Page 1

FEATURES AND USE

WARNING: Improper use of Dive Instruments may result in serious

injury or death. Read and understand these instructions thoroughly

before you dive with any Oceanic Analog Instrument.

Oceanic Instruments should not be used by anyone who has not re-

ceived proper training and certification in scuba diving.

Oceanic promotes responsible diving practices.

Never spray aerosols of any kind on, or near , an Instrument. Pr o-

pellants may chemically attack the plastic.

Never poke any object through slots or holes on the rear of the In-

strument. Doing so may damage mechanism resulting in inaccurate

readings.

Never attempt to disassemble an Instrument Module for any rea-

son.

SLIMLINE PRESSURE GAUGE:

Maximum Pressure = 5,000 psi (350 BAR)

Temperature = 0 to 100°F (-5° to 45°C)

Thread Size = 7/16 - 20 UNF

Attachment of the high pressure Hose to the Regulator First Stage should be performed

by your Authorized Oceanic Dealer. If this is not possible, proceed as follows:

Locate your Regulators high pressure Port (marked HP) and remove the Port Plug.

If there is more than one HP Port Plug, determine proper orientation of the First

Stage on the tank before selecting a Port.

Place a small dab of halocarbon based lubricant (Christo-Lube MCG 111) on the

hose end threads and o-ring.

Thread the Hose into the HP Port and tighten until secure (35 to 40 inch pounds).

To test the connection, attach the Regulator to a full Tank, pressurize the system,

and listen for leaks.

WARRANTY

Refer to the Warranty Registration Card provided by your Authorized Oceanic Dealer.

ANNUAL INSPECTION

Once each year, return the Gauge(s) to your Authorized Oceanic Dealer for inspection.

The authorized dealer service technician will inspect the gauges, verify accuracies, and

replace the Pressure Gauge High Pressure Swivel (Air Spool). Note that the cost of in-

spection is not covered by the product's limited warranty.

POST DIVE MAINTENANCE

After each day of diving:

Immerse the instrument in fresh water (warm water is best).

Soaking for one hour minimum is best.

Flush with running fresh water, flushing any holes or slots on the rear of the Instru-

ment Boot.

T owel dry before transporting or storing.

Keep out of direct sunlight.

Transport in a padded carrying case or equipment bag separated from heavy

items (i.e., first stage) that might

damage the instrument face. Do Not transport in the hot trunk of a car.

Store in a cool, dry place.

R

R

E

E

S

V

P

I

O

D

N

E

S

L

I

B

© 2002 Design 1998 Doc. No. 12-2124-r05 (4/19/06)

Always keep the Pressure Gauge dial away from your face when

turning on your tank valve.

Never obstruct the one-way vent valve located on the back side of

the Gauge.

Never attempt to remove the Hose Coupling from the Pressure

Gauge Module.

MAX DEPTH GAUGE:

The Black Needle with the Red Tip indicates Current Depth and as depth increases it

pushes the thinner Needle. As depth decreases, the Black Needle with the Red Tip con-

tinues to indicate Current Depth while the thinner Needle remains at the Maximum

Depth reading achieved.

To reset the Max Depth (thinner) Needle for a new dive, turn the slotted Knob located in

the center of the gauge face counter clockwise until it just makes contact with the Black

Needle with the Red Tip.

Never obstruct the Depth Sensor opening located on the back side

of the Gauge.

COMPASS:

The Compass has a luminous card (instead of a needle) that allows use of either the

relative or bearing methods of navigation. A side window with numeric heading assists

you in keeping on course. See your Authorized Oceanic Dealer for more information

about Navigation courses or Navigation methods.

ANALOG INSTRUMENT

(Pressure Gauge, Depth Gauge, Compass)

Owner's Guide

and

Boot Installation/Removal Instructions

for

Analog Instruments and Dive Computers

NOTE: This information does not apply to the SWIV or V eo line.

Page 2

INSTALLATION/REMOVAL INSTRUCTIONS

INSTRUMENT BOOT

REMOVAL OF INSTRUMENTS FROM WRIST BOOTS:

Peel the lips of the Boot downward off the Module while applying pressure from

underneath, working the Module out slowly.

Only if necessary and using extreme care not to damage the instrument case, in-

sert a blunt screwdriver down between the Boot and the Module until the tip rests

just underneath the Module.

DO NOT pry the Module from the Boot! Slowly increasing pressure under the

Module will cause it to slide up the screwdriver and out of the Boot.

INSTALLING INSTRUMENTS IN WRIST BOOTS:

Orient the Module over the cavity in the Boot and dip the bottom edge into the

cavity while pressing the top edge with the palm of your hand. Stop pressing

when the bottom ridge of the Module has just entered the Boot.

Correct the alignment of the Module as needed so that it is straight.

Press the Module completely into place, watching the alignment, until it snaps into

the Boot.

NOTE: The Removal Procedures for the Navcon and Combo style

Consoles are similar. Remove the Compass (or Slate) first, then the

Pressure Gauge, then the Depth Gauge (or Dive Computer module).

If the Console is rigid (Versa style), do not attempt to bend it during

these procedures.

REMOVAL OF INSTRUMENTS FROM NAVCON AND COMBO BOOTS:

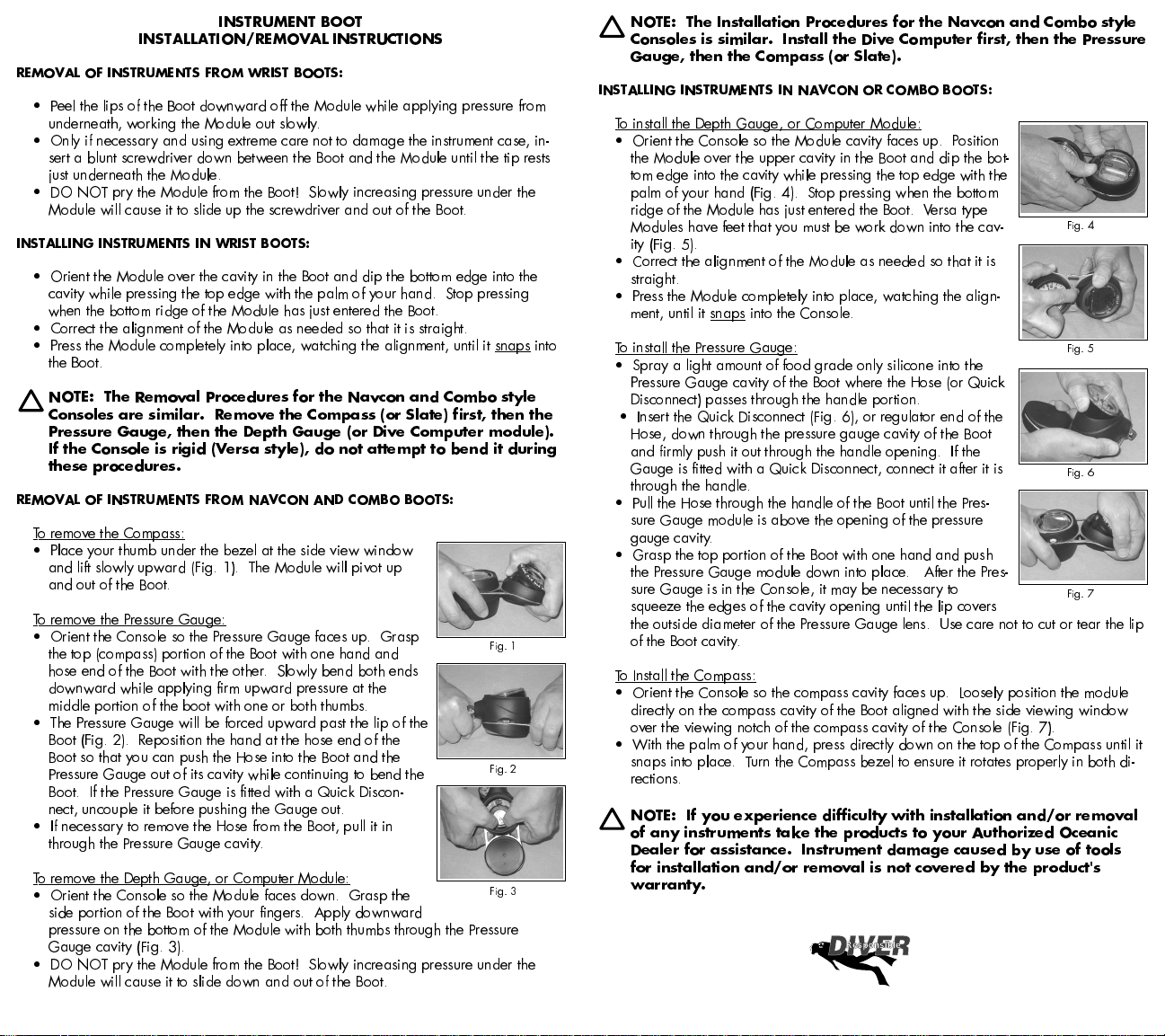

To remove the Compass:

Place your thumb under the bezel at the side view window

and lift slowly upward (Fig. 1). The Module will pivot up

and out of the Boot.

To remove the Pressure Gauge:

Orient the Console so the Pressure Gauge faces up. Grasp

the top (compass) portion of the Boot with one hand and

Fig. 1

hose end of the Boot with the other. Slowly bend both ends

downward while applying firm upward pressure at the

middle portion of the boot with one or both thumbs.

The Pressure Gauge will be forced upward past the lip of the

Boot (Fig. 2). Reposition the hand at the hose end of the

Boot so that you can push the Hose into the Boot and the

Pressure Gauge out of its cavity while continuing to bend the

Fig. 2

Boot. If the Pressure Gauge is fitted with a Quick Discon-

nect, uncouple it before pushing the Gauge out.

If necessary to remove the Hose from the Boot, pull it in

through the Pressure Gauge cavity.

To remove the Depth Gauge, or Computer Module:

Orient the Console so the Module faces down. Grasp the

Fig. 3

side portion of the Boot with your fingers. Apply downward

pressure on the bottom of the Module with both thumbs through the Pressure

Gauge cavity (Fig. 3).

DO NOT pry the Module from the Boot! Slowly increasing pressure under the

Module will cause it to slide down and out of the Boot.

NOTE: The Installation Procedures for the Navcon and Combo style

Consoles is similar. Install the Dive Computer first, then the Pressure

Gauge, then the Compass (or Slate).

INSTALLING INSTRUMENTS IN NAVCON OR COMBO BOOTS:

To install the Depth Gauge, or Computer Module:

Orient the Console so the Module cavity faces up. Position

the Module over the upper cavity in the Boot and dip the bot-

tom edge into the cavity while pressing the top edge with the

palm of your hand (Fig. 4). Stop pressing when the bottom

ridge of the Module has just entered the Boot. Versa type

Modules have feet that you must be work down into the cav-

Fig. 4

ity (Fig. 5).

Correct the alignment of the Module as needed so that it is

straight.

Press the Module completely into place, watching the align-

ment, until it snaps into the Console.

To install the Pressure Gauge:

Fig. 5

Spray a light amount of food grade only silicone into the

Pressure Gauge cavity of the Boot where the Hose (or Quick

Disconnect) passes through the handle portion.

Insert the Quick Disconnect (Fig. 6), or regulator end of the

Hose, down through the pressure gauge cavity of the Boot

and firmly push it out through the handle opening. If the

Gauge is fitted with a Quick Disconnect, connect it after it is

through the handle.

Fig. 6

Pull the Hose through the handle of the Boot until the Pres-

sure Gauge module is above the opening of the pressure

gauge cavity.

Grasp the top portion of the Boot with one hand and push

the Pressure Gauge module down into place. After the Pres-

sure Gauge is in the Console, it may be necessary to

squeeze the edges of the cavity opening until the lip covers

Fig. 7

the outside diameter of the Pressure Gauge lens. Use care not to cut or tear the lip

of the Boot cavity.

To Install the Compass:

Orient the Console so the compass cavity faces up. Loosely position the module

directly on the compass cavity of the Boot aligned with the side viewing window

over the viewing notch of the compass cavity of the Console (Fig. 7).

With the palm of your hand, press directly down on the top of the Compass until it

snaps into place. Turn the Compass bezel to ensure it rotates properly in both di-

rections.

NOTE: If you experience difficulty with installation and/or removal

of any instruments take the products to your Authorized Oceanic

Dealer for assistance. Instrument damage caused by use of tools

for installation and/or removal is not covered by the product's

warranty.

Responsible

Loading...

Loading...