Page 1

SECURITY

STATUS

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

Rev. 1.6 — April 15, 2019

Reference manual

dDocument information

Info

Content

Keywords

JN5189, 89T, 88, 88T, module

Abstract

Reference Manual for JN5189, 89T, 88, 88T modules and platform design.

Page 2

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

2 of 33

Contact information

For more information, please visit: http://www.nxp.com

Revision history

Rev

Date

Description

1.0

20180201

Creation

1.1

20180307

Added picture of the JN5189-001-M16 module

1.2

20180525

Manufacturer address added

1.3

20180528

Update of IC chapter

1.4

20181004

Update of FCCID / IC ID

1.5

20180321

JN5188/88T added

Temperature range explained

O-QPSK modulation frequency band added

1.6

20190415

Add comments in chapter 8.2

Page 3

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

3 of 33

1. Introduction

This manual describes the hardware for the reference designs for modules based around

the NXP JN5189 family of wireless microcontrollers. This family is composed by JN5189,

89T, 88, 88T modules. In this manual, JN5189 name can stand also for JN5189T,

JN5188 and JN5188T.

The NXP JN5189 modules are small, low-power and cost-effective evaluation and

development board or application prototyping and demonstration of the JN5189 device.

The JN5189 is an ultra-low-power, highly integrated single-chip device that enables

Standard IEEE 802.15.4 RF connectivity for portable, extremely low-power embedded

systems.

The JN5189 SoC integrates a radio transceiver operating in the 2.4 GHz ISM band

supporting O-QPSK modulation (2400MHz to 2483.5MHz), an ARM Cortex-M4

processor, up to 640 kB flash,152 kB SRAM and 128 kB ROM, 802.15.4 processor

hardware and peripherals optimized to meet the requirements of the target applications.

The design considerations presented in this manual are equally valid for bespoke

solutions where the JN5189 device is placed directly onto the product PCB.

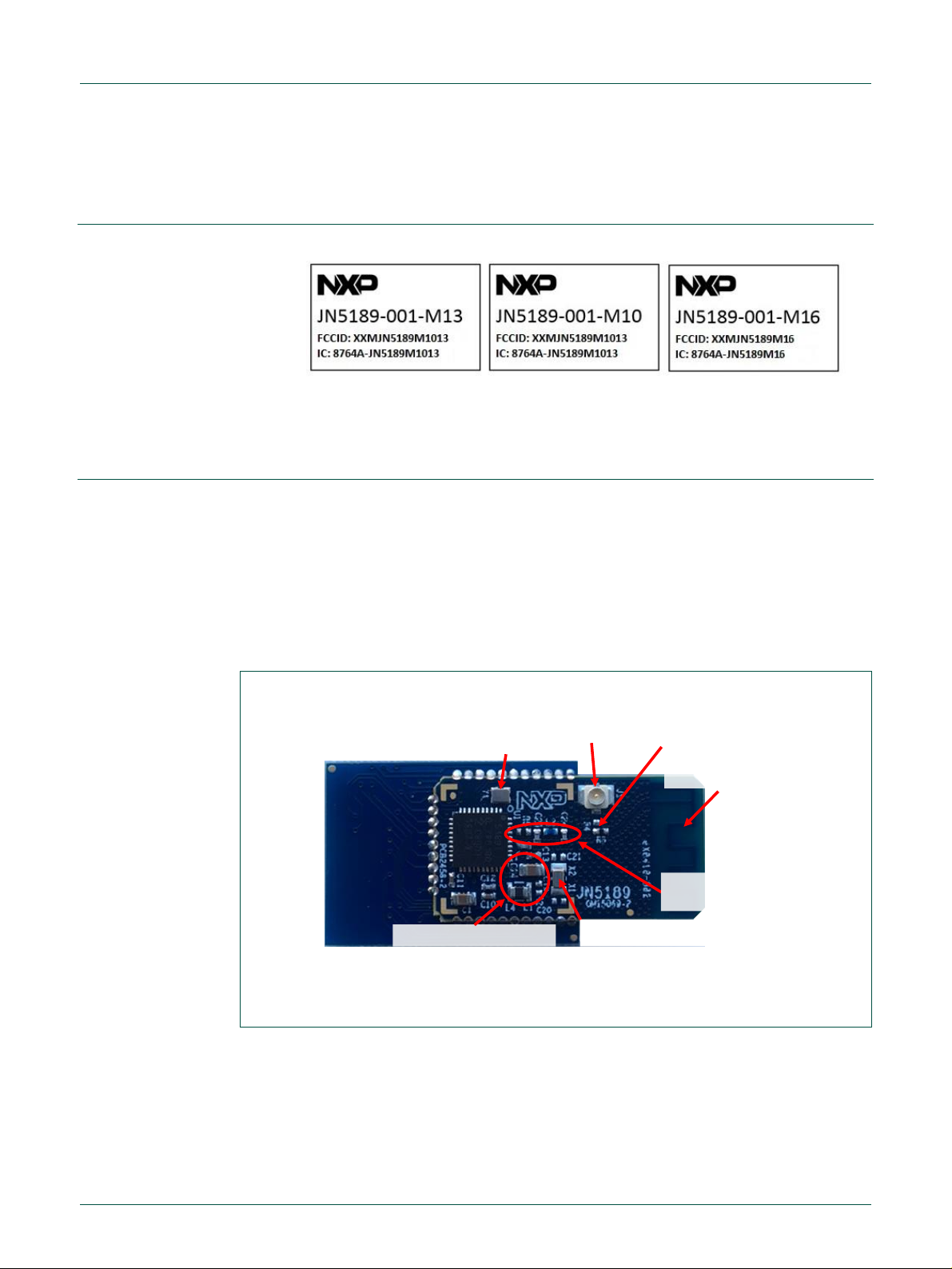

Three modules models are available:

JN5189-001-M10

JN5189-001-M13

JN5189-001-M16

The models available are described in Table 1.

In order to complete a successful PCB design by your own the hardware guidelines

described in this reference manual must be followed as strictly as possible. Further

information on the JN5189 characteristics are available in the “JN5189 IEEE802.15.4

Wireless Microcontroller” datasheet.

1.1 Audience

This guide is intended for systems designers

1.2 Manufacturer address

NXP Semiconductors

Campus EffiScience, Esplanade Anton Philips

14906 Caen

1.3 Regulatory approvals

France

The JN5189-001-M10 and M13 are compliant with:

RED 2014/53/UE

CFR 47 FCC part 15

Industry Canada requirements

Page 4

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

4 of 33

Part number

Description

Content

Reference

Manual

JN-RD-6054

JN5189

Module

Reference

Design

Package

OM15069

Standard Power

PCB Antenna

JN5189-001-M10

JN-RM-2078

OM15069

Standard Power

Fl connector

JN5189-001-M13

OM15072

High Power

Antenna diversity (PCB

antenna and Fl connector)

JN5189-001-M16

The high power JN5189-001-M16 is not approved for use in Europe. It is compliant with:

CFR 47 FCC part 15

Industry Canada requirements

2. Reference Design

The reference design package includes the following information for each module

variant:

Reference manual: JN-RM-2078

Schematics

Layout

Bill-of-Materials

Full design databases including schematics and layout source files are available on

request.

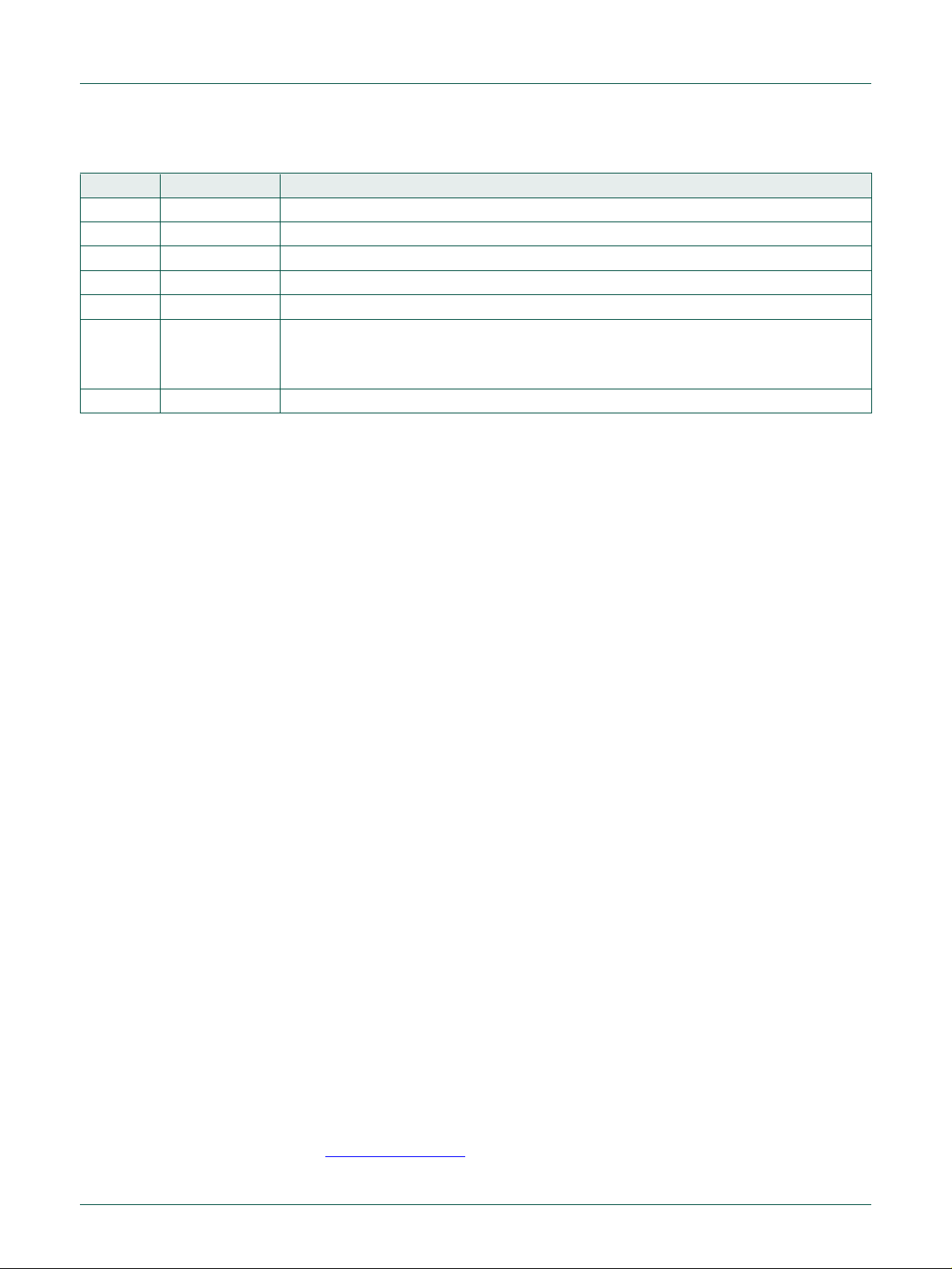

The following table provides a summary of the JN5189 Module Reference Design that is

available from the Wireless Connectivity area of the NXP web site.

Table 1. Modules references

Note: These reference designs are approved for the operating temperature range of

40 ºC to +105 ºC for JN5189T/JN5188T where NTAG is embedded and -40°C to

+125°C without embedded NTAG, as JN5188 and JN5189 modules. As reference, below

are the operating conditions from the datasheet.

Page 5

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

5 of 33

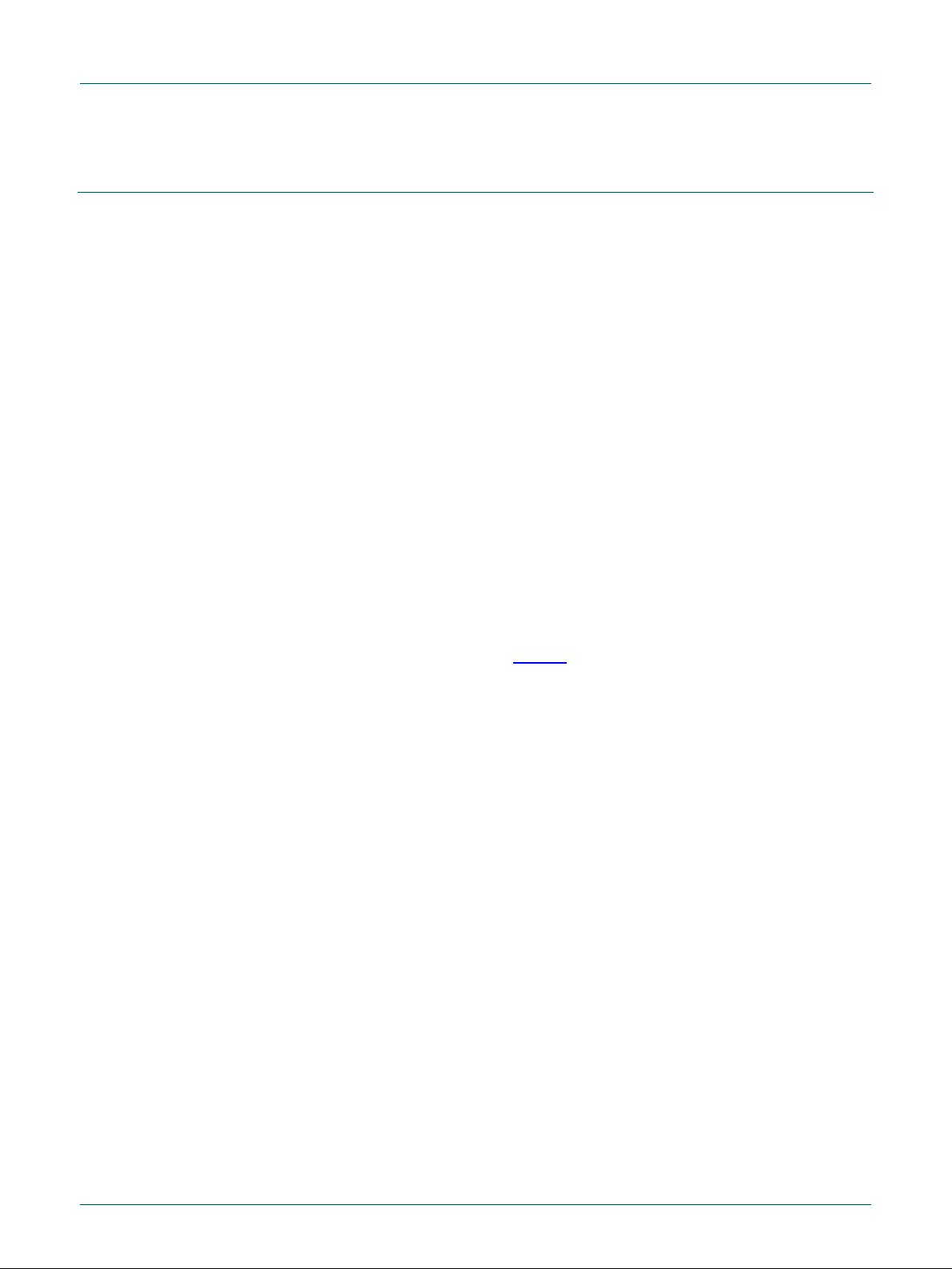

JN5189

Matching

µFl connector

JN5189-001-M10

JN5189

Matching

Printed antenna

JN5189-001-M13

Fig 1. JN5189-001-M10 & M13 block diagrams

JN5189SKY66403

Matching

JN5189-001-M16

Printed antenna

µFl connector

Fig 2. JN5189-001-M16 block diagram

Table 2. Operating conditions

3. Block diagram

Page 6

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

6 of 33

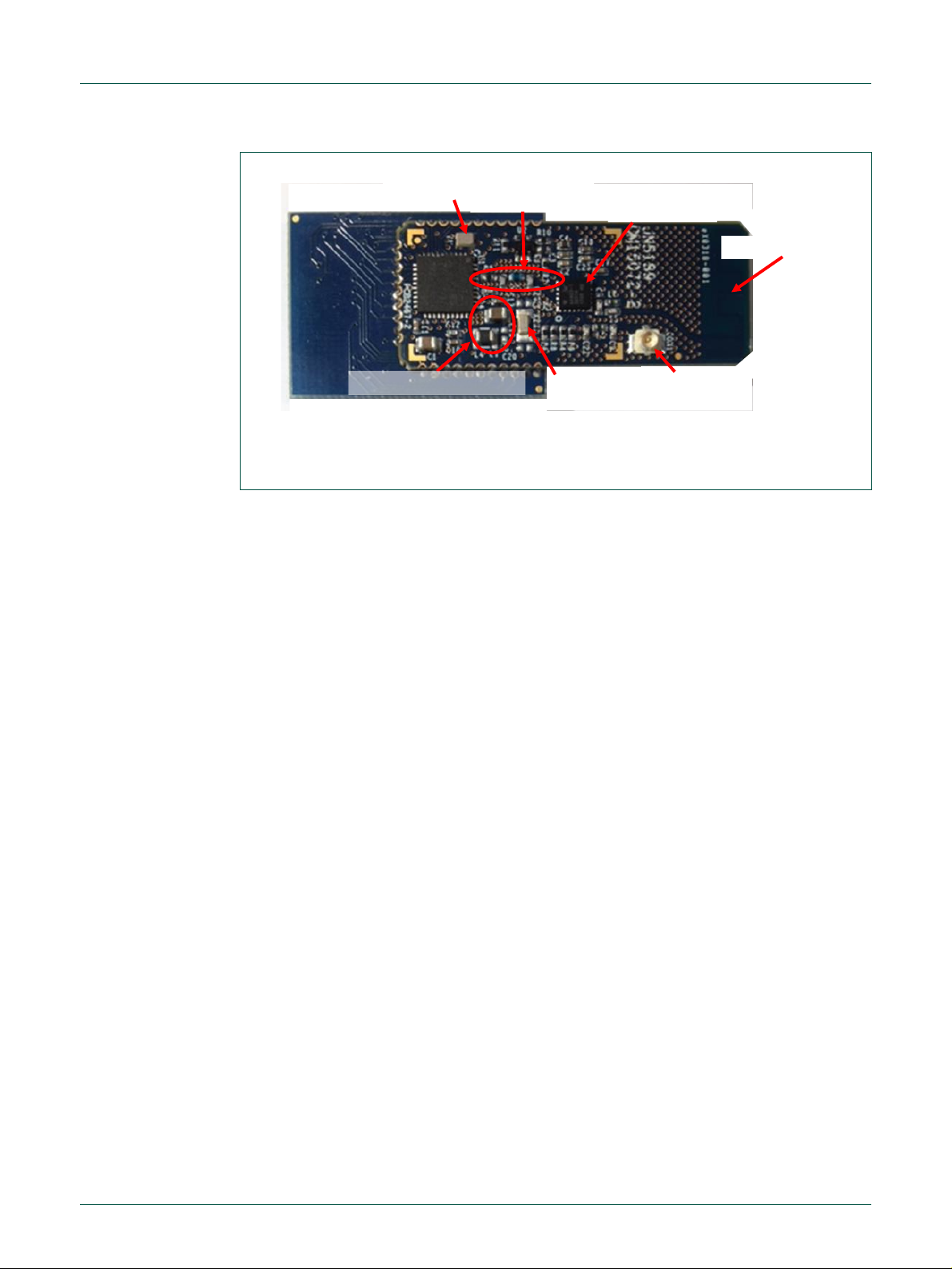

32 MHz XTAL

DCDC external components

IF Printed antenna

µFl connector

0 ohm resistor used to

configure the module in

M10 or M13 variant

RFIO &

Matching Network

32 kHz XTAL

Fig 3. JN5189-001-M10 & M13

4. Marking

The label is fixed on the bottom face of the modules

5. Design considerations

To have successful wireless hardware development, the proper device footprint, RF

layout, circuit matching, antenna design, and RF measurement capability are essential.

RF circuit design, layout, and antenna design are specialties requiring investment in tools

and experience. With available hardware reference designs from NXP, RF design

considerations, and the guidelines contained in this application note, hardware engineers

can successfully design IEEE 802.15.4 radio boards with good performance levels. The

following figures show the JN5189 M10 & M13 reference modules. They contain the

JN5189 device and all necessary I/O connections.

Page 7

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

7 of 33

DCDC external components

32 kHz XTAL

32 MHz XTAL

RFIO &

Matching Network

IF Printed antenna

µFl connector

FEM SKY66403

Fig 4. JN5189-001-M16

The device footprint and layout are critical and the RF performance is affected by the

design implementation. For these reasons, use of the NXP recommended RF hardware

reference designs are important for successful board performance. Additionally, the

reference platforms have been optimized for radio performance. Even small changes in

the location of components can mistune the circuit. If the recommended footprint and

design are followed exactly in the RF region of the board, sensitivity, output power,

harmonic and spurious radiation, and range will have a high likelihood of first time

success.

The following subsections describe important considerations when implementing a

wireless hardware design starting with the device footprint, PCB stack-up, RF circuit

implementation, and antenna selection. The following figure shows an example of a

typical layout with the critical RF section which must be copied exactly for optimal radio

performance. The less critical layout area can be modified without reducing radio

performance.

NOTE

Exact dimensions are not given in this document, but can be found in the manufacturing

files for the JN5189 modules

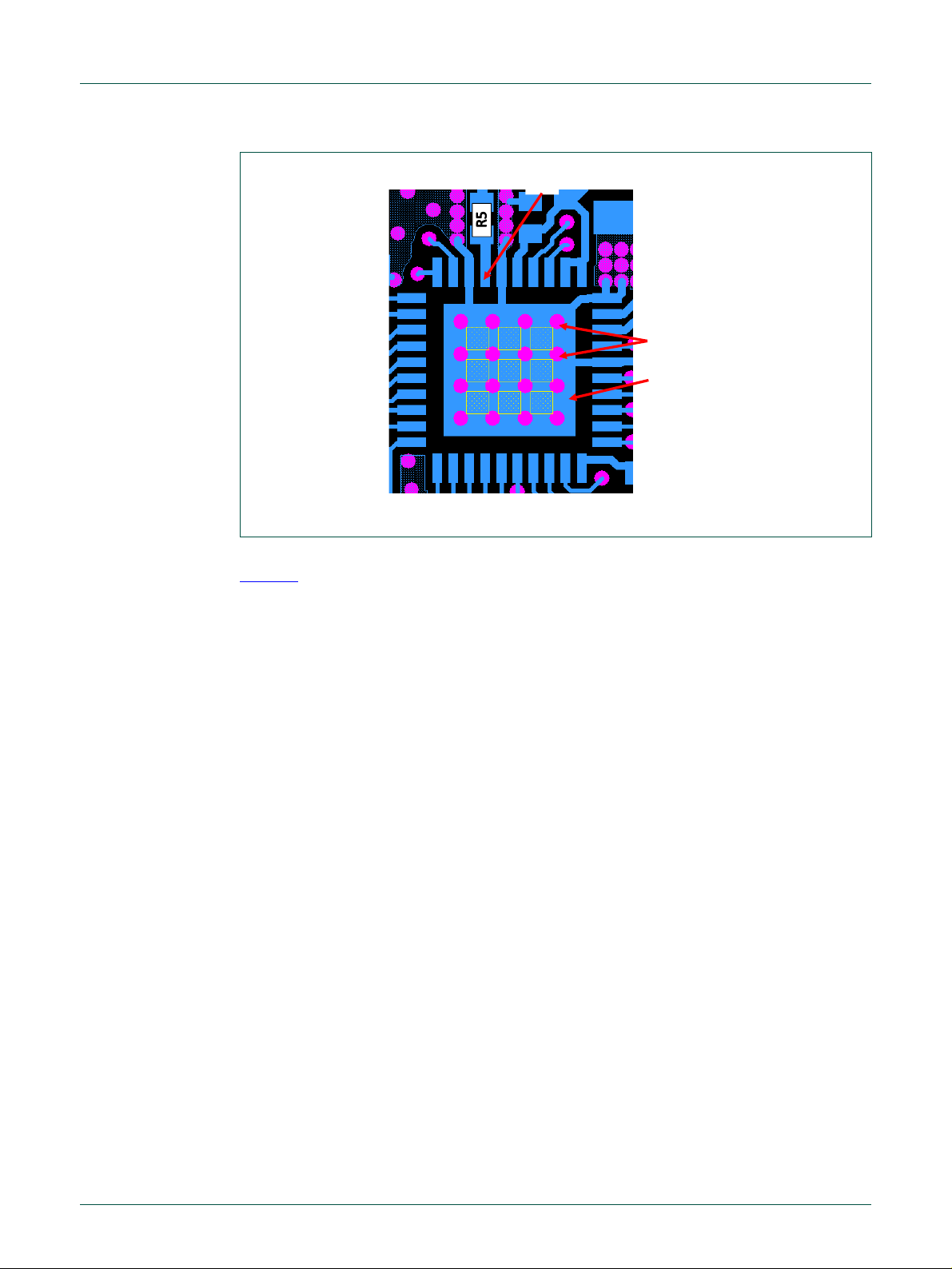

5.1 JN5189 device footprint

The performance of the wireless link is largely influenced by the device’s footprint. As a

result, a great deal of care has been put into creating a footprint so that receiver

sensitivity and output power are optimized to enable board matching and minimal

component count. NXP highly recommends copying the die flag exactly as it is shown in

the following figure; this includes via locations as well. Deviation from these parameters

can cause performance degradation.

Page 8

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

8 of 33

RFIO

GND vias

Die flag

Fig 5. Critical Layout of die flag area

Figure 5 shows the critical areas of the device die flag. These are the following:

• Ground vias and locations

• RF output and ground traces

• Die flag shape

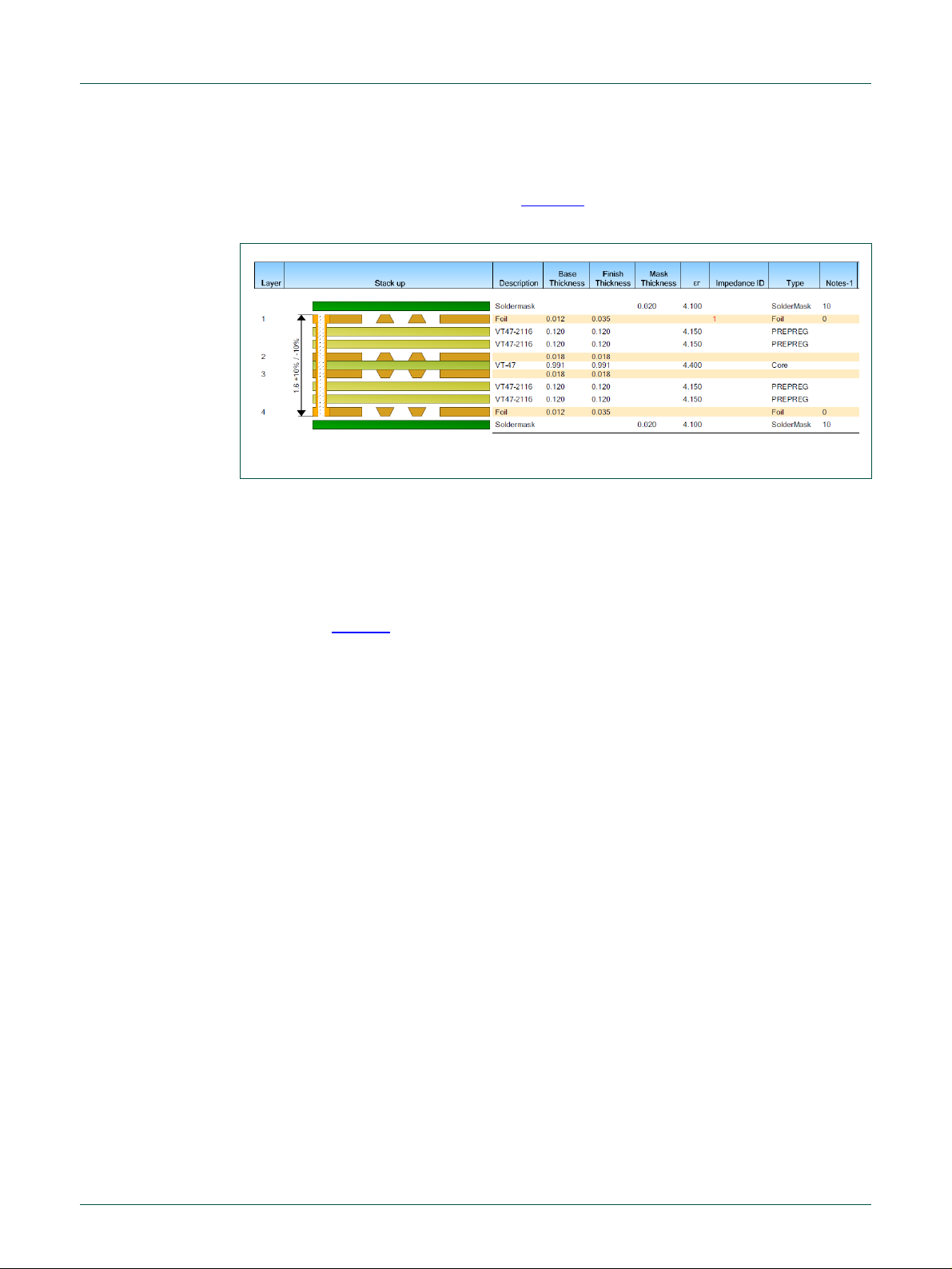

5.2 PCB Stack-Up

Complexity is the main factor that will determine whether the design of an application

board can be two-layer, four-layer, or more. From an RF point of view a 4 layers PCB

is preferred to a two layers PCB.Nevertheless in a very simple application it should be

possible to use a 2 layers PCB.

The recommended board stack-up for either a four-layer or two-layer board design is

as follows:

• 4-layer stack-up:

— Top: RF routing of transmission lines

— L2: RF reference ground

— L3: DC power

— Bottom: signal routing

• Two-layer stack-up:

— Top: RF routing of transmission lines, signals, and ground

— Bottom: RF reference ground, signal routing, and general ground

Page 9

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

9 of 33

Fig 6. PCB stack-up

The JN5789-001-M10 and JN5189-001-M13 (OM15069) and JN5189-001-M16

(OM15062) modules are built on a standard 4–layer printed circuit board (PCB) with the

individual layers organized as shown in Figure 6.

Note: The NXP PCB layouts assume use of the layers defined above. If a different PCB

stack-up is used then NXP does not guarantee performance.

NXP strongly recommends the use of the above stack-up.

As shown in Figure 6, regarding transmission lines, it is important to copy not just the

physical layout of the circuit, but also the PCB stackup. Any small change in the

thickness of the dielectric substrate under the transmission line will have a significant

change in impedance; all this information can be found on the fabrication notes for

each board design. As an illustration, consider a 50 ohm microstrip trace that is 18 mils

wide over 10 mils of FR4. If that thickness of FR4 is changed from 10 to 6 mils, the

impedance will only be about 36 ohms.

In any case the width of the RF lines must be re-calculated according to the PCB

characteristics in order to ensure a 50 ohm characteristic impedance.

When the top layer dielectric becomes too thin, the layers will not act as a true

transmission line, even though all the dimensions are correct. There is not universal

industry agreement on which thickness at which this occurs, but NXP prefers to use a

top layer dielectric thickness of no less than 8-10 mils.

There is also a limit to the ability of PCB fabricators to control the minimum width of a

PCB trace and the minimum thickness of a dielectric layer. +/- 1 mil will have less

impact on an 18 mils wide trace and a 10 mil thick dielectric layer, than it will on a much

narrower trace and thinner top layer.

This can be an especially insidious problem. The design will appear to be optimized

with the limited quantity of prototype and initial production boards, in which the bare

PCB's were all fabricated in the same lot. However, when the product goes into mass

production there can be variations in PCB fabrication from lot-to-lot which can degrade

performance.

The use of a correct substrate like the FR4 with a dielectric constant of 4.4 will assist you

in achieving a good RF design.

Page 10

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

10 of 33

While no special measures are required for the board design, it is recommended that

Class 1 tolerances be used.

5.3 RF circuit topology and matching

NXP always recommends that designers start by copying the existing NXP reference

design. This applies to both the circuit portion (schematic) of the design, and the PCB

layout. For all RF designs, particularly for designs at frequencies as high as 2.4 GHz,

the PCB traces are a part of the design itself. Even a very short trace has a small

amount of parasitic impedance (usually inductive), which has to be compensated for in

the remainder of the circuit.

What may seem like a minor change to the layout, or what would certainly be a minor

change at a lower frequency of operation, can actually be a significant change at 2.4

GHz. For example, we may consider that a metal trace on a PCB such as the JN5189001M1x modules is approximately 0.8 nH per mm. At lower frequencies, this would have

no impact, but at 2.4 GHz this would have a significant impact in any matching circuits.

The circuits used on the NXP reference designs are all tuned and optimized on the

actual layout of the reference design, such that the final component values take into

account the effects of the circuit board traces, and other parasitic effects introduced by

the PCB. This includes such issues as parasitic capacitance between components,

traces, and/or board copper layers, inductance of traces and ground vias, the non-ideal

effects of components, and nearby physical objects.

The layout of the RF portions of JN5189 based modules is critical. It is important that the

reference designs are strictly adhered to, otherwise the following may occur:

Reduction in RF output

Excessive spurious RF outputs leading to RF compliance issues

Unacceptable power slope across the full channel range

Poor range

Reduced Rx sensitivity

5.4 Transmission lines

Transmission lines have several shapes such as microstrip, coplanar waveguide,

and strip-line. For 802.15.4 applications built on FR4 substrates, the types of

transmission lines typically take the form of microstrip or coplanar waveguide

(CPW). These two structures are defined by the dielectric constant of the board

material, trace width, and the board thickness between the trace and the ground.

Additionally, for CPW, the transmission line is defined by the gap between the trace

and the top edge ground plane. These parameters are used to define the

characteristic impedance of the transmission line (trace) that is used to convey the

RF energy between the radio and the antenna.

JN5189 has a single ended RF output with a 3 components matching network

composed of a shunt capacitor, a series inductor then another shunt capacitor. In

addition a 0 ohm resistor has been placed between the RFIO port of the chip and

Page 11

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

11 of 33

Controlled impedance trace

(50 ohm microstrip)

RF Match

Printed antennaµFl connector

Fig 7. RF Matching Network

the first shunt capacitor. These elements transform the device impedance to 50

ohms. The value of these components may vary depending on your specific board

layout. The recommended RF matching network is shown in Figure 7.

Avoid routing traces near or parallel to RF transmission lines or crystal signals.

Maintaining a continuous ground under an RF trace is critical to maintaining the

characteristic impedance of that trace. Avoid any routing on the ground layer that

will result in disrupting the ground under the RF traces.

Keep the RF trace as short as possible.

5.5 Components

All electronic components have parasitic characteristics that cause the part to act in a

non-ideal way. Typically, these effects become worse as the frequency of operation is

increased.

For most component suppliers, this quality is expressed by the Self Resonant

Frequency (SRF) specification. For example, a capacitor has parasitic inductance

introduced by the metal leads of the components. As frequency increases, at some

point the impedance due to the parasitic inductance is greater than the impedance of

the capacitor, and at that frequency and higher, the component no longer acts as a

capacitor and now acts as an inductor. At the point at which the impedance from both

inductive and capacitive components is the same, the part will resonate as a LC

parallel resonant circuit, and this is called the Self Resonant frequency. Figure 8

shows some typical response curve.

Page 12

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

12 of 33

Fig 8. RF Plots for 3pF ceramic capacitor Murata GRM1555 type

The same is true of inductors. There is parasitic capacitance in an inductor, mainly due

to capacitive coupling between the turns of wire. At some point in frequency, this

capacitance will have a higher impedance than the inductance of the part. From this

frequency and higher the part acts as a capacitor and not as an inductor.

The Bill of Materials (BOM) is available for all NXP reference designs. The BOM

shows the specific vendors and part numbers used on NXP designs. It is certainly

possible to substitute another vendor's parts, but it may impact the performance of the

circuit, therefore, it may be necessary to use different component values when parts

from another vendor are used.

If there is a performance issue on a new design, and part substitutions were made on

that design, then it is strongly recommended that components identical to those used

in the NXP reference design be placed on the new design for test purposes. Once the

design is working properly with components that are identical to those used by NXP,

then it will be possible to substitute components from other vendors one at a time, and

test for any impact on circuit performance.

5.6 GND planes

It is recommended to use a solid (continuous) ground plane on Layer 2, assuming Layer

1 (top) is used for the RF components and transmission lines; avoid cut-outs or slots in

that area.

Keep top ground continuous as possible. This also applies for the other layers.

Connect ground on the components layer to the ground plane beneath with a large

quantity of vias.

Page 13

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

13 of 33

C10

C12

C 19

Fig 9. GND path between C10/C12 and C19

Ground pours or fingers can act as antennas that unintentionally radiate. To avoid this,

eliminate any finger that is not connected to the ground reference with a via; put a via in

any trace that doesn’t go anywhere.

5.7 Layers interconnections

Avoid vias in the RF traces.Typically for a 1.6mm thickness PCB material, a single via

can add 1.2nH of inductance and 0.5pF of capacitance, depending upon the via

dimensions and PCB dielectric material.

Provide multiple vias for high current and/or low impedance traces.

Connect carefully all the ground areas of any layer to the reference GND plane

5.8 DCDC components

Be sure that the smallest values capacitors C12 and C10 are placed close to the VBAT

pin.

The impedance of the GND connection between C10/C12 and C19 must be as low as

possible: connect them directly on the component layer (see the red path below)

5.9 Reference Oscillator

The NXP JN5189 device contains the necessary on-chip components to build a 32-MHz

reference oscillator with the addition of an external crystal resonator. There is no need to

use external capacitors because the JN5189 includes a bank of switchable capacitors

that can be tuned to adjust the load capacitance (CL) that needs to be seen by the XTAL.

The reference crystal serves many purposes, including the provision of a reference for

the 32-bit ARM processor, PHY controller, radio synthesizer and analogue peripherals. In

addition, the crystal provides timing references for external I/O (e.g. on-chip UARTs) and

Page 14

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

14 of 33

Best configuration

Wrong configuration:

• There are not enough vias

• The vias are too far from the

decouplingcapacitors

timer counters. Thus, it is important that the crystal reference is specified and built

correctly to ensure that the system functions properly.

The choice of crystal resonator is important for the following reasons:

Resonator tolerance: A number of parameters, ranging from on-chip timings to

radio centre-frequency, are derived directly from the tolerance of the crystal. As

indicated in the component list, we recommend that a total tolerance of less than

±25 ppm is used, as the maximum permissible offset specified in IEEE802.15.4

is ±40 ppm. Also, note that this tolerance should include both temperature and

ageing effects imparted on the resonator.

Resonator load capacitance: The active oscillator components on the JN5189

devices are designed for a crystal resonator with load capacitance (CL) of 6 pF.

This is a standard load and resonators of this type are widely available.

Lay-out recommendations:

Route the connections from the 32 MHz XTAL to the chip oscillator pins with traces as

short as possible. The layout of the oscillator circuit is such that tracks between

components are as short as possible. This improves the performance of the oscillator by

reducing stray capacitance which can introduce frequency errors.

The XTAL should be placed away from high frequency devices and traces in order to

reduce the capacitive coupling between XTAL pins and PCB traces.

Keep other digital signal lines, especially clock lines and frequently switching signal lines,

as far away from the crystal connections as possible.

Caution: Adherence to NXP’s recommendations will ensure that the module performs

correctly. The substitution of components is not recommended, as this may lead to both

oscillator start-up and frequency tolerance issues.

5.10 Decoupling

5.10.1 General considerations

Decouple the power supplies or regulated voltages as close as possible to the supply pin

of the IC. The decoupling capacitors must be connected to a localized ground pad on the

top layer that is connected to the main ground plane layer through multiple vias.

Ensure that each decoupling capacitor has its own via connection to ground. When

possible use 2 vias to connect the capacitor to the ground layer.

Page 15

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

15 of 33

Fig 10. GND vias placement

VDD

Main supply

trace on layer 3

VDD

Gnd

Gnd

Main supply trace

on layer 3

cap

best configuration

via

via

via

via

Wrong configuration:

The decoupling capacitor is not

placed between the main line and

the VDD pin

Fig 11. Decoupling capacitors placement

C13

C14

VDD(Radio

)

Fig 12. VDD(Radio) decoupling

The capacitor with a smaller capacitance must be placed nearer to the IC.

The decoupling capacitor must be placed between the main supply line and the supply

pin as shown below:

5.10.2 VDD(RADIO), FB, VDD_PMU, VDDE and VBAT decoupling

Copy as much as possible the placement of the decoupling capacitors of all the supply

pins as shown below.

Page 16

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

16 of 33

Fig 13. FB and VDD_PMU decoupling

C100

VDDE

Fig 14. VDDE decoupling

C10

C12

C 1

Fig 15. VBAT decoupling

5.11 Traces Isolation

When PCB traces are in close proximity, they can talk to each other through the

capacitor created by these traces.

Page 17

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

17 of 33

In order to mimimize the effect of this parasitic coupling, identify the most sensitive traces

or areas (RF trace, oscillator, power lines, ...) and separate them from any signal that is

likely to couple with them through parasitics.

Separation between 2 lines can be achieved by increasing the distance from one to the

other.

5.12 GPIOs

The GPIOs traces are generally long lines that can cover long distances. They can

carry undesirable signals that are likely to radiate in any direction. It is recommended to

avoid routing these signals

5.13 Screening can

The JN5189 doesn’t radiate high spurs and it is very robust to EMC interferers so there is

in principle no need for a screening can (or shielding can). Nevertheless a footprint for a

can has been added on the NXP modules and NXP recommends to add this footprint to

any PCB. In very specific cases under a very noisy environment it could be helpful to add

a can.

Page 18

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

18 of 33

Fig 16. PCB placement of a JN5189 module with a printed antenna

6. Optimal PCB placement of a module

In case the JN5189 is mounted on a module similar to the NXP JN5189-001-M10 care must be

taken when mounting this module onto another PCB.

The area around the antenna must be kept clear of conductors or other metal objects for an

absolute minimum of 20 mm. This is true for all layers of the PCB and not just the top layer. Any

conductive objects close to the antenna could severely disrupt the antenna pattern resulting in

deep nulls and high directivity in some directions.

The diagrams below show various possible scenarios. The top 3 scenarios are correct;

groundplane may be placed beneath JN5168-001-M00 module as long as it does not protrude

beyond the edge of the top layer ground plane on the module PCB.

The bottom 3 scenarios are incorrect; the left-hand side example because there is groundplane

underneath the antenna, the middle example because there is insufficient clearance around the

antenna (it is best to have no conductors anywhere near the antenna), finally the right hand

example has a battery’s metal casing in the recommended keep out area.

7. Manufacturing considerations

The HVQFN package must be considered carefully when using reflow solder techniques.

Package footprint information can be found in the JN5189 data sheet.

Page 19

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

19 of 33

Fig 17. Recommended PCB decal for HVQFN40 40-pin QFN

The decal is shown in Fig 17. The pad stacks used are 0.25 mm by 1 mm for the smaller

pads, and a 6.4 mm square pad for the paddle.

The solder mask used is shown in Fig 18. The pad stacks used are 0.25 mm by 1 mm

for the smaller pads, and four 1.6 mm square pads to apply paste to the paddle. The

solder paste mask has a thickness of 6-thou (0.152 mm). If the paste thickness needs

to deviate from that used NXP then it may be necessary to change the number of pads

that the paste is applied to. Paste thickness may be dictated by additional components

used in a design.

Page 20

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

20 of 33

Fig 18. Solder paste mask for HVQFN40 40-pin QFN

Fig 19. Vias on the paddle of the HVQFN40 40-pin QFN

25 vias are applied to the paddle. These allow excess solder paste and heated air to be

vented away from the device, preventing the device from being lifted during soldering.

In addition, these vias ensure that a low impedance ground is maintained, which is vital

for optimum RF performance.

Page 21

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

21 of 33

8. Regulations

8.1 Federal Communication Commission Statement

• This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules see Ref. 4. These limits are

designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one of

the following measures:

– Reorient or relocate the receiving antenna

– Increase the separation between the equipment and receiver

– Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected

– Consult the dealer or an experienced radio/TV technician for help

• OEM integrators instructions

– The OEM integrators are responsible for ensuring that the end-user has no manual

instructions to remove or install module

– The module is limited to installation in mobile or fixed applications, according to CFR

47 Part 2.1091(b)

– Separate approval is required for all other operating configurations, including portable

configurations with respect to CFR 47 Part 2.1093 and different antenna configurations

• User guide mandatory statements

– User's instructions of the host device must contain the following statements in addition

to operation instructions:

* “This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may

cause undesired operation”

* “Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment”

• FCC RF Exposure requirements

– User's instructions of the host device must contain the following instructions in

addition to operation instructions:

Avoid direct contact to the antenna, or keep it to a 20 cm minimum distance while using

this equipment. This device must not be collocated or operating in conjunction with

another antenna or transmitter.

Page 22

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

22 of 33

This module has been designed to operate with antennas having a maximum gain of

2 dBi. Antennas having a gain greater than 2 dBi are strictly prohibited for use with this

device. The required antenna impedance is 50 ohms.

8.1.1 FCC end product labelling

The final ‘end product’ should be labelled in a visible area with the following:

Contains TX FCC ID: XXMJN5189M1013 and XXMJN5189M16 to reflect the version of

the module being used inside the product.

8.2 Industry Canada statement

Under Industry Canada regulations, this

radio transmitter may only operate using an

antenna of a type and maximum (or lesser)

gain approved for the transmitter by Industry

Canada. To reduce potential radio

interference to other users, the antenna type

and its gain should be so chosen that the

equivalent isotropically radiated power

(e.i.r.p.) is not more than that necessary for

successful communication.

This radio transmitter (8764A-JN5189M1013

and 8764A-JN5189M16) has been approved

by Industry Canada to operate with the

antenna types listed below with the

maximum permissible gain and required

antenna impedance for each antenna type

indicated. Antenna types not included in this

list, having a gain greater than the maximum

gain indicated for that type, are strictly

prohibited for use with this device.

This module has been designed to operate with antennas having a maximum gain of

Conformément à la réglementation

d'Industrie Canada, le présent émetteur

radio peut fonctionner avec une antenne

d'un type et d'un gain maximal (ou inférieur)

approuvé pour l'émetteur par Industrie

Canada. Dans le but de réduire les risques

de brouillage radioélectrique à l'intention des

autres utilisateurs, il faut choisir le type

d'antenne et son gain de sorte que la

puissance isotrope rayonnée équivalente

(p.i.r.e.) ne dépasse pas l'intensité

nécessaire à l'établissement d'une

communication satisfaisante.

Le présent émetteur radio (8764AJN5189M1013 and 8764A-JN5189M16) a

été approuvé par Industrie Canada pour

fonctionner avec les types d'antenne

énumérés ci-dessous et ayant un gain

admissible maximal et l'impédance requise

pour chaque type d'antenne. Les types

d'antenne non inclus dans cette liste, ou

dont le gain est supérieur au gain maximal

indiqué, sont strictement interdits pour

l'exploitation de l'émetteur.

2 dBi. Antennas having a gain greater than 2 dBi are strictly prohibited for use with this

device. The required antenna impedance is 50 ohms.

As long as the above condition is met, further transmitter testing will not be required.

However, the OEM integrator is still responsible for testing their end-product for any

additional compliance requirements required with this module installed (for example,

digital device emissions, PC peripheral requirements, etc). The host equipment (including

Page 23

SECURITY

STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

23 of 33

This device complies with Industry Canada RF

radiation exposure limits set forth for general

population. This device must be installed to

provide a separation distance of at least 20cm

from all persons and must not be co-located or

operating in conjunction with any other

antenna or transmitter.

Le présent appareil est conforme aux niveaux

limites d’exigences d’exposition RF aux

personnes définies par Industrie Canada.

L’appareil doit être installé afin d’offrir une

distance de séparation d’au moins 20cm avec

l’utilisateur, et ne doit pas être installé à

proximité ou être utilisé en conjonction avec

une autre antenne ou un autre émetteur.

This device complies with Industry Canada

radiation exposure limits set forth for general

population. This device must not be co-located

or operating in conjunction with any other

antenna or transmitter.

This device complies with Industry Canada

licence-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this

device may not cause interference, and (2)

this device must accept any interference,

including interference that may cause

undesired operation of the device

Le présent appareil est conforme aux niveaux

limites d’exigences d’exposition RF pour la

population globale définies par Industrie

Canada. L’appareil ne doit pas être installé à

proximité ou être utilisé en conjonction avec

une autre antenne ou un autre émetteur.

Le présent appareil est conforme aux CNR

d’Industrie Canada applicables aux appareils

radio exempts de licence. L’exploitation est

autorisée aux deux conditions suivantes: (1) il

ne doit pas produire de brouillage, et (2)

l’utilisateur du dispositif doit être prêt a

accepter tout brouillage radioélectrique reçu,

même si ce brouillage est susceptible de

compromettre le fonctionnement du dispositif.

power supply system) still needs to re-confirm that the whole system complies with both

intentional and unintentional emission requirements.

8.2.1 Industry Canada end product labelling

For Industry Canada purposes the following should be used: Contains Industry Canada

ID IC: 8764A-JN5189M1013 and 8764A-JN5189M16

8.3 European Radio Equipment Directive 2014/53/EU statement

JN5189-001-M10 and JN5189-001-M13 are compliant with ETSI EN 300 328 V2.1.1,

EMC, EN 301 489-17 v3.2.0 and the Basic Safety Assessment (BSA) EN 60950-1:2006

(2006-06) and are subject to a Notified Body Opinion.

The JN5189-001-M16 module is not approved for use in Europe.

Page 24

E

C

U

RI

T

Y

S

T

A

T

NXP Semiconductors

JN5189, 89T, 88, 88T module

s development reference manual

JN

-

RM

-

2078

Reference manual

JN

-RM

-2078

Rev. 1.6

—

April 15, 2019

All information provided in this document is subject to legal disclaimers.

24

of

33

©

NXP B.V.

2016

. All rights reserved.

Check

number

SCHEMATICS

DESIGN-IN REVIEW CHECK-LIST

Y/N/NA

Customer comments and/or

actions

Check done

by

NXP Feedback

1

GENERAL

1.1

Have the schematics been checked versus NXP

reference schematics & Application Notes?

1.2

Have the schematics been reviewed by several

people?

1.3

Does the application use non standard components?

(e.g. components that had not previously used for

such applications)

1.4

Have the non standard components been qualified

so that they can be used in the application?

1.5

Are recommendations for layout/form factor written

on the schematics?

1.6

Are the components sized for the wanted current

drive capability?

1.7

Has the JN5189 symbol pinning been checked and

does it include the exposed pad?

2

RF IO

2.1

Is the characteristic impedance of the RF_IO

input/output line 50 ohm over the full RF range?

2.2

Have components with the correct type and value

been connected to the RF port of the JN5189?

2.3

For modules with external FEM is extra filtering

needed for harmonics rejection ?

3

32 MHz crystal reference Oscillator

3.1

Is the oscillator external configuration in accordance

with the Application Note?

3.2

Has XTAL model been recommended by NXP?

9. Check list schematic

Table 3. Schematic design-in check list

Page 25

E

C

U

RI

T

Y

S

T

A

T

NXP Semiconductors

JN5189, 89T, 88, 88T module

s development reference manual

JN

-

RM

-

2078

Reference manual

JN

-RM

-2078

Rev. 1.6

—

April 15, 2019

All information provided in this document is subject to legal disclaimers.

25

of

33

©

NXP B.V.

2016

. All rights reserved.

3.3

In case the XTAL model has not been recommended

by NXP have all the parameters been checked in

order they fulfill NXP, standard and application

requirements (load capacitance,pulling sensitivity,

equivalent resistance, frequency tolerance,

temperature range, frequency drift versus

temperature, ageing) ?

4

32 kHz crystal Oscillator

4.1

Has the need of a 32 kHz XTAL been discussed ? (

Zigbee specifications can be met without an external

XTAL)

4.2

In case the 32 kHz XTAL oscillator has been

implemented has the XTAL model been

recommended by NXP ?

4.3

In case the XTAL model has not been recommended

by NXP have all the parameters been checked in

order they fulfill NXP, standard and application

requirements (load capacitance,pulling sensitivity,

equivalent resistance, frequency tolerance,

temperature range, frequency drift versus

temperature, ageing) ?

5

Power Supply

5.1

Have all the VDD pins been connected according to

NXP recommendations?

5.2

Are the power supply regulators well sized?

5.3

Has the decoupling of the supply regulators output

been implemented?

5.4

Have the power supply pins of the IC been properly

decoupled (according to the Application Note and

Reference Design schematics?)

5.5

Have the recommendations for the values and

models of the components of the DCDC converter

been taken into account?

5.6

Has the exposed die pad been connected to GND?

6

PIOs

6.1

Has the compatibility of the logic levels with other

components been checked?

6.2

Does the max source/sink current fit the application?

7

ADC

7.1

Does the ADC characteristics fit the application?

Page 26

E

C

U

RI

T

Y

S

T

A

T

NXP Semiconductors

JN5189, 89T, 88, 88T module

s development reference manual

JN

-

RM

-

2078

Reference manual

JN

-RM

-2078

Rev. 1.6

—

April 15, 2019

All information provided in this document is subject to legal disclaimers.

26

of

33

©

NXP B.V.

2016

. All rights reserved.

8

Programming and Debug

8.1

Has the flash programming connector been

connected to the correct I/O on the microcontroler?

8.2

Has a connector for debug been added that allows

the microcontroler to be put into programming mode?

(RSTN & SPIMISO pins)

8.3

Is the reset pin RSTN properly connected?

8.4

Add a test point at an unused DIO in order a trigger

signal can be output from the pin for sensitivity

measurements

8.5

For printed and chip antenna: Is the RF line

implemented in such a way that the HW can be easily

modified in order to do conducted measurements on

one hand and measure the antenna characteristics

on the other hand ? For instance a 0 ohm resistor can

be used to connect the JN5189 RF port to the

antenna for the real application and a SMA or µFL

connector footprint can be added for debug; the SMA

or µFl connector will be connected/disconnected

to/from the JN5189 RF port or the antenna with 0

ohm resistors.

8.6

If I2C used, are the I2C lines pulled up?

9

External Memory

9.1

In case an external flash memory is used has the

correct type of memory been used and is it connected

to the microcontroller correctly?

9.2

Has the flash memory symbol pinning been checked?

Page 27

E

C

U

RI

T

Y

S

T

A

T

NXP Semiconductors

JN5189, 89T, 88, 88T module

s development reference manual

JN

-

RM

-

2078

Reference manual

JN

-RM

-2078

Rev. 1.6

—

April 15, 2019

All information provided in this document is subject to legal disclaimers.

27

of

33

©

NXP B.V.

2016

. All rights reserved.

Check

number

LAYOUT

DESIGN-IN REVIEW CHECK-LIST

Y/N/NA

Customer comments and/or

actions

Check done

by

NXP feedback

1

GENERAL

1.1

Has the number of layers been clearly discussed?

1.2

Has the layout been checked versus NXP reference

board ? (i.e OM15069-2_JN5189_ANTENNA_MODULE)

1.3

Have the HW recommendations of the JN-RM-2078

reference manual been followed?

1.4

Has the correct PCB material been specified?

1.5

Have the correct PCB thicknesses been specified?

2

RF IO

2.1

Is the RF_IO input/output line well sized for 50 ohm?

The line width must be calculated according to the

board thickness and PCB material.

2.2

Are the RF wires as short as possible (wires behave

as antenna so shortening them help to increase EMI

immunity)

2.3

Have vias been avoided in the RF line?

2.4

Has the placement of the RFIO matching network

been strictly copied from the NXP reference module?

3

Crystal reference Oscillator

3.1

Has the 32 MHz XTAL been placed close to the IC?

3.2

Are there GND vias around the 32 MHz XTAL ?

4

Power Supply

4.1

Have all the VDD capacitors been placed as close as

possible to the power pins and voltage regulators

outputs?

4.2

Provide multiple vias in the power lines when power is

routed on several layers

10. Check list layout

Table 4. Layout design-in check list

Page 28

E

C

U

RI

T

Y

S

T

A

T

NXP Semiconductors

JN5189, 89T, 88, 88T module

s development reference manual

JN

-

RM

-

2078

Reference manual

JN

-RM

-2078

Rev. 1.6

—

April 15, 2019

All information provided in this document is subject to legal disclaimers.

28

of

33

©

NXP B.V.

2016

. All rights reserved.

4.3

For low supply voltage application – close to 2.0V,

please ensure that the supply track is well

dimensioned so as to avoid IR drop and hence falsely

trigger the brown-out.

(IR drop is the voltage drop due to the supply current

flowing into the supply track resistance).

4.4

Have the VDD lines been isolated from potential

interferences?

4.5

Is GND plane continuous around and near all signals?

4.6

Has the die pad been properly connected to GND?

4.7

Are vias implemented in the die pad?

5

EMC and Misc

5.1

In case more than 2 layers are used, does one layer

act as a continuous ground plane (GND reference

plane)?

5.2

Are numerous vias added near capacitor, near

fingers,…?

5.3

Remove small GND areas and isolated fingers that

cannot be connected to the reference GND plane with

a via.

5.4

Have silk screens been added with relevant

information? (components ref, logo, board name…)

5.5

Are all silkscreen texts readable when the board is

populated?

5.6

Have traces been avoided below noisy or sensitive

components?

5.7

Check that traces do not cut across power or ground

planes unnecessarily.

5.8

Is the JN5189 footprint strictly similar to the NXP

reference?

5.9

If more than 2 layers are used, the inner layers must

be left empty below the RF components and the

antenna

5.10

Each connection between a component and GND

must be doubled with a via to the GND plane.

5.11

Have the soldering/non soldering areas been

respected?

Is solder resist layer check in the empty area?

5.12

If sold unit is a module is a CAN/shield implemented?

Page 29

SECURITY STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP B.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

29 of 33

Acronym

Description

EMC

Electro Magnetic Compatibility

ETSI

European Telecommunications Standards Institute

FCC

Federal Communications Commission

PAN

Personal Area Network

PCB

Printed Circuit Board

RF

Radio Frequency

SPI-bus

Serial Peripheral Interface-bus

TQFN

Thin Quad Flat No-lead

WPAN

Wireless Personal Area Network

11. Abbreviations

Table 5. Abbreviations

12. References

JN5189 Datasheet – IEEE802.15.4 Wireless Microcontroller

Page 30

SECURITY

STATUS

Erreur

!

Nom de

proprié

t

é de

docume

nt

inconnu.

Erreur

! Nom de propriété de document inconnu.

Erreur

! Nom de propriété de

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

30 of 33

13. Legal information

13.1 Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. NXP Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information included herein and shall have no liability for the consequences

of use of such information.

13.2 Disclaimers

Limited warranty and liability — Information in this document is believed to

be accurate and reliable. However, NXP Semiconductors does not give any

representations or warranties, expressed or implied, as to the accuracy or

completeness of such information and shall have no liability for the

consequences of use of such information. NXP Semiconductors takes no

responsibility for the content in this document if provided by an information

source outside of NXP Semiconductors.

In no event shall NXP Semiconductors be liable for any indirect, incidental,

punitive, special or consequential damages (including - without limitation lost profits, lost savings, business interruption, costs related to the removal or

replacement of any products or rework charges) whether or not such

damages are based on tort (including negligence), warranty, breach of

contract or any other legal theory.

Notwithstanding any damages that customer might incur for any reason

whatsoever, NXP Semiconductors’ aggregate and cumulative liability

towards customer for the products described herein shall be limited in

accordance with the Terms and conditions of commercial sale of NXP

Semiconductors.

Right to make changes — NXP Semiconductors reserves the right to make

changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This document supersedes and replaces all information supplied prior

to the publication hereof.

Suitability for use — NXP Semiconductors products are not designed,

authorized or warranted to be suitable for use in life support, life-critical or

safety-critical systems or equipment, nor in applications where failure or

malfunction of an NXP Semiconductors product can reasonably be expected

to result in personal injury, death or severe property or environmental

damage. NXP Semiconductors and its suppliers accept no liability for

inclusion and/or use of NXP Semiconductors products in such equipment or

applications and therefore such inclusion and/or use is at the customer’s

own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. NXP Semiconductors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

Customers are responsible for the design and operation of their applications

and products using NXP Semiconductors products, and NXP

Semiconductors accepts no liability for any assistance with applications or

customer product design. It is customer’s sole responsibility to determine

whether the NXP Semiconductors product is suitable and fit for the

customer’s applications and products planned, as well as for the planned

application and use of customer’s third party customer(s). Customers should

provide appropriate design and operating safeguards to minimize the risks

associated with their applications and products.

NXP Semiconductors does not accept any liability related to any default,

damage, costs or problem which is based on any weakness or default in the

customer’s applications or products, or the application or use by customer’s

third party customer(s). Customer is responsible for doing all necessary

testing for the customer’s applications and products using NXP

Semiconductors products in order to avoid a default of the applications and

the products or of the application or use by customer’s third party

customer(s). NXP does not accept any liability in this respect.

Export control — This document as well as the item(s) described herein

may be subject to export control regulations. Export might require a prior

authorization from competent authorities.

Translations — A non-English (translated) version of a document is for

reference only. The English version shall prevail in case of any discrepancy

between the translated and English versions.

Evaluation products — This product is provided on an “as is” and “with all

faults” basis for evaluation purposes only. NXP Semiconductors, its affiliates

and their suppliers expressly disclaim all warranties, whether express,

implied or statutory, including but not limited to the implied warranties of noninfringement, merchantability and fitness for a particular purpose. The entire

risk as to the quality, or arising out of the use or performance, of this product

remains with customer.

In no event shall NXP Semiconductors, its affiliates or their suppliers be

liable to customer for any special, indirect, consequential, punitive or

incidental damages (including without limitation damages for loss of

business, business interruption, loss of use, loss of data or information, and

the like) arising out the use of or inability to use the product, whether or not

based on tort (including negligence), strict liability, breach of contract, breach

of warranty or any other theory, even if advised of the possibility of such

damages.

Notwithstanding any damages that customer might incur for any reason

whatsoever (including without limitation, all damages referenced above and

all direct or general damages), the entire liability of NXP Semiconductors, its

affiliates and their suppliers and customer’s exclusive remedy for all of the

foregoing shall be limited to actual damages incurred by customer based on

reasonable reliance up to the greater of the amount actually paid by

customer for the product or five dollars (US$5.00). The foregoing limitations,

exclusions and disclaimers shall apply to the maximum extent permitted by

applicable law, even if any remedy fails of its essential purpose.

13.3 Patents

Notice is herewith given that the subject device uses one or more of the

following patents and that each of these patents may have corresponding

patents in other jurisdictions.

13.4 Trademarks

Notice: All referenced brands, product names, service names and

trademarks are property of their respective owners.

Page 31

SECURITY STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

31 of 33

14. List of figures

Fig 1. JN5189-001-M10 & M13 block diagrams .......... 5

Fig 2. JN5189-001-M16 block diagram ....................... 5

Fig 3. JN5189-001-M10 & M13 ................................... 6

Fig 4. JN5189-001-M16 .............................................. 7

Fig 5. Critical Layout of die flag area ........................... 8

Fig 6. PCB stack-up .................................................... 9

Fig 7. RF Matching Network ..................................... 11

Fig 8. RF Plots for 3pF ceramic capacitor Murata

GRM1555 type ................................................ 12

Fig 9. GND path between C10/C12 and C19 ............ 13

Fig 10. GND vias placement ....................................... 15

Fig 11. Decoupling capacitors placement ................... 15

Fig 12. VDD(Radio) decoupling .................................. 15

Fig 13. FB and VDD_PMU decoupling ........................ 16

Fig 14. VDDE decoupling ............................................ 16

Fig 15. VBAT decoupling ............................................ 16

Fig 16. PCB placement of a JN5189 module with a

printed antenna ............................................... 18

Fig 17. Recommended PCB decal for HVQFN40 40-pin

QFN ................................................................ 19

Fig 18. Solder paste mask for HVQFN40 40-pin QFN 20

Fig 19. Vias on the paddle of the HVQFN40 40-pin QFN

........................................................................ 20

Page 32

SECURITY STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

JN-RM-2078

All information provided in this document is subject to legal disclaimers.

© NXP Semiconductors N.V. 2016. All rights reserved.

Reference manual

Rev. 1.6 — April 15, 2019

32 of 33

15. List of tables

Table 1. Modules references .......................................... 4

Table 2. Schematic design-in check list ........................ 24

Table 3. Layout design-in check list .............................. 27

Table 4. Abbreviations .................................................. 29

Page 33

SECURITY STATUS

NXP Semiconductors

JN-RM-2078

JN5189, 89T, 88, 88T modules development reference manual

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in the section 'Legal information'.

© NXP Semiconductors N.V. 2016. All rights reserved.

For more information, please visit: http://www.nxp.com

Date of release: April 15, 2019

Document identifier: JN-RM-2078

16. Contents

1. Introduction ......................................................... 3

1.1 Audience ............................................................ 3

1.2 Manufacturer address ........................................ 3

1.3 Regulatory approvals ......................................... 3

2. Reference Design ................................................ 4

3. Block diagram ...................................................... 5

4. Marking ................................................................ 6

5. Design considerations ........................................ 6

5.1 JN5189 device footprint ..................................... 7

5.2 PCB Stack-Up .................................................... 8

5.3 RF circuit topology and matching ..................... 10

5.4 Transmission lines ........................................... 10

5.5 Components ..................................................... 11

5.6 GND planes...................................................... 12

5.7 Layers interconnections ................................... 13

5.8 DCDC components .......................................... 13

5.9 Reference Oscillator ......................................... 13

5.10 Decoupling ....................................................... 14

5.10.1 General considerations .................................... 14

5.10.2 VDD(RADIO), FB, VDD_PMU, VDDE and

VBAT decoupling ............................................. 15

5.11 Traces Isolation .......................................... 16

5.12 GPIOs .............................................................. 17

5.13 Screening can .................................................. 17

6. Optimal PCB placement of a module ............... 18

7. Manufacturing considerations ......................... 18

8. Regulations ........................................................ 21

8.1 Federal Communication Commission Statement

......................................................................... 21

8.1.1 FCC end product labelling ................................ 22

8.2 Industry Canada statement .............................. 22

8.2.1 Industry Canada end product labelling ............. 23

8.3 European Radio Equipment Directive

2014/53/EU statement ..................................... 23

9. Check list schematic ......................................... 24

10. Check list layout ................................................ 27

11. Abbreviations .................................................... 29

12. References ......................................................... 29

13. Legal information .............................................. 30

13.1 Definitions ........................................................ 30

13.2 Disclaimers....................................................... 30

13.3 Patents ............................................................. 30

13.4 Trademarks ...................................................... 30

14. List of figures ..................................................... 31

15. List of tables ...................................................... 32

16. Contents ............................................................. 33

Loading...

Loading...