Page 1

Temperature-regulated Cuvette

Holder

CUV-TLC-50F

Installation and Operation Manual

Document Number 000-30000-000-02-0205

Offices:

E-mail: Info@OceanOptics.com (General sales inquiries)

Ocean Optics, Inc.

830 Douglas Ave., Dunedin, FL, USA 34698

Phone (727) 733-2447

Fax (727) 733-3962

8:30 a.m.–6 p.m. EST

Ocean Optics B.V. (Europe)

Nieuwgraaf 108 G, 6921 RK DUIVEN, The Netherlands

Phone 31-(0)26-3190500

Fax 31-(0)26-3190505

Info@OceanOpticsBV.com (European sales inquiries)

Orders@OceanOptics.com (Questions about orders)

TechSupport@OceanOptics.com (Technical support)

Page 2

Copyright © 2001-2005 Ocean Optics, Inc.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, by any means, electronic,

mechanical, photocopying, recording, or otherwise, without written permission from Ocean Optics, Inc.

This manual is sold as part of an order and subject to the condition that it shall not, by way of trade or otherwise, be lent, re-sold, hired out or

otherwise circulated without the prior consent of Ocean Optics, Inc. in any form of binding or cover other than that in which it is published.

Trademarks

Microsoft, Windows, Windows 95, Windows 98, Windows Me, Windows NT, Windows 2000, Windows XP and Excel are either registered

trademarks or trademarks of Microsoft Corporation.

Limit of Liability

Every effort has been made to make this manual as complete and as accurate as possible, but no warranty or fitness is implied. The information

provided is on an “as is” basis. Ocean Optics, Inc. shall have neither liability nor responsibility to any person or entity with respect to any loss or

damages arising from the information contained in this manual

Page 3

Table of Contents

About This Manual .......................................................................................................... iii

Document Purpose and Intended Audience ............................................................................. iii

What’s New in this Document ................................................................................................... iii

Document Summary.................................................................................................................. iii

Product-Related Documentation ............................................................................................... iv

Upgrades......................................................................................................................... iv

Chapter 1: ......................................................................1Introduction

Overview.......................................................................................................................... 1

Features .......................................................................................................................... 2

System Setup .................................................................................................................. 2

Components .................................................................................................................... 3

Optional Equipment......................................................................................................... 3

Optical Components.................................................................................................................. 3

Additional Accessories ..............................................................................................................5

Packages for Specific Applications ...........................................................................................6

Chapter 2: ..........................................................................7Operation

Optics .............................................................................................................................. 7

Typical Configuration for Absorbance Measurements .............................................................. 7

Typical Configuration for Fluorescence Measurements............................................................ 8

Optical Adjustments................................................................................................................... 8

Converting an Imaging Lens into a Collimating Lens................................................................ 9

System Operation............................................................................................................ 9

Performance.................................................................................................................... 10

Temperature Equilibration ......................................................................................................... 11

Low Temperatures..................................................................................................................... 11

Temperature Ramping .............................................................................................................. 12

Error Conditions .............................................................................................................. 12

000-30000-000-02-0205 PRELIMINARY DRAFT i

Page 4

Table of Contents

Chapter 3: ...................................................................13Specifications

Specifications Table ........................................................................................................ 13

Temperature.................................................................................................................... 13

Variable Speed Magnetic Stirring.................................................................................... 14

Dry Gas Purge................................................................................................................. 14

Serial Interface ................................................................................................................ 14

Mechanical Diagram........................................................................................................ 15

Appendix A: ............................17Serial Control for the CUV-TLC-50F

Overview.......................................................................................................................... 17

Setup and Software Installation....................................................................................... 17

Uninstalling the Software........................................................................................................... 17

Serial Control from Other Programs ................................................................................ 18

The Example Programs................................................................................................... 18

Ramping Control ............................................................................................................. 19

Index.....................................................................................................21

ii 000-30000-000-02-0205

Page 5

About This Manual

Document Purpose and Intended Audience

This document provides you with an installation section to get your system up and running. In addition to

the Maxwell system installation and operation instructions, this manual also includes information for

locating the OOIBase32 installation instructions (see

What’s New in this Document

This version of the Temperature-regulated Cuvette Holder Installation and Operation Manual adds

performance data, new configuration drawings, and optional equipment.

Document Summary

Product-Related Documentation below).

Chapter Description

Chapter 1: Introduction Provides information on product features and

system setup.

Chapter 2: Operation Contains configuration information for absorbance

and fluorescence measurements, and optical

adjustments.

Chapter 3: System Operation Contains instructions for using the CUV-TLC-50F,

and a list of error conditions.

Chapter 4: Specifications Provides product specifications and a mechanical

drawing.

Appendix A: Serial Control for the

CUV-TLC-50F

Provides information specific to serial control via

the serial interface on the PC.

000-30000-000-02-0205 iii

Page 6

About This Manual

Product-Related Documentation

You can access documentation for Ocean Optics products by visiting our website at

http://www.oceanoptics.com. Select Technical → Operating Instructions, then choose the appropriate

document from the available drop-down lists. Or, use the Search by Model Number field at the bottom

of the web page.

You can also access operating instructions for Ocean Optics products on the Software and Technical

Resources CD included with the system.

Engineering-level documentation is located on our website at Technical → Engineering Docs.

Upgrades

Occasionally, you may find that you need Ocean Optics to make a change or an upgrade to your system.

To facilitate these changes, you must first contact Customer Support and obtain a Return Merchandise

Authorization (RMA) number. Please contact an Ocean Optics Application Scientist for specific

instructions when returning a product.

.

iv 000-30000-000-02-0205

Page 7

Chapter 1

Introduction

Overview

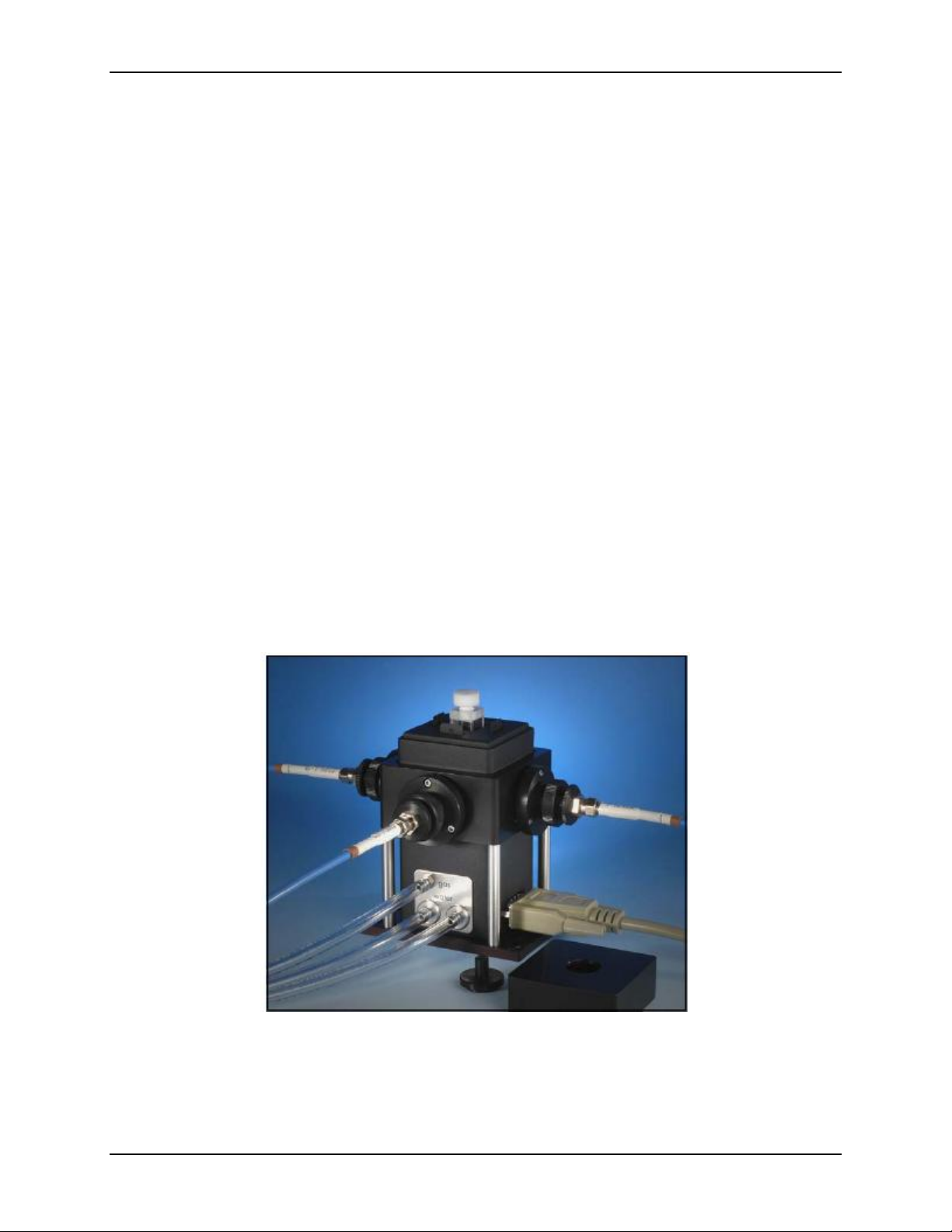

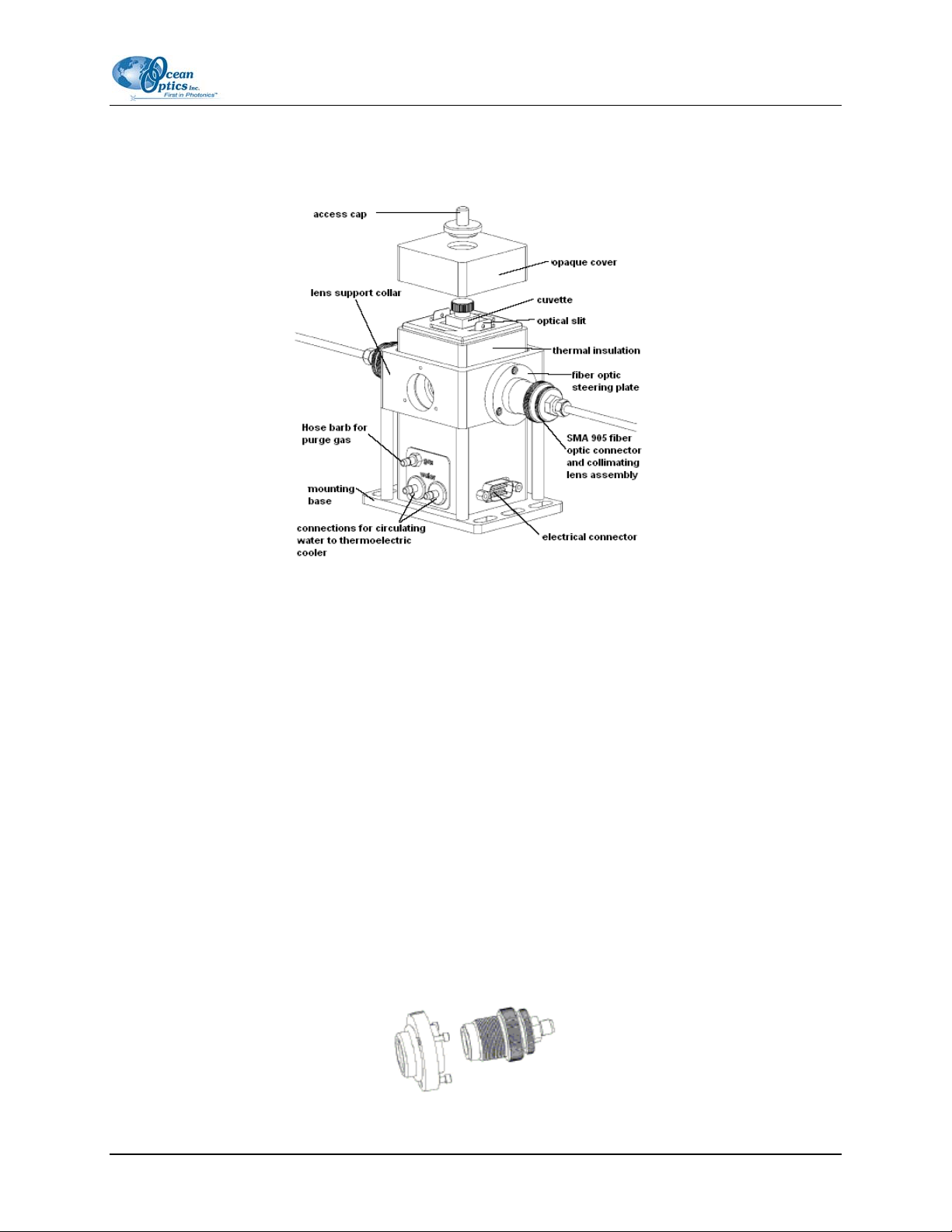

The CUV-TLC-50F Temperature-regulated Cuvette Holder is a high-quality, versatile sample chamber

with a Peltier temperature controller calibrated against a NIST-traceable thermometer. The device

controls the temperature of the holder from -40 °C to 85 °C and maintains a constant temperature within

±0.02 °C. The CUV-TLC-50F includes the cuvette holder and the external temperature controller box.

Both collimating and focusing lens systems are available in AR-coated fused silica. SMA 905 optical

fiber connectors are provided with the lens systems. To run the thermoelectric cooler efficiently, we offer

a simple water pump and water container.

The CUV-TLC-50F forms the core of a fiber optic spectroscopy system. The holder provides rapid and

precise control of the temperature of a standard 1 X 1-cm cuvette. Since the height of the optical

centerline (the center of the optical path through the cuvette) is 8.5 mm above the outside bottom of the

cuvette, the CUV-TLC-50F readily accommodates a variety of standard micro-cuvettes that depend on

this dimension for small volume work. Fibers and combined lenses can be attached at any combination of

the optical ports.

000-30000-000-02-0205 1

Page 8

1: Introduction

Features

Features of the CUV-TLC-50F include the following:

• Magnetic stirring (in the CUV-TLC-50F). A stir bar is included.

• Dry gas purge: Limits condensation and excludes oxygen from around the cuvette. Tubing for

water and gas connections is included.

• Optical slits: Control the illuminated volume. Several removable optical slits are included.

An optional PC-based CUV-TLC-ADP adapter package comes with Windows-compatible software that

allows you to remotely start a test sequence, operate the controller box and monitor experiments. Without

the CUV-TLC-ADP, you can control the cuvette holder’s temperature mechanically from the controller

box.

One side of the holder is open for visual inspection, or may be blocked with a blank slit. The other three

sides can be left open or fitted with a removable lens system. Both collimating and focusing lens systems

are available in either AR-coated BK7 glass or AR-coated fused silica and can be used in a variety of

configurations. Typically two collimating systems are used on opposite sides for absorbance

measurements, or two imaging lens assemblies are used at right angles for fluorescence measurements.

SMA 905 optical fiber connectors are provided with the lens systems.

System Setup

► Procedure

1. Firmly fasten the CUV-TLC-50F to your table using the holes in the base of the instrument.

2. Connect a water source to either one of the two hose barbs labeled “water” on the rear side of

the CUV-TLC-50F. Use a length of tubing with 1/8” (3mm) inside diameter such as the 3603

Tygon provided. Cooling water is required for the functioning of the thermoelectric cooler.

Tap water may be used. However, a more convenient source would be a circulating bath or a

small submersible pump in a container of water.

3. Connect tubing from the other hose barb to a drain or back into the source of circulating

water. Do not exceed an input water pressure of 25 psi (1.7 bar), as damage may occur inside

the TLC50.

4. Set and maintain a cooling water flow rate of about 200 – 300 ml per minute. This flow

should require a pressure of approximately 3 – 5 psi (0.2 – 0.3 bar). If a circulating bath is

used as the water source, it may not be possible to maintain this flow rate. However, a slower

rate will likely be adequate for low temperature work, if precooled circulating water is used.

5. If using dry gas, connect a source of dry gas (typically nitrogen or air that has passed through

a desiccant) using a length of tubing with 1/8” (3mm) inside diameter, to the hose barb

labeled “gas” on the side of the CUV-TLC-50F. A flow of gas must be used to prevent

condensation on the faces of the cuvette when working below the dew point temperature. Set

the dry gas flow rate to 50 – 200 cc/min.

6. Connect the Temperature Controller to a power source and to the CUV-TLC-50F using the

electrical cords provided.

2 000-30000-000-02-0205

Page 9

1: Introduction

Components

CUV-TLC-50F Components

Optional Equipment

The following optional components and packages are also offered for specific applications. Contact

Ocean Optics for additional information.

Optical Components

CUV-TLC-CL Collimating Lens

The CUV-TLC-CL is an AR-coated fused silica collimating lens with SMA 905 connector and fiber optic

steering plate The CL-UV collimating lens collimates the diverging light from the end of a fiber and

passes it through the cuvette, or alternatively focuses collimated light onto the end of another fiber. The

collimating lens is mounted on a fiber optic steering plate that provides fine adjustments of the position of

the end of the fiber relative to the cuvette. The secondary knurled ring shown in the picture permits the

movement of the end of the fiber relative to the lens and cuvette, thus permitting an adjustment of the

degree of collimation. Collimating lenses are typically used for absorbance measurements.

000-30000-000-02-0205 3

Page 10

1: Introduction

CUV-TLC-IL Imaging Lens

The CUV-TLC-IL is an AR-coated fused silica imaging lens doublet with SMA 905 connector and fiber

optic steering plate. The CUV-TLC-IL imaging lens doublet is identical to the CUV-TLC-CL, except that

an additional lens is snapped into place to shorten the focal length. The imaging lens images the end of

the optical fiber into the cuvette, or focuses an image of the center of the cuvette onto a fiber. Again, the

steering plate can be used to adjust the position of the focused image inside the cuvette, and to maximize

the detected signal. The secondary knurled ring shown below permits movement of the focused image to

nearly any depth in the cuvette. Imaging lens doublets are usually used for fluorescence measurements,

although they are also useful for absorbance measurements on small sample volumes. The CUV-TLC-IL

can be easily converted to the CUV-TLC-CL by removing the attached Convergence lens.

CUV-TLC-MP Spherical Mirror Plug

The spherical mirror plug replaces a fiber with a spherical mirror that reflects an image of the illuminated

volume at the center of the cuvette back onto itself. Thus the mirror plug can return the excitation beam

back through the sample for a second pass, or permit one detector to collect the light from opposite sides

of the cuvette. For some fluorescence experiments, use of two mirror plugs can nearly quadruple the

measured signal. Purchase the spherical mirror plug to perform fluorescence measurements when weak

signals are anticipated.

CUV-TLC-FH Filter Holder Assembly

The CUV-TLC-FH filter holder assembly with collimating lens, SMA 905 connector, and fiber optic

steering plate places standard 1-inch filters in a light-tight compartment after a collimating lens. The lighttight cap backs away and the filters, mounted in a filter holder insert, are lifted out of the assembly. The

filter holder insert holds a single 1-inch round optical filter or a stack of such up to a thickness of 3/8 of

an inch. One insert is provided with the filter holder assembly, although other inserts can be purchased

separately. The filter holder assembly, mounted on a fiber optic steering plate, can be used directly in

place of a collimating lens. You can add a convergence lens to convert the filter holder assembly to an

imaging lens system.

4 000-30000-000-02-0205

Page 11

1: Introduction

Additional Accessories

The following additional accessories are available from Ocean Optics for your CUV-TLC-50F:

• CUV-TLC-ADP PC adapter package for remotely operating the cuvette holder.

The serial interface is used for external computer control of the temperature controller. The

option includes a serial cable, a control program, a library of functions in DLL form to simplify

serial communications with the controller, and a sample script for demonstrating the basic

functions of the sample holder. The control program simplifies the entry of individual commands,

permits the use of prewritten scripts for external operation of the controller and provides a

convenient plot of the sample holder temperature as a function of time. The serial interface option

is required for temperature ramping.

• CUV-TLC-SP steering plate that mounts a lens or mirror plug onto the cuvette holder.

The fiber optic steering plate attaches to one of the optical ports and provides the

receptacle for a lens system. Adjustment of three screws in the plate provides small

movements of the end of the optical fiber that can be used to optimize alignment of the

image within the cuvette, thus optimizing signal output. Each lens or mirror assembly

is provided with its own fiber optic steering plate. An additional plate can be purchased

to allow an optical component to be moved frequently or to place a mirror plug at an

unoccupied site.

• CUV-TLC-BATH water pump and bucket for efficient

operation of the thermoelectric cooler. The CUV-TLCBATH circulates cooling water to the thermoelectric device

in the sample holder. The accessory consists of a

submersible pump, a brass fitting and plastic bucket. Attach

the fitting to the pump and connect the sample holder via

1/8-inch I.D. vinyl tubing. Run the return water back into

the bucket. To lower the temperature, just add ice to the

bucket. Add enough ice, and the water in the bucket goes

immediately to 0.0ºC.

000-30000-000-02-0205 5

Page 12

1: Introduction

Packages for Specific Applications

Application Item Code Description Figure

UV/VIS

spectroscopy

Fluorescence CUV-TLC-FLKIT CUV-TLC 50F cell holder, two CUV-

UV/VIS and

fluorescence

CUV-TLC-ABSKIT CUV-TLC 50F cell holder, two CUV-

TLC-CL collimating lenses (with SMA

fiber optic connectors, lenses and

steering plates), CUV-TLC-ADP serial

interface and CUV-TLC-BATH water

pump with bucket.

TLC-IL imaging lenses (with SMA fiber

optic connectors, lenses and steering

plates), two CUV-TLC-MP mirror

plugs, two additional CUV-TLC-SP

steering plates, CUV-TLC-ADP serial

interface and CUV-TLC-BATH water

pump with bucket.

CUV-TLC-MPKIT CUV-TLC-50F cell holder, two CUV-

TLC-IL imaging lenses, two CUV-TLCCL collimating lenses, two CUV-TLCMP mirror plugs, CUV-TLC-ADP serial

interface and CUV-TLC-BATH water

pump with bucket.

6 000-30000-000-02-0205

Page 13

Chapter 2

Operation

Optics

The CUV-TLC-50F provides ports for viewing or illuminating 1-cm square cuvettes from four directions.

Lenses are available to purchase separately to allow you to choose the best lenses for your application.

For absorbance and transmission measurements, position two CUV-TLC-CL Collimating Lenses at 180°.

For fluorescence applications, position two CUV-TLC-IL Imaging Lenses at 90° and position two CUVTLC-MP Mirror Plugs in the remaining two collimator positions to redirect energy to the sample or into a

lens.

• Collimating Lens—The Collimating Lens system, containing a single lens, collimates the fiber

output or focuses collimated light onto the end of another fiber. The collimating lens system is

typically used in absorption measurements.

• Imaging Lens—The Imaging Lens system, containing two lenses, focuses an image of the end

of the fiber into the cuvette, or light in the center of the cuvette onto another fiber (magnification

of approximately one). For added versatility, the second lens of the Imaging Lens system may be

removed so that it may be used as a Collimating Lens. The Imaging Lens system is typically used

in fluorescence measurements.

Typical Configuration for Absorbance Measurements

To measure Absorbance, a single collimating lens is placed on each side of the cuvette. In the following

figure, lenses and cuvette are shown in blue. Note that each lens holder has an alignment adjustment as

well as focusing capability.

CUV-TLC-50F Typical Configuration for Absorbance Measurements

000-30000-000-02-0205 7

Page 14

2: Operation

Typical Configuration for Fluorescence Measurements

To measure fluorescence, Imaging Lens systems are placed at 90 degrees to each other. The first lens

system focuses the light as a small image inside the cuvette Emitted light from this small illuminated

volume is then focused at a right angle onto the second fiber. Mirrors can be mounted opposite each lens

system, nearly quadrupling measured light intensities.

CUV-TLC-50F Typical Configuration for Fluorescence Measurements

The following figure shows the components of an imaging lens system.

Components of an Imaging Lens System

Optical Adjustments

The fiber position adjustment screws use the steering plate to compress a soft o-ring. They may be used to

wobble the end of the fiber horizontally and vertically about its position and can substantially enhance

optical throughput. Take care not to over compress the o-ring. Alternatively, no adjustment is possible if

the steering plate is not in contact with the o-ring. Screwing in or unscrewing the horizontal fiber position

knob may vary the distance between the end of the fiber and the center of the cuvette.

8 000-30000-000-02-0205

Page 15

2: Operation

Caution

Be sure to first loosen the fiberoptic SMA 905 connection, so as not to apply torsion

to the fiber.

This adjustment varies the position of focus in the sample when desired for specific experiments, or to

compensate for lens aberrations to maximize optical throughput. For normal operation the distance

between the knurled ring on the horizontal fiber position knob should be set 1/8 inch from the knurled

ring on the first lens holder (see the following figure).

Imaging and Collimating Lenses

Converting an Imaging Lens into a Collimating Lens

The second lens of the imaging lens system is simply snapped onto the end of a collimating lens (see

figure above). To remove the second lens, use a piece lens tissue to prevent your fingers from touching

the lens. With the lens tissue in your hand, firmly grasp the second lens holder and snap it off of the

collimating lens.

System Operation

► Procedure

1. Turn on the power to the CUV-TLC-50F system using the switch located on the left side of

the rear panel of the temperature control unit.

2. Place the liquid sample in a standard 1 x 1-cm square fluorescence cuvette to reach a height

of 22 mm.

000-30000-000-02-0205 9

Page 16

2: Operation

Note

The CUV-TLC-50F is intended to hold a cuvette with a standard wall thickness of

1.25 mm and total width of 12.5 mm. Cuvettes with unusually thick walls will not

properly fit and may damage the holder. Also, unusually short cuvettes will be difficult to

remove after being pushed all of the way to the bottom of the holder.

3. Place the cuvette and sample in the sample holder.

4. Use the provided optical slits or blanks around the cuvette in a manner that correctly limits

the excitation and emission light.

5. If needed, place the magnetic stir bar in the cuvette and turn the magnetic stirrer knob located

on the front of the temperature control until the desired speed is reached.

6. Place the opaque plastic cover over the cuvette holder.

7. Place the access lid in the hole in the plastic cover.

8. Set the target temperature using the up/down buttons located to the right of the display

window. The normal temperature range is -10 °C to +80 °C, although temperatures from –

40 °C to +85 °C may be used under special circumstances (see

Specifications).

Temperature in Chapter 3:

9. Briefly depressing either the up or down button displays the target temperature. Otherwise,

the current temperature will be displayed.

10. To begin controlling the temperature, press the Run/Stop button located to the left of the

display. Pressing the Run/Stop button a second time turns temperature control off.

11. When the sample holder approaches the target temperature, the red light (located on the upper

left corner of the front panel of the temperature controller) flashes slowly.

12. When the sample holder reaches within ± 0.02 °C of the target temperature, the red light will

remain constant.

13. After measurements are completed, depress the run/stop button to stop temperature control,

and turn off power and water sources.

Performance

The graphs in this section show typical performance results for the CUV-TLC-50F under the following

conditions:

Temperature Equilibration

•

Low Temperatures

•

Temperature Ramping

•

10 000-30000-000-02-0205

Page 17

2: Operation

Temperature Equilibration

The serial control option was used to automatically cycle the CUV-TLC-50F through a series of

temperatures. The blue line shows the resulting temperature of the sample holder next to one of the

optical ports. The red line shows the temperature measured inside a cuvette. The cuvette, containing

ethylene glycol and water, was stirred using the magnetic stirring feature of the CUV-TLC-50F. Note the

rapid changes in sample holder temperature, followed in a few minutes by the temperature equilibration

of the sample.

Low Temperatures

To go to low temperature, additional insulation was applied to the CUV-TLC-50F and the unit was

connected to a refrigerated water bath containing a methanol and water mixture at approximately -

13.00 °C. The sample holder was equilibrated at 0.00 °C, taken to -20.00 °C, and then taken down to

-40.00 °C. Dropping the sample holder temperature from 0.00 to -20.00 °C required about 4 minutes.

Dropping from -20.00 °C to -40.00 °C required about 20 minutes.

000-30000-000-02-0205 11

Page 18

2: Operation

Temperature Ramping

Each of the sample holders from Quantum Northwest has a function for temperature ramping

programmed into its microcontroller. The user first allows equilibration at a particular temperature. To

initiate the ramp, the user then specifies a final temperature and increments for temperature and time. The

serial control option, allowing external control from a computer, is required for temperature ramping.

Error Conditions

Rapid flashing of the red light indicates an error condition. The common errors that will display are the

following:

• Error conditions E5, E6 and E7 – Check Cables. One or more of these error conditions is

likely to arise if the electrical connection between the Temperature Controller and the CUV-TLC50F is not secure. In this case, turn off the power to the unit, check the cable, turn on the power,

and resume work.

• Error condition E8 – Low water flow. This error condition indicates that the heat exchanger

on the thermoelectric cooler is getting too warm. This heating will occur if insufficient cooling

water is flowing into the device. Error condition E8 will automatically shut down temperature

control to prevent damage to the unit. If this occurs, improve cooling water flow and restart

temperature control.

12 000-30000-000-02-0205

Page 19

Specifications

Specifications Table

Specification Value

Temperature -40 to 85 °C

Precision ±0.02 °C

Reproducibility ±0.05 °C

Chapter 3

Maximum Luminated Area (h x w) 12 x 10 mm

Height of Optical Center Above Table 70 mm

Optical Center Above Bottom of Cuvette 8.5 mm

Magnetic Stirring yes

Dry Gas Purge yes

Temperature

Thermoelectric temperature control maintains the sample to a precision of ±0.02 °C within a range of

-40.00 °C to +85.00 °C. Depending on the humidity and ambient temperature (with dry gas purge) the

CUV-TLC-50F will operate down to about -10 °C without the formation of frost on the optical

components. Below this temperature, the CUV-TLC-50F requires additional insulation. We recommend

that the sample holder be carefully wrapped in bubble wrap or similar packing materials. Such materials

are inexpensive and function well. Very low temperature operation (down to -40 °C) requires the use of

precooled circulating water of a temperature within about 25 degrees of the target temperature. It will also

operate safely between 80 °C and 85 °C, although such high temperatures may adversely effect the

lifetime of the thermoelectric device. Temperatures of the sample holder are reproducible within

±0.03 °C. Reproducibility represents the temperature range, expressed as ± one standard deviation, over

which the temperature of the cuvette holder may vary from hour-to-hour or day-to-day as measured by a

NIST-traceable thermometer. Calibration data is provided with each sample holder. For experiments in

which knowledge of the exact sample temperature is critical, independent verification is required.

000-30000-000-02-0205 13

Page 20

3: Specifications

Variable Speed Magnetic Stirring

Variable speed magnetic stirring is provided for experiments in which it is important to rapidly remove

photoproducts from the illuminated volume. A stir bar is included.

Dry Gas Purge

A dry gas purge is provided. The gas travels through the base of the cuvette holder for temperature

equilibration and then blows onto each of the four faces of the cuvette. The gas purge minimizes

condensation on optical surfaces. An opaque cap with access hole covers the top of the cuvette to provide

isolation from the ambient environment.

Serial Interface

An optional serial interface is available for remote computer control (see Appendix A: Serial Control for

the CUV-TLC-50F

).

14 000-30000-000-02-0205

Page 21

3: Specifications

Mechanical Diagram

000-30000-000-02-0205 15

Page 22

3: Specifications

16 000-30000-000-02-0205

Page 23

Appendix A

Serial Control for the

CUV-TLC-50F

Overview

Serial Control permits the remote temperature control via a serial interface on a computer using a

Windows operating system. The option consists of a cable that connects the Temperature Controller with

the computer, and software. The software includes QNW_SC.exe, a sample control program that enables

control, and recovers and plots temperature data. For those who wish to write their own control programs,

example programs and libraries of functions are provided for use with both Borland and Microsoft

development systems.

Setup and Software Installation

► Procedure

1. Use the provided cable to connect from the lower (9-pin) connector on the back of the

temperature controller to a serial interface of your computer (typically COM1).

2. Place the installation CD in the computer’s CD drive and run Setup.exe from the CD. All

files will be placed in the directory specified during installation (default is C:\QNW Serial

Control), except for QnwSerial.DLL, which will be installed in the Windows System

directory.

3. To check the interface, run the program QNW_SC.exe. For instructions on how to use the

program, use the program’s Help system.

Uninstalling the Software

To uninstall the Serial Control Program files, use the “Add/Remove Programs” control panel by selecting

“QNW” from the list.

000-30000-000-02-0205 17

Page 24

A: Serial Control for the CUV-TLC-50F

Serial Control from Other Programs

It may be useful to have temperature control for the CUV-TLC-50F system from other programs (for

example data acquisition programs). The installation CD includes code for a simple C++ program that

illustrates how to use QnwSerial.DLL for serial communications with the TLC 50™ hardware.

QnwSerial.dll provides functions that simplify opening and closing serial ports, and sending and receiving

data over a serial connection. This DLL was developed with Borland C++ Builder 3. QnwSerial.dll can

only be used by 32-bit programs. The “Borland Example” and “Microsoft Example” directories contain

the code and project files required by Borland C++, version 5.02, and Microsoft Developer Studio Visual

C++, version 4.0, respectively, to generate the application. If you have either of these development

systems (or newer versions) installed on your computer, you should be able to open the projects

(QnwExample.ide or QnwExample.mdp files) and compile and link them to generate the example

programs. You will probably need to modify the project directories for Borland’s header and library files

in the Borland project so that the system can find the standard Borland files.

The .C and .H files for the Microsoft Example differ from those for the Borland Example in minor ways

as described below. For the Microsoft Example, the QnwSerial DLL function prototypes and function

calls include an added underscore as the first character of the function names.

One of the standard include lines differs between the two examples, <DIR.H> for Borland and

<DIRECT.H> for Microsoft.

In several of the calls to SendDlgItemMessage() the parameter -1 for Borland was changed to

(WPARAM)(-1) for Microsoft to suppress a warning message during compilation in the latter

development system. The line “#pragma argsused” is included before two of the function definitions only

for Borland, again to suppress a warning message during compilation.

The Example Programs

Copies of the resulting executable files, QnwExample.exe and QnwExampleM.exe, are included if you

installed the example programming files (“typical” installation choice).

When the programming example is started, it obtains the information needed for connecting to and

configuring a serial port from a command list file, QnwExample.lst. If this list file does not exist in the

startup directory, default settings are used and a QnwExample.lst file will be created which includes those

settings when the program is closed. You can modify this information to change the serial port setup to be

used the next time the program is started. The setup line is in the form of a DOS “mode” command for

configuring a serial port — “COM1:19200,N,8,1” — and must be the only data on the first line of the file.

In the example line above, COM1 specifies the serial port to be used (typically COM1, COM2, etc., but

some computers may require different designations). The remaining parameters specify a baud rate of

19200, no parity, 8 data bits and no stop bits, respectively. The parameters “19200,N,8,1” are correct for

the CUV-TLC-50F, so you should only need to consider changing the port designation if COM1 does not

work.

18 000-30000-000-02-0205

Page 25

A: Serial Control for the CUV-TLC-50F

The list file also may contain a list of command lines which QnwExample loads and inserts into a

program drop down list to give the user access to the commands. To use the program, the user either

chooses one of the commands from the drop down list (and possibly edits it) or enters a command directly

into the edit control provided. That command is sent out the serial port when the user presses the “Send

Command” button. QnwExample displays the command at the top of a large display window and

subsequently displays any information received through the serial connection. The program also provides

a means of deleting commands from the drop down list and for adding new or modified commands to the

list. These changes are saved to the list file when the program exits. A “Start/Stop Logging” button is

provided to enable/disable logging into a file named QnwExample.log. All information displayed in the

large text window is logged as it appears when logging is enabled.

The command list provided with the examples (QnwExample.lst) includes many of the valid command

forms for the CUV-TLC-50F. Each command is annotated to the right of the command for convenience.

Note, however, that the annotations are possible only because the CUV-TLC-50F ignores any text

received that is not included between square brackets.

Ramping Control

Linear temperature changes may be controlled through the ramping option in the Serial Control software.

Two parameters, RT (Ramping Temperature – the temperature increment) and RS (Ramping Seconds –

the time increment) control the rate of temperature change. Normal temperature control will be replaced

by ramping only if both the RT and RS values are non-zero.

To create a temperature ramp, equilibrate the sample holder at the starting temperature. Briefly, stop

temperature control and set the RT and RS values. Set the target temperature to the final temperature

desired at the end of the ramp and restart temperature control.

RS must be an integer between 1 and 64000 seconds. RT must be an integer between 1 and 32000 in units

of hundredths of a °C.

Table 1: Serial Commands

Command Response

[F1 SS +]

[F1 SS -]

[F1 TC +]

[F1 TC -]

[F1 TT S 23.1]

[F1 TT ?]

[F1 TT 71.3]

Turn stirrer on (stir rate must be set manually)

Turn stirrer off

Turn temperature control on

Turn temperature control off

Set target temperature to 23.1° C

Query: What is the current target temperature?

Reply: Target temperature is 71.3° C

000-30000-000-02-0205 19

Page 26

A: Serial Control for the CUV-TLC-50F

Table 1: Serial Commands (Cont’d)

Command Response

[F1 IS ?]

[F1 IS 0+-S]

[F1 IS +5] Automatically report instrument status every 5 seconds

[F1 IS +] Automatically report instrument status whenever it changes (e.g., due

[F1 IS -] Stop, periodic or automatic reports of instrument status

[F1 CT ?]

[F1 CT 22.8]

[F1 ER +]

[F1 ER -]

Query: What is the current instrument status?

Reply: no unreported error (0 or 1)

temperature control is on (+ or -)

temperature is stable (S or C)

stirrer is off (+ or -)

to manual changes at controller)

Query: report the current temperature

Reply: the current temperature is 22.8° C

Automatically report errors when they occur

Stop automatic error reports

Ramping Commands

[F1 RS S XX] Set Ramping Seconds, the time increment of the ramp rate (positive

integer in seconds)

[F1 RT S XX] Set Ramping Temperature, the temperature increment of the ramp

rate (positive integer in hundredths of a °C)

When the Controller is restarted (by being powered off and back on again), it automatically sends the

message [F1 IS R] to notify the program of the restart.

20 000-30000-000-02-0205

Page 27

Index

A

absorbance measurements, 7

accessories, 5

B

bath, 5

C

collimating lens, 3, 9

components, 3

configuration

absorbance measurements, 7

fluorescence measurements, 8

CUV-TLC-ABSKIT, 6

CUV-TLC-ADP, 5

CUV-TLC-BATH, 5

CUV-TLC-CL, 3

CUV-TLC-FH, 4

CUV-TLC-FLKIT, 6

CUV-TLC-IL, 4

CUV-TLC-MP, 4

CUV-TLC-MPKIT, 6

CUV-TLC-SP, 5

E

error conditions, 12

example programs, 18

F

features, 2

filter holder assembly, 4

fluorescence, 6

fluorescence measurements, 8

I

imaging lens, 4, 9

L

lens, 9

lens conversion, 9

low tempertures, 11

M

magnetic stirring, 14

D

document

audience, iii

purpose, iii

summary, iii

dry gas purge, 14

000-30000-000-02-0205 21

mechanical diagram, 15

O

optical adjustments, 8

optics, 7

Page 28

Index

P

T

PC adapter, 5

performance, 10

product-related documentation, iv

purge

dry gas, 14

temperature, 13

temperature equilibration, 10

temperature ramping, 11

U

R

upgrades, iv

ramping commands, 20

ramping control, 19

UV/VIS spectroscopy, 6

W

S

what's new, iii

serial commands, 19

serial control, 17

from other programs, 18

setup and software installation, 17

uninstalling software, 17

serial interface, 14

specifications, 13

spherical mirror plug, 4

steering plate, 5

system operation, 9

system setup, 2

22 000-30000-000-02-0205

Loading...

Loading...