Oce ProCut 2500 L, ProCut 1600 XL, ProCut 1600 XXL, ProCut 1600 XXXL, ProCut 2500 M User Manual

...

Océ ProCut 1600, 2500, and 3200 Series Cutters

Revision E – July 23, 2010

Océ ProCut Site Prep

Océ Display Graphics Systems

Océ ProCut Site Preparation Guide - Revision: E ii

© 2010 All Rights Reserved

Part Number: 3010108370

Océ ProCut Site Prep

Table of Contents

Table of Figures...................................................................................................................... iv

Preface...................................................................................................................................... v

Copyright ....................................................................................................................................v

Document Summary...................................................................................................................v

Product Support, Documentation, and Service ..........................................................................v

Introduction.............................................................................................................................. 1

Considerations:...........................................................................................................................1

System Requirements............................................................................................................. 2

Receiving the Océ ProCut ..........................................................................................................2

Crate Dimensions and Weight....................................................................................................3

Facility Requirements ............................................................................................................. 5

Floor Loading..............................................................................................................................5

Electrical Placement ...................................................................................................................5

Location Dimensions ..................................................................................................................5

Electrical Requirements..............................................................................................................6

400V Electrical connection .........................................................................................................6

200V Electrical connection .........................................................................................................7

Ground Fault Requirements .......................................................................................................8

Router Vacuum Cleaner: ............................................................................................................9

Dust Extraction: ..........................................................................................................................9

Installation / Training............................................................................................................. 11

Specifications ........................................................................................................................ 12

Machine Dimensions and Weight: ............................................................................................12

Floor Conditions .......................................................................................................................15

Environment .............................................................................................................................16

Safety Information ....................................................................................................................16

Minimum PC Requirements......................................................................................................16

Océ ProCut Macintosh Prepress Client ................................................................................16

Océ ProCut Windows Prepress Client..................................................................................16

Océ ProCut Windows Server & ONYX RIP ..........................................................................17

Windows Cut Client...............................................................................................................17

Check list................................................................................................................................18

Océ ProCut Site Preparation Guide - Revision: E iii

Océ ProCut Site Prep

List of Tables

Table 1: Crate Dimensions and Weight ...................................................................................................4

Table 2: Cutter Extension Crate Dimensions and Weights.......................................................................4

Table 3: Location Dimensions..................................................................................................................5

Table 4: Power Consumption and Variance ............................................................................................6

Table 5: Electrical Connections with 1-9kW Vacuum Turbine/Generator ................................................6

Table 6: Power Consumption and Variance ............................................................................................7

Table 7: Electrical Connections with 1-9kW Vacuum Turbine/Generator ................................................7

Table 8: Electrical Connections with 2.2/2.55kW Vacuum Pumps ..........................................................8

Table 9: Electrical Connections with 2.2/2.55kW Vacuum Pumps ..........................................................8

Table 10: Vacuum Cleaner Specifications...............................................................................................9

Table 11: Compressed Air .....................................................................................................................10

Table 12: 1600 Series Machine Dimensions and Weight ......................................................................12

Table 13: 2500 Series Machine Dimensions and Weight ......................................................................13

Table 14: 3200 Series Machine Dimensions and Weight ......................................................................14

Table 15: Cutter Extension Dimensions and Weights............................................................................15

Table 16: Floor Conditions.....................................................................................................................15

Table 17: Environment...........................................................................................................................16

Table of Figures

Figure 1: Shipping Crate..........................................................................................................................2

Figure 2: 400V Electrical Connection.......................................................................................................6

Figure 3: 200V Electrical Connection.......................................................................................................7

Figure4: 400V Electrical Connection........................................................................................................8

Figure 5: 200V Electrical Connection.......................................................................................................8

Océ ProCut Site Preparation Guide - Revision: E iv

Océ ProCut Site Prep

Preface

Copyright

© 2010 Océ Display Graphics Systems. All rights reserved.

This document contains information proprietary to Océ, to its subsidiaries, or to third parties to

which Océ may have a legal obligation to protect such information from unauthorized disclosure,

use or duplication. Any disclosure, use, or duplication of this document or of any of the information

contained herein for other than the specific purpose for which it was disclosed is expressly

prohibited, except as Océ may otherwise agree to in writing. Due to continuing research and

product improvements, features or product specifications may change at any time without notice.

Document Summary

Date Revision Summary

Oct. 27, 2008 Revision A Initial release.

Dec 15, 2008 Revision B Added harmonics and flicker info

Mar 12, 2009 Revision C Added 1600 series and 3200 XXL and XXXL models

Added 1600 M and additional power connections for the use

Jul 29, 2009 Revision D

Jul 11, 2010 Revision E

of a 2.2kW vacuum pump.

Also modified the width of the 1600 series to include the

Router Option (B3).

Added Cutter Extension specifications.

Updated Compressed Air specifications

Product Support, Documentation, and Service

For further information on documentation and support for your Océ ProCut Cutter or for information

on other Océ Display Graphics Systems products visit our web site:

Web: http://www.dgs.oce.com

Comments on this manual? email to: DGSTechnical.Writer@oce.com

Océ maintains a comprehensive support structure for its customers. Upon installation of your cutter,

you will be provided with the name of the sales and service office responsible

Océ ProCut Site Preparation Guide - Revision: E v

Océ ProCut Site Prep

Introduction

This document contains information that will be helpful to you in determining the final location for

the cutter, transporting the cutter to its final location, and all specifications for power, space, and

environmental conditions required for the Océ ProCut manufactured by Zünd.

Considerations:

Determine where the cutter system will be located. Any and all construction measures must be

completed before the cutter system is installed.

Location of the cutter should not be in close proximity to printers due to the dust and particle

generation from this device.

Mark out the installation location to scale using adhesive tape. See the section "Technical data" for

the exterior measurements.

Ensure that the installation location meets the relevant requirements: - Room size - Subsurface Temperature - Cleanliness (free of dust and dirt)

Ensure that there are connections for electricity and compressed air at the installation location and

that these meet the required specifications.

Check whether it is possible to transport the cutter to the installation location. If necessary, arrange

for a forklift or mobile crane to be available on the installation day.

Examine the route to the desired location of the Cutter.

The following guidelines will help you determine the route and final location of your cutter:

• Ideally, the crates should be transported to the installation location using a forklift truck or

mobile crane. However, you can also transport the crates over short distances using a pallet

jack with long forks. The installation guide contains detailed information (center of gravity,

requirements) about transporting the crates.

• Determine a route to the installation location. Ensure that this route is as short as possible

and that it is sufficiently wide.

• Check the route for any obstacles (narrow passages, doors, railings, radiators, steps).

Remove these if required.

• Be aware of the size and weight of the cutter and be sure the floor of the route can support

the weight of the crates and forklift!

• This route must be wide and high enough to allow free movement of the cutter crate,

including corners and bends.

• For crate dimensions, see: section 5 Technical Data

Confirm a delivery/installation date.

• A well-prepared installation saves time and money for everyone involved!

Océ ProCut Site Prep

System Requirements

Receiving the Océ ProCut

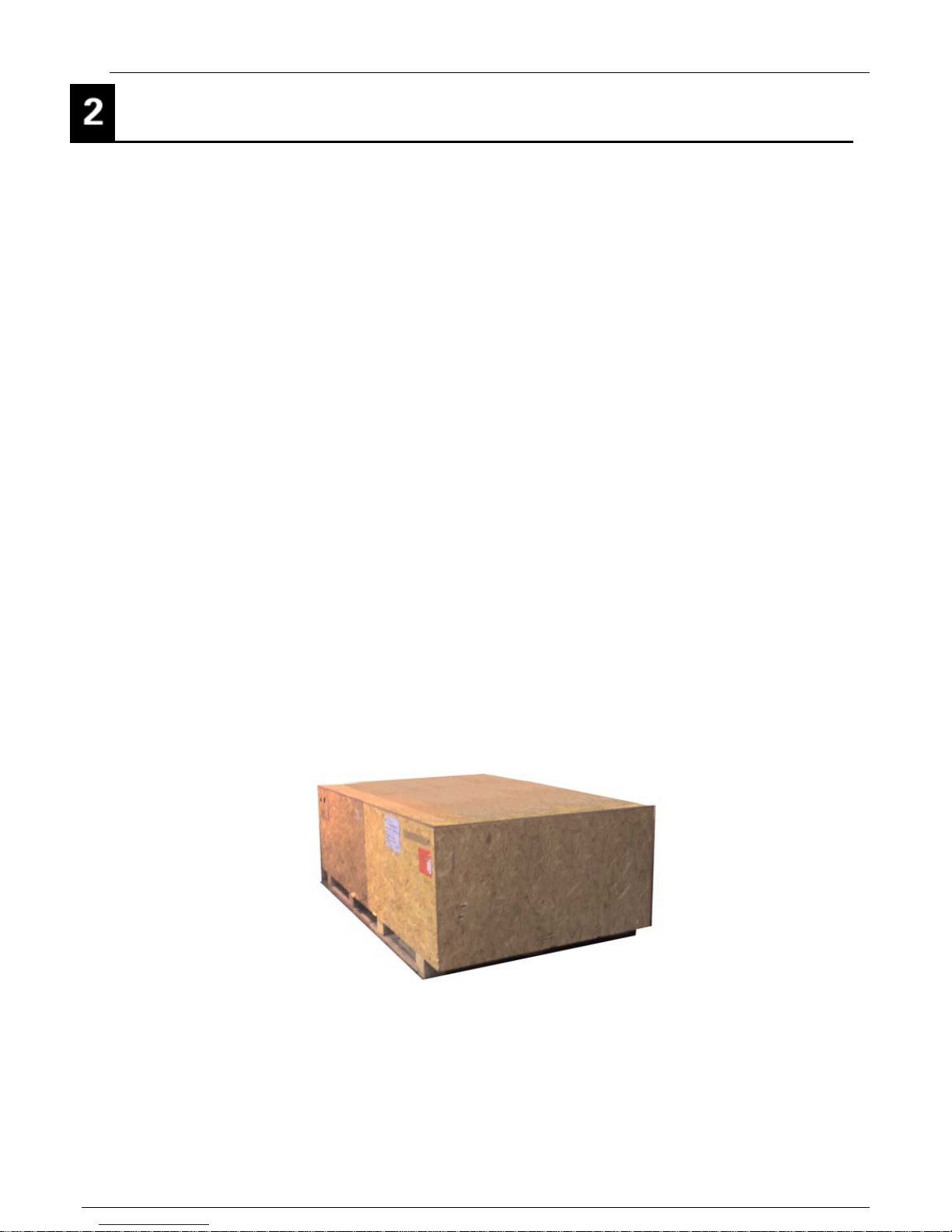

Packed in its crate, the Océ ProCut can withstand normal vibrations from road or air travel. Severe

shock, however, may damage the components within the machine. Document all visible damage to

the packaging immediately upon delivery. Verify that the shipper records this damage on the

delivery bill of lading and report to your Océ Operating Company.

Only Océ trained service technicians should only open crates. Internal parts can be damaged if

mishandled.

The Océ ProCut is typically shipped in three wooden crates and one pallet. See Dimensions and

Weight. Due to the weight and delicate nature of the cutter it is essential to have the proper

equipment available for handling and moving the shipping crates.

Important: The majority of the installation will be carried out by a Océ trained Service

Technician. However, additional support is required for some tasks (transportation,

moving heavy parts, holding parts in place during assembly etc). The Océ Service

Technician should arrange for an assistant to be available during the assembly

phase.

Because of the weight of each crate, we recommend using a forklift to prevent personal injury

and/or damage to the equipment. If you do not have a forklift, you can use one palette jack on

smaller crates and two palette jacks on larger crates.

If an Océ trained technician is not present for the delivery of the system, then the transport crates

are not to be opened and the machine must not be unpacked. This must be kept in a dry place from

the time of delivery until the arrival of the technician.

Storage temperature: -20º / 55º C (-4° / 126° F)

Océ ProCut Site Preparation Guide - Revision: E 2

Figure 1: Shipping Crate

Océ ProCut Site Prep

Crate Dimensions and Weight

1600 M

Crate 1:

Crate 2:

1600 XL

Crate 1: Basic unit 4250x1580x710 720

Crate 2: Basic unit 3790 x 1580 x 970 1080

1600 XXL

Crate 1: Basic unit 4250 x 1580 x 710 750

Crate 2: Basic unit 3790 x 1580 x 1220 1180

1600 XXXL

Crate 1: Basic unit 4250 x 1580 x 710 780

Crate 2: Basic unit 3790 x 1580 x 1220 1280

2500 L

Basic unit

Basic unit

Largest part (unpackaged)

Largest part (unpackaged)

Largest part (unpackaged)

Largest part (unpackaged)

Crate Dimensions [mm] In Crate [kg]

2260 x 1550 x 940 650 kg

3080 x 1550 x 600 900 kg

2512 x 300 x 300 100

Crate Dimensions [mm] In Crate [kg]

2512 x 300 x 300 100

Crate Dimensions [mm] In Crate [kg]

2512 x 300 x 300 100

Crate Dimensions [mm] In Crate [kg]

2512 x 300 x 300 100

Crate Dimensions [mm] In Crate [kg]

Crate 1: Basic unit 3550 x 1580 x 700 720

Crate 2: Basic unit 3160 x 1580 x 940 1030

2500 M

Crate 1: Basic unit 3550 x 1580 x 700 700

Crate 2: Basic unit 3160 x 1580 x 940 880

3200 L

Crate 1: Basic unit 4250 x 1580 x 710 750

Crate 2: Basic unit 3790 x 1580 x 970 1250

3200 XL

Crate 1: Basic unit 4250 x 1580 x 710 780

Crate 2: Basic unit 3790 x 1580 x 970 1350

3200 XXL

Crate 1: Basic unit 4250x1580x710 820

Crate 2: Basic unit 3790x1580x1220 1550

3200 XXXL

Largest part (unpackaged)

Largest part (unpackaged)

Largest part (unpackaged)

Largest part (unpackaged)

Largest part (unpackaged)

3412 x 300 x 300 115

Crate Dimensions [mm] In Crate [kg]

3412 x 300 x 300 115

Crate Dimensions [mm] In Crate [kg]

4112 x 300 x 300, 130

Crate Dimensions [mm] In Crate [kg]

4112 x 300 x 300 130

Crate Dimensions [mm] In Crate [kg]

4112 x 300 x 300 130

Crate Dimensions [mm] In Crate [kg]

Crate 1: Basic unit 4250 x 1580 x 710 850

Crate 2: Basic unit 3790 x 1580 x 1220 1700

Océ ProCut Site Preparation Guide - Revision: E 3

Largest part (unpackaged)

4112 x 300 x 300 130

Océ ProCut Site Prep

All Models

Pallet 1: Vacuum Generator 1200 x 800 x 970 140

Pallet 2: Workstation 2684 x 850 x 550 120

Note: Models ordered with a vacuum cleaner will ship with the workstation inside a crate.

Table 1: Crate Dimensions and Weight

Crate Dimensions [mm] In Crate [kg]

Cutter Extension Option Crate Dimensions and Weight

Cutter Extension

Crate Dimensions [mm] Weight [kg]

CE2500

2500 L

2500 M

Cutter Extension

2690 x 890 x 560 190

2690 x 890 x 560 165

Crate Dimensions [mm] Weight [kg]

CE3200

3200 L

3200XL

3200 2XL

3200 3XL

3200 x 890 x 560 230

3200 x 890 x 560 230

3790 x 890 x 560 290

3790 x 890 x 560 305

Table 2: Cutter Extension Crate Dimensions and Weights

Océ ProCut Site Preparation Guide - Revision: E 4

Océ ProCut Site Prep

Facility Requirements Facility Requirements

Determine where the cutter system will be located in advance of the installation. Mark this with

Determine where the cutter system will be located in advance of the installation. Mark this with

adhesive tape so that you can confirm the dimensions. Ensure that there is a gap of at least 1 meter

adhesive tape so that you can confirm the dimensions. Ensure that there is a gap of at least 1 meter

to the nearest wall all around the machine to allow access by operating and servicing personnel.

to the nearest wall all around the machine to allow access by operating and servicing personnel.

Two meters at the front end of the system will make media handling much easier.

Two meters at the front end of the system will make media handling much easier.

If the delivery includes a router option, the room must be at least 3 m high. See location

If the delivery includes a router option, the room must be at least 3 m high. See location

Dimensions below for specific model requirements.

Dimensions below for specific model requirements.

Check the room temperature and humidity. Be certain that the environment will meet or exceed the

Check the room temperature and humidity. Be certain that the environment will meet or exceed the

requirements all year long.

requirements all year long.

Provide supports with sufficient stability if the difference in height over the entire installation surface

Provide supports with sufficient stability if the difference in height over the entire installation surface

is greater than 2 cm.

is greater than 2 cm.

Floor Loading Floor Loading

The subsurface for the machine must be sufficiently level and stable. The floor in the operational

The subsurface for the machine must be sufficiently level and stable. The floor in the operational

location must have adequate load-carrying capacity and stiffness. Wood framed/constructed floors

location must have adequate load-carrying capacity and stiffness. Wood framed/constructed floors

are not suitable! Solid and level concrete surface is recommended. The difference in height over

are not suitable! Solid and level concrete surface is recommended. The difference in height over

the entire installation surface must be less than 2 cm.

the entire installation surface must be less than 2 cm.

Floor Loading: minimum 800 kg / 1,764 lbs. per square meter Floor Loading: minimum 800 kg / 1,764 lbs. per square meter

Electrical Placement Electrical Placement

If using wall-mounted power outlets, they can be located on either side or rear of the machine.

If using wall-mounted power outlets, they can be located on either side or rear of the machine.

Depending on distance, extension cords may be needed.

Depending on distance, extension cords may be needed.

If using ceiling power drops, they can be place anywhere behind the PC stand but need to be at

If using ceiling power drops, they can be place anywhere behind the PC stand but need to be at

least 20cm away from the side cover to allow for removal of the side covers during service.

least 20cm away from the side cover to allow for removal of the side covers during service.

Location Dimensions Location Dimensions

Model Width Length Height w/router

1600 M 4679 mm 4512mm 3000 mm/118”

1600 XL 5619 mm 4512mm 3200 mm/125”

1600 XXL 6089 mm 4512mm 3200 mm/125”

1600 XXXL 6559 mm 4512mm 3200 mm/125”

2500 L 5149 mm 5412 mm 3200 mm/125”

2500 M 4679 mm 5412 mm 3000 mm/118”

3200 L 5149 mm 6112 mm 3200 mm/125”

3200 XL 5619 mm 6112 mm 3200 mm/125”

3200 XXL 6089 mm 6112 mm 3200 mm/125”

3200 XXXL 6559 mm 6112 mm 3200 mm/125”

Note: A clear distance to the nearest wall etc. of approx. one-meter must be provided and

maintained for operator and service access. The values if the above table includes onemeter clearance on all sides. Two meters at the front end of the system will make media

handling much easier.

Océ ProCut Site Preparation Guide - Revision: E 5

Table 3: Location Dimensions

Océ ProCut Site Prep

Electrical Requirements

This apparatus is intended to be connected to a power network supplied from a high or medium

voltage transformer dedicated to the supply of an installation feeding manufacturing or similar plant.

This apparatus is not intended to be connected to public low-voltage networks. There are two

electrical voltage configurations: 200V or 400V, and two power frequency configurations: 50 Hz or

60 HZ. The configuration of a particular machine is chosen at time of sale based upon local power

specifications.

All cutter models use the 1-9kW Vacuum Generator (also called a Vacuum Turbine), except for the

1600 M, which uses the 2.2/2.5kW vacuum pump

The vacuum generator and optional milling/router spindle each have a frequency converter that is

used to control their variable speed drive motor. If a ground fault interrupter is used, it must be a

meet particular specifications, see Ground Fault Requirements for more details.

Electrical connection – 400 V system with 1-9kW Vacuum Generator

The cutter is connected with one power cord to the power supply system. All other (optional too)

devices are connected to the power box of the cutter.

• 1 power cord is included in the package content with a CEE32 connector

Warning! An electrical hazard exists if an incorrect ground fault interrupter protects the high-

frequency leakage current. See Ground Fault Requirements.

Power

Main supply voltage variance max. 5%

Power consumption - 3 phases max 12.6kW, typical 5.6kW

Table 4: Power Consumption and Variance

Figure 2: 400V Electrical Connection

“A” Cutter Power box Value Unit

Phases 3

Voltage 400 V

Power frequency, pump-depending 50/60 Hz

Power fusing min. 32 A

Wiring 3 phases, L1, L2, L3, N, PE

CEE-Plug 32A

Special-purpose ground fault interrupter required Fusing current:>30mA per converter

Table 5: Electrical Connections with 1-9kW Vacuum Turbine/Generator

Océ ProCut Site Preparation Guide - Revision: E 6

Océ ProCut Site Prep

Electrical connection – 208 V system with 1-9kW Vacuum Generator

The cutter is connected with one power cord to the power main. The vacuum generator is

connected with one power cord to the power main. The Cutter and Vacuum Generator need

separate circuit breakers. All other devices are connected to the power box of the cutter including

any optional equipment.

• 2 power cords are included in the package content. Customer must supplier connectors to

power supply.

Warning! An electrical hazard exists if an incorrect ground fault interrupter protects the high-

frequency leakage current. See Ground Fault Requirements.

Power

Main supply voltage variance max. 10%

Power consumption - 3 phases max 12.6kW, typical 5.6kW

Table 6: Power Consumption and Variance

Figure 3: 200V Electrical Connection

“A” Cutter Power box Value Unit

Phases 3

Voltage 208 V

Power frequency, pump-depending 50/60 Hz

Power fusing min. 16 A

Wiring 3 phases, L1, L2, L3, N, PE

CEE-Plug 30A, 208V, 5 Poles, Walther Electric Type 230 509

Special-purpose ground fault interrupter required Fusing current:>30mA per converter

“B” Vacuum Turbine/Generator Value Unit

Phases 3

Voltage 208 V

Power frequency, pump-depending 50/60 Hz

Power fusing min. 50 A

Wiring 3 phases, L1, L2, L3, N, PE

CEE-Plug 60A, 208V, 5 Poles, Walther Electric Type 261 509

Special-purpose ground fault interrupter required Fusing current:>30mA per converter

Table 7: Electrical Connections with 1-9kW Vacuum Turbine/Generator

Océ ProCut Site Preparation Guide - Revision: E 7

Océ ProCut Site Prep

Electrical connections - 400 V system with 2.2/2.55 kW vacuum pump (1600 M Only)

Comply with national instructions and laws at connection the cutter to the power supply system. The

cutter is connected with one power cord to the power supply system. The vacuum pump is

connected to the power box of the cutter. 1 power cord is included in the package content.

Figure 4: 400V Electrical Connection

“A” Cutter Power box Value Unit

Phases 3

Voltage 400 V

Power frequency, pump-depending 50/60 Hz

Power fusing min. 32 A

Wiring 3 phases, L1, L2, L3, N, PE

CEE-Plug 32A

Table 8: Electrical Connections with 2.2/2.55kW Vacuum Pumps

Electrical connections - 208 V system with 2.2/2.55 kW vacuum pump (1600 M Only

Comply with national instructions and laws at connection the cutter to the power supply system. The

cutter is connected with one power cord to the power supply system. The vacuum pump is

connected to the power box of the cutter. 1 power cord is included in the package content.

Figure 5: 200V Electrical Connection

“A” Cutter Power box Value Unit

Phases 3

Voltage 208 V

Power frequency, pump-depending 50/60 Hz

Power fusing min. 32 A

Wiring 3 phases, L1, L2, L3, N, PE

CEE-Plug 32A

Table 9: Electrical Connections with 2.2/2.55kW Vacuum Pumps

Océ ProCut Site Preparation Guide - Revision: E 8

Océ ProCut Site Prep

Ground Fault Requirements

Electrical rules and regulations and vary from country to country and sometimes even within a

country. A local electrician should be consulted to determine local ground fault requirements.

Some countries require residual current devices (RCD) or residual current circuit breakers (RCCB).

This is an electrical wiring device that disconnects a circuit whenever it detects that electrical

current is not balanced between the phase (“hot” or “live”) conductor and the neutral conductor.

In the United States and Canada, a residual current device is also known as a ground fault circuit

interrupter (GFCI), ground fault interrupter (GFI) or an appliance leakage current interrupter (ALCI).

In Australia they are sometimes known as "safety switches".

If a RCD/GFI is required, the standard general-purpose model may not work with the Océ ProCut

system. The vacuum generator and optional milling/router spindle each have a frequency converter

that is used to control their variable speed drive motor. A frequency converter has a higher than

typical leakage current and may trip a standard GFI (E.g in many areas in Europe the standard RFI

has a fusing current of 10 mA). If local regulations require a GFI, it must have a fusing current > 30

mA per converter.

In a 200V electrical configuration with the milling/router option there are two connections to power

supply system and if an RFI is required, both connections should have an RFI that has a fusing

current of > 30 mA.

(Compatible GFI model - Hager CDH440C or similar).

In a 400V electrical configuration with the milling/router option there is a single connection to the

power supply system and if an RFI is required it should have an RFI that has a fusing current of >

60 mA (30 mA for the vacuum generator and 30 mA for the milling spindle and cutter).

Please consult a local electrician to determine ground fault protection requirements.

Router Vacuum Cleaner / Dust Extraction:

If the Router option was ordered, a shop vacuum cleaner is required to remove the router debris.

Depending on the material being worked with, the dust generated may be toxic or potentially

explosive. Seek expert advice about the correct filter system and explosion protection when

choosing a dust extractor. Only use dust extractors with external air-cooling for industrial purposes.

In Europe, a router vacuum cleaner can be purchased from Océ or purchased directly by the

customer from another vendor. In North America the router vacuum cleaner must be purchased

directly by the customer from another vendor. If the customer purchases a shop vacuum

consuming more than 10 Amperes, a separate control via a relay box is required. Note: This is

common for 1KW milling equipment.

Technical Requirements for vacuum cleaner:

Value Units

Min. Flow volume

3800

1000

L/min

Gal/min

Océ ProCut Site Preparation Guide - Revision: E 9

Table 10: Vacuum Cleaner Specifications

Océ ProCut Site Prep

Compressed Air:

Compressed air is not supplied internally with the Océ ProCut cutter. The customer must supply

either house compressed air or an external air compressor that meets the following requirements:

Connector hose interior Ø 6 - 7 mm 0.24 – 0.28 In

Air purity class (ISO 8573-1) 4

Air pressure

Air flow (minimum)

Basic unit

Pneumatic Oscillating Tool

Router Module

Table 11: Compressed Air

Notes:

• Two separate compressed air connections are required if using the POT.

•

A Combination requires the highest pressure and the highest air flow. Example: Main unit + RM +

POT = 0.8 - 1.0 MPa and 300 - 400 l/min

Pressure Air flow

0.8 - 1.0 mPa

116 – 145 Psi

79 Gal/min

0.6 – 1.0 mPa

87 – 145 Psi

0.8 – 1.0 mPa

116 – 145 Psi

0.6 – 1.0 mPa

87 – 145 Psi

300 – 400 L/min

79 – 106 Gal/min

10.6 Gal/min

300 L/min

19 L/min

5 Gal/min

40 L/min

Océ ProCut Site Preparation Guide - Revision: E 10

Océ ProCut Site Prep

Installation / Training

The operator must have some technical skill and knowledge of PC operation. Only specially trained

personnel must operate the Cutter. Trainees must have prior knowledge of computers and basic

mechanical abilities. Trainees must be available during the entire time allocated for training.

Océ ProCut Site Preparation Guide - Revision: E 11

Océ ProCut Site Prep

Specifications

Machine Dimensions and Weight:

Table 12: 1600 Series Machine Dimensions and Weight

1600 M Dimensions [mm] Weight [kg]

Basic unit (L x B)

Operator console (B1)

Work Station (B2)

Router Option (B3)

2512 x 2055 670

300

624

330

1600 XL Dimensions [mm] Weight [kg]

Basic unit (L x B) 2512 x 2995 890

Operator console (B1) 300

Work Station (B2) 624 60

Router Option (B3) 330

1600 XXL Dimensions [mm] Weight [kg]

Basic unit (L x B) 2512 x 3465 980

Operator console (B1) 300

Work Station (B2) 624 60

Router Option (B3) 330

Océ ProCut Site Preparation Guide - Revision: E 12

Océ ProCut Site Prep

1600 XXXL Dimensions [mm] Weight [kg]

Basic unit (L x B) 2512 x 3935 1120

Operator console (B1) 300

Work Station (B2) 624 60

Router Option (B3) 330

2500 M Dimensions [mm] Weight [kg]

Basic unit (L x B) 3412 x 2055 840

Operator console (B1) 300

Work Station (B2) 624 60

2500 L Dimensions [mm] Weight [kg]

Basic unit (L x B) 3412 x 2525 970

Operator console (B1) 300

Work Station (B2) 624 60

Table 13: 2500 Series Machine Dimensions and Weight

Océ ProCut Site Preparation Guide - Revision: E 13

Océ ProCut Site Prep

3200 L Dimensions [mm] Weight [kg]

Basic unit (L x B) 4112 x 2525 1110

Operator console (B1) 300

Work Station (B2) 624 60

3200 XL Dimensions [mm] Weight [kg]

Basic unit (L x B) 4112 x 2995 1280

Operator console (B1) 300

Work Station (B2) 624 60

3200 XXL Dimensions [mm] Weight [kg]

Basic unit (L x B) 4112 x 3465 1420

Operator console (B1) 300

Work Station (B2) 624 60

3200 XXXL Dimensions [mm] Weight [kg]

Basic unit (L x B) 4112 x 3935 1610

Operator console (B1) 300

Work Station (B2) 624 60

Table 14: 3200 Series Machine Dimensions and Weight

Océ ProCut Site Preparation Guide - Revision: E 14

Océ ProCut Site Prep

Cutter Extension Dimensions and Weights:

Cutter Extension CE2500 T1 [mm] T2 [mm] Weight [kg]

2500 L

2500 M

Cutter Extension CE3200 T1 [mm] T2 [mm] Weight [kg]

3200 L

3200 XL

3200 2XL

3200 3XL

Floor Conditions

Value Unit

2445 1989 140

2445 1519 105

3145 1989 170

3145 2459 180

3145 2929 230

3145 3399 260

Table 15: Cutter Extension Dimensions and Weights

Evenness 2 cm

Min. loading capacity 800 kg/m2

Océ ProCut Site Preparation Guide - Revision: E 15

Table 16: Floor Conditions

Océ ProCut Site Prep

Environment

Temperature/Humidity Values

Operating temperature 10 °C to 35 °C (50° to 90° F)

Storage temperature -20º to 55º C (-4° to 126° F)

Relative humidity 10 % to 80 % non-condensing

Table 17: Environment

Note: Temperature fluctuations outside the given range can lead to detrimental effects on the

cutting quality and to stability problems

Safety Information

Ear and eye protection required.

Minimum PC Requirements

Please check the www.dgs.oce.com web site for the latest PC specifications.

Océ ProCut Macintosh Prepress Client

• Intel MAC / G4 or faster

• 2 GB RAM or more

• 20 GB available hard disk space or more

• CD / DVD drive

• TCP/IP network connection (100Mbit or faster)

• MAC OS X

• Nesting in Windows Client Only

Océ ProCut Windows Prepress Client

• Intel Pentium 3 GHz / Core2 Duo 2 GHz processor or faster

• 2 GB RAM or more

• 20 GB available hard disk space or more

• CD / DVD drive

• TCP/IP network connection (100Mbit or faster)

• Windows XP or Vista

Océ ProCut Site Preparation Guide - Revision: E 16

Océ ProCut Site Prep

Océ ProCut Windows Server & ONYX RIP

It is recommended that the Océ ProCut Windows Server and ONYX RIP run on the same

computer. Running the two applications on the same computer will provide the fastest file

handling since all data files are local.

• Intel Pentium IV or higher / Xeon 3+ GHz/Core2 Duo 2GHz processor or faster or

Athlon 64 / Opteron 2+ GHz

• Dual CPU {For Optimum Multiple RIP Performance}

• Two Hard Drives – One 80 GB Drive for OS and Applications, one 200+ GB for

data

• 2 GB RAM per CPU

• 1280 x 1024 16-bit Color Minimum

• 2x available USB Ports (for ONYX and Océ ProCut Server security keys/dongles)

• DVD-ROM Drive

• TCP/IP network connection (100Mbit or faster)

• Windows Vista or Windows XP Pro with the latest service pack

Windows ProCut Vision

• Intel Pentium 3 GHz / Core2 Duo 2 GHz processor or faster

• 2 GB RAM or more

• 20 GB available hard disk space or more

• CD / DVD drive

• TCP/IP network connection (100Mbit or faster)

• 2 x available USB port security key/dongle and barcode reader)

• 1 x available PCI slot (video frame grabber card) NOTE: The PCI card is a half-

length card, but full height (there are also half height cards)

• 1 x available RS232 com port / USB to RS232 converter (Zünd Cutter)

• Screen resolution 1280x1024 (minimum)

• 17” or larger Flat Panel Display (TFT screen)

• Windows XP or Vista

Océ ProCut Site Preparation Guide - Revision: E 17

Océ ProCut Site Prep

Check list

In order to avoid complications and misunderstandings, please use this list for your preparation

activities:

The delivery truck can reach the unloading location without obstruction.

A suitable forklift is available for installation.

Additional labor is available (if necessary) to get the machine to the installation location.

All the measures necessary to get the machine to the installation location are in place.

There are no obstructions on the route, e.g. steps, stairs.

A hand operated pallet jack or similar is available.

If the machine has to be stored temporarily, then a suitable place is available.

The size and weight of the machine have been taken into account and the floor is suitable

for the cutter.

The power main connection is ready.

The power main supply voltage is stable; the maximum fluctuation is within the tolerance

range (+/- 5%)

Compressed air system and connection is ready

If the Router Option was purchased the router vacuum cleaner will be available at

installation time.

The room complies with the requirements given in the “installation site and “Space

requirements” sections

An installation assistant has been arranged

The required PC’s are pre-installed and ready for installation/configuration of the ProCut

Software

The future operator is available during installation and training

Océ ProCut Site Preparation Guide - Revision: E 18

Loading...

Loading...