Oase BioMaster 250, BioMaster 600, BioMaster 350, BioMaster Thermo 600, BioMaster Thermo 250 Operating Instructions Manual

...Page 1

BioMaster 250/350/600

Downloaded from www.watergardeningdirect.com

BioMaster Thermo 250/350/600

Page 2

2 BioMaster 250/350/600, BioMaster Thermo 250/350/600

A

BMR0003

B

BMR0004

Downloaded from www.watergardeningdirect.com

Page 3

3

C

D

BMR0021

BMR0022

Downloaded from www.watergardeningdirect.com

Page 4

4 BioMaster 250/350/600, BioMaster Thermo 250/350/600

E

F

BMR0008

BMR0009

G

H

BMR0010

BMR0011

Downloaded from www.watergardeningdirect.com

Page 5

5

I

J

BMR0014

BMR0015

K

L

BMR0006

BMR0023

Downloaded from www.watergardeningdirect.com

Page 6

6 BioMaster 250/350/600, BioMaster Thermo 250/350/600

M

FSt0015

N

BMR0026

Downloaded from www.watergardeningdirect.com

Page 7

7

O

BMR0005

P

BMR0007

Downloaded from www.watergardeningdirect.com

Page 8

8 BioMaster 250/350/600, BioMaster Thermo 250/350/600

Q

R

BMR0012

BMR0013

S

T

BMR0016

BMR0017

Downloaded from www.watergardeningdirect.com

Page 9

9

U

BMR0024

Downloaded from www.watergardeningdirect.com

Page 10

10 BioMaster 250/350/600, BioMaster Thermo 250/350/600

V

W

BMR0018

BMR0019

X

BMR0020

Downloaded from www.watergardeningdirect.com

Page 11

- EN -

19

- EN -

Translation of the original Operating Instructions

WARNING

• This unit can be used by chil-

dren aged 8 and above and by

persons with reduced physical,

sensory or mental capabilities

or lack of experience and

knowledge if they are supervised or have been instructed

on how to use the unit in a safe

way and they understand the

hazards involved.

• Do not allow children to play

with the unit.

• Only allow children to carry

out cleaning and user maintenance under supervision.

• Switch off all units in the

aquarium or disconnect the

power plugs of all units before

reaching into the water.

• Do not use the unit if electrical

cables or housings are damaged.

• Only connect the unit if the

electrical data of the unit and

the power supply correspond.

The unit data is to be found on

the unit type plate, on the

packaging or in this manual.

• Disconnect the power plug before carrying out any work on

the unit.

SAFETY INFORMATION

• Never operate the unit if the housing is defective!

• Never operate the unit if any electrical cables are

defective!

• Never carry or pull the unit by the electrical cable.

• Route cables such that they are protected from

damage and do not present a tripping hazard.

• Only open the unit housing or its attendant components if this is explicitly specified in the operating instructions.

• Only carry out work on the unit that is described in

this manual. If problems cannot be overcome,

please contact an authorised customer service point

or, if in doubt, the manufacturer.

• Only use original spare parts and accessories for the

unit.

• Never carry out technical changes to the unit.

• Protect the plug connection from moisture.

• Only connect the unit to a correctly fitted socket.

Symbols used in these instructions

Warnings

The warning information is categorised by signal

words, which indicate the extent of the hazard.

WARNING

• Indicates a possibly hazardous situation.

• Non-observance may lead to death or serious inju-

ries.

NOTE

Information for the purpose of clarification or for preventing possible damage to assets or to the environment.

Additional information

A Reference to a figure, e.g. Fig. A.

→ Reference to another section.

Downloaded from www.watergardeningdirect.com

Page 12

- EN -

20 BioMaster 250/350/600, BioMaster Thermo 250/350/600

PRODUCT DESCRIPTION

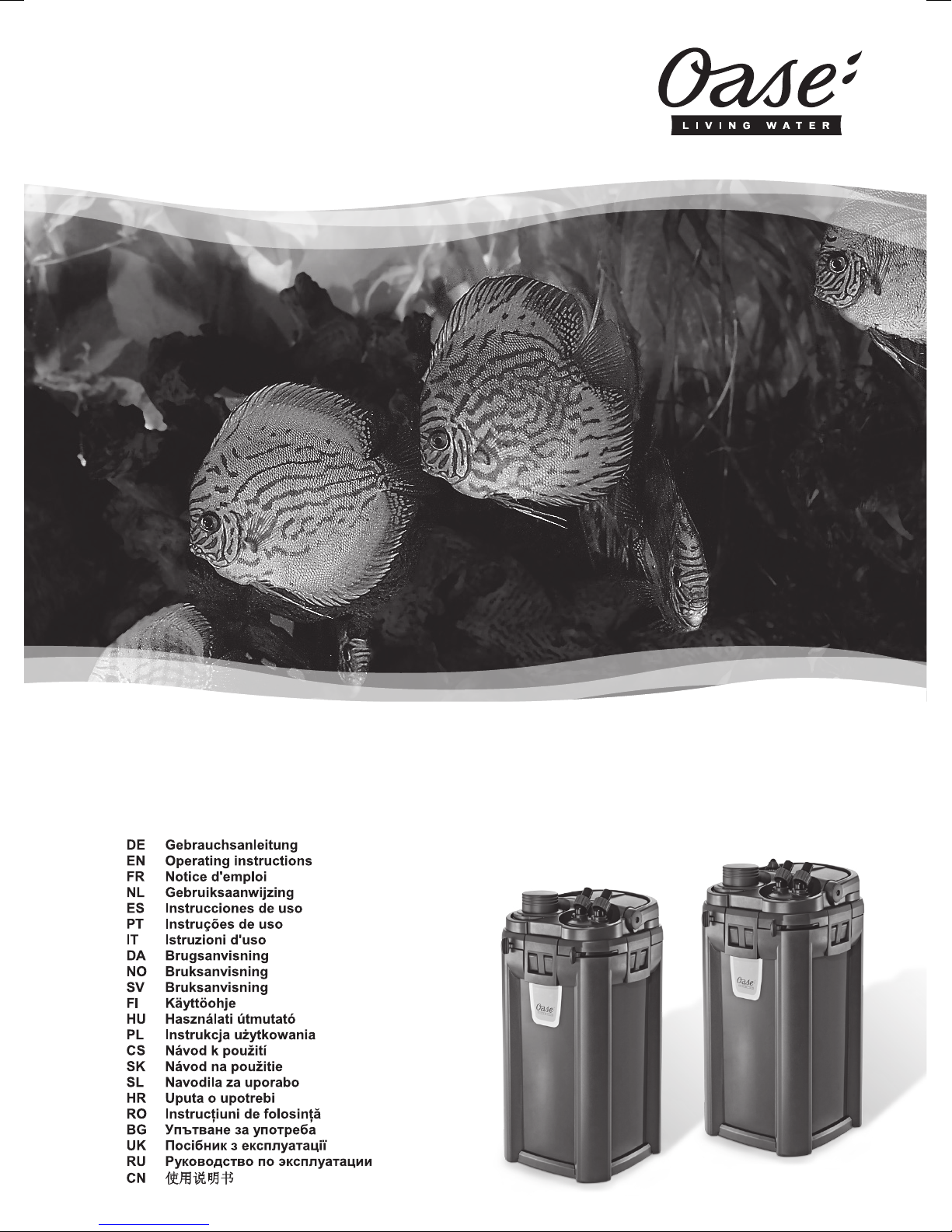

Scope of delivery

A

BioMaster Thermo

1

BioMaster Thermo 250: HeatUp 150

BioMaster Thermo 350: HeatUp 200

BioMaster Thermo 600: HeatUp 300

2

Operating instructions HeatUp 25/50/75/100/

150/200/250/300

BioMaster, BioMaster Thermo

3

Operating instructions

BioMaster 250/300/600,

BioMaster Thermo 250/300/600

4

Holding ring for HeatUp assembly

5

Blind plug

6

Handle, when the handle is hinged down there are

two fasteners (10), locked

7

Unit head

8

Pre-filter with suction button

9

Connection unit with hose connectors, outlet and inlet

10

Fastener

11

Container, filled with filter media

12

Rubber feet

B

Suction unit, flow-out unit

Quantity

1

Suction pipe

1

2

Hose

1

3

Flow-out pipe

2

4

Suction cup

5

5

Hose adapter, adjustable

2

6

Adapter, suction pipe

1

7

Suction basket

1

8

Terminal

5

9

Angle piece

1

10

Union nut

4

11

Short hose section as connecting piece

for flow-out pipes (3)

1

12

Water distributor

1

13

Cover cap

1

Intended use

BioMaster 250/350/600, BioMaster Thermo

250/350/600, referred to as "unit", may only be used

as specified in the following:

• BioMaster 250/350/600: Water filtering and recir-

culation.

• BioMaster Thermo 250/350/600: Water heating,

filtering and recirculation.

• For operation with freshwater or saltwater.

• Operation under observance of the technical data.

The following restrictions apply to the unit:

• O

nly use indoors and for aquaristic purposes in the

home (not for commercial use).

• Only operate with water at a water temperature of

+4 °C to +35 °C.

Function description

Dr

awn in by a pump in the unit head, the water first

flows through the pre-filter then from the bottom to

the top through the superimposed layers of filter media. The water then flows back into the aquarium via

the flow-out pipe or water distributor.

Foam filters with different pore densities, and Hel-X

bio-elements serve as filter media.

In units with heater, the water is heated during its passage through the filter system.

ACCESSING THE UNIT

NOTE

The following applies to all units with heater:

• Adhere to the rules for careful handling. (→ Careful

handling of the heater)

Careful handling of the heater

CAUTION

Hot surface!

Risk of burns when touching the glass bulb.

• Switch off the heater and allow it to cool down be-

fore removing it from the water.

CAUTION

Risk of breaking the glass!

The glass bulb of the heater can break and cause cuts.

• Take care when handling the heater.

• Allow the heater to cool down first. Do not immerse

it in cold water or pour cold water over it.

Downloaded from www.watergardeningdirect.com

Page 13

- EN -

21

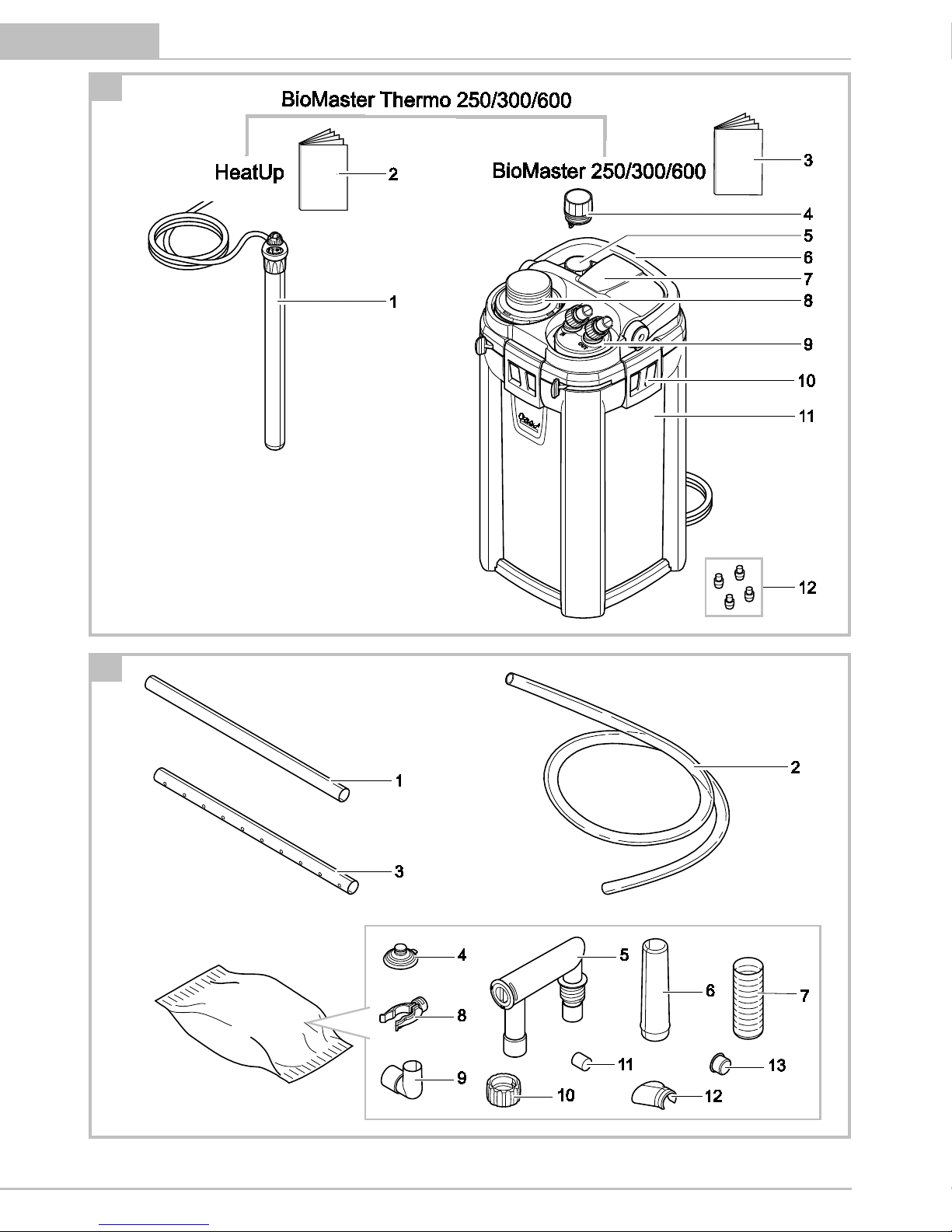

Removing the heater

The heater has to be removed for cleaning and maintenance, and for removing the unit head.

How to proceed:

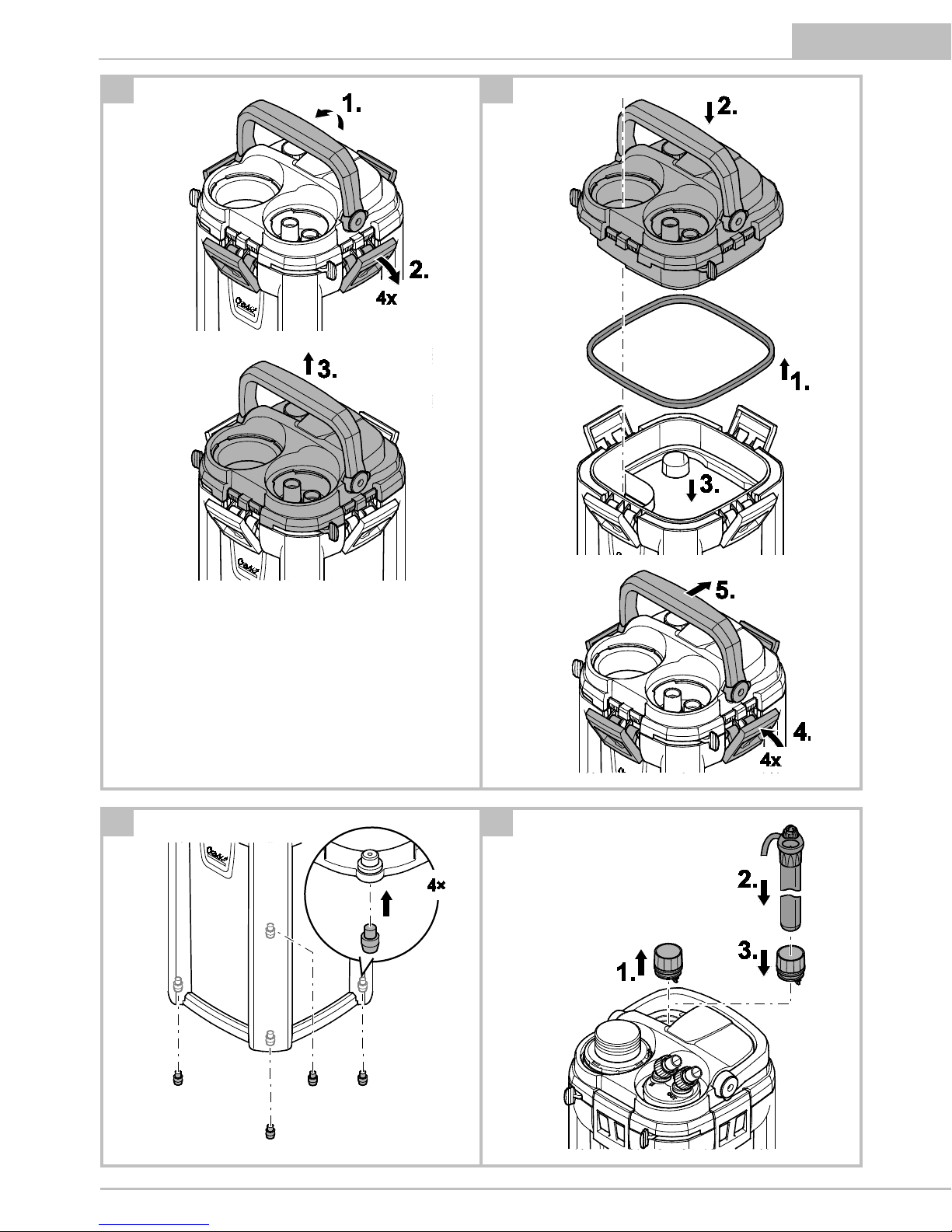

C

1. Hinge up the handle.

2. Unscrew the holding ring together with the heater

counter-clockwise.

Fitting the heater

H

ow to proceed:

D

1. Screw the holding ring with heater clockwise into

the threaded hole.

– T

o exchange the heater: Moisten the glass bulb

with water and push the heater into the holding

ring as far as it goes.

2. Place the power connection cable into the cable

guide.

3. Hinge the handle down.

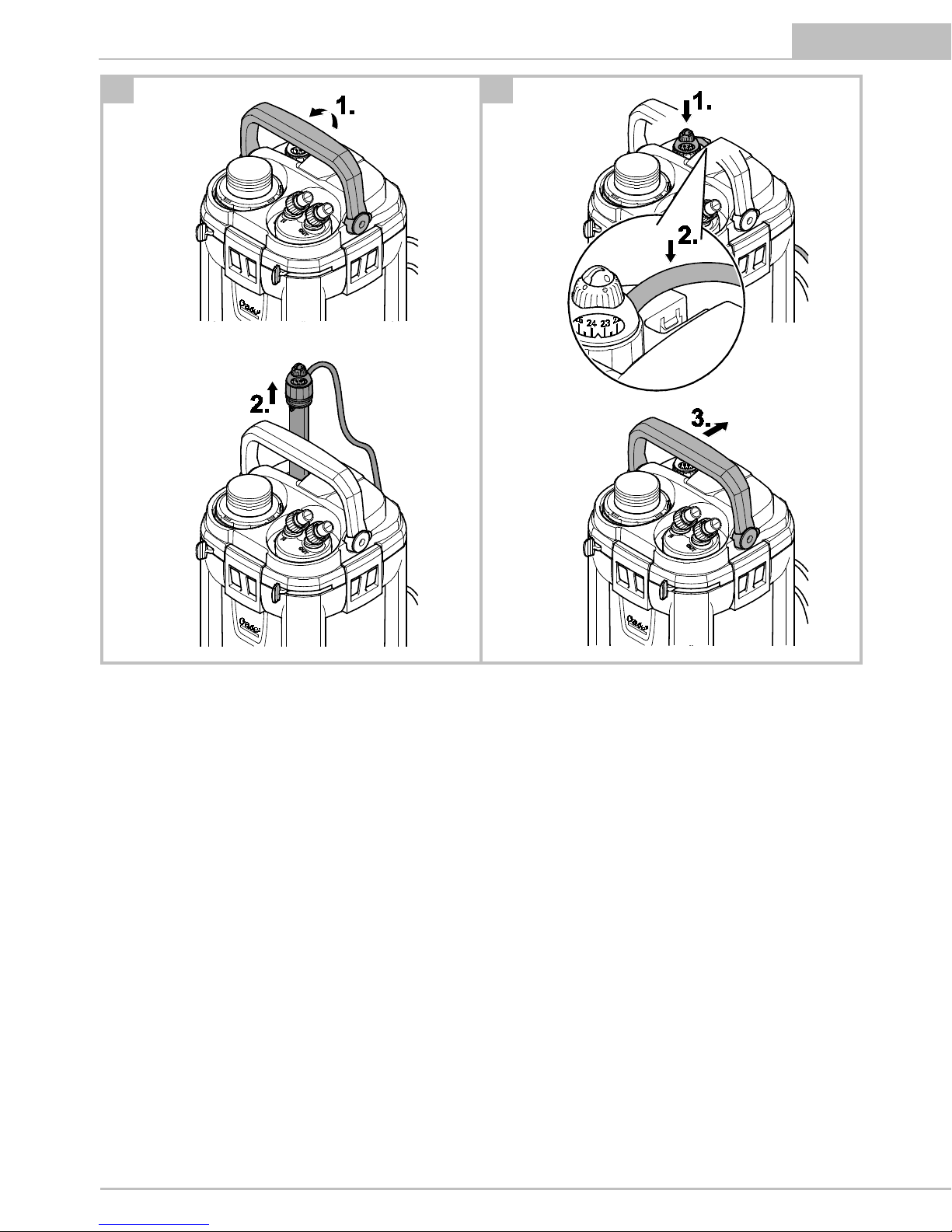

Removing the connection unit

The heater has to be removed for cleaning and maintenance, and for removing the unit head when hoses are

connected.

How to proceed:

E

1. Push the lever to the "UNLOCK" position.

– T

he lever can only be moved when the pre-filter

is locked.

– T

he inlet and outlet are closed.

2. Remove the connection unit.

Fitting the connection unit

How to proceed:

F

1. Fit the connection unit and push it into the unit

head as far as it goes.

– Ens

ure that the ridges on the connection unit are

correctly aligned to the recesses on the unit

head.

2. Push the lever in the direction "LOCK".

– T

he inlet and outlet are open.

Removing the pre-f

ilter

It has to be removed for cleaning and maintenance

and for removing the unit head.

Prerequisite:

• The inlet and outlet are closed. (→ Removing the

connection unit)

How to proceed:

G

1. P

ush the lever to the "UNLOCK" position.

– T

he lever can only be moved when the inlet and

outlet are closed.

2. Pull out the pre-filter.

Fitting the pre-filter

How to proceed:

H

1. Fit the pre-filter into the opening and firmly push it

into the unit head as far as it goes.

– Ens

ure that the ridges on the pre-filter are cor-

rectly aligned to the recesses on the unit head.

2. Push the lever to the "padlock closed" symbol.

– T

he pre-filter is locked.

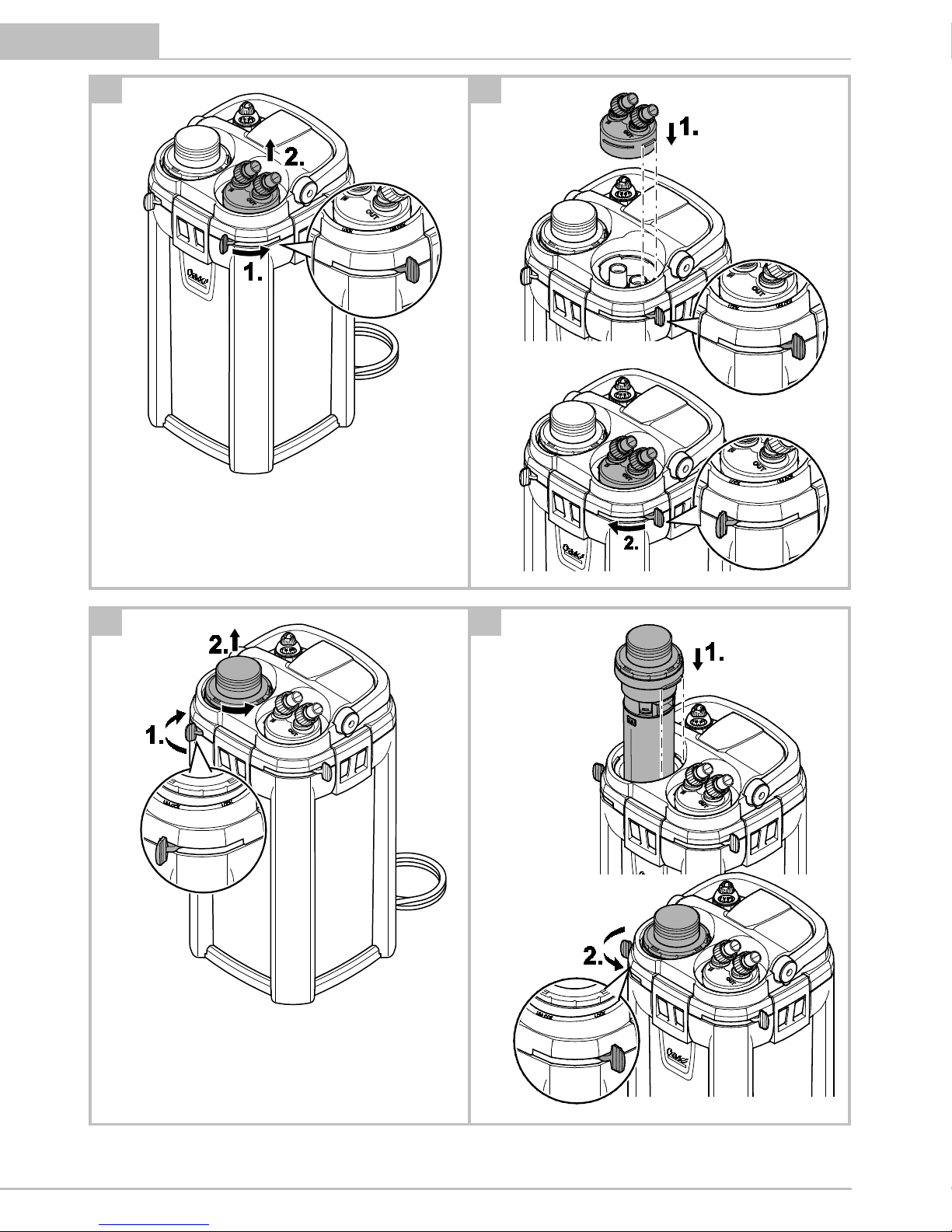

Dismantling the unit head

I

t has to be removed for cleaning and maintenance

and for changing the filter media.

Prerequisite:

• The heater has been removed. (→ Removing the

heater)

• The connection unit has been removed.

(→ Removing the connection unit)

• The pre-filter has been removed. (→ Removing th

e

p

re-filter)

How to proceed:

I

1. Hinge up the handle.

2. Undo the fasteners.

3. Remove the unit head.

Fitting the unit head

How to proceed:

J

1. Check that the seal on the unit head is correctly positioned.

– C

lean the seal, replace it if damaged.

2. Ensure that the filter baskets are correctly assembled and aligned.

3. Fit the unit head onto the container.

– Ens

ure that the opening for the pre-filter is

aligned to the recess in the filter baskets.

4. Lock the fasteners in place.

5. Hinge the handle down.

Downloaded from www.watergardeningdirect.com

Page 14

- EN -

22 BioMaster 250/350/600, BioMaster Thermo 250/350/600

INSTALLATION AND CONNECTION

Order of tasks to be carried out:

1. Fit the unit feet (→ Fitting the unit feed)

2. Prepare the filter media (→ Cleaning/replacing the

filter media)

3. As an option: OASE HeatUp Retrofitting (heater)

(→ Retrofitting the heater)

4. Install the unit.

– I

nstall the unit next to or under the aquarium.

Note the maximum head height. (→ Technical

data)

5. Establish the connections (→ Establishing the con-

nections)

Fitt

ing the unit feed

How to proceed:

K

• Twist the rubber feet into the openings of the container base.

Retrofitting the heater

Bi

oMaster 250/350/600 can be retrofitted with OASE

HeatUp.

• A holding ring is required for fitting (provided in the

delivery scope).

BioMaster

250

350

600

HeatUp

25

50

75

100

150

200

–

250 – –

300 – –

: Suitable : Particularly recommended

Prerequisite:

• The pump is switched off. (→ Switching off the unit)

NOTE

When the filter is filled with water, water may spill

when the heater is inserted.

• Take measures to collect any spillage.

How to proceed:

L

1. Unscrew the blind plug counter-clockwise and remove.

2. Push the heater into the holding ring as far as it

goes.

– Tip: Moisten the glass bulb with water before in-

serting.

3. Fit the heater. (→ Fitting the heater)

Establishing the connections

Assembling the suction unit

How to proceed:

M

• Assemble the suction unit.

• Set the flow rate.

• Use a coin to turn the flow regulator in the hose

adapter to MAX.

Assembling the flow-o

ut unit

How to proceed:

N

• Assemble the flow-out unit.

– T

he water distributor can be used instead of the

flow-out pipe.

• Use a coin to turn the flow regulator in the hose

adapter to MAX.

Connecting the hose

T

he procedure is identical for the inlet (IN) and outlet

(OUT).

How to proceed:

O

• Fasten the suction unit and flow-out unit in the

aquarium using suction cups.

P

1. Shorten the hose to the required length.

– Cho

se the length so that the hose cannot kink in

the intended installation position.

2. Screw the union nut onto the hose connector of the

connection unit.

3. Push the hose onto the hose connector and turn the

union nut counter-clockwise to fix the hose in place.

4. Push the other end of the hose onto the hose connector at the suction unit/flow-out unit and turn the

union nut counter-clockwise to fix the hose in place.

Downloaded from www.watergardeningdirect.com

Page 15

- EN -

23

COMMISSIONING/START-UP

For initial start-up or after thorough cleaning, it is necessary to expel air from the filter system. When the

container, suction unit and hose are free of trapped

air, the pump can convey the water by itself through

the filter system. (→ Expelling air from the filter system)

NOTE

Thoroughly rinse out all filter material with warm tap

water before using for the first time in order to remove

any soiling. (→ Cleaning/replacing the filter media)

Expelling air from the filter system

Prerequisite:

• The pump is switched off. (→ Switching off the unit)

How to proceed:

Q

1. Press the suction button and release it until the water flows out of the tank into the filter.

– The filter is completely flooded when water

emerges from the flow-out unit.

Switching on the unit

NOTE

Ensure that the pump never runs dry!

The pump will be destroyed.

• Regularly check the water level and circulation in

the filter and in the aquarium.

NOTE

Risk of fire due to the hot surface of the heater!

The heater and filter can be destroyed by the generated heat.

• Do not switch the heater on until the filter is completely filled with water, switched on and the water

is continuously circulated.

• Switch off the heater and allow it to cool down before removing it from the water.

How to proceed:

R

1. Route each power connection cable such that it

forms a drip loop.

2. Connect the power connection cable to the power

supply.

– T

he pump will switch on immediately.

– T

rapped air in the filter can cause noise. The

trapped air escapes shortly after the pump starts

up.

3. Unit with heater: Set the water temperature on the

heater and switch on the heater. (→ Heater operating manual).

Switching off the unit

H

ow to proceed:

• Disconnect the unit from the power supply

• Unit with heater: Disconnect the unit and heater

from the power supply

Setting the flow rate

H

ow to proceed:

S

• Move the lever on the connection unit to set the desired flow rate

– "

LOCK": Maximum flow rate

– "

UNLOCK": No flow, the outlet is closed.

Downloaded from www.watergardeningdirect.com

Page 16

- EN -

24 BioMaster 250/350/600, BioMaster Thermo 250/350/600

REMEDY OF FAULTS

Malfunction

Cause

Remedy

Unit does not start up.

No mains voltage

Check the mains voltage.

Impeller unit blocked

Clean

Air in the filter

Vent the filter. Move the filter from side to

side, if necessary, to allow the remaining air

to escape.

Water flow insufficient

Impeller unit soiled

Clean

Impeller unit worn

Replace the impeller unit.

The flow is not correctly set.

Correct the setting.

Foam filter of the pre-filter soiled

Clean

Filter media in the container soiled

Clean

Suction basket clogged

Clean

Pipework soiled

Clean suction unit, flow-out unit and hoses.

Insufficient filtering performance

Foam filter of the pre-filter soiled

Clean

Foam filter of the pre-filter worn

Replace

Filter media in the container soiled

Clean

Filter media in the container worn

Replace

Insufficient water heating

(only units with heater)

Heater defective

Replace

Heater not calibrated

Calibrate

Water temperature incorrectly set on the

heater

Correct the water temperature setting on

the heater.

Water flow insufficient

See malfunction "Water flow insufficient"

The filter cannot be vented.

Valve box in the pre-filter blocked

Clean the valve box.

Filter is not below the surface of the water.

Install the filter below the surface of the

water.

Increased noise

Air in the filter

Move the filter from side to side to allow

the remaining air to escape.

MAINTENANCE AND CLEANING

• If necessary, clean with clear water using a soft

br

ush.

• Do not use cleaning agents or chemical solutions.

We recommend using OASE PumpClean for removing calcium deposits.

• Cleaning and replacement cycles for filter media are

dependent on the size of the aquarium and the

number of fish. Therefore, it is necessary to clean

and replace the filter media as required to ensure

optimum filter performance.

• If there are several foam filters: Clean or replace the

foam filters at different times. This saves enough

useful bacteria to ensure good biological filtration

of the water.

NOTE

Thoroughly rinse out all filter material with warm tap

water before using for the first time in order to remove

any soiling. (→ Cleaning/replacing the filter media)

Cleaning and maintenance work:

Area

Tasks to be carried out

Foam filter, pre-filter

(→ Cleaning/replacing the foam filter of the pre-filter)

Filter media, container

(→ Cleaning/replacing the filter media)

Heater

HeatUp 25/50/75/

100/150/200/250/300

Impeller unit, pump

casing

(→ Cleaning/replacing the impeller

unit)

Valve box, pre-filter

(→ Cleaning the valve box of the prefilter)

Suction chamber, prefilter

(→ Cleaning the suction chamber of

the pre-filter)

NOTE

The cycle for cleaning the foam filter in the pre-filter is

longer if a coarser foam filter is used.

Downloaded from www.watergardeningdirect.com

Page 17

- EN -

25

Cleaning/replacing the foam filter of the pre-filter

Prerequisite

• The pre-filter has been removed. (→ Removing th

e

p

re-filter)

How to proceed:

T

1. Press in the engagement hooks on the pre-filter and

pull off the housing.

2. Remove the pre-filter pipe and foam filters.

– Bi

oMaster 250: 4 foam filters.

– BioMaster 350: 5 foam filters.

– Bi

oMaster 600: 6 foam filters.

3. Rinse the foam filters in warm water. If necessary,

replace the foam filters.

4. Assemble the pre-filter in the reverse order.

Cleaning/replacing the filter media

U

Filter media on delivery:

a

Foam filter 30 ppi

b

Foam filter 20 ppi

c

Hel-X bio-elements, always place them contained

in the bag into the strainer casing

Prerequisite

• The unit head is removed. (→ Dismantling the unit

head)

How to proceed:

U

1. Remove all filter baskets.

2. Clean the filter baskets and container.

3. Rinse the filter media in warm water. If necessary,

replace the filter media.

4. Place the parts into the container in the reverse order.

– Ca

refully fit the filter baskets in the bottom recess in the container. Correctly position the prefilter.

5. Reassemble the unit in the reverse order.

Cleaning/replacing the impeller unit

Prerequisite

• The unit head is removed. (→ Dismantling the unit

head)

How to proceed:

V

1. Turn the pump lid counter-clockwise (bayonet lock)

and remove.

2. Remove the impeller unit and clean. If necessary, replace.

3. Fit the impeller unit, replace the pump lid and lock

(turn clockwise).

– Ens

ure that the two rubber bearings are correctly

seated.

4. Reassemble the unit in the reverse order.

Cleaning the valve box of the pre-filter

The valve box only has to be cleaned if venting does

not function even though the foam filters of the prefilter have been cleaned.

Prerequisite

• The pre-filter has been removed. (→ Removing th

e

p

re-filter)

How to proceed:

W

1. Undo the fasteners and pull off the valve box.

– I

f necessary, carefully lift the fasteners using a

screwdriver.

2. Remove the valve seal and both valve flaps. Clean

all parts.

3. Assemble the valve box in the reverse order.

– Ens

ure that the fitted valve flaps can be easily

moved.

– Note: Ensure that the opening in the valve seal is

precisely aligned to the opening in the suction

chamber.

Cleaning the suction cham

ber of the pre-filter

The suction chamber only has to be cleaned if venting

does not function even though the foam filters and

valve box of the pre-filter have been cleaned.

Prerequisite

• The pre-filter has been removed. (→ Removing th

e

p

re-filter)

CAUTION

There is a strong spring in the suction chamber that

can act like a projectile.

Risk of injury due to parts flying around

• When opening the suction button, do not point it at

persons.

• Firmly hold the suction button.

How to proceed:

X

1. Press in the engagement hooks, hold and turn the

locking ring counter-clockwise (bayonet lock).

2. Carefully lift the suction button until the tension of

the spring is relieved.

3. Remove the suction button and spring.

4. Clean the suction chamber.

5. Assemble the suction chamber in the reverse order.

Downloaded from www.watergardeningdirect.com

Page 18

- EN -

26 BioMaster 250/350/600, BioMaster Thermo 250/350/600

WEAR PARTS

• Filtration medium

• Impeller unit

• Suction cups

DISPOSAL

NOTE

Do not dispose of this unit with domestic waste.

• Render the unit unusable beforehand by cutting the

cables and dispose of the unit via the return system

provided for this purpose.

SPARE PARTS

The use of original parts from OASE ensures continued

safe and reliable operati

on of the unit.

Please visit our website for spare parts drawings and

spare parts.

www.oase-livingwater.com/spareparts

TECHNICAL DATA

Description

BioMaster, BioMaster Thermo

250

350

600

Rated voltage

V AC

230

230

230

Mains frequency

Hz

50

50

50

Protection type

IPX4

IPX4

IPX4

Power consumption, filter

W

15

18

22

BioMaster Thermo

Power consumption, heater

W

150

200

300

Flow rate

Max.

l/h

900

1100

1250

Head height

Max. m 1.3

1.4

1.8

Max. head height

Max. m 1.8

1.8

1.8

Filter volume

l

4.4

5.6

6.8

Pre-filter volume

l

0.4

0.5

0.6

Recommended for an aquarium volume of

l

250

350

600

Length of power connection cable

m

1.5

1.5

1.5

Connection of hose connectors

Diameter

mm

17

17

17

Dimensions

Length

mm

240

240

240

Width

mm

240

240

240

Height

mm

370

425

480

Weight

kg

4.1

4.5

5.0

SYMBOLS ON THE UNIT

Splash-water protected on all sides.

Protection class II, protection insulation which could become live in the event of a fault.

For use indoors.

Do not dispose of with household waste.

Read and adhere to the instructions for use.

Downloaded from www.watergardeningdirect.com

Page 19

54737/0

8-17

Downloaded from www.watergardeningdirect.com

Loading...

Loading...