Page 1

Freescale

User’s Guide

KIT912J637EVME User’ s Guide

Document Number: KT912J637UG

Rev. 1.0, 2/2012

Figure 1. KIT912J637EVME Evaluation Board

Table of Contents

KIT912J637EVME Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Required Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setup Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Software Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Board Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Bill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

© Freescale, Inc., 2012. All rights reserved.

Page 2

Kit Contents / Packing List

1 Kit Contents / Packing List

• MM912J637 Evaluation Board (EVB)

•Cable, 6 FT. USB 2.0 A-M to B-M

• Warranty Card, Freescale

• CD912J637 - Contains CodeWarrior Code Template and CodeWarrior software

2 Freescale

KIT912J637EVME, Rev. 1.0

Page 3

2 Important Notice

Freescale provides the enclosed product(s) under the following conditions:

This evaluation kit is intended for use of ENGINEERING DEVELOPMENT OR EVALUATION

PURPOSES ONLY. It is provided as a sample IC pre-soldered to a printed circuit board to make

it easier to access inputs, outputs, and supply terminals. This EVB may be used with any

development system or other source of I/O signals by simply connecting it to the host MCU or

computer board via off-the-shelf cables. This EVB is not a Reference Design and is not intended

to represent a final design recommendation for any particular application. Final device in an

application will be heavily dependent on proper printed circuit board layout and heat sinking

design as well as attention to supply filtering, transient suppression, and I/O signal quality.

The goods provided may not be complete in terms of required design, marketing, and or

manufacturing related protective considerations, including product safety measures typically

found in the end product incorporating the goods. D ue to the open construction of the product, it

is the user's responsibility to take any and all appropriate precautions with regard to electrostatic

discharge. In order to minimize risks associated with the customers applications, adequate design

and operating safeguards must be provided by the customer to mini mize inherent or procedural

hazards. For any safety concerns, contact Freescale sales and technical support services.

Should this evaluation kit not meet the specifications indicated in the kit, it may be returned within

30 days from the date of delivery and will be replaced by a new kit.

Freescale reserves the right to make changes without further notice to any products herein.

Freescale makes no warranty, representation or guarantee regarding the suitability of its products

for any particular purpose, nor does Freescale assume any liability arising out of the applicati on

or use of any product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters can and do vary in different

applications and actual performance may vary over time. All operating parameters, including

“Typical”, must be validated for each customer application by customer’s technical experts.

Freescale does not convey any license under its patent rights nor the rights of others. Freescale

products are not designed, intended, or authorized for use as components in systems intended

for surgical implant into the body, or other applications intended to support or sustain life, or for

any other application in which the failure of the Freescale product could crea te a situation where

personal injury or death may occur.

Should the Buyer purchase or use Freescale products for any such unintended or unauthori zed

application, the Buyer shall indemnify and hold Freescale and its officers, employees,

subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal

injury or death associated with such unintended or unauthorized use, e ven if such clai m alleges

that Freescale was negligent regarding the design or manufacture of the part.Freescale™ and the

Freescale logo are trademarks of Freescale Semiconductor, Inc. All other product or service

names are the property of their respective owners. © Freescale Semiconductor, Inc., 2011. All

rights reserved.

Important Notice

Freescale 3

KT912J637UG, Rev. 1.0

Page 4

KIT912J637EVME Introduction

3 KIT912J637EVME Introduction

Freescale Semiconductor’s KIT912J637EVME is a system solution that gives the user the capability to easily

evaluate most of the features provided by the MM912J637 - Xtrinsic Battery Sensor. The 912J637 feature s two

die in a single package. The 16-bit core and the analog die are connected via the die to die interface that

provides direct address access to the registers on the analog die. The analog die contains three 16-bit sigma

delta converters and enables simultaneous sampling of battery volt age and current, timer module, SCI module,

LIN physical interface, and other general registers. All external signals are accessible via header connectors,

and most of the signals can also be checked via test points. The evaluation module board also includes the

TBDML programming/debugging interface, so n o exte rnal interface is neede d. The board is powere d fr om two

4.0 mm banana connectors. For quick familiarization with the device, a CodeWarrior Template is provided

together with the EVB.

3.1 MM912J637 Features

• Battery voltage measurement

• Battery current measurement in up to eight ranges

• On-chip temperature measurement

• Normal and two low-power modes

• Current threshold detection and current averaging in standby => wake-up from low-power mode

• Triggered wake-up from LIN and periodic wake-up

• Signal low pass filtering (current, voltage)

• PGA (programmable low-noise gain amplifier) with automatic gain control feature

• Accurate internal oscillator (an external quartz oscillator may be used for extended accuracy)

• Communication via a LIN 2.1, LIN 2.0 bus interface

• S12 microcontroller with 128 kByte flash, 6.0 kByte RAM, 4.0 kByte data flash

• Background debug module

• External temperature sensor option (T

• Optional 2nd external voltage sense input (VOPT)

•4 x 5.0 V GPIO including one wake-up capable high voltage input (PTB3/L0)

• 8 x MCU general purpose I/O including SPI functionality

• Industry standard EMC compliance

SUP

, V

TEMP

)

3.2 Warnings

When working with the kit, always use an isolated laboratory power supply.

Keep in mind all ESD rules when handling the board. Avoid touching the connector pins. They are directly

connected to the device pins. Even though the device pins are ESD protected, this protection has its limits.

Some ESD events can destroy or damage the device, or cause its malfun ction.

4 Freescale

KIT912J637EVME, Rev. 1.0

Page 5

KIT912J637EVME Introduction

3.3 Acronyms

Table 1. Acronyms

Acronym Explanation Acronym Explanation

D2D Die to Die bus interface MCU Microcontroller Unit

BDM Background Debug Module LIN Local Interconnect Network

EVB Evaluation Board LS Low Side (switch)

ESD Electrostatic Discharge, Electrostatic Sensitive Device SCI Serial Communication Interface

GND In the document: main supply ground TBDML Turbo BDM Lite

GPIO General Purpose Input/Output

GUI Graphical User Interface

ADC Analog to Digital Conversion

Freescale 5

KT912J637UG, Rev. 1.0

Page 6

Required Equipment

4 Required Equipment

• PC Computer running Windows XP or higher

•12 V Power Supply

• USB Cable (supplied)

6 Freescale

KIT912J637EVME, Rev. 1.0

Page 7

Setup Guide

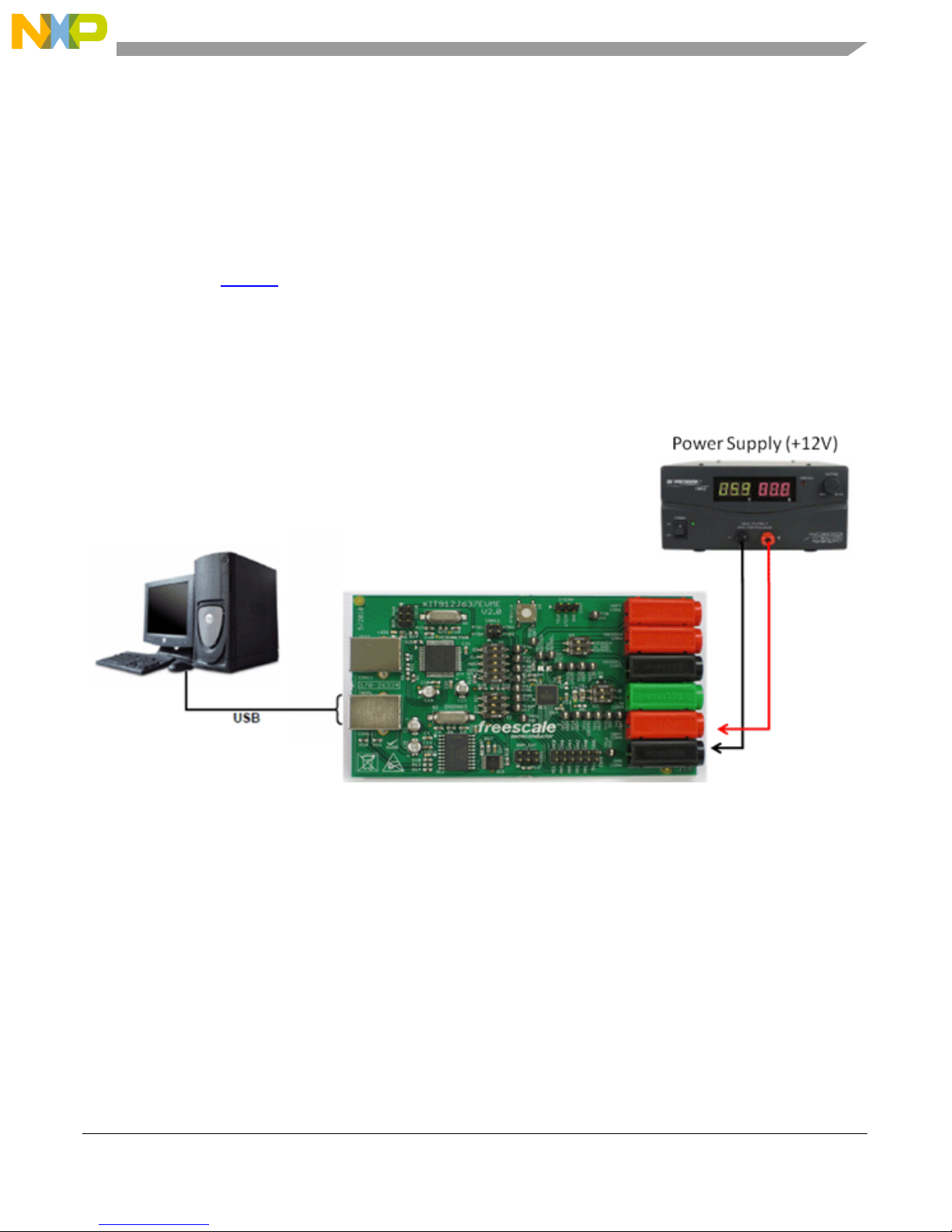

5 Setup Guide

5.1 Hardware Setup

Setup and connections for the KIT912J637EVME are straightforward.

The KIT912J637EVME requires a connection to the power sup

the USB cable. Figure

Follow these steps to set up the board:

1. Plug the USB cable into the connector CON13 and connect the othe

2. Connect a laboratory power supply via banana connectors to the board, using CON5 (VBATT supply) and

N6 (GND). The supply voltage has to be in the range of 8.0 to 18 V.

CO

2 depicts a complete setup.

ply and a connection to the PC or notebook via

r end of the cable to the PC or notebook.

Figure 2. KIT912J637EVME Basic Hardware Setup

Freescale 7

KT912J637UG, Rev. 1.0

Page 8

Hardware Description

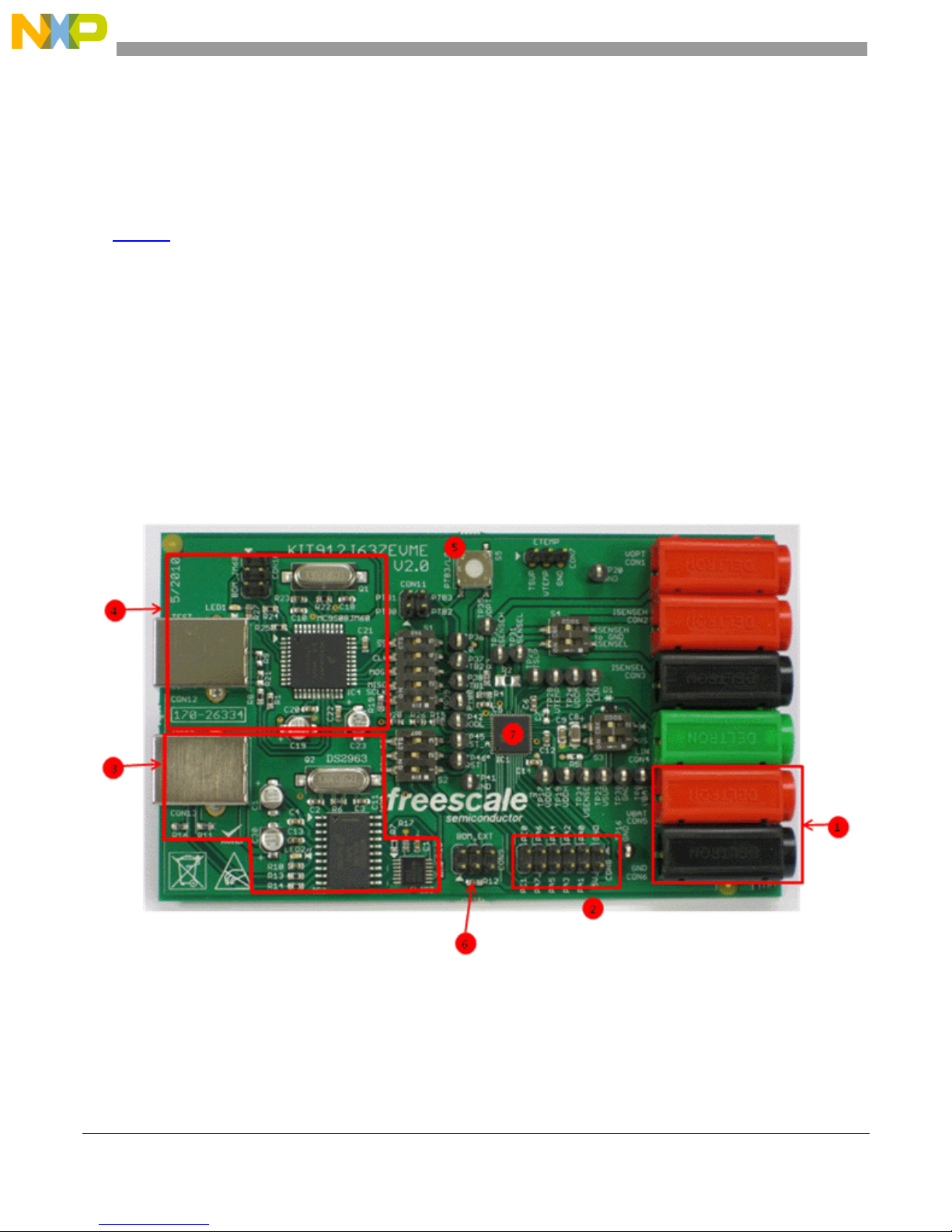

6 Hardware Description

6.1 Board Description

Figure 3 is a snapshot of the EVB with key co mponent and conn ector locations. Th e following list cor responds

with the numbers listed on the picture.

1. Input power connectors

2. MCU Port A & Port E connector

3. TBDML interface

4. TEST SPI to USB Interface

5. PTB3/L0 Reset button (requires software configuration)

6. BDM connector for external programming/debugging BDM interface

7. MM912J637CV1AE

The board is protected against reverse battery volt ag

current. The board operation is straightforward. As well as the TDBML interface (3), the board contains the

active and passive components required for pro per operation of the 912J637. Connectors and test points

ovide access to the device for important signals.

pr

e by diode D1, which can withstand up to 3.0 A continuous

Figure 3. KIT912J637EVME Evaluation Module Board

8 Freescale

KIT912J637EVME, Rev. 1.0

Page 9

Hardware Description

6.1.1 MCU

The MM912J637 enables precision measurement of key battery parameters in automotive and other

applications.

The device integrates an HCS12 microcontroller and a SMARTMOS analog control IC into a single package

solution. The analog die combines system basis and application specific functions, including a Local

Interconnect Network (LIN) transceiver, and 3 dedicated16-bit sigma delta analog to digital converters (ADC)

for synchronous measurement of battery voltage, current, and temperature.

An integrated temperature sensor combined with battery mounting allows for measurement of battery

temperature. Control of the analog die is via a n ew high performa nce internal die-to-die interface (D2D), which

seamlessly integrates the analog IC registers into the MCU register map, providing faster access than

SPI-based systems. The MM912J637 also includes an internal oscillator, 128 k Bytes of Flash memory, and

6.0

k bytes of RAM. An optional external temperature sensor is also supported.

The 912J637 has three main operating modes: Normal (all functions available) ; Sleep (VDD off, Wake-up via:

the LIN bus, PTB3/L0 input, current threshold, current averaging, calibration request, lifetime counter, internal

timer, or external reset), and Stop (V

input, current threshold, current averaging, calibration request, life time counter , internal timer , or external reset).

on with limited current capability, Wake-up via: the LIN bus, PTB3/L0

DD

6.1.2 TBDML

The Turbo BDM Light interface is a programming and debugging tool, and constitutes an interface between a

PC and the BDM debugging port of Freescale microcontr ollers. It enables the debugger and other soft ware tools

to communicate with the microcontroller, and download code into its on-chip flash, etc. Among the benefits of

using the TBDML on the EVB is a much higher communicatio n speed than other USB/BDM interfaces. It is also

unnecessary to connect external devices to the EVB when programming/debugging is needed.

A BDM connector (CON9) is placed on the EVB to allow the connection of another BDM tool, such as the P&E

USB BDM Multilink. In this case, DIP switches S2-1 and S2-2 should be set to “OFF”, to disable the TBDML

interface.

In either case, S2-3 should be set to “OFF” during programming to disconnect RESET from RESET_A.

6.1.2.1 Switch Settings

Figure 4 summarizes the location of all DIP switches and settings.

Freescale 9

KT912J637UG, Rev. 1.0

Page 10

Hardware Description

Figure 4. Position of DIP Switches on the EVB

Table 2. DIP Switch Settings

me Switch # Function ON OFF

Na

S1 1-5 Analog Die Test SPI connect to USB Connected Disconnected

S2 1-2 On Board TBDML Connected to

MM912J637

3 Analog Die and MCU Reset connection Resets Connected Resets Disconnected

S3 1 VSENSE connected to VBAT Connected Disconnected

2 Reverse Battery Diode Short Shorted (V

S4 1-2 Current Sense Inputs short to GND Short to GND Not shorted to GND

KIT912J637EVME, Rev. 1.0

10 Freescale

Connected Disconnected (External BDM)

BAT=VSUP

) Diode in path

(V

= V

SUP

BAT

- V

DIODE

)

Page 11

Hardware Description

6.2 Connector Description

There are 13 connectors on the EVB. A list of the connector and pin assignments is in the following paragraphs.

6.2.1 Connectors

Figure 5. Connectors

Table 3. Connectors

Name

CON1 VOPT Optional Voltage Sense Input

CON2 ISENSEH High Level Current Sense Input

CON3 ISENSEL Low Level Current Sense Input

CON4 LIN LIN Physical Layer I/O

CON5 VBAT Battery Level Supply

CON6 GND Device Ground

CON7 ETEMP External Temperature Sensor

CON8 PTA/E MCU Port A and E

CON9 BDM_EXT External BDM for MM912J637

CON10 BDM_JM60 External BDM for JM60 (not used in this application)

CON1 1 PTB Analog Die Port B

CON12 TEST TEST SPI USB Interface

CON13 TBDML TBDML USB Interface

Freescale 11

Symbol Function

KT912J637UG, Rev. 1.0

Page 12

Hardware Description

6.2.2 Voltage Sense Input (Optional) CON1

Connector CON1 is a socket for a 4.0 mm banana jack. It enables connection of an optional voltage sense input

to pin 34.

6.2.3 High Level Current Sense Input H/L CON 2 & Con3

Connectors CON2 (red) and CON3 (black) are sockets for 4.0 mm banana jacks.

6.2.4 LIN Connector CON4

Connector CON4 (green) is a socket for a 4.0 mm banana jack. It enables con nection of the LIN bus to pin 22.

6.2.5 Power Connectors CON5 and CON6

Power connectors CON5 (positive supply - red) and CON6 (ground - black) are sockets for 4.0 mm banana

jacks.

12 Freescale

KIT912J637EVME, Rev. 1.0

Page 13

Hardware Description

6.2.6 External Temperature Sensor CON 7

Connector CON1 is a header type 3 X 1, 2.54 mm (0.1”) pitch. It enables connection of an optional temperature

sense input.

Table 4 shows the pin assignments.

Table 4. External Temperature Sensor CON7

Pin # Description

1 TSUP temp sensor supply output (pin 29)

2 VTEMP temp sensor input (pin 28)

3GND

6.2.7 MM912J637 Port A & E CON 8

Connector CON 8 is a header type 6 x 2, 2.54 mm (0.1”) pitch.Table 5 shows the pin assignments.

Table 5. MCU Port A & E CON8

Pin # Description

1GND

25V

3PA0

4PA1

5PA2

6PA3

7PA4

8PA5

9PA6

10 PA7

11 PE0

12 PE1

Freescale 13

KT912J637UG, Rev. 1.0

Page 14

Hardware Description

6.2.8 External BDM for MM912J637 CON 9

A standard BDM Connector (hea der 2 X 3 , 2.54 mm (0.1”) pitch) is placed on the EVB to provide the user with

an external BDM programming/debugging interface connection. The pin assignment is listed in

Table 6.

Table 6. Signal Connector CON9

Pin # Description

1 BKGD

2GND

3

4 /RESET

5

6 +5.0V

6.2.9 External BDM for JM60 (TEST_SPI USB MCU) CON 10

A standard BDM Connector (hea der 2 X 3 , 2.54 mm (0.1”) pitch) is p laced on the EVB to p rovide the user with

an external BDM programming/debugging interface connection. This conn ector is not supported by the included

software. The pin assignments are listed in

Table 7.

Table 7. Signal Connector CON10

Pin # Description

1 BKGD

2GND

3

4 /RESET

5

6 +5.0V

6.2.10 ANALOG DIE PORT B CON 11

The J8 connector is header type 2x2, 0.1” (2.54 mm) pitch. The pin assignments are listed inTable 8.

Table 8. Signal Connector CON 11

Pin # Description

1PTB0

2PTB1

3PTB2

4L0

14 Freescale

KIT912J637EVME, Rev. 1.0

Page 15

Hardware Description

6.2.11 Test SPI USB Interface CON12

Connector CON12 is a standard USB connector type B. The pin assignments are listed in Table 9.

.

Table 9. USB Connector J9

Pin # Description

1 +5.0 V

2 USBDM

3 USBDP

4GND

6.2.12 TBDML USB Interface CON13

Connector CON13 is a standard USB connector type B. It enables connection of the EVB to a PC or notebook.

Table 10. USB Connector J9

Pin # Description

1 +5.0 V

2 USBDM

3 USBDP

4GND

6.3 Test Points

There are 22 test points on the EVB, allowin g easy monitoring of the key pins on the MM912J637. The test point

reference numbers indicate the corresponding pins on the MM912J637. The schematic and board are marked

with both reference numbers and signal names.

Reference designator Signal name Reference designator Signal name

TP16 GND TP32 ISENSEH

TP17 VDDX TP34 VSENSE

TP19 VDDH TP35 VOPT

TP20 GND TP36 PTB3/L0

TP21 VSUP TP37 PTB2

TP22 LIN TP38 PTB1

TP26 VDDA TP39 PTB0

TP28 VTEMP TP41 GND

TP29 TSUP TP42 VDDL

TP30 GND TP45 RST_A*

TP31 ISENSEL TP46 RESET*

Table 11 summarizes the test points.

Table 11. Test Points

Freescale 15

KT912J637UG, Rev. 1.0

Page 16

Hardware Description

Figure 6. Test Point Locations

KIT912J637EVME, Rev. 1.0

16 Freescale

Page 17

Software Description

7 Software Description

7.1 Important Notes on Programming and Debugging of the Board

7.1.1 Hardware Considerations

During device programming the switch configuration for S2 should conform to the settings in Table 2 for either

TBDML or BDM programming respectively. The minimum supply voltage during the programming and

debugging is 8.0 V.

In normal operation, RESET and RESET_A must be connected by setting S2-3 “ON”.

NOTE: While the EVB is being programmed, if TBDML is not used for debug, it is recommended to switch off

TBDML.

7.1.2 Programming and Debugging Via the TBDML Interface

A TBDML interface is placed on the kit board for programming/d ebugging of the board. It is necessa ry to install

TBDML supporting files (USB driver , interface DLL, GDI DLL plug-in for the Fre escale’s Hi-wave debugger) and

implement modifications in the settings of the CodeW arrior Hi-wave debugger , to be able to prog ram/debug the

board. The enclosed CD contains documentation an d complete sour ce files to this open source tool. Read th e

tbdml_manual_15.pdf (user’s manual), especially the 3.2 Installing Windows Drivers section, and follow the

listed instructions. Omit the jumper J2 settings. This refers to another board. Installation is easy and does not

require any special skills.

7.1.3 Software Included on the CD

A basic template is included on the CD in the MM912J637 folder. It initializes the MM912J637 and provides a

framework for evaluation. CodeWarrior must be installed on your system before open ing this template.

To install, copy and paste the subfolder KIT912J637_Template onto your desktop or other other appropriate

local location. Open the subfolder and double click on the CodeWarrior project file titled

"KIT912J637_template.mcp." This will open the template in the CodeWarrior environment.

The code may be downloaded to the EVB using TBDML or a programmer such as the PE Micro Cyclone Pro.

Freescale 17

KT912J637UG, Rev. 1.0

Page 18

Schematics

8 Schematics

18 Freescale

Figure 7. KIT912J637EVME Schematic 1

KIT912J637EVME, Rev. 1.0

Page 19

Schematics

Freescale 19

Figure 8. KIT912J637EVME Schematic 2

KT912J637UG, Rev. 1.0

Page 20

Board Layout

9 Board Layout

Figure 9. Top Copper Layer

Figure 10. Bottom Copper Layer (from bottom)

20 Freescale

KIT912J637EVME, Rev. 1.0

Page 21

Figure 11. Top Silk-screen Layer

Board Layout

Freescale 21

KT912J637UG, Rev. 1.0

Page 22

Bill of Materials

10 Bill of Materials

Table 12. Part List - KIT912J637EVME - V2.0

Part Value Package DIGIKEY Count

C1 10 μ 153CLV-0405 565-2100-1-ND 1/3

C2 20 pF C0603

C3 20 pF C0603

C4 100 n CAP CER 0.10 μF 5% 16 V X7R 0603

C5 47 n CAP CER 47000 PF 16 V X7R 0603

C6 47 n CAP CER 47000 PF 16 V X7R 0603

C7 opt. C0603

C8 4.7 μ CAP CER 4.7 μF 50 V X5R 1206 399-5507-1-ND 1/1

C9 100 n CAP CER 0.10 μF 50 V X7R 0805

C10 20 pF C0603

C11 470 n CAP CER 0.47 μF 25 V X7R 0603

C12 1.0 μ CAP CER 1.0 μF 16 V X5R 0603

C13 100 n CAP CER 0.10 μF 5% 16 V X7R 0603

C14 220 n CAP CER 0.22 μF 16 V X7R 0603

C17 100 n CAP CER 0.10 μF 5% 16 V X7R 0603

C18 20 pF C0603

C19 10 μ 153CLV-0405

C20 100 n CAP CER 0.10 μF 5% 16 V X7R 0603

C21 100 n CAP CER 0.10 μF 5% 16 V X7R 0603

C22 470 n CAP CER 0.47 μF 25 V X7R 0603

C23 4.7 μ 153CLV-0405

C30 10 μ 153CLV-0405

CON1 VOPT DELTRON - Red

CON2 ISENSEH DELTRON - Red

CON3 ISENSEL DELTRON - Black

CON4 LIN DELTRON - Green (opt. Red)

CON5 VBAT DELTRON - Red

CON6 GND DELTRON - Black

CON7 ETEMP 1X03 (3 of 40)

CON8 PTA,E 2X06 (6 of 40)

CON9 BDM_EXT 2X03 (3 of 40)

CON10 BDM_JM60 2X03 (3 of 40)

CON11 PTBx 2X02 (2 of 40)

CON12 TEST USB REC R/A TYPE B 4POS

CON13 TBDML USB REC R/A TYPE B 4POS

490-1410-1-ND 1/4

490-1410-1-ND 2/4

478-3726-6-ND 1/5

587-1239-1-ND 1/2

587-1239-1-ND 2/2

open

399-1170-1-ND 1/1

490-1410-1-ND 3/4

490-3291-2-ND 1/2

399-5090-1-ND 1/1

478-3726-6-ND 2/5

399-5619-1-ND 1/1

478-3726-6-ND 3/5

490-1410-1-ND 4/4

565-2100-1-ND 2/3

478-3726-6-ND 4/5

478-3726-6-ND 5/5

490-3291-2-ND 2/2

565-2128-2-ND 1/1

565-2100-1-ND 3/3

Mouser Catalog:

http://www.mouser.com/cat-

alog/629/930.pdf

WM8095-ND 1/1

WM8156-ND 1/4

WM8156-ND 2/4

WM8156-ND 3/4

WM8156-ND 4/4

A31725-ND 1/2

A31725-ND 2/2

1/6

2/6

3/6

4/6

5/6

6/6

22 Freescale

KIT912J637EVME, Rev. 1.0

Page 23

Bill of Materials

Table 12. Part List - KIT912J637EVME - V2.0

D1 D0603 DIODE SCHOTTKY 200 mA 45 V 641-1284-1-ND 1/1

IC1 MM912J637 7X7QFN48_EP_WF

IC2 MC908JB16JDWE SO20W

IC3 74LV125PW TSSOP14

IC4 MC9S08JM60 LQFP44

LED1 CHIP-LED0603 LED0603

LED2 CHIP-LED0603 LED0603

Q1 12 MHz (20p) HC49UP

Q2 12 MHz (20p) HC49UP

R1 27R RES 27 OHM 1/16 W 5% 0603

R2 opt. M1206

R3 1.0 k RES 1.0 k OHM 1/10 W 1% 0603 SMD P1.0KDBTR-ND 1/4

R4 47 k R0603

R5 1.0 k RES 1.0 k OHM 1/10 W 1% 0603 SMD

R6 10 M R0603

R7 1.0 k5 R0603

R8 27R RES 27 OHM 1/16 W 5% 0603

R9 open R0603

R10 680R R0603 RGH16P680CT-ND 1/2

R11 470 k R0603

R12 3.3 k RES 3.3 k OHM 1/10 W 1% 0603 SMD

R13 27R RES 27 OHM 1/16 W 5% 0603

R14 27R RES 27 OHM 1/16 W 5% 0603

R15 47 k R0603

R16 470 k R0603

R17 47R R0603

R18 47R R0603

R19 47 k R0603

R20 1.0 k RES 1.0 k OHM 1/10 W 1% 0603 SMD

R21 open R0603

R22 1.0 M R0603 P1.0MGCT-ND 1/1

R23 0 R0603

R24 4.7 k R0603

R25 4.7 k R0603

R26 1.0 k RES 1.0 k OHM 1/10 W 1% 0603 SMD

R27 680R R0603

S1 219-05J CTS-219-05J 219-5LPSTJ 1/1

S2 219-03J CTS-219-03J

S3 219-02J CTS-219-02J

Freescale supplied 1/1

MC68HC908JB16JDW 1/1

568-4596-5-ND 1/1

MC9S08JM60CLD-ND 1/1

160-1435-1-ND 1/2

160-1435-1-ND 2/2

XC736CT-ND 1/2

XC736CT-ND 2/2

27CHCT-ND 1/4

open

311-47.0KHRCT-ND 1/3

P1.0KDBTR-ND 2/4

P10MGCT-ND 1/1

P1.5KYCT-ND 1/1

27CHCT-ND 2/4

open

31 1-470KGRCT-ND 1/2

P3.3KDBTR-ND 1/1

27CHCT-ND 3/4

27CHCT-ND 4/4

311-47.0KHRCT-ND 2/3

31 1-470KGRCT-ND 2/2

RHM47.0HCT-ND 1/2

RHM47.0HCT-ND 2/2

311-47.0KHRCT-ND 3/3

P1.0KDBTR-ND 3/4

open

P0.0GCT-ND 1/1

311-4.70KHRCT-ND 1/2

311-4.70KHRCT-ND 2/2

P1.0KDBTR-ND 4/4

RGH16P680CT-ND 2/2

219-3LPSTJ 1/1

219-2LPSTJ 1/2

Freescale 23

KT912J637UG, Rev. 1.0

Page 24

Bill of Materials

Table 12. Part List - KIT912J637EVME - V2.0

S4 219-02J CTS-219-02J 219-2LPSTJ 2/2

S5 PTB3/L0 Key switch (check dim!)

TP0 VBAT TESTPOINT-BLK,1.4 mm drl

TP16 GND TESTPOINT-BLK,1.4 mm drl

TP17 VDDX TESTPOINT-BLK,1.4 mm drl

TP19 VDDH TESTPOINT-BLK,1.4 mm drl

TP20 GND TESTPOINT-BLK,1.4 mm drl

TP21 VSUP TESTPOINT-BLK,1.4 mm drl

TP22 LIN TESTPOINT-BLK,1.4 mm drl

TP26 VDDA TESTPOINT-BLK,1.4 mm drl

TP28 VTEMP TESTPOINT-BLK,1.4 mm drl

TP29 TSUP TESTPOINT-BLK,1.4 mm drl

TP30 GND TESTPOINT-BLK,1.4 mm drl

TP31 ISENSEL TESTPOINT-BLK,1.4 mm drl

TP32 ISENSEH TESTPOINT-BLK,1.4 mm drl

TP34 VSENSE TESTPOINT-BLK,1.4 mm drl

TP35 VOPT TESTPOINT-BLK,1.4 mm drl

TP36 L0 TESTPOINT-BLK,1.4 mm drl

TP37 PTB2 TESTPOINT-BLK,1.4 mm drl

TP38 PTB1 TESTPOINT-BLK,1.4 mm drl

TP39 PTB0 TESTPOINT-BLK,1.4 mm drl

TP41 GND TESTPOINT-BLK,1.4 mm drl

TP42 VDDL TESTPOINT-BLK,1.4 mm drl

TP45 RST_A TESTPOINT-BLK,1.4 mm drl

TP46 RST TESTPOINT-BLK,1.4 mm drl

FEED1…4 Rubber feet SJ-5003 (BLACK) 1 1.2 mm

CKN9362-ND 1/1

5118K-ND (chk drill!) 1/23

5118K-ND (chk drill!) 2/23

5118K-ND (chk drill!) 3/23

5118K-ND (chk drill!) 4/23

5118K-ND (chk drill!) 5/23

5118K-ND (chk drill!) 6/23

5118K-ND (chk drill!) 7/23

5118K-ND (chk drill!) 8/23

5118K-ND (chk drill!) 9/23

5118K-ND (chk drill!) 10/23

5118K-ND (chk drill!) 11/23

5118K-ND (chk drill!) 12/23

5118K-ND (chk drill!) 13/23

5118K-ND (chk drill!) 14/23

5118K-ND (chk drill!) 15/23

5118K-ND (chk drill!) 16/23

5118K-ND (chk drill!) 17/23

5118K-ND (chk drill!) 18/23

5118K-ND (chk drill!) 19/23

5118K-ND (chk drill!) 20/23

5118K-ND (chk drill!) 21/23

5118K-ND (chk drill!) 22/23

5118K-ND (chk drill!) 23/23

SJ5003-0-ND 4x

24 Freescale

KIT912J637EVME, Rev. 1.0

Page 25

11 References

Table 13 provides URLs where you can obtain information on other Freescale products and application

solutions.

Table 13. References

Products Links

Data Sheet MM912_637 www.freescale.com/files/analog/doc/data_sheet/MM912_637D1.pdf

Freescale’s Web Site www.freescale.com

Freescale’s Analog Web Site www.freescale.com/analog

Freescale’s Power Management Web Site www.freescale.com/powermanagement

References

Freescale 25

KT912J637UG, Rev. 1.0

Page 26

Revision History

12 Revision History

Revision Details

1.0 First Release.

Table 14. Revision History

26 Freescale

KIT912J637EVME, Rev. 1.0

Page 27

Revision History

Freescale 27

KT912J637UG, Rev. 1.0

Page 28

How to Reach Us:

Home Page:

www.freescale.com

Web Support:

http://www.freescale.com/support

USA/Europe or Locations Not Listed:

Freescale Semiconductor, Inc.

Technical Information Center, EL516

2100 East Elliot Road

Tempe, Arizona 85284

1-800-521-6274 or +1-480-768-2130

www.freescale.com/support

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

www.freescale.com/support

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor China Ltd.

Exchange Building 23F

No. 118 Jianguo Road

Chaoyang District

Beijing 100022

China

+86 10 5879 8000

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or +1-303-675-2140

Fax: +1-303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and

software implementers to use Freescale Semi conductor prod ucts. There are

no express or implied copyright licenses granted hereunder to design or

fabricate any integrated circuits or integrated circuits based on the

information in this document.

Freescale Semiconductor reserves the right to m ake changes without furt her

to products herein. Freescale Semiconductor makes no warranty,

representation or regarding the suitability of its products for any particular

purpose, nor does Freescale Semiconductor assume any liability arising out

of the or use of any product or circuit, and specifically disclaims any and all

liability, including without limitation consequential or incidental damages.

“Typical” param eters that may be provid ed in Freescal e Semicond uctor dat a

sheets and/or specifications can and do vary in different applications and

actual performance may vary over time. All operating parameters, including

“Typicals”, be validated for each customer application by technical experts.

Freescale Semiconductor does not convey any licens e under its paten t rights

nor the rights of others. Freescale Semiconductor products are des i gned,

intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or

sustain life, or for any other application in which the failure of the Freescale

Semiconductor product could create a situation where personal injury or

death may occur. Should Buyer purchase or use Freescale Semiconductor

products for any such unintended or unauthorized application, Buyer shall

indemnify and hold Freescale Semiconductor and its officers, employees,

subsidiaries, affiliates, and harmless against all claims, costs, da mages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly,

any claim of personal injury or death associated with such uninten ded or

unauthorized use, even if such claim alleges that Freescale Semiconductor

was negligent regarding the design or manufacture of the part.

Freescale and the Freescale logo are trademarks of Freescale

Semiconductor, Inc., Reg. U.S. Pat. & Tm. Off. Qorivva, S 12 MagniV,

SMARTMOS and Xtrinsic are trademarks of Freescale

Semiconductor, Inc. ARM is the registered trademark of ARM

Limited. The Power Architecture and Power.org word marks and the

Power and Power.org logos and related marks are trademarks and

service marks licensed by Power.org. All other product or service

names are the property of their re spective ow ners. ©2 011 Freescal e

Semiconductor, Inc.

KT912J637UG

Rev. 1.0

2/2012

Loading...

Loading...