Page 1

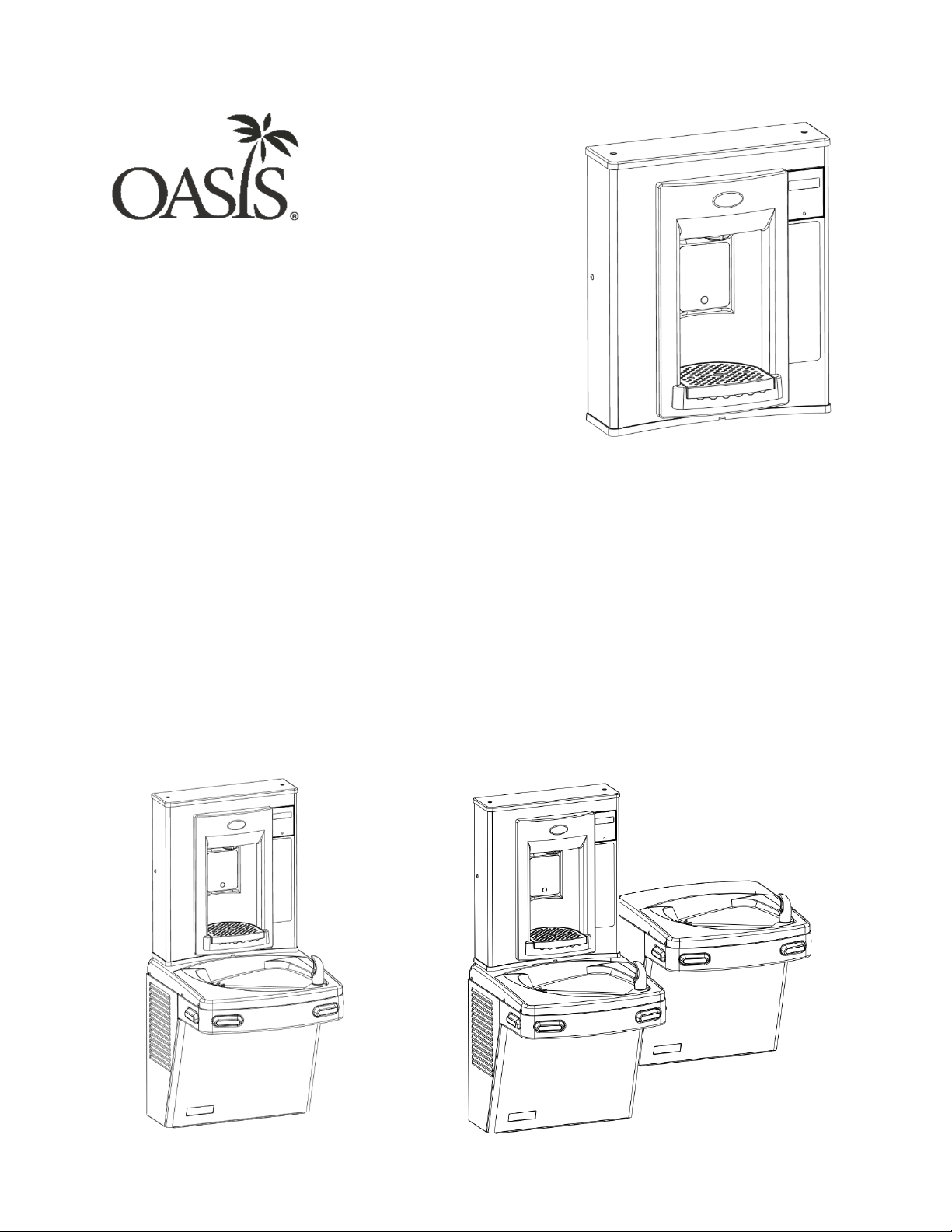

Water Coolers

VERSAFILLER®

Model PWEBF

Fountains/VersaFiller combo.

Installation Instructions

The Hands-Free VersaFiller is an extension of the Aqua Pointe® product line

that mounts directly above Versacooler® I and II products. If the cooler outlet

does not have two useable plugs, an outlet splitter will need to be used.

If installed onto a refrigerated cooler, chilled water can be dispensed through

the VersaFiller. Otherwise, room temperature water will be dispensed.

The VersaFiller is shipped partially assembled.

On the combo units, the cooler is plumbed and ready to attach to the

VersaFiller.

When completed, the finished assembly will look like this:

OR

1

Page 2

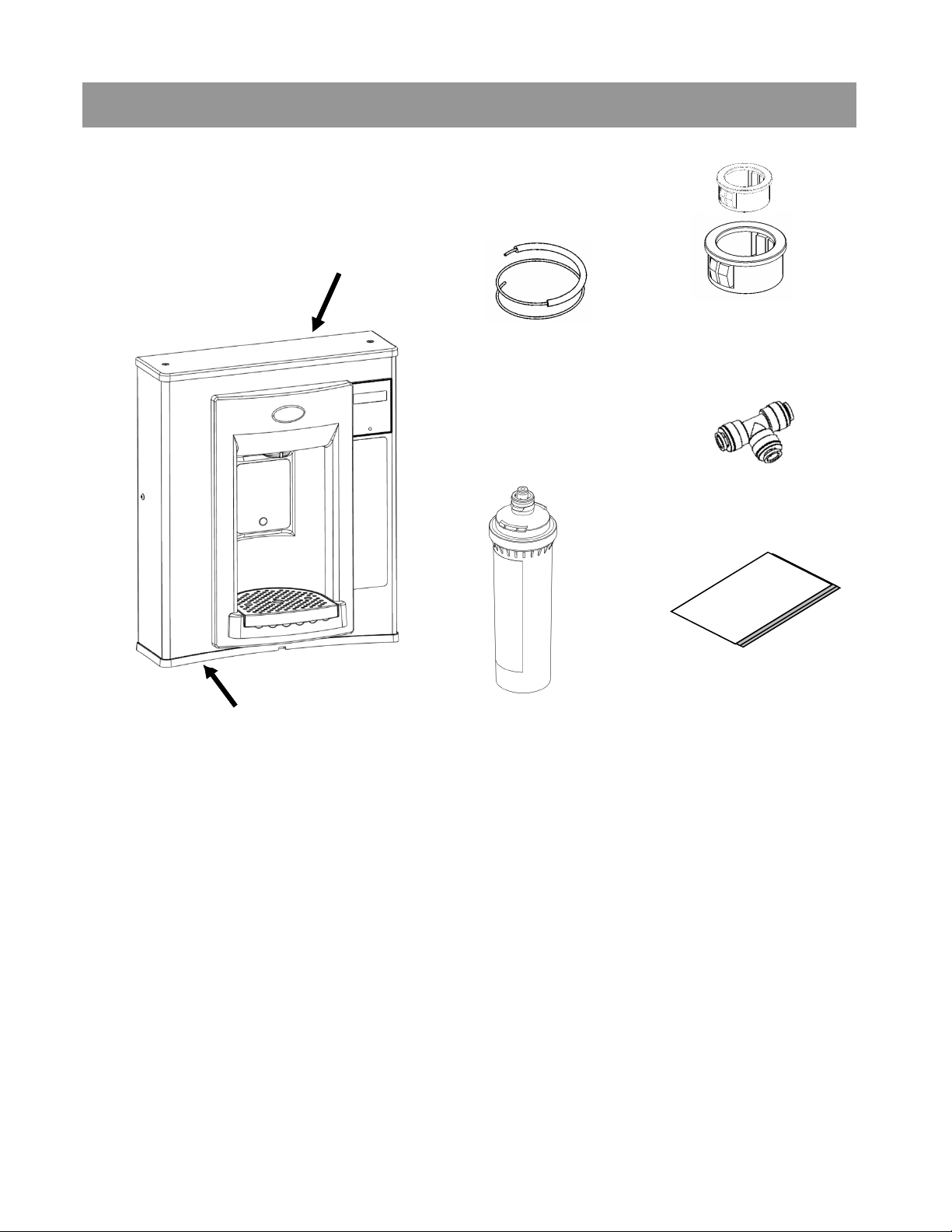

Section 1: Getting Started

What’s Included:

Top Cap

VersaFiller Hands-Free

Bottle Filler

38” of ¼ OD plastic

tubing with 19” of

sponge tubing

insulation (included

with “Versafiller ready”

coolers)

Snap bushings 7/8”

and 1½”

Quick connect tee

fitting

Installation

instructions

Rubber

Gasket

Versafilter II

Versafilter II is optional

Tools required:

3/8” pilot drill and either a step drill bit up to 7/8” diameter that will drill

through SS top or 7/8” diameter punch die (retrofit version only)

Electric drill; wrench for punch die

Small tubing cutter for copper tube

1/4“ nut driver

# 2 Phillips screw driver

#15 torx bit driver

2

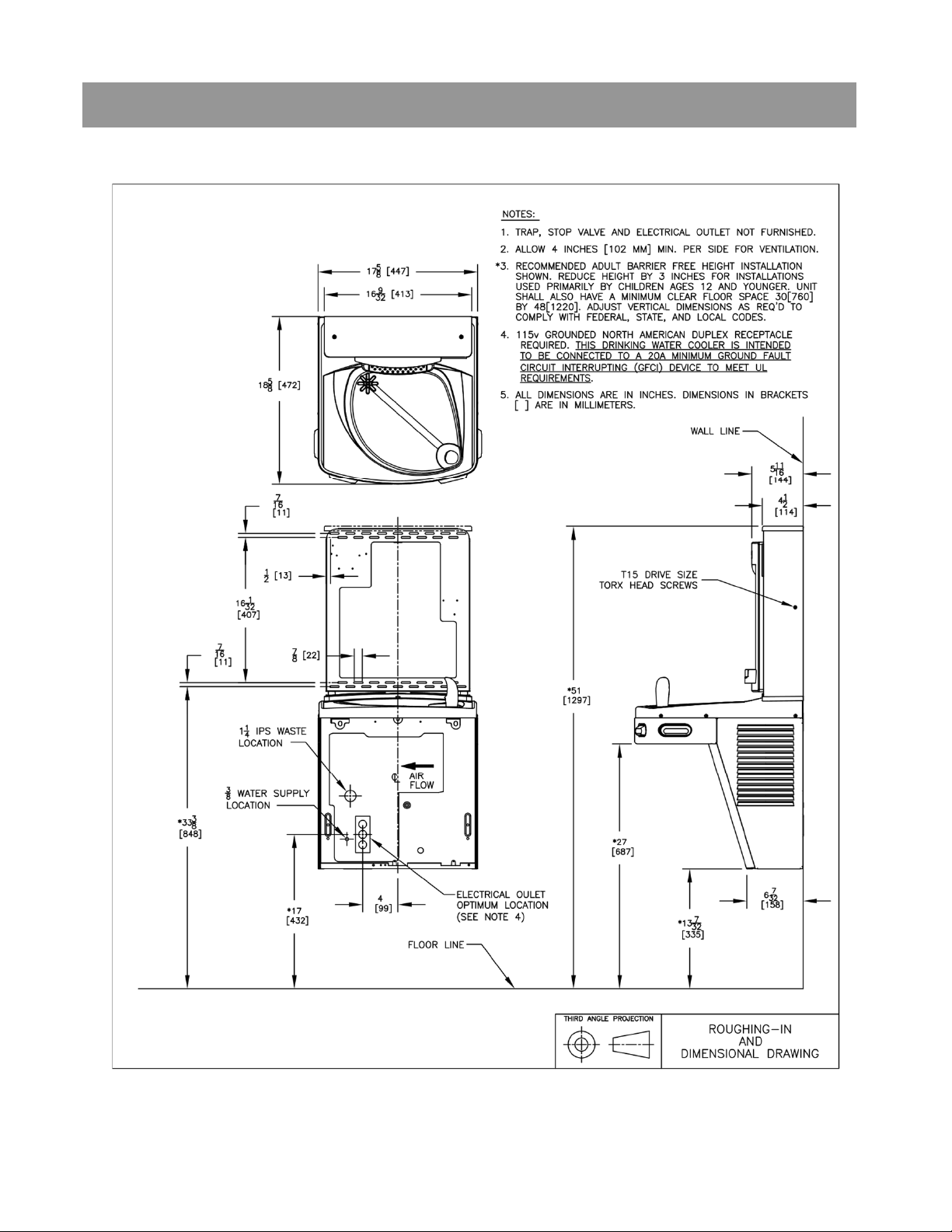

Page 3

Section 2: Rough In Drawing

Oasis PWEBF: Versacooler® II Models PGAC, PG8AC with Hands-Free VersaFiller

3

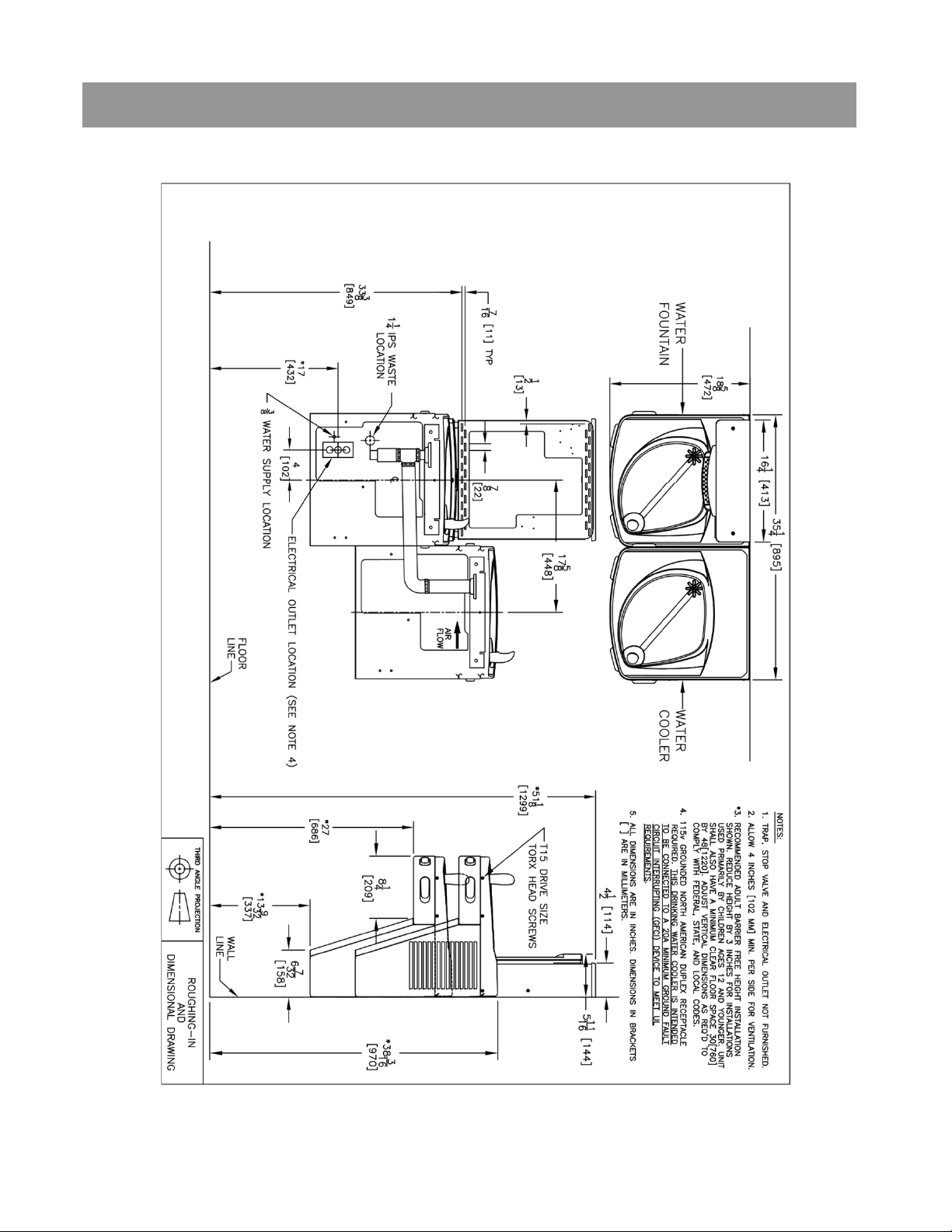

Page 4

Section 2: Rough In Drawing

Oasis PWEBF: Versacooler® II Split Level Models with Hands-Free VersaFiller

* On split level models, the VersaFiller must be mounted

on the low unit in order to meet ADA guidelines.

4

Page 5

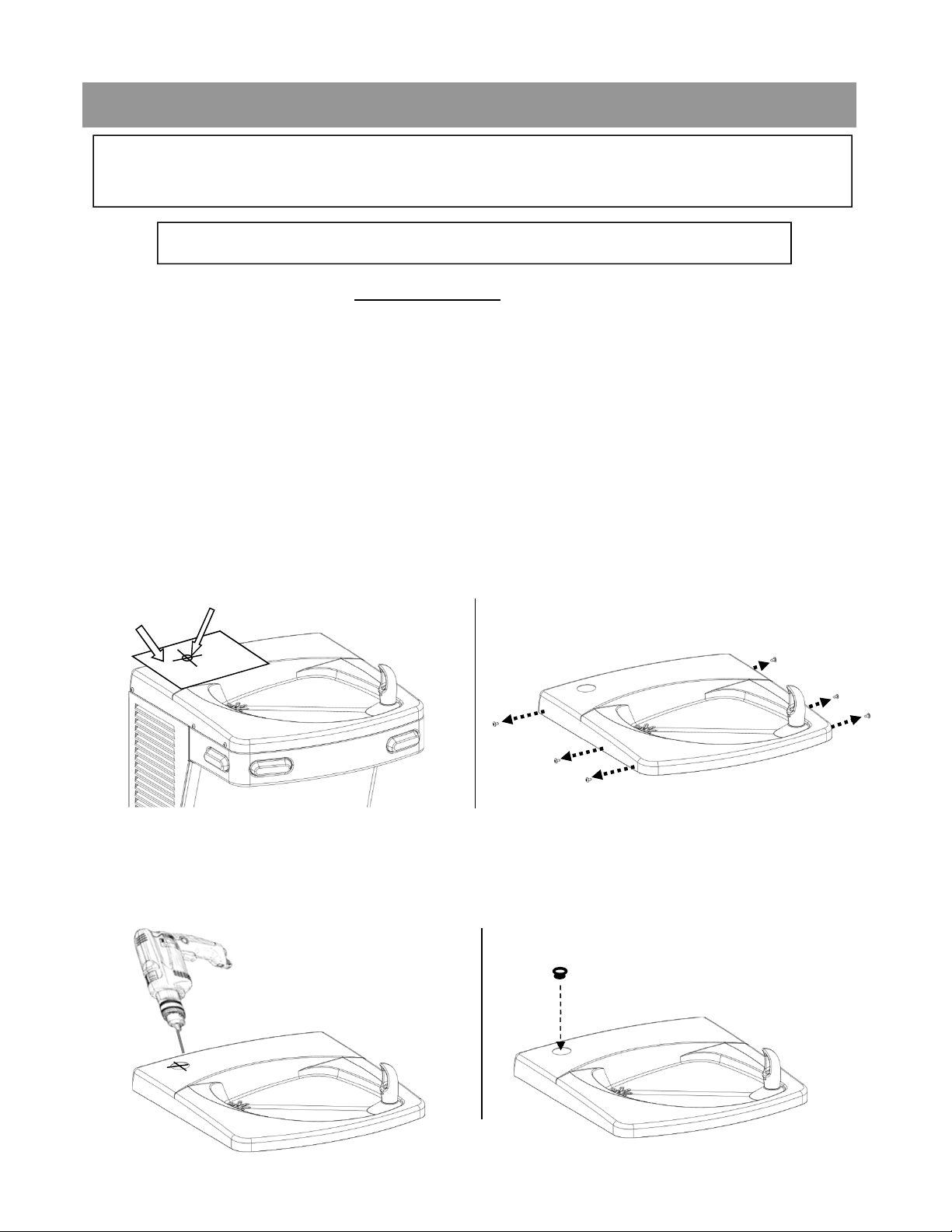

Section 3A: Installation

Note: Proceed to Sect 3B Step 5 “Final steps for both product

families” if the cooler is purchased “VersaFiller ready”.

A: Drilling hole in the top for water line connection.

1. Disconnect power by UNPLUGGING unit. It might be necessary to

remove the front panel to get access to the power.

2. Turn OFF water supply to the unit. It might be necessary to remove the

front panel to access the water stop valve.

3. Place hole template onto cooler top so it is aligned with the left side of

unit and wall. SEE NEXT PAGE FOR TEMPLATE

4. Mark hole location

5. Remove top from unit.

Mark hole location.

Template

Remove top from cooler by

removing six, #15 torx head

screws on sides of top.

6. Using a step drill bit or 7/8” punch die, make a 7/8” hole through top. You

may want to drill a pilot hole to get these started.

7. Install snap bushing into hole to protect tubing from being cut.

Install bushing

Drill

5

Page 6

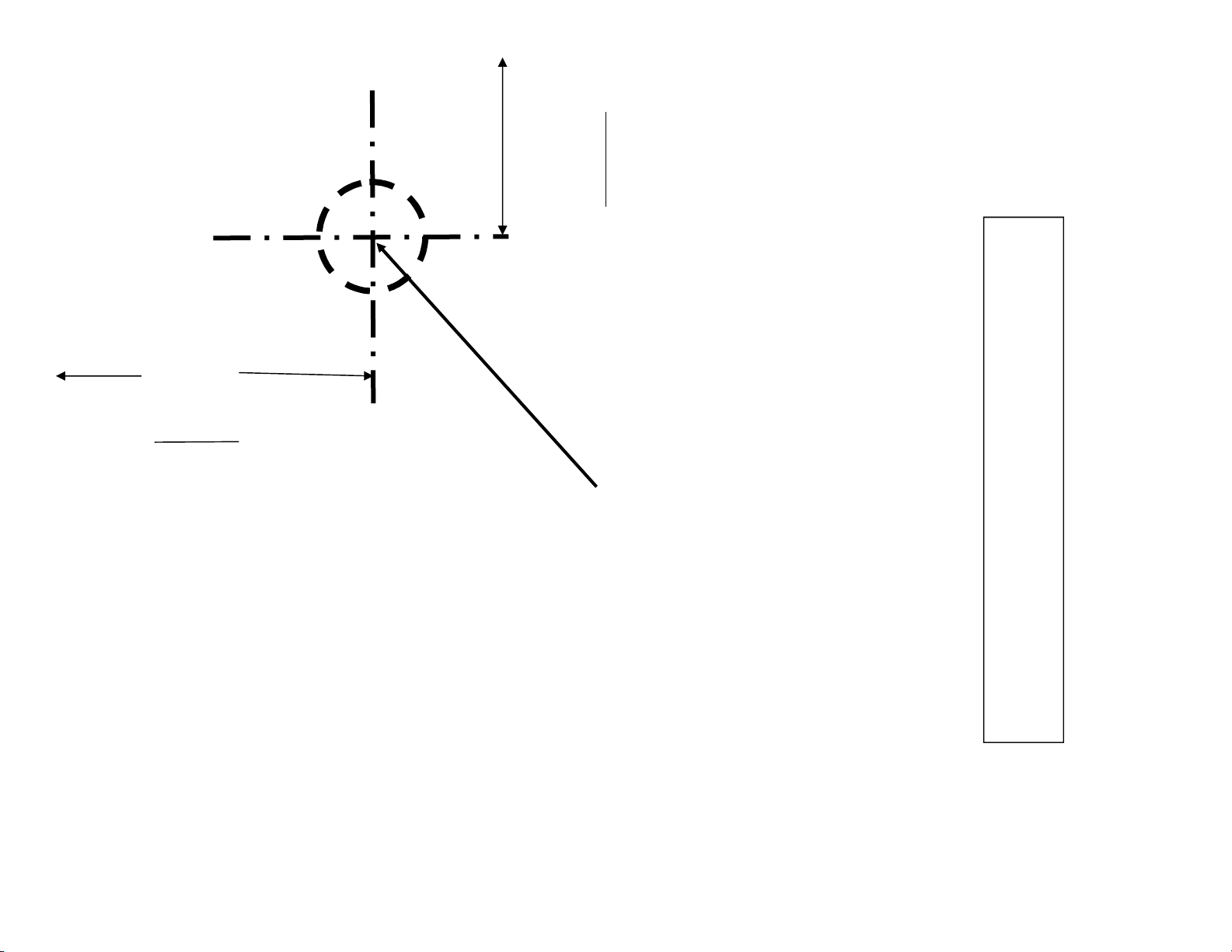

3-1/4”

from

edge of

paper

ALIGN THIS EDGE

WITH LEFT EDGE OF

COOLER TOP

2-1/8”

from

edge of

paper

PLACE THIS EDGE

AGAINST WALL

Mark this center point on the

top. Remove the top from the

6

cooler. Then create a 7/8”

diameter hole through the top

at the marked center point

(step drill bit or punch die).

USE THIS TEMPLATE TO MARK THE

HOLE LOCATION ON COOLER TOP

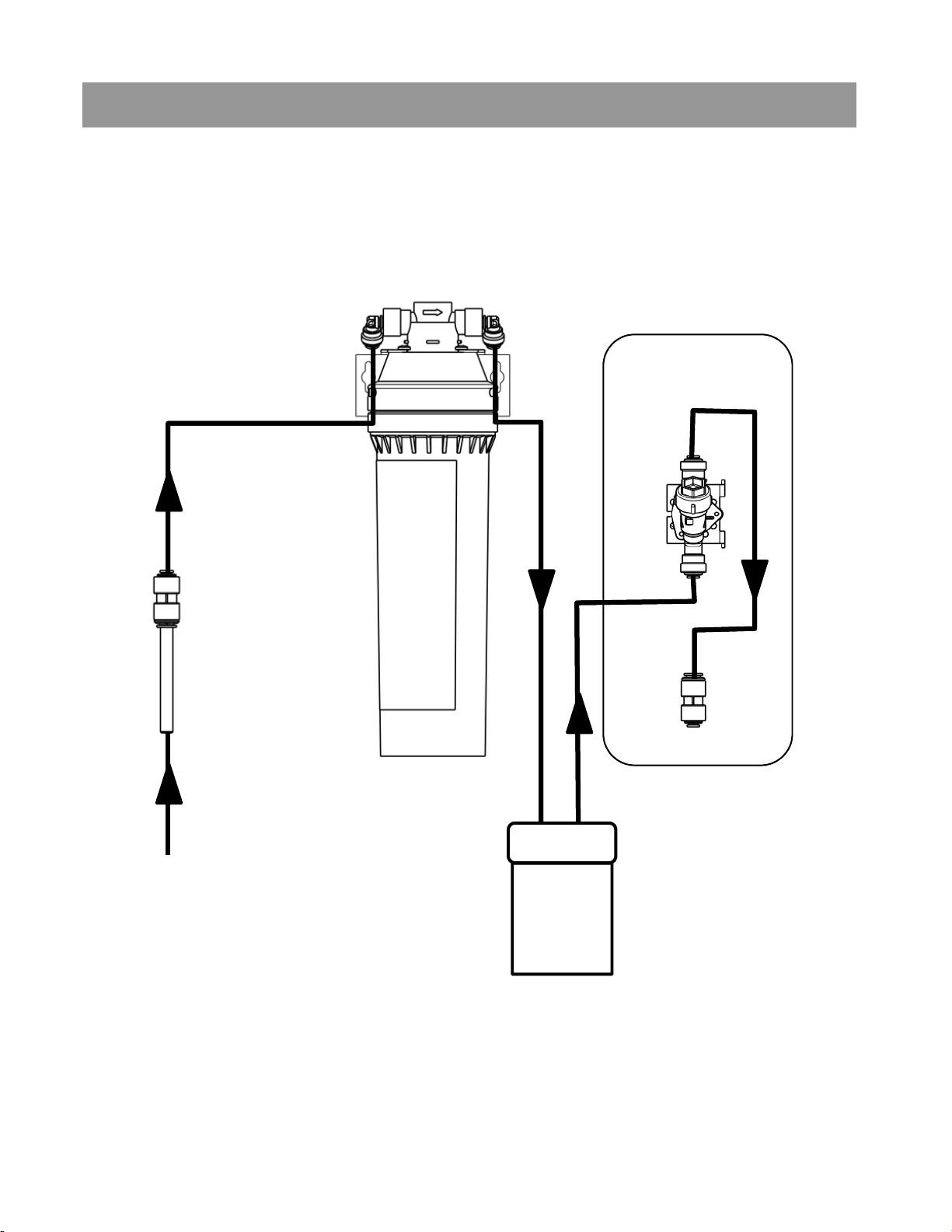

Page 7

Section 3A: Installation

Versacooler to Bottle Filler Plumbing Diagram

OPTIONAL VERSAFILTER II

BOTTLE FILLER

DISPENSE

SOLENOID

INLET STRAINER,

TUBE, AND

REDUCER FTG.,

PROVIDED WITH

FOUNTAIN.

BUILDING

INLET WATER

VERSACOOLER

7

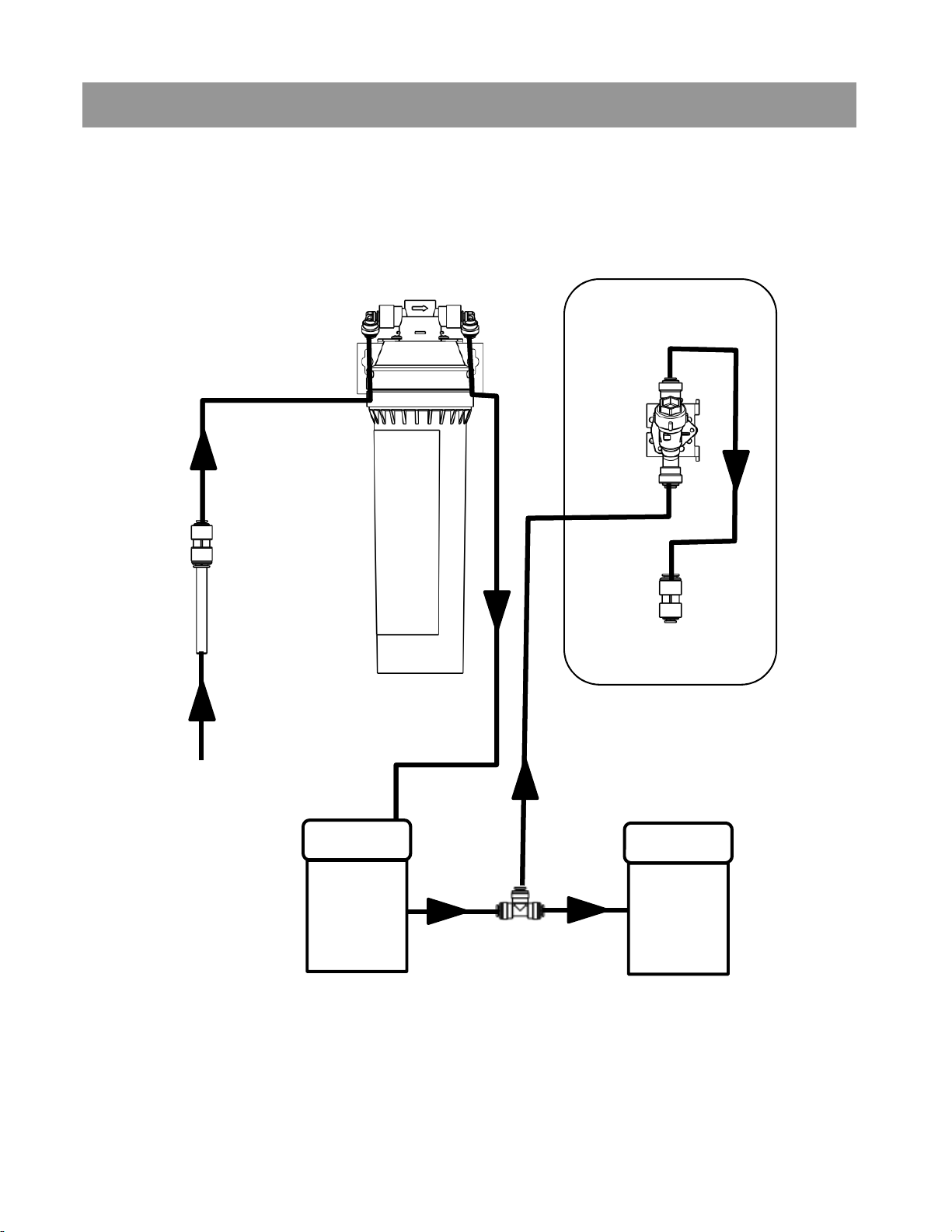

Page 8

Section 3A: Installation

Two Versacoolers to Bottle Filler Plumbing Diagram

INLINE

STRAINER,

TUBE, AND

REDUCER FTG.,

PROVIDED

WITH FOUNTAIN

OPTIONAL

VERSAFILTER II

BOTTLE FILLER

DISPENSE

SOLENOID

BUILDING

INLET WATER

VERSACOOLER

T-FITTING

VERSACOOLER

8

Page 9

Section 3B: Installation

B: Connecting the water line

Note: If you are retrofitting the Versafiller to an existing cooler,

follow the instructions starting on page 11.

For the single “Versafiller ready” cooler, the tube to connect to the Versafiller

is found inside the access panel (the compressor compartment). This tube

supplies cold water from the cooling tank to the Versafiller.

¼” OD tube to connect

to Versafiller

For split level “Versafiller ready” coolers, the tube to plumb in the

Versafiller is packaged in the dummy unit.

Remove tube from bag.

First, remove plug from

fitting on tank drain

Next, insert end of

tube into fitting.

9

Page 10

The tee and tube to the Versafiller are packaged with the PWEBF

unit. One branch of the tee will supply the valve on the dummy unit,

the other branch of the tee will connect to the Versafiller.

If a filter is being installed, cut a piece of tubing about 3” long to

insert (optional) flow switch right after filter and before tee. This

allows Versafiller counter to accurately calculate amount of water

passing through filter.

Tube to connect valve

on dummy unit

Tube to connect chilled

water to dummy unit

and Versafiller

Tube to connect

Versafiller

Go to Step 5 “Final steps for both product families:”

10

Page 11

To retrofit the Versafiller to an existing unit, follow the

instructions below:

If the cooling tank is non-pressurized, then go to the “Pressurizing the

cooling tank” addendum section. Otherwise, proceed to step 1 below.

Non-pressurized units are single units made since December of 2009.

Refer to the schematic below to identify the system that you have.

Water

valve/

regulator

tank

Supply

Water

Water

valve/

regulator

tank

Cooling

NON-

PRESSURIZED

COOLING TANK

Supply

Water

Cooling

PRESSURIZED

COOLING

TANK

1. With the cooler top removed, find the tube going from the cooling

tank outlet to the valve. The TEE fitting (supplied) will need to

connect between the cooling tank and valve.

Outlet Tube (insulated plastic)

Outlet Tube (insulated copper)

Valve

P8AC family

Valve

P8AM family

11

Page 12

Section 3B: Installation: For the P8AC Version: Versacooler II

2. Disconnect tubing from the

elbow on the valve.

3. Using the 38” piece

of tubing provided,

cut 6” and install it

on the end of the

TEE. Install the

remaining tubing

onto the branch of

the TEE. Connect

the other end of the

TEE to the tank

outlet tubing (tube

that was

disconnected from

the elbow).

TEE

32” tubing

6” tubing

4. Route the TEE and

tubing under the

waste drain and

connect the 6” length

to the water valve

elbow.

Go to Step 5 “Final steps for both product families:”

Water

valve

elbow

12

Page 13

Section 3B: Installation: For the P8AM Version: Versacooler I

Remove tar tape

2. Remove tar tape from

the insulation on the

outlet tube.

3. Pull back insulation and cut

the copper tube with a

tubing cutter. Cut where

there is at least 1 inch of

straight tubing on each side

of the cut.

4. Install TEE fitting by

connecting the copper

tubing to each end. Then

install the 32” piece of

plastic tubing to the TEE

branch.

32” plastic

tubing

(supplied)

13

Page 14

Section 3B: Installation: Final steps for both product families:

5. Feed black and blue tubing up through bushing in top.

• For single unit, also feed white tube attached to tee through bushing.

• For split level, connect tee and white tube packed with bottle filler per

schematic below.

Attach top to cooler. If flow switch was installed, cord from flow switch must

also pass through this bushing.

To solenoid valve inlet.

TIP: For the P8AM, it is easier to

connect the outlet tube to the bubbler if

the front nose is removed.

14

Page 15

Section 3C: Installation of the Versafiller Sports Bottle Filler

C: Mounting the frame to the wall

1. Place rubber gasket on top of the cooler so it is centered left/right

and against the wall.

2. Set the wall frame onto the gasket. Center it left/right and push it against

the wall and mark hole locations for wall fasteners. The gasket will set

the frame at the proper height.

Use mounting slots that

will provide the proper

securing location.

Make sure to pull

the plastic tubing

up through the hole

in the frame.

Connects to the

solenoid valve

inlet.

Rubber Gasket

3. Secure frame to the wall with fasteners (not provided). Pull plastic

tubing up through the hole in the frame.

15

Page 16

Section 3C: Installation

4. Slide sponge tubing insulation over water line. Connect the tubing to

the INLET of the solenoid on the back of the Hands-free VersaFiller

assembly and (optional) flow switch connector into port on circuit

board.

Connect tube

Insert

Insert connector on

connector on

end of (optional)

end of flow

flow switch wire

switch wire

into port on circuit

into port on

board. (not shown)

circuit board

Now shown

to inlet of the

valve

Plastic tubing

Sponge tubing

insulation

16

Page 17

Section 3D: Installation

D: Attaching the Tether

5. Install bottle filler tether with the steps below.

Attach the tether line assembled to the bottle

filler dispense bracket to the cleat on the

mounting frame.

1.

Push loop through hole.

3.

2.

Put loop around one side

of the cleat.

4.

Pull loop around other

side of the cleat.

Pull tight.

17

Page 18

Section 3D: Installation

The tether keeps the bottle filler secured to the frame when changing the

filter, if installed. Make sure the tether is installed properly to avoid

accidental damage to the unit.

6. Before the Bottle Filler cabinet is set into place, feed the terminals on

the power supply power cord and the long green ground wire through

the bushing on the cooler top.

7. Connect male terminals on the bottle filler power supply to female

terminals on power cord. Make sure that the power cord is firmly

connected to the power supply.

8. Attach the long green ground wire to cooler power cord ground located

on cooler frame or to electrical box ground.

18

Page 19

Section 3D: Installation

9. MAKE SURE the cabinet fits into the groove in the rubber gasket on

both sides and front of the wrapper.

VersaFiller

cabinet

Groove in the gasket

See next page to secure Bottle Filler assembly to frame

with torx screws.

19

Page 20

Section 3D: Installation

Torx screw

Torx screw

Insert bottle

10. Attach Bottle Filler assembly to the frame using two (2) torx screws. If

you are going to change the electronics default settings, remove the

Top Cap and two (2) torx screws.

11. Plug bottle filler cord into the electrical outlet. The program should be

set up specific for that installation. See the program guide on next

page. Access programing Pushbutton through top of Bottle Filler.

12. Turn ON water supply and check for leaks. Place a container in the

alcove to release any trapped air from the system. Plug in the power

cord and replace the front panel.

13. If everything works correctly, place the Top Cap back on the Bottle

Filler and the two (2) torx screws to fasten it in place. Otherwise,

calibrate the sensor per the instructions on the next page.

INSTALLATION COMPLETE

20

Page 21

Section 4: Set-up guide for bottle filler electronics

GAL

or momentary press to advance to next menu.

UNFILT UNIT

or momentary press to advance to next menu.

RATE SELECTED

or momentary press to advance to next menu. Not included on all models.

Hold button 3 seconds to advance to the next menu.

[LTR COUNT]

[4731 LTR]

or momentary press to advance to next menu.

(The 3 Sec rule increases the bottle count based on a 3 second dispense.)

BOT COUNT?

or momentary press to advance to next menu.

AGAIN?

or momentary press to advance to next menu.

Factory default program settings are:

• Units - Gallons

• Unfiltered unit

• Flow Meter = Rate Selected

• Filter Capacity = 1250 gallons [4731 liters] for a

VersaFilter

To change the program settings, follow these steps:

Display Action

000000000

BOTTLES REUSED

(Home Screen)

LTR/GAL

UNFILT/FILT?

Depress button for 3 seconds to enter into the following menu settings and make changes.

Note: at anytime it will exit menu and save settings when idle for 10 seconds (no button

press) and revert back to Home Screen.

Depress button 3 seconds to change from Gallons to Liters,

Depress button 3 seconds to change from Unfiltered to Filtered unit,

• Bottle Count = 0.5L (1 Bottle)

• Flow Rate = 1.2 GPM

• 20 second maximum dispense

time

Pushbutton

FLOW METER?

SELECT RATE

1.2 GPM UNIT

RESET 00000000

GALLON CNT

FILT CAPAC

OF 1250 GAL

3 sec rule?

0.5L

Reset 00000000

Bot Filler

Set_time: 20 s

RUN CAL

Depress button 3 seconds to change from Rate Selected to (Flow) Meter Enabled,

To change flow rate, momentarily depress button to change whole gallon digit.

Hold button 3 seconds to advance to TENTHS of gallon digit.

Depress momentarily to change the digit.

Depress button for 3 seconds to reset Gallon or Liter count,

or momentary press to advance to next menu.

Depress button for 3 seconds to change filter capacity to 3000 GAL [11355 liters] for

Versafilter II or Galaxi green filter,

Depress button for 3 seconds to switch from 0.5L bottle to 3 sec rule,

or momentary press to advance to next menu.

Depress button for 3 seconds to reset (Home Screen) BOTTLES REUSED count,

Depress button for 3 seconds to change maximum dispense time to 10, 20 or 30 seconds,

or momentary press to advance to next menu.

Depress button 3 seconds to run calibration again,

•

21

Page 22

Addendum Section: Pressurizing Cooling Tank

The water should

already be turned OFF

and the power

disconnected.

Unit as it appears with

top removed

STEP 1

Unplug un-insulated water

line from water valve inlet

(quick-connect elbow

located left side of water

valve facing the front of

the cooler). Set tubing

aside (careful to not

contaminate water contact

end).

STEP 2

Unplug tubing from

quick-connect elbow

leading to cooling tank

inlet.

22

Page 23

STEP 3

Plug un-insulated tubing

that was removed in step 1

into quick-connect elbow

leading to the cooling tank

from step 2.

STEP 4

Unplug tubing that is

connected to the water

valve outlet (quickconnect elbow located

on the right side of valve

facing the cooler).

STEP 5

Connect tubing from

step 4 to quick-connect

elbow on the left side of

the valve.

23

Page 24

Step 6

Unplug quick-connect

tubing from the

cooling tank outlet.

Do not set it down.

Step 7

Using tubing removed

in step 6, plug into

quick-connect elbow

on the right side of the

valve. (be sure to route

the tubing under

existing tubing

installed in step 4 as

shown)

Step 8

Using tubing that is

connected to the

quick-connect elbow

left side of valve (done

in step 4), and plug the

other end into the

quick-connect fitting at

the top of the cooling

tank.

Return to Section 3 B

“Connecting the water line”

24

Page 25

Section 5: Parts Breakdown

026630-022

041073-001

030152-046-SP

ITEM QTY P/N Description ITEM QTY P/N Description

1 1 036687-003 FRAME, PWFSBF-K12 21 1 027189-001 BUSHING, SNAP

2 1 036689-001 GASKET, PWSBF 22 1 038168-001 CORD ASSY, DC POWER SUPPLY

3 1 036686-001 CAP, PWSBF 23 1 038036-003 POWER SUPPLY,100-240VAC/12VDC

4 2 031875-003 SCREW, TRUSS HD TAPPING TORX 24 1 036191-002 DRAIN, MSBF, SHORT

5 1 038026-002 ELECTRONICS ASSY, IR/LCD 25 2 036049-002 SCREW, OVAL HD PLASTITE

6 1 038027-001 LENS, IR BOTTLE FILLER 26 1 036695-001 TRAY, GRILLE DRIP

7 4 026824-026 NUT, HEX NYLON 27 1 036688-001 TRAY, DRIP PWSBF

8 1 038030-002 SOLENOID VALVE 12VDC 28 1 036697-001 CAP, DRIP TRAY BOTTOM

9 1 030152-009 TUBE, PE WHITE 7.5" 29 2 026642-023 SCREW, HEX HD TAPPING #8

10 1 028668-101 FTG, PP REDUCING UNION 30 1 036701-001 DRIP TRAY ASSEMBLY

11 1 038032-001 FLOW NOZZLE 31 1 030152-046-SP TUBE, PE WHITE 38"

12 1 031434-014 NAMEPLATE, OASIS 32 1 017681-008-SP INSULATION, SPONGE TUBE 19"

13 1 036190-003 ALCOVE, EBF 33 1 029994-103 FTG, PP ELBOW, PLUG IN

14 1 036691-007 WRAPPER, PWEBF 34 4

15 2 031875-003 SCREW, TRUSS HD TAPPING TORX 35 1

16 1 038031-005 LABEL, LCD BEZEL 36 1 041072-001 FILTER HEAD, VERSAFILTER II

17 1 038031-007 LABEL, PANEL EBF 37 1 041071-001 FILTER CARTRIDGE, VERSAFILTER II

18 1 038031-006 LABEL, ALCOVE SENSOR 38 1

19 1 029199-103 FTG, PP UNION TEE WHITE 39 1 030152-014 TUBE, PE WHITE 48.0"

20 1 027189-008 BUSHING, SNAP

SCREW, PAN HD TAPPING

BRKT, VERSAFILTER II

TUBE, PE WHITE 38.0"

25

Page 26

Section 5: Parts Breakdown

Accessories:

Vandal resistant screw kit: P/N 036704-001, includes torx bits and replacement screws.

Gasket, Sunroc/Haws : P/N 036689-101: (replaces item 2) KIT P/N 036752-001

Gasket Adapter Elkay/Halsey Taylor P/N 041114-001

P/N 0300999-570 REV D Date: 01/2020

© 2020 LVD Acquisition, LLC

Oasis, Aqua Pointe, Versacooler and VersaFiller are registered trademarks of

LVD Acquisition, LLC dba Oasis International

Haws is a registered trademark of HAWS Corporation.

Elkay and Halsey Taylor are registered trademarks owned or licensed by Elkay

Sales Inc. and/or its parent Elkay Manufacturing Company

OASIS INTERNATIONAL

222 East Campus View Blvd.

Columbus, OH 43235

614-861-1350

www.oasiscoolers.com

26

Loading...

Loading...