Page 1

OPERATING AND INSTALLATION

INSTRUCTIONS OF

BUILT-IN HOB

EN

OCEACPM2G2V

Page 2

Dear Customer,

Our goal is to offer you products with high quality that exceed your expectations.

Your appliance is produced in modern facilities carefully and particularly tested for

quality.

This manual is prepared in order to help you use your appliance that is manufactured

by the most recent technology, with confidence and maximum efficiency.

Before using your appliance, carefully read this guide that includes the basic

information for right and safe installation, maintenance and use. Please contact to

the nearest Authorized Service for the installation of your product.

CE Declaration of conformity

This appliance has been designed to be used only for home cooking. Any other use

(such as heating a room) is improper and dangerous.

This appliance has been designed, constructed, and marketed in compliance with:

• Safety requirements of the "Gas" Directive 2009/142/EC;

• Safety requirements of the "Low voltage" Directive 2006/95/EC;

• Safety requirements of the "EMC" Directive 2004/108/EC;

• Requirements of the Directive 93/68/EC.

Page 3

2

Note:All figures in manual are schematic.

CONTENTS:

1. BRIEF PRESENTATION OF PRODUCT

2. WARNINGS

3. INSTALLATION AND PREPARATIONS FOR USE

3.1

3.2

3.3

3.4 Gas conversion

Electrical Connection Of Your Hob

4. USE OF YOUR PRODUCT

4.1 Use of gas burners

4.2

4.3

5. CLEANING AND MAINTENANCE

5.1 Cleaning

5.2 Maintenance

6. SERVICE AND TRANSPORT

6.1

6.2 Information related to the transport

Environment where your appliance will be installed

Installation of product

Gas connection

3.5

Control of the hob burners

Control of the electric hobs

Basic troubleshooting before contacting service

4.4 Accesorries

Page 4

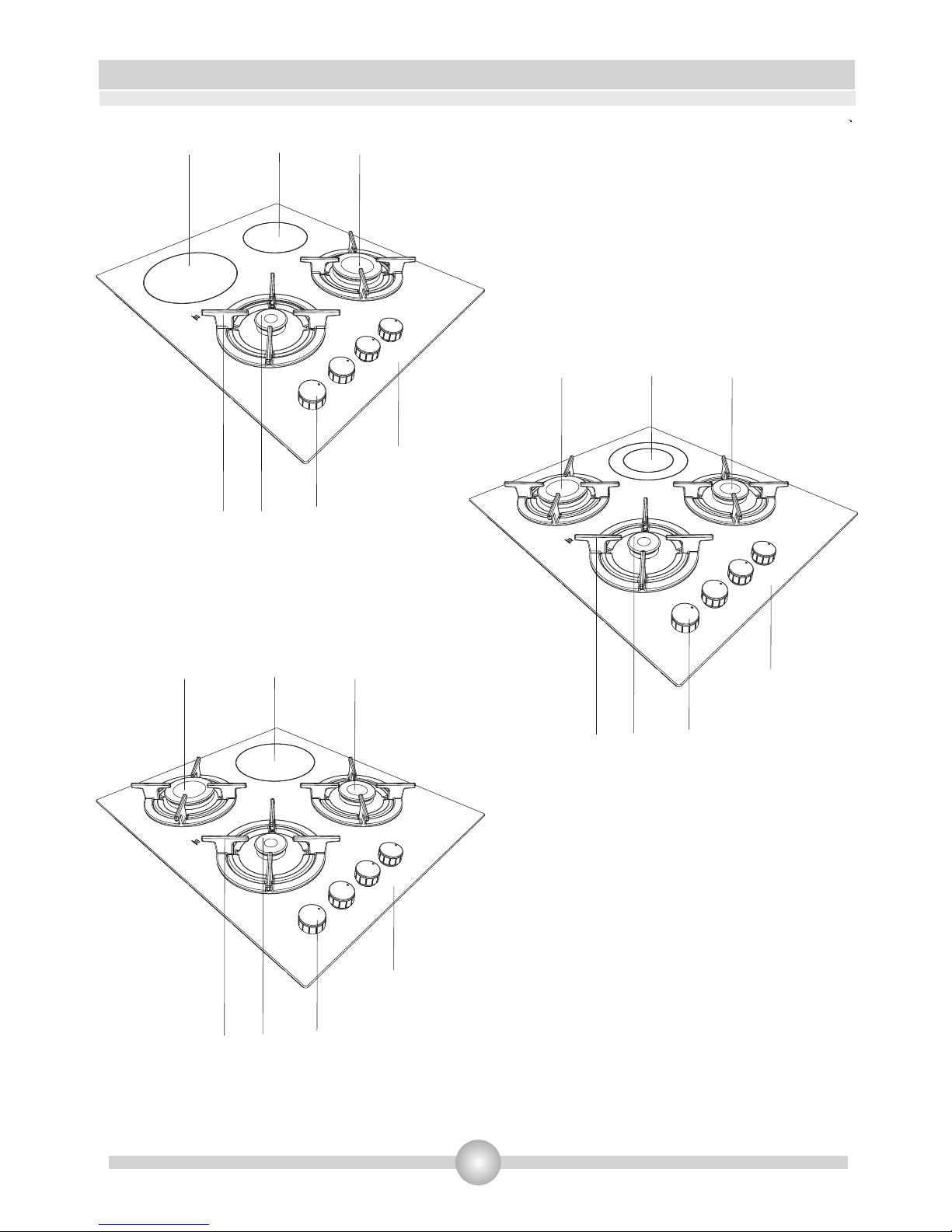

1.BRIEF PRESENTATION OF PRODUCT

* The appearance of your hob may be different than the model shown above due to its configuration.

12- Semi-Rapid Burner

3- Auxillary Burner

4- Rapid Burner

5- Control Knobs

67- Worktop

8-Pan Support

9-

Electrical Heater (145 mm)

Electrical Heater (180 mm)

Electrical Heater (Dual 180 mm)

1 4

7

6

3

5

8

2

7

5

3

4

8

9

7

5

2

3

4

6

8

3

Page 5

SAFETY WARNINGS

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE USING YOUR APPLIANCE, AND KEEP IT IN A

CONVENIENT PLACE FOR REFERENCE WHEN NECESSARY.

THIS MANUAL IS PREPARED FOR MORE THAN ONE MODEL IN COMMON. YOUR APPLIANCE MAY NOT HAVE

SOME OF THE FEATURES THAT ARE EXPLAINED IN THIS MANUAL. PAY ATTENTION TO THE EXPRESSIONS THAT

HAVE FIGURES, WHILE YOU ARE READING THE OPERATING MANUAL.

General Safety Warnings:

Your appliance is produced in accordance with all applicable local and international standards and regulations.

Maintenance and repair work must be made only by authorized service technicians. Installation and repair work

that is carried out by unauthorized technicians may endanger you. It is dangerous to alter or modify the

specifications of the appliance in any way.

Prior to installation, ensure that the local distribution conditions (nature of the gas and gas pressure or

electricity voltage and frequency) and the adjustments of the appliance are compatible. The adjustment

conditions for this appliance are stated on the label.

CAUTION: This appliance is designed only for cooking food and is intended for indoor domestic household use

only and should not be used for any other purpose or in any other application, such as for non-domestic use or

in a commercial environment or room heating.

This appliance can be used by children aged from 8 years

and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning

use of the appliance in a safe way and understand the

hazards involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by

children without supervision.

This appliance is not connected to a combustion products evacuation device. It shall be installed

and connected in accordance with current installation regulations. Particular attention shall be

given to the relevant requirements regarding ventilation.

If after 15 s the burner has not lit, stop operating the device and open the compartment door

and/or wait at least 1 min before attempting a further ignition of the burner.

These instructions are only valid if the country symbol appears on the appliance. If the symbol does

not appear on the appliance, it is necessary to refer to the technical instructions which will provide

the necessary instructions concerning modification of the appliance to the conditions of use of the

country.

WARNING: The appliance and its accessible parts become

hot during use. Care should be taken to avoid touching

heating elements. Children less than 8 years of age shall be

kept away unless continuously supervised.

4

Page 6

5

SAFETY WARNINGS

WARNING: Unattended cooking on a hob with

fat or oil can be dangerous and may result in

fire. NEVER try to extinguish a fire with water,

but switch off the appliance and then cover flame

e.g. with a lid or a fire blanket.

WARNING: Danger of fire: do not store items on

the cooking surfaces.

WARNING: If the surface is cracked, switch off

the appliance to avoid the possibility of electric

shock.

For hobs incorporating a lid, any spillage should

be removed from the lid before opening. And

also the hob surface should be allowed to cool

before closing the lid.

The appliance is not intended to be operated by

means of an external timer or separate remotecontrol system.

Do not use harsh abrasive cleaners or sharp

metal scrapers to clean the oven door glass and

other surface since they can scratch the surface,

which may result in shattering of the glass or

damage to the surface.

Do not use steam cleaners for cleaning the

appliance.

All possible security measures have been taken to ensure your safety. Since the glass may

break, you should be careful while cleaning to avoid scratching. Avoid hitting or knocking on

the glass with accessories.

Page 7

6

SAFETY WARNINGS

Ensure that the supply cord is not wedged during the installation. If the supply cord is damaged, it

must be replaced by the manufacturer, its service agent or similarly qualified persons in order to

prevent a hazard.

Installation Warnings:

Do not operate the appliance before it is fully installed.

The appliance must be installed by an authorized technician and put into use. The producer is not

responsible for any damage that might be caused by defective placement and installation by

unauthorized people.

When you unpack the appliance, make sure that it is not damaged during transportation. In case of

any defect; do not use the appliance and contact to the authorized maintenance service

immediately. As the materials used for packaging (nylon, staplers, styrofoam...etc) may cause

harmful effects to children, they should be collected and removed immediately.

Protect your appliance against atmospheric effects. Do not expose it to effects such as sun, rain,

snow etc.

The surrounding materials of the appliance (cabinet) must be able to withstand a temperature of

min 100°C.

During usage :

Do not put flammable or combustible materials, in or near the appliance when it is operating.

Do not leave the cooker while cooking with solid or liquid oils. They may catch fire on condition of

extreme heating. Never pour water on to flames that are caused by oil. Cover the saucepan or

frypan with its cover in order to choke the flame that has occured in this case and turn the cooker

off.

Always position pans over the centre of the cooking zone, and turn the handles to a safe position so

they cannot be knocked or grabbed.

If you will not use the appliance for a long time, plug it off. Keep the main control switch off. Also

when you do not use the appliance, keep the gas valve off.

Make sure the appliance control knobs are always in the "0" (stop) position when it is not used.

CAUTION: The use of a gas cooking appliance results in the production of heat, moisture and

products of combustion in the room in which it is installed. Ensure that the kitchen is well

ventilated especially when the appliance is in use, keep natural ventilation holes open or install a

mechanical ventilation device (mechanical extractor hood).

Prolonged intensive use of the appliance may call for additional ventilation, for example opening of

a window, or more effective ventilation, for example increasing the level of mechanical ventilation

where present.

During cleaning and maintenance:

Always turn the appliance off before operations such as cleaning or maintenance. You can do it

after plugging the appliance off or turning the main switches off.

Do not remove the control knobs to clean the control panel.

TO MAINTAIN THE EFFICIENCY AND SAFETY OF YOUR APPLIANCE, WE RECOMMEND YOU ALWAYS

TO USE THE ORIGINAL SPARE PARTS AND TO CALL ONLY OUR AUTHORIZED SERVICES IN CASE OF

NEED.

Page 8

7

3. INSTALLATION AND PREPARATIONS FOR USE

This modern, functional and practical cooker, that was manufactured with the parts and

materials of highest quality, will meet your cooking needs in every aspect. You must surely

read this manual so that you don't have any problem in future and to be able to have

satisfactory results. The following information are the required rules for right installation and

service processes. It must be read especially by the technician who will install the appliance

Important: This appliance must be installed by a qualified people according to the

manufacturers installation instructions, local building regulations, gas authority codes and

electrical wiring instructions.

Your product must be set up and used in a place where it will always have ventilation

While operating, this appliance needs

There must be a natural ventilation enough to provide the gas to be used in the environment.

The average air flow must directly come in through the air holes that will be opened on the

walls that are opened towards outside.

.

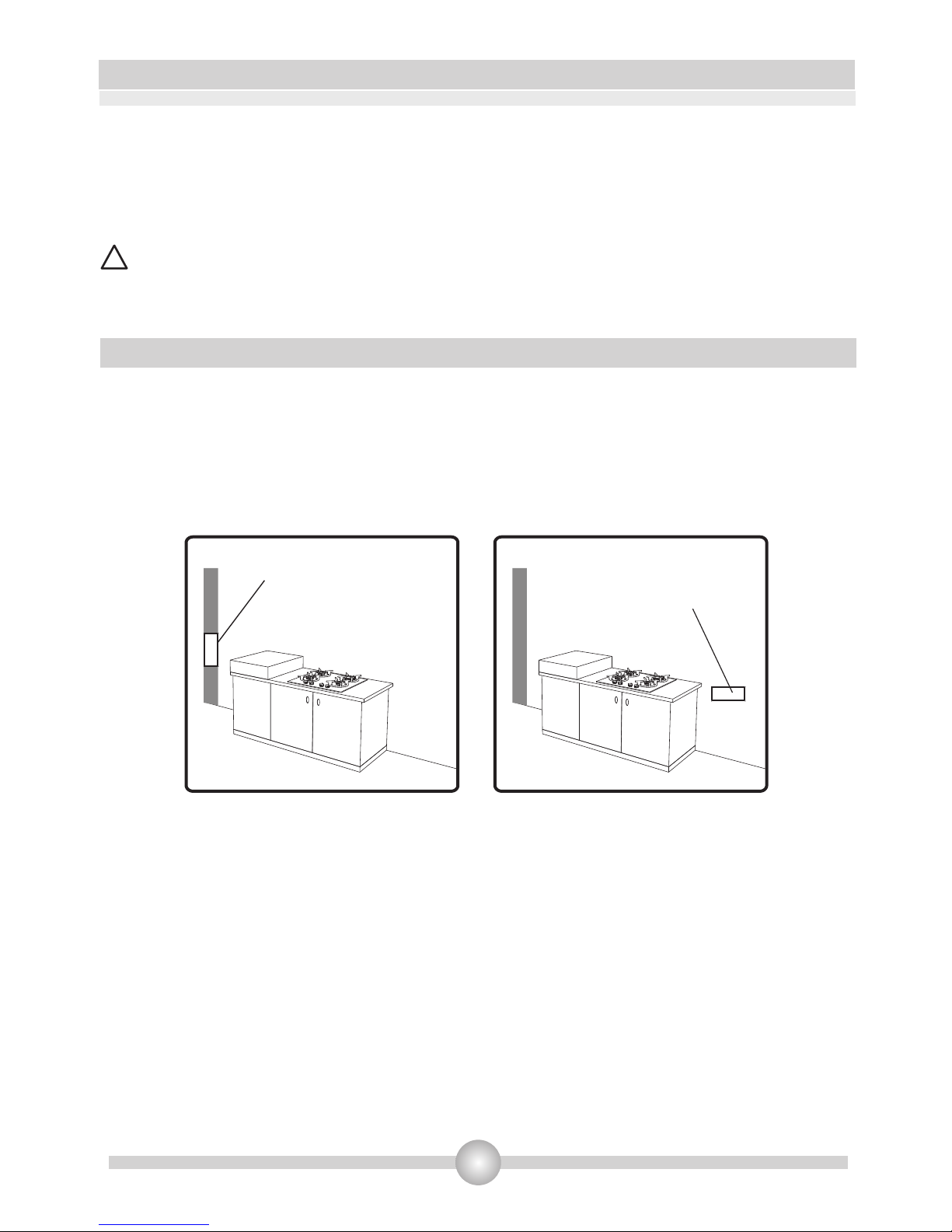

Environment where your appliance will be installed 3.1.

• .

3

• 2m /h air per kw input.

•

!

• 2These air holes must have at least the effective cross section of 100cm for fresh air circulation

(One or more air holes can be opened.). This hole (or holes) must be opened so that they

shouldn't be blocked. Preferably they must be placed close to the bottom and at opposite side of

the smokes of the burned gases that were emptied. If it seems not possible to open these

ventilations in the place where the appliance is set up, the needed air can also be obtained

through the next room, provided that this place is not a bedroom or a dangerous place. In this

case this “next room” must also be ventilated as required.

Emptying of the Burned Gases from Environment

The cooking appliances that operate with gas, throw the burned gas wastes out directly to the

outside or through the cooker hoods that are connected to the a chimney that opens directly to the

outside. If it seems not possible to install a cooker hood, it is required to set an electric fan on the

window or wall that has access to fresh air. This electric fan must have the capacity to change the air

of the kitchen environment 4-5 times of its own volume of air per hour.

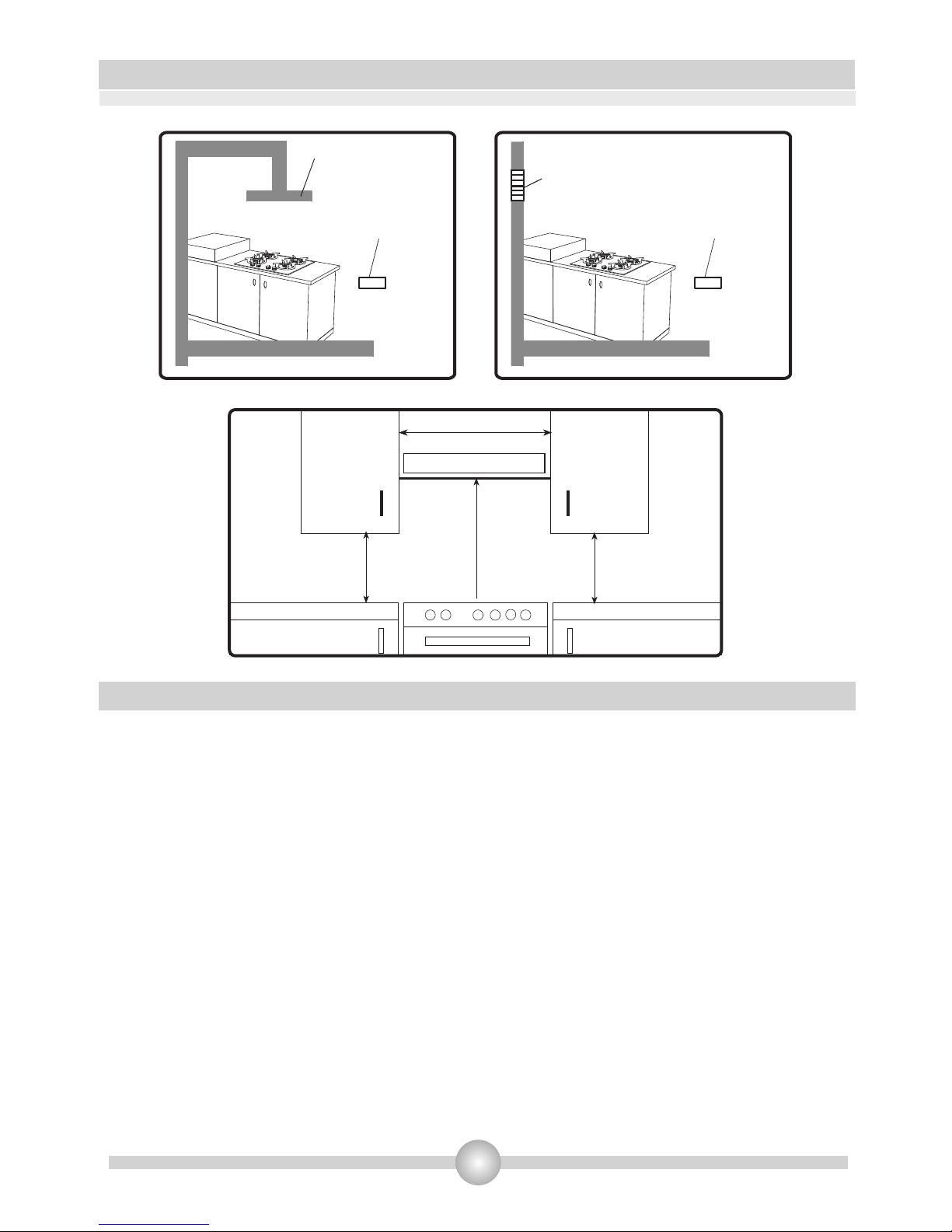

Figure 1

Air inlet section

2

min. 100cm

Figure 2

Air inlet section

2

min. 100cm

Page 9

8

INSTALLATION AND PREPARATIONS FOR USE

3.2 Installation of product

•

.

•

.

• .

• 100°C.

•

There are some factors that must be paid attention to while installing your product. Surely be very

careful to while installing your product. Pay attention to our below instructions in order to be able

to prevent any problems and/or dangerous situations that may occur later

The appliance can be placed close to other furniture on condition that in the area where the

oven is set up, the furniture's height does not exceed the height of the cooker panel

Pay attention not to place it near the refrigerator, there must be no flammable or inflammable

materials such as curtain, waterproof cloth, etc. that will begin to burn quickly

It is required that there must be least a 2cm blank space around the product for air circulation

The furniture close to product must be manufactured resistant to temperatures up to

If the kitchen furniture are higher than the cooktop, it must be at least 10cm away from the

cooker's side.

The minimum heights from the pan support and wall cupboards to cooker hoods with fan over the

product, are shown in figure 5. Thus, the cooker hood must be at minimum 65cm height from the

pan support. If there is no cooker hood, this height must not be less than 70cm.

.

Figure 5

Min. 60cm

COOKER HOOD

Min. 42cm

Min. 42cm

Min. 65cm(with hood)

Min. 70cm(without hood)

Air inlet section

2

min. 100cm

Cooker hood

flue

Air inlet section

2

min. 100cm

Figure 3 Figure 4

Electrical ventilator

Page 10

9

INSTALLATION AND PREPARATIONS FOR USE

The appliance is supplied with an installation kit including adhesive sealing material and fixing

brackets&screws are included with the appliance.

• Cut the aperture dimensions as indicated in Figure - 1. Locate the aperture on the worktop such

that after the hob is installed the following reguirements are ensured;

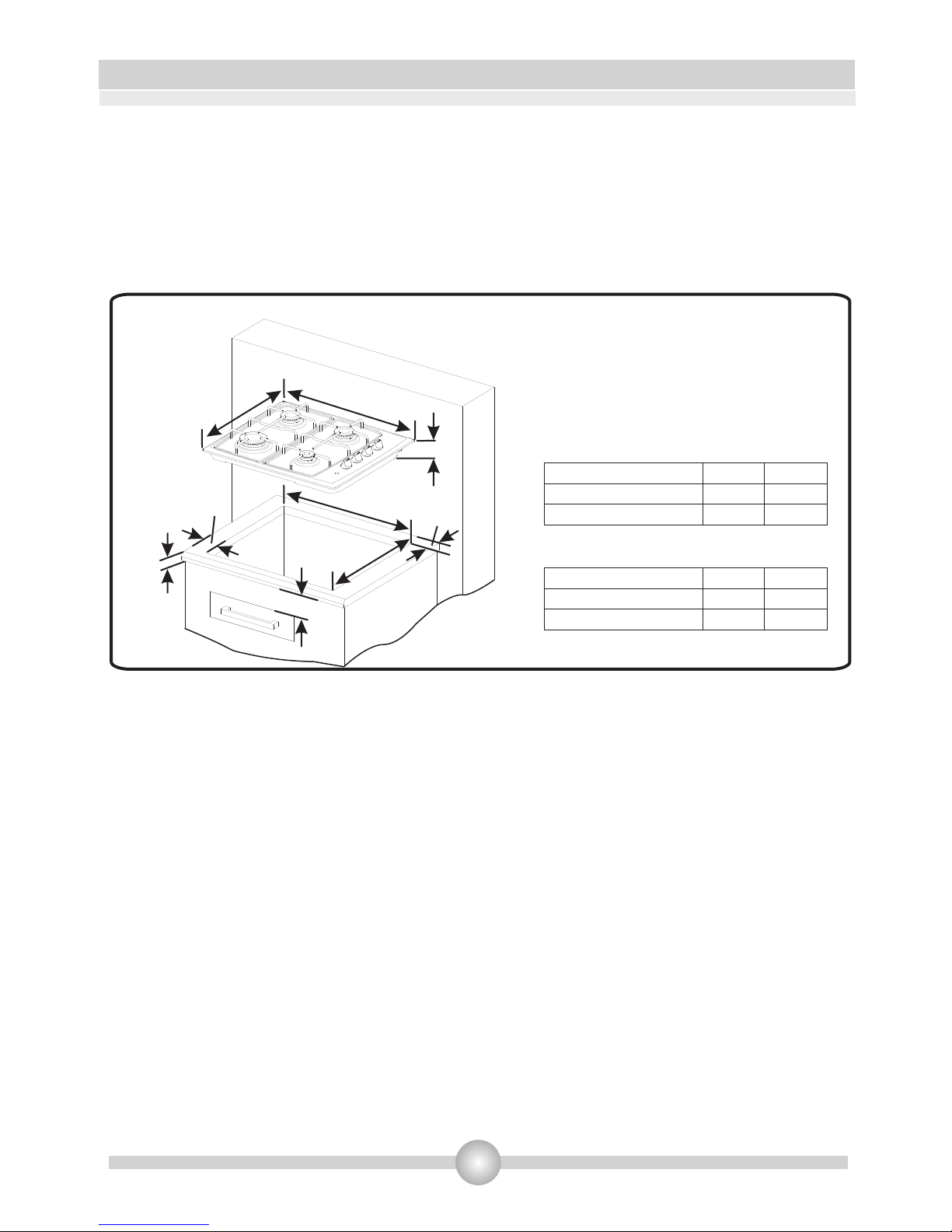

Figure 6

510 mm

Min.

A

490 mm

Min.

B

Min.

100mm

Min.

25mm

580 mm

560 mm

42 mm

Neighbourhood walls

Combustible

Non-combustible

A[mm]

60

40

B[mm]

150

50

If your appliance have four hobs ;

Neighbourhood walls

Combustible

Non-combustible

A[mm]

60

40

B[mm]

150

100

If your appliance have five hobs ;

Page 11

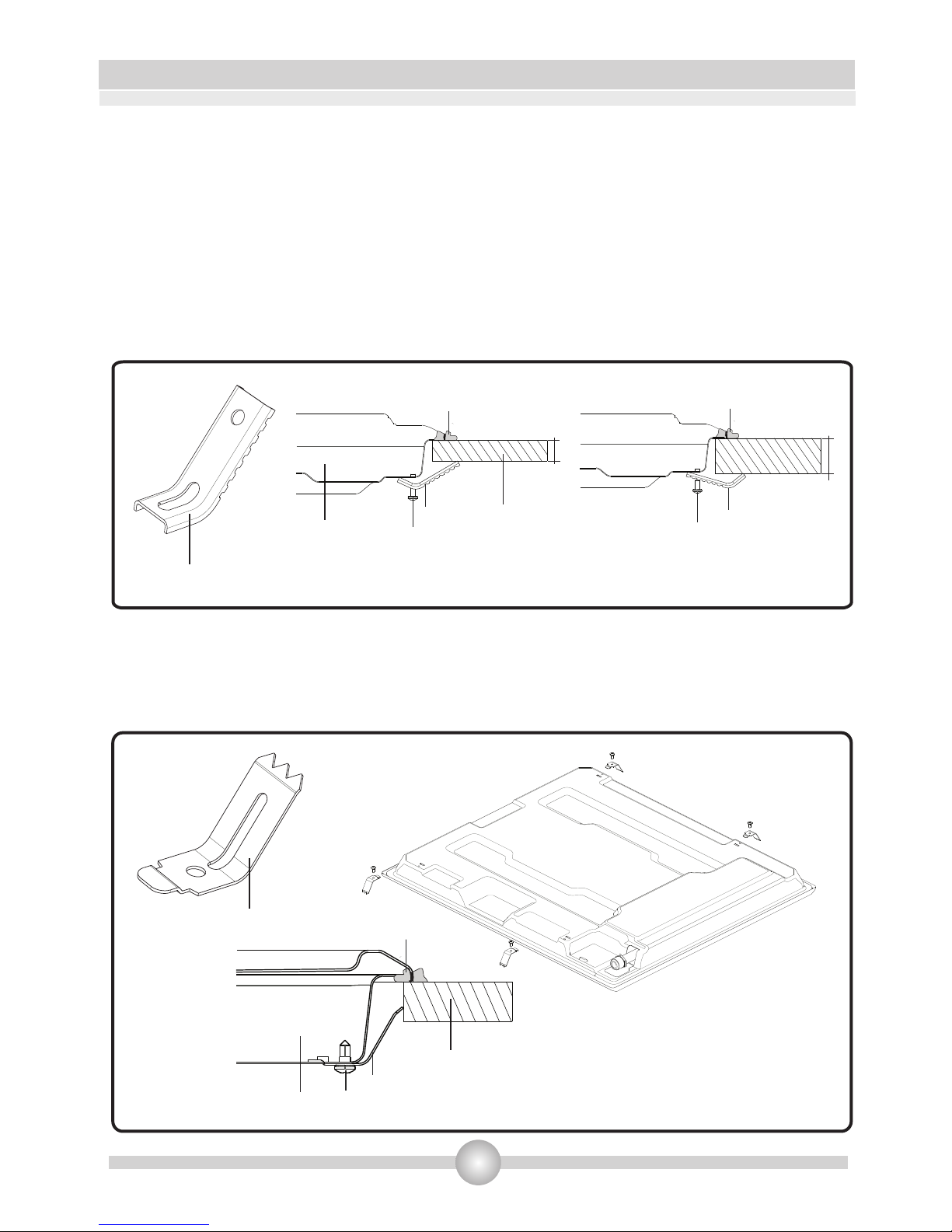

•

the outher perimeter edge of the appliance. Ensure that the junctions overlap at the corners

and no gap is left along the sealing material.

• Check the type of the brackets supplied in the assembly kit in Figure-7 and Figure-8 and

continue accordingly;

Brackets of Type-1

Insert the appliance into the aperture and fix in position via the brackets (A) and screws (B).

Adjust the position of the brackets depending on the thickness of the worktop as indicated in

Figure-7 and tighten the screws evenly.

Apply the adhesive sealing material “C” all the way round the aperture on the worktop to match

Brackets of Type-2

Fix the brackets (A) via the screws (B) on the bottom cover of the appliance as shown in Figure-8.

Insert the appliance into the aperture and apply pressure on the cooktop, ensure the appliance

is positioned tightly.

10

INSTALLATION AND PREPARATIONS FOR USE

Figure 7 - Installation with

Figure 8 - Installation with

Bracket Type 1

Bracket Type 2

Bracket Type 1

Tt

C

B

A

Hob

Worktop

t<25mm

B

A

Tt

C

B

A

t>25mm

Bracket Type 2

Hob

Worktop

C

Page 12

INSTALLATION AND PREPARATIONS FOR USE

11

3.3. Gas connection

The connection of the appliance should be performed in accordance with local and international

standards and regulations applicable. You can find the information related to appropriate gas types

and appropriate gas injectors on technical data table. If the pressure of used gas is different than

these values stated or not stable in your area, it may be required to assemble an available pressure

regulator on the gas inlet. It is certainly required to contact to the authorized service to make these

adjusments.

The points that must be checked during flexible hose assembly

If the gas connection is made by a flexible hose that is fixed on the gas inlet of appliance, it must be

fixed by a pipe collar as well. Connect your appliance with a short and durable hose that is as close

as possible to the gas source. The hose's permitted maximum lenght is 1.5m. The hose that brings

gas to the appliance must be changed once a year for your safety.

0

The hose must be kept clear from areas that may heat up to temperatures in excess of 90 C. The

hose must not be ruptured, bent or folded. It must be kept clear of sharp corners, moving things,

and should not be defective. Before assembly, it must be checked whether there is any production

defect.

As gas is turned on, all connection parts and hose must be checked with soapy water or leakage

fluids. Do not use naked flame to check gas leakage. All metal components used during gas

connection must be clear of rust. Also check the expiry dates of components to be used.

Assembly of gas supply and leakage check

The points that must be checked during fixed gas connection assembly

To assemble a fixed gas connection (gas connection made by threads, e.g. a nut), there are different

methods used in different countries. The most common parts are already supplied with your appliance.

Any other part can be supplied as spare part.

•

Important: If the appliance is to be installed above a cupboard or drawer it is absolutely

essential that you place a seperator between the base of the appliance and the drawer unit.

Carefully trim away the excess sealing material “C” from around the appliance.

!

Page 13

INSTALLATION AND PREPARATIONS FOR USE

12

During connections always keep the nut on the gas manifold fixed, while rotating the counter-part.

Use spanners of appropriate size for safe connection. For all surfaces between different

components, always use the seals provided in the gas conversion kit. The seals used during

connection should also be approved to be used in gas connections. Do not use plumbing seals for

gas connections.

Remember that this appliance is ready to be connected to gas supply in the country for which it has

been produced. The main country of destination is marked on the rear cover of the appliance. If you

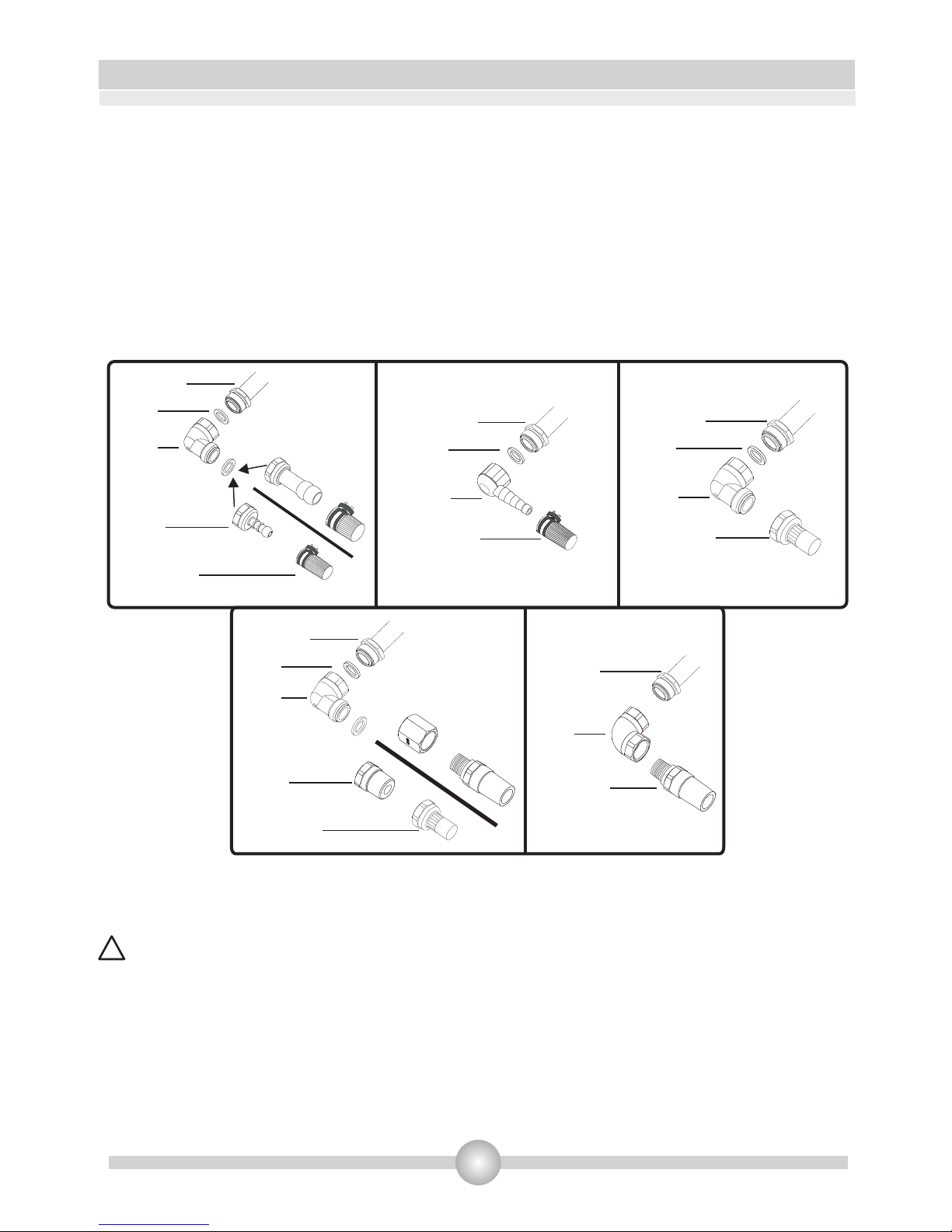

need to use it in another country, any of the connections in the figure below can be required.

In such a case, contact local authorities to learn the correct gas connection.

It is required to call the authorized service to be able to make the gas connections appropriately

and in compliance with safety standards.

ATTENTION! Surely do not use any match or lighter for control of gas leakage.

!

Seal

Hose

Fitting

Hose

Fitting

Gas Hose

with Collar

Gas Pipe

Figure 9

Seal

Hose

Fitting

Gas Hose

with Collar

Gas Pipe

Mechanical

Gas Hose

Seal

Hose

Fitting

Gas Pipe

Seal

Hose

Fitting

Hose

Fitting

Mechanical

Gas Hose

Gas Pipe

Mechanical

Gas Hose

Hose

Fitting

Gas Pipe

Page 14

INSTALLATION AND PREPARATIONS FOR USE

13

3.4 Gas conversion

:

Changing injectors:

• .

•

•

•

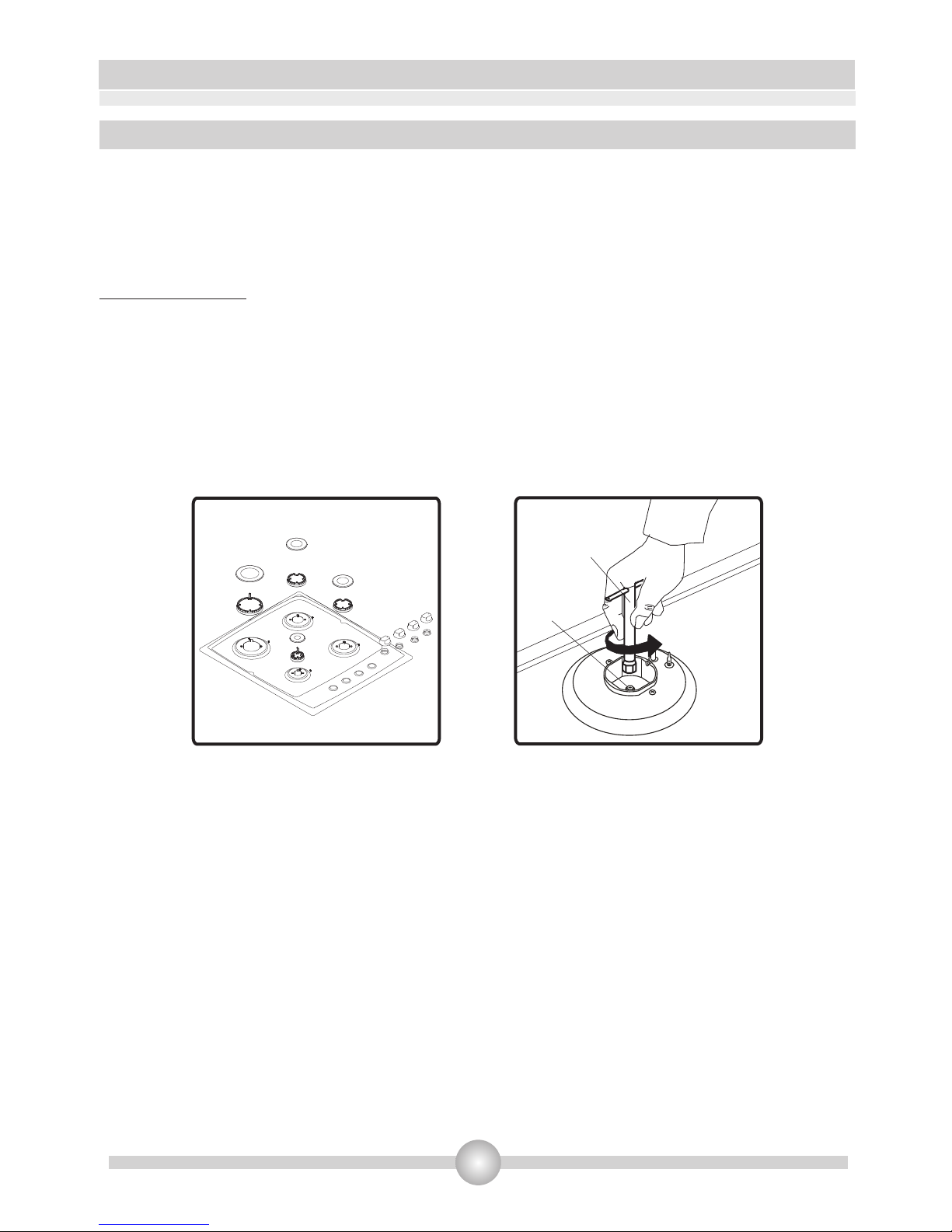

Caution: The following procedures must be undertaken by authorized service people.

Your appliance is adjusted to be operated with LPG/NG gas. The gas burners can be adapted to

different types of gas, by replacing the corresponding injectors and adjusting minimum flame length

suitable to the gas in use. For this purpose, following steps should be performed

Cut off the main gas supply and unplug from the electric mains

Remove the burner cap and the adapter(Figure 10).

Unscrew the injectors. For this, use a 7mm spanner(Figure 11).

Replace the injector with the ones from the gas conversion kit, with corresponding diameters

suitable to the type of gas that is going to be used, according to the information chart (which is

also supplied in the gas conversion kit).

Figure 11

Injector

Spanner

Figure 10

Adjusting the reduced flame position

The flame length in the minimum position is adjusted with a flat screw located on the valve. For

valves with flame failure device, the screw is located on the side of the valve spindle(Figure 8-9). For

valves without flame failure device, the screw is located inside the valve spindle(Figure 10). For

easier reduced flame adjustment, it is advised to remove the control panel (and microswitch, if

present) during adjustment.

To determine the minimum position, ignite the burners and leave them on in minimum position.

Remove the with the help of a small screwdriver fasten or loosen the bypass screw around 90

angular degrees. When the flame has a length of at least 4mm, the gas is well distributed. Make

sure that the flame does not die out when passing from the maximum position to the minimum

position. Create an artificial wind with your hand toward the flame to see if the flames are stable.

:

Page 15

INSTALLATION AND PREPARATIONS FOR USE

14

Changing the gas inlet:

For some countries, the gas inlet type can be different for NG/LPG gases. In such a case, remove the

current connection components and nuts (if any) and connect the new gas supply accordingly. In all

conditions, all components used in gas connections should be approved by local and/or

international authorities. In all gas connections, refer to the “Assembly of gas supply and leakage

check” clause explained before.

Figure 13

Figure 14

Figure 12

Valve with flame failure device Valve with flame failure device Valve without flame failure device

Bypass screw

Bypass screw

Bypass screw

(Inside the hole)

The position the bypass screw must be loosened for conversion from LPG to NG. For conversion

from NG to LPG, the same screw must be fastened. Make sure that the appliance is unpluged from

the electric mains and the gas supply is open.

Page 16

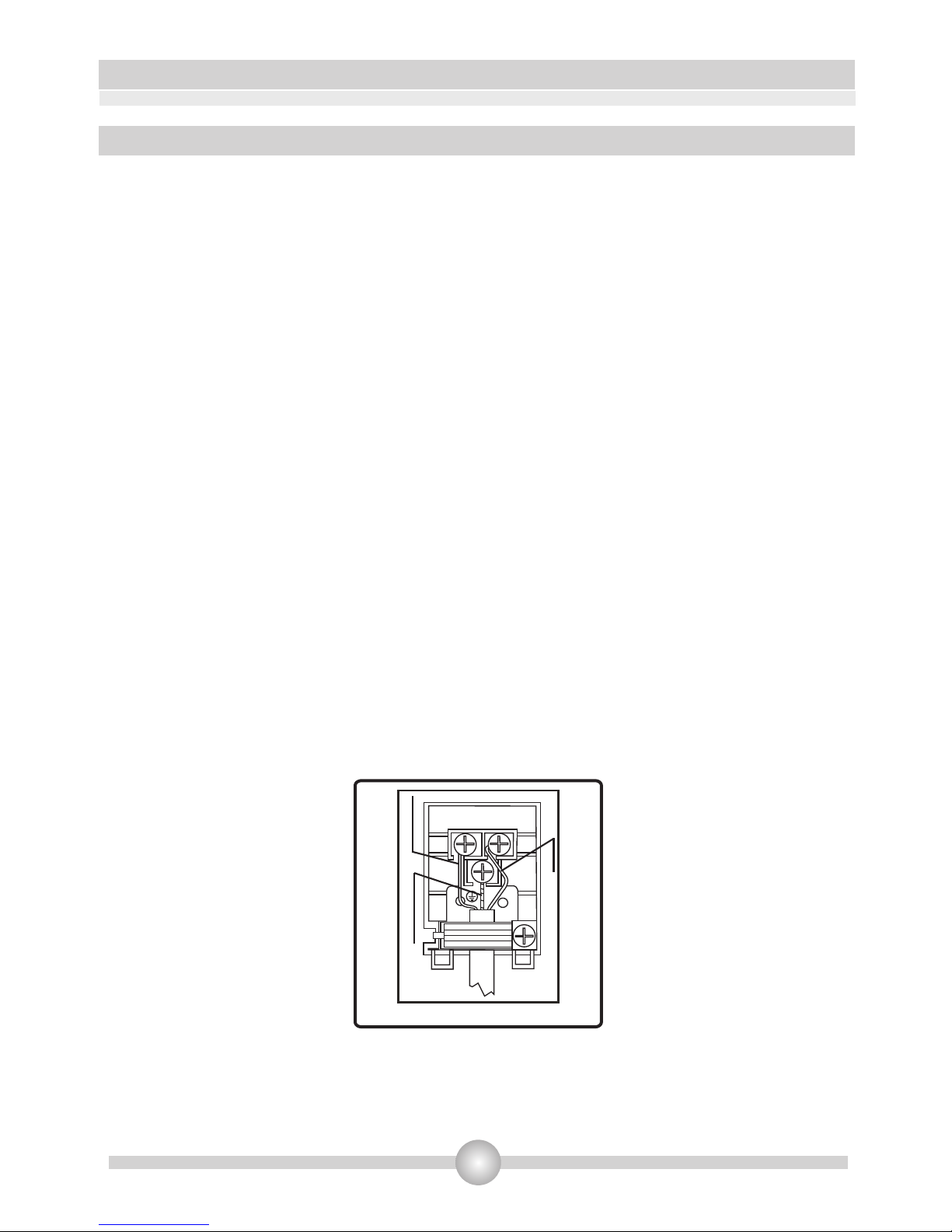

· Before proceeding with the electrical connection, verify that the current carrying capacity of

the system and the socket is adequate for the maximum power rating of the hob.

· Electrical installation of the residence and the electrical current plug in use must be earthed

and conform with safety regulations.

· If there is no dedicated hob circuit and fused switch, they must be installed by a qualified

electrician before the hob is connected.

. Fused switch must be easily accessible once the hob has been installed.

· Do not use adaptors, multiple sockets and/or extension leads.

· This appliance conforms with the requirements ofthe following EEC Directives:

1. Vitroceramic hob EEC/73/23 and 93/68, EEC/89/336 relating to radio interference,

2. EEC/89/109 relating to contact with foods.

· A circuit breaker with a contact opening of at least 3mm must be installed inside the supply

circuit.

· For the knob controlled vitroceramic hob with two heating elements, the cable must be

H05VV-F 3X1,5mm². For the knob controlled vitroceramic hob with one heating elements, the

cable must be H05VV-F 3X1,0mm². You will find the connection diagram shown on the bottom

of your appliance.

INSTALLATION AND PREPARATIONS FOR USE

15

Figure 15

L

N

BROWN

YELLOW+GREEN

BLUE

3.5 Electrical Connection Of Your Hob

Page 17

4. USE OF YOUR PRODUCT

16

4.1 Use of gas burners

•

:

•

.

Flame safety device:

.

Ignition of the burners

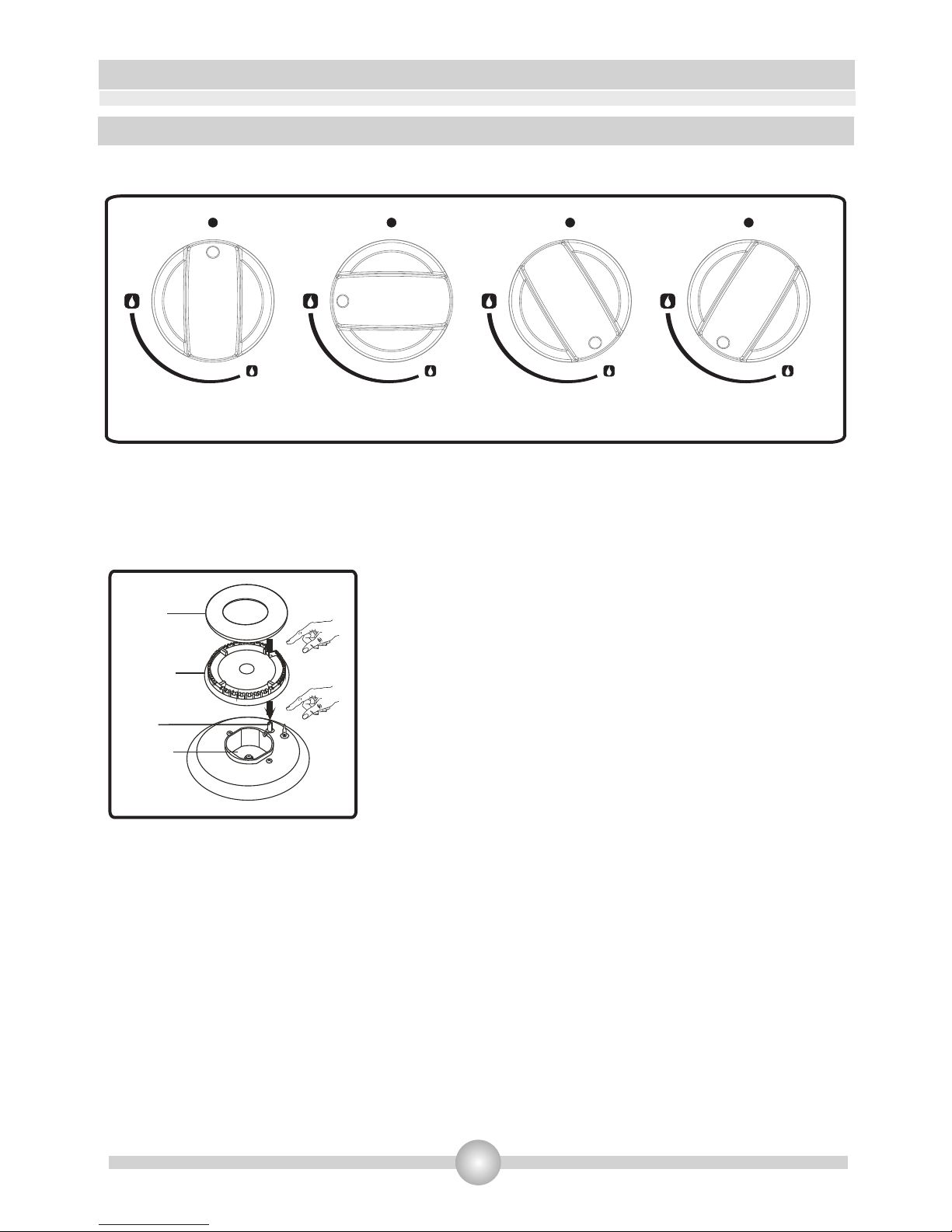

To determine which knob controls which burner, check the position symbol above the knob.

Manual Ignition

If your appliance is not equipped with any ignition aid or in case there is a failure in the electric

network, follow the procedures listed below

To ignite one of the burners, press and turn its knob counter-clockwise so that the knob is in

maximum position, approach a match, taper or another manual aid to its upper circumference.

Move the ignition source away as soon as you see a stable flame.

Electrical Ignition

Electrical ignition of gas burners can be performed in two ways; depending on the configuration of

your appliance

Ignition by Hob Control Knob: Press the hob control knob of the burner you want to operate and

turn the hob control knob in the counterclockwise direction so that the knob is in maximum

position while keeping the knob pressed. The spark plugs will generate sparks as long as you keep

the control knob pressed. The micro switch placed under the knob will automatically create sparks

through the spark plug of the burner. Continue pressing the knob until you see a stable flame on

the burner.

Hob Burners (If your hob is equipped with gas safety device)

Hobs equipped with flame failure device provide security in case of accidentally extinguished flame.

If such a case occurs, the device will block the burners gas lines and will avoid any accumulation of

unburned gas. Wait 90 seconds before re-igniting an extinguished gas burner

Ignition by Spark Button: Press the valve of the burner you want to

operate and turn the valve in the counter-clockwise direction so that the

knob is in maximum position and with your other hand, press the ignition

button (Figure 16) at the same time. Press the ignition button

immediately, because if you wait, a build up of gas may cause the flame to

spread. Continue pressing the ignition button until you see a stable flame

on the burner.

Figure 16

Page 18

USE OF YOUR PRODUCT

17

Control of the hob burners

The knob has 3 positions: Off (0), maximum (big flame symbol) and minimum (small flame symbol).

After you ignite the burner in maximum position; you can adjust the flame length between

maximum and min. positions. Do not operate the burners when the knob position is between

maximum and off positions.

After the ignition, check the flames visually. If you see yellow

tip, lifted or unstable flames; turn the gas flow off, and check

the assembly of burner caps and crowns (Figure 18). Also,

make sure that no liquid has flown into the burner cups. If

the burner flame goes out accidentally, turn the burner off,

ventilate the kitchen with fresh air, and do not attempt reignition for 90 sec.

When turning the hob off, turn the knob in the clockwise

direction so that the knob shows "0" position or the marker

on the knob points upwards.

Your hob has burners of different diameters. The most economic way of using gas is to choose the

correct size gas burners for your cooking pan size and to bring the flame to minimum position once

the boiling point is reached. It is recommended to always cover your cooking pan.

In order to obtain maximum performance from the main burners, use pots with the following flat

bottom diameters. Using smaller pots than the minimum dimensions stated below will cause

energy loss.

Rapid / Wok Burner: 22-26cm

Semi-rapid Burner: 14-22cm

Auxiliary Burner: 12-18cm

MAX. position

OFF position

Figure 17

MODULATE

MIN. position

Figure 18

Cap

Crown

Spark

Plug

Burner

Cup

4.2 Control of the hob burners

Page 19

USE OF YOUR PRODUCT

18

Make sure that the tips of the flames do not spread out of the outer circumference of the pan, as

this may also harm the plastic accessories around the pan (handles etc.)

When the burners are not in use for prolonged periods, always turn the main gas control valve off.

Do not use cooking containers that protrude from the cookers' table andwhich are likely to

overheat the control levers

.

Warning:

• Use only flat pans and with a sufficiently thick base.

• Ensure that the base of the pan is dry before placing it on the burners.

• The temperature of accessible parts may be high when the appliance is operating. So it is

imperative to keep children and animals out of the reach of the burners during and after

cooking.

• After use, the hob remains very hot for a prolonged period of time, do not touch it and do not

place any object on top of the hob.

• Never place knives, forks, spoons and lids on the hob as they will get hot and could cause

serious burns.

•

!

Figure 19

Page 20

4.3. Control of the electric hobs

USE OF YOUR PRODUCT

19

The appliance is operated by using knob control and the heat stored is confirmed by residual heat indicator

lamp on the vitroceramic surface.

Knob controlled cooker is designed for operating at 6 heat levels:

1 Keeping warm position

2-3 Heating position at low heat

4-5-6 Cooking – roasting and boiling position

Dual heaters have two heating zones. To activate the outer zone of a dual heater, turn the knob to

position once. In this way both outer zones switches on.

To deactivate the outer zone of a dual heater, turn the knob to position once. In this way, both outer

zones switches off.

Residual Heat Functions

After all cooking processes there is some heat stored in the vitroceramic glass called residual heat. The

control can calculate roughly how hot the glass is in the worst case. If the calculated temperature is higher

than + 60 °C, then this will be indicated in the related residual heat indicator lamp. The residual heat

display is shown as long as the calculated heater temperature is > + 60 °C.

After reapplying the supply voltage to the hob control after an interruption of the supply voltage occurred,

causes that the residual heat display flashes, if the corresponding heater had a residual heat of greater +

60 ° C before the power interruption occurred. The display will flash until the max. residual heat time has

expired or the heater will be selected and activated.

Page 21

Warning:

When the operating for the first time or whenever the hotplate has not been used for a prolonged

time it is necessary to eliminate any humidity which may have accumulated around the electrical

elements of the plate by operating the hotplate on its lowest setting for about 20 minutes.

Use only flat pans and with a sufficiently thick base.

Never use a pan with a smaller diameter than of the hotplate.

Ensure that the base of the pan is dry before placing it on the hotplate. While the hotplate is in

operation, it is important to ensure that the pan is centered correctly above the hotplate.

•

•

•

20

USE OF YOUR PRODUCT

!

CORRECT

INCORRECT

circular saucepan base

INCORRECT

saucepan’s base had not settled

INCORRECT

small saucepan diameter

Figure 20

• Never operate the hob without pans on the hotplate.

• The temperature of accessible parts maybe high when the appliance is operating. So it is

imperative to keep children and animals out of the reach of the hotplate during and after the

operation.

• If you note a crack on the hotplate it must be immediately switched off and replaced.

Page 22

USE OF YOUR PRODUCT

21

Place coffee adaptor on the Auxiliary burner grid when small

cookware is used to prevent the cookware from tipping over.

Coffee Adaptor (Optional)

Wok adaptor should be placed on the pan support of wok burner.

WARNING: Using wok pans without wok adaptor may cause the burner

to malfunction.

Please do not use wok adaptor with flat-bottomed saucepans. Likewise,

do not use convex-bottomed saucepans without the wok adaptor.

Wok Adaptor (Optional)

CORRECT

INCORRECT

• To ensure long life, the hotplate must be thoroughly cleaned with appropriate cleaning

products. To avoid rustiness and to keep them new it is recommended to rub the hotplate

lightly with tissue with a small amount of oil. Do not use a steam cleaner.

• After use, the hotplate remain very hot for a prolonged of time, do not touch them and to not

place any object on top of the hotplate.

4.4 Accesorries

• The product already supplied with accessories. You can also use accessories you purchase from

the market, but they must be heat and flame resistant. You can also use glass dishes, cake

molds, special oven trays that are appropriate for use in oven. Pay attention to the using

instructions by the manufacturer of those acessories.

Page 23

22

5. CLEANING AND MAINTENANCE

5.1 Cleaning

Be sure that all control switches are off and your appliance cooled before cleaning your oven. Plug

off the appliance. Check whether they are appropriate and recommended by the manufacturer

before using the cleaning materials on your oven. As they may damage the surfaces, do not use

caustic creams, abrasive cleaning powders, thick wire wool or hard tools. In case the liquids that

overflow around your oven burn, the enameled parts may be damaged. Immediately clean the

overflown liquids.

Cleaning of Your Hob

• Lift up the pan supports, caps and crowns of hob burners.

• Wipe and clean the back panel with a soapy cloth.

• Wash the caps and crowns of hob burners and rinse them. Do not leave them wet, immediately

dry them with paper cloth.

• After cleaning, make sure that you re-assemble the parts correctly.

• Do not clean any part of the hob with metal sponge. It causes the surface be scratched.

• The pan support top surfaces may be scratched in time due to usage. In this case,these parts

may get rusted and it is not a production fault.

• During cleaning of the hob plate, make sure that no water flows inside the burner caps, as this

may block the injectors.

Burner Caps:

Periodically, enameled pan support, enameled covers, burner heads must be washed with soapy

warm water rinsed and dried. After drying them thoroughly, replace them correctly.

Enamelled Parts:

In order to keep them a new, it is necessary to clean them frequently with mild warm soapy water

and then dry with cloth. Do not wash them while hot and never use abrasive powders or abrasive

cleaning materials. Do not leave vinegar, coffee, milk, salt, water, lemon, or tomato juice to remain

in contact with enameled parts for long periods of time.

Stainless Steel:

Stainless steel parts must be cleaned frequently with mildly warm soapy water and a soft sponge

and then dry with a soft cloth. Do not use abrasive powders or abrasive cleaning metarials. Do not

leave vinegar, coffee, milk, salt, water, lemon or tomato juice to remain in contact with stainless

steel parts long periods of time.

Page 24

Cleaning hotplates:

Clean the hotplates with a damp sponge and then dry them by turning them on for a few seconds.

To maintain their appearance, apply a small amount of oil on the surface of hotplates.

The hotplate trim rings can be cleaned with products intended for stainless steel. The rings can

become yellowed as a result of heating. This is normal.

If a hotplate is to be out of use for a long time, apply the special grease periodically.

5.2 Maintenance

Periodically check the gas connection pipe. Even if any simple abnormality is felt, inform the

technical service to have it changed. We recommend the gas connection parts to be changed once

a year. If any abnormality is felt while operating the control knobs of cooker, contact to the

authorized service.

23

CLEANING AND MAINTENANCE

Page 25

6.1 Basic troubleshooting before contacting service

If the electrical ignition/hotplate does not operate :

• The hob may be plugged off, there has been a black out.

If the hotplate does not heat :

• The heat may be not adjusted correctly with hob heater control switch.

The hob burners do not operate correctly :

• Check if the burner parts are correctly assembled(especially after cleaning).

• The gas supply pressure may be too low/high. For appliances working with bottled LPG, the

LPG cylinder may be depleted.

Except these, if you still have any problem with your product, please call to the Authorized

Service.

6.2 Information related to transport

If you need any transport; keep the original case of product and carry it with its original case when

needed to be carried. Follow the transport signs on packaging. Tape the hob on upper parts, caps

and crowns and pan supports to the cooking panels.

If you do not have the original packaging; prepeare a carriage box so that the appliance, especially

external surfaces (glass and painted surfaces) of oven is protected against external threats.

24

6. SERVICE AND TRANSPORT

Page 26

Table

G30 28-30mbar 4,8 kW 345g/h

II2H3+ GB Classe 3

LPG

G30 28-30 mbar

NG

G20 20 mbar

LARGE BURNER

DIA. of INJECTOR (1/100mm) 85 115

NOMINAL RATING (KW) 3 3

CONSUMPTION 218,1 g/h 285,7 l/h

MEDIUM BURNER

DIA. of INJECTOR (1/100mm) 65 97

NOMINAL RATING (KW) 1,75 1,75

CONSUMPTION 127,2 g/h 166,7 l/h

25

FR

Page 27

The symbol on the product or on its packaging indicates that this product

may not be treated as household waste. Instead it shall be handed over to

the applicable collection point for the recycling of electrical and electronic

equipment. By ensuring this product is disposed of correctly, you will help

prevent potential negative consequences for the environment and human

health, which could otherwise be caused by inappropriate waste handling of

this product. For more detailed information about recyling of this product,

please contact your local city office, your household waste disposal service or

the shop where you purchased the product.

Page 28

INSTRUCTIONS DE FONCTIONNEMENT

ET D'INSTALLATION DU PLAN DE

CUISSON ENCASTRABLE

FR

OCEACPM2G2V

Page 29

Chère cliente, cher client,

Notre objectif est de vous offrir des produits de qualité supérieure qui vont au-delà

de vos attentes. C'est pourquoi nous les fabriquons dans des infrastructures

modernes soigneusement et particulièrement testées pour leur qualité.

Ce manuel contient toutes les informations nécessaires à l'utilisation de cet appareil

conçu avec une technologie de pointe, en toute confiance et efficacité.

Avant de commencer à utiliser votre appareil, nous vous suggérons de lire ce guide

qui contient tous les renseignements de base pour une installation correcte et fiable,

l'entretien l'utilisation du produit. Veuillez contacter le service agrée le plus proche

pour procéder à l'installation de votre appareil.

Déclaration de conformité CE

Cet appareil a été conçu pour être utilisé uniquement à des fins de cuisson

domestique. Toute autre forme d'utilisation (le chauffage d'une pièce par exemple)

est inappropriée et dangereuse.

Cet appareil a été conçu, construit, et commercialisé conformément aux :

Consignes de sécurité de la directive 2009/142/CE portant sur le « gaz » ;

Consignes de sécurité de la directive 2006/95/CE portant sur la « basse tension »;

Consignes de sécurité de la directive 2004/108/CE portant sur l' « EMC » ;

Consignes relatives à la directive 93/68/CE.

•

•

•

•

Page 30

1

Remarque: Tous les chiffres figurant dans le manuel sont illustratifs.

TABLE DES MATIÈRES

1. BRÈVE PRÉSENTATION DU PRODUIT

2. AVERTISSEMENTS

3. INSTALLATION ET PRÉPARATION À L'UTILISATION

3.4 Conversions des gaz

4. UTILISATION DE VOTRE FOUR

4.1: Utilisation des brûleurs

4.2

4.3

5. NETTOYAGE ET ENTRETIEN

5.1 : Nettoyage

5.2: Entretien

6. SERVICE APRES-VENTE ET TRANSPORT

6.2:Informations relatives au transport

3.1:Environnement d'installation de l'appareil

3.2: Installation de l'appareil

3.3 Raccordement au gaz

3.5 Branchement électrique de votre table de cuisson

Commande des brûleurs de la table de cuisson

Commande des brûleurs des plaques électriques

6.1:Dépannage de base à effectuer avant de contacter le service Clients

4.4 Accessoires

Page 31

1.BRÈVE PRÉSENTATION DU PRODUIT

* Votre plaque peut être différente du modèle présenté ci-dessus à cause de

sa configuration.

1 -

2 Brûleur semi-rapide

3- Brûleur auxiliaire

4 Brûleur rapide

5-boutons de commande

6 - Chauffage électrique (180 mm)

7 Plan de travail

8-Plateau de support

9-Chauffage électrique (Double 180 mm)

Chauffage électrique (145 mm)

1 4

7

6

3

5

8

2

7

5

3

4

8

9

7

5

2

3

4

6

8

2

Page 32

AVERTISSEMENTS EN MATIÈRE DE SÉCURITÉ

LISEZ ATTENTIVEMENT ET ENTIEREMENT CETTE NOTICE AVANT D’UTILISER VOTRE APPAREIL DE

CUISSON, ET CONSERVEZ-LA AFIN DE POUVOIR LA CONSULTER LORSQUE CE SERA NECESSAIRE.

Cette notice est conçue pour plusieurs modèles. Votre appareil de cuisson n’est peut-être pas

équipé de toutes les caractéristiques décrites dans cette notice. Veuillez contrôler dans la notice

les caractéristiques dans les paragraphes comportant des images.

Consignes de sécurité générales:

• La fabrication de votre appareil de cuisson respecte toutes les normes et réglementations

nationales et internationales en vigueur en la matière.

• Les travaux de maintenance et d'entretien doivent être effectués exclusivement par des

techniciens qualifiés. Les travaux de réparation et d'entretien effectués par des personnes nonqualifiées vous exposent à des dangers. Il est fortement déconseillé de modifier les spécifications

de votre appareil de cuisson de quelque manière que ce soit. Evitez d'effectuer vous-mêmes les

réparations au risque d’être victime d’une électrocution.

• Avant l'installation, assurez-vous que les conditions de distribution locale (nature et pression du

gaz, tension et fréquence de l'électricité) sont compatibles avec les caractéristiques indiquées sur

la plaque signalétique de votre appareil de cuisson. En cas de dommage provoqué par un

branchement ou une installation inadaptée, la garantie ne sera pas valide.

• La sécurité électrique de votre appareil de cuisson n'est garantie que s'il est branché à une

alimentation électrique avec terre, conforme aux normes de sécurité électrique en vigueur. Si vous

n’êtes pas sûr de votre installation électrique avec terre, consultez un électricien qualifié.

• ATTENTION: Votre appareil de cuisson est conçu uniquement pour la cuisson des aliments et il

est prévu uniquement pour un usage domestique. Il ne doit absolument pas être utilisé à d'autres

fins, par exemple, dans un environnement commercial ou pour le réchauffage d'une salle. La

responsabilité du fabricant ne saurait être engagée en cas de dommages liés à une utilisation

inappropriée, incorrecte, ou négligente

• Cet appareil de cuisson ne doit pas être utilisé par des

enfants de moins de 8 ans, ou par des personnes dont les

capacités physiques, sensorielles ou mentales sont

limitées, ou manquant d’expérience ou de connaissances

requises, les empêchant d’utiliser cet appareil de cuisson

sans risque lorsqu’ils sont sans surveillance ou en l’absence

d’instructions d’une personne responsable leur assurant

une utilisation de l'appareil de cuisson sans danger, après

une explication des risques auxquels ils s'exposent. Les

enfants ne doivent pas jouer avec l'appareil de cuisson. Les

3

2.CONSIGNES DE SÉCURITÉ

Page 33

4

AVERTISSEMENTS EN MATIÈRE DE SÉCURITÉ

opérations de nettoyage et d'entretien effectués par des

enfants doivent se faire sous la supervision d'une personne

responsable.

• Cet appareil de cuisson n'est pas connecté à un dispositif de d'évacuation des produits de la

combustion. Il doit être installé et raccordé conformément aux règles d'installation en vigueur. Une

attention particulière doit être accordée aux exigences concernant la ventilation.

• Si au bout de 15 secondes le brûleur gaz ne s'est pas allumé, fermez la manette du brûleur

concerné, ouvrez la porte de la cuisine et attendez au moins une minute avant d'essayer de le

rallumer à nouveau.

• Ces instructions ne sont valides que si le symbole du pays est sur votre appareil de cuisson. Si le

symbole du pays n’est pas sur votre appareil de cuisson, il importe de se référer aux instructions

techniques fournissant les informations nécessaires relatives aux conditions d'utilisation

particulières

MISE EN GARDE : L’appareil et ses parties accessibles

peuvent devenir très chauds durant l’utilisation. Attention à

ne pas toucher les éléments chauffants. Les enfants de

moins de 8 ans doivent être maintenus à l’écart sauf s’ils

sont constamment supervisés. AVERTISSEMENT: Pendant

l'utilisation, tous les éléments accessibles de votre appareil

de cuisson deviennent chauds, et gardent pendant un

certain temps leur température élevée, même quand

l'appareil de cuisson est arrêté. Ne touchez pas les surfaces

chaudes (manettes et poignée du four comprise) et

empêchez les enfants de moins de 8 ans d’approcher de

l'appareil de cuisson. Il est recommandé de laisser refroidir

les parties directement exposées à la chaleur avant de les

toucher.

AVERTISSEMENT: Ne laissez pas votre appareil de cuisson

sans surveillance lorsque vous faites cuire des matières

grasses liquides ou solides, des huiles liquides ou solides.

Portées à très haute température, ces matières peuvent

Page 34

5

AVERTISSEMENTS EN MATIÈRE DE SÉCURITÉ

prendre feu et engendrer un incendie. N'ESSAYEZ jamais

d'éteindre avec de l'eau des flammes provenant d’huile en

feu, mais éteignez votre appareil de cuisson et couvrez la

casserole ou la poêle avec un couvercle, afin d’étouffer la

flamme. Si vous avez une hotte, ne jamais la mettre en

route sans surveillance quand vous faites chauffer de

l’huile. Ne laissez pas de matière inflammable près de votre

appareil de cuisson lorsqu’il fonctionne.

MISE EN GARDE: Danger de feu: Ne jamais placer d'objets

sur la plaque de cuisson. AVERTISSEMENT: Risque

d'incendie: Ne rangez pas d'objets sur les surfaces de

cuisson et ne rangez aucun contenant pressurisé tel que les

aérosols, les matériaux inflammables (objets en papier, en

plastique et en tissu), dans le tiroir placé sous le four ou

sous la plaque de cuisson. Les ustensiles de cuisine en

plastique en font également partie (ainsi que les manches

d’ustensiles).

MISE EN GARDE: Si la surface est fêlée, déconnecter

l'appareil de l'alimentation

pour éviter un risque de choc électrique. AVERTISSEMENT:

Si votre appareil de cuisson est équipé d'un plan de cuisson

en verre (vitro ou induction) et si la surface est fissurée,

mettez les manettes sur "0" pour éviter un éventuel choc

électrique. De même, si des fissures apparaissent sur les

plaques électriques, il est impératif d’arrêter

immédiatement l’alimentation électrique afin de prévenir

toute électrocution.

Page 35

AVERTISSEMENTS EN MATIÈRE DE SÉCURITÉ

6

Il convient d'enlever du couvercle tout résidu de

débordement avant de l'ouvrir. Si votre appareil de cuisson

est équipé d'un couvercle, ce couvercle doit être soulevé

avant la mise en fonction des zones de cuisson. Avant de

refermer le couvercle, il faut s'assurer que l'appareil de

cuisson a bien refroidi. Les couvercles en verre peuvent se

casser lorsqu'ils sont chauffés. Éteignez tous les brûleurs

avant de fermer le couvercle.

Cet appareil n'est pas destiné à être mis en

fonctionnement au moyen d'une minuterie extérieure ou

par un système de commande à distance séparé. Votre

appareil de cuisson ne doit jamais être branché sur une

rallonge, sur une minuterie extérieure, une prise triplite ou

un système de commande à distance séparée ou tout

autre dispositif qui mettrait l'appareil sous tension

automatiquement.

• N'utilisez pas des produits de nettoyage abrasifs, des

crèmes caustiques, des éponges abrasives ou des grattoirs

métalliques pour nettoyer tous les éléments de votre

appareil de cuisson (verre, émail, inox, plastique et

peinture), car cela raierait les surfaces, et pourrait

entraîner l'éclatement des surfaces en verre ou la

destruction des autres éléments de votre appareil de

cuisson. Ne pas utiliser de produits d'entretien abrasifs ou

de grattoirs métalliques durs pour nettoyer

la porte en verre du four, ce qui pourrait érafler la surface

et entraîner l’éclatement du verre.

Page 36

• N'utilisez pas de nettoyeurs à vapeur pour nettoyer votre

appareil de cuisson.

• Toutes les mesures de sécurité possibles ont été prises pour garantir votre sécurité. Pour éviter de

casser les éléments en verre, vous devez faire attention de ne pas les rayer pendant le nettoyage.

Evitez aussi de taper ces surfaces en verre ou de laisser tomber des accessoires dessus, et de

monter sur le verre (dans le cas d’un travail au-dessus de votre appareil de cuisson).

• Ne faites aucune pression sur le fil électrique (si équipé) lors de l'installation de votre appareil de

cuisson. Assurez-vous aussi que la câble n’est pas coincé derrière votre appareil de cuisson. Si le

câble d'alimentation est endommagé, il doit être remplacé par un câble présentant les mêmes

caractéristiques que celui d’origine, et ceci par un technicien qualifié afin d'écarter tout danger.

Avertissements d'installation:

• N'utilisez votre appareil de cuisson que lorsque l'installation est terminée.

• Votre appareil de cuisson doit être installé et mis en service par un technicien qualifié. Le

fabricant décline sa responsabilité pour tout dommage résultant d'un mauvais emplacement ou de

l'installation de votre appareil de cuisson par un technicien non qualifié.

• Après avoir déballé votre appareil de cuisson, vérifiez soigneusement si celui-ci n'a pas été

endommagé pendant le transport. En cas de dommage, ne l’utilisez pas et contactez

immédiatement votre Revendeur. Etant donné que les matériaux d’emballage (polystyrène, nylon,

agrafes, etc...) peuvent être dangereux pour les enfants, veuillez les rassembler et les éliminer

immédiatement (mettez-les dans les conteneurs spécifiques pour le recyclage)

• Protégez votre appareil de cuisson contre les effets atmosphériques. Ne l'exposez pas au soleil, à

la pluie, la neige, la poudre, etc.

• Les matériaux entourant l'appareil (meubles) doivent être capables de supporter une

température minimale de 100°C.

Lors de l'utilisation:

• Ne placez pas de matériaux inflammables ou combustibles à proximité de votre appareil de

cuisson pendant son fonctionnement.

• Ne laissez pas votre appareil de cuisson sans surveillance lorsque vous faites cuire des matières

grasses liquides ou solides, des huiles liquides ou solides. Portées à très haute température, ces

matières peuvent prendre feu et engendrer un incendie. N'ESSAYEZ jamais d'éteindre avec de l'eau

des flammes provenant d’huile en feu, mais éteignez votre appareil de cuisson et couvrez la

casserole ou la poêle avec un couvercle, afin d’étouffer la flamme. Si vous avez une hotte, ne jamais

la mettre en route sans surveillance quand vous faites chauffer de l’huile. Ne laissez pas de matière

inflammable près de votre appareil de cuisson lorsqu’il fonctionne.

• Toujours poser les ustensiles de cuisson au centre de la zone de cuisson et positionner les

poignées de telle sorte qu'elles ne puissent pas gêner ou être attrapées par un enfant.

• N'utilisez pas les zones de cuisson avec des casseroles vides ou sans casseroles.

• Sur les plaques électriques, utilisez uniquement des ustensiles à fond plat.

• Sur les dessus vitro et inductions, ne coupez pas du pain sur le verre. Le plan de travail en verre ne

doit pas être utilisé comme surface de travail. Faites attention de ne pas poser sur la dessus des

récipients qui pourraient abîmer le verre. Des récipients ayant des bords tranchants peuvent rayer

la surface du dessus et l'endommager. Un conseil, essuyez systématiquement le dessous des

casseroles avec un chiffon avant de les poser sur la surface en verre, ceci afin d’enlever des

microparticules sous le récipient, qui risqueraient de rayer le verre.

AVERTISSEMENTS EN MATIÈRE DE SÉCURITÉ

7

Page 37

• Sur les dessus vitro, utilisez uniquement des ustensiles à fond plat.

• Sur les dessus induction, utilisez uniquement des ustensiles à fond plat spécifiques pour l’induction

(indiqué sous l’ustensile par le Fabricant).

• Il est possible que vous entendiez un petit bruit à la mise en marche d’une zone de cuisson.

• Les utilisateurs qui utilisent un pacemaker implanté, doivent tenir la partie supérieure de leur

corps à au moins 30 cm des zones de cuisson à induction allumées.

• Si vous n'avez pas l'intention d'utiliser votre appareil de cuisson pendant une longue période, nous

vous conseillons de le débrancher électriquement. Veillez aussi fermer en même temps le robinet de

gaz (pour les appareils de cuisson à gaz).

• Si vous ne vous servez pas pendant un certain temps des vos plaques électriques, il sera nécessaire

de mettre un peu d’huile dessus afin d’éviter qu’elles ne rouillent (plaque en fonte).

• Assurez-vous toujours que les manettes de commande de votre appareil de cuisson sont toujours à

la position « 0 » lorsque votre appareil de cuisson n'est pas utilisé.

• ATTENTION: L'utilisation d’un appareil de cuisson à gaz produit de la chaleur, de l'humidité, des

odeurs et des produits de la combustion gaz dans la pièce au sein de laquelle est installée votre

appareil de cuisson. Assurez-vous que la cuisine est bien ventilée lorsque l'appareil de cuisson

fonctionne, laissez les ouvertures ouvertes ou bien installez un dispositif de ventilation mécanique

(genre hotte aspirante mécanique. Pour les appareils de cuisson avec énergie électrique, la cuisson

produira aussi de l’humidité et des odeurs. Il sera nécessaire d’installer aussi un dispositif de

ventilation mécanique

• Une utilisation prolongée de votre appareil de cuisson peut nécessiter une aération

supplémentaire, à titre d'exemple l'ouverture d'une fenêtre ou l'augmentation du niveau de la

ventilation mécanique si installée.

Pendant le nettoyage et l'entretien:

• Arrêtez toujours le fonctionnement de votre appareil de cuisson avant le nettoyage ou l'entretien,

en le débranchant, ou en éteignant l'interrupteur principal.

Ne retirez jamais les boutons de commande pour nettoyer le panneau de commande.

• N’utilisez jamais de nettoyeur vapeur pour nettoyer les éléments de votre appareil de cuisson.

DANS L'OPTIQUE DE MAINTENIR L'EFFICACITE ET GARANTIR LA SECURITE DE VOTRE APPAREIL, NOUS

VOUS RECOMMANDONS DE TOUJOURS UTILISER LES PIECES D'ORIGINE ET D'APPELER NOS

REPRESENTANTS EN CAS DE BESOIN.

AVERTISSEMENTS EN MATIÈRE DE SÉCURITÉ

8

Page 38

9

3. INSTALLATION ET PRÉPARATION À L'UTILISATION

.

Cette cuisinière moderne, fonctionnelle et pratique, fabriquée avec les meilleurs pièces et

matériaux, saura répondre à vos besoins sous tous les aspects. Vous devez lire ce manuel afin

de ne pas rencontrer de problèmes dans le futur, et afin de pouvoir obtenir des résultats

satisfaisants. Les renseignements suivants sont les règles requises pour une installation et un

service corrects. Ils doivent particulièrement être lus par le technicien qui doit installer

l'appareil.

Important : Cet appareil doit être installé par un technicien qualifié conformément aux

consignes d'installation prescrites par le fabricant, la réglementation locale en matière de

construction, les codes de l'autorité en charge du gaz, ainsi que les consignes relatives au

câblage électrique

Environnement d'installation de l'appareil

Votre appareil doit être installé et utilisé à un endroit où il y aura toujours une ventilation.

Pendant son fonctionnement, cet appareil nécessite 2m3/h d'air par kw. Il doit y avoir une

ventilation naturelle suffisante pour que le gaz puisse être utilisé dans cet environnement. Le

flux d'air moyen doit entrer par les trous d'air ouverts sur les parois ouvertes vers l'extérieur.

3.1.

!

• Ces trous d'air doivent avoir au moins une section transversale de 100 cm2 efficace pour la

transition de l'air (un trou d'air ou plus peut être ouvert.) Ce(s) trou(s) doi(ven)t être ouvert(s)

pour ne pas être obstrué(s). Ils doivent de préférence être situés tout près du fond et à l'opposé

des fumées qui s'échappent des gaz brûlés qui ont été vidés. S'il s'avère impossible d'ouvrir ces

ventilations à partir de l'emplacement où l'appareil est installé, l'air requis peut également être

obtenu à travers la pièce voisine, pourvu que cette pièce ne soit pas une chambre à coucher ou

un endroit dangereux. Dans ce cas la « pièce voisine » doit également être aérée comme requis.

Echappement des gaz brûlés de l'environnement

Les cuisinières à gaz émettent le gaz brûlé directement vers l'extérieur ou à travers les hottes

d'échappement branchées à une cheminée qui donne directement à l'extérieur. S'il n'est pas

possible d'installer une hotte de cuisinière, installez un ventilateur électrique sur la fenêtre ou le

mur ouvert vers l'extérieur. Le ventilateur électrique doit pouvoir changer l'air de la cuisine 4-5 fois

son propre volume d'air par heure.

Figure 1

Section d'entrée d'

air min. 100cm2

Figure 2

Section d'entrée d'

air min. 100cm2

Page 39

10

INSTALLATION ET PRÉPARATION À L’UTILISATION

3.2: Installation de l'appareil

Il existe quelques facteurs auxquels vous devez prêter attention lors de l'installation de l'appareil.

Soyez très attentif lors de l'installation de l'appareil. Tenez compte des consignes suivantes afin

d'éviter tout problème et/ou toute situation dangereuse.

La cuisinière peut être placée près d'un autre meuble de telle façon que la hauteur du meuble

ne dépasse pas la hauteur de la table de cuisson de la cuisinière

Veillez à ne pas la placer près d'un réfrigérateur, à ce qu'il n'y ait pas matières flammables ou

inflammables comme les rideaux, les chiffons imperméables...etc. qui pourraient prendre feu

rapidement

Prévoyez un espace d'environ 2cm tout autour de l'appareil pour la circulation de l'air

Le meuble proche de l'appareil doit être fabriqué avec un matériel résistant à une température

atteignant 100°C.

Si le meuble de cuisine est plus haut que la table de cuisson, il doit y avoir un espace d'au moins

10cm entre leurs côtés

Les hauteurs minimales entre le support de plateau et les placards et les hottes de cuisine avec

ventilateur sur le produit sont présentées dans la figure 5. Ainsi, la hotte de cuisine doit être à fixée

à une hauteur minimale de 65 cm du support de tableau. S'il n'y a pas de hotte, la hauteur ne doit

pas être inférieure à 70cm

•

•

•

•

•

Figure 5

Min. 60cm

COOKER HOOD

Min. 42cm

Min. 42cm

Min. 65cm(with hood)

Min. 70cm(without hood)

Section d'entrée d'

air min. 100cm2

Carneau de hotte

Section d'entrée d'

air min. 100cm2

Figure 3 Figure 4

Ventilateur électrique

Page 40

11

INSTALLATION ET PRÉPARATION À L’UTILISATION

L'appareil est fourni avec un kit d'installation comprenant un matériel de scellage adhésif, des

supports de fixation et des vis

Coupez les dimensions comme indiqué au schéma 1. Repérez l'aperture sur le plan de travail de

sorte qu'après avoir installé la table de cuisson, les éléments ci-après soient garantis

•

Figure 6

510 mm

Min.

A

490 mm

Min.

B

Min.

100mm

Min.

25mm

580 mm

560 mm

42 mm

Murs du voisinage

Combustible

Non-combustible

A[mm]

60

40

B[mm]

150

50

Si votre appareil a quatre plaques ;

Murs du voisinage

Combustible

Non-combustible

A[mm]

60

40

B[mm]

150

100

Si votre appareil a cinq plaques ;

Page 41

•

•

Appliquez le matériel de scellage adhésif “C” tout autour de l'aperture sur le plan de travail afin

d'épouser les contours du périmètre de l'appareil. Veillez à ce que les raccordements se

chevauchent aux coins et qu'aucun espace ne soit laissé tout au long du matériel de scellage.

Vérifiez le type de supports fournis dans le kit de montage présenté dans les figures 7 et 8 et

continuez en conséquence

Supports de type 1

Insérez l'appareil dans l'aperture et fixez en position à travers les supports (A) et les vis (B).

Ajustez la position des supports en fonction de l'épaisseur du plan de travail comme indiqué à la

figure 7 et serrez les vis uniformément

Supports de type 2

Fixez les supports (A) grâce aux vis (B) sur le couvercle inférieur de l'appareil comme indiqué à la

figure 8. Insérez l'appareil dans l'aperture et exercez une certaine pression sur la table de

cuisson, assurez-vous que l'appareil est bien positionné

12

INSTALLATION ET PRÉPARATION À L’UTILISATION

Figure 7 - Installation avec

Figure 8 - Installation with

Type de support 1

Type de support 2

Type de support 1

Tt

C

B

A

Hob

Plan de travail

t<25mm

B

A

Tt

C

B

A

t>25mm

Type de support 2

Hob

Plan de travail

C

Page 42

INSTALLATION ET PRÉPARATION À L’UTILISATION

13

3.3. Raccordement au gaz

.

Assemblage de l'alimentation en gaz et vérification des fuites

La connexion du gaz doit respecter les standards et la réglementation applicables dans la localité et

sur le plan international. Vous trouverez l'information relative aux types de gaz appropriés et les

injecteurs de gaz appropriés dans le tableau des caractéristiques techniques. Si la pression des gaz

utilisés est différente des valeurs en vigueur dans votre localité, il peut s'avérer nécessaire de

monter un régulateur de pression disponible sur l'alimentation en gaz. Nous vous recommandons

de contacter le service agréé afin d'effectuer ces réglages.

Points à vérifier pendant le montage du tuyau flexible

Si la connexion de gaz a été faite à travers un tuyau flexible relié à l'alimentation en gaz de

l'appareil, elle doit également être fixée par un collier. Connectez votre appareil à la ressource de

gaz avec un tuyau court et durable. La longueur maximale autorisée du tuyau est 1,5m. Le tuyau qui

achemine le gaz vers l'appareil doit être changé (1) une fois par an pour assurer la sécurité.

Le tuyau doit être éloigné des endroits susceptibles de chauffer à des températures excédant 900C.

Le tuyau ne doit pas être tordu ou plié. Il doit être loin des recoins tordus, des objets mobiles, et ne

doivent pas être défaillants. Avant de procéder au montage, vérifiez un éventuel défaut de

production.

Après avoir allumé le gaz, vérifiez tous les tuyaux et points de connexion avec de l'eau ou un fluide

savonneux pour voir s'il y a fuite. Évitez d'utiliser une flamme nue pour vérifier les fuites de gaz.

Aucune composante métallique utilisée pendant la connexion du gaz ne doit être rouillée. Vérifiez

également les dates d'expiration des composantes à utiliser

Points à vérifier pendant le montage du tuyau fixe

Pour procéder au montage d'une connexion au gaz fixe (connexion de gaz effectuée à l'aide d'un

écrou par exemple), il existe différentes méthodes utilisées dans différents pays. Les pièces les plus

usuelles ont déjà été fournies avec votre appareil. Toutes les autres pièces peuvent être fournies en

pièces détachées..

•

Réduisez soigneusement l'excès d'enduit d'étanchéité « C » qui se trouve autour de l'appareil

Important : Si vous comptez faire installer l'appareil au-dessus d'une armoire ou d'un classeur,

il est absolument nécessaire de mettre un séparateur entre le socle de l'appareil et l'unité du

tiroir

!

Page 43

INSTALLATION ET PRÉPARATION À L’UTILISATION

14

Pendant les connexions, assurez-vous que l'écrou de la rampe d'alimentation en gaz reste fixe

pendant la rotation. Pour une connexion sécurisée, utilisez des clés de taille appropriée. Pour toutes

les surfaces existantes entre les différentes composantes, veuillez toujours utiliser les joints fournis.

Les joints utilisés doivent également avoir été approuvés dans une telle opération de connexion de

gaz. Évitez d'utiliser les joints de plomberie pour connecter le gaz.

N'oubliez pas que la connexion de cet appareil au gaz a été prévue dans le pays pour lequel il a été

fabriqué. Le principal pays de destination figure sur le couvercle arrière de l'appareil. Si vous avez à

vous en servir dans un autre pays, n'importe quelle connexion présentée dans l'illustration cidessous peut être requise.

Il est recommandé de contacter le service agréé pour être en mesure d'effectuer les connexions de

gaz de façon appropriée et conformément aux standards de sécurité

ATTENTION! Ne pas utiliser de briquet ou d'allumette pour contrôler les fuites de gaz.

!

Seal

Raccord

pour tuyau

Raccord

pour tuyau

Tuyau à gaz

avec collier

Tuyau à gaz

Figure 9

Seal

Raccord

pour tuyau

Tuyau à gaz

avec collier

Tuyau à gaz

Tuyau à gaz

mécanique

Seal

Raccord

pour tuyau

Tuyau à gaz

Seal

Raccord

pour tuyau

Raccord

pour tuyau

Tuyau à gaz

mécanique

Tuyau à gaz

Tuyau à gaz

mécanique

Raccord

pour tuyau

Tuyau à gaz

Page 44

INSTALLATION ET PRÉPARATION À L’UTILISATION

15

3.4 Conversions des gaz

Attention : Les procédures suivantes doivent être réalisées par un technicien qualifié.

Votre appareil a été conçu pour fonctionner avec du gaz GPL/GN. Les brûleurs peuvent être adaptés

à différents types de gaz, en remplaçant les injecteurs correspondants et en ajustant la longueur de

flamme minimale adaptée au gaz utilisé. Pour cette raison, les étapes ci-après doivent être suivies:

Changement d'injecteurs

Coupez l'alimentation principale en gaz et débranchez la du réseau électrique

Retirez le couvercle du brûleur et l'adaptateur (Figure 10).

Dévissez les injecteurs. Utilisez à cet effet une clé de 7 mm (Figure 11).

Remplacez l'injecteur en utilisant un autre parmi ceux qui ont été prévus dans le kit de

conversion, avec des diamètres correspondants adaptés au type de gaz à utiliser, en fonction du

diagramme d'information (également fourni)

•

•

•

•

Figure 11

Injecteur

Clé

Figure 10

Réglage de la position de flamme réduite :

La longueur de la flamme à la position minimale peut s'ajuster à l'aide d'une vis plate située sur le

robinet. Pour les robinets équipés d'un dispositif d'échec de flammes, la vis se trouve sur le côté de

la tige du robinet (Figure 8-9). Pour les robinets sans dispositif d'échec de flammes, la vis se trouve à

l'intérieur de la tige du robinet (Figure 10). Pour un réglage plus facile de réduction de la flamme, il

est conseillé de retirer le panneau de commande (ainsi que le micro interrupteur, si disponible)

pendant le réglage.

Pour déterminer la position minimale, allumez les brûleurs et laissez-les à la position minimale. À

l'aide d'un petit tournevis, serrez ou desserrez la vis de dérivation de 90° environ. Lorsque la

flamme a atteint une longueur d'au moins 4mm, le gaz est bien réparti. Assurez-vous que la flamme

ne s'éteint pas en passant de la position maximale à la position minimale. Créez un vent artificiel

avec votre main en direction de la flamme pour voir si celle-ci est stable.

Page 45

INSTALLATION ET PRÉPARATION À L’UTILISATION

16

Changement du tuyau d'alimentation en gaz:

Pour certains pays, le type d'alimentation en gaz peut être différent des gaz NG/GPL. Dans ce cas,

enlevez les composantes de connexion actuelles et les écrous (le cas échéant) et connectez la

nouvelle alimentation en gaz en conséquence. Dans toutes les conditions, toutes les composantes

utilisées dans les connections de gaz doivent être approuvées par les autorités locales et/ou

internationales. Dans toutes les connexions de gaz, reportez-vous à la clause intitulée « assemblage

de l'alimentation en gaz et vérification des fuites » expliquée précédemment.

Figure 13

Figure 14

Figure 12

Vanne avec appareil de

contrôle de flamme

Vanne avec appareil de

contrôle de flamme

Vanne sans appareil de

contrôle de flamme

Vis de dérivation

Bypass screw

Vis de dérivation

(à l’intérieur du trou)

Pour une position de flamme, la vis de dérivation doit être dévissée pendant la conversion du GPL

au GN. Lors de la conversion de NG à LPG, cette même vis doit être resserrée. Assurez-vous que

l'appareil est débranché du courant électrique et que l'alimentation de gaz est ouverte.

Page 46

· Avant d'effectuer le branchement électrique, vérifiez si l'alimentation électrique du système

et la prise sont appropriées pour la puissance d'alimentation maximum de la plaque.

· L'installation électrique de la maison et la prise électrique utilisée doivent être reliées à la

terre selon les normes de sécurité

· S'il n'y a aucun circuit dédié à la plaque et aucun interrupteur de fusible, ceux-ci doivent être

installés par un électricien qualifié avant de brancher la plaque.

. L'interrupteur de fusible doit être facilement accessible quand la plaque est installée.

· Adaptateurs, prises multiples et/ou rallonges ne doivent pas être utilisés.

· Cet appareil est conforme aux Directives CEE suivantes :

1. Plaque vitrocéramique CEE/73/23 et 93/68, CEE/89/336 sur l'interférence radio,

2. CEE/89/109 sur le contact avec les aliments

·Un disjoncteur doté d'une ouverture de contact d'au moins 3mm doit être installé à l'intérieur

du circuit électrique.

· Pour le bouton de commande de la plaque vitrocéramique équipé de deux éléments chauffants, le

câble doit être de type H05VV-F 3x1, 5mm ². Pour le bouton de commande de la plaque

vitrocéramique équipé d' un élément chauffant, le câble doit être de type H05VV-F 3X1, 0mm ².

Vous trouverez le schéma de raccordement indiqué sur le bas de l'appareil

INSTALLATION ET PRÉPARATION À L’UTILISATION

17

Figure 15

3.5 Branchement électrique de votre table de cuisson

BL

EU

JAUNE+VER

T

BR

U

N

L

N

Page 47

4. UTILISATION DE VOTRE FOUR

18

4.1: Utilisation des brûleurs

Allumage des brûleurs

Pour savoir quel bouton va avec quel brûleur, vérifiez le symbole de la position au-dessus du bouton

Allumage manuel

Si votre appareil n'est équipé d'aucun accessoire pour l'allumage ou en cas de panne électrique,

suivez les procédures ci-dessous: pour allumer l'un des brûleurs, appuyez et tournez le bouton dans

le sens inverse d'une aiguille de montre afin qu'il soit en position maximale, approchez l'allumette,

la bougie ou tout autre accessoire d'allumage de sa périphérie supérieure. Éloignez la source

d'allumage aussitôt que vous voyez une flamme stable.

Allumage électrique

L'allumage électrique des brûleurs à gaz peut se faire de deux façons, en fonction de la

configuration de votre appareil

Allumage par le bouton de commande du brûleur: Appuyez sur le bouton de commande du

brûleur que vous voulez utiliser et tournez-le dans le sens antihoraire jusqu'à ce que le bouton se

retrouve à la position maximale. Pendant ce temps, maintenez le bouton enfoncé. Les bougies

d'allumage génèreront des étincelles tant que vous maintiendrez le bouton de contrôle appuyé. Le

microrupteur qui se trouve sous le bouton produira automatiquement des étincelles à travers la

bougie d'allumage du brûleur. Continuez à appuyer sur le bouton jusqu'à ce qu'une flamme stable

apparaisse sur le brûleur.

Dispositif de sécurité contre les flammes :

Brûleurs à gaz (Si votre table de cuisson est dotée d'un dispositif de sécurité contre le gaz)

Les tables de cuisson dotées d'un dispositif d'échec de flammes assurent la sécurité lorsque la

flamme s'éteint accidentellement. En pareille situation, le dispositif bloquera les canaux utilisés par

les brûleurs à gaz et évitera toute accumulation de gaz non brûlé. Patientez 90 secondes avant de

rallumer un brûleur à gaz éteint.

•

•

Allumer à l'aide d'allumeur-étincelle : Appuyez sur le robinet du brûleur

que vous voulez utiliser et tournez le bouton dans le sens antihoraire

jusqu'à ce que le bouton se retrouve à la position maximale. Ensuite, avec

l'autre main, appuyez parallèlement sur le bouton (Figure 16) d'allumage.

Appuyez immédiatement sur le bouton d'allumage, parce que si vous

attendez, une accumulation de gaz peut amener la flamme à se propager.

Continuez à appuyer sur le bouton d'allumage jusqu'à ce qu'une flamme

stable apparaisse sur le brûleur.

Figure 16

Page 48

UTILISATION DE VOTRE FOUR

19

Commande des brûleurs de la table de cuisson

La table de cuisson a 3 positions: Off (0), Max (symbole de grosse flamme) et Min (symbole de

petite flamme). Après avoir allumé le brûleur à la position « Max. », vous avez la possibilité

d'ajuster la longueur de la flamme entre les positions « Max. » et « Min. ». Évitez d'utiliser les

brûleurs lorsque le bouton se trouve entre les positions « Max. » et « Off ».

Après l'allumage, procédez à une vérification visuelle des

flammes. Si vous voyez une pointe jaune, des flammes

suspendues ou instables, fermez le robinet à gaz, et vérifiez

au niveau des bouchons et des couronnes (Figure 18). Bien

plus, veillez à ce qu'aucun liquide ne se soit écoulé à

l'intérieur des coupelles de brûleur. Si les flammes du brûleur

s'échappent accidentellement, fermez les brûleurs, aérez la

cuisine avec de l'air frais, et n'essayez pas de rallumer avant

les 90 prochaines secondes.

En fermant la table de cuisson, tournez le bouton dans le

sens horaire jusqu'à ce que le bouton pointe sur « 0 » ou

jusqu'à ce que le marqueur du bouton pointe vers le haut.

Votre table de cuisson a des brûleurs de diamètres différents. Le moyen le plus économique

d'utiliser le gaz consiste à choisir les brûleurs à gaz aux tailles correspondantes à celles des

récipients de cuisson et à ramener la flamme à la position minimale une fois le point d'ébullition

atteint. Nous vous recommandons de toujours couvrir votre récipient de cuisson.

Pour une performance maximale des brûleurs principaux, utilisez les récipients ayant les diamètres