Page 1

Océ User Manual

Perfect Binder-C1

Operating information

Page 2

Copyright

Copyright 2011 by Canon Inc. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, or by any information

storage or retrieval system without the prior written permission of Canon Inc.

© 2011, Océ

All rights reserved. No part of this work may be reproduced, copied, adapted, or transmitted

in any form or by any means without written permission from Océ.

Océ makes no representation or warranties with respect to the contents hereof and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose.

Furthermore, Océ reserves the right to revise this publication and to make changes from

time to time in the content hereof without obligation to notify any person of such revision

or changes.

Edition: 07-2011

Page 3

Contents

Contents

Chapter 1

Preface.................................................................................................................5

Notes for the reader...................................................................................6

Naming conventions for finishers (commercial naming and naming in

User Interfaces)..........................................................................................8

Chapter 2

Periodic test of the breaker................................................................................9

Check the breaker.....................................................................................10

Check sheet for periodic testing of the Perfect Binder-C1....................13

Chapter 3

Before you start using this machine...............................................................15

Parts and their functions..........................................................................16

Exterior view.......................................................................................16

Outline of the binder's mechanisms.................................................18

Outline of bookbinding procedure....................................................20

Main power...............................................................................................22

Turn the main power on....................................................................22

Turn the main power off....................................................................23

Energy saver and energy save mode...............................................24

Chapter 4

Basic operations................................................................................................27

Make a perfect-bound book.....................................................................28

Types of paper that can be used.............................................................29

Finished sizes of booklets........................................................................32

Remove finished booklets.......................................................................36

Discard cuttings........................................................................................40

Replenish glue..........................................................................................42

Clean the binder.......................................................................................45

Chapter 5

Troubleshooting................................................................................................47

Clearing paper jams.................................................................................48

Clear a paper jam inside the top cover.............................................48

Clear a paper jam inside the front cover..........................................52

Clear a paper jam in the stacker........................................................58

Reduce frequent paper jams or errors..............................................61

Other..........................................................................................................63

Job cannot be perfect-bound error scenario...................................63

3

Page 4

Contents

Check the status of the trimmer waste box......................................64

Check if the blade and the blade receptor must be replaced.........65

Check the status of the glue..............................................................66

Adjust cover position.........................................................................67

Adjust glue amount............................................................................68

Alarm list.............................................................................................70

Power does not turn on.....................................................................72

When the main power is turned off during operations (check the

stacker)................................................................................................73

Appendix A

Miscellaneous....................................................................................................75

Specifications............................................................................................76

Glossary....................................................................................................79

4

Page 5

Chapter 1 Preface

Page 6

Notes for the reader

Notes for the reader

Introduction

This manual helps you to use the Perfect Binder-C1. The manual contains a description

of the product and guidelines to use and operate the Perfect Binder-C1.

Definition

Attention-Getters

Parts of this manual require your special attention. These parts can provide the following:

•

Additional general information, for example, information that is useful when you

perform a task.

•

Information to prevent personal injuries or property damage.

Warning, Caution and Note

The words Warning, Caution and Note draw your attention to important information.

Overview of the attention-getters#

Warning

IndicatesIconWord

Ignoring this warning could cause serious injury or

even death.

The Warning indication has several icons that warn

against various hazards. The icons are shown below.

General hazardWarning

Hot surfaceWarning

Electric shockWarning

Moving partsWarning

Laser beamWarning

Chapter 1 - Preface6

Page 7

Caution

Important safety instructions

Warning:

The following caution label is attached to the machine. To use the machine safely, pay

attention indicated on the caution labels.

Notes for the reader

IndicatesIconWord

Ignoring this warning could cause injury or damage to

property.

Indicates additional important information.Note

The use of heat-resistant gloves is mandatory when you

carry out these actions.

Illustration

Chapter 1 - Preface 7

Page 8

Naming conventions for finishers (commercial naming and naming in User Interfaces)

Naming conventions for finishers (commercial naming and

naming in User Interfaces)

Hardware and hardware naming in User Interfaces

To improve the readability of texts in User Interfaces of operator panels and software,

the finishers are generally referred to by their function. The table below shows the naming

conventions for finishers (commercial product names and the way these are referred to

in User Interfaces).

Note:

In some cases, there is only 1 name for several modules. The reason is that a configuration

can only contain 1 of the available types of modules.

Conversion table for commercial names versus user-friendly names in User Interfaces#

Commercial product name:

In UI, printer driver and software referred to as:

'Stacker/stapler'Finisher-AF1

'Stacker/stapler'Saddle Finisher-AF2

'Puncher'Puncher Unit-BP1/BQ1/BR1

'Folder'Paper Folding Unit-F1

'Inserter'Document Insertion Unit-F1

'Stacker'High-Capacity Stacker-E1

'Trimmer'Booklet Trimmer-D1

'Trimmer'Two-Knife Trimmer-A1

'Perfect Binder'Perfect Binder-C1

'Scanner'Duplex Color Image Reader Unit-D1

Chapter 1 - Preface8

Page 9

Chapter 2

Periodic test of the breaker

Page 10

Check the breaker

Check the breaker

Introduction

A breaker that detects over current and short circuits is equipped in order to prevent

electric shock on the product.

Be sure to perform the following procedure once or twice a month to periodically test

the breaker.

Caution:

Periodic testing of the breaker should be performed with the binder's power switch turned

on. Turn off the power to the printer so that the binder does not operate during the test.

Caution:

If a breaker test reveals that it is not operating normally, contact your local authorized

dealer.

Caution:

Do not keep the test button pressed down. Press and immediately release it.

Caution:

The test button is not intended to be used to turn power on and off.

Chapter 2 - Periodic test of the breaker10

Page 11

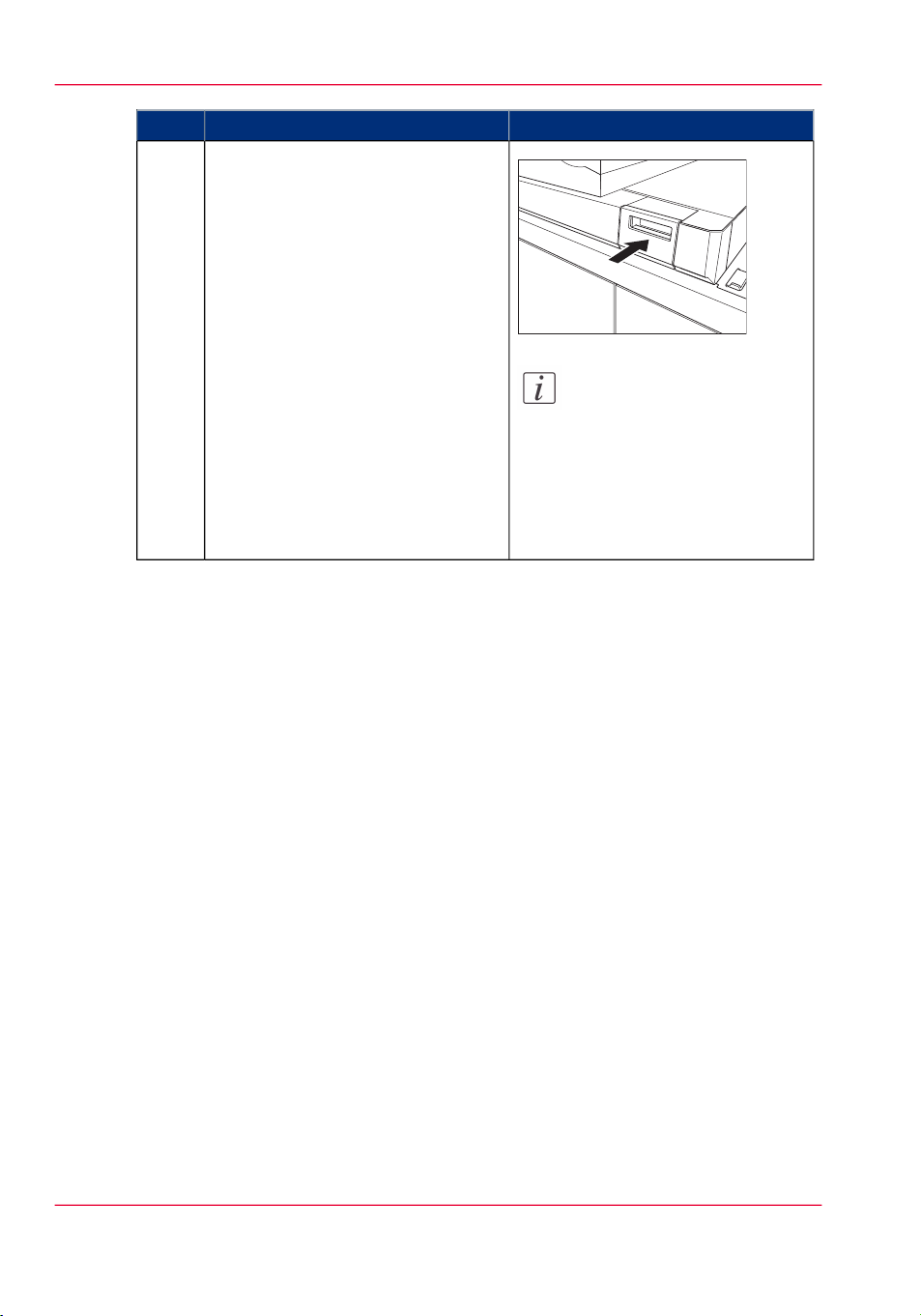

How to check the breaker

ON

( )

OFF

( )

#

1

Use a ballpoint pen or some other

thin, pointed object to press the

breaker test button on the back of

the unit.

Check the breaker

RemarksActionStep

Note:

The breaker is located on the

back of the unit.

2

Confirm that the breaker switch toggles to the OFF (O) side and the

power turns off.

Note:

If the breaker switch does

not toggle to the OFF (O)

side, perform step 1 again.

Note:

If the breaker switch does

not toggle to the OFF (O)

side even though you perform step 1 two or three

times, contact your local authorized dealer.

Chapter 2 - Periodic test of the breaker 11

Page 12

ON

( )

OFF

( )

ON

( )

OFF

( )

ON

( )

OFF

( )

Check the breaker

3

RemarksActionStep

After performing the above test, turn

off the power switch.

4

Return the breaker switch to the ON

(I) side.

Turn on the power switch.5

6

Enter the date and time of the test

into the next available entry of the

breaker test check sheet.

Chapter 2 - Periodic test of the breaker12

Page 13

Check sheet for periodic testing of the Perfect Binder-C1

Check sheet for periodic testing of the Perfect Binder-C1

Introduction

Copy the breaker test checklist sheet and use the copy to record entries. After recording

entries, store the checklist sheet in a safe place next to the product.

#

RemarksActionStep

Periodic breaker test.1

Perform the test of the breaker once

or twice a month.

Filling in the breaker test check sheet.2

#

•Check the breaker, on page 10

Fill in the date of the test and the

name of the person performing it.

Put a check in the "OK" column if

the test results are normal. If test results are not normal, put a check in

the "NG" column and contact your

local authorized dealer.

Test resultTesterTest date

NGOK

Chapter 2 - Periodic test of the breaker 13

Page 14

Check sheet for periodic testing of the Perfect Binder-C1

Chapter 2 - Periodic test of the breaker14

Page 15

Chapter 3 Before you start using this machine

Page 16

[1]

[2]

[10]

[11]

[12]

[3]

[4]

[8]

[9]

[5]

[7]

[6]

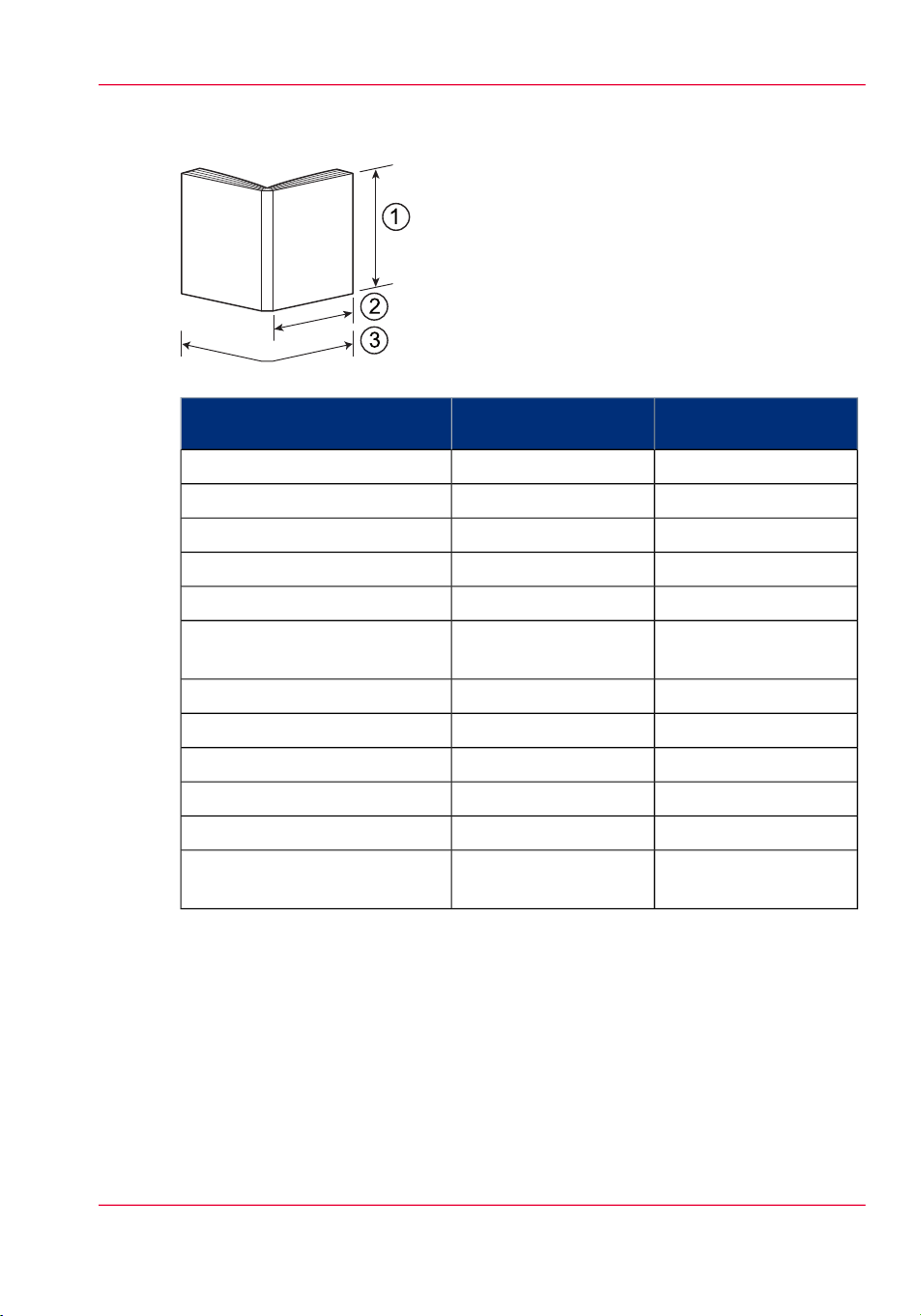

Exterior view

Parts and their functions

Exterior view

Illustration

[16] Exterior view

Parts and their functions

#

Top cover1

3

Energy

saver/LED

Open this cover when clearing a paper jam from the

gathering tray.

Turns power on and off.Power switch2

Enters and exits the energy

save mode. Also, it lights

green in energy save mode

and flashes when adjustment

of the glue temperature

starts.

More informationFunctionPart

‘Clear a paper jam inside the

top cover’ on page 48

‘Turn the main power on’ on

page 22

‘Turn the main power off’ on

page 23

‘Energy saver and energy save

mode’ on page 24

Chapter 3 - Before you start using this machine16

Page 17

Exterior view

More informationFunctionPart

Glue unit4

‘Replenish glue’ on page 42Open when replenishing

glue.

5

Front cover

(left/right)

Open these covers when

clearing a paper jam.

‘Clear a paper jam inside the

top cover’ on page 48

‘Clear a paper jam inside the

front cover’ on page 52

6

Front cover

LED

Lights orange during a

binding operation to indicate that the front cover is

locked. Goes out to indicate

that the cover is unlocked

when clearing a paper jam

is required or the binder is

not doing a binding operation.

Breaker7

Use to do periodic tests of

the breaker. This breaker is

‘Check the breaker’ on page

10

to completely prevent short

circuits.

Test button8

Press when performing testing breaker inspection.

9

‘Check the breaker’ on page

10

‘Discard cuttings’ on page 40Open to discard cuttings.Trimmer

waste unit

11

Stacker open

button/LED

Full LED12

Holds completed bookletsStacker10

Press when removing booklets from the finished booklets receptacle. Also, it lights

green when the stacker is

open and flashes while

preparing to open/close.

Lights green when the

stacker is full and flashes

while a binding operation is

in progress.

Chapter 3 - Before you start using this machine 17

‘Remove finished booklets’ on

page 36

Page 18

[1]

[2]

[3]

[5]

[4]

[8]

[6]

[7]

Outline of the binder's mechanisms

Outline of the binder's mechanisms

Illustration

[17] Binder

Parts and functions

#

Gathering tray1

3

Chapter 3 - Before you start using this machine18

Binder/pass-through transfer

section

FunctionPart

Gathers and collates finished booklet paper.

Transfers paper to the gathering tray.Gathering tray transfer section2

Transfers covers up to the binding position. When the booklet finishing function

is not being used, passes paper over to the

next device.

Applies glue to a stack of collated paper.Gluing section4

Page 19

Outline of the binder's mechanisms

FunctionPart

Binds stacks of paper with cover.Binding position5

Cutter section6

Cuts stacks of paper and transports finished booklets to the booklet receptacle.

Holds booklets.Stacker7

Holds paper cuttings.Trimmer waste tray8

Chapter 3 - Before you start using this machine 19

Page 20

[1]

[2]

[3]

[4][5]

[6]

[7]

[8]

[9]

[10]

Outline of bookbinding procedure

Outline of bookbinding procedure

Illustration

[18] Bookbinding procedure

Bookbinding procedure

#

1

Chapter 3 - Before you start using this machine20

DescriptionStage

Paper (body pages/slip sheets) is transferred to the gathering

tray.

Paper stack is collated by the gathering tray.2

Collated paper stack is transported to the gluing section.3

Transfers paper (covers).4

Glue is applied to the spine of the paper stack.5

Paper stack with glue applied is bound with a cover.6

Page 21

Outline of bookbinding procedure

DescriptionStage

Paper stack bound with cover is transported to the cutter section.7

Paper stack bound with cover is rotated and cut.8

Finished item is transported to the stacker.9

Cuttings are discharged to the trimmer waste tray.10

Chapter 3 - Before you start using this machine 21

Page 22

Turn the main power on

Main power

Turn the main power on

Warning:

Never plug in or unplug the power plug while your hands are wet. Doing so creates the

risk of electric shock.

Caution:

If the unit does not operate when you turn on the power switch, check if the breaker is

OFF. See ‘Power does not turn on’ on page 72.

How to turn on power

#

1

Confirm that the power plug is

plugged securely into a power

outlet.

RemarksActionStep

2

Open the power switch cover

and press the ON side (I) of the

power switch to turn on power.

Note:

The binder goes to energy save

mode immediately after the

power switch is turned on. To

turn off the energy save mode,

press the energy saver. See ‘Energy

saver and energy save mode’ on

page 24.

Close the power switch cover.3

Chapter 3 - Before you start using this machine22

Page 23

Turn the main power off

Warning:

If the power plug is disconnected from power outlet such as during service maintenance,

be sure to put a tag which warns other persons not to operate the power source, to avoid

improvident connection of the power plug.

Note:

To completely cut off the power to the binder, disconnect the power plug.

How to turn off the power

#

1

Open the power switch cover

and press the OFF side (O) of

the power switch to turn off

power.

Turn the main power off

RemarksActionStep

Close the power switch cover.2

Chapter 3 - Before you start using this machine 23

Page 24

Energy saver and energy save mode

Energy saver and energy save mode

Introduction

Turning on the energy saver (LED lights) enters the energy save mode and cuts electric

power in order to melt glue and adjust temperature. Use the energy saver when you want

to keep only the functions that transport paper (pass-through transfer) to the next device

operational, without performing binding.

The energy save mode also is entered automatically for the amount of time set from the

settings editor, when a prescribed amount of time has passed following completion of a

booklet, etc. To recover from the energy save mode, press the energy saver.

The time for entering the energy save mode following completion of a booklet can be set

from the settings editor.

Adjust the time for entering the energy save mode from the settings editor. Consult the

manual that comes with the printer for the procedure.

The energy saver LED indicates the following.

•

Lit: Glue temperature adjustment is not being done, the binder is in energy save mode.

•

Flashing: Glue temperature is being adjusted to the correct binding temperature.

•

Off: Binding is possible, the glue is at the correct temperature for binding.

Energy save mode

#

1

Press the energy saver to enter

the energy save mode.

Chapter 3 - Before you start using this machine24

RemarksActionStep

The energy save LED will light and glue

temperature adjustment will stop.

Page 25

Energy saver and energy save mode

RemarksActionStep

2

To recover from the energy save

mode, press the energy saver

again.

The energy save LED will flash and then

go out, indicating binding can now be

done.

Note:

When you do binding settings on

the printer, the Perfect BinderC1 automatically recovers from

the energy save mode.

Chapter 3 - Before you start using this machine 25

Page 26

Energy saver and energy save mode

Chapter 3 - Before you start using this machine26

Page 27

Chapter 4 Basic operations

Page 28

Make a perfect-bound book

Make a perfect-bound book

Introduction

The perfect binder is an optional finisher. This finisher enables you to create a perfectbound book.

Before you begin

Load the media for the body sets and, if needed, the covers.

Note:

Perfect binding is only available for print jobs, not for copy jobs.

Note:

Perfect binding can only be applied to a job via job preparation software like the driver,

PRISMAprepare, or other job preparation applications.

Note:

On the operator panel perfect binding can only be disabled for a job, but can not be

enabled for a job.

Make a perfect-bound book

Define the book that you want to be perfect-bound, via the driver, PRISMAprepare, or

1.

other job preparation applications.

Send it to the printer.

2.

Change job properties, if needed.

3.

Note:

You are only allowed to change the trimming, or the used paper (but not the paper size).

See the manual of the printer how to change these properties.

And of course you can disable perfect-binding in the job properties.

Print the perfect-bound book.

4.

Chapter 4 - Basic operations28

Page 29

Types of paper that can be used

Introduction

Use the appropriate paper to get the best results from the binder. If the wrong type of

paper is used, it could cause defect in binding or paper jams.

This machine can use the following types of paper for perfect binding.

Note:

All of the available paper in the printer can go through the pass-through transfer section.

Note:

Do not use the cover that contains images or text in the bonded part. It may cause defect

in a binding, since they impede adhesion of the glue.

Note:

If the paper size is not registered in the printer, be sure to use it after registering in the

printer as an irregular paper size.

Types of paper that can be used

Note:

If the position of the images or text on the body pages or the slip sheets is crooked, the

bound booklets will be poorly finished with uneven thickness. To produce nicely finished

booklets keep the position of the images and text on the body pages and slip sheets

centered.

Caution:

Do not use the curled paper. Using curled paper may cause defect in binding or paper

jams.

Types of paper that can be used

+: available; -: unavailable#

CoverPaper type

Body pages/Slip

sheets

+-Thin paper

++Plain paper

++Heavy paper

Chapter 4 - Basic operations 29

Page 30

Types of paper that can be used

Paper weight

#

90 to 300 g/m² (24 lb Bond to

110 lb Cover)

CoverPaper type

Body pages/Slip

sheets

++Recycled paper

++Color paper

++Coated paper

-+Texture paper

+-Bond paper

Body pages/Slip sheetsCover

52 to 163 g/m2 (14 lb Bond to 90 lb Index)

*1

Paper weights and the number of sheets that can

be bound are listed below.

•

52 to 63 g/m² (14 lb Bond to 17 lb Bond): 20

to 200 sheets*2 (booklet thickness: 25 mm / 1"

or less)

•

64 to 80 g/m² (17 lb Bond to 20 lb Bond): 10

to 200 sheets (booklet thickness: 25 mm / 1"

or less)

•

81 to 105 g/m² (20 lb Bond to 28 lb Bond):

10 to 150 sheets (booklet thickness: 25 mm /

1" or less)

•

106 to 163 g/m² (28 lb Bond to 90 lb Index):

1 to 10 sheets (slip sheets only)

Paper size

The binder can use the following paper sizes as covers and body pages / slip sheets.

•

•

Chapter 4 - Basic operations30

*1

Use grain short paper for cov-

ers if the paper has a paper

*2

These values may differ, depending on the image

data.

weight that is 251 g/m² (140 lb

Index) or higher.

Cover

Width (1): 257.0 to 330.2 mm (10.12" to 13")

Length (3): 364.0 to 487.7 mm (14.34" to 19.2")

Body page / slip sheets

Width (1): 257.0 to 320.0 mm (10.12" to 12.59")

Page 31

Length (2): 182.0 to 228.6 mm (7.17" to 9")

+: can be used; -: can not be used#

CoverPaper size

Types of paper that can be used

Body pages / Slip

sheets

-+A3

-+B4

-+13" x 19" (330 x 483 mm)

-+12" x 18" (305 x 457 mm)

-+11" x 17" (Tabloid)

x 17.72")

12.60")

-+SRA3 (320 x 450 mm) (12.50"

+-A4

+-B5

+-9" x 12" (226 x 305 mm)

+-Letter

+-EXEC

+-SRA4 (225 x 320 mm) (8.86" x

Chapter 4 - Basic operations 31

Page 32

Finished sizes of booklets

Finished sizes of booklets

Introduction

This machine can bind various sizes of booklets.

The sizes of the finished booklets differ according to the cutting method. The following

table shows relations between sizes of the finished booklets and sizes of cover and body

pages / slip sheets.

Be sure to confirm the cutting range is within the available ranges shown below.

Top/bottom cutting range is the total of top cutting range and bottom cutting range.

therefore, half the value of top/bottom cutting range is equal to each value of the top

range and the bottom range.

Top/bottom cutting range (C1): 13 to 79 mm (0.52" to 3.11")

Foredge cutting range (C2): 6.5 to 49.5 mm (0.26" to 1.94")

Booklet thickness (D): less than 25 mm (1")

Caution:

Be sure to use paper that is less than 297 mm (11.69") wide when cutting in one direction

or when not cutting.

Caution:

The edges of bound booklets may be folded when binding booklets with covers that are

larger than the body pages if cutting is not done.

Caution:

Use body pages and slip sheets that are the same size.

Caution:

The top/bottom cutting range of this machine is 13 to 79 mm (0.52" to 3.11"), and the

foredge cutting range is 6.5 to 49.5 mm (0.26" to 1.94") ( (you can also adjust +/- 1 mm

(0.04") for the top/bottom, and +/- 0.5 mm (0.02") for the foredge by finishing size fine

adjustment). If the finished sizes of booklets set on the printer or printer driver go over

the cutting range of this machine, the cutting will not operate correctly. Be sure to adjust

the printer's cutting range within the available value of this machine.

Chapter 4 - Basic operations32

Page 33

Cutting method and paper size

#

Cutting method

3-direction cutting (top, bottom,

foredge cutting)

Size of finished

booklet

Width:

*2

W

203 to

297

mm (8"

to

11.69")

*1

Length:

L

138 to

216

mm

(5.44"

to 8.5")

pages / slip sheets

Width:

W1

W +

top/bottom cutting

range

(C1)

Length:

L1

L +

foredge

cutting

range

(C2)

*3

Finished sizes of booklets

Size of coverSize of body

Width:

W2

W +

top/bottom cutting

range

(C1)

Length:

L2

364.0 to

L1 x 2 +

30.5 mm

(14.34"

to

L1x2+1.2")

*4

1-direction cutting (foredge cutting)

257

[B5] to

297

mm

(10.12"

to

138 to

216

mm

(5.44"

to 8.5")

W mm

(in.)

L +

foredge

cutting

range

(C2)

W mm

(in.)

364.0 to

L1 x 2 +

30.5 mm

(14.34"

to

L1x2+1.2")

*4

11.69")

No cutting

257

[B5] to

297

mm

(10.12"

to

182

[B5] to

216

mm

(7.17"

to 8.5")

W mm

(in.)

L mm

(in.)

W mm

(in.)

364.0 to

L1 x 2 +

30.5 mm

(14.34"

to

L1x2+1.2")

*4

11.69")

*1

You can also adjust the width (W) in the range of ± 1 mm (± 0.04"), and length (L) in

the range of ± 0.5 mm (0.02") by finishing size fine adjustment.

*2

If the length (L) defined as 1, be sure to set the ration of the width (W) between 1.25

and 1.5.

*3

Be sure to make the width of W1 (width of body pages / slip sheets) less than the width

of W2 (width of cover), when 3-direction cutting is done.

*4

For good looking finished booklets, the maximum length of cover you can set is 487.7

mm (19.2"). 487.7 mm (19.2") includes the total of the following values.

Length of body pages / slip sheets x 2, maximum booklet thickness (25 mm [1"]), and

maximum value of cover image placement adjustment (5 mm [0.2"]).

Chapter 4 - Basic operations 33

Page 34

Finished sizes of booklets

Cutting range

For good looking finished booklets, be sure to set the top/bottom cutting range and

foredge cutting range as follows.

#

Top/bottom cutting range

C1 = W2 - W

Cutting range is width of

cover minus width of finished booklet.

Foredge cutting range.

If length of cover is longer

than the length of body

pages / slip sheets.

C2 = (L2 - D) / 2 - L

Cutting range is length of

cover minus the booklet

thickness, divided by two.

And the length of the finished booklet is subtracted

from the result.

Foredge cutting range.

If length of cover is shorter

than the length of body

pages / slip sheets.

C2 = L1 - L

Cutting range is length of

body pages / slip sheets

minus length of finished

booklet.

Examples of finished size of booklets (3-direction cutting)

The following table shows examples that the combination of cover and body pages / slip

sheets when 3-direction cutting is done.

The paper sizes inside the wide frame of the table are the finished size of the booklets

#

Cover

13" x 19"

(320 x

450 mm)

B411" x 17"A3SRA3

Chapter 4 - Basic operations34

Page 35

pages /

slip sheets

Finished sizes of booklets

LTR9" x 12"Body

A4SRA4

(320 x

225 mm)

A4

B5

7" x 9"

7" x 9"LTR

A5B5

Note:

If the paper size is not registered in the printer, be sure to use it after registering in the

printer as an irregular paper size.

Chapter 4 - Basic operations 35

Page 36

Remove finished booklets

Remove finished booklets

Introduction

Use the following procedure to remove bound booklets from the stacker.

Note:

This operation can be performed while the device is operating.

Note:

The stacker can hold up to approximately 127 mm (5") (equivalent to 10 booklets of

100 pages of 64 g/m² (17 lb Bond) body pages / slip sheets and a cover of one 128 g/m²

(32 lb Bond) sheet) or approximately 1,000 sheets as a total. However, if the booklets

contain body pages / slip sheets that are heavier than 81 g/m² (20 lb Bond), the stacker

may not be able to hold booklets up to approximately 127 mm (5").

Note:

The stacker has two LED's: a full LED and an open LED. Each LED indicates the following.

- Full LED

Lit: The stacker is full or almost full.

Flashing: Binding operation is in progress.

- Open LED

Lit: the stacker is open.

Flashing: The stacker is preparing to open or close.

Off: The stacker is closed.

Caution:

The cuttings may enter into the stacker. If this happens, remove the cuttings from the

stacker.

Caution:

Be sure to remove all the booklets when the stacker is open. The stacker is recognized as

full if any booklets are left in it.

Chapter 4 - Basic operations36

Page 37

Remove finished booklets

Caution:

Do not use the stacker as storage. Using the stacker as storage could cause a malfunction.

Caution:

Do not move the stacker's guide with your hand. Moving the guide may cause a malfunction.

Warning:

Take care to avoid cutting your hands on the edges of the booklets when removing them.

Warning:

Be careful not to pinch your fingers in the gaps when the stacker is closing.

Warning:

Do not do operations other than removing booklets. Putting your hand into the binder

from the stacker may cause an injury.

Chapter 4 - Basic operations 37

Page 38

Remove finished booklets

Illustration

Removing finished booklets

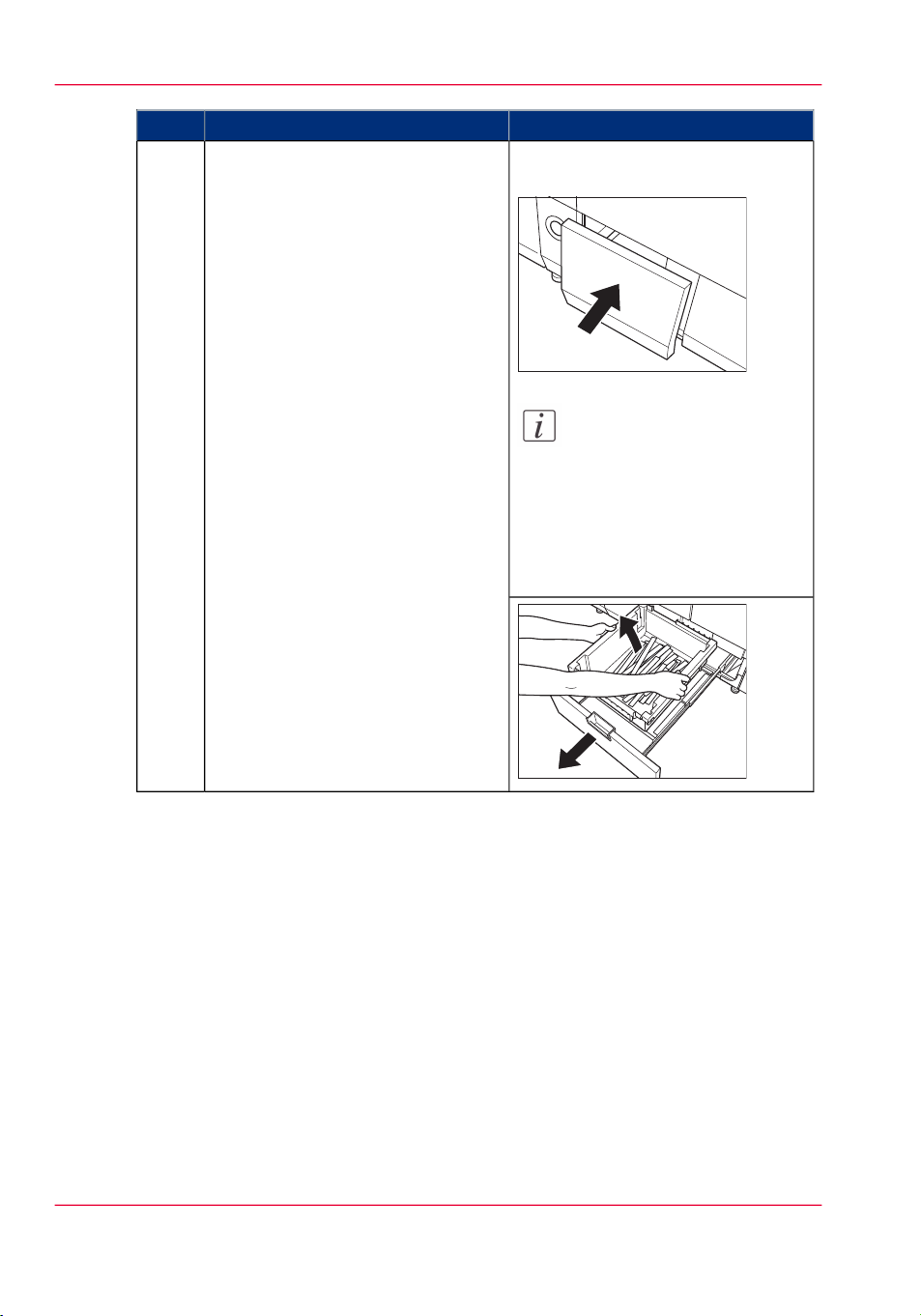

#

1

Press the open button and pull out the

stacker.

RemarksActionStep

The open LED flashes, then

lights and the stacker automatically opens. Pull the stacker out

all the way until it stops.

Note:

If the cutting is being

operated inside the machine, the stacker may

need some time to open.

Remove the booklets from the stacker.2

Chapter 4 - Basic operations38

Page 39

Remove finished booklets

RemarksActionStep

Close the stacker.3

Close it until it clicks into place.

Note:

If you open the stacker

while the binder is operating, quickly remove

the booklets and close

the stacker. If the stacker

is open, binding operations, except transferring

paper to the gathering

tray and gluing, stop. If

this happens, remove all

booklets from the stacker and then close it to

restart binding operations.

Chapter 4 - Basic operations 39

Page 40

Discard cuttings

Discard cuttings

Introduction

Use the following procedure to remove cuttings from the trimmer waste unit.

Note:

This operation can be performed while the device is operating.

Caution:

Do not place a plastic bag or other secondary container in the trimmer waste tray. Doing

so reduces the capacity of the trimmer waste tray and does not allow it to collect enough

cuttings. It might also cause a malfunction.

Caution:

Do not use the trimmer waste unit as storage. Using the trimmer waste unit as storage

could cause a malfunction.

Discard cuttings

#

Chapter 4 - Basic operations40

RemarksActionStep

Pull out the trimmer waste unit.1

Note:

The trimmer waste unit

may lock so you cannot

open it during binding

operations. If this happens, wait a short time

and try again.

Page 41

Discard cuttings

RemarksActionStep

2

Remove the trimmer waste tray and discard the cuttings.

3

Place back the trimmer waste tray and

close the trimmer waste unit.

Close the trimmer waste unit by

pressing until it clicks into place.

Note:

If you open the trimmer

waste unit while the

binder is operating,

quickly remove the cuttings and close the trimmer waste unit. If the

cuttings for a single

booklet cannot be discharged to the trimmer

waste unit, binding operations stop until it can

be discharged to the

trimmer waste unit. If

this happens, remove

the cuttings from the

trimmer waste unit and

then close it to restart

binding operations.

Chapter 4 - Basic operations 41

Page 42

Replenish glue

Replenish glue

Introduction

Use the following procedure to refill the glue.

Note:

Glue can be replenished even while the device is operating.

Caution:

Note the following precautions when storing the glue.

•

Avoid places near open flame.

•

Avoid locations subject to high temperature or humidity.

•

Store it someplace that is out of reach of children.

Caution:

Use the supplied scoop to replenish the glue. Do not use the supplied scoop except for

replenishing the glue. Also store the scoop in a safe place for future use.

Caution:

Do not use glue that has fallen on the floor because it might have dust or dirt in it.

Caution:

Use the genuine glue for this binder to replenish the glue. Using a type of glue other than

the genuine glue may cause the binder to malfunction.

Caution:

Do not allow glue to get into the binder's mechanical parts through the gaps in the binder.

If glue gets into the binder's mechanical parts it could cause a malfunction.

Chapter 4 - Basic operations42

Page 43

Caution:

Do not put anything other than glue into the glue container. If something other than

glue gets into the glue container it could cause a fire or a malfunction.

Caution:

Do not add so much glue that it goes over the limit mark. Doing so may prevent the glue

container from closing or cause glue to spill inside the mechanical parts of the binder.

Caution:

When the glue is filled up, it may be difficult to open the glue container. If this happens,

open the glue container slowly again and again. Opening it too hard might cause a malfunction.

Replenish glue

#

1

Pull on the handle to open the glue

container.

Replenish glue

RemarksActionStep

Extend the glue container until it

stops.

2

Open the glue container's lid and its

inner lid and replenish the glue.

Fill the glue container with glue so it

is even and level and does not go over

the limit mark.

Chapter 4 - Basic operations 43

Page 44

Replenish glue

3

RemarksActionStep

Close the glue container's lid and its

inner lid and close the glue container

by pressing until you hear it click into place.

Note:

The glue that is added to the

glue container is transferred

to the binder as the glue in

the binder is consumed. The

binder can hold about 380 g

(0.8 lb) of glue.

Chapter 4 - Basic operations44

Page 45

Clean the binder

Introduction

Clean the outside of the machine if it gets dirty after using it for a long period of time.

Please note the following points to prevent malfunctions or electric shock when cleaning

the machine.

Caution:

Do not use any cleanser other than water or a neutral cleanser diluted with water. Doing

so may cause the machine's plastic parts to deteriorate or crack.

Caution:

Be sure to dilute any neutral cleanser with water.

Caution:

The machine does not need to be lubricated. Do not lubricate the machine.

Clean the binder

Warning:

Turn off the power switch and unplug the power plug (see ‘Turn the main power off’ on

page 23). It may result in a fire or electric shock.

Warning:

Never plug in or unplug the power plug while your hands are wet. Doing so creates the

risk of electric shock.

Warning:

Do not use alcohol, benzene, paint thinner, or other flammable substances. The volatile

or flammable materials could come in contact with the machine's electronic components

and cause a fire or a short circuit.

Chapter 4 - Basic operations 45

Page 46

Clean the binder

Clean the binder

#

1

RemarksActionStep

Open the power switch cover and press

the OFF side of the power switch to turn

off the power before removing the power

plug.

2

Dampen a soft cloth in water or neutral

cleanser that has been diluted with water

and thoroughly wring it out before wiping

any dirt from the machine.

After cleaning the machine with

a neutral cleanser, be sure to

wipe off the neutral cleanser with

a cloth that has been dampened

with water.

3

After cleaning the machine, use a soft dry

cloth to dry it.

4

Plug the power plug into to power outlet

and press the ON side of the power

switch and then close the power switch

cover.

Chapter 4 - Basic operations46

Page 47

Chapter 5 Troubleshooting

Page 48

Clear a paper jam inside the top cover

Clearing paper jams

Clear a paper jam inside the top cover

Introduction

When a paper jam occurs, the printer display will indicate its location. The display will

continue to indicate the location until the paper jam is cleared.

When to do

Perform this procedure when a paper jam occurs on the transfer path to the gathering

tray in the top cover.

Note:

If paper jams at multiple locations, clear each one in the sequence indicated on the

printer display.

Warning:

When clearing a paper jam, take care that you do not cut your hands on the edges of the

paper.

Warning:

When removing jammed paper from inside the product, take care that you do not cut

your hands on internal components. If you experience difficulties removing paper, contact

your local authorized dealer.

Warning:

Frequent paper jams at the same location can mean that there are pieces of torn paper

inside the mechanism. If you experience difficulties removing pieces of torn paper, contact

your local authorized dealer.

Warning:

Be careful not to pinch your fingers in the gaps when the top cover is closing.

Chapter 5 - Troubleshooting48

Page 49

Clear a paper jam inside the top cover

#

Open the top cover.1

Clear a paper jam inside the top cover

RemarksActionStep

Note:

When the top cover is

opened, the interlock switch

is activated, power to the

gathering tray is cut off, and

then the gathering tray stops

operating.

Note:

If the machine and equipment with the sheet inserter

are connected, remove the

paper set on the upper tray

and open it, and then open

the top cover.

Chapter 5 - Troubleshooting 49

Page 50

Clear a paper jam inside the top cover

Lift the gatherings tray's guide (A1).2

RemarksActionStep

Note:

The gathering tray's guide

(A1) returns to its normal

position automatically during operations.

3

Remove the jammed paper from the

gathering tray (A1).

Note:

If there are many sheets of

paper in the gathering tray,

remove them from the left

side of the gathering tray

without pulling on them too

hard.

Chapter 5 - Troubleshooting50

Page 51

Clear a paper jam inside the top cover

RemarksActionStep

4

Open the guide of he gathering tray

transfer section (A2).

Remove any jammed paper if there

is any.

5

Close the guide of the gathering tray

transfer section (A2).

Close the top cover.6

7

Perform operations in accordance

with the instructions that appear on

the printer display.

Note:

If the display continues to

indicate a paper jam clearing

procedure, continue to perform the applicable procedure until the paper jam is

cleared.

Chapter 5 - Troubleshooting 51

Page 52

Clear a paper jam inside the front cover

Clear a paper jam inside the front cover

Introduction

When a paper jam occurs, the printer display will indicate its location. The display will

continue to indicate the location until the paper jam is cleared.

Note:

If paper jams at multiple locations, clear each one in the sequence indicated on the

printer display.

Note:

The front cover LED is on the front cover

Lit: The front cover is locked and cannot be opened.

Off: The front cover is unlocked and can be opened.

Warning:

When clearing a paper jam, take care that you do not cut your hands on the edges of the

paper.

Warning:

When removing jammed paper from inside the product, take care that you do not cut

your hands on internal components. If you experience difficulties removing paper, contact

your local authorized dealer.

Warning:

Frequent paper jams at the same location can mean that there are pieces of torn paper

inside the mechanism. If you experience difficulties removing pieces of torn paper, contact

your local authorized dealer.

Warning:

Close the front cover carefully so you do not pinch your fingers in the gaps when it is

closing. Failure to do so could cause injury.

Chapter 5 - Troubleshooting52

Page 53

Clear a paper jam inside the front cover

#

Open the front right cover.1

Clear a paper jam inside the front cover

RemarksActionStep

Make sure that the front cover LED

is off.

Note:

The front cover is locked

during binding operations.

It unlocks when a paper jam

occurs.

Note:

When the front cover is

opened, the interlock switch

is activated and power to all

the operating parts of the

binder is cut off. However,

power to the stacker and

trimmer waste unit is not cut

off. Therefore, even if the

front cover is opened, you

can remove finished booklets

from the stacker and remove

cuttings from the trimmer

waste unit.

Chapter 5 - Troubleshooting 53

Page 54

Clear a paper jam inside the front cover

2

Open the lower guide for gathering

tray transfer section (B).

RemarksActionStep

3

Remove any paper jammed inside the

lower guide for gathering tray transfer

section (B), and then close the guide.

4

Open the entrance transfer guide

(C)).

5

Remove any paper jammed inside the

entrance transfer guide (C)), and

then close it.

Open the front left cover.6

Chapter 5 - Troubleshooting54

Page 55

Clear a paper jam inside the front cover

RemarksActionStep

7

Open the left guide (D1) of the

binder/pass-through transfer section.

Open the exit guide (D2).8

9

11

Remove any paper jammed inside the

guide.

Close the exit guide (D2).10

Close the left guide (D1) of the

binder/pass-through transfer section.

Chapter 5 - Troubleshooting 55

Page 56

Clear a paper jam inside the front cover

12

Open the right guide (D3) of the

binder/pass-through transfer section.

RemarksActionStep

13

14

Remove any paper jammed inside the

guide.

Note:

When making booklets using

thin paper, a paper jam may

occur inside the guide. In

this case, pull out the paper

(cover) slowly to remove it.

If the paper is under the guide or is

difficult to remove, turn the dial

(D4) to the right to shift the paper

out.

15

Close the right guide (D3) of the

binder/pass-through transfer section.

Chapter 5 - Troubleshooting56

Page 57

16

Clear a paper jam inside the front cover

RemarksActionStep

Close the front left cover and then

close the front right cover.

17

Perform operations in accordance

with the instructions that appear on

the printer display.

Note:

If the display continues to

indicate a paper jam clearing

procedure, continue to perform the applicable procedure until the paper jam is

cleared.

Chapter 5 - Troubleshooting 57

Page 58

Clear a paper jam in the stacker

Clear a paper jam in the stacker

Introduction

When a paper jam occurs, the printer display will indicate its location. The display will

continue to indicate the location until the paper jam is cleared.

When to do

Perform this procedure when a paper jam occurs in the stacker.

Note:

If paper jams at multiple locations, clear each one in the sequence indicated on the

printer display.

Caution:

Do not move the stacker's guide with your hand. Moving the guide may cause a malfunction.

Warning:

When clearing a paper jam, take care that you do not cut your hands on the edges of the

paper.

Warning:

When removing jammed paper from inside the product, take care that you do not cut

your hands on internal components. If you experience difficulties removing paper, contact

your local authorized dealer.

Warning:

Frequent paper jams at the same location can mean that there are pieces of torn paper

inside the mechanism. If you experience difficulties removing pieces of torn paper, contact

your local authorized dealer.

Warning:

Be careful not to pinch your fingers in the gaps when the stacker is closing.

Chapter 5 - Troubleshooting58

Page 59

Clear a paper jam in the stacker

#

1

Press the open button and pull out

the stacker.

Remove all booklets from the stacker.2

Clear a paper jam in the stacker

RemarksActionStep

Pull the stacker out all the way until

it stops.

Chapter 5 - Troubleshooting 59

Page 60

Clear a paper jam in the stacker

Close the stacker.3

RemarksActionStep

Close the stacker until it clicks into

place.

Note:

If the paper jam has occurred

again even though you removed all booklets from the

stacker, pull out the trimmer

waste unit to discard the

cuttings.

Chapter 5 - Troubleshooting60

Page 61

Reduce frequent paper jams or errors

Introduction

Frequent paper jams, errors or defect in binding such as follow can mean that paper is

curled or paper weight is out of available range for this machine.

•

Defect in attaching the glue.

•

Unequal cutting size.

•

Folded bonding area in corner of inserted paper.

If paper jams, errors or defect in binding occur frequently, refer to the instructions described below to confirm paper curl and perform the curl correction, or see ‘Specifications’

on page 76 to confirm available paper weight of this machine. Also before performing

perfect binding, we recommend you to check the curl state of the used paper.

Reduce frequent paper jams or errors

#

RemarksActionStep

1

Select the paper source in the printer

used for perfect binding.

Reduce frequent paper jams or errors

2

Make copies without performing

perfect binding and discharge the

paper to the finisher.

Chapter 5 - Troubleshooting 61

Page 62

Reduce frequent paper jams or errors

3

Confirm the curl is in the range of

specified value.

RemarksActionStep

The specified values are as follows:

•

Total height of curl: -10 mm to

+10 mm (-0.4" to +0.4").

Upper (1) : 0 mm to +10 mm (0"

to +0.4")

Lower (1) : 0 mm to -10 mm (0"

to -0.4")

•

Length of curl (2): More than 50

mm (2")

Note:

If downward curl is measured, it may cause incorrect

value since the curl is negated. Be sure to measure upward curl.

4

If the curl state of paper exceeds

specified value, adjust the curl correction to make it an appropriate range.

You can adjust the curl correction for

a specific paper in the Settings Editor, section 'Media management',

option 'Printer adjustment'.

Note:

If the curl can not be corrected within the specified range

by following the adjustment

above, or paper jams, errors

or defects in bindings occur

frequently, load other paper

type into the paper source.

Chapter 5 - Troubleshooting62

Page 63

Job cannot be perfect-bound error scenario

Other

Job cannot be perfect-bound error scenario

Introduction

In some case a perfect bound book cannot be handled by the perfect binder. An error

scenario is given on the operator panel.

When to do

Error scenario is present on the operator panel.

Solve the perfect-bound error scenario

Put the printer on hold to prevent it from sending the job again after the error has been

1.

solved. See the manual of the printer how to do this.

Touch 'OK' to proceed.

2.

Delete the job, or move the job to the 'Waiting jobs'. In the latter, case you can disable

3.

perfect binding.

Open job properties and disable perfect binding. See the manual of the printer how to

do this. Then you can print the job again, without perfect binding.

Chapter 5 - Troubleshooting 63

Page 64

Check the status of the trimmer waste box

Check the status of the trimmer waste box

Introduction

The Perfect Binder has a trimmer waste box. The trimmer waste box contains the cuttings

that result from the trimming process. You can check the status of the trimmer waste box

in the dashboard (see the manual of the printer) and in the 'System' view of the printer.

The icons in the following table indicate the status of the trimmer waste box.

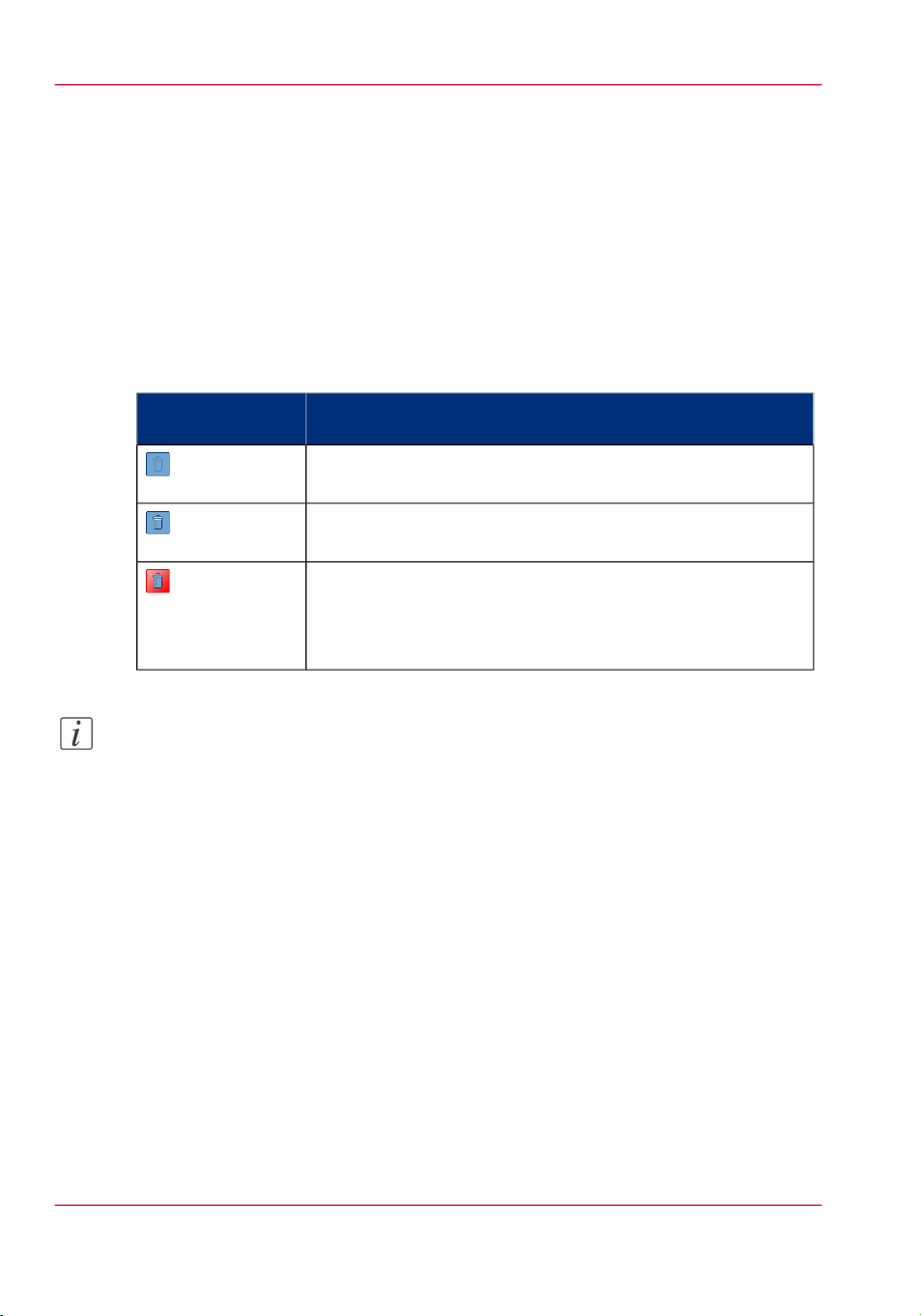

The meaning of the trimmer waste box icons

The trimmer waste box icons#

DescriptionTrimmer waste

box icon

The trimmer waste box icon is blue. The waste box inside the

icon is grayed out. The trimmer waste box status is: 'Absent'.

The trimmer waste box icon is blue. The trimmer waste box is

not full. The trimmer waste box status is: 'OK'.

The trimmer waste box icon is red. The trimmer waste box

status is: 'Full'. The printer stops.

To continue printing, empty the trimmer waste box (see ‘Discard

cuttings’ on page 40).

Note:

The dashboard will only display an icon when the trimmer waste box is either absent of

full.

How to check the status of the trimmer waste box

When the trimmer waste box is absent, the dashboard displays the grayed out waste box

1.

icon.

When the trimmer waste box is full, the dashboard displays the red waste box icon.

2.

On the operator panel, touch 'System' -> 'Printer'.

3.

The 'Finishers' view displays the status of the trimmer waste box.

Chapter 5 - Troubleshooting64

Page 65

Check if the blade and the blade receptor must be replaced

Check if the blade and the blade receptor must be replaced

Introduction

The perfect binder contains a blade and a blade receptor. The blade and blade receptor

perform the cutting. Both can wear out. When the blade or blade receptor must be replaced, the dashboard (see the manual of the printer) will display the maintenance required

icon. When the dashboard displays this icon, a maintenance action is required. This icon

does not indicate which action is required, so you must check which action is required.

The procedure below describes how to find the required maintenance actions.

The meaning of the maintenance required icon

The maintenance required icon#

DescriptionMaintenance re-

quired icon

Maintenance is required. Follow the procedure below to check

which maintenance is required.

How to check if the blade and blade receptor must be replaced

When the dashboard displays the maintenance required icon, touch 'System' -> 'Mainte-

1.

nance'.

Touch 'Start maintenance' to open the list of 'Maintenance tasks'.

2.

When the list of 'Maintenance tasks' indicates that the blade or the blade receptor must

be replaced, you must call Service.

Note:

Only Service is allowed to replace the blade and the blade receptor.

Chapter 5 - Troubleshooting 65

Page 66

Check the status of the glue

Check the status of the glue

Introduction

The Perfect Binder contains a glue container. You can check the status of the glue container in the dashboard (see manual of the printer) and in the 'System' view of the

printer. The icons in the following table indicate the status of the glue container.

The meaning of the status of the glue container icons

The glue container icons#

DescriptionGlue container

icon

The glue container icon is blue. The glue container is not

empty. The glue container status is: 'OK'.

The glue container icon is red. The glue container is empty.

The glue container status is: 'Empty'. The printer stops.

To continue printing, refill the glue (see ‘Replenish glue’ on page

42).

Note:

Only when the glue container is empty, the status is visible in the dashboard.

How to check the status of the glue container

When the glue container is empty, the dashboard displays the red glue container icon.

1.

On the operator panel, touch 'System' -> 'Printer'.

2.

The 'Finishers' section displays the status of the glue container.

Chapter 5 - Troubleshooting66

Page 67

Adjust cover position

Introduction

You can adjust the cover position, if the cover is out of position in relation to the stacked

body pages.

When to do

If the cover is out of position in relation to the stacked body pages.

Before you begin

Be sure that the system is in standby.

Adjust cover position

Touch the 'System' button.

1.

Press 'Maintenance'.

2.

Touch 'Start maintenance' to open the list of 'Maintenance tasks'.

3.

In the list of 'Maintenance tasks' the task to adjust the cover position can be selected.

Touch this task and follow the instructions.

4.

Adjust cover position

Chapter 5 - Troubleshooting 67

Page 68

Adjust glue amount

Adjust glue amount

Introduction

When you make a booklet in the perfect binding mode, you must use the correct amount

of glue, or the bound booklets may be poorly finished, as shown below.

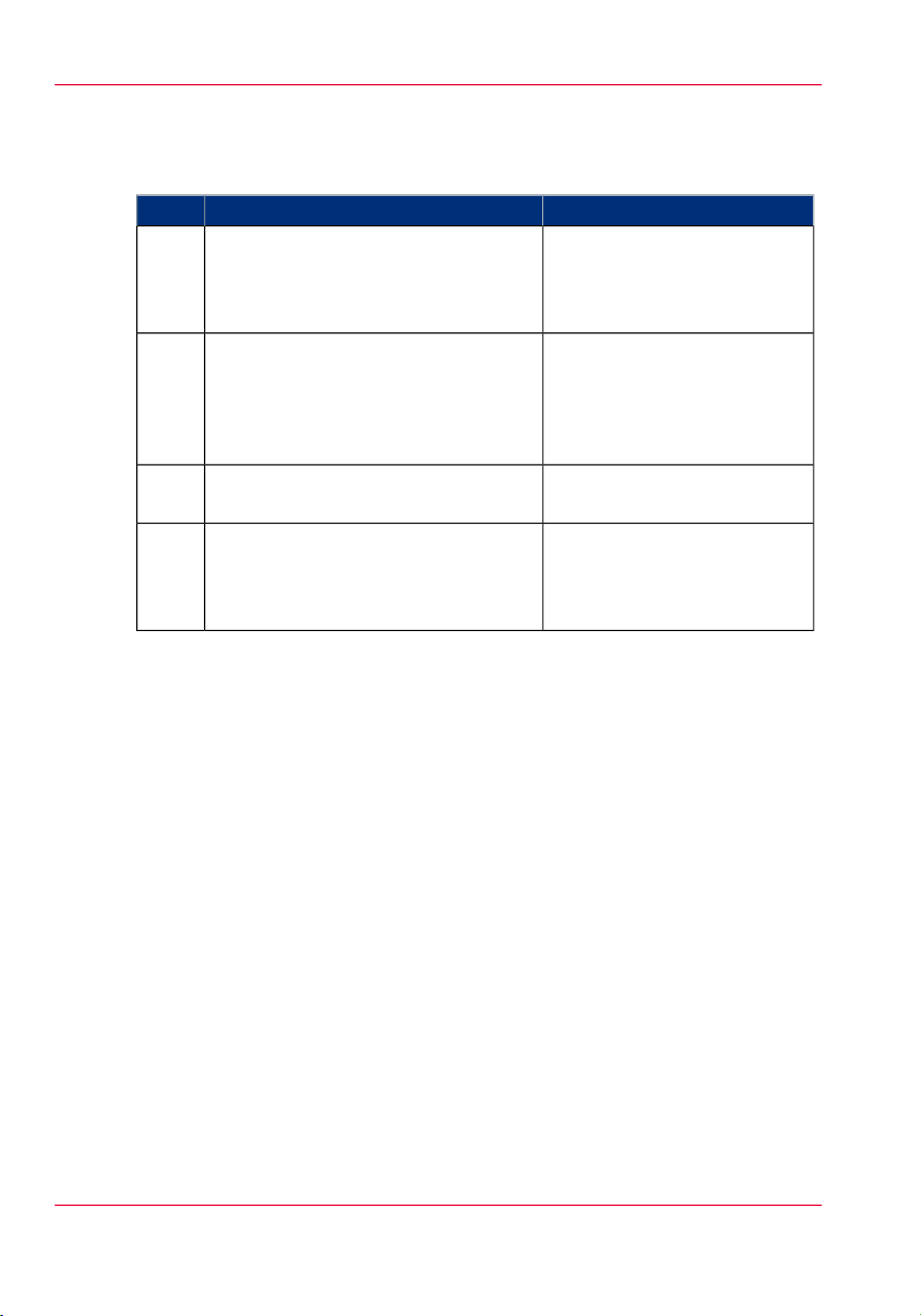

#

Normal

Finishing conditionAmount of glue

Too much glue

Too little glue

When to do

When the bound booklets are poorly finished.

Glue protrudes from

booklet.

Booklet jam occurs.

Spine is not attached

evenly to the main document.

Main document detaches

from the cover.

Chapter 5 - Troubleshooting68

Page 69

Note:

When you adjust the amount of glue, make a booklet every time you change the amount

of glue in one level increments, and check the finishing condition of the bound booklet.

Adjust glue amount

Touch the 'System' button.

1.

Press 'Maintenance'.

2.

Touch 'Start maintenance' to open the list of 'Maintenance tasks'.

3.

In the list of 'Maintenance tasks' the task to adjust the glue amount can be selected.

Touch this task and follow the instructions.

4.

Adjust glue amount

Chapter 5 - Troubleshooting 69

Page 70

Alarm list

Alarm list

Introduction

This section explains the alarm that can occur with this product.

Alarm will be indicated on the printers display. See the manual that comes with the

printer for information about alarm message or required action.

Alarm list

#

the gathering tray.

More informationRequired actionAlarm timing

Error scenarioPaper remaining in

Remove the paper

from the gathering

tray.

‘Clear a paper jam

inside the top cover’

on page 48

‘Clear a paper jam

inside the front cover’ on page 52

‘Clear a paper jam

in the stacker’ on

page 58

Out of glue.

Trimmer waste

unit is full.

Blade reaching its

replacement limit.

board (see ‘Check

the status of the glue’

on page 66)

Status in the dashboard (see ‘Check

the status of the

trimmer waste box’

on page 64)

Status in the dashboard (see ‘Check if

the blade and the

blade receptor must

be replaced’ on page

65)

Replenish the glue.Status in the dash-

Remove cuttings

from the trimmer

waste tray.

Replace the blade.

Call Service or

contact your local

authorized dealer.

‘Replenish glue’ on

page 42

‘Discard cuttings’ on

page 40

Chapter 5 - Troubleshooting70

Page 71

Blade receptor

reaching its replacement limit.

Status in the dashboard (see ‘Check if

the blade and the

blade receptor must

be replaced’ on page

65)

Alarm list

More informationRequired actionAlarm timing

Replace the blade

receptor. Call Service or contact

your local authorized dealer.

Error scenarioDefective booklets.

Remove the paper

stack of the defective booklets from

‘Remove finished

booklets’ on page

36

the stacker.

Error scenarioStacker is full.

Remove the finished booklets from

the stacker.

‘Remove finished

booklets’ on page

36

Chapter 5 - Troubleshooting 71

Page 72

Power does not turn on

Power does not turn on

Warning:

If the product's breaker is tripped, do not reset it. Doing so creates the risk of electric

shock, fire, smoke, or tripping the room's breaker.

Power does not turn on

#

1

If the product does not operate when you

turn on the power switch, be sure to

check if the breaker is OFF.

RemarksActionStep

2

If the breaker is OFF, do not reset it.

Contact your local authorized dealer.

Chapter 5 - Troubleshooting72

Page 73

When the main power is turned off during operations (check the stacker)

When the main power is turned off during operations (check

the stacker)

Introduction

If the main power is tuned off during operations, the cuttings may remain in the stacker.

Caution:

Do not operate the machine when the cuttings remain in the stacker, as this may result

in a malfunction.

When the main power is turned off during operations (check the stacker)

After turning the main power on again, open the stacker and check if the cuttings remain

1.

in it.

If the cuttings remain in the stacker, remove all of the cuttings from the stacker.

2.

Chapter 5 - Troubleshooting 73

Page 74

When the main power is turned off during operations (check the stacker)

Chapter 5 - Troubleshooting74

Page 75

Appendix A Miscellaneous

Page 76

Specifications

Specifications

Perfect Binder-C1

Specifications of Perfect Binder-C1#

method

SpecificationsItem

Perfect bindingBinding

Cutting

method

Booklet size

(after 3-direction cutting)

Booklet thickness

Cutting range

*1

Body pages /

slip sheets

*1

Number of

sheets

Stack rotation 3-direction or 1-direction (foredge)

cut

(no cutting is also possible)

Width: 203 to 297 mm (8" to 11.69")

Length: 138 to 216 mm (5.44" to 8.5")

Recommended booklet size: A4, B5, A4, LTR, 7"

x 9"

Approximately 1 to 25 mm [0.04" to 1"] (not including covers)

Top/bottom: 13 to 79 mm (0.52" to 3.11"),

foredge: 6.5 to 49.5 mm (0.26" to 1.94")

•

Paper weight 52 to 63 g/m² (14 lb to 17 lb

Bond): 30 to 200 sheets

*2

(booklet thickness: 25 mm [1"] or less)

•

Paper weight 64 to 80 g/m² (17 lb to 20 lb

Bond): 10 to 200 sheets

(booklet thickness: 25 mm [1"] or less)

•

Paper weight 81 to 105 g/m² (20 lb to 28 lb

Bond): 10 to 150 sheets

(booklet thickness: 25 mm [1"] or less)

•

Paper weight 106 to 163 g/m² (28 lb Bond to

90 lb Index): 1 to 10 sheets

(slip sheets only)

Sizes

Width: 257.0 to 320.0 mm (10.12" to 12.59")

Length: 182.0 to 228.6 mm (7.17" to 9")

Recommended paper size: A4, B5, 9" × 12", LTR,

EXEC, 225 x 320 mm (8.86" × 12.59" [SRA4])

52 to 163 g/m² (14 lb Bond to 90 lb Index)Paper weight

Appendix A - Miscellaneous76

Page 77

Covers

Specifications

SpecificationsItem

1 sheetNumber of

sheets

go through the

binder/passthrough transfer section

Glue capacity

Trimmer

waste unit capacity

Stacker capacity

Sizes

Paper weight

Width: 257.0 to 330.2 mm (10.12" to 13")

Length: 364.0 to 487.7 mm (14.34" to 19.2")

Recommended paper size: A3, B4, 13" × 19", 12"

× 18", 11" × 17", 320 x 450 mm (12.60" × 17.72"

[SRA3])

*3

90 to 300 g/m² (24 lb Bond to 110 lb Cover)

According to the printer specificationsSizesPaper that can

52 to 300 g/m² (14 lb Bond to 110 lb Cover)Paper weight

Approximately 380 g [0.8 lb] (Enough for approximately 135 booklets when binding 100 sheets of

A4 80 g/m² (20 lb Bond)

*

Including the capacity of the glue container.

*4

When binding 100 sheets of A4 80 g/m² (20 lb

Bond) and cutting them to B5 size: Space for cut-

tings from approximately 15 booklets.

Approximately 127 mm [5"] (equivalent to 10

booklets of 100 pages of 64 g/m² (17 lb Bond)

body / slip sheets and a cover of one 128 g/m² (32

lb Bond) sheet *4) or approximately 1000 sheets

as a total.

*4

Warm up time

Installation environment

Power

power consumption

Dimensions

(W x D x H)

440 seconds max. (Temperature: 20°C [68 °F],

Humidity: 50% RH)

Temperature 15 to 27 °C (59 to 81 °F)

Humidity 20 to 80% RH (no condensation)

US: 208V AC, 60 Hz, 2.6 A

EUR/Oceania: 220-240 V AC, 50/60 Hz, 2.6 A

Approximately 623 WMaximum

922 mm × 791 mm × 1,300 mm (36 3/8" × 31

*5

1/8" × 51 1/4")

Appendix A - Miscellaneous 77

Page 78

Specifications

*1

(foredge) in the range of +/- mm by finishing size fine adjustment. If the length defined

as 1, be sure to set the ration of width between 1.25 and 1.5.

*2

*3

or higher.

*4

*5

machine.

SpecificationsItem

Approximately 306 kg (674.6 lb)Weight

You can also adjust the width (top/bottom) in the range of +/- 1 mm, and length

Paper weight differs depending in the connected host machine.

Use grain short paper for covers if the paper has a weight that is 251 g/m² (140 lb Index)

These values are for reference purposes. They may differ from actual values.

These values do not include the size of the port and the power cord on the back of the

Appendix A - Miscellaneous78

Page 79

Glossary

#

Perfect binding

Glossary

Description

A binding method that used glue to bind the body pages into a

cover.

This machine does not need to mill (grind) the body pages to firmly

attach the covers to the body pages.

Foredge

Slip sheets

Bottom

Top

Grain short

The outside edge of the book where the book opens (opposite of

the spine).

Cut when doing 3-direction of 1-direction cutting.

Paper that separates part of the body pages into text blocks or

chapter pages.

The lower edge of the book.

Cut when doing 3-direction cutting.

The upper edge of the book.

Cut when doing 3-direction cutting.

Paper whose fibers run parallel to the short dimension of the sheet.

Use grain short paper for covers if the paper has a paper weight that

is 251 g/m² (140 lb Index) or higher.

Appendix A - Miscellaneous 79

Page 80

Index

Index

Adjust

Glue amount ..................................................69

B

Binder

Cleaning .........................................................45

Binder transfer section

Binder transfer section ....................................18

Binding position

Binding position .............................................18

Blade

Blade ..............................................................65

Replacement ...................................................65

Status .......................................................65, 70

Blade receptor

Blade receptor .................................................65

Replacement ...................................................65

Status .......................................................65, 70

Body page

Number of sheet .............................................76

Paper ..............................................................29

Paper weight ...................................................76

Size .................................................................76

Bookbinding procedure

Bookbinding procedure ..................................20

Booklet

Finished ..........................................................36

Size ..........................................................32, 76

Thickness .......................................................76

Bottom

Bottom ...........................................................79

Breaker

Breaker .......................................10, 13, 16, 72

Check sheet ....................................................13

Test .........................................................10, 13

Test button .....................................................16

C

Capacity

Glue ...............................................................76

Stacker ............................................................76

Trimmer waste unit ........................................76

Cleaning

Cleaning .........................................................45

Conversion table for commercial names and user

interface names

Conversion table for commercial names and user

interface names .................................................8

Cover

Cover ..............................................................67

Number of sheet .............................................76

Paper ..............................................................29

Paper weight ...................................................76

Size .................................................................76

Cover position

Cover position ................................................67

Adjust .............................................................67

Curl

Curl ................................................................61

Cutter section

Cutter section .................................................18

Cutting method

Cutting method .......................................33, 76

Cutting range

Cutting range ...........................................34, 76

Cuttings

Cuttings .........................................................40

Remove ..........................................................40

D

Define

Perfect binding ...............................................28

Dimension

Perfect binder .................................................76

Disable perfect binding

Disable perfect binding ............................28, 63

E

Energy save mode

Energy save mode ...........................................24

Energy saver

Energy saver ...................................................24

LED .........................................................16, 24

Error

Error ...............................................................61

Reduce ...........................................................61

Error handling

Error handling ............................48, 52, 58, 70

Breaker ...........................................................72

Perfect binding ...............................................63

Power .......................................................72–73

80

Page 81

Index

Stacker ............................................................73

Error scenario

Error scenario .................................................70

Perfect binding ...............................................63

F

Finished booklet

Finished booklet ................................32, 36, 68

Defective ........................................................70

Problem ..........................................................68

Foredge

Foredge ...........................................................79

Front cover

LED ...............................................................16

Left .................................................................16

Paper jam .......................................................52

Right ..............................................................16

G

Gathering tray

Gathering tray ................................................18

Transfer section ..............................................18

Glue

Glue ..................................................42, 66, 68

Capacity .........................................................76

Refill ...............................................................42

Replenish ........................................................42

Status .......................................................66, 70

Glue amount

Glue amount ..................................................68

Adjust .............................................................69

Glue container

Glue container .........................................42, 66

Status .......................................................66, 70

Glue container icon

Glue container icon ........................................66

Glue icon

Glue icon ........................................................66

Glue unit

Glue unit .................................................16, 42

Gluing section

Gluing section ................................................18

Grain short

Grain short .....................................................79

H

Hardware naming in User Interfaces

Hardware naming in User Interfaces .................8

I

Installation

Environment ..................................................76

M

Main power

Main power .......................................72–73, 76

Off .................................................................23

On ..................................................................22

Maintenance required icon

Maintenance required icon .............................65

N

Number of sheets

Body page .......................................................76

Cover ..............................................................76

Slip sheet ........................................................76

P

Paper

Paper ..............................................................29

Body page .......................................................29

Cover ..............................................................29

Curl ................................................................61

Size .................................................................30

Slip sheet ........................................................29

Type ...............................................................29

Weight ...........................................................30

Paper jam

Paper jam .............................48, 52, 58, 61, 70

Front cover .....................................................52

Reduce ...........................................................61

Stacker ............................................................58

Top cover .......................................................48

Paper weight

Body page .......................................................76

Cover ..............................................................76

Slip sheet ........................................................76

Pass-through transfer section

Pass-through transfer section ..........................18

Perfect binder

Cleaning .........................................................45

Dimension ......................................................76

81

Page 82

Weight ...........................................................76

Perfect binding

Perfect binding .........................................28, 79

Define ............................................................28

Disable ...........................................................28