is”.

BUYER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY IS THAT

THE SELLER EITHER AGREES TO REPAIR OR REPLACE, AT SELLER’S SOLE

OPTION, ANY PART OR PARTS OF SUCH PRODUCTS THAT UNDER PROPER

AND NORMAL CONDITIONS OF USE, PROVE(S) TO BE DEFECTIVE WITHIN

THE APPLICABLE WARRANTY PERIOD. ALTERNATELY, SELLER MAY AT ANY

TIME, IN ITS SOLE DISCRETION, ELECT TO DISCHARGE ITS WARRANTY

OBLIGATION HEREUNDER BY ACCEPTING THE RETURN OF ANY DEFECTIVE

PRODUCT PURSUANT TO THE TERMS SET FORTH HEREIN AND REFUNDING

THE PURCHASE PRICE PAID BY BUYER.

Place of Service

Seller shall use its best efforts to assist buyer to resolve all warranty related issues

through Polychromix customer and technical support as soon as reasonably

practicable after notification by the Buyer of a possible defect. However, the Seller

reserves the right to require the Buyer return the Product to Seller’s production

facility, transportation charges prepaid, when necessary, to provide proper warranty

service.

Polychromix DTSTM Near-Infrared Spectrometer iii

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 4

Warranty

Effective Date

The effective date of this warranty shall begin on the date of shipment/date of

invoice, whichever is later. Products are warranted to be free from defects in

materials and workmanship for parts and labor for 1 year with the exceptions

indicated below:

Limitations

Products are warranted to be free from defects in materials and workmanship for

parts and labor for 1 year with the following exceptions:

• Any components of the system that are in direct contact with corrosive materials

are warranted to be free from defects in materials and workmanship at time of

delivery but cannot be further warranted due to the unknown nature of the use of

the product.

• Consumable items such as lamps, cuvettes and optical filters are excluded from

this warranty. If a lamp undergoes a catastrophic failure (e.g., no light at all)

within 90 days of shipment from the factory, it will be replaced at no charge.

• Loss, damage, or defects resulting from transportation to the Buyer’s facility,

improper or inadequate maintenance by Buyer, software or interfaces supplied

by the buyer, unauthorized modification or operation outside the environmental

specifications for the instrument, use by unauthorized or untrained personnel or

improper site maintenance or preparation.

• The sole and exclusive warranty applicable to software and firmware products

provided by Seller for use with a processor internal or external to the Product will

be as follows: Seller warrants that such software and firmware will conform to

Seller’s program manuals or other publicly available documentation made

available by Seller current at the time of shipment to Buyer when properly

installed on that processor, provided however that Seller does not warrant the

operation of the processor or software or firmware will be uninterrupted or errorfree.

• Products that have been altered or repaired by individuals other than

Polychromix personnel or its duly authorized representatives, unless the

alteration or repair has been performed by an authorized factory trained service

technician in accordance with written procedures supplied by Polychromix.

• Products that have been subject to misuse, neglect, accident, or improper

installation.

The warranty herein applies only to Products within the country of original delivery.

Products transferred outside the country of original delivery, either by the Seller at the

direction of the Buyer or by Buyer’s actions subsequent to delivery, may be subject to

additional charges prior to warranty repair or replacement of such Products based on

the actual location of such Products and Seller’s warranty and/or service surcharges

for such location(s).

The warranty period for data processing equipment, including data storage devices,

processors, printers, terminals, communication interfaces, tape drives, and/or all

similar devices, is in all cases limited to ninety (90) days from the date of shipment to

Buyer.

Repaired products are warranted for 90 days with the above exceptions.

iv Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 5

License Agreement

IMPORTANT - READ THE FOLLOWING TERMS AND CONDITIONS BEFORE USING THIS

SOFTWARE. OPERATING THE SOFTWARE ON THE EQUIPMENT INDICATES YOUR ACCEPTANCE

OF THESE TERMS AND CONDITIONS.

Polychromix, (hereinafter “Polychromix”) provides this Licensed Program, as defined below, to you, the

end user (hereinafter referred to as “Licensee”), and you, Licensee, accept the Licensed Program on the

following terms and conditions:

1) DEFINITIONS. As used herein, “Licensed Program” means the computer software and

accompanying documentation provided with the System; and “System” means a spectrometer and

accompanying equipment supplied by Polychromix to you, Licensee.

2) GRANT OF LICENSE. Polychromix grants to you, Licensee, a nonexclusive, non-transferable

LICENSE to use a copy of the Licensed Program with a single spectrometer in accordance with this

license agreement.

3) OWNERSHIP OF THE LICENSED PROGRAM. Polychromix owns and will retain all title, copyright,

trademark and other proprietary rights in and to the Licensed Program. This LICENSE is not a sale of

the Licensed Program or any copy of it. You, the Licensee, obtain only such rights as are provided in

this Agreement. You understand and agree as follows: You may use the Licensed Program on a

single system. You may make one backup copy of the Licensed Program for archival purposes as

permitted by the United States Copyright Act. You must reproduce and include the copyright notice

with the backup copy. You may not reverse compile, reverse assemble, reverse engineer, modify,

incorporate it in whole or in part in any other product or create derivative works based on all or any

part of the Licensed Program. You may not remove any copyright, trademark, proprietary rights,

disclaimer or warning notice included on or embedded in any part of the Licensed Program. You may

not sell, license, sublicense, assign, rent, or otherwise transfer the Licensed Program without the

written permission of Polychromix. Polychromix will not withhold permission to transfer the LICENSE

as long as you permanently transfer the Licensed Program (including all components and archival

copies, if any) in conjunction with the System with which it was acquired, and the person who wishes

to obtain the System and the LICENSE agrees to the terms and conditions of this Agreement. You

may not use the Licensed Program in any country other than that in which it was obtained or

otherwise export the Licensed Program.

4) TERM. The term of this LICENSE will continue until Polychromix provides written consent to

assignment or transfer of this LICENSE or until Polychromix terminates this LICENSE as provided

herein. Polychromix may terminate this LICENSE by giving the buyer written notice specifying any

failure or default in the performance of any provisions of this LICENSE if the buyer fails to cure said

failure or default within 30 days after such notice. Upon termination of this License, you will promptly

return to Polychromix or destroy all copies of the Licensed Program.

5) LICENSEE’S RESPONSIBILITIES FOR SELECTION AND USE OF THE LICENSED PROGRAM

AND THE SYSTEM . The Spectrometer and the Licensed Program when used together is a tool that

Polychromix hopes you will find useful in your efforts to test and analyze chemicals. HOWEVER,

POLYCHROMIX DOES NOT WARRANT THAT THE SYSTEM AND/OR THE LICENSED PROGRAM

IS SUITABLE FOR ANY SPECIFIC TASK OR IS ACCURATE TO ANY SPECIFIC DEGREE. You

are responsible for the supervision, management and control of the use of the System and the

Licensed Program, and output thereof, including, but not limited to: (a) selection of the System and

the Licensed Program to achieve your intended results; (b) determining the appropriate uses of the

System and the Licensed Program in your business; (c) establishing adequate independent

procedures for testing the accuracy of the System and the Licensed Program; and (d) establishing

adequate backup to obtain accurate data and prevent the loss of data in the event of a malfunction of

the System or the Licensed Program.

Polychromix DTSTM Near-Infrared Spectrometer v

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 6

License Agreement

6) LIMITED WARRANTY. Subject to the other provisions in this Agreement, Polychromix warrants that,

for a period of 1 year from receipt by you, the Licensed Program will conform in all material respects

to the user documentation furnished to the buyer. Polychromix’s sole responsibility under this

warranty will be, at its option, (1) to use reasonable efforts to correct documented errors in said

Licensed Program that are reported to it within the foregoing warranty period or (2) to refund the fees

paid for the LICENSE to the Licensed Program if not sold with the spectrometer as a package.

Polychromix does not warrant that the Licensed Program will be error free, nor that all program errors

will be corrected. All requests for warranty assistance shall be directed to Customer Service,

Polychromix, Inc, 30 Upton Dr., Wilmington MA 01887 USA. Asserted errors must be documented by

the buyer to Polychromix, detailing the error, describing how to recreate the error, and including, if

available, sample output.

EXCEPTIONS. Polychromix’s warranty does not apply insofar as: (a) any Licensed Program is

subjected to misuse, neglect, accident or exposure to environmental conditions beyond those

specified by the documentation; (b) claims result from acts or omissions caused by persons other

than Polychromix or from products, material or software not provided by Polychromix; or (c) you use a

version of the Licensed Program that does not include all required updates provided by Polychromix.

NO OTHER WARRANTIES. THE EXPRESSED WARRANTY SET FORTH IN THIS ARTICLE 6 IS

THE ONLY WARRANTY GIVEN BY POLYCHROMIX WITH RESPECT TO THE LICENSED

PROGRAM, EITHER BY ITSELF OR IN CONJUNCTION WITH THE SYSTEM; POLYCHROMIX

MAKES NO OTHER WARRANTIES, EXPRESSED, IMPLIED OR ARISING BY CUSTOM OR

TRADE USAGE, AND SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

NONINFRINGEMENT, MERCHANTABILITY OR OF FITNESS FOR ANY PARTICULAR PURPOSE.

SAID EXPRESS WARRANTY SHALL NOT BE ENLARGED OR OTHERWISE AFFECTED BY

POLYCHROMIX’S RENDERING OF TECHNICAL OR OTHER ADVICE OR SERVICE IN

CONNECTION WITH THE SYSTEM OR THE LICENSED PROGRAM. POLYCHROMIX SHALL

NOT BE HELD RESPONSIBLE FOR THE PERFORMANCE OF OR OUTPUT OBTAINED FROM

THE LICENSED PROGRAM AND/OR THE SYSTEM NOR FOR ANY LIABILITY TO ANY PARTY

ARISING OUT OF USE THEREOF OR USE OF ITEMS DESIGNED WITH THE SYSTEM OR THE

LICENSED PROGRAM.

7) LIMITATIONS ON REMEDIES. Polychromix’s liability in contract, tort or otherwise arising out of or in

connection with use of the Licensed Program and/or the System, any output thereof, and/or this

Agreement shall not exceed the amounts that Licensee has paid Polychromix or its authorized

distributor hereunder. An essential purpose of the limitation on remedies provided in this paragraph

is the allocation of risks between Licensee and Polychromix. IN NO EVENT SHALL POLYCHROMIX

BE LIABLE FOR SPECIAL, INCIDENTAL, TORT, CONSEQUENTIAL OR ANALOGOUS

DAMAGES (INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING FROM LOSS OF

USE, LOSS OF DATA, LOSS OF PROFITS, LOSS OF GOODWILL, OR LOSS OF BUSINESS)

ARISING OUT OF OR IN CONNECTION WITH THE PERFORMANCE OF THE LICENSED

PROGRAM AND/OR THE PERFORMANCE OF THE SYSTEM AND/OR POLYCHROMIX’S

PERFORMANCE OF SERVICES, EVEN IF POLYCHROMIX HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES.

8) U.S. GOVERNMENT RESTRICTED RIGHTS. If the buyer is a government agency, you

acknowledge that the Licensed Program was developed at private expense and that the computer

software component is provided to you subject to RESTRICTED RIGHTS. Notwithstanding any other

lease or license agreement that may pertain to, or accompany the delivery of, this restricted computer

software, the rights of the government regarding its use, duplication, reproduction or disclosure by the

Government is subject to the restrictions set forth in subparagraph (c)(1)(ii) of the rights in Technical

Data and Computer Software clause of DFARS 252.227-7013, and subparagraphs (c)(1) and (2) of

the Commercial Computer Software -- Restricted Rights clause at FAR 52.227-19.

Contractor/manufacturer is Polychromix 30 Upton Dr. Wilmington MA 01887.

9) GENERAL. The terms of this LICENSE shall be construed in accordance with the substantive laws

of the Commonwealth of Massachusetts. Without limiting the generality of the foregoing, this

Agreement and such relations shall not be governed by the United Nations Convention on Contracts

for the International Sale of Goods even if such Convention would otherwise be applicable in some

respect to this license of software. The English language text of this Agreement shall be the

authorized text for all purposes.

If you have any questions about this Agreement, you may contact Customer Service, Polychromix at (978)

284-6000.

YOU ACKNOWLEDGE THAT YOU HAVE READ THIS LICENSE AGREEMENT, UNDERSTAND IT AND

AGREE TO BE BOUND BY ITS TERMS AND CONDITIONS. YOU FURTHER AGREE THAT IT IS THE

COMPLETE AND EXCLUSIVE STATEMENT OF THE LICENSE AGREEMENT BETWEEN YOU AND

POLYCHROMIX WHICH SUPERSEDES ANY PROPOSAL, OR PRIOR AGREEMENT, ORAL OR

WRITTEN, AND ANY OTHER COMMUNICATIONS BETWEEN YOU AND POLYCHROMIX RELATING

TO THE SUBJECT MATTER OF THIS LICENSE AGREEMENT.

Copyright © Polychromix, Inc. 2005.

vi Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 7

Table of Contents

Warranty......................................................................................................iii

License Agreement......................................................................................v

Table of Contents.......................................................................................vii

1 Introduction.........................................................................................1-1

1.1 Overview......................................................................................1-1

1.2 Description of the Spectrometer...................................................1-3

1.3 Hardware connections..................................................................1-3

1.4 Overview of the Manual................................................................1-3

2 Installation...........................................................................................2-1

2.1 Overview......................................................................................2-1

2.2 Unpacking the Spectrometer........................................................2-2

2.3 Environmental Considerations......................................................2-2

2.4 Interfacing the Spectrometer to the Sample Holder and the Source2-3

2.5 Connecting the Spectrometer to the Computer.............................2-5

2.5.1 For Computers with the Windows Me Operating System..2-5

2.5.2 For Computers with the Windows 2000 Operating System 2-6

2.5.3 For Computers with the Windows XP Operating System..2-7

2.6 Installing the Polychromix DTS SpectralCode Software................2-8

2.6.1 For Computers with the Windows Me/2000/XP Operating

Systems.......................................................................................2-8

3 Quick Start...........................................................................................3-1

4 The SpectralCode Application Program............................................4-1

4.1 Introduction...................................................................................4-1

4.2 General Layout of the SpectralCode Window...............................4-2

4.3 The Menu Bar...............................................................................4-2

4.3.1 The File Menu...................................................................4-2

4.3.2 The Settings Menu............................................................4-3

4.3.3 The Data Collection Menu................................................4-4

Polychromix DTSTM Near-Infrared Spectrometer vii

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 8

Table of Contents

4.3.4 Spectrum Manipulation.....................................................4-5

4.3.5 Help..................................................................................4-5

4.4 Tool Bars......................................................................................4-5

4.4.1 Upper Tool Bar.................................................................4-6

4.4.2 Lower Tool Bar.................................................................4-7

4.5 The Spectral Region.....................................................................4-8

4.6 The PlotLegend Dialog Box..........................................................4-8

4.7 MultiScan...................................................................................4-11

5 Collecting Spectra and Manipulating Data........................................5-1

5.1 Overview......................................................................................5-1

5.2 Collecting Spectra........................................................................5-1

5.2.1 Collecting the Background Spectrum................................5-1

5.2.2 Collecting a Transmittance Spectrum...............................5-3

5.3 Performing Mathematical Manipulations on the Spectra...............5-6

5.4 Saving and Retrieving Spectra .....................................................5-7

5.5 The Light Meter............................................................................5-9

6 Measuring the Spectrum of a Sample................................................6-1

6.1 Overview......................................................................................6-1

6.2 Using a Cuvette and Sample Holder.............................................6-2

6.2.1 The Cuvette......................................................................6-2

6.2.2 The Sample......................................................................6-2

6.2.3 Collecting a Spectrum.......................................................6-3

6.2.4 Standards.........................................................................6-3

6.2.5 Sample Related Spectra Issues........................................6-3

6.2.6 Quantitative Measurements..............................................6-4

6.3 Using an Integrating Sphere.........................................................6-5

6.3.1 The Sample......................................................................6-5

6.3.2 Collecting a Reflectance Spectrum...................................6-5

6.3.3 Standards.........................................................................6-5

6.4 Spectrum Averaging.....................................................................6-6

7 Maintenance and Troubleshooting....................................................7-1

7.1 Overview......................................................................................7-1

7.2 Maintenance.................................................................................7-1

7.3 Troubleshooting............................................................................7-2

7.3.1 Introduction.......................................................................7-2

7.3.2 If the Spectrum is Noisy....................................................7-3

7.3.3 There is no Signal.............................................................7-3

7.3.4 The Signal Intensity is not Constant..................................7-4

7.3.5 The Wavelength for a Peak has Shifted............................7-4

Appendix A Specifications .................................................................................. A1

Index............................................................................................................I1

viii Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 9

1 Introduction

1.1 Overview

The Polychromix DTS

innovative, self- contained instrument that is incorporated into a system that

includes a VIS-NIR light source and a cuvette holder or an integrating sphere.

Figure 1-1: The Polychromix DTS

TM

Near-Infrared Spectrometer (Figure 1-1) is an

TM

Near-Infrared Spectrometer

Polychromix DTSTM Near-Infrared Spectrometer 1-1

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 10

Chapter 1

Three versions of the spectrometer are available:

• DTS™-1700 which covers the 900 - 1700 nm region

• DTS™-2500 which covers the 1700 - 2500 nm region

• DTS™-NB which covers the 1100 - 1300 nm region

Operation of the three systems is identical, except for the wavelength range

that each spectrometer covers.

The spectrometer provides the user with a number of important benefits

including:

• Rapid data acquisition - A spectrum can be acquired in 1 second.

• A minimum power requirement - The spectrometer is driven by a standard

USB port of a personal computer.

• Rugged design - There are no moving parts.

• The performance is unaffected by stray light

• The system is compact and lightweight.

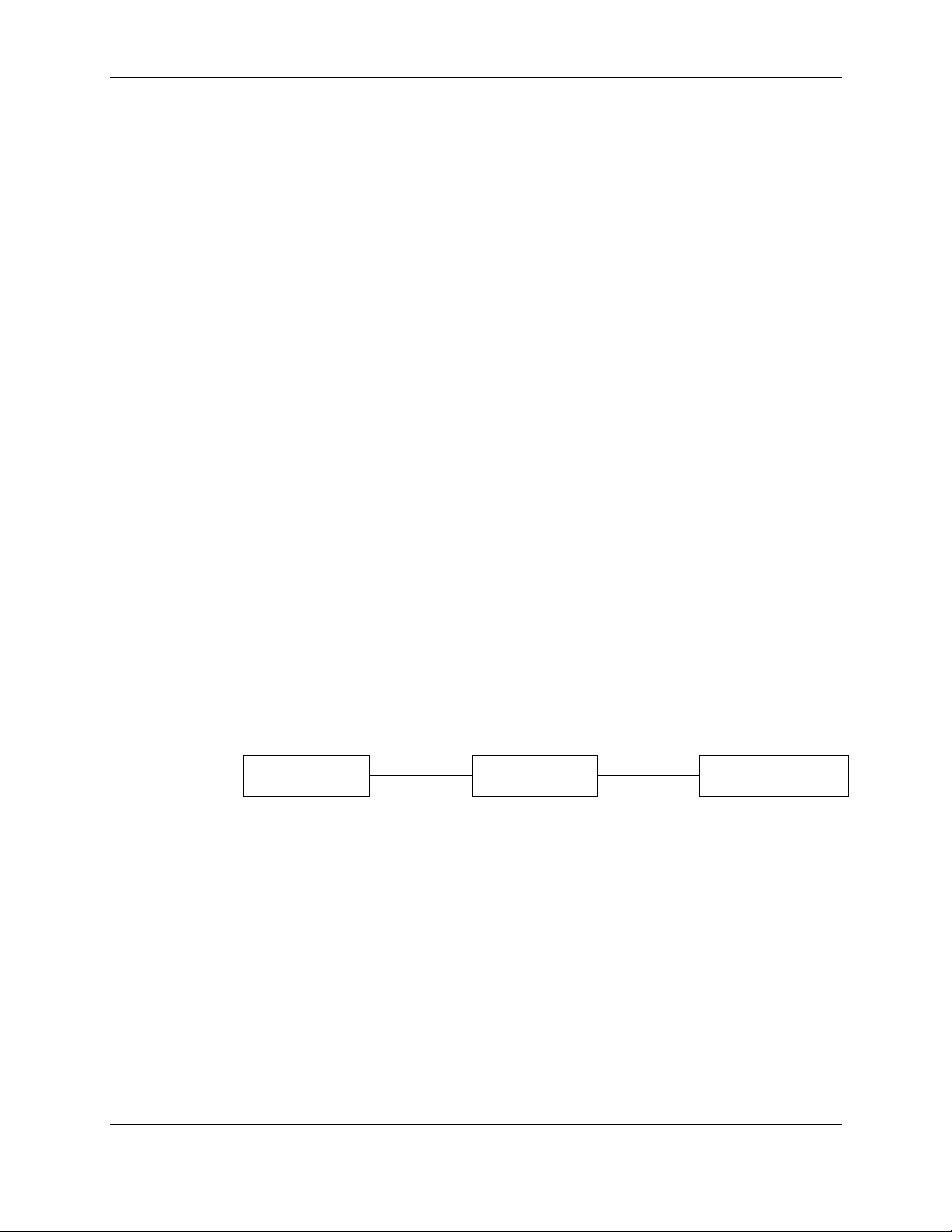

The spectrometer is typically employed as a part of a system that includes a

source and a sample holder (a cuvette holder or a reflectance sphere) as

shown in Figure 1-2. As an example, the spectrometer can be used with the

Ocean Optics HL-2000 Tungsten Halogen Light Source and the Ocean

Optics CUV-UV Holder for 1-cm cuvettes or the Ocean Optics ISP-REF

Integrating Sphere. The source and cuvette holder or reflectance sphere are

acquired separately (e.g. Ocean Optics, Inc., Dunedin FL,

www.oceanoptics.com). As an alternative, the spectrometer can be directly

connected to the source to obtain the spectrum provided by the source).

SOURCE

Figure 1-2: Typical Optical System

SAMPLE

SPECTROMETER

The Polychromix DTS Near-Infrared Spectrometer can be used in a broad

range of applications including

• Portable Field Measurements

• Laboratory Analyses

• Industrial Process Control

1-2 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 11

1.2 Description of the Spectrometer

The mode of operation of the detector involves the dispersion of the spectrum

using a standard fixed grating. Each spectral component from the fixed

grating is then imaged onto a pixel region of a microelectromechanical

(MEMS) micro-diffraction grating which is programmed to selectively filter the

light that is directed to a single InGaAs detector. Digital transform encoding is

employed; in this system, a series of 100 pixels are actuated in a sequence of

100 filter masks. Each mask consists of a combination of 50 pixels that are

“on” and 50 pixels that are “off”, thereby providing a 50 % optical throughput,

and sharing an advantage that is employed in Fourier transform infra-red

spectroscopy.

1.3 Hardware connections

The Polychromix DTS™ has two input connectors: (1) a FSMA receptacle

which accepts a fiber optic cable with a standard SMA-905 connector and (2)

a USB mini-B port which connects to a USB host via a standard USB cable.

Introduction

1.4 Overview of the Manual

This manual consists of the following information:

• Chapter 2 Installation – Describes the receipt of the instrument,

interfacing it to other components of the system and environmental

considerations.

• Chapter 3 Quick Start – Presents a sample experiment to demonstrate

that the spectrometer is operating properly.

• Chapter 4 The SpectralCode Application Program – Includes a

detailed description of the operating program.

• Chapter 5 Collecting Spectra and Manipulating Data – Describes how

the SpectralCodeTM operating program is employed to collect and process

spectroscopic data.

• Chapter 6 Measuring the Spectrum of a Sample – Discusses how data

is collected using the spectrometer and discusses sample handling.

• Chapter 7 Maintenance and Troubleshooting – Presents information

about routine operations to optimize the utility of the spectrometer.

An appendix that lists the spectrometer specifications is included.

Polychromix DTSTM Near-Infrared Spectrometer 1-3

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 12

Page 13

2 Installation

2.1 Overview

This chapter describes the steps required to install the Polychromix DTSTM

NIR Spectrometer in your laboratory and verify that the system is operating in

acceptable manner. It includes the following information:

• Unpacking the spectrometer (Section 2.2)

• Environmental considerations (Section 2.3)

• Connecting the system to other components in the system (Section 2.4)

• Loading the software (Section 2.5 and 2.6)

Please refer to the documentation provided with other components of the

system including the light source and sample holder for additional

information.

Polychromix DTSTM Near-Infrared Spectrometer 2-1

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 14

Chapter 2

2.2 Unpacking the Spectrometer

The Polychromix DTS spectrometer is packed in a single carton. When you

receive the shipment, examine the carton for external damage. If damage is

observed, make certain that the damage is reported on the shipping receipt

and contact Polychromix for further information.

The following items are shipped with the spectrometer:

a) Spectrometer Module

b) USB Interface Cable

c) CD Containing the Operating Program and Manual

If any parts are missing, contact the shipper and Polychromix for further

information.

NOTE: If there appears to be any damage to the spectrometer, do not

continue the installation. Instead, contact Polychromix for more

information.

2.3 Environmental Considerations

The spectrometer should be placed on a sturdy table or laboratory bench in a

facility where the temperature is between 5oC and 40oC (41oF and 104oF),

and the relative humidity is between 0 and 80%.

NOTE: Do not place the spectrometer near a heating or cooling source

(e.g. avoid placing it near a window or an air conditioning duct).

While the system is not subject to stray light, we recommend that the sample

should not be placed in the general vicinity of a strong light, or a location in

which the light intensity can change dramatically. General laboratory lighting

conditions are acceptable.

2-2 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 15

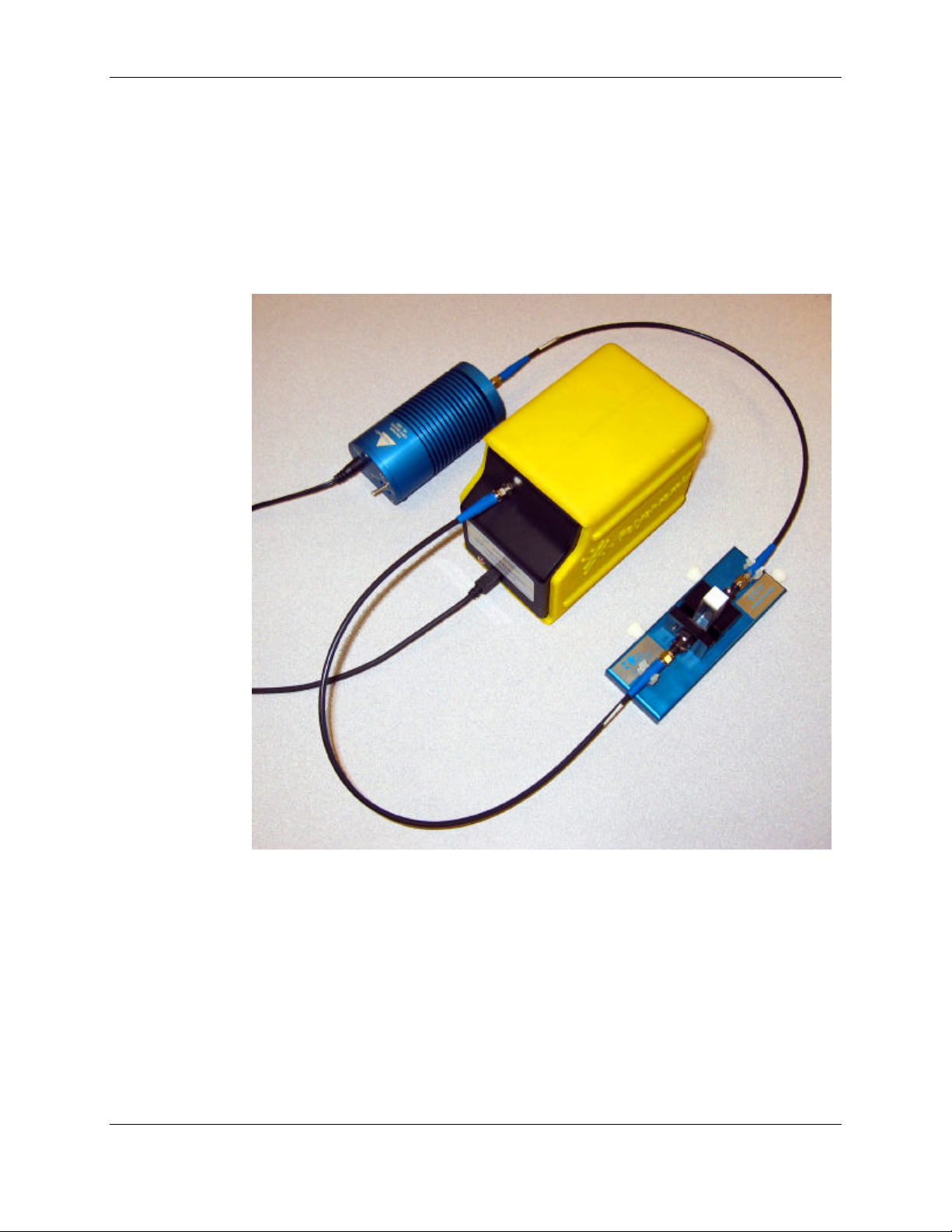

2.4 Interfacing the Spectrometer to the Sample

Holder and the Source

The spectrometer is typically used with the Ocean Optics HL-2000 Tungsten

Halogen Light Source and the Ocean Optics CUV-UV Holder for 1-cm2

cuvettes or the Ocean Optics ISP-REF Integrating Sphere as shown in Figure

2-1 and Figure 2-2.

Installation

Figure 2-1: Polychromix DTS Spectrometer with Source and Cuvette Holder

Polychromix DTSTM Near-Infrared Spectrometer 2-3

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 16

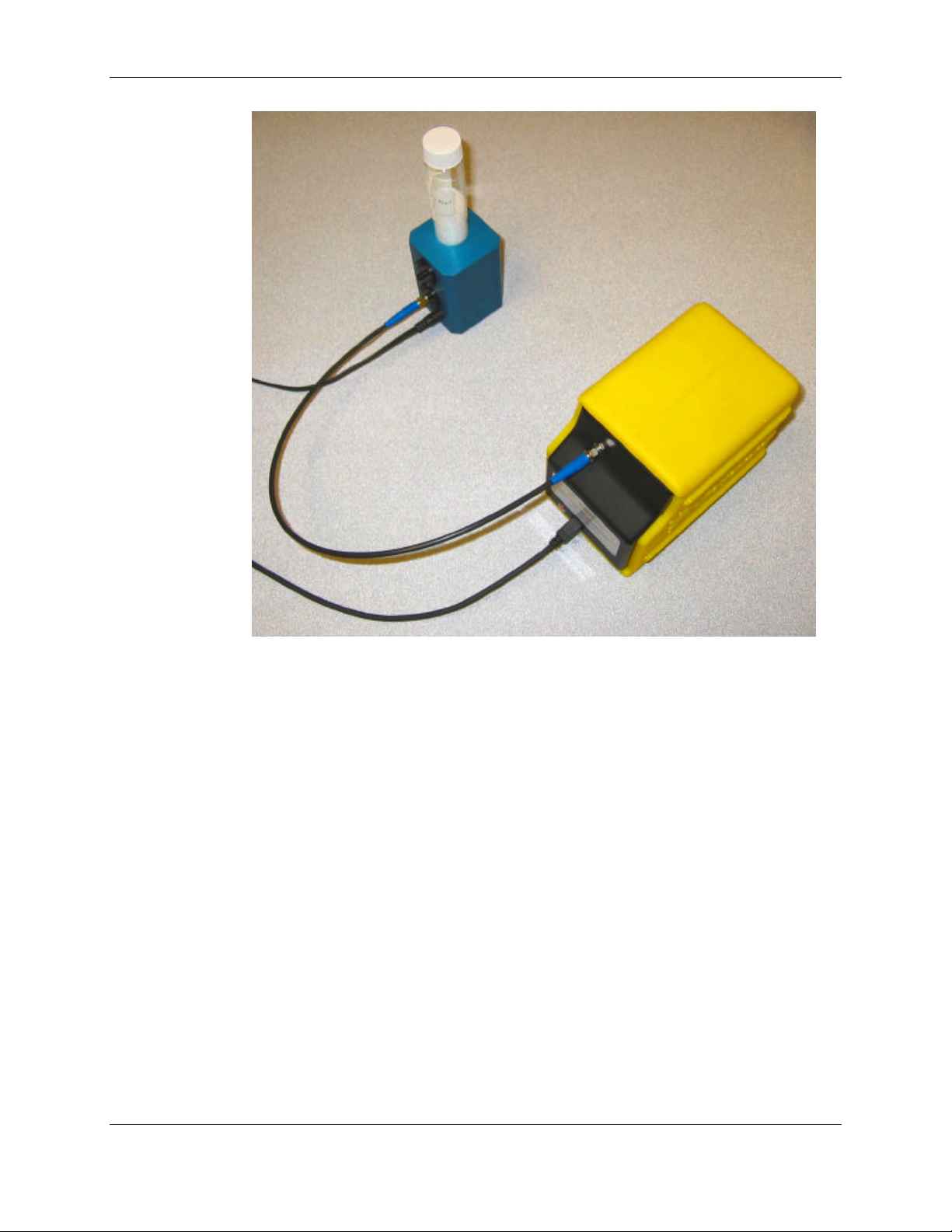

Chapter 2

Figure 2-2: Polychromix DTS NIR Spectrometer with Ocean Optics Integrating

Sphere

For additional information about the source, the cuvette holder and the

integrating sphere, refer to the documentation provided with these

components. As an alternative, the spectrometer can be directly connected to

the source to obtain the spectrum provided by the source.

The sample holder and spectrometer are interfaced by a 600 µm core low OH

fiber optic cable with a standard SMA-905 connector that is provided with the

system. When the system is positioned on the table, take care that the cables

are not bent with a small radius; we suggest that all bends have a radius of at

least 10 cm. Once the system is laid out, tape the fiber optic cables to the

laboratory bench so that they are firmly fixed in position to avoid variations in

intensity.

2-4 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 17

Installation

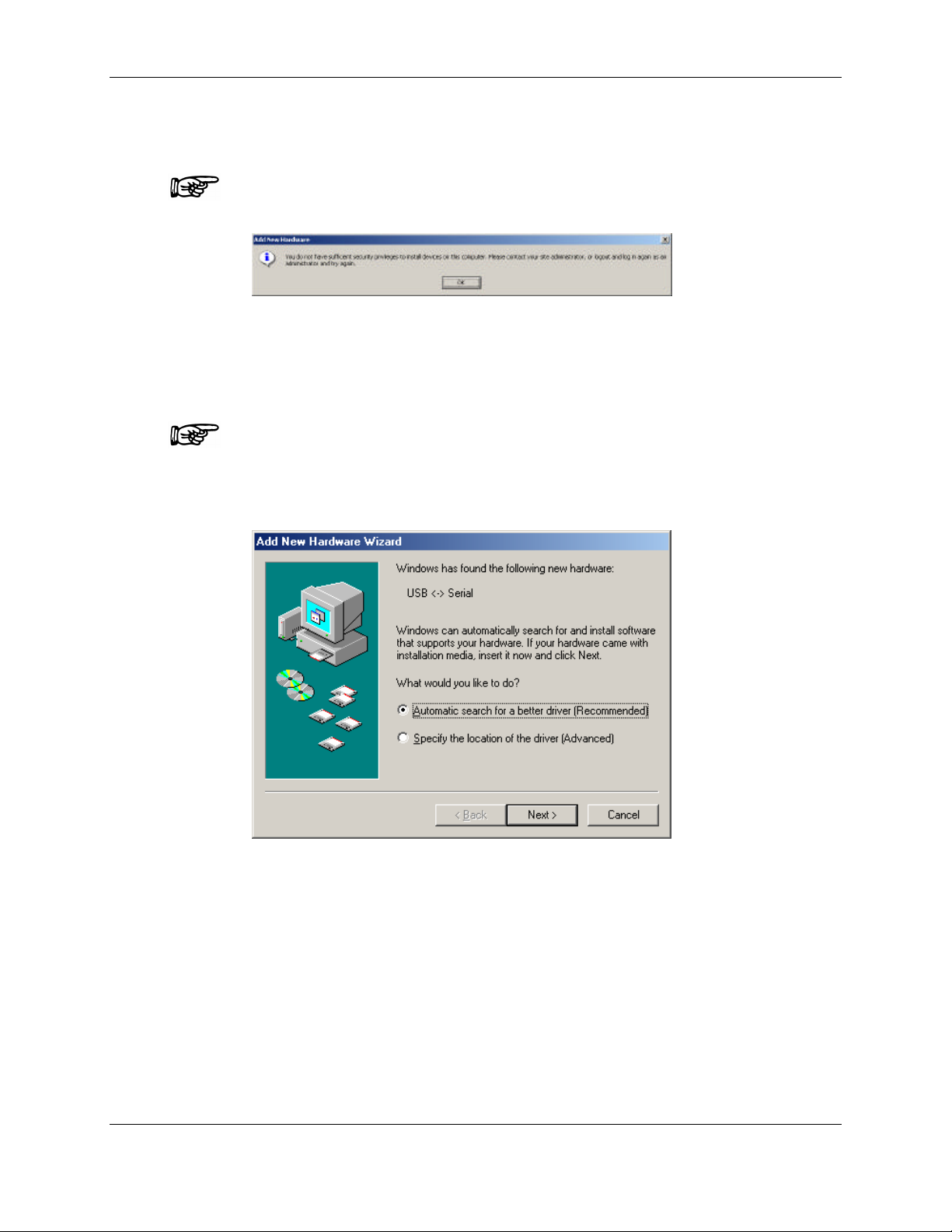

2.5 Connecting the Spectrometer to the Computer

NOTE: Administrative access is required to install the spectrometer

hardware and Polychromix SpectralCode Software.

Figure 2-3: Security Dialog Box

Connect the USB cable that is supplied with the spectrometer to an available

USB port on the computer. The operating system should detect new

hardware.

NOTE: Two hardware devices must be installed for your spectrometer

to function properly: USB -> Serial and USB Serial Port.

2.5.1 For Computers with the Windows Me Operating System

Figure 2-4: Add New Hardware Dialog Box

a) Add New Hardware Wizard dialog box will be presented.

b) Insert the Polychromix distribution CD.

c) Select Automatic search and press Next to search for a recommended

driver.

d) Select Finish to complete the installation.

e) Repeat the above procedure for the USB Serial Port.

Polychromix DTSTM Near-Infrared Spectrometer 2-5

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 18

Chapter 2

2.5.2 For Computers with the Windows 2000 Operating System

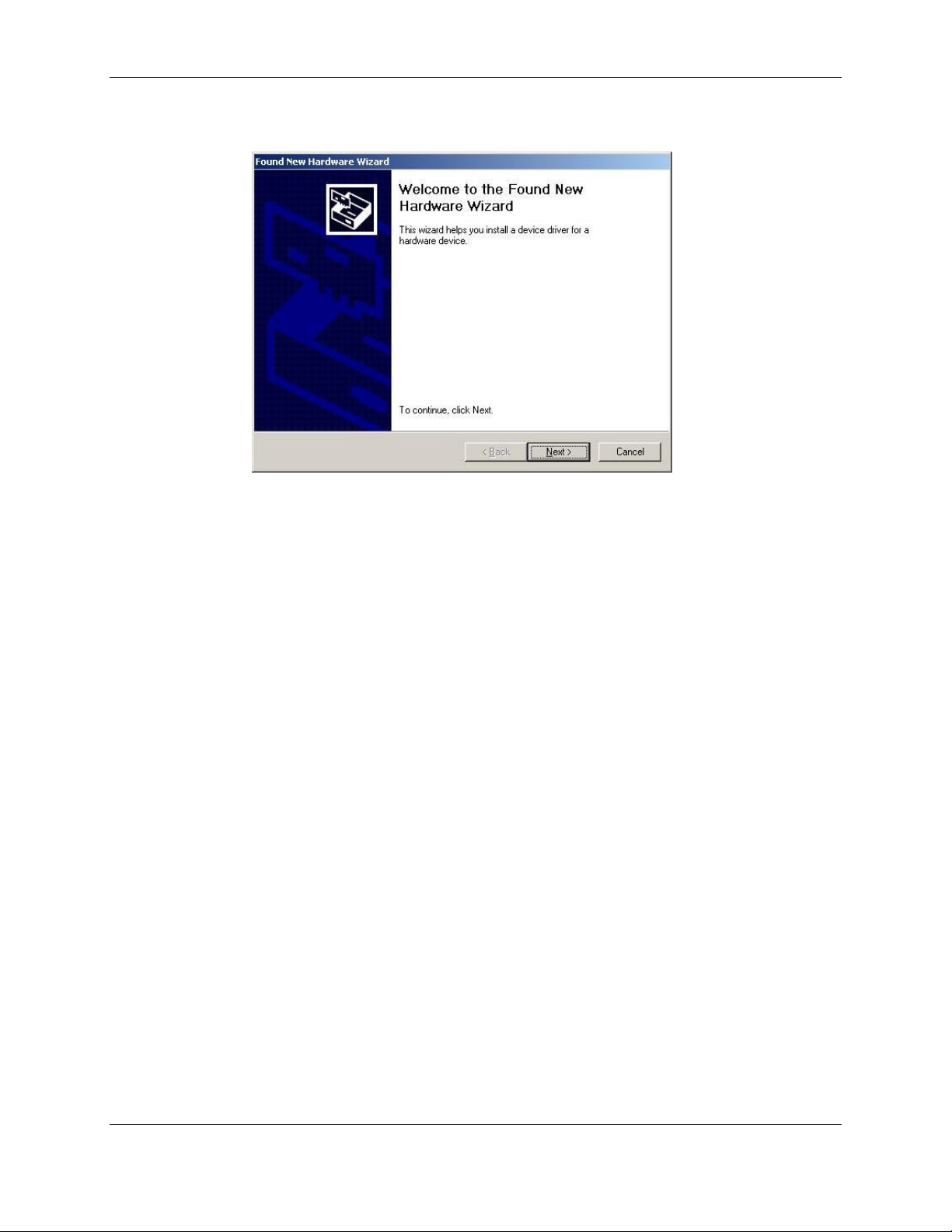

Figure 2-5: Found New Hardware Dialog Box

a) Press Next to present the Welcome to the Found New Hardware Wizard

dialog box.

b) Press Next to present the Install Hardware Device Drivers (USB-Serial)

dialog box.

c) Select the Search for a suitable driver for my device option, and press

Next.

d) The computer will present the Locate Driver Files dialog box. Check

Specify a Location and press Next.

e) A dialog box will be presented to select the location of the driver files.

Insert the Polychromix distribution CD and select the \Drivers\USB

directory, then press Open and finally press OK.

f) The computer will present the message Driver Files Search Results –

Windows found a device for this device. Press Next.

g) The computer will present the message Completing the Found New

Hardware Wizard. Press Finish.

h) Repeat the above procedure for the USB Serial Port.

2-6 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 19

2.5.3 For Computers with the Windows XP Operating System

Figure 2-6: New Hardware Dialog Box

Installation

a) Select No, not this time and press Next. The display will present a display

to choose between automated installation or installation from a user

selected location and prompt you to insert the CD provided with the

device (Figure 2-4).

b) Insert the Polychromix distribution CD, select the Install the software

automatically option and press Next.

c) A dialog box will be presented to select the location of the driver files.

Select the \DRIVERS\USB\ directory, then press Open and finally press

OK.

d) The computer will present the message Driver Files Search Results –

Windows found a device for this device. Press Next.

e) The computer will present the message Completing the Found New

Hardware Wizard. Press Finish.

f) Repeat the above procedure for the USB Serial Port.

Polychromix DTSTM Near-Infrared Spectrometer 2-7

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 20

Chapter 2

2.6 Installing the Polychromix DTS SpectralCode

2.6.1 For Computers with the Windows Me/2000/XP Operating Systems

Software

NOTE: Microsoft .NET v1.1 is required for the Polychromix DTS

SpectralCode Software to function. The installation software is included

on the distribution CD and will present the installation dialog if required.

Figure 2-7: .Net Installation Dialog Box

a) Use Windows Explorer to access the Polychromix DTS SpectralCode

Software on the distribution CD.

b) Select Setup (or setup.exe).

Figure 2-8: .Software Setup Dialog Box

c) Follow the installation instructions. It is suggested that you select the

default options for installation.

Once the DTS software has been installed, the software can be run by

selecting the Polychromix SpectralCode icon on the desktop or via the Start

Menu (Programs/Polychromix Spectral Code/Polychromix Spectral Code).

2-8 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 21

3 Quick Start

NOTE: The experiment described below is provided to allow the

operator to verify that the spectrometer is functioning properly. A

detailed discussion of the program is presented in Chapter 4.

a) Start the program to present the Polychromix SpectralCode window

(Figure 3-1). The wavelength range on the horizontal axis is dependent

on the particular spectrometer that is employed. In this manual, all

windows have been collected for the DTS-1700. If the DTS-2500 is

employed, the range will be 1700-2500 nm and if the DTS-NB is

employed, the range will be 1100-1350 nm.

Figure 3-1: The Polychromix SpectralCode Window

NOTE: If the legend No Device Found is presented in the left corner of

the status line, it is probable that the USB cable has not been plugged

in or the drivers are not properly installed. Close the program, reconnect the cable, check that the drivers are installed and then restart

the program.

Polychromix DTSTM Near-Infrared Spectrometer 3-1

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 22

Chapter 3

b) Turn on the source and allow it to warm up for a few minutes.

c) Verify that the button is depressed and press the

button. A background scan of air will be collected (Figure 3-2).

Figure 3-2: Background Spectrum of Air

NOTE: If the detector is saturated, a warning will be presented

prompting the user to adjust the level using the light meter mode

(Section 5.5).

If you are using a cuvette holder:

a) Place a sample (e.g. 1 cm2 cuvette with water or a piece of polystyrene) in

the light path.

b) Press the (absorbance) button and then press the

button. The spectrum will be collected and displayed (Figure 3-3). The

shape of the spectrum will depend on the wavelength range of the

spectrometer and the sample that is employed. At this juncture, the

critical point is that the spectrum is different than the background

spectrum collected above.

3-2 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 23

Quick Start

Figure 3-3: Absorbance Spectrum of Polystyrene

If you are using an integrating sphere:

a) Set the scan count to 8 using the field adjacent to the button.

b) Place a reflectance reference on the integrating sphere (e.g. Spectralon

TM

or roughened gold).

c) Verify that the button is depressed and press the

button. A background spectrum will be collected.

d) Place a vial filled with a solid (e.g. sugar) over the opening of the

integrating sphere.

e) Press the button and then press the button. The

spectrum will be collected and displayed (Figure 3-4). The shape of the

spectrum will depend on the wavelength range of the spectrometer and

the sample that is employed. At this juncture, the critical thing is to view a

spectrum that is different than the background spectrum collected above.

Polychromix DTSTM Near-Infrared Spectrometer 3-3

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 24

Chapter 3

Figure 3-4: Reflectance Spectrum of Sugar Referenced to Gold

3-4 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 25

4 The SpectralCode

Application Program

4.1 Introduction

The Polychromix DTS spectrometer is controlled by the SpectralCode

application program and all data is presented on the main window (Figure

4-1) which is presented when the program is opened.

Figure 4-1: Polychromix SpectralCode Main Window

Polychromix DTSTM Near-Infrared Spectrometer 4-1

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 26

Chapter 4

4.2 General Layout of the SpectralCode Window

The window includes the following:

• the Menu bar (Section 4.3)

• the Button bar (Section 4.4)

• the Spectral region (Section 4.5)

In general, the program conforms to standard Windows conventions. For

sake of brevity, features that are common to other windows programs (e.g.

the dialog box for saving a spectrum is similar to that used for saving files in

other programs) are not described.

If desired, the user can place the PlotLegend window (Figure 4-2) on the

main window. This sub-window lists the contents and status of the various

storage registers that are in use. A detailed discussion of the sub-window is

presented in Section 4.6.

Figure 4-2: The Plot Legend Window

4.3 The Menu Bar

4.3.1 The File Menu

The File menu (Figure 4-3) is used to access a variety of data storage and

retrieval functions.

Figure 4-3: The File Menu

4-2 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 27

The SpectralCode Application Program

Open File - Accesses a standard Windows dialog box to open an existing

data file and presents the spectrum.

Save File - Presents a standard Windows dialog box to save the active

spectrum. The file is saved as a comma separated Windows Excel file and

can be used for further data processing and/or presentation. If you want to

open the file in Excel, select All Files for the Files of Type field on the Open

dialog box.

The format of the file name is x_yyyymmdd_hhmmss.csv, where x can be

any alphanumeric information you wish to assign, yyyymmdd indicates the

date of collection and hhmmss indicates the time of collection. As an

example, a typical file name might be sugar_20050504_081245, which was

collected at 8:12:45 AM on May 5, 2005. In this instance, the operator

entered the file name sugar; the date and time information is automatically

added to the file name.

Print Plot - Presents a dialog box to enter the name of the spectrum and any

comments that you want to annotate to the spectrum. After entering the

desired information, the annotated plot can be printed by pressing the printer

icon in the upper left corner of the window. The plot is printed by the printer

that is indicated as the default printer in Windows.

Copy - Copies the present window for pasting into another application (e.g. a

word processor). A printer compatible plot is presented.

Exit - Closes the program.

4.3.2 The Settings Menu

The Settings menu (Figure 3-4) is used to change the nature of the window to

meet the specific desires of the user.

Figure 4-4: The Settings Menu

Toolbars - Used to indicate if the Data Collection and Spectral Manipulation

tool bars should be presented in the window. A detailed discussion of the

toolbars is presented in Section 4.4).

Screen Colors - Used to change the color of various elements of the main

window including the background, the chart grid, the axes and the axes

labels. Each selection presents the standard Windows color palette.

Plot Legend - Presents/removes the PlotLegend window (see Section 4.6).

Polychromix DTSTM Near-Infrared Spectrometer 4-3

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 28

Chapter 4

4.3.3 The Data Collection Menu

The Data Collection menu (Figure 4-5) is used to indicate the type of data

acquisition that is to be performed.

Figure 4-5: The Data Collection Menu

Get Scan - Initiates the scan.

Scan Type - Indicates the type of scan to be collected. The options are

Background, Absorbance, Transmittance, Reflectance and Light Meter. A

Background scan must be collected before an Absorbance, Transmittance or

Reflectance scan can be collected.

Scans to Avg. - presents a dialog box to indicate the number of scans that

are to be collected and averaged to obtain the desired spectrum (the range is

1-999). This feature can be used to reduce noise in the reported spectrum.

When the scans are collected, they will be run on a continuous basis until the

data collection process is complete.

Autoscale - Expands/contracts the vertical axis so that the minimum and

maximum intensity of the spectrum are at the minimum and maximum of the

plot.

Overlay - Indicates that the present spectrum (spectra) should not be erased

when a new scan is initiated.

Data Points – Indicates that the actual data points should be presented on

the spectra as dots.

Multiscan - Accesses a dialog box that initiates multiple timed spectral

measurements and recording (Section 4.7).

Continuous Scan - If this is selected, the spectrometer will collect spectra on

a continuous basis until the Cancel button is pressed.

Light Meter - Starts a time scan of the intensity over all wavelengths with all

MEMS pixels set to maximum throughput (see Section 5.5).

4-4 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 29

4.3.4 Spectrum Manipulation

The Spectrum Manipulation menu (Figure 4-6) is used to access post-run

processing of spectral data.

Figure 4-6: Spectrum Manipulation Menu

Save to Reg. - The manipulated data will be saved to a new register.

4.3.5 Help

The Help menu (Figure 4-7) provides access to the on-line help file and the

version number.

The SpectralCode Application Program

Figure 4-7: The Help Menu

Help - Accesses the on-line help file

About - Presents a dialog box with the serial number of the spectrometer, the

version number of the firmware, the version number of the application

program and related information.

4.4 Tool Bars

Two tool bars are presented in the window (Figure 4-8). The upper toolbar is

used for data acquisition and contains the commands presented on the Data

Collection menu while the lower toolbar includes commands for Spectrum

Manipulation.

Figure 4-8: The Toolbars

Polychromix DTSTM Near-Infrared Spectrometer 4-5

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 30

Chapter 4

ndicates that a transmission scan is desired. If an absorbance

4.4.1 Upper Tool Bar

Initiates the selected operation. When the scan is started, the

legend changes to STOP and the sphere is RED.

The number drop down field indicates the number of times that

the operation should be performed and averaged. As an

alternative, the number can be entered via the keyboard. The

range is 1-999.

Indicates that a background scan is desired.

I

spectrum is presented on the screen, it will convert the

spectrum to a transmittance spectrum.

Indicates that an absorbance scan is desired. If a

transmittance spectrum is presented on the screen, it will

convert the spectrum to an absorbance spectrum.

Indicates that a reflectance spectrum is desired.

Indicates that a Light meter measurement is desired (see

Section 5.5).

Indicates that spectra should be collected on a repetitive basis.

Data collection is initiated upon selecting this option, and is

terminated by pressing the Stop button.

Indicates that Multiple scans are desired (see Section 4.7).

4-6 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 31

Indicates that the spectrum should be auto scaled.

Indicates that spectra should be overlaid on the display.

Indicates that each data point should be shown on the

spectrum.

4.4.2 Lower Tool Bar

The SpectralCode Application Program

Presents a dialog box to allow the user to

move the spectrum to another register (see

Section 4.6 for details).

The first and third fields are used to indicate

the spectra to be manipulated and the

second field is used to indicate the desired

operator (+, -, /). The drop down menus will

list all absorbance, transmittance, and

reflectance spectra in the various registers

(except register 0).

Performs the desired manipulation. The

new spectrum will be the active spectrum

(register 0) and can be moved in the same

manner as a spectrum indicated above.

Polychromix DTSTM Near-Infrared Spectrometer 4-7

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 32

Chapter 4

4.5 The Spectral Region

The spectral region presents the data that was collected.

If desired, one can expand (zoom) a region of the spectrum by placing the

mouse on one corner of the desired region to be enlarged, clicking the left

button and dragging the mouse to the opposite corner and then releasing the

mouse button. To return to the auto-scaled plot, click the right button on the

mouse.

The Autoscale command (Section 4.4) can be used to expand/contract the

spectrum so that it appears full scale in the spectral region.

The colors of each element of the window can be selected as described in

Section 4.3.2 and the color of the active spectrum can be selected as

described in Section 4.4.

The bottom line of the window is a status bar and provides information to the

operator.

• The left field indicates the Com Port that is employed for the

spectrometer. If the spectrometer is not connected, the legend No Device

Found will be presented.

• The center field is used if the multiple scan feature is employed. The

number of remaining scans and the time until the next scan will be

indicated.

• The right field will indicate the position of the cursor if the mouse is in the

spectral region (e.g. X:1356.2, Y:0.02433).

4.6 The PlotLegend Dialog Box

The PlotLegend dialog box is used to indicate the status of the active

registers. Figure 4-9 shows the dialog box when the instrument is started.

Figure 4-9: The Plot Legend Dialog Box

4-8 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 33

The SpectralCode Application Program

After a spectrum is collected, the PlotLegend dialog box will be updated as

shown in Figure 4-10. The green traffic light indicates that the spectrum is

displayed (the color of the traffic light in the PlotLegend window indicates the

status of the register as described below) and the B in the right box indicates

that the scan is a Background scan. The final box indicates the color of the

spectrum; if desired, you can change the color by clicking on the box.

Figure 4-10: The Plot Legend Dialog Box after a Background Scan

To move the background scan to register 1, press the key to present

the RegOverwrite dialog box (Figure 4-11) and press OK. If a register(s) is

occupied, the display will list all of the occupied register(s) and the lowest

unoccupied register. The user may select any register to overwrite by clicking

on it. By default, the next unoccupied register is initially selected.

Figure 4-11: The RegOverwrite Dialog Box

The dialog box will appear as shown in Figure 4-12. The red circle for register

0 indicates that the register is not displayed.

Figure 4-12: The Plot Legend Dialog Box after Moving the Background Scan

Polychromix DTSTM Near-Infrared Spectrometer 4-9

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 34

Chapter 4

If the user now performs a transmittance scan, that scan will be placed in

register 0 and can be moved with the key to register 2 (Figure 4-13).

Figure 4-13: The Plot Legend Dialog Box after Collecting a Transmittance Scan

and moving it.

The color of the traffic light in the PlotLegend dialog box indicates the display

status of the register.

Red - The contents of the register are not displayed.

Yellow – The contents of the register can be displayed if the appropriate

spectral type is active (e.g. a reflectance scan cannot be displayed if the

absorbance mode is active, but could be displayed if the active mode was

changed to reflectance).

Green - The contents of the register are displayed.

To change the display state:

• To display a register that is not currently displayed, click on the traffic light

until it turns green.

• To turn off a register that is currently displayed, click on the traffic light

until it turns red.

The highlighted scan in the Plot Legend dialog box (which is indicated with a

gray background) can be renamed as desired by typing in the desired name.

4-10 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 35

4.7 MultiScan

The spectrometer can be used to schedule scans at user specified times via

the SCMultiScan dialog box (Figure 4-14).

The SpectralCode Application Program

Figure 4-14: The SCMultiScan Dialog Box

To schedule a series of spectra, indicate the number of spectra to be saved,

the number of scans to be averaged for a single spectrum, the time between

spectra and the file name root (e.g. sugar). The date and time will be

automatically added to the file name in the same manner as before. Any

comments will be included in the file.

If the Single File radio button is selected, all data will be stored in a single

data file, while if the Multiple Files radio button is selected, each spectrum will

be stored as a separate data file.

Polychromix DTSTM Near-Infrared Spectrometer 4-11

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 36

Chapter 4

When the Start button is pressed, the first scan will be initiated. The status

line will indicate the number of scans remaining and the time before the next

spectrum.

4-12 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 37

5 Collecting Spectra

and Manipulating

Data

5.1 Overview

This chapter demonstrates how the operator uses the Polychromix

SpectralCode application software program to collect spectra, manipulate

data, and store and retrieve data. The material in this chapter should be used

in conjunction with Chapter 6, which describes sample handling and related

issues.

NOTE: The general approach for collecting spectra and manipulating

data using SpectralCode is identical for all types of data (absorbance,

transmittance and reflectance). For the sake of brevity, only the

collection and processing of transmittance spectra are presented.

5.2 Collecting Spectra

5.2.1 Collecting the Background Spectrum

To Collect the Background Spectrum:

a) Place the blank in the sample compartment (e.g. an empty cuvette)

b) Press the button

c) Press the button to collect the spectrum (Figure 5-1).

Polychromix DTSTM Near-Infrared Spectrometer 5-1

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 38

Chapter 5

Figure 5-1: The Background Spectrum

NOTE: If the background spectrum is too noisy, repeat this operation

and increase the number of scans to be averaged using the field that is

adjacent to the scan button. If the background scan is an averaged

scan, it is common practice (but not necessary) to use the same

number of scans for the collection of the transmission spectrum.

d) After you have obtained a suitable background spectrum, use the

key to move it into Register 1 in the PlotLegend dialog box (Figure 5-2).

Figure 5-2: The Plot Legend Dialog Box

NOTE: If you are collecting data on a continuous basis or on a timed

basis, the Stop button can be used to stop the operation.

5-2 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 39

Collecting Spectra and Manipulating Data

5.2.2 Collecting a Transmittance Spectrum

To collect a Transmittance spectrum:

a) Place the sample in the system.

b) Press the button. The background spectrum in the spectral region

of the window will be erased and the vertical axis will be labeled

Transmission % (for an absorbance spectrum, the vertical axis will be

labeled Absorbance).

c) Press the button to obtain the spectrum. The display will look

like Figure 5-3.

NOTE: If you are collecting data on a continuous basis or on a timed

basis, the Stop button can be used to stop the operation.

Figure 5-3: Transmission Spectrum of Polystyrene

The transmission spectrum stored in register 0 is the spectrum that was just

collected. It is indicated with a green light and the letter T, while the

background spectrum collected above is in register 1 and is indicated by the

letter B.

Polychromix DTSTM Near-Infrared Spectrometer 5-3

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 40

Chapter 5

If the transmittance spectrum in register 0 is acceptable and you want to

collect data from another sample; press the key and move the

spectrum into register 2 or save it as a file. The updated PlotLegend dialog

box will appear as shown in Figure 5-4.

Figure 5-4: Plot Legend after Moving the Transmission Spectrum

If you want to save a spectrum, make sure that it is displayed in the spectral

region, as only displayed spectra can be saved.

NOTE: If you press the scan key again without moving the data, the data

in register 0 will be overwritten.

If desired, you can copy the data in register 0 to an existing register and

overwrite the data in that register. This feature might be used if you noted that

there was an error in the data in register 2 and wanted to repeat the scan.

If you want to overlay spectra, press the key. An example of the

overlay of two transmission spectra is shown in Figure 5-5 (the pale blue

spectrum in Register 1 is from polystyrene and the dark blue spectrum in

Register 2 is polymethylmethacrylate. Only the newest spectrum will be the

active spectrum in the register (i.e. it can be saved).

5-4 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 41

Collecting Spectra and Manipulating Data

Figure 5-5: Overlaid Transmission Spectra

A spectrum can be named by highlighting it in the PlotLegend dialog box and

typing the desired name.

If you want to save a spectrum, make sure that it is the most recently

displayed in the spectral region, as only the most recently displayed spectrum

can be saved.

Polychromix DTSTM Near-Infrared Spectrometer 5-5

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 42

Chapter 5

5.3 Performing Mathematical Manipulations on the

Spectra

The Polychromix SpectralCode application software program provides the

ability to perform a variety of mathematical operations on spectra stored in

the registers, including the addition, subtraction or division of two spectra. In

this section, we will describe how to divide one spectrum by another. The

general principle for all operations is identical.

To perform a mathematical operation:

a) Ensure that the spectra on which the processing is to be performed have

been transferred to registers 1 and higher (data in register 0 cannot be

processed via this procedure).

b) Go to the bottom tool bar (Figure 5-6) and open the first field to present a

list of the registers that contain data available for processing.

Figure 5-6: Mathematical Processing Fields

c) Select the desired register and open the second field, which presents a

list of the available operators (+, -, /).

d) Select the desired operator and open the third field, which again presents

a list of the registers that contain available data.

e) Select the desired register. A typical operation might be 1/2, indicates that

spectrum 1 should be divided by spectrum 2.

f) Press the button to perform the operation. The result will be displayed

in the spectral area and will be indicated in the PlotLegend dialog box as

Math Result (Figure 5-7). This spectrum can be moved or renamed in the

same manner as any other spectrum.

Figure 5-7: Result of a Mathematical Operation

5-6 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 43

Collecting Spectra and Manipulating Data

5.4 Saving and Retrieving Spectra

The active spectrum can be saved by selecting the Save File command on

the File menu and indicating the desired storage location. Data is saved as a

.csv file (comma separated values). If the spectrum was obtained by

averaging a number of scans, the averaged spectrum will be saved (but not

the individual scans).

The saved spectrum can be retrieved by selecting the Open File command

on the File menu and selecting the desired file. As an alternative, the file can

be opened in Microsoft Excel in a tabular format for customized data

processing and presentation as well as in many other applications.

If data is collected on a time scan basis using the SCMultiScan dialog box

(see Section 4.7), the Save options field can be used to store each spectrum

on an automated basis as it is being collected and the Excel spreadsheet will

display a column for each spectrum. As an alternative, if you select the

Multiple Files radio button, each set of scans will be given a separate file.

A part of an Excel spreadsheet for a single spectrum is shown in Figure 5-8

and a part of a spreadsheet for multiple spectra is presented in Figure 5-9

(see Section 4.7).

Wavelength (nm) Absorbance 5/26/2005 11:56:51 Abs Polystyrene

0

936.9 0.03506013

944.7 0.03423788

952.4 0.03391358

960.2 0.03462744

967.9 0.03427535

975.7 0.03541862

983.4 0.03574646

991.1 0.0360106

998.8 0.03682216

1006.6 0.03748415

1014.3 0.03631843

1022 0.03653189

1029.7 0.03704398

1037.5 0.03592357

1045.2 0.03496345

1052.9 0.03526047

1060.6 0.03398799

1068.3 0.0326819

1076 0.03347766

1083.7 0.0337929

1091.4 0.03389158

1099.1 0.03401419

1106.8 0.03735034

1114.5 0.04052372

1122.2 0.04250975

1129.9 0.04695749

1137.5 0.04944238

1145.2 0.04932098

Figure 5-8: Spectroscopic Data in Excel Spreadsheet - Single Spectrum

Polychromix DTSTM Near-Infrared Spectrometer 5-7

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 44

Chapter 5

Wavelength (nm) Absorbance 5/26/2005 13:31:36 Abs Muti-scan Test File

936.9 0.09025412 0.090592 0.090402 0.090459 0.09025057

944.7 0.08943115 0.089006 0.088848 0.089381 0.0894325

952.4 0.08780692 0.087835 0.087834 0.087979 0.08778944

960.2 0.08811077 0.088223 0.087686 0.088082 0.08816743

967.9 0.08733211 0.087411 0.08746 0.087631 0.08730432

975.7 0.0874955 0.087252 0.087432 0.087495 0.08727504

983.4 0.08811556 0.087986 0.08792 0.087986 0.08787344

991.1 0.08811787 0.088511 0.088154 0.088253 0.08801024

998.8 0.08659166 0.086658 0.086628 0.086726 0.08685371

1006.6 0.08725458 0.087219 0.087082 0.087205 0.08717126

1014.3 0.08846609 0.088375 0.088372 0.088423 0.08837023

1022 0.08773003 0.087792 0.087779 0.087797 0.08786082

1029.7 0.08703371 0.087194 0.086977 0.087162 0.0870512

1037.5 0.08632153 0.086383 0.086266 0.086541 0.08639798

1045.2 0.08746875 0.087413 0.087481 0.087402 0.0874313

1052.9 0.08707132 0.087134 0.08711 0.087155 0.08702853

1060.6 0.08575796 0.085668 0.085668 0.085744 0.08570843

1068.3 0.08560116 0.085949 0.085886 0.085859 0.08597612

1076 0.08530499 0.085306 0.085297 0.08545 0.08536568

1083.7 0.08482784 0.084715 0.084817 0.084837 0.08482236

1091.4 0.08510091 0.085198 0.084983 0.085085 0.08498126

1099.1 0.08650035 0.086497 0.086545 0.086356 0.08647406

1106.8 0.08698642 0.087085 0.086858 0.086988 0.08698384

1114.5 0.0939277 0.093941 0.093886 0.093763 0.09399594

0 0.177612 0.344798 0.511983 0.679168493

Figure 5-9: Spectroscopic Data in Excel Spreadsheet – Multiple Spectra

The saved data files are in “Comma Separated Variable” format. All

alphanumeric values are stored in ASCII format and separated by commas.

Each row is terminated with a carriage return and linefeed (ascii value 13 and

10).

Row 1 - Always has 6 entries. These are Horizontal Axis Type, Vertical Axis

type, Date, Time, Scan type, and Comments.

Row 2 - Has as many entries as there are saved spectra plus 1. The first

entry is blank, the second entry is the time (in minutes from the start of the

session) of the first recorded spectrum. The remaining entries are the times

of the remaining spectra in the file.

Row 3 and higher - Row 3 and all data after comprise a table in which the first

column is wavelength and each column thereafter (to the right) is one of the

recorded spectra.

Each row has as many entries as there are saved spectra plus 1. The first

entry is the wavelength of the row. The second entry is the value of the

spectrum (e.g. absorbance, transmittance) of the first spectrum at the

wavelength represented by the first entry. Similarly, the third entry in the row

is the value of the spectrum for the second recorded spectrum. This follows

until the last recorded spectrum.

5-8 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 45

5.5 The Light Meter

The Light Meter option is provided to allow the user to monitor a source.

When this function is selected, the spectrometer will present a time-based

record of the intensity summed over all wavelengths (all MEMS pixels set to

maximum throughput). A typical output is shown in Figure 5-10. The value in

the lower right corner of the status line is the instantaneous value of the

current (not the position of the cursor).

Collecting Spectra and Manipulating Data

Figure 5-10: Typical Light Meter Output

During light meter data collection, the left mouse button will freeze the plot

but data will continue to be collected. To update the plot, press the right

mouse button.

The light meter is often used to optimize the signal level. Ideally, the signal

from the source should be adjusted, when possible, to just below saturation

of the detector, which occurs at 1,500 nA.

Polychromix DTSTM Near-Infrared Spectrometer 5-9

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 46

Page 47

6 Measuring the

Spectrum of a

Sample

6.1 Overview

The Polychromix DTS spectrometer is typically used to measure the

spectrum of a liquid using a cuvette and a sample holder and a solid using an

integrating sphere or reflectance probe. This chapter describes the general

approach to collecting data and presents a series of suggestions to optimize

the quality of data that is obtained.

Since the spectrometer can measure the spectrum of a broad range of

samples in a large number of applications, the information presented in this

chapter is somewhat general in nature. The analyst will likely find specific

information about sampling and collecting spectra for the specific sample in

the general scientific literature.

Polychromix DTSTM Near-Infrared Spectrometer 6-1

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 48

Chapter 6

6.2 Using a Cuvette and Sample Holder

6.2.1 The Cuvette

A cuvette and a sample holder are used when the spectrum of a liquid is to

be obtained. The standard cuvette has a 1 cm path length (although other

lengths may be used) and requires approximately 2 mL of sample. If the

available sample is less than 2 mL, a number of smaller cuvettes are

available and an adapter can be used to reproducibly position the cuvette.

NOTE: It should be noted that the absorbance of a sample is

proportional to path length, and using a smaller cuvette will be

beneficial for samples with large absorbance values.

The cuvette is an integral part of the optical system, and should be handled

with care. The following points should be noted to ensure the fidelity of

collected spectra:

• Always place the cuvette in the light path so that the same wall plane

faces the incoming light to ensure a constant path length.

• Do not get fingerprints on the optical faces of the cuvette. If you

accidentally touch an optical surface, wipe it off with a lint free tissue

saturated with methanol and allow the methanol to evaporate.

• If an optical surface of the cuvette is scratched, chipped or becomes

cloudy, position the cuvette in the sample holder so that the light does not

go through that surface.

6.2.2 The Sample

The sample should be dissolved in a suitable solvent and should be

homogeneous. Spectroscopic grade or other highly purified solvents should

be used whenever possible. If the source of the solvent is changed, verify

that the new solvent and the old solvent are equivalent and collect a new

background spectrum.

If the sample contains particulate matter, make sure that it is filtered to

remove the solid material.

If there are air bubbles in the sample, remove them before taking a

measurement. Air bubbles are occasionally observed in aqueous samples

that have been allowed to sit undisturbed for a period of time.

6-2 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 49

6.2.3 Collecting a Spectrum

To collect a spectrum:

a) Place a cuvette containing the reference sample in the sample holder and

collect the background spectrum as described in Section 5.2.1.

The reference sample should contain everything in the sample except the

compound(s) of interest. As an example, if the sample is dissolved in

methanol:water (1:1), that solvent should be used as the reference

sample. Similarly, if the sample is dissolved in a buffer, the buffer should

be used as the reference sample.

NOTE: If appropriate, the background spectrum can be taken using an

empty cuvette.

b) Remove the reference sample, place the sample in the sample holder

and collect the transmittance or absorbance spectrum as described in

Section 4.2. A plot of Transmission vs. Wavelength or Absorbance vs.

Wavelength will be presented.

Measuring the Spectrum of a Sample

6.2.4 Standards

The spectrum of a standard should be collected on a periodic basis (in many

laboratories, a sheet of a polymer is employed as a standard). The standard

should have a number of absorbance bandsspread across the spectral

region. When the spectrum of a standard is collected, the analyst should

check that the intensity of the bands and the wavelength remains constant

over time.

If difficulties are observed with the system, the spectrum of a standard should

be collected and compared to spectra that have been previously collected

using the same conditions.

6.2.5 Sample Related Spectra Issues

If the instrument appears to be working in an acceptable manner (e.g. the

spectra of the standard is acceptable) and unacceptable sample spectra are

obtained, it is probable that the difficulty is related to the sample. Typical

sample related issues are indicated in Table 6-1. General instrument

troubleshooting is discussed in Chapter 7.

Polychromix DTSTM Near-Infrared Spectrometer 6-3

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 50

Chapter 6

6.2.6 Quantitative Measurements

Table 6-1: Sample Related Issues

Problem Cause Solution

The absorbance is

weak or % T is very

The sample is too dilute

or too thin

Prepare a more

concentrated sample

high (noisy spectrum)

Use Spectrum

Averaging to reduce

noise (Section 6.4)

The absorbance is too

strong or % T is near

The sample is too

concentrated or thick

Dilute the sample or

use a thinner cuvette

zero

Intensity of peaks

change

Spectrum does not

compare to spectrum in

Sample Decomposition Use a thermostated

cuvette holder

Interaction between

Replace solvent

sample and solvent

another solvent

The transmission (T) of a sample is defined by equation 6-1.

T = P/P

o

6-1

where: P is the power of the light that is transmitted by the sample

Po is the power of the light incident on the sample

The absorbance (A) of a sample is the logarithm (base 10) of the reciprocal of

the transmittance (equation 6-2).

A = -log T = log (1/T) 6-2

Beer’s Law (equation 6-3), can be used to determine the concentration of the

compound of interest.

A = e x c x l 6-3

where: A is the absorbance

e is the molar absorbance coefficient, which is a constant for a

compound in a given solvent at a given temperature

c is the concentration of the compound

l is the path length.

6-4 Polychromix DTSTM Near-Infrared Spectrometer

Operator’s Manual

Document Number 04-91-0201-00 Rev A

Page 51

6.3 Using an Integrating Sphere

An integrating sphere is normally used when the analyst wants to obtain the

spectrum of the surface of a solid or a turbid solution. The sample is placed

on the orifice of the sphere and is an integral part of the optical pathway.

6.3.1 The Sample

The following points regarding sample handling should be noted to ensure

the fidelity of collected spectra:

• Do not get fingerprints on the surface of the sample. If you accidentally

touch the surface, wipe it off with a lint free tissue saturated with methanol

and allow the methanol to evaporate.

• If a sample is contained in a bottle (flask, etc.) make certain that the

surface through which the infrared radiation passes is clean and is not

scratched, chipped or cloudy.

• If the sample is believed to be homogeneous, collect spectra at a few

positions on the sample to ensure that you are viewing a representative

sample.

Measuring the Spectrum of a Sample

• If the sample contains imperfections due to handling (e.g. scratches on a

piece of plastic) avoid the areas containing the imperfections.

6.3.2 Collecting a Reflectance Spectrum

To collect a spectrum:

a) Collect the background scan of an appropriate high reflectance material

such as “Spectralon” polymer or roughened gold as described in Section

5.2.

b) Place the sample on the integrating sphere and measure the reflectance.

6.3.3 Standards

The spectrum of a standard should be collected on a periodic basis. The

standard should have a number of absorbance bands spread across the

spectral region. When the spectrum of a standard is collected, the analyst

should check that the intensity of the bands and the wavelength remains

constant over time.

If difficulties are observed with the system, the spectrum of a standard should

be collected and compared to spectra that have been previously collected

using the same conditions.

Polychromix DTSTM Near-Infrared Spectrometer 6-5

Operator’s Manual