Page 1

Collimation Tester Instructions

Description

Use shear-plate collimation testers to examine and adjust the collimation of laser light, or to measure

the wavefront curvature and divergence/convergence magnitude of large-radius optical components.

The setting up of a laser beam expander to give a collimated or parallel beam can be a problem if the

full capability of any precision laser optics is to be achieved. Methods using autocollimation or

measuring beam diameter over some distance are inadequate to obtain diffraction-limited performance

unless tedious measurements are made. To accomplish this task, Ocean Optics has an interferometer

that is extremely simple to use, requires almost no adjustment and produces results in a few moments.

Method of Use

The method of use is so simple it maybe hard to realize that the device is a precision interferometer.

►

Procedure

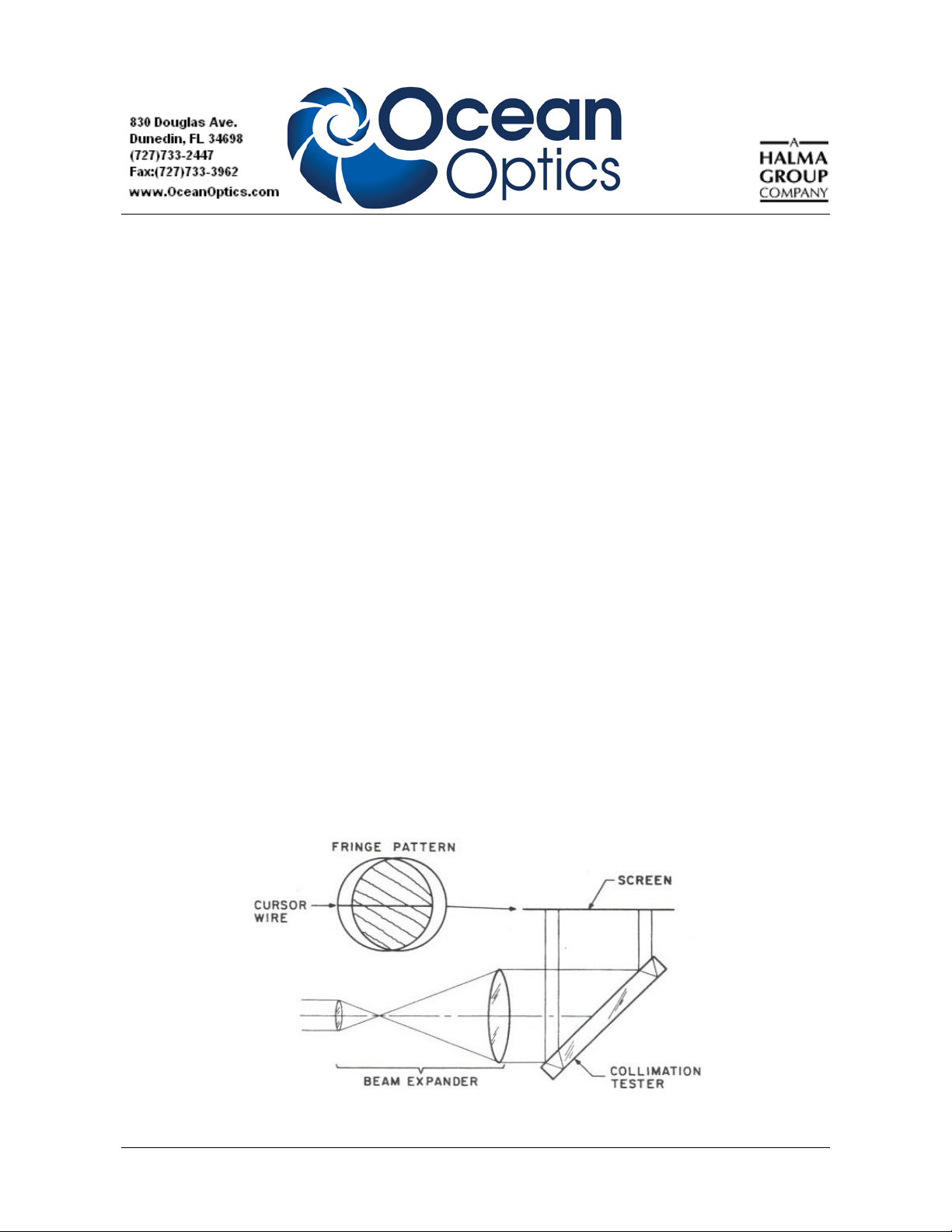

1. Set up the beam expander with the lenses spaced according to their focal lengths.

2. Place the collimation tester in the beam so as to illuminate the front face as fully as possible,

and to reflect the beam by about 90° to a screen placed at right angles to the reflected beam

(see figure below).

CT-10000-000-05-201401 1

Page 2

Collimation Tester Instructions

3. The maximum sensitivity of the collimation tester is achieved when the reflected angle is

108°, but sensitivity is reduced by only 1% at 90°, so the angle is not critical. Two overlapping

images will be seen on the screen, one from each face of the collimation tester. Fringes

(parallel patterns of light and dark) will be seen in the overlap region.

4. Adjust the lens spacing until the fringes are parallel to the shadow of the cursor wire of the

tester. The beam is now collimated.

Tips

If the fringes are not straight, check to see that the lenses of the beam expander are

centered, square to the beam and with the proper face towards the collimated light (if

these adjustments are appropriate). Any residual fringe curvature or wiggles indicates

aberrations or errors that cannot be focused out.

If no fringes are seen in the initial setup, it may be that the beam is so far from

collimation that the fringes are too fine to be seen. In that case, redu ce the ref le cted

beam angle to 45°or even 30°, and move the screen accordingly. This reduces the

sensitivity of the tester. Make the initial adjustment for collimation and then return to

90° for the final tuning.

USEFUL RANGE, APERTURE, WAVELENGTH

Each size of collimation tester is designed to have 5 – 6 horizontal fringes across the aperture when

illuminated by a parallel beam. In theory,

that can be tested is about 1/5 full aperture. In practice, it is found that the fringe slope changes from

positive to negative when going through collimation and that the fringe spacing decreases away from

collimation so that smaller aperture beams can be collimated by finding the center position between

two defocused positions. When testing smaller apertures, it may also be necessary to reduce the

reflected beam angle to get an appropriate amount of overlap of the two beams. The fringes only

appear in the overlap area.

The choice of 5 – 6 fringes across the aperture is a trade-off between sensitivity and utility. For

sensitivity, it is desirable to have only one full fringe over the aperture. The actual design allows an

individual tester to be usable over a range of beam sizes of at least 5 to 1. If a collimation tester is to

be used at a specific wavelength for a single aperture with critical demands on collimation, you can

either select a larger aperture such that one fringe will be seen across your aperture or a custom design

can be made for optimum sensitivity. Collimation testers are usable in wavelength over the

transmission range of the glass, that is, from about 350 nm to about 2500 nm. To observe the fringes in

the UV, a fluorescent screen may be necessary while in the IR, an image converter is suitable out to

1200 nm and an IR phosphor card can be used further out.

to have at least one fringe to set against, the smallest beam

2 CT-10000-000-05-201401

Page 3

Collimation Tester Instructions

Collimation Tester Aperture Size (in millimeters) Center thickness in

inches +/-.005"

CT-10 10 .040 22.5

CT-20 20 .118 11.8

CT-50 50 .375 4.7

CT-75 75 .500 3.2

CT-100 100 .500 2.4

CT-125 125 .625 1.9

CT-150 150 .767 1.6

CT-200 200 1.50 1.2

Wedge angle in arc

seconds

Using the Collimation Tester for Quantati ve Measurements

Ocean Optics’ collimation testers are shearing interferometers. There are many shearing

interferometers but what they have in common is that the wavefront divided in amplitude, some shift

applied to one or both portions, which are then recombined to form an interference pattern. In the

collimation tester, the division arises from reflection at two faces of a slightly wedged plate. The shift

is due to the displacement from the plate thickness and the recombination occurs in the overlapped

images on the screen. Since the wavefront is being compared to itself rather than a reference flat

wavefront, interpretation of the fringes differs from the usual interferometer where the departure from

planarity is indicated by a fringe displacement. In the collimation tester, departure from planarity is

indicated by fringe slope. A treatment of the complete interpretation and analysis of shearing

interferograms is given by Rimmer(1).

Wavefront Curvature

The collimation tester was designed as a null instrument to indicate when the incident beam is parallel.

However, with large radius, spherical wavefronts, the fringes remain linear and can be analyzed to

determine the wavefront curvature (2)(3). With two, separated, spherical wavefronts, the interference

pattern can be treated in the same manner as the 2-pinhole experiment.

In the collimation tester, there are two separations:

• A vertical angle due to the wedge, and

• A horizontal angle proportional to the shear (beam displacement) and inversely proportional to

the wavefront radius.

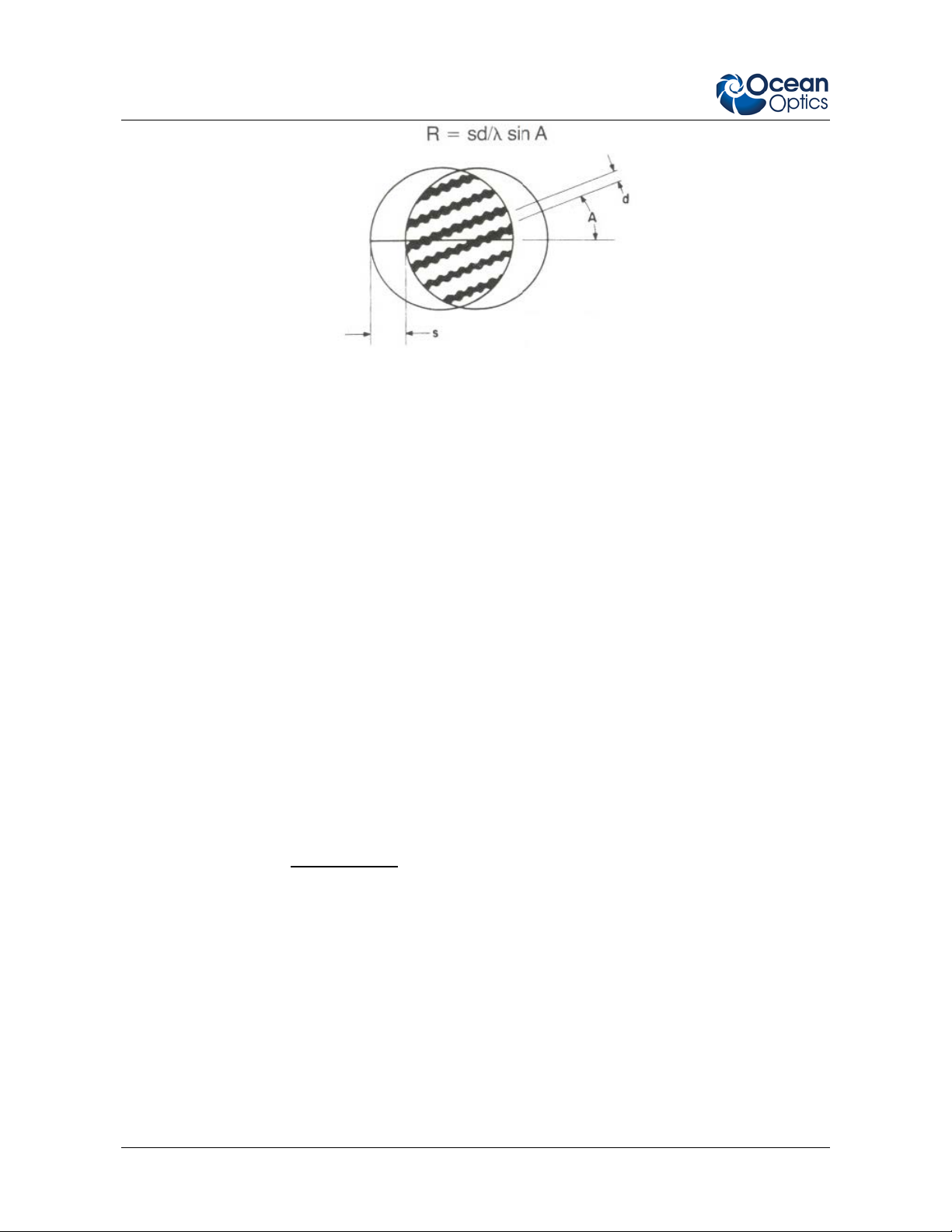

The figure below illustrates the measurements required,

Where: d = Fringe spacing perpendicular to the fringes

A = Angle of the fringes with respect to the cursor

S = Shear

CT-10000-000-05-201401 3

Page 4

Collimation Tester Instructions

The wavefront radius, at the observation screen, is given by the following equation, with the

wavelength, 'λ, in the same units as S and d:

R = sd/λ sin A

► Procedure

To find the wavefront radius at the lens plane,

1. Add the distance of the lens from the screen for a converging wavefront, or subtract the

distance for a diverging wavefront.

2. Measure the values of

3. Divide the distance between several fringes by the number of fringes to get the average

spacing.

Where the shear is appreciable, it can be measured by placing a thin wire in the beam and measuring

the separation of the two images. Shear can be calculated by the following relation,

Where:

I = Angle of incidence

N = Index of refraction

T = Plate thickness

shear, fringe spacing and angle.

S = T sin 2I

(N2- sin2I) ½

The index of the glass used is:

• 1.530 at 405 nm,

• 1.522 at 489 nm,

• 1.515 at 633 nm, and

• 1.507 at 1060 nm.

To find the divergence of the laser beam, divide the width of the lens or beam by the radius of the

curvature.

4 CT-10000-000-05-201401

Page 5

Collimation Tester Instructions

Component Testing

The collimation tester is suitable for measuring mirrors with a large radius of curvature. Murty (4) has

examined various techniques and has found the shearing interferometer one of the more accurate

methods. The setup is shown in the figure below:

The wavefront radius at the mirror is calculated by adding or subtracting the mirror screen distance to

the radius measured at the screen. The mirror radius is twice the wavefront radius. The collimation

tester can also be used to measure optical material homogeneity as suggested by De Vany (5). It

provides a simple method of obtaining single pass effects without the complica tio ns of a MachZehnder interferometer.

The collimation tester can be used to do more complex wavefront analysis including lens aberration

testing. For these applications, the reader is referred to the classical literature on interferom eters as

well as the references cited.

References

(1)M.P.

Rimmer, "Method For Evaluating Lateral Shearing Interferograms:” Applied Optics,

13.3.1974. P 623

(2) F.M. Dickey and TM. Harder, "Shearing Plate Optical Alignment". Optical Engineering, 17,3,

1978,P 295

(3) M.E. Riley and M.A. Gusinow, "Laser Beam Divergence Using A Lateral Shearing

Interferometer". Applied Optics; 16. 10. 1977,P 2753

(4) M.V.RK Murty and R.P. Shukla, "Measurement of Long Radius of Curvature", Optical

Engineering, 22, 2,1983, P 231

(5) A.S. De Vany, Applied Optics,10, 6. 1971, P 1459

CT-10000-000-05-201401 5

Page 6

Collimation Tester Instructions

6 CT-10000-000-05-201401

Loading...

Loading...