Oce ProCut 2500 L, ProCut 1600 XL, ProCut 1600 XXL, ProCut 1600 XXXL, ProCut 2500 M User Manual

...

Océ ProCut 1600, 2500, and 3200 Series Cutters

Revision E – July 23, 2010

Océ ProCut Site Prep

Océ Display Graphics Systems

Océ ProCut Site Preparation Guide - Revision: E ii

© 2010 All Rights Reserved

Part Number: 3010108370

Océ ProCut Site Prep

Table of Contents

Table of Figures...................................................................................................................... iv

Preface...................................................................................................................................... v

Copyright ....................................................................................................................................v

Document Summary...................................................................................................................v

Product Support, Documentation, and Service ..........................................................................v

Introduction.............................................................................................................................. 1

Considerations:...........................................................................................................................1

System Requirements............................................................................................................. 2

Receiving the Océ ProCut ..........................................................................................................2

Crate Dimensions and Weight....................................................................................................3

Facility Requirements ............................................................................................................. 5

Floor Loading..............................................................................................................................5

Electrical Placement ...................................................................................................................5

Location Dimensions ..................................................................................................................5

Electrical Requirements..............................................................................................................6

400V Electrical connection .........................................................................................................6

200V Electrical connection .........................................................................................................7

Ground Fault Requirements .......................................................................................................8

Router Vacuum Cleaner: ............................................................................................................9

Dust Extraction: ..........................................................................................................................9

Installation / Training............................................................................................................. 11

Specifications ........................................................................................................................ 12

Machine Dimensions and Weight: ............................................................................................12

Floor Conditions .......................................................................................................................15

Environment .............................................................................................................................16

Safety Information ....................................................................................................................16

Minimum PC Requirements......................................................................................................16

Océ ProCut Macintosh Prepress Client ................................................................................16

Océ ProCut Windows Prepress Client..................................................................................16

Océ ProCut Windows Server & ONYX RIP ..........................................................................17

Windows Cut Client...............................................................................................................17

Check list................................................................................................................................18

Océ ProCut Site Preparation Guide - Revision: E iii

Océ ProCut Site Prep

List of Tables

Table 1: Crate Dimensions and Weight ...................................................................................................4

Table 2: Cutter Extension Crate Dimensions and Weights.......................................................................4

Table 3: Location Dimensions..................................................................................................................5

Table 4: Power Consumption and Variance ............................................................................................6

Table 5: Electrical Connections with 1-9kW Vacuum Turbine/Generator ................................................6

Table 6: Power Consumption and Variance ............................................................................................7

Table 7: Electrical Connections with 1-9kW Vacuum Turbine/Generator ................................................7

Table 8: Electrical Connections with 2.2/2.55kW Vacuum Pumps ..........................................................8

Table 9: Electrical Connections with 2.2/2.55kW Vacuum Pumps ..........................................................8

Table 10: Vacuum Cleaner Specifications...............................................................................................9

Table 11: Compressed Air .....................................................................................................................10

Table 12: 1600 Series Machine Dimensions and Weight ......................................................................12

Table 13: 2500 Series Machine Dimensions and Weight ......................................................................13

Table 14: 3200 Series Machine Dimensions and Weight ......................................................................14

Table 15: Cutter Extension Dimensions and Weights............................................................................15

Table 16: Floor Conditions.....................................................................................................................15

Table 17: Environment...........................................................................................................................16

Table of Figures

Figure 1: Shipping Crate..........................................................................................................................2

Figure 2: 400V Electrical Connection.......................................................................................................6

Figure 3: 200V Electrical Connection.......................................................................................................7

Figure4: 400V Electrical Connection........................................................................................................8

Figure 5: 200V Electrical Connection.......................................................................................................8

Océ ProCut Site Preparation Guide - Revision: E iv

Océ ProCut Site Prep

Preface

Copyright

© 2010 Océ Display Graphics Systems. All rights reserved.

This document contains information proprietary to Océ, to its subsidiaries, or to third parties to

which Océ may have a legal obligation to protect such information from unauthorized disclosure,

use or duplication. Any disclosure, use, or duplication of this document or of any of the information

contained herein for other than the specific purpose for which it was disclosed is expressly

prohibited, except as Océ may otherwise agree to in writing. Due to continuing research and

product improvements, features or product specifications may change at any time without notice.

Document Summary

Date Revision Summary

Oct. 27, 2008 Revision A Initial release.

Dec 15, 2008 Revision B Added harmonics and flicker info

Mar 12, 2009 Revision C Added 1600 series and 3200 XXL and XXXL models

Added 1600 M and additional power connections for the use

Jul 29, 2009 Revision D

Jul 11, 2010 Revision E

of a 2.2kW vacuum pump.

Also modified the width of the 1600 series to include the

Router Option (B3).

Added Cutter Extension specifications.

Updated Compressed Air specifications

Product Support, Documentation, and Service

For further information on documentation and support for your Océ ProCut Cutter or for information

on other Océ Display Graphics Systems products visit our web site:

Web: http://www.dgs.oce.com

Comments on this manual? email to: DGSTechnical.Writer@oce.com

Océ maintains a comprehensive support structure for its customers. Upon installation of your cutter,

you will be provided with the name of the sales and service office responsible

Océ ProCut Site Preparation Guide - Revision: E v

Océ ProCut Site Prep

Introduction

This document contains information that will be helpful to you in determining the final location for

the cutter, transporting the cutter to its final location, and all specifications for power, space, and

environmental conditions required for the Océ ProCut manufactured by Zünd.

Considerations:

Determine where the cutter system will be located. Any and all construction measures must be

completed before the cutter system is installed.

Location of the cutter should not be in close proximity to printers due to the dust and particle

generation from this device.

Mark out the installation location to scale using adhesive tape. See the section "Technical data" for

the exterior measurements.

Ensure that the installation location meets the relevant requirements: - Room size - Subsurface Temperature - Cleanliness (free of dust and dirt)

Ensure that there are connections for electricity and compressed air at the installation location and

that these meet the required specifications.

Check whether it is possible to transport the cutter to the installation location. If necessary, arrange

for a forklift or mobile crane to be available on the installation day.

Examine the route to the desired location of the Cutter.

The following guidelines will help you determine the route and final location of your cutter:

• Ideally, the crates should be transported to the installation location using a forklift truck or

mobile crane. However, you can also transport the crates over short distances using a pallet

jack with long forks. The installation guide contains detailed information (center of gravity,

requirements) about transporting the crates.

• Determine a route to the installation location. Ensure that this route is as short as possible

and that it is sufficiently wide.

• Check the route for any obstacles (narrow passages, doors, railings, radiators, steps).

Remove these if required.

• Be aware of the size and weight of the cutter and be sure the floor of the route can support

the weight of the crates and forklift!

• This route must be wide and high enough to allow free movement of the cutter crate,

including corners and bends.

• For crate dimensions, see: section 5 Technical Data

Confirm a delivery/installation date.

• A well-prepared installation saves time and money for everyone involved!

Océ ProCut Site Prep

System Requirements

Receiving the Océ ProCut

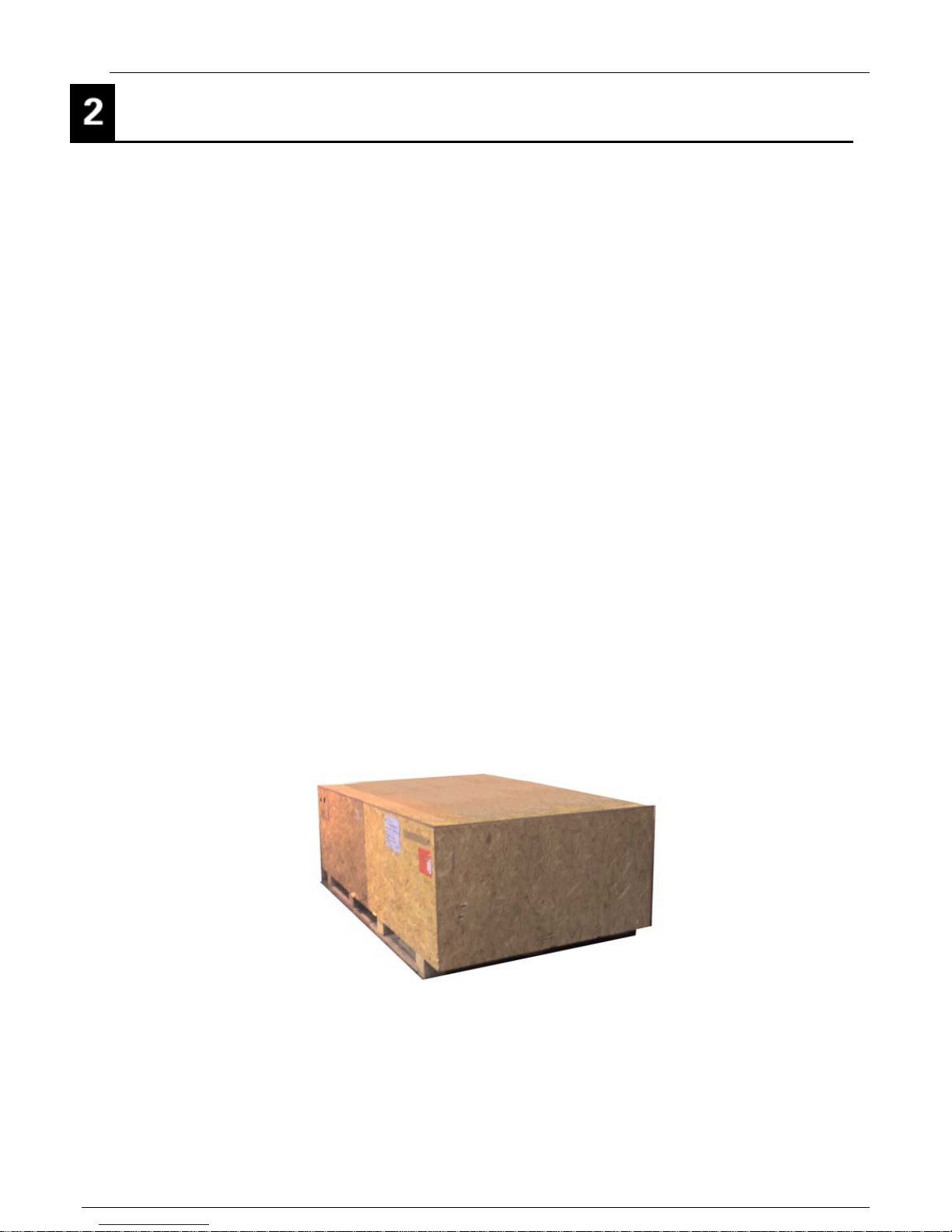

Packed in its crate, the Océ ProCut can withstand normal vibrations from road or air travel. Severe

shock, however, may damage the components within the machine. Document all visible damage to

the packaging immediately upon delivery. Verify that the shipper records this damage on the

delivery bill of lading and report to your Océ Operating Company.

Only Océ trained service technicians should only open crates. Internal parts can be damaged if

mishandled.

The Océ ProCut is typically shipped in three wooden crates and one pallet. See Dimensions and

Weight. Due to the weight and delicate nature of the cutter it is essential to have the proper

equipment available for handling and moving the shipping crates.

Important: The majority of the installation will be carried out by a Océ trained Service

Technician. However, additional support is required for some tasks (transportation,

moving heavy parts, holding parts in place during assembly etc). The Océ Service

Technician should arrange for an assistant to be available during the assembly

phase.

Because of the weight of each crate, we recommend using a forklift to prevent personal injury

and/or damage to the equipment. If you do not have a forklift, you can use one palette jack on

smaller crates and two palette jacks on larger crates.

If an Océ trained technician is not present for the delivery of the system, then the transport crates

are not to be opened and the machine must not be unpacked. This must be kept in a dry place from

the time of delivery until the arrival of the technician.

Storage temperature: -20º / 55º C (-4° / 126° F)

Océ ProCut Site Preparation Guide - Revision: E 2

Figure 1: Shipping Crate

Loading...

Loading...