Page 1

Sauna & Steam

Vision Sauna Manual

14.7.18

Wall Hung Heater Version

(Covers all models)

Oceanic Ltd, Pountney Street, Wolverhampton, WV2 4HX

Phone: 01902 450 550 sales@oceanic-saunas.co.uk www.oceanic-saunas.co.uk

Page 2

Vision Sauna Manual

Sauna & Steam

Table of contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4. Wiring (please refer to heater manual for more detail) . . . . . . . . . . . . . . . . . . 3

5. Step 1 Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Back Corner Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

7. Wooden to Glass Panel Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

8. Front Corner (Fixing Column) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

9. Glass Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

10. Door Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

11. Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

12. Heater Wire & Wooden Trunking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

13. Benches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

14. Internal Trim (Fix in this order) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

15. Bench Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

16. Back Rests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

16.1. Optional Back Rest LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1. Optional Back Rest LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

17. External Trim (Fix in this order) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 3

Vision Sauna Manual

Sauna & Steam

1. Introduction

Welcome to the instruction manual for the Oceanic Saunas Vision Range. This guide is meant to be used

alongside a “Part List” which has specic information for the cabin you have been supplied.

Please take time to familiorize youself with both the steps in the manual and the specic layout of benches

and panels for the cabin your are building before making a start on assembly.

We recommend that this cabin is installed by a compentent carpenter to achieve the most professional

nished product.

The cabin has been designed so no xtures can be easily seen, the use of a F16 or F18 brad nailer is advised

for all trim and there is some ller and sand paper supplied for nishing up the holes.

Once the cabin has been completed you may want to apply a nish, we advise to use a satin water based

varnish (do not apply inside the cabin only on the external faces).

The cabin is self supporting and does not need to be xed to the ground so it is possible to assemble and

slide (with 2 or more people with care) if this is something you require to assemble into a specic area.

2. Tools

• 3 or 4mm pilot drill with countersink or separate counter sink.

• 12mm drill bit.

• Bit extension, PZ2 and PH2 screw driver bits.

• Cordless Screw Driver / Drill

• Spirit level, set square, tape measure, pencil,

• Hand saw or preferrably mitre saw.

• Brad nailer F16 or F18.

• Wood Chisel

• Filler knife or piece of plastic (e.g window packer or similar)

• Safety glasses, dust mask, safety gloves for glass, site specic PPE.

3. Safety

You must wear safety gloves and glasses at all times when handling the glass panels and door.

Please refer to the bather safety rules card supplied before turning the sauna on.

4. Wiring (please refer to heater manual for more detail)

• This sauna should be hard wired to an all pole isolator with RCD protection.

• Note any wires entering the cabin must be 150oC rated silicone. This wire is usually red in colour.

• Heater - The heater wire will either be a 3 or 5 core cable depending if you have built in controls

or separate remote controls. This wire can be hidden using trunking we supply see section 12 in

the instructions for more help.

• If you have remote controls they will rstly have a main brain which should be hidden from view,

then secondly a keypad which goes on a wall outside of the sauna and thirdly a temperature

sensor which will need to be mounted on one of the internal wall panels usually 300mm down

from the ceiling but check with the heater manual.

• Finally you will have the lighting wires, either spot lights in the ceiling or back rest LED strips.

The lighting may be powered o the remote controls if this function is available, alternatively

you can power them o a switched fuse spur.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 4

Vision Sauna Manual

Sauna & Steam

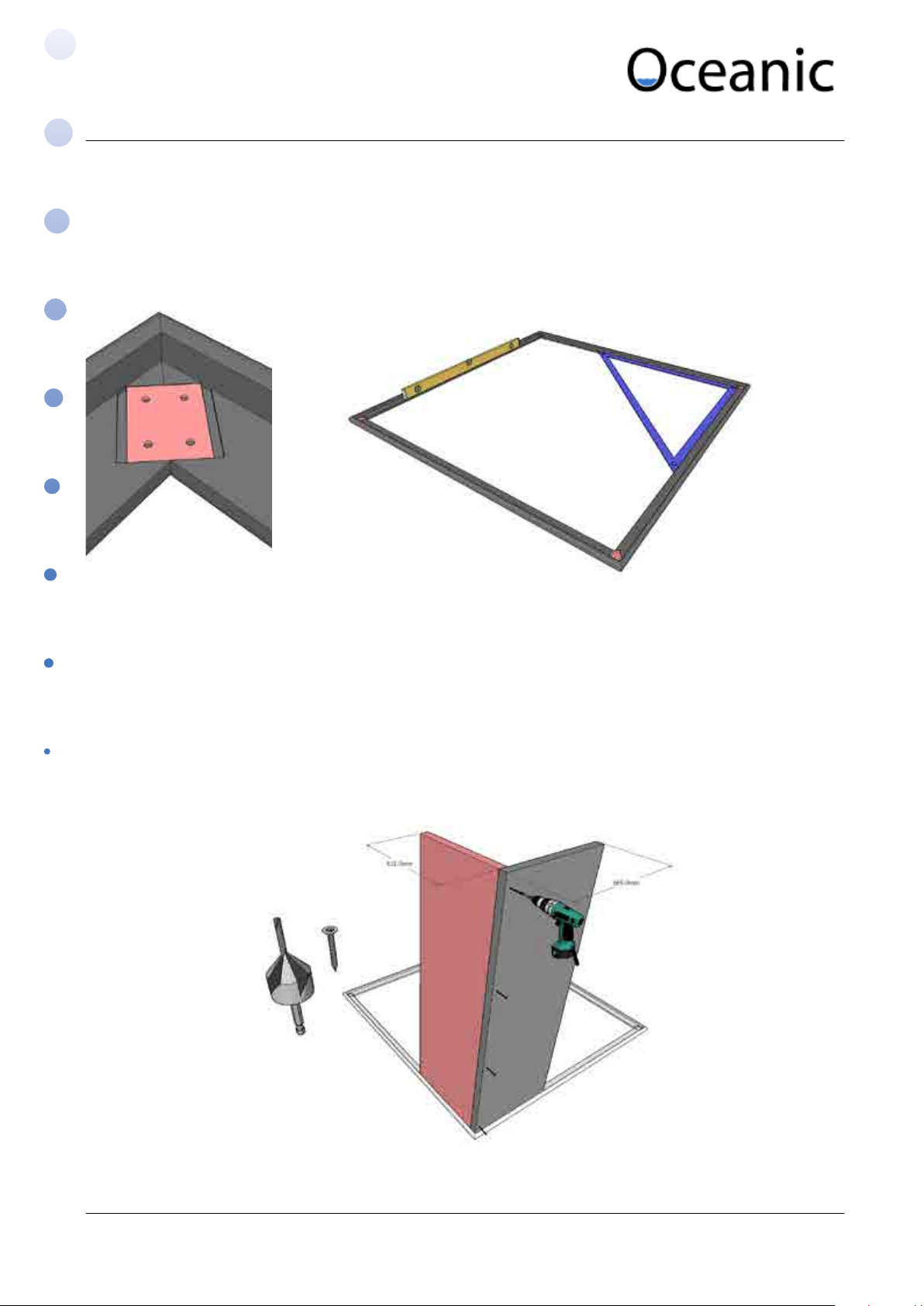

5. Step 1 Base

i. Locate the base drawing on page 2 of the parts list for reference to dimensions.

ii. Use the 4 at brackets supplied to join each corner of the base together.

iii. Mark the holes and pilot with 3 or 4mm drill, use 4 x 15mm screws in each corner.

6. Back Corner Joint

i. The image to the right is showing the back panel in grey which is 665mm on all models.

ii. Countersink drill 4 holes evenly down the panel.

iii. Fix from the back panel into the end of the side panel using 80mm screws.

iv. The panels simply just sit onto the base, don’t x down.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 5

Vision Sauna Manual

Sauna & Steam

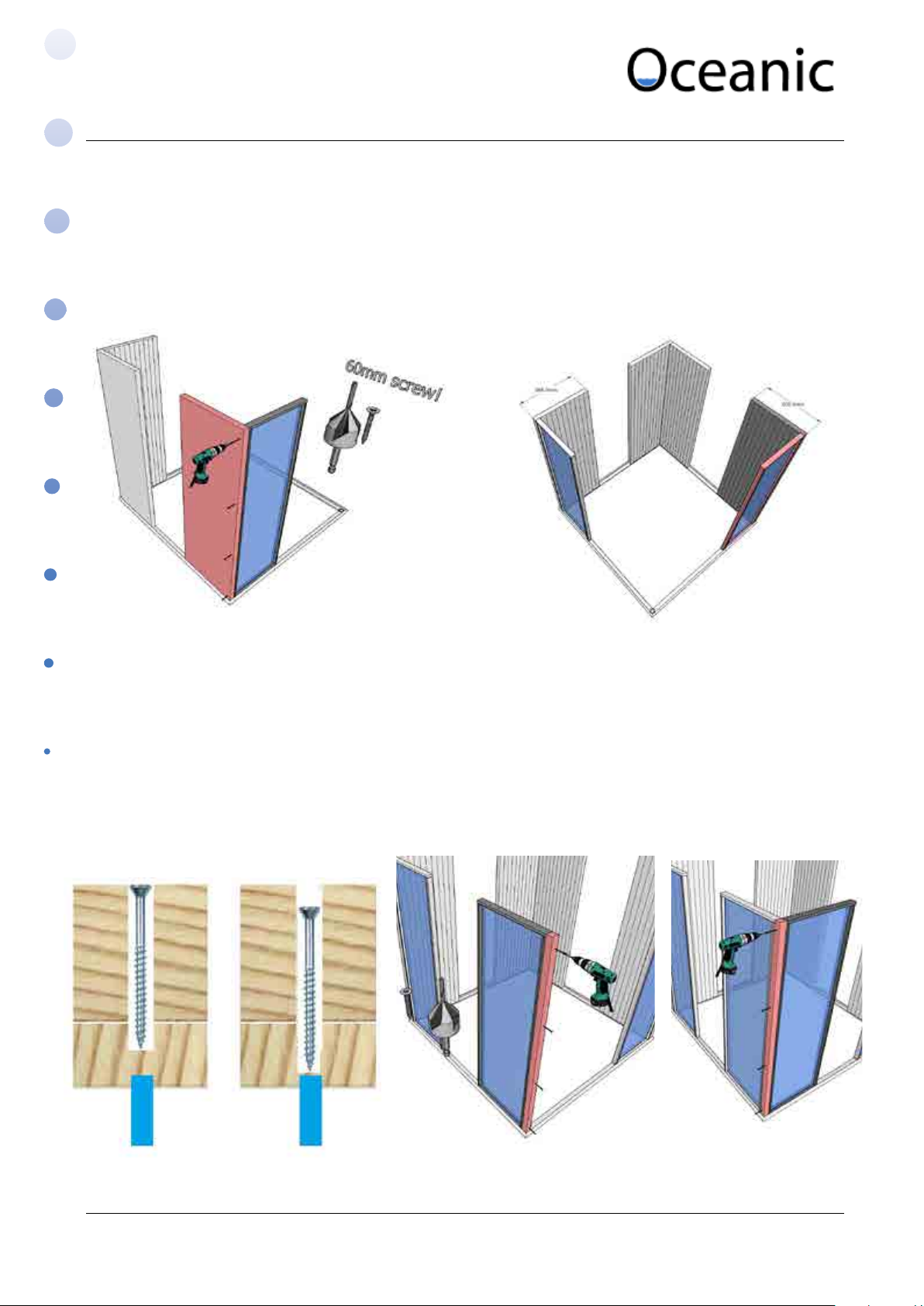

7. Wooden to Glass Panel Joint

i. Similarly to how the back corner was done x 4 x 60mm screws from the back panel into the side

of the glass panel. It is very important not to tighten the screw any deeper than surface level as

the screw could reach through and hit the glass.

ii. Repeat for the other corner.

8. Front Corner (Fixing Column)

i. There is a 50x50 xing column supplied, x this to edge of the glass panel using 4 x 60mm

screws. Again do not overtighten the screws and pilot and countersink holes.

Correct Depth Too Deep!

Column

Glass Frame

Glass Panel

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 6

Vision Sauna Manual

Sauna & Steam

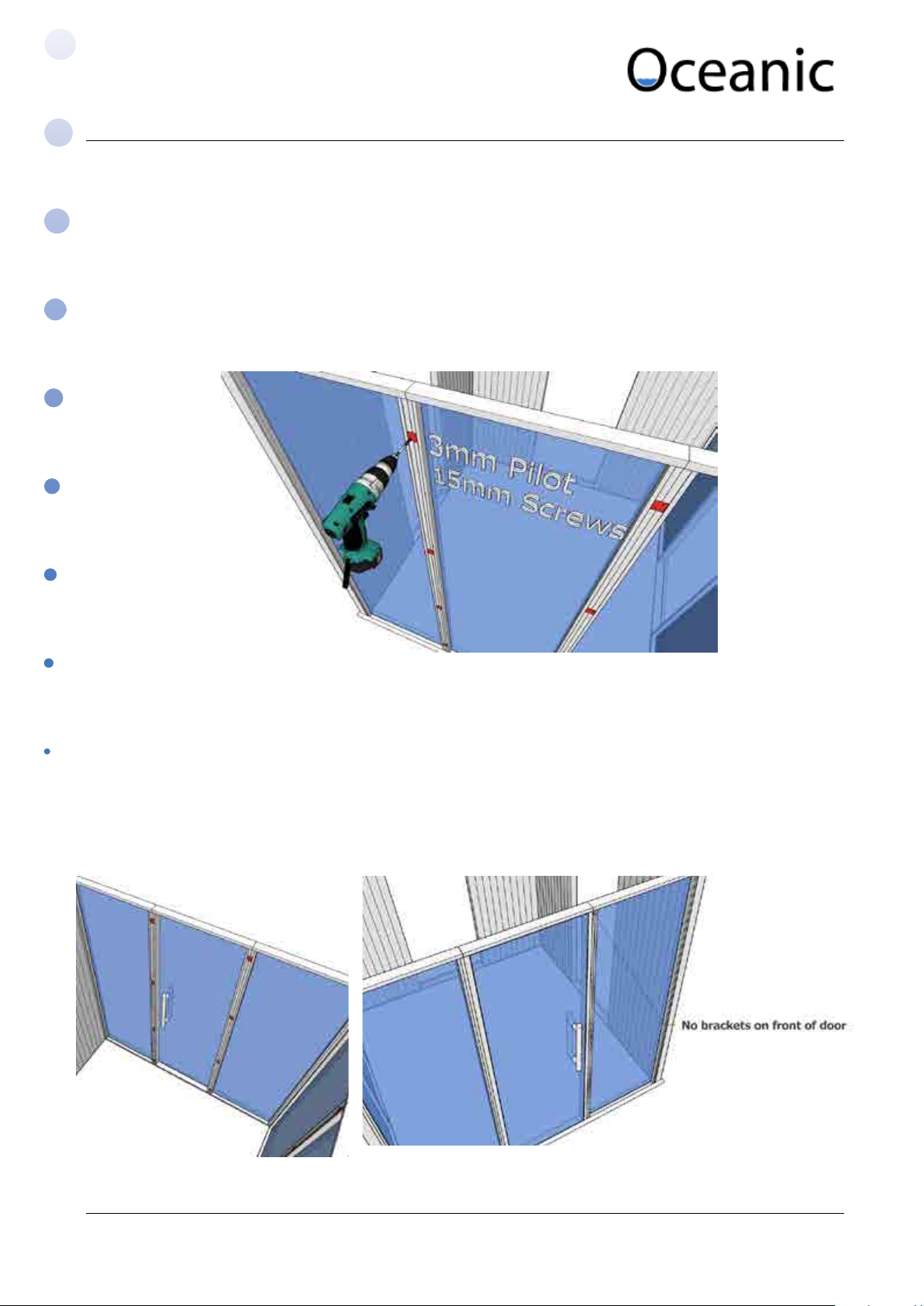

9. Glass Panels

i. The glass panels are xed together using at brackets in the channel as shown below.

ii. Mark all holes with pencil and use 3mm pilot drill for all holes.

iii. Position the brackets evenly but make sure they are staggered from inside and out so the screws

don’t clash. (For example inside face go 50mm down and 700mm down then externally 100mm

and 600)

iv. Fix 4 brackets on the inside and 4 on the outside join. Use 2 x 15mm screws for each bracket.

10. Door Frame

i. The door frame doesn’t have a channel on the external face so only t the brackets to the

internal join.

ii. The door must be installed opening outwards. You can hinge the door from the left or right

hinge by just rotating the frame 180 degrees.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 7

Vision Sauna Manual

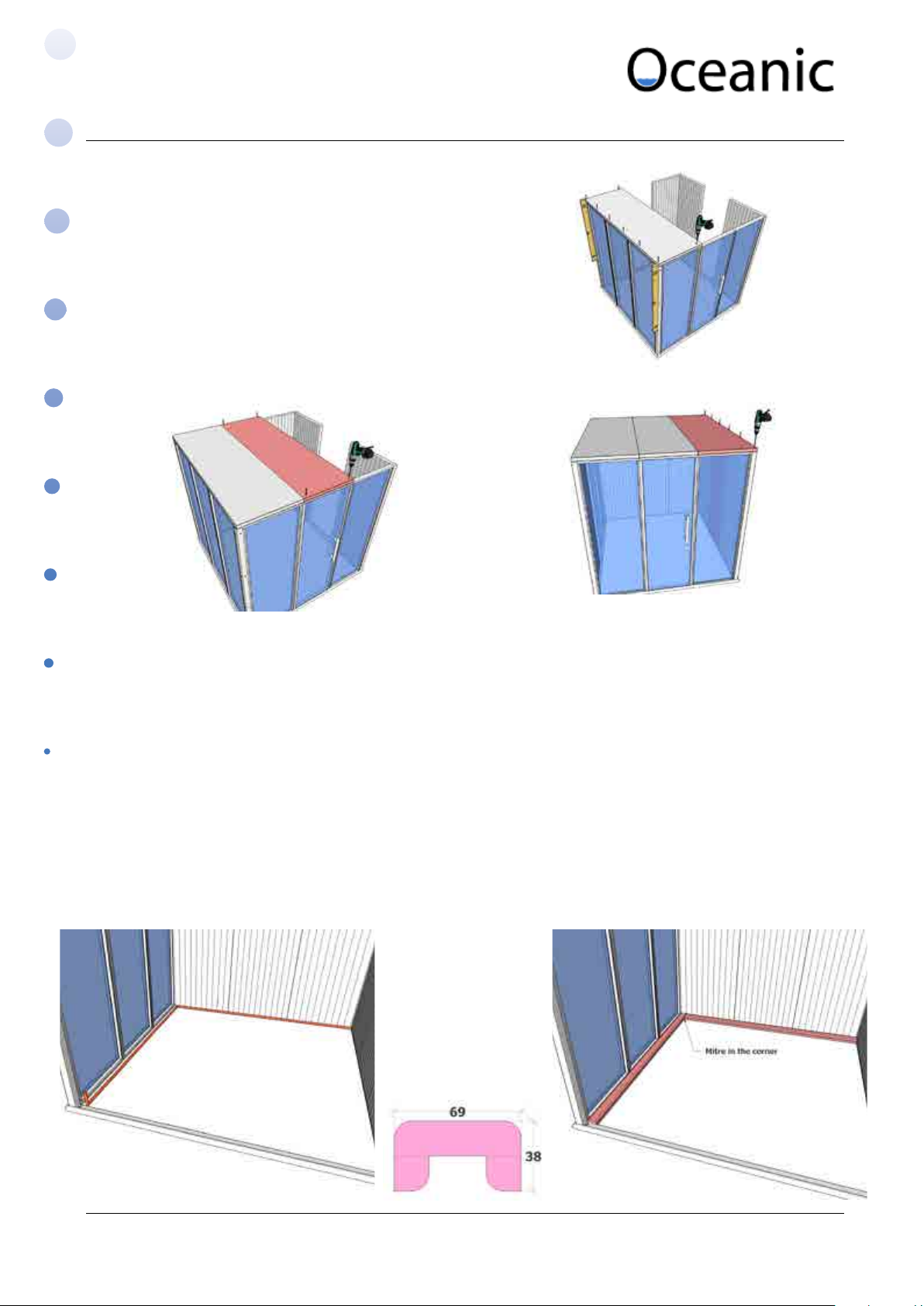

11. Roof

i. Fix the roof panels down using 60mm

screws, countersink drill and don’t

overtighten.

ii. Start in the front or back corner then work

along xing 2 screws down into each wall

panel. All joins should be ush.

iii. Continue to add the remaining wall panels.

Sauna & Steam

12. Heater Wire & Wooden Trunking

i. In some cabin layouts you may just bring the wire through one of the solid wooden panels

behind where the heater will be located. But for some of the larger models the heater is

positioned in between glass panels.

ii. We supply enough wooden trunking to go around two sides of the cabin so you will always have

enough no matter where the cable comes into the cabin from.

iii. Route the cable rst and make sure there is enough spare at the heater end for the electrician.

iv. Then measure and cut the trunking along the one or two edges that you require, if you mitre the

trunking the cable will run around the corner perfectly without any other holes or notches being

made.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 8

Vision Sauna Manual

Sauna & Steam

13. Benches

i. Refer to your parts list for the bench layouts.

ii. For a high bench you will need to x the bench rail at 781mm from the oor and for low bench

481mm.

iii. For one tier of benches x one 640mm rail as shown to the right either at 481 or 781mm from

the oor

iv. For two tiers of benches the second rail 665 will be xed as shown.

v. Dowel plugs have been suppied to ll the holes, these are to be xed in using the ller and cut

o using a wood chisel, sanded at then lled and sanded again if required.

vi. This image shows how

the bench rails are

supported by the 50mm

double round trim and

corner mould with the

concave front. We don’t

recommend that you add

these until the cornice and

skirt is on rst. We think

this gives the best asthetic

look.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 9

Vision Sauna Manual

14. Heater Guard

i. Fix the guard together using 30mm screws as shown in the two below image.

Sauna & Steam

ii. Hammer the dowels into the holes to cover the

screws.

iii. Chisel o the dowels, don’t chisel level

chisel about 2mm proud.

iv. Sand the dowels level.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 10

Vision Sauna Manual

v. Fix the guard with 4 x 30mm screws. Plug, chisel and sand.

Sauna & Steam

vi. Fix two 30mm screws at the positions shown to

hang the heater.

vii. Drop the heater onto the mounting screw

then secure using 2 x 30mm screws.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 11

Vision Sauna Manual

15. Internal Trim (Fix in this order)

i. Cornice (convex)

(Mitre cuts if preferred)

ii. Skirt

iii. Corner Trim (concave)

Sauna & Steam

iv. Overlap Mould (x over every joint between glass and wooden panels as shown)

Measure cut and x the pieces on using 25 or 35mm brads. (Optionally ll holes, then sand down when

ller is dry)

16. Bench Assembly

Important Safety Information.

The benches may have to support the body weight of several bathers. It is important that they are

correctly assembled; the holes for all screws must be predrilled to prevent the timber splitting. To

tighten the screws use a hand held screwdriver or an electrically operated one with a torque setting

that allows the screw to be fully tightened but not to spin as spinning reduces the holding power of

the screw.

Note the use of a good quality PVA adhesive (not supplied) will improve the durability of the

benches.

Maximum loadings;

Up to 1200 mm no centre support 2 x 12.5 stone people

Up to 1800 mm with 1 extra support 3 x 12.5 stones people

Before commencing the construction of the benches nd the specication sheet for the sauna you

are building. This will give detail of the correct quantities and positions of timbers and xings.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 12

Vision Sauna Manual

Sauna & Steam

i. Screw the supporting frame together using the 4 large brackets and 20mm screws.

ii. Lay the 5 or 6 bench slats face down on a work bench, use two pieces of scrap timber along the edges

of your bench to create a square corner to work o. Use small pieces of corner mould as 19mm spaces.

scrap timber

scrap timbersquare corner bench slat 19mm corner

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

work bench

mould spacer

Page 13

Vision Sauna Manual

Sauna & Steam

iii. Lay the supporting frame onto the slats, use spacers along the two edges to give a 19mm overhang

each side.

19mm corner

mould spacer

iv. Add the cross members, two are positioned 100mm from the ends, the third is centred, a dimension for A

can be found on your parts list.

under frame

19mm corner

mould spacer

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 14

Vision Sauna Manual

v. Evenly space out the 14 L brackets and x using 20mm screws.

Sauna & Steam

vi. Use the 30mm screws provided to x down through the cross members into the slats.

vii. If your parts list shows you have a bench leg, add this now as shown. Use 6x 40mm Screws.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 15

Vision Sauna Manual

viii. Screw the benches onto the wall rails using 2 x 30mm screws and 2 x 30mm washers.

ix. Fix L Benches together uising 2 x 50mm screws and 2 x 30mm washers.

Sauna & Steam

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 16

Vision Sauna Manual

17. Back Rests

Sauna & Steam

i. Located the drawing in the parts list for the back rest(s).

ii. We recommend xing the back rests together from behind so there are no xings seen. You

can alternatively pin the slats onto the uprights using brad nails and ll / sand.

iii. Use 2 x 30mm screws for the top chambered slat, then use 2 x 40mm screws for the two lower

slats.

iv. Use pieces of corner mould as 19mm spacers.

v. The back rests are to be positioned 75mm from an adjacent wall. Mark with a pencil at 121mm

from the adjacent wall and 375mm up from the bench. (As there is a gap behind the bench

we recommend using a piece of wood and marking 375mm on it, then using this to mark your

xing points)

vi. For the remaining xing positioned measure between the keyways (dimension A)

vii. We recommend a height of around 250mm o the bench so 375mm for the screws will give

you this.

viii. Pilot with 3mm drill and x 30mm screrws where needed.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 17

Vision Sauna Manual

LED strip xed beneath the backrest

Routered overlap for

mounting LED strip

Sauna & Steam

IMPORTANT

Check male / female connection

to power supply before installing

17.1. Back Rest LEDs

i. Find the length(s) of overlap mould with the routered channel for the LED strip to mount into.

ii. If necessary cut the piece of timber to the required length so that it can be mounted beneath

the two outermost vertical timbers on the back rest as shown above.

iii. The LED strip has male connector on one end and female connector on the other.

IMPORTANT make sure the correct end is at the correct location to be connected to the power

supply.

iv. If there are two back rests you will be supplied with 2 separate rolls of LED which can be

connected via an extension cable (also supplied). See diagram on page 19 for more details

v. Unravell the LEDs and marry the strip up along the channel, make sure you have the input end

where you will want to bring the holes through the wall.

vi. When you are happy with the length of the LED cut the strip across the incidated lines on the

stip cleanly through the copper tracks.

vii. Remove the self adhesive tape and x the LED into the wooden track.

viii. Fix the assembled LED unit to the underside of the backrest timbers using the nail gun or use a

hammer.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 18

Vision Sauna Manual

Sauna & Steam

ix. To get the right position for the LED wire just mount the back rest on the wall and pencil a

point close to the connector.

x. Take the back rest o and drill a 12 mm hole for the wire.

xi. Route the wire from the roof or

control box location through the

wall.

xii. Connect up and mount the back

rest back on the wall.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 19

Vision Sauna Manual

Diagram 1 - Single Downlight, Single LED strip

Sauna & Steam

240V Mains supply

240V Mains supply

12v DC

12v transformer

12V extension lead connector

12v downlight

DIagram 2 - Double Downlight, Double LED strip

240V Mains supply

12v DC

LED strip

LED stripMale / Female connectors

12V extension lead connector

240V Mains supply

12v transformer

DIagram 3 - Triple Downlight

240V Mains supply

12v transformer

12v transformer

connector block

connector block

12v downlight

12v downlight

12v downlight

12v downlight

12v downlight

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Page 20

Vision Sauna Manual

18. External Trim (Fix in this order)

i. Top facia and uprights (75mm single

round)

ii. Front corner facia (75mm double round)

iii. Internal door frame Trim

Sauna & Steam

iv. Overlap (50mm double round)

v. Door trim (44mm double round)

vi. Door trim (26mm double round)

External trim

Internal door trim

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

External door trim

Page 21

Vision Sauna Manual

Sauna & Steam

19. Floor Mat(s)

i. You will be provided with pre-cut timber to create a oor in which to cover the area in front of the

benches and underneath the heater.

ii. Please make sure you measure the oor area rst before screwing together the matt. If you have

ordered a special size cabin the timbers may be slightly larger to allow you to achieve a neatly

tted matt by cutting to size.

iii. Assemble the oor mats using left over corner mould as 19mm spacers between the slats.

iv. Ensure the cross lengths aligned equally beneath the length of the mat as shown in pink in the

diagram below.

v. Fix with glue and 30mm screws from the underside. (Pilot drill screw holes with 4mm countersink)

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Loading...

Loading...