Optical DO Sensor

Note

Note

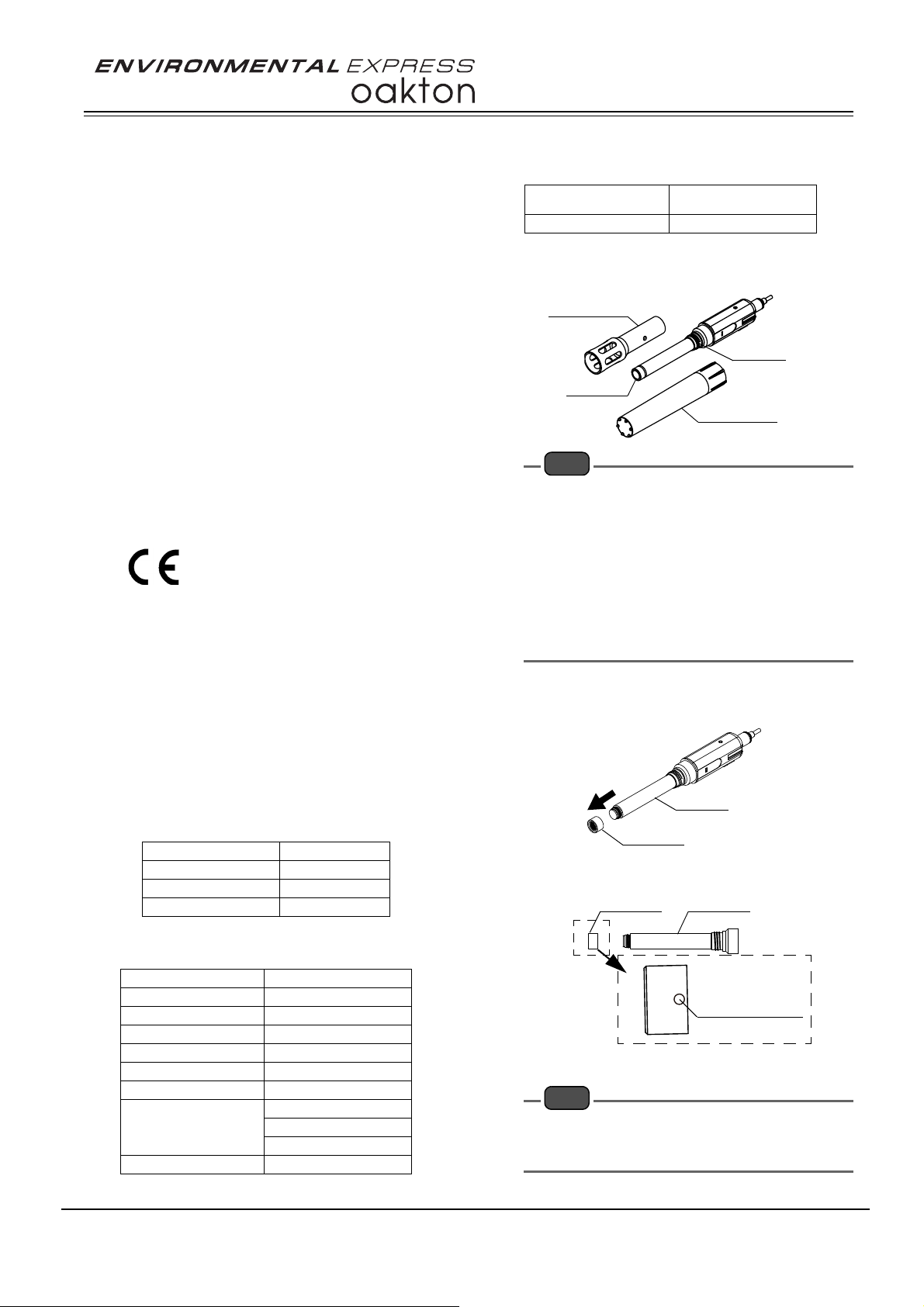

DO sensor

Calibration bottle

Sensor cap

Protective guard

(35661-00)

DO sensor

Sensor cap

xxxx

Sensor cap DO sensor

Membrane parameter

Enlarged

35660-96 / 35660-98

*”DO” is an abbreviation of Dissolved Oxygen.

Warranty and Responsibility

Oakton Instruments. warrants DO sensor shall be free from defects in

material and workmanship and agrees to repair or replace free of

charge, at option of Oakton Instruments, any malfunctioned or

damaged product attributable to responsibility of Oakton Instruments.

for a period of Three (3) years from the delivery unless otherwise

agreed in a written statement. Sensor cap is eligible for a

replacement against incipient defects within Two (2) years from the

delivery. In any one of the following cases, none of the warranties set

forth herein shall be extended:

Any malfunction or damage attributable to improper operation

Any malfunction attributable to repair or modification by any

person not authorized by Oakton Instruments.

Any malfunction or damage attributable to the use in an

environment not specified in this manual

Any malfunction or damage attributable to violation of the

instructions in this manual or operations in the manner not

specified in this manual

Any malfunction or damage attributable to any cause or causes

beyond the reasonable control of Oakton Instruments. such as

natural disasters

Any deterioration in appearance attributable to corrosion, rust,

and so on

OAKTON INSTRUMENTS. SHALL NOT BE LIABLE FOR ANY

DAMAGES RESULTING FROM ANY MALFUNCTIONS OF THE

PRODUCT, ANY ERASURE OF DATA, OR ANY OTHER USES OF

THE PRODUCT.

Conformable standards

This equipment conforms to the following standards:

EN50581

RoHS:

9. Monitoring and control instruments

Authorised representative in EU

Cole-Parmer UK

9 Orion Court, Ambuscade Road

Colmworth Business Park

St Neots

Cambridgeshire

PE19 8YX, United Kingdom

Phone: +44-(0)1480-272279

Fax: +44-(0)1480-212111

Cautions during handling

Do not allow the sensor to be in contact with any hard surface.

The surfaces of the sensor cap is covered with fluorescent

materials. Do not allow the sensor cap to come in contact with

dirt and operate carefully when immersing into a solution.

Avoid continuous measurements in solutions with strong acids,

solutions with strong alkalis and solutions with organic solvents.

Electromagnetic interferences may cause malfunctions in the

DO sensor.

Packaged contents

DO sensor (with sensor cap) 1 pc.

Calibration bottle 1 pc.

Protective guard 1 pc.

Instruction manual 1 copy

CODE:M0038633200839762GZ0000590219

December, 2019

Lead cable length

Waterproof IP67

*For a calibration perfomed in saturated water

Names of parts

The sensor cap is delivered equiped with the DO sensor.

Perform a calibration before any measurement.

The calibration method is indicated in the instruction

manual of the meter.

It is recommended to make a calibration in liquids for a

better accuracy during measurements.

Make sure there are no air bubbles visible on the surface of

the cap during a measurement.

After finishing a measurement, clean the sensor by using a

soft cloth. Take care not to scratch the sensor cap. After

cleaning, rinse the sensor cap with distilled water.

Store the DO sensor with the sensor cap and the calibration

bottle in a cool, dark location. The sponge inside the

calibration bottle should be kept wetted.

2 m (35660-96)

5 m (35660-98)

Sensor cap replacement instruction procedure

1. Remove the old sensor cap from the DO sensor.

2. Tighten the new sensor cap on the DO sensor.

3. Input the membrane parameter indicated on the sensor cap in

the meter.

Specifications and names of parts

Specifications

Model 35660-96 / 35660-98

Measurement method Fluorescence quenching

Measurement range 0 to 20 mg/L

Accuracy (DO) ±2 % *

Temperature range 0 to 50 °C

Accuracy (Temperature) ±0.5 °C

Response time 35 s (t :90)

DO sensor: PC/ABS

Watted materials

DO sensor size 16×200 mm

Sensor cap: PMMA

Protective guard: SUS316L

Oakton Instruments

625 E. Bunker Ct. Vernon Hills, IL. 60061, USA

E-mail: info@4oakton.com

Phone number: (1)888-462-5866

4. Perform calibration.

The instruction procedure has been completed.

The membrane parameter of the sensor cap delivered is set

in the meter.

The setting method of the membrane parameter is indicated

in the instruction manual of the meter.

For any questions regarding this product, please contact your local agency,

or inquire from the following website.

http://www.4oakton.com/

Loading...

Loading...