Page 1

Sauna & Steam

Heavy Duty Commercial

STEAM GENERATOR

PRODUCT IMAGE

15.06.17

Oceanic Ltd, Pountney Street, Wolverhampton, WV2 4HX

Phone: 01902 450 550 sales@oceanic-saunas.co.uk www.oceanic-saunas.co.uk

Page 2

Steam Generator Manual

Sauna & Steam

Table of contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4. Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.1. Steam Generator Unit Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.8. Wiring multiple steam generators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.2. Steam Generator Frame Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.3. Clearance distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.4. Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.5. Steam Generator Parts Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.6. Table 2. OC-D Controller Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.7. Temperature Sensor Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6. OC-A Controller Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.1. Generator Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.2. Steam Generator Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.3. Water and Steam Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.4. Installation for controller and temperature probe. . . . . . . . . . . . . . . . . . . . 13

7.5. Installations for power supply and control cable . . . . . . . . . . . . . . . . . . . 13

7.6. Installing a light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8. Steam on Demand Function (Only supplied with commercial generators) . . . . . 14

9. Circuit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10. Testing and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10.1. Setting time and temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10.2. Steam on Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

11. Troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

12.1. Descaling procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13. Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

2

Page 3

Steam Generator Manual

Sauna & Steam

1. Introduction

Thank you for choosing to buy our Oceanic steam generator, please take the time to read these

instructions before you begin as they contain important information about the installation and

maintenance requirements.

“Oceanic” heavy duty steam generators are available in specications from 6kw to 12kw and are

equipped with a programmable thermostatic controller. The controller is set with the time and

day and allows you to program the generator to turn on and o automatically when you require,

the generator can also bet set to clean itself automatically. Once these settings have been saved

the machine can be left to work on it’s own. The machine still must be checked on a regular basis

for safety.

It is also possible to have the generator working o a push button which you place outside of the

steam room, when customers push the button it illuminates and they get 30 minutes of steam.

The machine can also just work on a count down timer for say the next 90 minutes.

Our display tells you everything that the generator is doing, if it takes in water, heats, reached

temperature, draining, descaling, light on, fan on, timer set.

You can also Lock the keys so other users can’t play with the settings. light of the steam room, the

automatic drain valve, key-lock, alter the temperature display between Centigrade and Fahrenheit;

as well as displaying the steam generator‘s status by the 8 LED’s on the panel, heating, water inlet,

temperature, drain status etc. note also that one “OC-D” controller can control multiple “Oceanic”

steam generators.

Every “Oceanic” steam generator is thoroughly tested before leaving the factory so there may be

the remains of water inside the boiler.

2. Important Notes

• Read the manual before installation and operation.

• This Equipment must be installed by competent person.

• This equipment must be connected to an all pole isolator

• Disconnect the power supply before exposing electrical connections.

• Conrm the correct voltage to your steam generator 1 or 3 phase.

• For hard water areas please use a water softener.

• Water supply must have maximum of 1 bar pressure, we recommend the use of a pressure

reducing valve if necessary

3. Safety Precautions

• Elderly persons, pregnant women, or these suering heart disease, high blood pressure,

diabetes or not in good health are advised to seek medical opinion before using a steam room.

• Do not smoke in the steam room.

• Avoid using the steam room immediately after strenuous exercise.

• Do not use the steam room when under the inuence of alcohol.

• Leave the steam room at once if you feel sleepy, sick or uncomfortable.

• Ensure there is good ventilation for the steam room.

• We do not recommend that children under 16 use this product.

• Commercial operators should post a notice of these precautions in a prominent position.

Steam entering the steam room will be scalding hot; take care to position the inlet nozzle

away from where users will sit and/or provide adequate guarding, post a notice to caution

users.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

3

Page 4

Steam Generator Manual

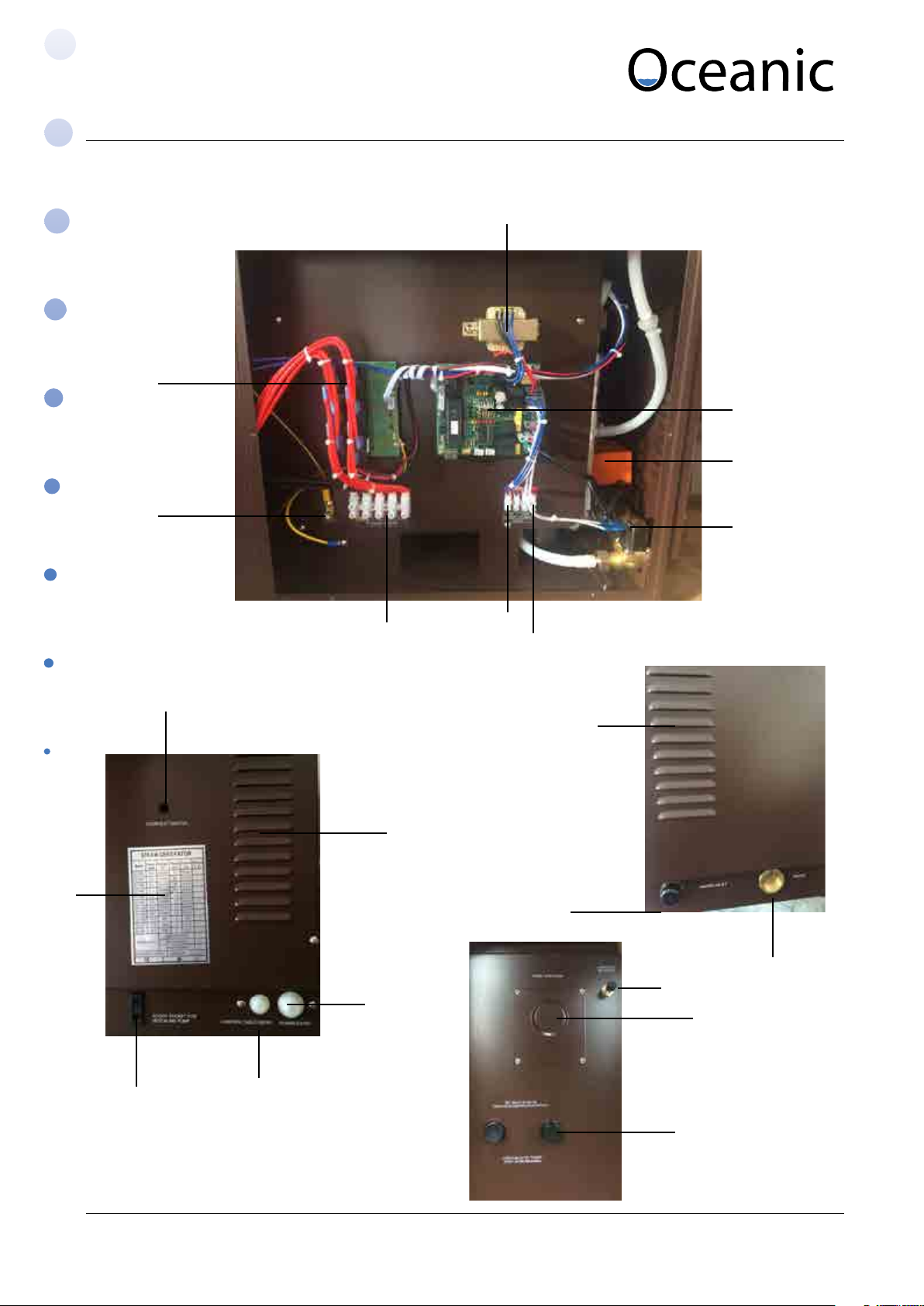

4. Steam Generator Parts

9

Sauna & Steam

1

2

3

15

8

10

7

4

6

5

11

11

17

12

13

14

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

18

16

19

20

4

Page 5

Steam Generator Manual

Sauna & Steam

No. Part Description

1 Transformer 240v - 9v + 12v

2 Main Circuit Board Control Centre

3 Drain Valve 3/4” Motorised Ball Valve

4 Inlet Valve 240v Brass Solenoid Valve

5 Light Connection 230v Light Output Switched by Keypad Max (100w)

6 Fan Connection 230v Fan Output Switched by Keypad Max (100w)

7 Power In Connection Terminal for connection of 230 or 400v power.

8 Earth Connection Earth Connection

9 Relay Circuit Board Electrically operated switches for elements.

10 Overheat switch Boil dry protector operates at 105oC Use Pin to reset

11 Louvers Ventilation

12 Main Power Cable Entry Cable entry and restraint for in coming power.

13 Control lead entry Cable entry for control wire.

14 Descaling Pump

Socket for descaling pump

Connection

15 Information Chart For info on Model, Voltage, Wattage and Ampage.

16 Drain connection 3/4” Female Brass

17 Water In Connection 1/2 Male Brass

18 Acid Inlet Hose Nipple for Silicone Descaling Tube Secure with

cable tie

19 Water Probe Access Water Probe Access Plate

20 Steam Outlets 3/4” male steam outlets. Use brass ttings supplied

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

5

Page 6

Steam Generator Manual

Sauna & Steam

5. Electrical and plumbing connections

A qualied electrician will have no problem installing this system with the provided wiring

schematic and with the help of the circuit diagram mounted inside the respective control unit.

According to the valid regulations, the electrical connection of the steam generator and the

control box has to be carried out by an authorised electrician. In case of a warranty claim, you are

kindly requested to present a copy of the invoice from the electrician.

Model Power Current

(amps)

Size (mm) Steam

outlet

Water

Inlet

Drain Nozzle

Type

Kw 1N~ 3N~ L W H inches inches inches

Steam On Demand

OCD-60 6 26 8.6 535 260 380 3/4 (2of) 1/2” 1/2” Red

OCD-90 9 39 13 535 260 380 3/4 (2of) 1/2” 1/2” Red

OCD-120 12 52 17.3 535 260 380 3/4 (2of) 1/2” 1/2” Red

Temperature Sensor

OC-D Controller

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Descaler Pump

3/4”

Steam outlet

5m DIN cable main

circuit board to

controller

3/4”

Steam Inlet Nozzles

Pressure relief

valve

Steam On Demand

button

6

Page 7

Steam Generator Manual

Sauna & Steam

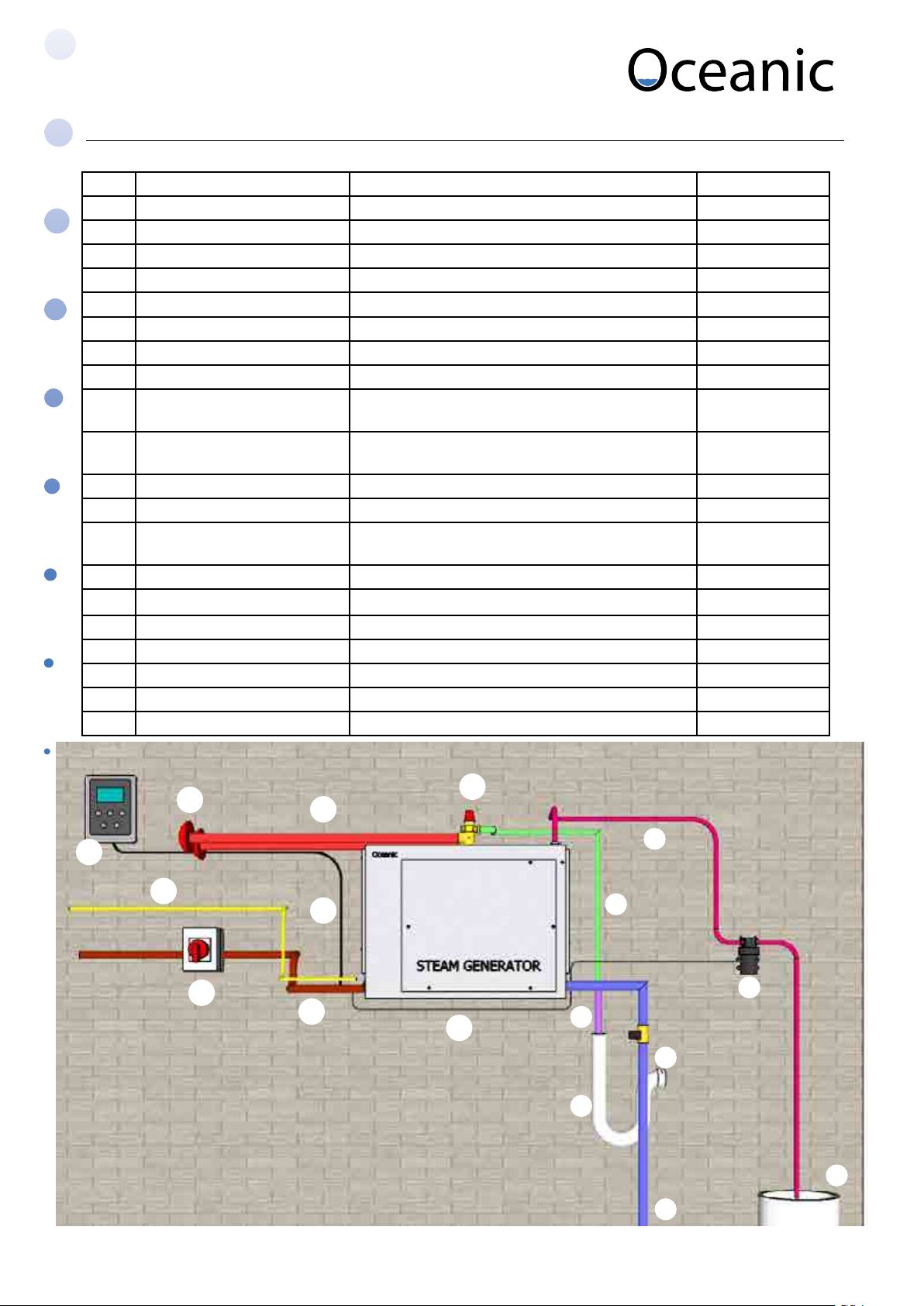

5.1. Connections diagram and table

No. Part Description Supplied

1 Water inlet 1/2 “ copper pipe (maximum pressure 1bar) Not supplied

2 Pressure reducer valve Set to 1bar maximum. Not supplied

3 Washing machine trap Both drain and steam overow feed into Not supplied

4 Drain 3/4” exible hose Not supplied

5 Steam Overow 1/2” copper pipe Not supplied

6 Descaler inlet Flexible silicon pipe secured with cable tie Supplied

7 Descaling pump Pumps descaling solution into generator Supplied

8 Descaling solution container Large plastic container lled with descaling solution Optional 120L

9 Pressure relief valve Operates if the pressure in the boiler exceeds 1.2kg/

c m2

10 Brass T junction 3/4” to 3/4” and 1/2” brass tting to t steam pipe

and pressure relief valve

11 Brass T 3/4” T tting for secondary steam outlet Supplied

12 3/4” female cap To block o secondary steam outlet Not supplied

13 Steam pipe Copper pipe from generator to steam inlet

inside steam room (10m max length)

14 Steam inlet nozzle 3/4” nozzle tted inside steam room Supplied

15 Control cable 5m 6 core cable to control keypad Supplied

16 Control keypad To be mounted inside or outside steam room Supplied

17 Lighting circuit 230V cable to lighting circuit (optional) Not supplied

18 Mains input Single or Three phase supply Not supplied

19 Isolator Switch Mains isolator Not supplied

20 Power to descaler pump 230V power cable for descaler pump Supplied

Supplied

Supplied

Not supplied

14

16

17

19

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

13

15

18

20

11

6

5

7

4

2

3

8

1

7

Page 8

Steam Generator Manual

Sauna & Steam

16

17

18

15

14

19

20

13

5

3

1

6

2

8

Jubilee clip /

cable tie

1

2

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

5

6

Jubilee clip /

20

4

7

3

cable tie

8

Page 9

Steam Generator Manual

5.2. Steam Pipe Connection Options

Sauna & Steam

Option A

Installation with two steam pipes.

Recommended for generators above 9kw

9

10

11

13

13

Important note: Steam outlet must not be reduced

Option B

Installation with one steam pipe

Use a 3/4” female cap to block o the secondary

outlet

13

9

10

12

5.3. Electrical connection schematic

Refer the the circuit diagram on the following page for further details.

230V lighting circuit

Low voltage to

temperature sensor

Low voltage to

Controller

Isolator

switch

Controller

Mains in

230V ~ 1N

400V ~ 3N

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

9

Page 10

Steam Generator Manual

D10

AC230V

AC230V

AC230V

AC230V

AC230V

AC230V

AC230V

AC230V

NL

J12

J13

J14

J15

J16

J17

DRAIN

J18

J9

Fro m Transfor mer

F3AL250V

J11

INPUT

J10

OVERHEAT

J7

D9

J6

TEMP2

D8 D7 D6 D5 D4 D3 D2 D1

NONC

Water Inlet

Hi-Temp Cut Off

(Manual Reset)

Light(Max=100W

V=230AC)

Fan

(V=230AC)

Transformer

Temp2

2

4

D10

AC230V

AC230V

AC230V

AC230V

AC230V

AC230V

AC230V

AC230V

NL

J12

J13

J14

J15

J16

J17

DRAIN

J18

J9

Fro m Transfor mer

F3AL250V

J11

INPUT

J10

OVERHEAT

J7

D9

J6

TEMP2

D8 D7 D6 D5 D4 D3 D2 D1

NONC

Water Inlet

Hi-Temp Cut Off

(Manual Reset)

Light(Max=100W

V=230AC)

Fan

(V=230AC)

Transformer

Temp2

2

4

D10

AC230V

AC230V

AC230V

AC230V

AC230V

AC230V

AC230V

AC230V

NL

J12

J13

J14

J15

J16

J17

DRAIN

J18

J9

Fro m Transfor mer

F3AL250V

J11

INPUT

J10

OVERHEAT

J7

D9

J6

TEMP2

D8 D7 D6 D5 D4 D3 D2 D1

NONC

Water Inlet

Hi-Temp Cut Off

(Manual Reset)

Light(Max=100W

V=230AC)

Fan

(V=230AC)

Transformer

Temp2

2

4

5.4. Circuit Diagram

Sauna & Steam

Note: To use the steam generator in single phase the L1 L2 and L3 must be linked

together with the copper bridges that are supplied

YELLOW/ GREEN

BLA CK

BLA CK

22

L1 L2 L3N

AC400V /3N

LN

AC230V /1N

7-12Kw Steam Generator Circuit Diagram

RED

RED

RED

RED

RED

RED

RED

RED

Tank

H1

H2

JP1

Switch C / F

RED

oo

BLUE

WHI TE

WHI TE

RED

RED

RED

Se nsor

Con troller

4

(V= DC5 V)

Con troller

CONT ROL

PANEL

(V=DC 5V)

4

OC- S

P4

J2

Water Lev el Probe

J8

J7

Hi-Temp Cu t Off

(Manua l Res et)

Temp2

OVERHEAT

TEMP2

J10

J6

D10

D8 D 7 D6 D5 D4 D3 D2 D1

D9

J3

From Mas ter

R-CO NTROL

(V= 230 AC)

Transformer

4

J4

TO SLAVE

AC power ad apter

(AC 230V /D C24V)

Fan

2

F3AL250V

J9From Trans former

2

3

Des cale Li quid

Inl et Pu mp

Lig ht( Max=10 0W

V=230AC)

AC230V

L

N

INPUT

J11

J12

AC230V

J13

AC230V

Water Inle t

J14

AC230V

J15

AC230V

J16

AC230V

DRAIN

J17

AC230V

NONC

J18

AC230V

Dra in

Valve

Water Inle t

Valve

2

5.5. Wiring Multiple Generators

If greater power is required one OC-D controller may be used to control two or more steam

generators, e.g. if you need a 24KW steam generator you can use one OC-D controller to control

two 12kw steam generator or three 10kw steam generators.

J4

TO SL AVE

R-C ONTR OL

J3

Fro m Master

J4

TO SL AVE

R-C ONTR OL

J3

Fro m Master

J4

TO SL AVE

To next slave

Master Slave 1 Slave 2

R-C ONTR OL

J3

Fro m Master

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

10

Page 11

Steam Generator Manual

6. Parameters

6.1. Steam Generator Frame Sizes

Model A B C D E F

OCD - 60 535 260 380 25 135 45

OCD-90 535 260 380 25 135 45

OCD-120 535 260 380 25 135 45

E

F

Sauna & Steam

C

D

A B

6.2. Clearance distances

>300mm

>500mm

>200mm

>400mm

6.3. Ventilation

Ensure air ow into area where steam generator is housed.

For commercial use ensure good ventilation from at least two ducts within the housing of the

generator

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

11

Page 12

Steam Generator Manual

6.4. Table 2. OC-D Controller Parameters

Sauna & Steam

Model Temperature

O

(

C)

o

OC-D 30 - 60

C 155 x 115 x 20

Dimension

(mm)

6.5. Temperature Sensor Parameters

MODEL Detected Scope Max Cut out

Size (mm)

Temperature

o

C

o

F

o

C

o

F L W H

OC-S 0-110 32-230 60 248 76 42 27

Diagram to show location of temperature sensor and steam inlet nozzle

Temperature sensor

1800mm

>500mm

Steam nozzle

300mm

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

12

Page 13

Steam Generator Manual

Sauna & Steam

7. Installation

• Isolate the power supply before installation

• Conrm the model you have selected is suitable for your steam room, please refer to chart

below

• Mount the steam inlet nozzle approximately 300mm up from the oor and it should be at least

200mm from person’s body.

• If the steam generator is installed in an inaccessible place ensure that both the electrical

power and water supply can be isolated in an emergency.

• To use the steam generator in single phase the L1 L2 and L3 must be linked together with the

copper bridges that are supplied. See circuit diagram on page 9.

• The minimum water inlet pressure is 0.25 bar (2.5 Mpascals) and the maximum is 2 bar (20

Mpascals), for pressures in excess of this use a reducer before the valve as shown in diagrams

on page 6 and 7.

• The steam pipe from steam generator to steam room should be kept to a minimum, pipes

longer than 3 meters should be insulated to prevent heat loss. Steam pipes will be hot during

use and must be protected against accidental contact. Steam entering the steam room will

be scalding hot; take care to position the inlet nozzle away from where users will sit and/or

provide adequate guarding, post a notice to caution users.

• Keep the number of right angle bends to a minimum and ensure that the run does not create

a trap into which condensate would gather and cause a blockage I.e. the pipe must not go

down and then up.

• There must be no valve or other blockage in the steam pipe

• The steam pipe should be metal of other material that can endure 150°C temperature, copper

pipe is recommended.

• It is not recommended to install the steam generator outdoors or where it might be aected

by frost. Allow for a minimum space of 0.5 cubic meters to install the generator.

• Steam generator should be level side-to-side and front to back and should be installed so that

the arrows on the case point up.

• Do not install the steam generator in close proximity to hazardous substances.

7.1. Generator Size

The table opposite should be referred to for guidance only.

Please note that the size of generator required to heat a

particular size of steam room will vary according to a number

of factors including the type of material used for construction,

the height of the steam room and the ambient temperature.

For lightweight materials such as plastics and laminates 1 KW will

heat up to 1 cubic meter of air for dense materials such as stones

and ceramics which will conduct the heat away more rapidly allow

for up to 2KW per cubic meter of air. Hot air rises so restricting

the height to around 2 meters will ensure the user is sitting in the

steam for higher ceilings you may need to increase the power

requirement.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Generator Model Steam Room

Volume (m

OC-60 4.5 - 6

OC-90 6 - 10

OC-120 8 - 12

OC-150 11 - 15

3

13

)

Page 14

Steam Generator Manual

Sauna & Steam

7.2. Steam Generator Location

The steam generator should be installed in dry well ventilated place in close proximity to the steam room. It

can be placed on the oor or hung on wall.

To hang the generator on a wall drill 3 holes 8mm in diameter in accordance with the table below. Fix the top

2 screws in place rst then hang the generator by the 2 keyhole shaped holes in the back plate. Then with the

front cover removed x the 3rd screw to secure the unit in place.

465mm

The steam generator can be installed anywhere that is dry and has an airow.

Example locations:

• Plant Room

• Cupboard in an adjacent room

• In the loft

• Up to 1.5m beneath the unit in a basement

Important notes:

• The steam pipe should be insulated and not travel further than 10 metres

• Do not reduce size of steam pipe at any point

• the steam pipe must not go down and then up, as this will create a trap and damage the

steam generator.

<10m

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

14

Page 15

Steam Generator Manual

Sauna & Steam

7.3. Water and Steam Connections

i. The water supply pipe and steam pipe should comply with local standards

ii. Connect the water inlet valve of the generator to the mains water supply using a exible

hose with 1/2 inch ttings.

iii. Steam outlet (1/2 inch or 3/4 inch) use the same dimension copper pipe to connect it, if the

steam pipe is longer than 5 meter it should be insulated. During use the steam pipe will

be very hot and must be protected against accidental contact. Note that according to the

location it may be necessary to attach an additional length of pipe to the pressure relief valve

in order to divert the steam ow to a safe direction should the valve operate.

iv. Connect the drain outlet to a suitable drain via a copper pipe with the appropriate ttings.

7.4. Installation for controller and temperature probe.

OC-D controller is waterproof and can be installed inside or outside the steam room according

to customer preference.

i. For a better connection and to eliminate any future connection problems spray connection

uid or aerosol oil spray on the pins of the PS/2 cable(5pin cable) before plugging into the

circuit board.

ii. Ideally the control panel should be installed at a height of approximately 1200mm for ease of

use.

iii. Installation method: Open the front cover of steam generator. Pin the control cable (6 cores)

and temperature sensor cable (2 cores) to the relevant ports.

iv. Control panel installation: pin one end to circuit board ports in steam generator connect the

other end to the controller’s cable.

v. Temperature probe installation: the temperature probe is installed inside the steam room at

approximately 1.2 to 1.5 meters high and away from the steam outlet. Use a 4mm screw x it

in place and then connect to the wire from the controller.

vi. Fix protective cover (supplied) over the temperature

Temperature Sensor

4mm Screw

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

Cover to protect the temperature sensor

15

Page 16

Steam Generator Manual

Sauna & Steam

7.5. Installations for power supply and control cable

Conrm the correct voltage of power supply and wires.

Remove the knock out for the power cable entry and use a rubber grommet to protect the cable,

connect to the conductors to the correct terminals – for single phase power supply use the copper

bridge connectors, for 3 phase supply remove them. (Extra bridges can be found it provided)

Remove the knock out for the control cable entry and use a rubber grommet to protect the cable,

connect the cable to the relevant port on circuit board.

Ensure the power supply wire and control cable remain separated to prevent magnetic eld of

power supply wire from disturbing control cable signal.

7.6. Installing a light

There is a 230v power supply inside the steam generator labelled “Light”. This is rated to 100w

Max. The button on the keypad will turn this power supply o and on. This power supply is

protected by a fuse on the main circuit board but you can add your own fused spur for extra

protection if you prefer.

7.7. Installing a Fan

Same as above for a light.

7.8. Connecting to descaler

i. OCD Generator is able to run automatically descale cycle by pumping descaling solution

directly into the tank. This can be set to occur at regular intervals using the contoller as

described on page 20.

ii. The pump supplied should be connected via silicon hose to the generator and the container

of descaling solution.

iii. The diagram on pages 6 and 7 show how the descaling solution should be connected via the

pump. Ensure the the ends of the hose are held in place with cable ties.

iv. Both descaling crystals and 120 litre container can be purchased from Oceanic-Saunas.co.uk

8. Steam on Demand Function

Commercial operators may wish to take advantage of the steam on demand function which

will allow customers to press the steam on demand button located inside or outside the steam

room after which the generator will create steam for 30 minutes then return to an idle state until

activated again. This function reduces running costs and frequency of maintenance.

See instructions on page 19 for how to set up the function on the OCD Controller.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

16

Page 17

Steam Generator Manual

9. Programmable Controller User Instructions

9.1. Display and Buttons

1 Time 24hr

2 Heat Symbol

3 Current Temperature In Room

4 Work Mode e.g Normal, SOD, Auto

5 Centrigrade or Farienheit

6 Set Temperature Has Been Reached

7 Descale Cycle On

8 Draining

9 Water Needed, Filling - Valve Open

If ashing - No Water Supply

10 Generator Has Overheated

Sauna & Steam

11 Fan On

15

16

17

12 Light On

13 Keypad Locked

14 Auto Timer Set

15 Fan On / Decrease (-)

16 Setting

17 Drain (Must Be O) / Increase (+)

18 Light On / Left Scroll

19 Machine On/O / Right Scroll

1918

9.2. Turning On/O

When power has been switched on to the machine the keypad will sound a short beep to indicate that it has

been powered up.

To turn on push

You should now see the default display which should look like this.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

17

Page 18

Steam Generator Manual

Sauna & Steam

9.3. Time and Day

Push push until you reach Push for ok

You can now use the increase and

decrease, left and right buttons to

set the hours, minutes and day.

9.4. Setting Temperature

i. You can set the temperature between 35 and 600C and between 95 and 1400F.

ii. If you are a novice user we advise to start at around 38oC and when you are comfortable with this

temperature start to increase slowly by 1oC between each bathing session.

Increase

Push

Push

Push

or

to enter

setting

to enter

temperature

settings

to save

Decrease

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

18

Page 19

Steam Generator Manual

9.5. Working Modes

Sauna & Steam

i. Mode A - This is a count

down timer. You can set

for upto 4 hours or for

continuos heating.

iv. Mode B - Steam On

Demand. (Commercial

only) Install a button

outside of the steam

room, when a customer

pushes the button they

get 30 minutes of steam.

With steam on demand

you only need to set the

temperature of the room.

When the red button is

push it will illuminate to let

users know the generator

is working. Once set the

home screen should look

like this.

v. Mode Auto - Program specic

times for the generator to

turn on and o throughout

the day. Once setup machine

will remember to turn on

or o at these same times

everyday.

ii. Change the time using

the up and down keys.

Press

to save the

setting

vi. You can choose in the morning from between 0.00 - 12:00

noon. And in the afternoon from 12:00 - 23:59.

vii. To activate morning(1) or afternoon(2) change the X to a Tick,

iii. Once set the home screen

should look like this.

now set the time you want the machine to turn on and o. As

you can see above we have set from 6 to 12 in the morning

and from 12 noon to 23:55 at night.

viii. Once setup the home screen

should look like this.

ix. If you isolate power to the

machine it will forget your

settings and go back to

default.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

19

Page 20

Steam Generator Manual

Sauna & Steam

9.6. Auto Descale

i. Set the machine to automatically descale itself once per week. Once set the machine will

descale itself at the same time every week.

ii. The descaling solution will still need to be topped up, our 120 litre drums will do about

10 descales before relling with acid. Mix 5kgs of acid for the whole 120 litres of acid or

around 40-50gs of acid per litre.

iii. For some operators is may not be neccessary for you to be descaling the generator every

week as you may not be in a hard water area or you may only be operating the machine

for a few hours per day. In this case we advise not to have the machine set up for a regular

descale and to only turn the descaling cycle on when you need it. You must remember

though that once the cycle has been completed you must turn the Tick to a X to turn the

weekly descale o.

Push

To setup

descaling push

to enter

iv. The default is Sunday between midnight 00:00 and 8:00 in

the morning.

v. To activate descale change the X to a Tick.

vi. You can also adjust the day and time that the descale will

operate. We advise a minimum of 4 hours.

vii. Note the screen must be turned o for the descale cycle to

run.

9.7. Drain

i. You won’t ever really need to drain the machine as it automatically drains itself. While steaming

the generator will drain out the water so that there is never a concentrated solution of limescale

in the tank. It will also completely drain and ush itself after it has been turned o. (not isolated)

ii. To drain the machine you rst need the screen to be o, so if it is already on push the On/o

button to turn it o. Now push the Drain button, scree will illuminate and indicate the drain

symbol as shown below on the right.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

20

Page 21

Steam Generator Manual

Sauna & Steam

9.8. Light and Fan

i. The light and fan will stay on if the keypad is o, so that if you use the room as a shower the light

can still remain on.

ii. To turn the fan or light on or o just push the button with the light or fan symbol.

iii. The Light has maximum load of 100watts, the Fan has a maximum load of 100watts.

9.9. Screen Lock

i. To lock the screen push the ‘+” button for 5 seconds.

ii. When the controller is locked the ‘light’ button and ‘on/o ‘ button will still be functional.

10. Troubleshooting guide

Please note that we recommend all repairs are carried out be a suitably qualied person.

Trouble description Cause

Something is wrong with:

No Steam Settings not correct

Connection

Power supply

Transformer.

Main circuit board controller

Control cable or port

Connection

Fuse

Water coming out of steam

nozzle.

Circuit breaker tripping

out.

Temperature window

displays “LC”

Temperature window

display “HC”

Water runs through steam

nozzle in room.

Generator works when

switched o on the control

panel.

Filling symbol is ashing Check water supply

Overheat symbol Overheat sensor tripped

Water Level Probe Remove and clean water level probe

Element failure

Loose Earth Wire

Faulty connection

The temp sensor connection 1. Check connection or change temp sensor.

Temp sensor is short circuit. 1. Check connection or change temp sensor.

Water inlet valve.

Level sensor.

Relays 1. Replace relay PCB.

within generator

Solution

Has the control been set up correctly, follow user guide

page 19.

Is water light on - check water supply - check valve coil

for continuity.

Remove and clean water level probe with emery cloth

Descale machine

Check fuse

Check power output from transformer

Replace Main PCB

Check connections to and from water level probe

Check water pressure is <1bar

1. To check elements use a insulation tester, or fault nd

by disconnecting individual elements one by one.

2. Check earth connections are tight.

3. Check drain valve

4. If above fails, return generator to supplier for repair,

guarantee information below.

2. If above fails replace sensor.

2. If above fails replace sensor.

1. Turn machine o, if water continues clean inlet valve

or replace.

2. If runs while machine is on try above if fails clean

water probe and check connection to circuit board.

Clean probe and descale

Reset Overheat button manually on the side of

the generator (see page 4 - part No.10) using small

screwdriver through hole. If in doubt remove casing to

reset

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

21

Page 22

Steam Generator Manual

Sauna & Steam

11. Maintenance

The single biggest problem with steam generation is the build up of scale resulting from

dissolved solids within the water. Scaling can cause the elements to fail, the water level sensors

not to function, premature failure of the O-rings resulting in leaks from around the elements. The

extent of the problem will vary according to the degree of hardness in the local water supply.

For all commercial operators we recommend the use of a water softener.

Expect 2500 hours element life, this can be serious depleted by poor maintenance.

All users commercial and domestic must ensure a regular maintenance routine to descale

the generator – the frequency of this will vary according to the degree of hardness in the

local water supply and the amount of time the generator is used for. Check the water for

hardness and arrange the descaling routine accordingly: High levels of hardness descale once every 50 to 100 hours of operation.

Medium levels of hardness descale once every 100 to 250 hours operation.

Low levels of hardness descale once every 250 to 1000 hours of operation.

To descale the generator use a solution of weak acid crystals (such as citric acid) mixed with

water

Citric acid can be purchased from:

www.thebathingplace.com

www.oceanic-saunas.eu

12. Guarantee

All generators are guaranteed for 12 months for domestic and commercial use from the date of

purchase. This guarantee excludes consumable items such as the electrical elements and failures

resulting from misuse or abuse such as a not descaling the machine.

If you are using the generator for more than 20 hours a week in a hard water area without a

water softener your guarantee will be invalidated.

If you encounter any diculty with this assembly procedure or think we could have explained

anything more clearly we would welcome your comments, please call T: 01902 655425 or T:

01902 871127 technical help line.

Oceanic Saunas 01902 450 550 sales@oceanic-saunas.co.uk

22

Loading...

Loading...