OPERATING INSTRUCTIONS

OAKTON®35607-00

CON 10

Basic Conductivity/TDS Meter

Printed in Singapore 08/00 R2

TDS/Conductivity/°C meter

CON 10 Series

HOLD

MODE

ON

OFF

CAL

MEAS

ENTER

RANGE

C

MEAS

µ s

COND

ATC

Table of Contents

1. Introduction ............................................................................................3

2. Display and Keypad Functions............................................................ 4-5

2.1 LCD display...........................................................................................................................4

2.2 Keypad....................................................................................................................................5

3. Preparation ..........................................................................................6-9

3.1 Inserting the batteries ...........................................................................................................6

3.2 Connecting the probe and temperature sensor ................................................................7

3.3 Attaching the probe holder to the meter...........................................................................8

3.4 Inserting the probe into the probe holder .........................................................................8

3.5 Connecting the AC adapter.................................................................................................9

4. Calibration........................................................................................10-13

4.1 Preparing for calibration....................................................................................................10

4.2 Calibrating for Conductivity.............................................................................................11

4.3 Calibrating for TDS .......................................................................................................12-13

5. Temperature Calibration.......................................................................14

5.1 One-point temperature compensation.............................................................................14

6. Measurement....................................................................................15-16

6.1 Range Selection ...................................................................................................................15

6.2 Measurement using Automatic Temperature Compensation......................................15

6.3 Measurement using Manual Temperature Compensation ...........................................16

7. HOLD......................................................................................................17

8. Probe Care and Maintenance................................................................18

9. Probe Replacement ...............................................................................19

9.1 Zero calibration ...................................................................................................................19

9.1 Two point temperature calibration...................................................................................20

10. Troubleshooting..................................................................................21

11. Error Messages ....................................................................................22

12. Specifications ......................................................................................23

13. Accessories...........................................................................................24

14. Addendum 1: Conductivity to TDS Conversion Factors......................25

15. Addendum 2: Calculating TDS Conversion Factors ............................26

16. Warranty .............................................................................................28

17. Return of Items ...................................................................................28

3

1. Introduction

Thank you for selecting the Oakton® 35607-00 conductivity/TDS meter. Included

with your meter is an epoxy-body stainless steel probe with built-in temperature

sensor and cable, a built-in four position probe attachment and a built-in meter

stand.

Your meter includes electrode holders and batteries.

Please read this manual thoroughly before operating your meter.

MEAS

µ s

C

COND

TDS/Conductivity/°C meter

CON 10 Series

ATC

HOLD

CAL

MEAS

ON

OFF

MODE

ENTER

RANGE

4

2. Display and Keypad Functions

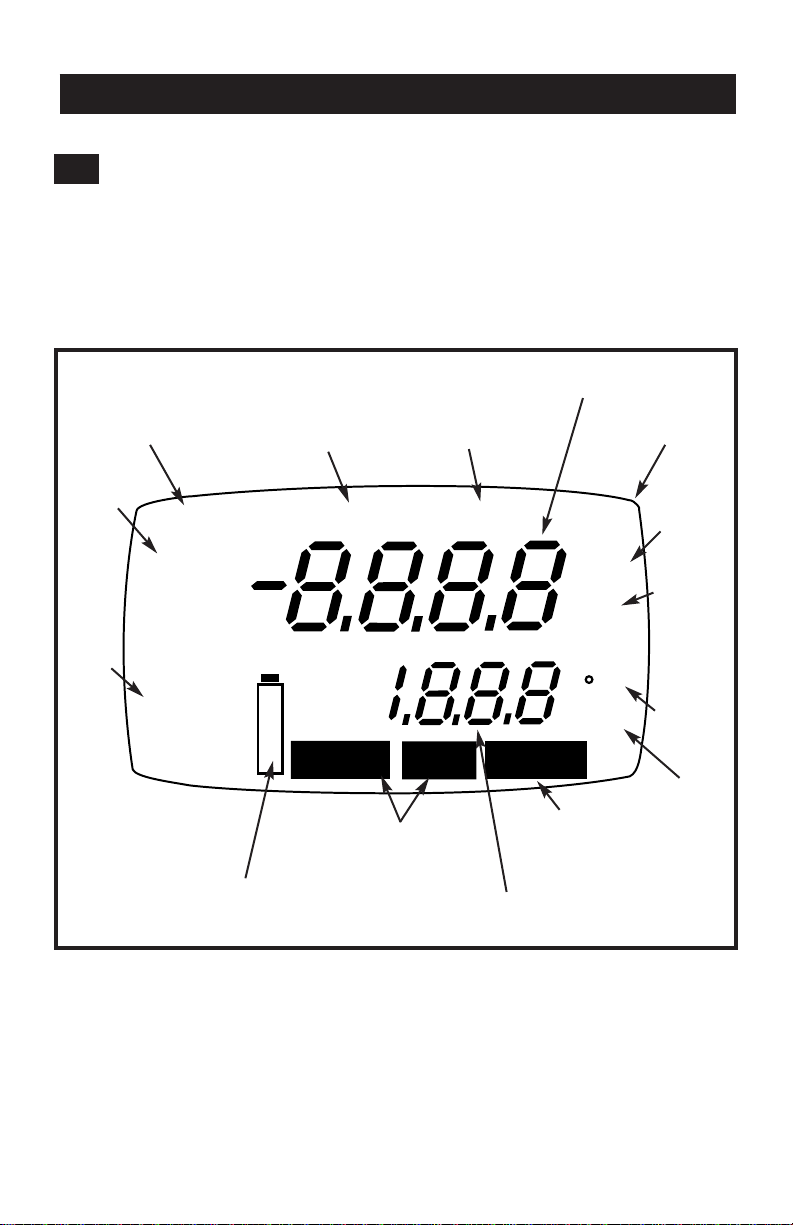

Display

The LCD has a primary and secondary display.

• The primary display shows the measured Conductivity or TDS reading.

• The secondary display shows the temperature of the reading in °C.

The display also shows error messages, keypad functions and program functions.

2.1

Primary display

Secondary display

MEASurement

mode indicator

READY

indicator

HOLD

indicator

Auto-Ranging

indicator

ERRor

indicator

Low battery

indicator

Conductivity

or TDS mode

indicator

ppm or ppt

indicator

µS or mS

indicator

Temperature

calibration

mode indicator

Automatic

Temperature

Compensation

indicator

°C

indicator

MEMory

indicator

HOLD

READY

ERR

AUTO

ON

OFF

COND

MEAS

TDS

Temp

CAL

ppmt

µmS

C

ATC

5

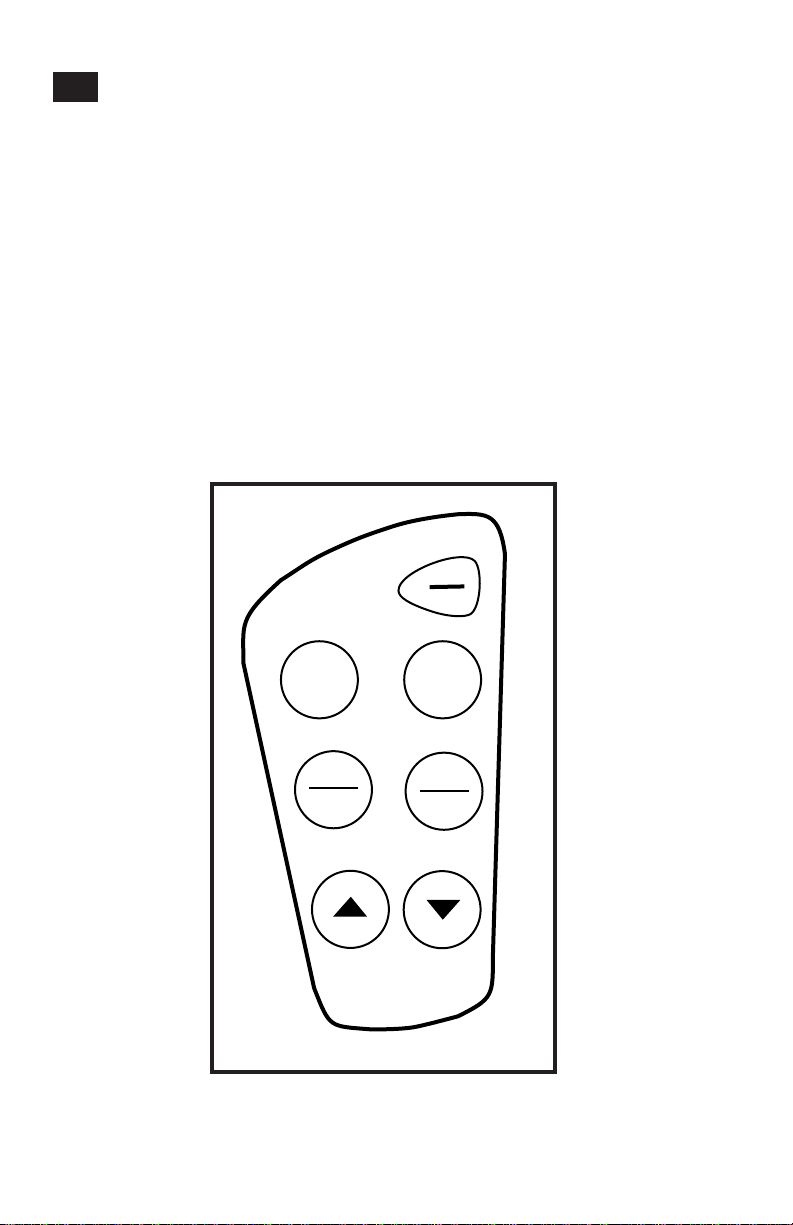

Keypad

The large membrane keypad makes the instrument easy to use. Each button, when

pressed, has a corresponding graphic indicator on the LCD.

ON/OFF ................Powers and shuts off the meter.

HOLD ....................Freezes the measured reading. To activate, press HOLD while in

measurement mode. To release, press HOLD again

MODE ....................Selects the measurement parameter: COND (Conductivity), TDS

(total dissolved solids) or TEMP .

CAL/MEAS ..........Toggles user between Calibration and Measurement mode.

ENTER/RANGE ..Confirms your values. Switches to manual ranging and can scroll

to your selected measurement range for conductivity or TDS

▲ /▼........................scrolls values up and down to the values you want

2.2

ON

OFF

HOLD

CAL

MEAS

MODE

ENTER

RANGE

6

3. Preparation

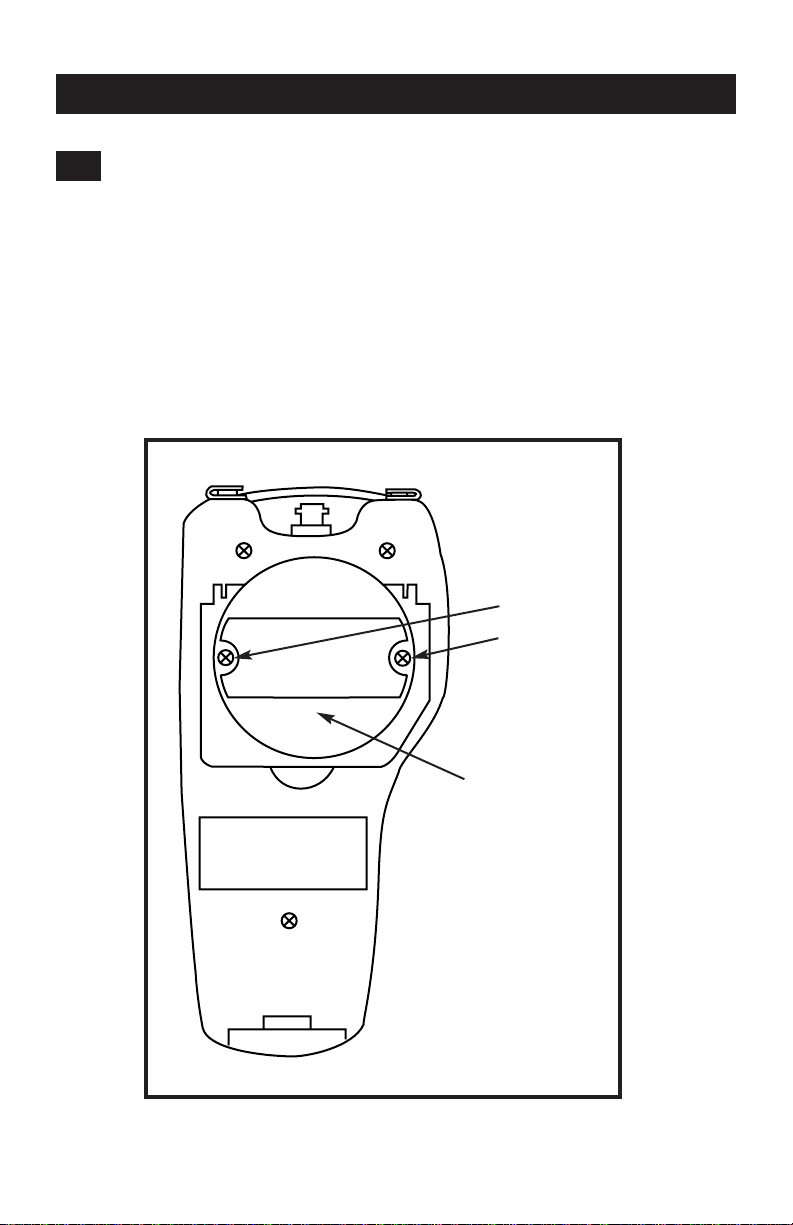

Inserting the Batteries

Four AAA batteries are included with your meter.

1. Use a Phillips screwdriver to remove the two screws holding the battery cover.

See Figure below.

2. Lift meter stand to expose battery cover. Remove battery cover.

3. Insert batteries. Follow the diagram inside the cover for correct polarity.

4. Replace the battery cover into its original position using the two screws

removed earlier.

3.1

Battery

compartment

Remove these

two screws to

access battery

compartment

7

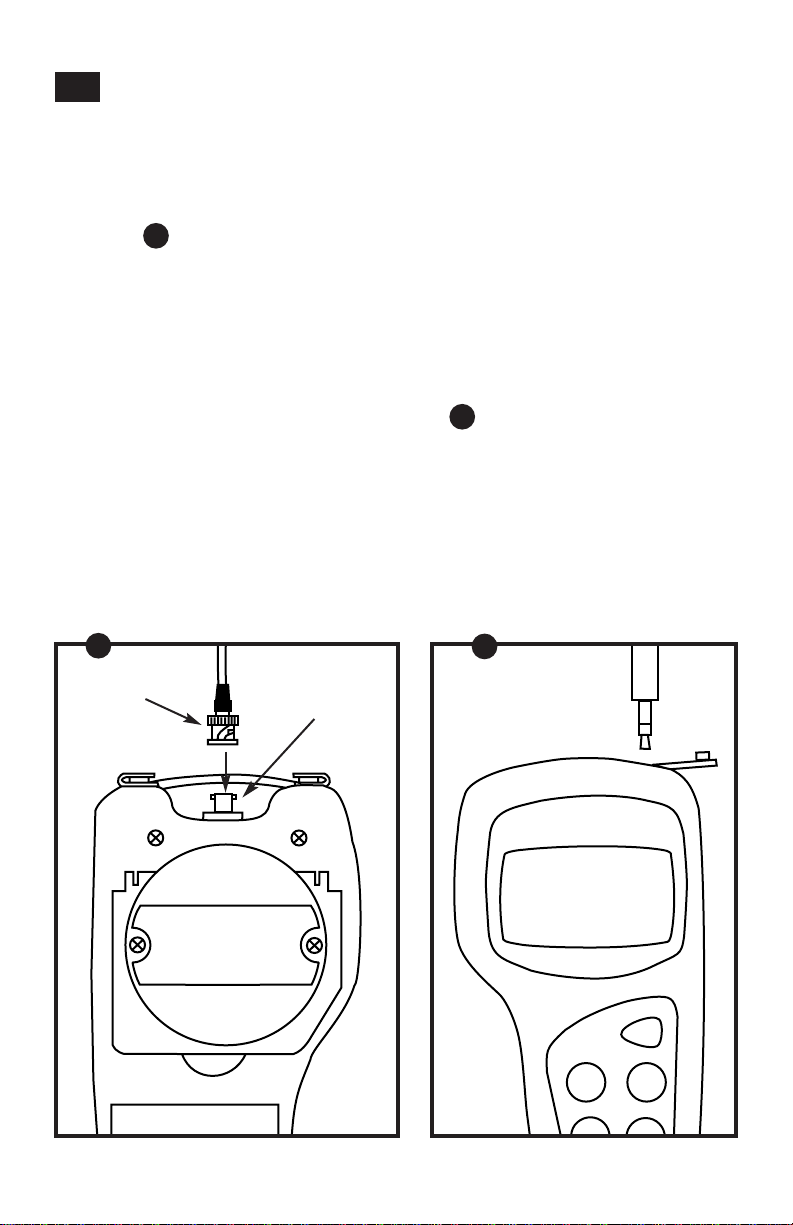

Connecting the Probe and Temperature Sensor

NOTE: Keep connector dry and clean. Do not touch connector with soiled hands.

1. Slide the BNC connector of the probe over the BNC connector socket on the

meter. Make sure the slots of the connector are in line with the posts of the

socket. Rotate and push the connector clockwise until it locks

See figure

2. To remove probe, push and rotate the connector counter clockwise . While

holding onto the metal part of the connector, pull probe away from the meter.

CAUTION: Do not pull on the probe cord or the probe wires might disconnect.

Temperature Sensor

The temperature sensor uses a phono jack to connect with the socket on the meter.

Insert the jack into the socket as shown in figure

3.2

BNC connector socket

BNC connector

A

B

A

B

8

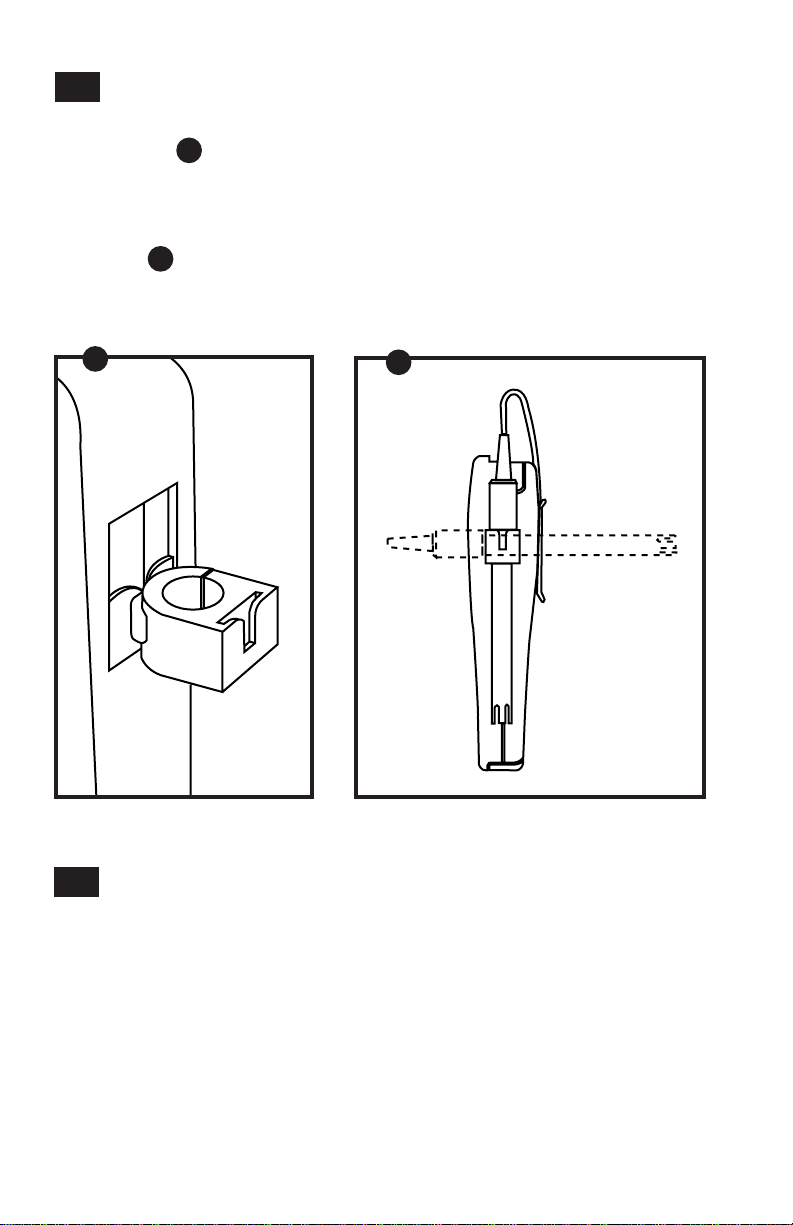

3.3

Attaching the Probe Holder to the Meter

1. Place the probe holder with the flange facing the slot on the meter.

See Figure

2. Gently slide the flange of the holder into the slot on the meter. Make sure the

holder is secured properly into the slot.

You can attach the probe holder in different positions.

See figure

This flexibility facilitates one-handed operation.

Inserting the Probe into the Probe Holder

One probe holder is included with your meter.

NOTE: Do not use excessive force when inserting probe into holder.

1. Insert the probe into the opening of the holder until the top housing of

the probe touches the top of the holder.

B

A

B

A

3.4

9

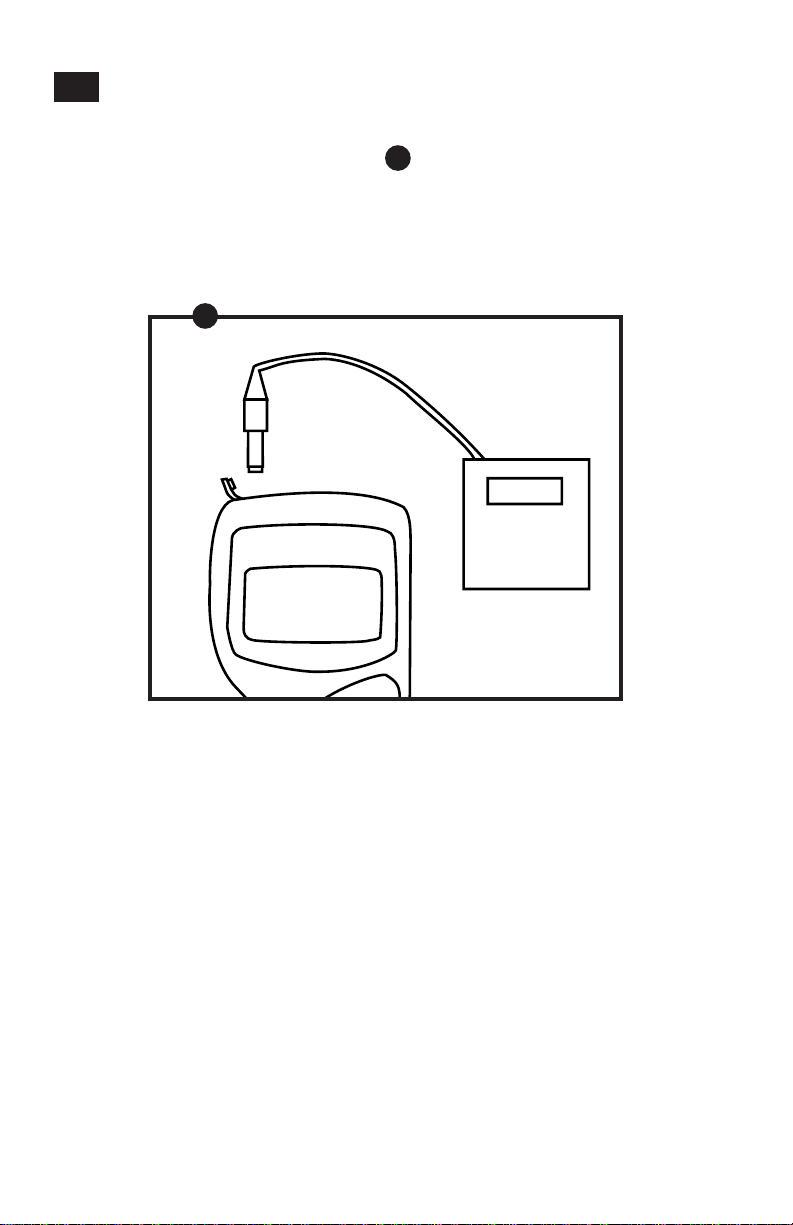

Connecting the AC Adapter

The AC adapter is not included with your meter; order separately on page 24.

1. Insert the AC jack as shown in figure below.

2. Switch off the meter before plugging the adapter into the power source.

This safety precaution protects the software in your meter.

3. Press the ON/OFF button to switch meter on.

D

D

3.5

10

4. Conductivity/TDS Calibration

Preparing for calibration

Selecting a calibration standard

For best results, select a conductivity or TDS standard near the sample value you are

measuring. Alternatively, use a calibration solution value that is approximately 2/3 the

full scale (F.S.) value of the measurement range you plan to use. For example, in the 0

to 1999 µS range, use a 1413 µS solution for calibration.

Calibrating the meter in conductivity range(s) also calibrates the corresponding TDS

range. Acalibration value in the TDS mode of a particular range replaces a prior calibration value in the corresponding conductivity mode if both fall in the same range,

and vice versa. The following table lists the corresponding ranges:

You only need one calibration for measurement of the entire range of the meter. If a

range is not calibrated, the meter automatically detects the closest range calibrated and

uses that calibration information. However, only the ranges that have been calibrated

have maximum accuracy.

When to calibrate

If you are measuring in solutions with conductivity lower than 100 µS, or TDS lower

than 50 ppm, calibrate the meter at least once a week to get specified ±1% F.S. accuracy.

If you are measuring in the mid ranges, calibrate the meter at least once a month. If you

make measurements at extreme temperatures, calibrate at least once a week.

4.1

Conductivity range TDS range

0.00 to 19.99 µS 0.00 to 9.99 ppm

0.0 to 199.9 µS 10.0 to 99.9 ppm

0 to 1999 µS 100 to 999 ppm

0.00 to 19.99 mS 1.00 to 9.99 ppt

11

Conductivity calibration

1. Select the conductivity standard for calibration. Select a standard with a value

closest to the expected value of measurements in the sample.

2. Pour 3 cm of the standard into two separate clean containers.

3. Turn the meter on. All the LCD segments display for a few seconds. The LCD

then switches into the conductivity measurement mode.

4. Rinse the probe in one of the containers. Gently stir the probe. Rinsing removes

contaminants that offset the calibration, and prevents error.

5. Dip the rinsed probe into the other container.Tap probe on bottom of container to

remove air bubbles. Let the probe stabilize to the solution temperature.

6. Press MODE to select conductivity mode. The COND indicator should show

at the bottom of the display.

7. Press CAL to begin calibration. The CAL

annunciator blinks showing the calibration

mode is on. Example: the display shows

712 µS for 708 µS calibrating solution.

See figure

8. Press the ▲ or ▼ keys to scroll to the

calibration standard value of 708 µS.

See figure

9. Press ENTER/RANGE to confirm

calibration. The CAL indicator stops

flashing and remains on the screen for

3 seconds. The meter than switches back

to measurement mode.

See figure

10. Repeat for other ranges if desired.

NOTE: At any time during the calibration,

you may exit the Calibration mode and return

to Measurement mode by pressing the CAL/

MEAS key. The meter will keep the old

calibration data and be unharmed.

Calibration error

For conductivity calibration, ERR on the

display shows whenever the calibration value

input into the meter is different from the

initial value displayed by more than 20%.

ERR displayed warns you of improper probe

use or bad calibration technique.

See figure

B

4.2

B

C

D

D

C

A

A

AUTO

READY

COND

CAL

µ S

C

ATC

AUTO CAL

µ S

C

COND

ATC

AUTO

COND

MEAS

µ S

C

ATC

AUTO MEAS

µ S

ERR

COND

C

ATC

12

TDS calibration

Option 1: TDS calibration using TDS standards

1. Select the TDS standard for calibration. Our OAKTON calibration solutions

have TDS values on the labels. For conversion factors other than those listed,

see Addenda 1 and 2, pages 25-26.

2. Pour 3 cm of the standard into two separate clean containers.

3. Turn the meter on. All the LCD segments display for a few seconds. The LCD then

switches into the conductivity measurement mode.

4. Rinse the probe in one of the containers. Gently stir the probe. Rinsing removes

contaminants that offset the calibration, and prevents error.

5. Dip the rinsed probe into the other container.Tap probe on bottom of container to

remove air bubbles. Let the probe stabilize to the solution temperature.

6. Press MODE to select TDS mode. The TDS indicator should show at the bottom

of the display.

7. Press CAL to begin calibration. CAL annun-

ciator blinks showing the calibration mode

is on. Example: display shows 747 ppm for

706 ppm (or 1413 µS) calibrating solution.

See figure

8. Press the ▲ or ▼ keys to scroll to the

calibration standard value of 706 ppm

See figure

9. Press ENTER/RANGE to confirm

calibration. The CAL indicator stops

flashing and remains on the screen for

3 seconds. The meter than switches back

to measurement mode.

See figure

10. Repeat for other ranges if desired.

NOTE: At any time during the calibration,

you may exit the Calibration mode and return

to Measurement mode by pressing the CAL/

MEAS key. The meter will keep the old

calibration data and be unharmed.

Confirmation error

An error message means the meter does not allow the slope adjustment to the calibration procedure given the value of Conductivity-to-TDS conversion factor. See Option 2

for another TDS calibration method for adjusting the Conductivity-to-TDS conversion

factor. Press CAL/MEAS to escape the ERR message and abort the calibration attempt.

4.3

B

C

A

B

C

A

AUTO

READY

CAL

ppm

TDS

C

ATC

AUTO CAL

ppm

TDS

C

ATC

TDS

MEAS

ppm

C

ATC

AUTO

READY

13

Option 2: TDS calibration using conversion factors

TDS values are related to conductivity. You

can calibrate the meter using conductivity

standards as described above and then

program the meter with a given conversion

factor.

1. Perform the conductivity calibration

procedure on page 11.

2. Select the correct Conductivity-to-TDS

conversion factor. Addendum 1 on page 25

lists some commonly used conversion factors. You can calculate the TDS conversion

factor for other solutions using the formula show in Addendum 2, page 26.

3. Turn the meter off if necessary; then hold down the CAL/MEAS key and press

ON/OFF. Release ON/OFF before releasing CAL/MEAS.

4. Press the ENTER key three times. The TDS factor displays.

See figure

5. Press the ▲ or ▼ keys to adjust the value of the primary display until it is the same

or close to the selected/calculated value.

6. Press ENTER to confirm selected value.

7. Turn the meter off, then turn meter back on.

The meter is now ready for measurement.

A

A

TDS

CAL

14

5. Temperature Calibration

The built-in temperature sensor included in the probe is factory calibrated. Over

time, the temperature sensor response may vary. If you suspect temperature errors,

calibrate your sensor using the following one-point calibration procedure.

If you purchase a replacement probe, you must complete a two-point temperature

calibration. See section 8, Probe Replacement, for details (pages 19-20).

1-point temperature calibration

1. Press the MODE key and select temper-

ature mode (TEMP). (Make sure you are

in MEAS before you begin calibration

See figure

2. Press CAL. This brings you into the

calibration mode. The primary display

shows the measured Conductivity value

and the secondary display shows the

temperature at factory calibration value.

See figure

3. Compare the displayed temperature to

that of an NIST thermometer or other

thermometer known to be accurate.

4. Press the ▲ or ▼ keys to adjust the

reading to agree with your temperature

standard. In the figure at right, the

desired temperature is 22.0. Use the

▲ key to increase the temperature

reading to 22.0°C.

See Figure

NOTE: Temperature calibration with the

probe is restricted to ±5°C from the initial

value displayed during calibration.

Attempts to adjust reading beyond this

range will result in ERR displaying on

the LCD.

4. Press ENTER/RANGE to confirm your

selected correct temperature. The meter

reverts to the measurement mode. The

meter is now calibrated for temperature

compensation.

See Figure

A

B

B

A

C

D

C

D

5.1

AUTO MEAS

TEMP

AUTO CAL

TEMP

AUTO

AUTO MEAS

CAL

TEMP

TEMP

C

ATC

C

ATC

C

ATC

C

ATC

15

6. Measurement

Range Selection

The 35607-series meters will default to the auto-ranging mode. Auto-ranging determines and selects the range that gives you the greatest resolution and accuracy.

Alternatively, you can manually select one of four ranges using the range key. For

example, if you prefer the meter to display a reading as 0.50 mS rather than 500 µS,

while in measurement mode, select the 0 to 19.99 mS range using the range key.

NOTE: Accuracy is a percent of full-scale, so using your meter in the lowest range

that will display your measurement will result in the greatest accuracy.

Measurement with Automatic Temperature Compensation

1. Switch on the meter. The MEAS annunciator and the AUTO (Auto-ranging)

annunciator display on the top center of the LCD.

See figure

2. Rinse the probe with deionized or

distilled water before use to remove

any impurities adhering to the

electrode body.

3. Dip the probe into the sample.

Make sure there are no air bubbles

trapped in the slot of the probe. To

remove air bubbles, give the probe a

gentle shake, making sure the electrode

tip is submerged.

4. Stir the probe gently in the sample

to create a homogenous sample.

Allow a few seconds for the temperature

reading to reach solution temperature.

5. Take readings. When the reading is

stable, a READY annunciator displays.

See figure

The READY annunciator appears when the reading stabilizes within a range of ±1

unit/15 seconds. The reading holds until the measured value exceeds the specified

range and the READY annunciator turns off.

A

B

B

A

6.1

6.2

AUTO MEAS

µ S

C

COND

AUTO

READY

COND

MEAS

ATC

µ S

C

ATC

16

Measurement with Manual Temperature Compensation

1. Leave the temperature sensor phono jack unplugged from the meter.

Attach the probe with only the BNC connector.

2. Switch on the meter. The MEAS annunciator and the AUTO (Auto-ranging)

annunciator display on the top center

of the LCD.

3. Press MODE and select temperature

mode (TEMP). Make sure you are

in MEAS.

4. Press CAL to enter the calibration

mode. The primary display shows

the measured Conductivity value and

the secondary display shows the temp-

erature previously set for manual

temperature compensation (factory

default of 25.°C).

See figure

5. Press the ▲ or ▼ keys to adjust your

temperature readings, in this example:

35.0°C.

See figure

6. Press ENTER to confirm settings. The meter reverts to measurement mode. You

may now take measurements following steps 2-5 in the section “Measurement

with Automatic Temperature Compensation” (page 15).

A

B

B

A

6.3

AUTO MEAS

CAL

AUTO CAL

ppm

C

TEMP

ppm

C

TEMP

17

7. HOLD function

This feature lets you freeze the value of

the Conductivity or TDS and temperature

readings for a delayed observation.

HOLD can be used any time when in

MEAS mode.

1. To hold a measurement, press the

HOLD key while in measurement

mode. "HOLD" will appear on the

display.

See Figure

2. To release the held value, press HOLD

again. Continue to take measurements.

NOTE: This meter will hold a reading

for up to 20 minutes, because it

features automatic shutoff after

20 minutes to conserve batteries.

A

A

HOLD

µ S

C

COND

ATC

18

8. Probe Care and Maintenance

Keep the conductivity probe clean. Rinse the probe twice, and gently swirl it while

you take readings. For best accuracy, soak a dry probe for at least 5 to 10 minutes or

longer before calibration or taking readings. Wash the probe with deionized or tap

water before storing it. Never scratch the stainless steel portions with a hard substance. Do not strike the probe against any hard surface.

Do not make continuous contact with your solutions. Readings rise over a continuous period of time if you soak your probe.

Do not immerse the probe in oily solutions. Clean the electrode thoroughly by

immersing it in an agitated mild detergent bath. Wipe the probe with a soft tissue

paper. Wash thoroughly in tap water and then in deionized water. Recalibrate the

meter after cleaning the probe.

19

9. Probe Replacement

Your meter and probe have been factory calibrated to each other for maximum

accuracy. If you notice a reduction in accuracy after replacing your probe, perform

a zero calibration and two-point temperature calibration.

Zero calibration

NOTE: the probe must be dry and in air for zero adjustment.

1. Connect the BNC and phone jacks of the probe to the conductivity meter.

2. Turn the meter off.

3. Press CAL/MEAS and then press ON/OFF, while still holding down

CAL/MEAS. Release ON/OFF before releasing CAL/MEAS.

4. Press ENTER three times, and then press

CAL/MEAS one time. The LCD shows

r1.0 on the secondary display and 0.00 µS

on the primary display. The r1.0 indicates

that you are in the first, or lowest range.

See figure

5. Press ENTER to calibrate the range

or CAL/MEAS to skip calibration

of the range.

6. At each of the measurement ranges, press

ENTER if zero adjustment is required.

Once ENTER is pressed, a value displays

on the LCD. Wait until the value is low

and as stable as it can be before pressing

ENTER again. This step adjusts zero

for the selected range.

See figure

7. Repeat step 6 for the other ranges if

necessary. If you do not want to repeat

this step, press CAL/MEAS to skip to

the next range.

B

A

A

B

9.1

COND

COND

CAL

µ S

CAL

20

Two point temperature calibration

After zero calibration, the meter proceeds to program 6.0, for temperature calibration

of the probe. The temperature in °C shows in the primary display and “r6.0” shows

in the secondary display.

See figure

1. Press CAL/MEAS until the meter

automatically switches off to skip

this section of the calibration.

Do NOT press ENTER unless you

have completed the steps below.

Pressing ENTER replaces current

temperature calibration data and

causes measurement errors.

2. Prepare two constant temperature baths, one at a temperature below

5°C (low temperature bath) and the other at between 50°C to 60°C

(high temperature bath).

3. Dip the probe into the low temperature bath. Allow 5 to 10 minutes for

the probe to stabilize.

4. Press the ▲ or ▼ keys to fine tune temperature reading to match bath temperature.

5. Press ENTER. The screen now shows the A-to-D count corresponding to your

low temperature calibration point. This is a five digit number with the first digit

appearing in the secondary display and

the rest of the digits in the primary display.

In our example at right, the A-to-D count

is 13490.

See figure

6. Let the count stabilize, then press

ENTER again. This confirms your low

temperature calibration point, and moves

you into high temperature calibration

(“r6.1) If you do not want to confirm your calibration, press CAL/MEAS.

7. Repeat steps 4-6 with high temperature bath.

To exit from the hardware calibration at any point, press ON/OFF to switch off the

meter and abort the calibration. Only calibration points that have been confirmed

by pressing ENTER will be retained.

A

B

A

B

9.2

CAL

TEMP

CAL

TEMP

21

10. Troubleshooting

Problem Cause Solution

No display a) Batteries not in place. a) Check that batteries are in

place and making good

contact.

b) Batteries not in correct b) Reinsert batteries with

polarity (+ and –). correct polarity.

c) Weak batteries. c) Replace batteries or attach

optional AC adapter.

Unstable a) Air bubbles in probe. a) Tap probe to remove bubbles.

readings

b) Dirty probe. b) Clean the probe and

recalibrate.

c) Low conductivity c) Avoid atmospheric contact

with solution.

d) Probe not deep d) Make sure sample entirely

enough in sample. covers the probe sensors.

e) External noise pickup e) Move or switch off

or induction caused by interfering motor.

nearby electric motor.

f) Broken probe. f) Replace probe. See page 19.

Slow response a) Dirty/Oily probe. a) Clean probe. See "Probe

Care & Maintenance",

page 18.

Not able to a) Dirty/Oily probe. a) Clean probe. See "Probe

calibrate Care & Maintenance",

page 18.

b) Incorrect probe b) Replace probe. See page 19.

cell constant

c) Poor calibration standards c) Use fresh calibration

standards

22

11. Error Messages

LCD

Indicates Cause Solution

Display

Err Unrecognized input Wrong input in Release key. Select

annunciator from keypad selected mode. valid operations

depending on mode.

CAL & Err Calibration error Wrong value Check value, clean probe

annunciators input at calibration. See Probe Maintenance

blink Dirty probe. section, page 18.

Battery Low battery level Need new batteries Clean battery contacts.

indicator blinks or battery Replace batteries with fresh

connection is bad ones, noting polarity

Err. 1 Memory write Hardware failure Turn meter on and off

(in primary error again. If message persists,

display) return unit*

Err. 2 Memory checksum Batteries too weak. Press ENTER, then turn off

(in primary error Hardware failure. meter. Change batteries.

display) Recalibrate. If message

persists, return unit*

Err. 3 ACD converter Hardware failure. Turn meter on and off

(in primary error again. If message persists,

display) return unit*

Err. 4 Keypad error Fault in keypad Turn meter on and off

(in primary again. If message persists,

display) return unit*

* See "Warranty" and "Return of Items" on page 28

If an error message appears in the primary display (the upper row of larger digits),

switching off the meter and switching it on again may eliminate the error message.

See figure

If error persists, or the meter shows

incorrect values, return the meter.

ERR 1 in primary display

A

A

23

12. Specifications

Mode Conductivity TDS Temperature

0.00 to 19.99 µS 0.00 to 9.99 ppm 0 to 80°C

Range

0.0 to 199.9 µS 10.0 to 99.9 ppm (epoxy body probe)

0 to 1999 µS 100 to 999 ppm 0 to 100°C

0.00 to 19.99 mS 1.00 to 9.99 ppm (glass body probe)

0.01 µS 0.01 ppm

Resolution

0.1 µS 0.1 ppm

0.1 °C

1 µS 1 ppm

0.01 mS 0.01 ppt

Accuracy: ±1% F.S.

Cell constant: 1

Temperature compensation: automatic (ATC) or manual

Reference temperature: factory set at 25°C.

Temperature coefficient: factory set at 2% per °C.

Operating temperature: 0 to 50°C

Power: four 1.5 V AAA batteries (included), approx. 60 hours

or AC adapter (optional; order separately on page 24)

Dimensions:

Meter: 7.5"L x 3.5"W x 1.75"H

(19.1 cm x 8.9 cm x 4.5 cm)

Boxed: 9.2"L x 8.5"W x 2.75"H

(23.3 cm x 21.6 cm x 7 cm)

Shipping weight:

Meter: 1 lb (0.5 kg)

Probe: 0.35 lb (0.2 kg)

Complete: 2 lbs (0.9 kg)

24

13. Accessories

Replacement probes and accessories

WD-35607-02 Replacement probe for CON 10

WD-35615-07 AC adapter, 9 VDC to 110 VAC.

WD-35615-08 AC adapter, 9 VDC to 220 VAC.

WD-35615-06 Replacement probe holder.

WD-35615-75 Belt loop portable meter carrying case. Soft case with clear plastic

front panel protects your meter while allowing you to take measurements. Top

and side openings let probe and probe connections remain accessible.

OAKTON calibration solutions (in pint bottles)

Conductivity solutions have ±1% accuracy at 25°C

WD-00653-23 Conductivity standard solution 23 µS

WD-00653-16 Conductivity standard solution 84 µS

WD-00653-47 Conductivity standard solution 447 µS

WD-00653-18 Conductivity standard solution 1413 µS

WD-00653-15 Conductivity standard solution 1500 µS

WD-00653-27 Conductivity standard solution 2070 µS

WD-00653-20 Conductivity standard solution 2764 µS

WD-00653-89 Conductivity standard solution 8974 µS

WD-00606-10 Conductivity standard solution 12,880 µS

WD-00653-50 Conductivity standard solution 15,000 µS

WD-00653-32 Conductivity standard solution 80 mS

OAKTON “Singles” calibration solutions

OAKTON “Singles” are convenient go-anywhere solution pouches filled with fresh,

premixed calibration standard solutions. ±1% accuracy at 25°C.

WD-35653-10 “Singles” Conductivity standard solution pouches 447 µS

WD-35653-11 “Singles” Conductivity standard solution pouches 1413 µS

WD-35653-12 “Singles” Conductivity standard solution pouches 2764 µS

WD-35653-13 “Singles” Conductivity standard solution pouches 15,000 µS

WD-35653-00 “Singles” solution pouches, rinse water

To order OAKTON accessories, contact your OAKTON distributor.

25

14. Addendum 1: Conductivity-to-TDS conversion factors

1. Factor—the conductivity-to-ppm TDS conversion factor. Multiply conductivity

by this factor to get ppm TDS for the type of TDS reading needed.

2. 442—a formulation that most closely represents the conductivity-to-ppm

relationship, on average, for naturally occurring fresh water.

3. TDS Your Material—these columns are for you to write in your application-

specific conductivity-to-ppm values and conversion factors for future reference.

Conductivity

TDS KCl TDS NaCl TDS 442

2

TDS Your Material

3

at 25°C

ppm

Factor

1

ppm

Factor

1

ppm

Factor

1

ppm

Factor

1

Value Value Value Value

23 µS 11.60 0.5044 10.69 0.4652 14.74 0.6409

84 µS 40.38 0.5048 38.04 0.4755 50.50 0.6563

447 µS 225.6 0.5047 215.5 0.4822 300.0 0.6712

1413 µS 744.7 0.5270 702.1 0.4969 1000 0.7078

1500 µS 757.1 0.5047 737.1 0.4914 1050 0.7000

2070 µS 1045 0.5047 1041 0.5030 1500 0.7246

2764 µS 1382 0.5000 1415 0.5119 2063 0.7463

8974 µS 5101 0.5685 4487 0.5000 7608 0.8478

12880 µS 7447 0.5782 7230 0.5613 11,367 0.8825

15000 µS 8759 0.5839 8532 0.5688 13,455 0.8970

80 mS 52,168 0.6521 48,384 0.6048 79,688 0.9961

26

15. Addendum 2: Calculating TDS conversion factors

The meter can be calibrated using TDS calibration standard solutions. The

calibration standard only needs to give the TDS value at a standard temperature

such as 25°C. To determine the Conductivity-to-TDS conversion factor use the

following formula:

Factor = Actual TDS ÷ Actual Conductivity @ 25°C

Definitions:

Actual TDS: Value from the solution bottle label or as a standard you make using

high purity water and precisely weighed salts.

Actual Conductivity: Value measured using a properly calibration

Conductivity/TDS/Temperature meter.

Both the actual TDS and the actual conductivity values must be in the same magni-

tude of units. For example, if the TDS value in is ppm, the conductivity value must

be in µS; if the TDS value is in ppt, the conductivity value must be in mS.

Check this number by multiplying the conductivity reading by the factor in the

above formula and the result is the TDS in ppm.

27

NOTES:

701-21

16. Warranty

OAKTON warrants this meter to be free from significant deviations in material

and workmanship for a period of one year from date of purchase. OAKTON

warrants this probe to be free from significant deviations in material and

workmanship for a period of six months from date of purchase. If repair or

adjustment is necessary and has not been the result of abuse or misuse within

the warrantied time period, please return—freight prepaid—and correction will

be made without charge. OAKTON alone will determine if the product problem

is due to deviations or customer misuse.

Out-of-warranty products will be repaired on a charge basis.

17. Return of items

Authorization must be obtained from our Customer Service Department before

returning items for any reason. When applying for authorization, please include

data regarding the reason the items are to be returned. For your protection, items

must be carefully packed to prevent damage in shipment and insured against possible damage or loss. We will not be responsible for damage resulting from careless or

insufficient packing. Arestocking charge will be made on all unauthorized returns.

NOTE: We reserve the right to make improvements in design, construction, and

appearance of products without notice.

Loading...

Loading...