Page 1

DO250

DO260

Page 2

Page 3

• Preface

This manual describes the operation of the following instrument.

Brand: OAKTON

Series name: OAKTON 200 series Handheld meters

Model: DO250, DO260

Model description: Dissolved Oxygen Meter

Be sure to read this manual before using the product to ensure proper and safe operation of

the product. Also, safely store the manual so it is readily available whenever necessary.

Product specifications and appearance, as well as the contents of this manual are subject to

change without notice.

• Warranty and responsibility

Oakton Instruments. warrants that the product shall be free from defects in material and

workmanship and agrees to repair or replace free of charge, at option of Oakton Instruments.,

any malfunctioned or damaged product attributable to responsibility of Oakton Instruments. for

a period of Three (3) years from the delivery unless otherwise agreed in a written statement. In

any one of the following cases, none of the warranties set forth herein shall be extended:

• Any malfunction or damage attributable to improper operation

• Any malfunction attributable to repair or modification by any person not authorized by Oakton Instruments.

• Any malfunction or damage attributable to the use in an environment not specified in this

manual

• Any malfunction or damage attributable to violation of the instructions in this manual or

operations in the manner not specified in this manual

• Any malfunction or damage attributable to any cause or causes beyond the reasonable

control of Oakton Instruments. such as natural disasters

• Any deterioration in appearance attributable to corrosion, rust, and so on

• Replacement of consumables

Oakton Instruments. SHALL NOT BE LIABLE FOR ANY DAMAGES RESULTING FROM ANY

MALFUNCTIONS OF THE PRODUCT, ANY ERASURE OF DATA, OR ANY OTHER USES OF

THE PRODUCT.

• Trademarks

• Microsoft, Windows, Windows Vista are registered trademarks or trademarks of Microsoft

Corporation in the United States and other countries.

Other company names and brand names are either registered trademarks or trademarks of the

respective companies. (R), (TM) symbols may be omitted in this manual.

CODE:M003810-3200828207-GZ0000581080

November, 2019 © 2019 Oakton Instruments.

I

Page 4

Regulations

• Regulations

• EU regulations

• Conformable standards

This equipment conforms to the following standards:

EMC: EN61326-1

RoHS: EN50581

Warning: This product is not intended for use in industrial environments. In an

industrial environment, electromagnetic environmental effects may

cause the incorrect performance of the product in which case the

user may be required to take adequate measures.

Class B, Basic electromagnetic environment

9. Monitoring and control instruments

• Information on disposal of electrical and electronic equipment and disposal of batteries and accumulators

The crossed out wheeled bin symbol with underbar shown on the product or accompanying

documents indicates the product requires appropriate treatment, collection and recycle for

waste electrical and electronic equipment (WEEE) under the Directive 2012/19/EU, and/or

waste batteries and accumulators under the Directive 2006/66/EC in the European Union.

The symbol might be put with one of the chemical symbols below. In this case, it satisfies

the requirements of the Directive 2006/66/EC for the object chemical. This product should not

be disposed of unsorted household waste. Your correct disposal of WEEE, waste batteries and

accumulators will contribute to reducing wasteful consumption of natural resources, and

protecting human health and the environment from potential negative effects caused by

hazardous substance in products.

Contact your supplier for information on applicable disposal methods.

II

Page 5

Regulations

• Authorised representative in EU

Cole-Parmer UK

9 Orion Court, Ambuscade Road

Colmworth Business Park

St Neots

Cambridgeshire

PE19 8YX, United Kingdom

Phone: +44-(0)1480-272279

Fax: +44-(0)1480-212111

Email: sales@coleparmer.co.uk

www.coleparmer.co.uk

• FCC rules

FCC Compliance Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Responsible Party for FCC matter

Oakton Instruments

625 East Bunker Court,

Vernon Hills, IL, 60061, USA

Tel: 1-888-462-5866

Note

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference

at his own expense.

Any changes or modifications not expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment.

III

Page 6

For Your Safety

• For Your Safety

• Hazard classification and warning symbols

Warning messages are described in the following manner. Read the messages and follow the

instructions carefully.

• Hazard classification

This indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This is to be

limited to the most extreme situations.

This indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

This indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also

be used to alert against unsafe practices.

• Warning symbols

Description of what should be done, or what should be

followed.

VI

Description of what should never be done, or what is

prohibited.

Page 7

For Your Safety

• Safety precautions

This section provides precautions for using the product safely and correctly and to prevent

injury and damage. The terms of DANGER, WARNING, and CAUTION indicate the degree of

immanency and hazardous situation. Read the precautions carefully as it contains important

safety messages.

• Instrument and electrode

Do not disassemble or modify the instrument. Otherwise, it may heat up or be ignited

resulting in a fire or an accident.

Harmful chemicals

Some electrodes are used with hazardous standard solutions. Handle them with care.

The internal solution of DO electrode is highly concentrated potassium hydroxide

(KOH). If the internal solution comes in contact with the skin, wash it off immediately. If

it gets into the eyes, flush with plenty of water and then consult a doctor.

Do not use the phono jack under wet or humid conditions. Otherwise, it may cause a

fire, electric shock, or breakage.

VII

Page 8

For Your Safety

• Battery

Keep batteries out of reach of children. If someone accidentally swallows a battery,

consult a doctor immediately.

If alkaline fluid from a battery gets into the eyes, do not rub the eyes, rinse with clean

water immediately and then consult a doctor. Contact with alkaline fluid could cause

blindness.

Do not put batteries in a fire, expose to heat, disassemble or remodel.

Doing so can case fluid leakage, overheating or explosion.

VIII

Page 9

Product Handling Information

• Product Handling Information

• Operational precautions (instrument)

• Only use the product including accessories for their intended purpose.

• Do not drop or physically impact the instrument.

• The instrument is made of solvent-resistant materials but that does not mean it is resistant

to all chemicals. Do not expose the instrument in strong acid or alkali solution, or wipe with

such solution.

• If the instrument is dropped into water or gets wet, wipe it using soft cloth. Do not heat to

dry it.

• The instrument has a dust-proof and waterproof structure i.e., the instrument does not

malfunction even when immersed in water of 1 m depth for 30 minutes. This does

guarantee non-destructive, trouble-free, dust-proof, and waterproof performance in all

situations.

• When replacing the batteries or when a serial cable connected, the instrument does not

have the dust-proof and waterproof performance. The dust-proof and waterproof

performance is maintained only when the covers are attached correctly.

• After replacing the batteries or removing the serial cable connected, make sure that the

waterproof gasket attached to the cover is not deformed or discolored, or has foreign

matter adhering to it. If the waterproof gasket is deformed, discolored or has foreign matter

adhering to it, dust could get inside, water leaks could occur that could lead to instrument

malfunction.

• To disconnect an electrode or serial cable, hold the connector and pull it off. If you pull at

the cable, it may cause breakage.

• The phono jack communication between the instrument and a personal computer (referred

to as PC in the rest of this document) may fail because of environmental conditions, such

as electromagnetic noise.

• Do not replace the batteries in a dusty place or with wet hands. Dust or moisture could get

inside the instrument, possibly causing instrument malfunction.

• Do not use an object with a sharp end to press the keys.

• If the power supply is interrupted while measurement data is being saved in the instrument,

the data could be corrupted.

• A Ni-MH rechargeable battery can be used in this instrument.

• Operational precautions (battery)

• Do not short circuit a battery.

• Position the + and - side of the battery correctly.

• When the battery has depleted or the instrument will not be used for a long time, remove

the batteries.

• Of the specified battery types, make sure to use two batteries of the same type.

• Do not use a new battery together with a used battery.

• Do not use a fully charged nickel-metal hydride battery together with a partially charged

battery.

• Do not attempt to charge a non-rechargeable battery.

IX

Page 10

Product Handling Information

• Environmental conditions for use and storage

• Temperature: 0 °C to 45 °C

• Humidity: under 80% relative humidity and free from condensation

• Avoid the following conditions:

• Strong vibration

• Direct sunlight

• Corrosive gas environment

• Locations close to an air-conditioner

• Direct wind

• Transportation

When transporting the instrument, repackage it in the original package box. Otherwise, it may

cause instrument damage.

• Disposal

• Standard solution used for the calibration must be under neutralized before the disposal.

• When disposing of the product, follow the related laws and regulations of your country for

disposal of the product.

X

Page 11

Contents

■ Product Overview ............................................................... 1

● Package Content........................................................ 1

● Key Features .............................................................. 2

● Product components................................................. 3

■ Basic operations ................................................................. 7

● Mode and measurement............................................ 9

● Calibration ................................................................ 11

● DO Calibration.......................................................... 11

● Temperature Calibration ......................................... 17

■ Data .................................................................................... 19

● Data capture and storage........................................ 19

● Data transfer............................................................. 20

■ Setup .................................................................................. 21

● P1 DO setup ............................................................. 21

● wP2 Data setup ........................................................ 25

● P3 General setup ..................................................... 29

● P4 CLK setup ........................................................... 34

■ Maintenance and storage ................................................. 37

● Maintenance and storage of the instrument ......... 37

● Maintenance and storage of the DO electrode ..... 38

■ Error messages and trouble shooting ............................ 39

■ Appendix ........................................................................... 43

● Appendix 1 ............................................................... 43

● Appendix 2 ............................................................... 44

● Appendix 3 ............................................................... 47

XI

Page 12

MEMO

XII

Page 13

Product overview

4

1

3

2

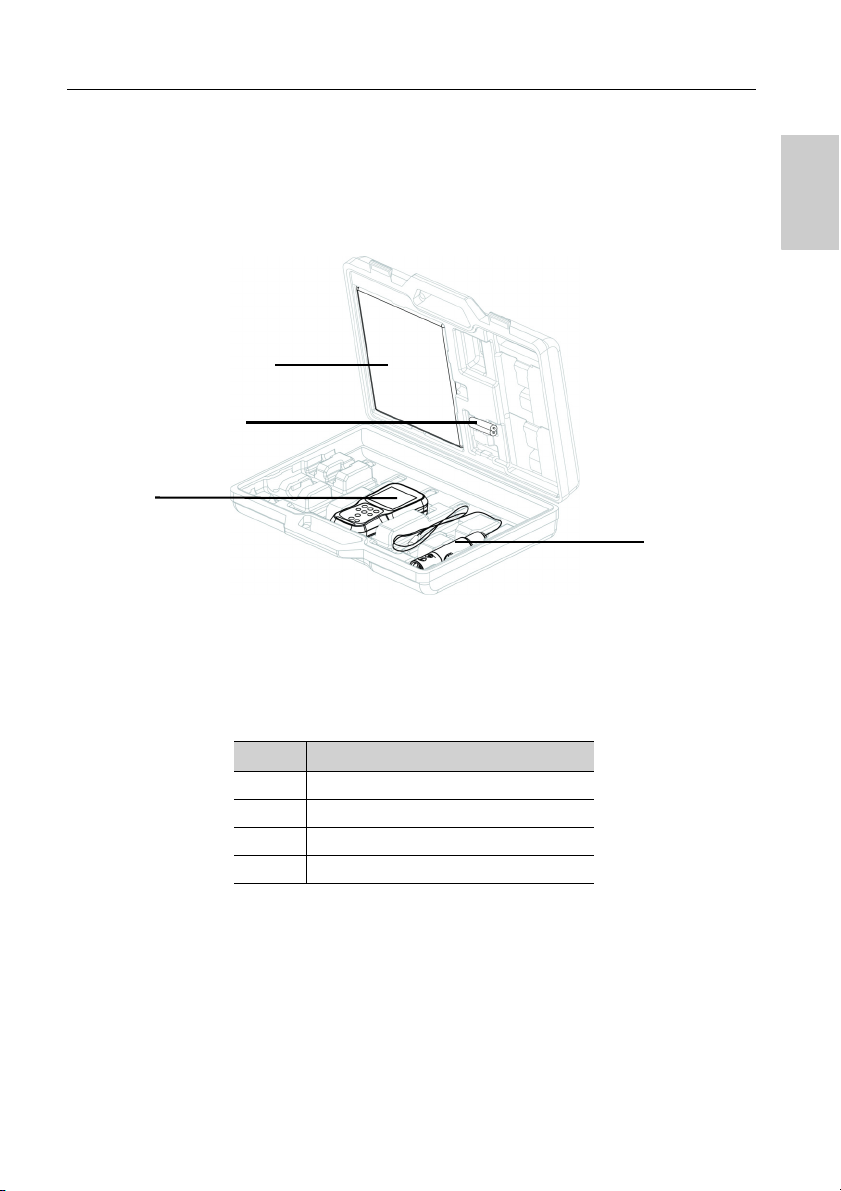

■ Product Overview

This section describes the package content, key features and product components of OAKTON

DO200 series Handheld meters.

● Package Content

After opening the carry case, remove the meter and check for damage on the instrument and

confirm that the standard accessories all exist. If damage or defects are found on the product,

contact your dealer.

OAKTON DO200 series Handheld meters and meter kit include the following items:

S.NO. Name

1 Instrument

2 Instruction manual

3 2 AA batteries

4 Electrode (Electrode kit only)

1

Page 14

Product overview

● Key Features

• IP67 water ingress, dust-proof, shock-resistant, anti-slip meter housing.

• Large monochrome LCD (50 x 50 mm) with white LED back lighting.

• Built-in electrode holder (up to 2 electrodes).

• Foldable meter stand.

• Simple user interface and single parameter display.

• 500 (for DO250) / 1000 (for DO260) data memory.

• Automatic Temperature Compensation (ATC) with temperature calibration.

• Adjustable auto shut-off time (1 to 30 minutes).

• Auto-hold / Auto stable / Real-time measurement modes with stability indicators.

• Powered by 2 x AA batteries.

• Real-time clock (only for DO260).

• PC (standard USB) / Printer (25 pin serial) connection via 2.5 mm diameter phono jack.

2

Page 15

Product overview

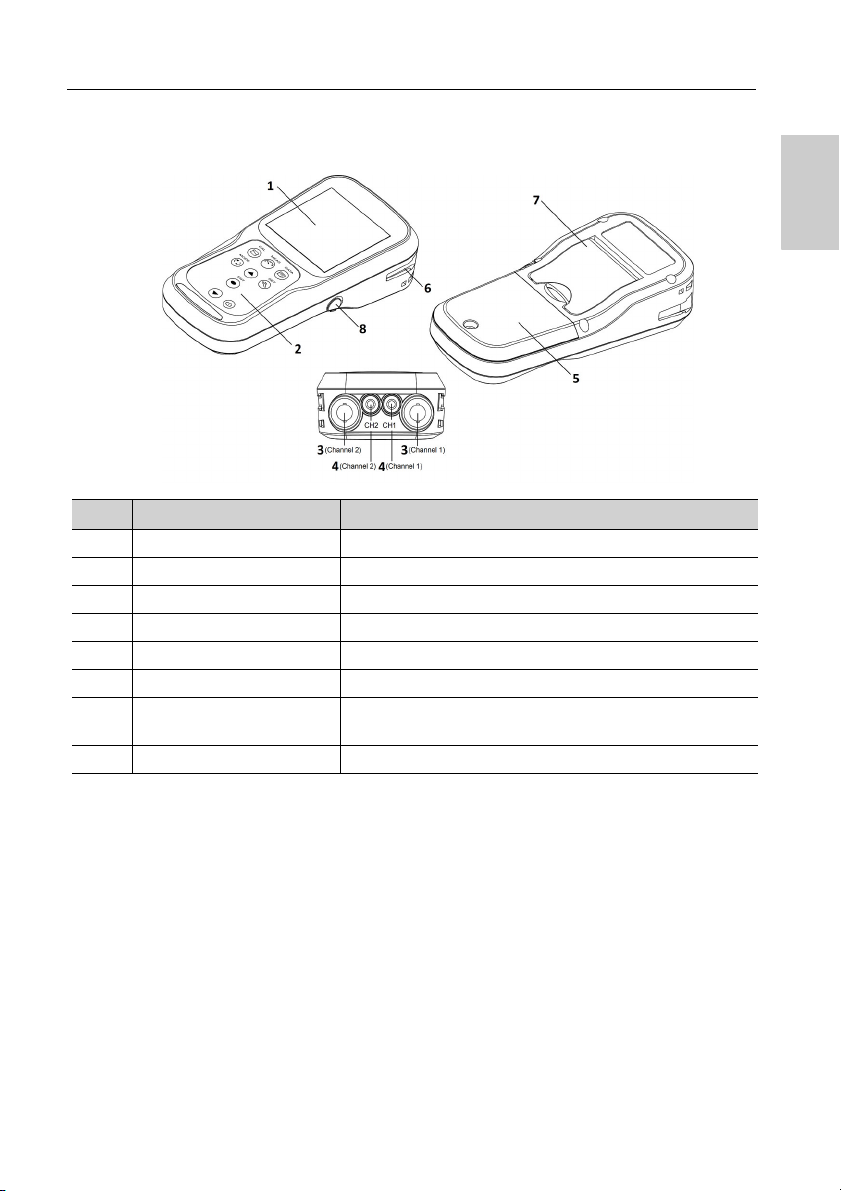

● Product components

No Name Function

1 Monochrome LCD Displays the measured value

2 Operation keys Used for instrument operation

3 Electrode connector Connect to the BNC connector of the electrode

4 Temperature connector (T) Connect to the temperature sensor of the electrode

5 Battery cover Open/close to insert/remove batteries

6 Electrode holder Hold the electrode to carry with the instrument

7 Meter stand

8 Serial connector Connects to the PC or printer with the appropriate cable

Open stand to place the meter at an inclined position on a

flat surface

3

Page 16

Product overview

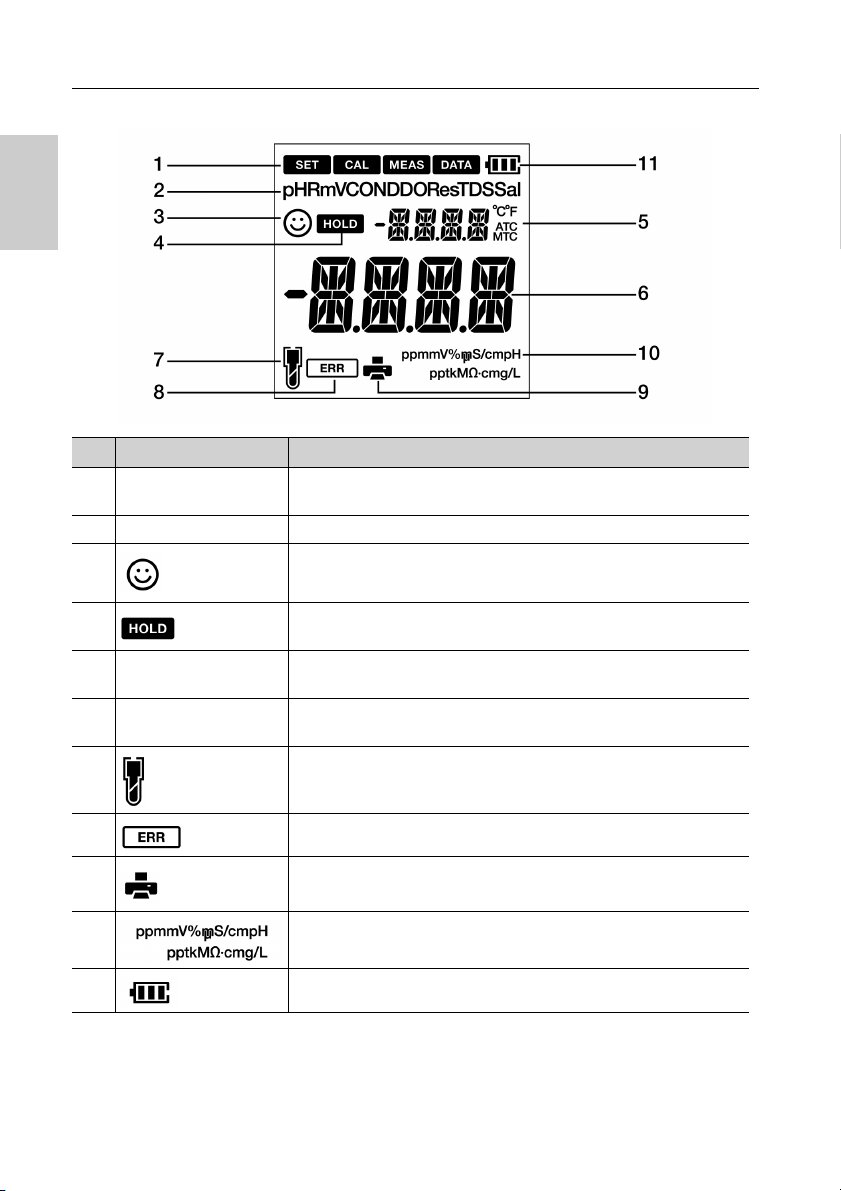

● Display

No Name Function

1 Status Icon

2 Parameters Displays the measured parameters like DO

3

4

Temperature display

5

area

Measured value, set

6

item display area

7

Displays the current operation mode (Setup, Calibration,

Measurement and Data mode)

Stability indicator shows value is stable for the documentation in

auto-stable and auto-hold modes

Appears when the measured value display is stable and fixed in

auto-hold mode

Displays the measured temperature

Displays the measured value and the set value

Indicates electrode sensitivity level

8

9 Indicates data being transfered to the printer or computer

10 Displays the unit for the measurement parameter

11 Displays the battery level

Indicate error situations

4

Page 17

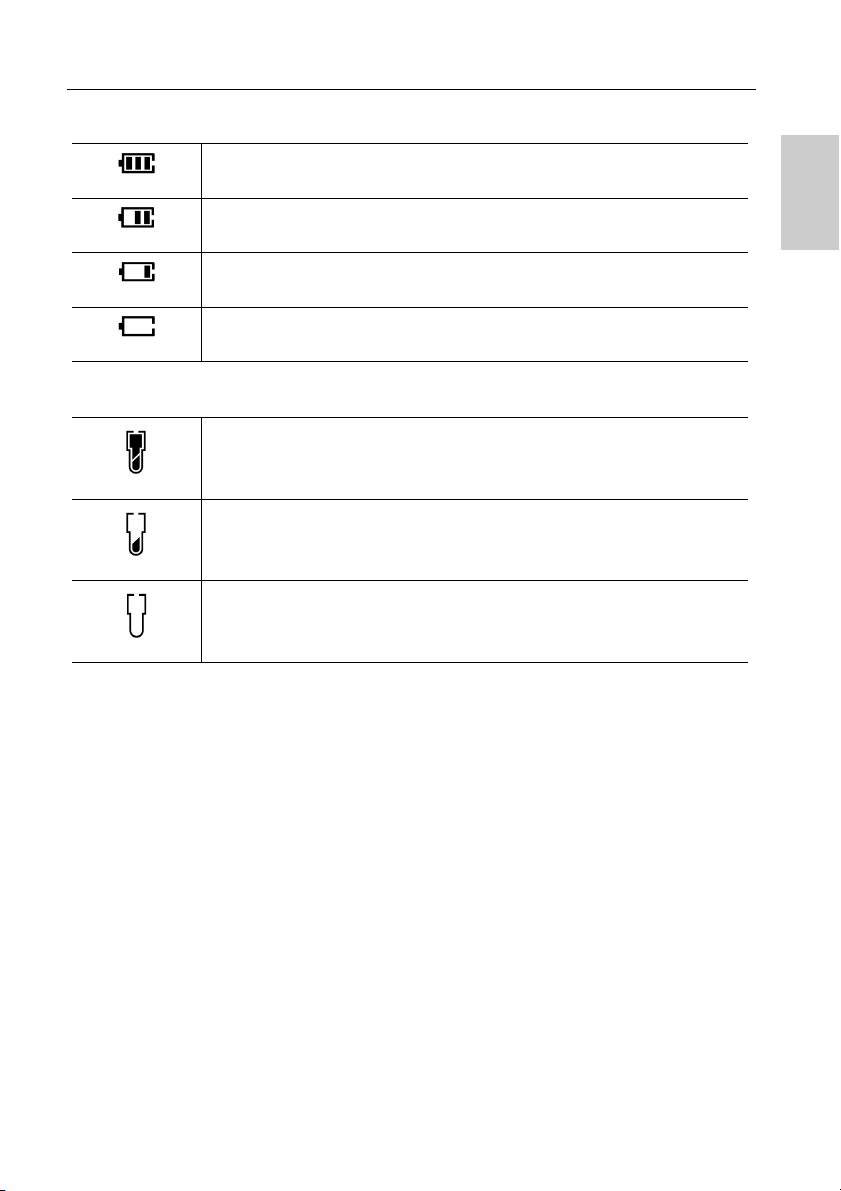

● Battery level display

100% battery life

50% battery life

20% battery life

Batteries are weak and need replacement. Refer “BATT LOW” on page 39 to

solve this

● Electrode sensitivity level

Electrode sensitivity 80% (excellent)

Electrode sensitivity between 80% to 60% (very good)

Electrode sensitivity between 60% to 50% (good). Refer “SLPE ERR” on

page 39 to solve this

Product overview

5

Page 18

Product overview

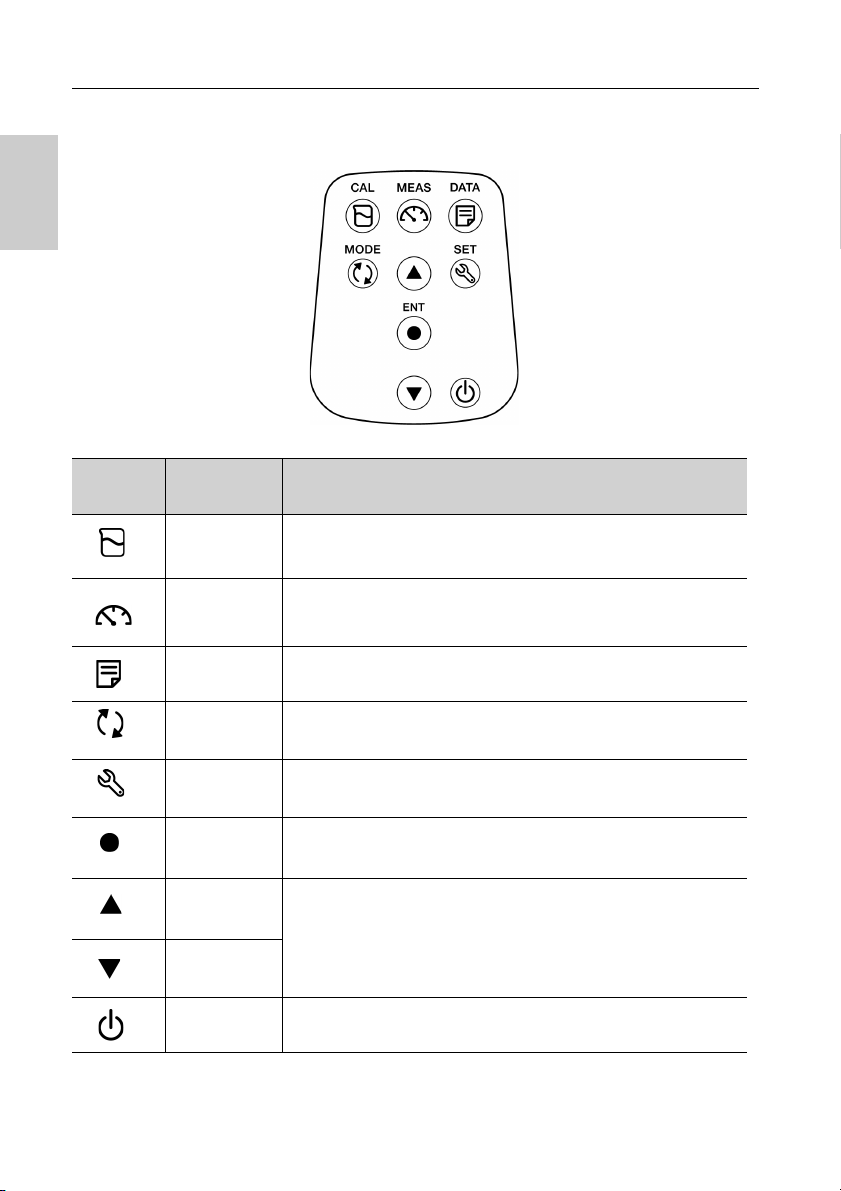

● Keypad operation

Keypad

operation

Name Function

CAL key

MEAS key

DATA key Switches from the measurement mode to the data mode.

MODE key In the measurement mode, changes measurement parameters.

SET key

ENTER key

UP key

DOWN key

POWER key Powers ON/OFF the instrument.

Switches from the measurement mode to the calibration mode.

Starts calibration in the calibration mode.

Switches from the operation mode to the measurement mode.

Releases the fixed measurement value mode in the auto hold

mode and begins a new measurement.

Switches from the measurement mode to the setup mode.

Determines the selection or setup.

Saves data in the measurement mode and calibration mode.

In the setup mode, navigates between the setup.

Selects preferred option in some setup screens.

Increases or decreases selected digit when entering numbers.

6

Page 19

Basic operations

Note

■ Basic operations

This section describes function and basic operation method of each part of OAKTON DO200

series Handheld meters.

● Turning on the instrument

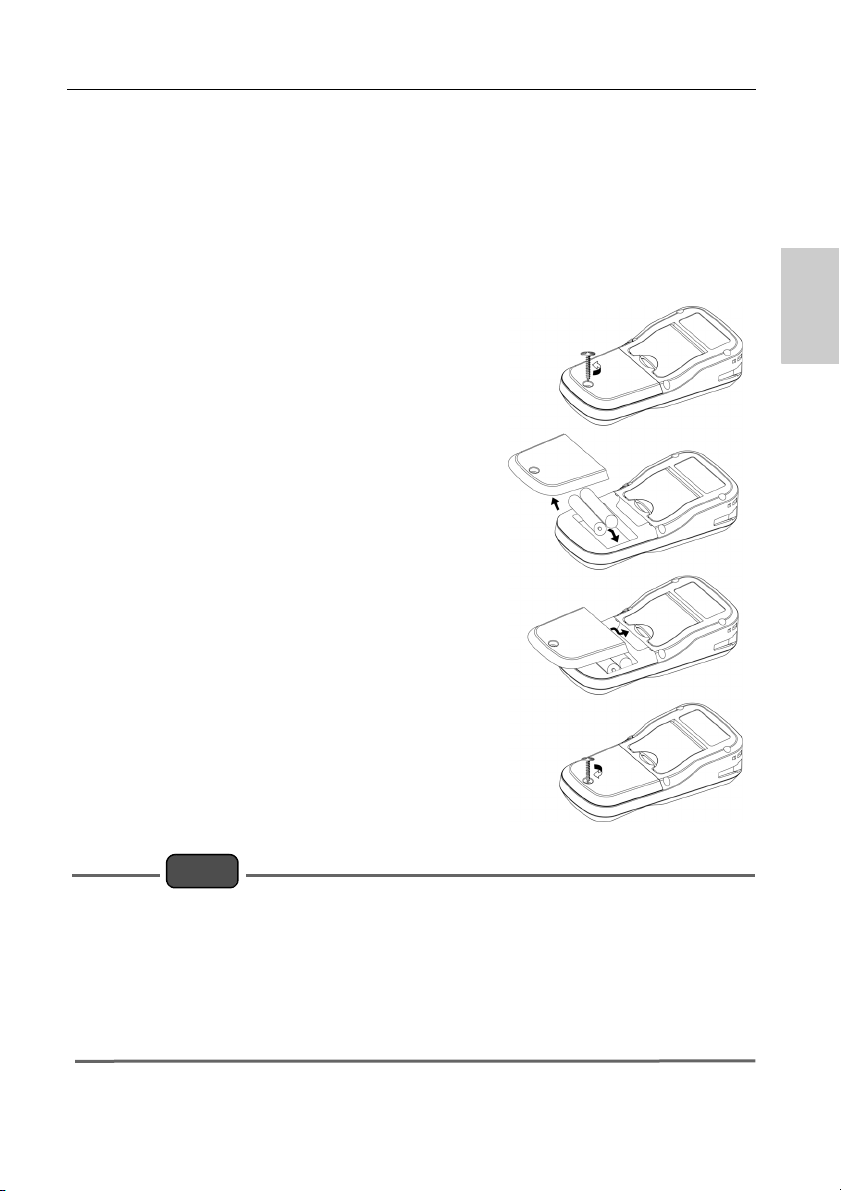

Inserting the batteries

This instrument is operated by batteries. You can use AA

alkaline batteries or AA Ni- MH chargeable batteries.

Perform the following procedure to insert batteries in the

instrument.

1. Unscrew the battery cover on the back of the

instrument counter-clock wise to unlock the battery cover.

2. Remove the battery cover and set the batteries inside.

3. Replace battery cover.

4 . S c r e w t h e b a t t e r y c o v e r o n t h e b a c k

of the instrument clockwise to lock the battery

cover.

• Do not replace the batteries in a dusty place or with wet hands. Dust or moisture could get

inside the instrument and possibly cause an instrument malfunction.

• Do not short-circuit a battery.

• Note polarity as shown in the battery compartment.

• When the battery has depleted or the instrument will not be used for a long time, remove

the batteries.

• Of the specified battery types, make sure to use two batteries of the same type.

• Do not use a new battery together with an used battery.

7

Page 20

Basic operations

Electrode connector

Temperature jack (T)

● Connecting an electrode

To perform calibration / measurement, it is necessary to use the appropriate electrode for

measurement parameter. Use the following procedure to correctly connect the electrode to the

instrument.

1. Insert the electrode connector by fitting its groove with the connector pin of the instrument.

2. Turn the electrode connector clockwise by following the grooves.

3. Slide the connector cover on the connector.

4. When using a combination electrode equipped with a temperature sensor, insert the temperature jack (T) to the ATC socket on the meter.

8

Page 21

Basic operations

● Mode and measurement

● Changing the operation mode

You can change the operation mode to four available modes depending on the purpose of use.

The status icon indicates the current mode.

Icon Name Function

Setup mode Perform various setup functions.

Calibration mode Performs calibration.

Measurement

mode

Data mode Performs data setup. Displays the saved data.

You can change the operation mode using the corresponding key:

• Measurement mode: Press the key to change to the measurement mode.

• Calibration mode: In the measurement mode, press the key to change to the

calibration mode.

• Data mode: In the measurement mode, press the key to change to the data mode.

• Setup mode: In the measurement mode, press the key to change to the setup mode.

Performs measurement.

9

Page 22

Basic operations

● Changing the measurement parameter

This instrument measures multiple parameters. For measurement, an electrode corresponding

to the measurement parameter is required. In the measurement mode, the measurement

parameter can be changed by pressing the key.

10

Page 23

DO calibration

Note

Note

Tip

● Calibration

This section describes the basic calibration method using OAKTON DO200 series Handheld

meters and DO electrode.

● DO Calibration

Calibration is necessary for accurate dissolved oxygen measurement. Two calibration modes

are available in DO meter for calibration,

• Saturated oxygen concentration mode (%)

• Dissolved oxygen measurement mode (mg/L)

To perform various DO calibrations, follow the procedures detailed below:

Set the air pressure value (default setup is 101.3 kPa) before calibration for accurate

measurement.

● Calibration in saturated oxygen concentration mode (%)

Prerequisites

• Clean the membrane at the tip of the DO electrode with DI (deionized) water and wipe it

with tissue paper.

• Switch on the DO meter and plug in the DO electrode.

• Press the key to keep the DO meter in saturated oxygen concentration mode (%)

mode.

• Calibration performed in clean air is referred as air calibration.

• Perform the air calibration in clean air at a location not subjected to dramatic temperature

change, rain or direct wind.

• Do not hold the tip of DO electrode with hand during calibration, as the electrode may be

affected by temperature causing instability in calibration value.

To abort an ongoing calibration process at any point of time, press the key.

11

Page 24

DO calibration

Note

Note

● Air calibration

5. Hold the DO electrode still in clean air.

6. Press the key. Meter starts checking various calibration values with a blinking on

screen.

7. Wait for the to stabilize (stable calibration reading).

8. Press the ENT key to confirm and save calibration data.

9. Meter displays DONE indicating end of the air calibration procedure.

The electrode responds slightly differently to atmospheric air as compared to water. As such,

100% calibration in air will be shown as approximately 105%. Don't be alarmed by this.The

reading in water will be accurate.

If you want to know previous calibrated values, press the key when you are in the CAL

mode.The display scrolls through the calibrated values and indicates slope and offset values.

12

Page 25

DO calibration

Note

● Zero calibration

1. Dip the DO electrode in the zero standard solution.

2. Press the key. Meter starts checking various calibration values with a blinking on

screen.

3. Wait for the to stabilize (stable calibration reading).

4. Press the key again to move to Zero Calibration mode.

5. Press the ENT key to confirm and save calibration data.

6. Meter displays DONE indicating end of the zero calibration procedure.

• Calibration performed with zero standard solution is referred as zero calibration.

• Prepare zero standard solution by adding 50 g of sodium sulfite (Na

deionized water and stirring the mixture to completely dissolve the Na

) to 1000 mL

2SO3

.

2SO3

13

Page 26

DO calibration

Note

Tip

● Calibration in dissolved oxygen measurement mode (mg/L)

Prerequisites

• Clean the membrane at the tip of the DO electrode with DI (deionized) water and wipe it

with tissue paper.

• Prepare required standard solutions (high-concentration and low-concentration solutions).

• Switch on the DO meter and plug in the DO electrode.

• Dip the DO electrode at least 6 cm in the standard solution.

• Press the key to keep the DO meter in dissolved oxygen measurement mode (mg/L)

mode.

• Calibrate in the dissolved oxygen measurement mode in the order from high-concentration

solution to a low-concentration solution.

• User can adjust the measured dissolved oxygen reading by calibration and the adjusted

value is applied as an off set to the actual measurement.

• Prepare high-concentration solution by aerating a sample of fresh water for about 2 hours.

To abort an ongoing calibration process at any point of time, press the key.

14

Page 27

DO calibration

● 1st point calibration

1. After placing the DO electrode in the high concentration solution, press the key.

Meter starts checking various calibration values with a blinking on screen.

2. Wait for the to stabilize (stable calibration reading).

3. Use the

4. Press the ENT key to confirm and save calibration data.

5. Meter displays CAL DONE indicating end of the calibration procedure.

keys to adjust the DO reading.

15

Page 28

DO calibration

● 2nd point calibration

1. After placing the DO electrode in the low concentration solution (zero standard

solution), press the key. Meter starts checking various calibration values with a

blinking on screen.

2. Wait for the to stabilize (stable calibration reading).

3. Press the key again to move to Zero Calibration Mode.

4. Use the

5. Press the ENT key to confirm and save calibration data.

6. Meter displays CAL DONE indicating end of the calibration procedure.

keys to adjust the DO reading.

16

Page 29

Temperature calibration

Note

Tip

● Temperature Calibration

Temperature calibration is required to accurately match the DO electrode to the meter. Check

the temperature reading and if its acceptable, no temperature calibration is required. If you

need to calibrate, please follow the procedure detailed below:

Prerequisites

• Clean the DO electrode with DI (deionized) water and wipe it with tissue paper.

• Switch on the DO meter and plug in the DO electrode and temperature sensor.

• Dip the DO electrode in the standard solution till its temperature sensor is immersed.

• Wait for 5 minutes to ensure temperature stability.

• Meter displays MTC if the temperature sensor is not plugged in and displays AT C if the

temperature sensor is plugged in.

• Temperature calibration must be performed using a known temperature solution or against

a calibrated thermometer.

To abort an ongoing calibration process at any point of time, press the key.

17

Page 30

Temperature calibration

Calibration

7. After placing the DO electrode in the standard solution, press the key.

8. Press the key to switch to temperature calibration mode. Meter displays measured temperature value.

9. Use the keys to adjust the temperature to the required value.

10. Press the ENT key to save calibration data.

11. Meter displays DONE indicating end of the temperature calibration procedure.

18

Page 31

Data capture and stor age

Note

■ Data

This section describes the basic method of data transferring using OAKTON DO200 series

Handheld meters.

● Data capture and storage

In OAKTON DO200 series Handheld meters DO200, data measured by the instrument can be

stored in the internal memory.

To save the measured data:

• Press the ENT key to save the displayed data.

• Meter displays the saved data for 2 seconds and then the display returns to the previous

screen automatically.

• If the data storage limit reaches 500 in DO250 model or 1000 in DO260 model, memory full

error occurs and MEM FULL is displayed.

• In such case, print the data or transfer necessary data to a PC (only for DO260) and delete

the data from the internal memory of the instrument.

Viewing stored data

• To view stored data, press key .

• Use keys to review different stored records.

• Press key to return to measurement mode.

19

Page 32

Data capture and storage

Tip

● Data transfer

● Transfer data to PC

Connect the instrument to a PC using the phono plug to USB cable to transfer saved data to

the PC (for OAKTON DO200 series Handheld meters). Connect the phono jack at the

instrument side to the communication port on the PC.

● Print data

To print a desired data set:

12. When the instrument is in the measurement mode, press key.

13. Use keys to view desired stored data.

14. Press key to print that individual data.

● Printer format- measurement

Meter Model : OAKTON DO200

Serial Number : 123456789

SW Revision : 1.00

Date : 20 Aug 2018

Time : 10:10:28

Mode : DO

DO : 100.0 %

Temperature : 25.0 C (MAN)

Electrode Status : Excellent

User Name :

Signature :

To print entire stored data log, refer “P2.2 Print data setup” on page 27.

20

Page 33

DO set up

Note

Tip

■ Setup

This section describes all the setup functions available in OAKTON DO200 series Handheld

meters DO200.

● P1 DO setup

Using P1 DO setup function of the meter, you can:

• Set salinity value

• Set barometric pressure

• Erase calibration data

To set the DO functions using OAKTON DO200 series Handheld meters, follow the procedure

detailed below:

Prerequisites

Switch on the DO meter.

• Default salinity value is 0.0 ppt. You can set a value in between 0.0 to 40.0 ppt.

• Default barometric pressure is 101.3 kPa. You can set a value in between 10.0 to 200.0 kPa.

• Erasing previous calibration data is recommended for accurate calibration. Default setup is

NO but to erase the calibration data, you need to change the setup to YES.

To return to the measurement mode, press the key.

21

Page 34

DO set up

● P1.1 Salinity value setup

15. Press the key, P1 DO screen appears.

16. Press the ENT

17. Press the ENT

18. Use the keys to adjust the salinity value in between 0.0 to 40.0 ppt.

19. Press the ENT

ity value setup.

key, P1.1 SAL screen appears.

key, by default SAL 0.0 ppt appears.

key, P1.1 SAL screen appears. This indicates completion of salin-

22

Page 35

DO set up

● P1.2 Barometric pressure setup

1. Press the key, P1 DO screen appears.

2. Press the ENT

3. Press the

4. Press the ENT key, by default PRES 101.3 appears.

5. Use the keys to adjust the barometric pressure in between 10.0 to 200.0 kPa.

6. Press the ENT key, P1.2 PRES screen appears. This indicates completion of barometric pressure setup.

key, P1.1 SAL screen appears.

key, P1.2 PRES screen appears.

23

Page 36

DO set up

● P1.3 Erase calibration data

1. Press the key, P1 DO screen appears.

2. Press the ENT

3. Press the key, P1.2 PRESS screen appears.

4. Press the key, P1.3 C.CLr appears.

5. Press the ENT

6. Use the keys to change the setup to YES. This erases the calibration data.

7. Press the ENT

calibration data.

key, P1.1 SAL screen appears.

key, C.CLr NO screen appears with NO as default setup.

key. P1.3 C.CLr screen appears. This indicates erasure of

24

Page 37

Data set up

Note

Tip

● wP2 Data setup

Using P2 Data setup function of the meter, you can:

• Set data log interval

• Print data log

• Erase data log

To set the data functions using OAKTON DO200 series Handheld meters, follow the procedure

detailed below:

Prerequisites

Switch on the DO meter.

Data log interval can be set from 2 to 999 seconds.

To return to the measurement mode, press the key.

25

Page 38

Data set up

● P2.1 Data log interval setup

8. Press the key, P1 DO screen appears.

9. Press the key, P2 DATA screen appears.

10. Press the ENT key, P2.1 LOG screen appears.

11. Press the ENT key, previously set log interval appears.

12. Use the keys to set the data log interval.

13. Press the ENT key, P2.1 LOG screen appears. This indicates completion of data log interval setup.

.

26

Page 39

Data set up

● P2.2 Print data setup

1. Press the key, P1 DO screen appears.

2. Press the key, P2 DATA screen appears.

3. Press the ENT key, P2.1 LOG screen appears.

4. Press the key, P2.2 PrNT screen appears.

5. Press the ENT key, default setup is NO.

6. Use the keys to change the setup to YES.

7. Press the ENT key, P2.2 PrNT screen appears. This indicates completion of the print data.

27

Page 40

Data set up

● P2.2 Erase data

1. Press the key, P1 DO screen appears.

2. Press key, P2 DATA screen appears.

3. Press the ENT key, P2.1 LOG screen appears.

4. Press the key, P2.2 PRNT screen appears.

5. Press the key, P2.3 D.CLR screen appears.

6. Press the ENT key, default setup is NO.

7. Use the keys set it to YES to erase all the data.

8. Press the ENT key, P2.3 D.CLR screen appears. This indicates completion of the erase data.

28

Page 41

General set up

Note

Tip

● P3 General setup

Using P3 General setup function of the meter, you can:

• Select stability mode of the meter

• Set auto shut-off time

• Select temperature measurement

• Reset the meter

To set the general functions using OAKTON DO200 series Handheld meters, follow the

procedure detailed below:

Prerequisites

Switch on the DO meter.

• In the calibration mode, the auto stable (AS) mode is activated. Default stability setup in

measurement mode is “auto stable” (AS). You can change it to “auto hold” (AH) or “real

time” (RT).

• Default auto shut-off time is 30 minutes. You can set the time from ---- to 30 minutes, where

---- indicates “no auto shut-off time” has been set and meter will be on continuously.

• Default temperature unit is °C and you can change the unit to °F.

• Default reset meter setup is NO. If you like to reset the meter, you can change it to YES.

• Stability judgment criteria remains same for both auto stability mode and auto hold mode.

• To return to the measurement mode,

press the key.

29

Page 42

General set up

● P3.1 Auto Stable, Auto Hold and Real Time mode setup

Auto Stable (AS) mode - the meter shows live readings annunciator blinks until the reading

is stable.

Auto Hold (AH) mode - the meter locks the stable reading; annunciator blinks until reading is

stable and then lights up.

Real Time (RT) mode - the meter shows live readings; Both and annunciators are

inactive.

9. Press the key, P1 DO screen appears.

10. Press key, P2 DATA screen appears.

11. Press key, P3 GEN screen appears.

12. Press the ENT key, P3.1 STBL screen appears.

13. Press the ENT key, Default the stability mode is AS (auto stable).

14. Use the keys to change the stability mode as AH (auto hold) or RT (real time).

15. Press the ENT key, P3.1 STBL screen appears. This indicates completion of the stability mode selection.

30

Page 43

General set up

Note

● P3.2 Auto shut-off time setup

1. Press the key, P1 DO screen appears.

2. Press the key, P2 DATA screen appears.

3. Press the key, P3 GEN screen appears.

4. Press the ENT key, P3.1 STBL screen appears.

5. Press the key, P3.2 A.OFF screen appears.

6. Press the ENT key, default auto shut-off time is 30 minutes.

7. Use the keys to adjust the auto off time.

8. Press the ENT key, P3.2 A.OFF screen appears. This indicates completion of the auto shut-off time setup.

The default shut off time is 30 minutes. This can be adjusted from 1 minute to 30 minutes. If

you set the display to ‘----’ it indicates Auto Off is disabled. Meter will be on indefinitely till the

user switches off the meter.

31

Page 44

General set up

● P3.3 Temperature unit setup

1. Press the key, P1 DO screen appears.

2. Press the key, P2 DATA screen appears.

3. Press the key, P3 GEN screen appears.

4. Press the key, P3.1 STBL screen appears.

5. Press the key, P3.2 A.OFF screen appears.

6. Press the key, P3.3°C°F screen appears.

7. Press the ENT key, default temperature unit is °C.

8. Use the keys to change the unit to °F.

9. Press the ENT key, P3.3°C°F screen appears. This indicates completion of the end temperature unit selection.

32

Page 45

General set up

● P3.4 Reset meter (factory default)

1. Press the key, P1 DO screen appears.

2. Press the key, P2 DATA screen appears.

3. Press the key, P3 GEN screen appears.

4. Press the ENT key, P3.1 STBL screen appears.

5. Press the key, P3.2 A.OFF screen appears.

6. Press the key, P3.3 °C°F screen appears.

7. Press the key, P3.4 r.SET screen appears.

8. Press the ENT key, default meter re-setup is NO.

9. Use the

10. Press the ENT key. Meter displays DONE and automatically switches off.

key to set it YES.

33

Page 46

Clock set up

Note

Tip

Tip

● P4 CLK setup

Real-time clock functionality is available only for OAKTON DO200 series Handheld meters.

Using P4 Clock setup function of the meter, you can set:

• Date

• Time

To set the clock function using OAKTON DO200 series Handheld meters, follow the procedure

detailed below:

Prerequisites

Switch on the DO meter.

• Setup date and time is necessary before using the instrument for the first time or after

replacing the batteries.

• Set date and time data is captured correctly while saving data in the internal memory.

To return to the measurement mode, press the key.

34

Page 47

Clock set up

● P4.1 Date setup

11. Press the key, P1 PH screen appears.

12. Press the key, P2 DATA screen appears.

13. Press the key, P3 GEN screen appears.

14. Press the key, P4 CLK screen appears.

15. Press the ENT key, P4.1 DATE screen appears.

16. Press the ENT key, default set year appears.

17. Use the

18. Press the ENT key, default set month appears.

19. Use the

20. Press the ENT key, default set day appears.

21. Use the keys to adjust the day.

22. Press the ENT key, P4.1 DATE screen appears. This indicates completion of the

date setup.

keys to adjust the year.

keys to adjust the month.

35

Page 48

Clock set up

● P4.2 Time setup

1. Press the key to switch to the setup mode, P1 PH screen appears.

2. Press the key, P2 DATA screen appears.

3. Press the key, P3 GEN screen appears.

4. Press the key, P4 CLK screen appears.

5. Press the ENT key, P4.1 DATE screen appears.

6. Press the key, P4.2 TIME screen appears.

7. Press the ENT key, default set hour appears.

8. Use the keys to adjust the hour.

9. Press ENT key, default set minute appears.

10. Use the keys to adjust the minute.

11. P r ess ENT key, P4.2 TIME screen appears. This indicates completion of the time setup.

36

Page 49

Maintenance and storage

■ Maintenance and storage

This section describes maintenance of OAKTON DO200 series Handheld meters, DO

electrodes used with the meter.

● Maintenance Contract

Please contact your dealer for the product maintenance contract.

● Maintenance and storage of the instrument

● How to clean the instrument

• If the instrument is dirty, wipe it gently with a soft dry cloth. If it is difficult to remove the dirt,

wipe it gently with a cloth moistened with alcohol.

•The instrument is made of solvent resistant materials but is not resistant to all chemicals.Do

not dip the instrument in strong acid or alkali solution, or wipe it with such solutions.

• Do not wipe the instrument with polishing powder or other abrasive compound.

● Environmental conditions for storage

• Temperature: 0 °C to 45 °C

• Humidity: under 80% relative humidity and free from condensation

● Avoid the following conditions

• Dusty place

• Strong vibration

• Direct sunlight

• Corrosive gas environment

• Close to an air-conditioner

• Direct wind

37

Page 50

Maintenance and storage

Note

DO Tip

Shorting plug

+

Rubber cap

Shorting Plug

● Maintenance and storage of the DO electrode

This section describes an overview of the procedures for maintenance and storage of DO

electrode to be performed as part of daily use.

● How to clean the membrane of DO electrode

The membrane of DO electrode is extremely thin. Take care, not to tear the membrane when

cleaning. Clean the membrane with deionized water and wipe it with a soft cloth, take care not

to damage it.

When using a neutral cleaning solution to clean the DO electrode, keep the neutral cleaning

solution away from the membrane in order to prevent deterioration of the membrane.

● Daily storage of the DO electrode

Follow the steps below to store the electrode correctly.

9552-20D, 9552-50D

12. Clean the DO electrode well with deionized water.

13. Store electrode in carry case in a dry condition.

● When the DO electrode will not be used for a long time

Follow the steps below to store the electrode correctly.

9552-20D, 9552-50D

1. Clean the DO electrode well with tap water, then dry it with cotton gauze.

2. Remove the DO tip from the DO electrode.

3. Attach the socket on the DO tip, then store it in a cool, dark location.

38

Page 51

Error mess ages and t rouble shoot ing

■ Error messages and trouble shooting

● Error message

This section describes the causes of typical errors and the actions to be taken to resolve

respective errors.

If ERR is displayed while you are using the instrument, check the error, its cause and action to

be taken in the error list below:

Meter display ERR description Cause of error

and

How to solve the problem

BATT LOW Low battery

OFFS ERR Offset voltage error Electrode is dirty. Clean the electrode.

SLPE ERR Slope error

STD ERR

MEM FULL

Can not auto recognize

standard solution

Calibration interval

alarm error

Memory data full

If user selects the enter

key before stable in

calibration mode

Battery power is low. Please replace with new

batteries.

Electrode sensitivity is low. Please clean and

recalibrate. If the problem persists, replace the

electrode with new one.

The instrument cannot identify the standard

solution. Check the calibration solution and use

fresh one if required.

Exceeds the calibration interval setup.

Calibrate the meter.

The number of the data saved has exceeded

the specified number of items. Print or transfer

the data. Or, clear stored data.

key is pressed before the calibration value

has stabilized. Wait for the value to be stable

and then press the key.

39

Page 52

Error messages and trouble shooting

● Trouble shooting

This section describes causes and actions to take for problems that customers frequently ask.

The indicated value fluctuates

< Problem with the electrode >

Cause How to solve problem

The electrode is dirty. Clean the electrode.

The electrode is broken. Replace the electrode.

< Problem with the instrument >

Cause How to solve problem

There is a motor or other device

causing electrical interference.

The electrode is not connected

correctly.

The response is slow

Measure at a place where no influence from induction

is given. Ground all AC-powered equipment.

Connect the electrode properly.

Cause How to solve problem

The electrode is dirty. Clean the electrode.

The electrode is broken. Replace the electrode.

40

Page 53

Error mess ages and t rouble shoot ing

The indicated value does not change

Cause How to solve problem

The electrode is broken. Replace the electrode.

The electrode is not connected

correctly.

Keys are locked.

The instrument is in HOLD state. Cancel the HOLD state.

Instrument defect. Consult your dealer.

The measured value is out of the measurement range

When the measured value is below the display range, “Ur” appears. When the measured value

is over the display range, “Or” appears.

Connect the electrode correctly.

Turn OFF the power, remove the batteries, and then

turn ON the power again.

Cause How to solve problem

The electrode cable is broken. Replace the electrode.

Calibration is not performed or

performed incorrectly.

Instrument defect Check as explained below.

Perform calibration correctly.

● How to check for instrument defect

Short the metal part of the outer tube to the center pin of the electrode

connector of the corresponding channel of the instrument. If “Ur” or “Or”

appears in this condition, consult your dealer.

Repeatability of the measured value is poor

Cause How to solve problem

Effect of the sample solution.

The electrode is dirty. Clean the electrode.

The internal solution of the

electrode is partially depleted or

contaminated.

Repeatability becomes poor when the DO of the sample

changes over time.

Replace the electrode.

41

Page 54

Error messages and trouble shooting

Nothing appears when the power is turned ON

Cause How to solve problem

Power is not supplied. Insert batteries.

Battery polarity (+, ) is reversed.

Battery life is low. Replace the batteries.

Instrument defect Consult your dealer.

Swelling of keypad

Insert the batteries with the polarity (+, ) correctly

oriented.

Cause How to solve problem

Using the instrument at high

elevation or other location where

the air pressure is different from

sea level.

Instrument defect Consult your dealer.

Part of the display is missing

To eliminate the pressure difference between the inside and

outside of the instrument, briefly open and then close the

serial connector cover and battery cover. After opening,

correctly close the cover to maintain dust and water

proofing.

Cause How to solve problem

Instrument defect

Check the display by switching ON the instrument when all

the LCD segments are lit.

42

Page 55

Technical note

■ Appendix

● Appendix 1

This section describes technical information and option for OAKTON DO200 series Handheld

meters.

● Saturated DO levels in water at various temperatures

ISO17289 (JIS K0102)

Tem p.

(°C)

1 14.22 11 11.03 21 8.92 31 7.43

2 13.83 12 10.78 22 8.74 32 7.31

3 13.46 13 10.54 23 8.58 33 7.18

4 13.11 14 10.31 24 8.42 34 7.07

5 12.77 15 10.08 25 8.26 35 6.95

6 12.45 16 9.87 26 8.11 36 6.84

7 12.14 17 9.67 27 7.97 37 6.73

8 11.84 18 9.47 28 7.83 38 6.62

9 11.56 19 9.28 29 7.69 39 6.52

10 11.29 20 9.09 30 7.56 40 6.41

Saturated

DO

(mg/L)

Tem p.

(°C)

Saturated

DO

(mg/L)

Tem p.

(°C)

Saturated

DO

(mg/L)

Tem p.

(°C)

Saturated

DO

(mg/L)

43

Page 56

Printout summary

● Appendix 2

Printer format - Measurement

DO - mg/L

Meter Model : OAKTON DO200

Serial Number : 123456789

SW Revision : 1.00

Date : 20 Aug 2018

Time : 10:10:28

Mode : DO

DO : 7.26 mg/L

Temperature : 25.0 C (MAN)

Electrode Status : Excellent

User Name :

Signature :

Do - %

Meter Model : OAKTON DO200

Serial Number : 123456789

SW Revision : 1.00

Date : 20 Aug 2018

Time : 10:10:28

Mode : Do

Do : 100.0 %

Temperature : 25.0 C (MAN)

Electrode Status : Excellent

User Name :

Signature :

44

Page 57

Printo ut summa ry

Printer format - Data log

Meter Model : OAKTON DO200

Serial Number : 123456789

SW Revision : 1.00

User Name :

Signature :

Logged Data

Location : 2

Date : 10 Aug 2018

Time : 10:10:28

Mode : pH

pH : 7.00 pH

mV : 0.0 mV

Temperature : 25.0 C (MAN)

Electrode Status : Excellent

Location : 1

Date : 10 Aug 2018

Time : 10:09:28

Mode : mV

mV : 178.0 mV

Temperature : 25.0 C (MAN)

45

Page 58

Printout summary

Printer format - Calibration

DO (%)

Meter Model : OAKTON DO200

Serial Number : 123456789

SW Revision : 1.00

Date : 20 Aug 2018

Time : 10:10:28

Cal Points : 100.0 %, 0.0 %

Span. Coef : 1.23

Zero. Coef : 0.12

Cal Temp. : 25.0 C (ATC)

Electrode Status : Excellent

User Name :

Signature :

DO (mg/L)

Meter Model : OAKTON DO200

Serial Number : 123456789

SW Revision : 1.00

Date : 20 Aug 2018

Time : 10:10:28

Cal Points : 8.26 mg/L, 0.0 mg/L

Span. Coef : 1.23

Zero. Coef : 0.12

Cal Temp. : 25.0 C (ATC)

Electrode Status : Excellent

User Name :

Signature :

46

Page 59

● Appendix 3

Specifications

Model

Dissolved Oxygen (DO) Range 0.0 to 20.00 mg/L

Resolution 0.01 mg/L, 0.1%

Accuracy ±0.1 mg/L

Salinity Compensation 0.0 to 40.0 ppt

Barometric Pressure Compensation Yes

DO Probe Type Galvanic integrated with temperature sensor

Calibration Points Up to 2

Temperature Range -30.0 to 130.0 °C / -22.0 to 266.0 °F

Resolution 0.1 °C / °F

Accuracy ± 0.5 °C / ± 0.9 °F

Calibration Option Yes

Memory 500 1000

Auto Data Log

Real-time Clock -

Date & Time Stamp -

Auto Hold / Auto Stable / Real Time

Auto Shut-Off (1 to 30 mins.)

Electrode Status

Diagnostic Messages

Software Upgrade

PC Communication

Printer Communication

Meter Inputs BNC, phono

Display Custom LCD with backlight

Housing IP67, shock & resistant, non-slip

Power Requirement 2 × AA batteries

Battery Life > 500 hours

Dimensions 160 (L) × 80 (W) × 40.60 (H) mm

Weight

1

1

2

DO250 DO260

DO/Temp (°C/°F)

0.0 to 200.0%

-

-

Approx. 260 g (with batteries) /

216 g (without batteries)

47

Page 60

Specifications

48

Page 61

625 East Bunker Court, Vernon Hills, IL, 60061, USA

Oakton Instruments

Tel : 1-888-462-5866

Fax: 1-847-247-2984

info@4oakton.com

www.4oakton.com

For any questions regarding this product, please contact your local agency

Page 62

Loading...

Loading...