Page 1

Freescale Semiconductor SLK0101UG

User Guide Rev. 0, 9/2006

Application Module Student Learning Kit Users

Guide featuring the Freescale MC9S12C32

For use with the following part numbers:

CSM-12C32

APS12C32SLK

PBS12C32SLK

© Freescale Semiconductor, Inc., 2006. All rights reserved.

_______________________________________________________________________

Page 2

CONTENTS

CAUTIONARY NOTES ..............................................................................................................4

FEATURES................................................................................................................................5

REFERENCES...........................................................................................................................6

INTRODUCTION........................................................................................................................7

GETTING STARTED..................................................................................................................7

OPERATION..............................................................................................................................7

POWER................................................................................................................................. 8

PWR.................................................................................................................................. 8

CONNECTOR J1............................................................................................................... 8

PWR_SEL JUMPER.......................................................................................................... 8

RESET SWITCH ................................................................................................................... 9

LOW-VOLTAGE DETECT..................................................................................................... 9

TIMING.................................................................................................................................. 9

COMMUNICATIONS............................................................................................................. 9

COM CONNECTOR........................................................................................................ 10

CONNECTOR J1............................................................................................................. 11

USER OPTIONS ................................................................................................................. 11

SWITCHES ..................................................................................................................... 11

LED’S............................................................................................................................... 12

DEVELOPMENT SUPPORT....................................................................................................12

ASCII MONITOR OPERATION........................................................................................... 12

ASCII MONITOR MEMORY MAP ................................................................................... 12

MONITOR COMMANDS................................................................................................. 13

INTERRUPT SUPPORT.................................................................................................. 13

INTERRUPT VECTOR TABLE........................................................................................ 14

SERIAL MONITOR OPERATION........................................................................................ 15

SERIAL MONITOR MEMORY MAP................................................................................ 15

BDM_PORT HEADER......................................................................................................... 16

2 Freescale Semiconductor

Page 3

FIGURES

Figure 1: PWR_SEL ...................................................................................................................8

Figure 2: COM Connector.........................................................................................................10

Figure 3: MCU_PORT Connector.............................................................................................11

Figure 4: BDM_PORT...............................................................................................................16

TABLES

Table 1: Serial COM Signals ....................................................................................................10

Table 2: User Option Jumper Settings......................................................................................11

Table 4: Monitor Commands ....................................................................................................13

Table 5: Monitor Memory Map..................................................................................................12

Table 6: MON12 Interrupt Vector Table....................................................................................14

Table 7: Serial Monitor Memory Map........................................................................................15

REVISION

August 25, 2006 A Initial release

Freescale Semiconductor 3

Page 4

Cautionary Notes

♦ Electrostatic Discharge (ESD) prevention measures should be used when handling this

product. ESD damage is not a warranty repair item.

♦ Axiom Manufacturing does not assume any liability arising out of the application or use of

any product or circuit described herein; neither does it convey any license under patent

rights or the rights of others.

♦ EMC Information on the APS12C32SLK module:

a) This product as shipped from the factory with associated power supplies and cables, has

been verified to meet with requirements of CE and the FCC as a CLASS B product.

b) This product is designed and intended for use as a development platform for hardware or

software in an educational or professional laboratory.

c) In a domestic environment, this product may cause radio interference in which case the

user may be required to take adequate prevention measures.

d) Attaching additional wiring to this product or modifying the products operation from the

factory default as shipped may effect its performance and cause interference with nearby

electronic equipment. If such interference is detected, suitable mitigating measures should

be taken.

TERMINOLOGY

This module uses option selection jumpers and cut-traces to setup default configuration.

Terminology for application of the option jumpers is as follows:

Jumper – a plastic shunt that connects 2 terminals electrically

Jumper on, in, or installed - jumper is installed such that 2 pins are connected together

Jumper off, out, or idle - jumper is installed on 1 pin only. It is recommended that

jumpers be idled by installing on 1 pin so they will not be lost.

Cut-Trace – a circuit trace connection between component pads. The circuit trace may

be cut using a razor knife to break the default connection. To reconnect the circuit,

simply install a suitably sized 0-ohm resistor or attach a wire across the pads.

4 Freescale Semiconductor

Page 5

FEATURES

The APS12C32SLK is an educational application module for the Freescale Semiconductor

MC9S12C32 microcontroller. Application module SLK’s include components for out-of-box

operation and are preprogrammed with a serial monitor to make application development quick

and easy. A background DEBUG port is provided for development tool use and is compatible

with HCS12 BDM interface cables and software. The 40-pin connector allows the

APS12C32SLK module to be connected to an expanded evaluation environment such as the

Microcontroller Project Board Student Learning Kit (PBMCUSLK) or user’s custom PCB.

Features:

♦ MC9S12C32 MCU, 48 QFP

♦ 32K Byte Flash EEPROM

♦ 2K Bytes RAM

♦ 31 I/O lines

♦ Timer/PWM

♦ SCI and SPI Communications Ports

♦ Key Wake-up Port

♦ BDM DEBUG Port

♦ CAN 2.0 Module

♦ Analog Comparator

♦ 8 MHz Internal Bus Operation Default

♦ 25 MHz Bus Operation using internal PLL

♦ +3.3VDC to +5VDC operation

♦ Power Input Selection Jumper

♦ On-board, regulated +5V power supply

♦ Optional power input/output from Connector J1

♦ 16 MHz Ceramic Resonator

♦ RS-232 Serial Port w/ DB9 Connector

♦ 8-Ch, 10-bit, Analog Comparator with full rail-to-r ail operation and

external trigger capability

♦ 8-Channel, 16-bit Timer with Input Capture, Output Compare, and

PWM capabilities

♦ User Components Provided

♦ 3 Push Button Switches: 2 User, RESET

♦ 3 LED Indicators: 2 User, VDD

♦ Jumpers

♦ Disable User Components

♦ Power Select

♦ Connectors

♦ 40 pin connector provides access to most MCU I/O signals

♦ 2.0mm Barrel Connector Power Input

♦ DEBUG BDM Connector

♦ DB9 Communications Connector

♦ Supplied with DB9 Serial Cable, Documentation (CD), Manual, and Wall plug type power supply.

Specifications:

Module Size 2.2” x 1.6”

Power Input: +9VDC @ 200 mA typical, +6 to +16VDC range

Freescale Semiconductor 5

Page 6

References

Reference documents are provided on the support CD in Acrobat Reader format. More

information can be found in the Application Notes section of the Freescale Web site.

APS12C32SLKSCHEM.pdf APS12C32SLK Application Module Schematic

APS12C32SLKUG.pdf APS12C32SLK User Guide

9S12C32DGV1.pdf MC9S12C32 Device User Guide

9S12C32_ZIP.zip Zip file containing Device Block User Guides

APS12C32SLKQSUG.pdf Quick Start Guide for use with stand-alone module

APS12C32SLKSW.zip CodeWarrior project for use with

APS12C32SLK_QSUG

AN2548.pdf Serial Monitor Program for HCS12 MCU’s

The following reference documents are for using the application module in conjunction with the

Freescale Microcontroller Project Board Student Learning Kit:

PBS12C32SLKQSUG.pdf Quick Start Guide for application module use with

PBMCUSLK

PBS12C32SLKSW.zip CodeWarrior project for use with

PBS12C32SLK_QSUG

Visit www.freescale.com\universityprogram for current product information, reference materials

and updates.

6 Freescale Semiconductor

Page 7

INTRODUCTION

Before using this module, the user should be familiar with the hardware and software operation

of the target MCU. Refer to the MC9S12C32 User Manual and MC9S12C32 Reference

Manual for details on MCU operation. The module’s purpose is to promote the features of the

MC9S12C32 and to assist the user in quickly developing an application in a known working

environment. Users should be familiar with memory mapping, memory types, and embedded

software design for quick, successful, application development.

The APS12C32SLK Educational Module is a fully assembled, fully functional module

supporting Freescale MC9S12C32 microcontroller. The module comes with a serial cable,

power supply, and an embedded monitor for stand-alone operation. Support software for this

module is provided for Windows 95/98/NT/2000/XP operating systems.

Application development may be performed by using the embedded monitor, or any

compatible BDM cable with supporting host software. The embedded monitor provides an

effective, low cost, debug method. Note that when a BDM cable is used for debugging, the

BDM pod should be powered from an external supply.

GETTING STARTED

Please refer to the APS12C32SLK Quick Start Users Guide to quickly setup the stand-alone

application module or PBS12C32SLK Quick Start Users Guide to get started with the

microcontroller project board (PBMCUSLK).

Operation

The APS12C32SLK module provides input and output features designed to assist embedded

application development. Access to the MCU port signals is available through module

connector J1. This connector may also be used to input power to the module or to output

power to attached modules. RS-232 communications signals may also be input through

connector J1. Care must be exercised when using the J1 to power the module, as only

regulated voltage in the range of +3.3V to +5V should be supplied to this connection. The onboard regulator provides a fixed +5V voltage to the module.

Five user option jumpers and 3 cut-traces control module operation. Enabling a user option

requires installing a jumper across the associated header pins. Removing the jumper disables

the associated option. An option enabled by a cut-trace can be disabled by removing the

circuit trace between the cut-trace component pads. Use a sharp knife to cut the embedded

circuit trace. Be careful not to damage adjacent circuitry. To re-enable the option, simply

install a 1206 sized 0-ohm resistor or piece of wire across the cut-trace component pads.

Freescale Semiconductor 7

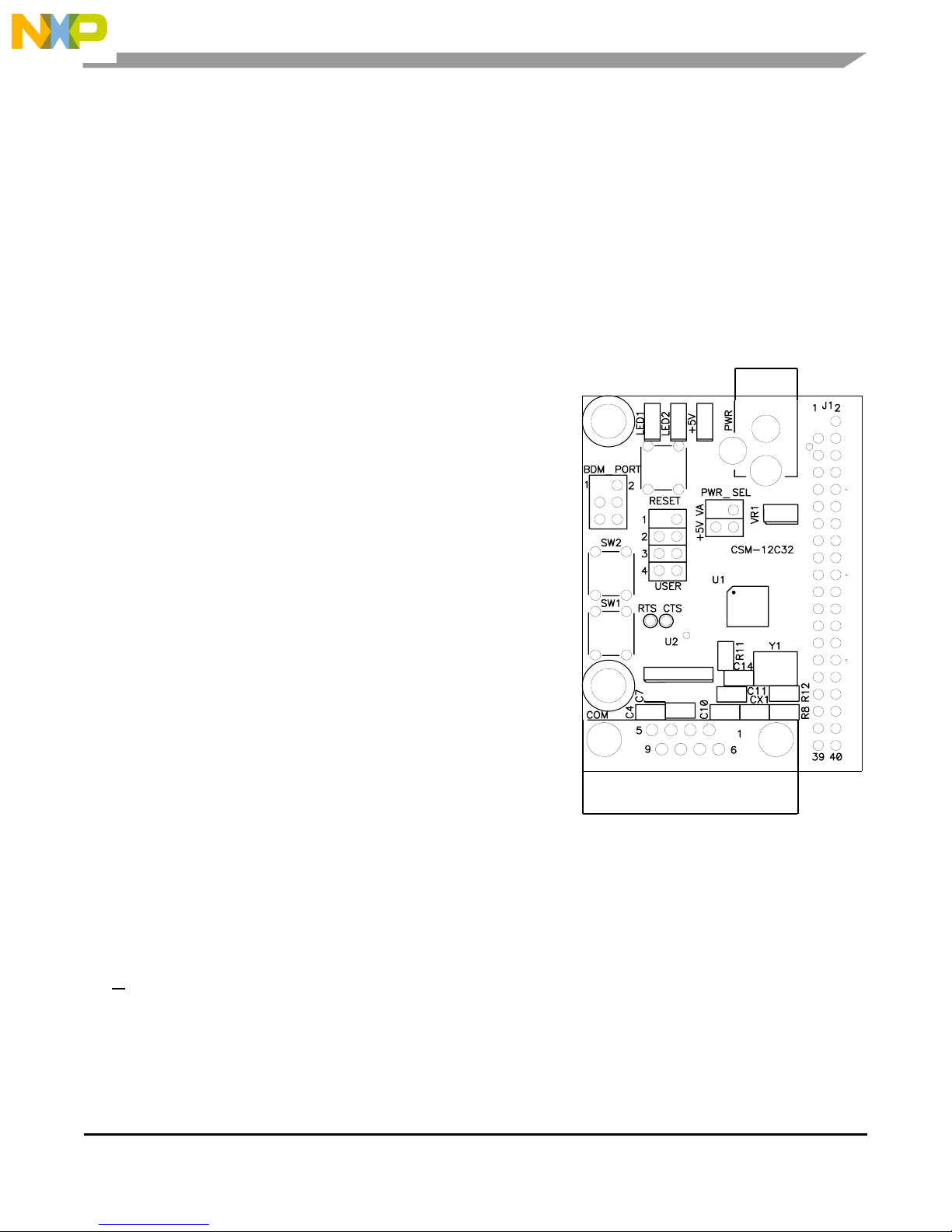

Page 8

Power

Power is supplied to the module through a 2.0mm barrel connector at location PWR for standalone operation. The module may also be powered through connector J1 when connected to

the PBMCUSLK. Power may be sourced off-module through connector J1 to external circuitry.

Power routing on the module is determined by the PWR_SEL jumper.

PWR

The PWR connector accepts a 2.1mm, center-positive, barrel plug that allows the module to be

powered from a wall-plug transformer or from a desktop power supply. Input voltage should be

limited to between +7V and +20V. Input voltage of +9VDC is typical. This input supplies the

on-board +5V regulator that powers the module.

Connector J1

Power may be supplied to the module through the pins J1-1 and J1-2. Use of this option

requires a regulated voltage input limited to the range of +3.3VDC to +5VDC. This input is

connected directly to the module power and ground planes. Care should be exercised not to

over-drive this input. Use of connector J1 to supply +3.3V to the module requires disabling the

voltage supervisor (LV1) by opening cut-trace CT-1. See the Low-Voltage Detect section

below. To re-enable the low-voltage supervisor, install a 1206 sized 0-ohm resistor at CT1.

Connector J1 may also be used to source +5V power from the on-board regulator to external

modules attached to connector J1. The PWR_SEL option header determines how power is

routed to the module.

PWR_SEL Jumper

The PWR_SEL jumper is a 4-position option header that configures power routing on the

APS12C32SLK module. The module may be powered by an external transformer connected

to the PWR connector or through connector J1. The module may also source power to

auxiliary modules connected to the connector J1. Damage may occur if the J1 power input

pins are over-driven. Refer to the Figure 1 to determine correct PWR_SEL jumper setting.

Figure 1: PWR_SEL

1

2

1

2

1

2

8 Freescale Semiconductor

Source power input from barrel connector PWR.

Source power input from connector J1.

Source power from barrel connector PWR and supply power to external

circuitry connected to J1.

Page 9

Reset Switch

The RESET switch provides an asynchronous reset input to the MCU. Pressing the RESET

switch produces a low-voltage level on the RESET input to the MCU. The low-voltage

supervisor (LV1) holds the RESET line low for approximately 150 ms after the pushbutton is

released.

Low-Voltage Detect

A DS1813 (LV1) provides POR, low-voltage detect, and pushbutton reset services for the

module. At power-on, LV1 holds the MCU in reset for 150 ms after VCC reaches approximately

4.35V. During normal operation, LV1 asserts RESET when VCC falls below 4.35V and holds

RESET true for 150 ms after VCC returns to normal. The push-button operation is described

in the paragraph above. Use of connector J1 to supply +3.3V to the module requires disabling

LV1.

LV1 may be disabled by opening the cut-trace CT1. Simply remove the circuit trace between

the cut-trace pads to open the circuit. To restore the circuit functionality, install a 1206 size, 0ohm, resistor or a short piece of wire across the cut-trace pads.

Timing

A ceramic resonator (Y1) provides a 16.0 MHz base operating frequency to the MCU. This

supports a default 8.0 MHz internal operating frequency. Higher frequencies are possible

using the embedded PLL. The resonator output is routed to the MCU only and is not available

at the MCU Port connector (J1). The MCU ECLK output is available to the user at connector

J1 if enabled.

Communications

The APS12C32SLK module provides a single RS-232 communications port. An RS-232

transceiver (U2) provides RS-232 signal level to TTL/CMOS logic level translation. RS232

signals TXD and RXD are routed between the transceiver and the MCU. These signals are

also routed to connector J1. RS-232 communication signals input on J1 must be TTL/CMOS

logic levels; no translation support is provided through this path. The transceiver output may

also be driven off-module if the signals are suitably buffered. As added development support,

hardware flow control signals RTS and CTS are available on the logic side of U2. These

signals are routed to vias located near the transceiver (U2). RTS has been biased properly to

support 2-wire RS-232 communications.

Freescale Semiconductor 9

Page 10

Use of the J1 connector to input RS-232 signals requires disabling the on-board RS-232

transceiver. Otherwise, signal corruption may occur. Disabling the on-board transceiver is

accomplished by opening cut-traces CT1, and CT2. Simply remove the circuit trace between

the cut-trace pads to open the circuit. To restore the circuit functionality, install a 1206 size, 0ohm, resistor or a short piece of wire across the cut-trace pads.

Table 1: Serial COM Signals

COM Signal MCU Port Connector Disable

TXD PS1/TXD J1-5 CT5

RXD PS0/RXD J1-7 CT4

COM Connector

A standard 9-pin D- Sub connector provides external connections for the COM port. The COM

port is configured as a DCE device. Component U2 provides RS-232 translation services.

The figure below shows the DB9 connector.

Figure 2: COM Connector

TXD

RXD

GND

1

2

3

4

5

6

7

8

9

RTS

CTS

NC

Female DB9 connector that interfaces to the DCE serial port via an

RS232 transceiver. It provides simple 2-wire asynchronous serial

communications without flow control. A straight-through serial cable may

be connected to a DTE device such a PC

Pins 1, 4, and 6 are connected together.

10 Freescale Semiconductor

Page 11

Connector J1

Connector J1 provides access to APS12C32SLK I/O port signals.

Figure 3: MCU_PORT Connector

V

GND

PS1/TXD

PS0/RXD

PP5/KWP5

PE0/XIRQ*

PT0/PW0/IOC0

PT1/PW1/IOC1

PM4/MOSI

PM2/MISO

PM5/SCK

PM3/SS*

PE4/ELCK

PE7/XCLKS

PAD02/AN02

PAD03/AN03

PAD04/AN04

PAD05/AN05

PAD06/AN06

PAD07/AN07

1 2

x

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

PE1/IRQ* Default Signal Assignments

RESET* MCU PORT Signal Disable

MODC/BKGD

NC PS1/TXD COM1 TXD CT-5

NC PS0/RXD COM1 RXD CT-4

NC PE1/IRQ* SW1 User1

NC PP5/KWP5 SW2 User2

NC PA0 LED1 User3

PAD00/AN00 PB4 LED2 User4

PAD01/AN01

PB4

PA0

PM1/TXCAN

PM0/RXCAN

PT2/PW2/IOC2

PT3/PW3/IOC3

PT4/PW04/IOC4

PT5/IOC5

PT6/IOC6

PT7/IOC7

Note: Default signal assignment should be

disabled to use the signal at connector J1

User Options

User options include 2 LED’s, and 2 pushbutton switches. Each user option may be enabled

individually using the USER option header. When the appropriate USER option jumper is

installed, the associated user option is enabled. Removing a jumper disables the associated

user option.

Table 2: User Option Jumper Settings

Jumper On Off MCU Signal

User 1 Enable SW1 Disable SW1 PE0/XIRQ*

User 2 Enable SW2 Disable SW2 PP5 /KWP5

User 3 Enable LED1 Disable LED1 PA0

User 4 Enable LED2 Disable LED2 PB4

Switches

Two push button switches provide momentary, active low, input to the MCU for user

applications. Pressing a switch provides a momentary low logic level input tot the MCU. SW1

and SW2 provide input to MCUI/O ports PE0 and PP5 respectively.

Freescale Semiconductor

11

Page 12

LED’s

Two LED’s provide active-low, visual output for user applications. A low voltage level driven

out on the appropriate MCU port causes the LED to light. MCU ports PA0 and PB4 drive

LED1 and LED2 respectively.

Development Support

The APS12C32SLK ships from the factory with a serial monitor installed in FLASH. An ASCII

monitor is also installed to provide quick and easy debug access to the user. The text monitor

is available out of RESET. The serial monitor is available by pressing and holding SW1 as the

module exits RESET. In the discussion below, the terms text and ASCII are used

interchangeably.

ASCII Monitor Operation

The debug monitor provides a simple application development platform for developing

application code. The debug monitor allows the user to quickly and easily develop and debug

RAM based application code.

The debug monitor is accessible through the COM port using an ASCII terminal program such

as HyperTerminal or AxIDE. The terminal should be configured for 9600, 8, N, 1 with no flowcontrol. The monitor relocates the hardware interrupt vector table from 0xFF8A:0xFFFF to

0X0F8A:0x0FFF(see Table 3 below). The vectors remain in the same order as the default

hardware table. The Reset vector is reserved; user should use autostart to start applications

from reset.

ASCII Monitor Memory Map

Table 3: Monitor Memory Map

$0000 $03FF

Reserved

$0800 $0DFF

$0E00 $0F8B

$0F8A $0FFF

Reserved

$8000 $BFFF

$C000 $FFFF

Registers 1K bytes

Internal RAM. 1.5K bytes

Monitor Reserved

Relocated Interrupt Vector Table

User Program Memory 16K bytes

Protected Monitor Space 16K bytes

512 bytes

12 Freescale Semiconductor

Page 13

Monitor Commands

Table 4: Monitor Commands

BF <StartAddress> <EndAddress> [<data>] Block Fill memory range with data

BR [<Address>] Set/Display user breakpoints

CALL [<Address>] Call user subroutine at <Address>

GO [<Address>] Begin/continue execution of user code

HELP Display the Mon12 command summary

LOAD [P] Load S-Records into memory, P = Paged S2

MD <StartAddress> [<EndAddress>] Memory Display Bytes

MM <Address> Modify Memory Bytes (8 bit values)

MW <Address> Modify memory Words (16 bit values)

MOVE <StartAddress> <EndAddress>

<DestAddress>

RD Display all CPU registers

OFFSET – [arg] Offset for download

Proceed Continue program execution

RM Modify CPU Register Contents

STOPAT <Address> Trace until address

T [<count>] Trace <count> instructions

Move a block of memory

NOTE: Items in Italics are not implemented at this time.

Interrupt Support

All interrupt services under are provided through the relocated vector table, see Table 5 below.

Each location in the table is initialized to a value of $0000 to cause the trap of an unscheduled

interrupt. Any nonzero value will allow the interrupt to proceed to the user's service routine

that should be located at the address indicated. The interrupt service delay is +21 cycles over

the standard interrupt service.

To use vectors specified in the table, the user must insert the address of the interrupt service

routine during software initialization into the ram interrupt table. For an example, for the IRQ

vector, the following is performed:

Example: IRQ Service routine label = IRQ_SRV

Ram Vector Table address is defined in table below, IRQ vector definition:

VIRQ EQU $0FF2 ; define ram table vector location

Place IRQ service routine address in the table:

MOVW #IRQ_SRV,VIRQ

This vector initialization will remain in effect until a RESET is invoked.

Freescale Semiconductor

13

Page 14

Interrupt Vector Table

Table 5: MON12 Interrupt Vector Table

Ram Interrupt Vector

Address

MCU Interrupt Vector

Address

TRAP code Vector

Source

0F8A FF8A 02 LVI

0F8C FF8C 04 PWME

0F8E FF8E 06 PTPI

0F90 FF90 08 C4TX

0F92 FF92 0A C4RX

0F94 FF94 0C C4ERR

0F96 FF96 0E C4WU

0F98 FF98 10 C3TX

0F9A FF9A 12 C3RX

0F9C FF9C 14 C3ERR

0F9E FF9E 16 C3WU

0FA0 FFA0 18 C2TX

0FA2 FFA2 1A C2RX

0FA4 FFA4 1C C2ERR

0FA6 FFA6 1E C2WU

0FA8 FFA8 20 C1TX

0FAA FFAA 22 C1RX

0FAC FFAC 24 C1ERR

0FAE FFAE 26 C1WU

0FB0 FFB0 28 C0TX

0FB2 FFB2 2A C0RX

0FB4 FFB4 2C C0ERR

0FB6 FFB6 2E C0WU

0FB8 FFB8 30 FEPRG

0FBA FFBA 32 EEPRG

0FBC FFBC 34 SPI2

0FBE FFBE 36 SPI1

0FC0 FFC0 38 I2C

0FC2 FFC2 3A BDLC

0FC4 FFC4 3C CRGC

0FC6 FFC6 3E CRGL

0FC8 FFC8 40 PACBO

0FCA FFCA 42 MCNT

0FCC FFCC 44 PTHI

0FCE FFCE 46 PTJI

0FD0 FFD0 48 ADC1

0FD2 FFD2 4A ADC0

0FD4 FFD4 4C SCI1

0FD6 FFD6 4E SCI0

0FD8 FFD8 50 SPI0

0FDA FFDA 52 PACAI

0FDC FFDC 54 PACAO

0FDE FFDE 56 TOF

0FE0 FFE0 58 TC7

0FE2 FFE2 5A TC6

14 Freescale Semiconductor

Page 15

Ram Interrupt Vector

Address

0FE6 FFE6 5E TC4

0FE8 FFE8 60 TC3

0FEA FFEA 62 TC2

0FEC FFEC 64 TC1

0FEE FFEE 66 TC0

0FF0 FFF0 68 RTI

0FF2 FFF2 6A IRQ

0FF4 FFF4 6C XIRQ

0FF6 FFF6 6E SWI

0FF8 FFF8 70 TRAP

0FFA FFFA 72 COP

0FFC FFFC 74 CLM

0FFE FFFE 76 RESERVED

MCU Interrupt Vector

Address

TRAP code Vector

Source

Serial Monitor Operation

A serial binary monitor is loaded in the MCU internal flash memory. Press and hold SW1 while

pressing the RESET button or applying power. This section provides a brief description of this

serial monitor operation. Refer to application note AN2548 for complete details on the serial

monitor operation. This application note may be found on the Support CD received with the

module or from the Freescale web site.

Serial Monitor Memory Map

Table 6: Serial Monitor Memory Map

0x0000 –

0x03FF

Reserved

0x3800 –

0x3FFF

0x8000 –

0xBFFF

0xC000 –

0xF77F

0xF780 –

0xF7FF

0xF800 –

0xFFFF

NOTE: Although the monitor does not support external memory, the user can enable external

memory accesses in the unfilled areas of the memory map.

The 2K-byte serial monitor program provides an RS-232 serial interface to a host PC. Serial

data rate is 115.2K bps. The monitor is compatible with Metrowerks CodeWarrior

Registers 1K bytes

Internal RAM

(Relocated)

Reserved

Fixed Flash EEPROM Block 1

(visible at RESET)

Fixed Flash EEPROM Block 2

User Vectors (Relocated)

User Reset Vector F7FE:F7FF

Vectors (Protected)

2K bytes

16K bytes

13.8K bytes

2.12K bytes

Freescale Semiconductor

15

Page 16

Development Studio and other serial monitor interface IDE’s. The serial monitor is not

compatible with ASCII interface programs such as HyperTerm or AxIDE. The monitor supports

23 primitive commands to control the target MCU. To allow a user to specify the address of

each interrupt service routine, this monitor redirects interrupt vectors to an unprotected portion

of FLASH.

To boot to the serial monitor, the user simply pressed and holds SW1 while pressing the

RESET switch or applying power. The status of SW1 is read only during the rising edge of

RESET. To load user application on start-up, the user is responsible for programming the

pseudo-reset vector (0xF7FE:0xF7FF). Pressing SW1 after the MCU exits reset will not

access the serial monitor. After exiting reset, pressing SW1 has effect as defined in the user

application.

BDM_PORT Header

BDM access is gained through the BDM_PORT header. This is a 6-pin header that allows

connection of a compatible HCS12 BDM cable. Refer to the documentation for the specific

BDM cable used for details on its use. The figure below shows the pin-out for the DEBUG

header.

Figure 4: BDM_PORT

MODC/BKGD

1 2

3 4

5 6

GND

RESET*

VDD

See the HC12 Reference Manual for complete

DEBUG documentation

16 Freescale Semiconductor

Page 17

f

A

How to Reach Us:

Home Page:

www.freescale.com

E-mail:

support@freescale.com

USA/Europe or Locations Not Listed:

Freescale Semiconductor

Technical Information Center, CH370

1300 N. Alma School Road

Chandler, Arizona 85224

+1-800-521-6274 or +1-480-768-2130

support@freescale.com

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

support@freescale.com

:

Japan

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064, Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSeminconductor@hibbertgroup.com

Design and/or Manufacturing services for this

product provided by:

Axiom Manufacturing

2813 Industrial Lane

Garland, Tx. 75041

Phone: 972-926-9303

Web: www.axman.com

Email: sales@axman.com

Information in this document is provided solely to enable system and

software implementers to use Freescale Semiconductor products. There are

no express or implied copyright licenses granted hereunder to design or

fabricate any integrated circuits or integrated circuits based on the

information in this document.

Freescale Semiconductor reserves the right to make changes without further

notice to any products herein. Freescale Semiconductor makes no warranty,

representation or guarantee regarding the suitability of its products for any

particular purpose, nor does Freescale Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation consequential or

incidental damages. “Typical” parameters that may be provided in Freescale

Semiconductor data sheets and/or specifications can and do vary in different

applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer

application by customer’s technical experts. Freescale Semiconductor does

not convey any license under its patent rights nor the rights of others.

Freescale Semiconductor products are not designed, intended, or authorized

for use as components in systems intended for surgical implant into the

body, or other applications intended to support or sustain life, or for any

other application in which the failure of the Freescale Semiconductor product

could create a situation where personal injury or death may occur. Should

Buyer purchase or use Freescale Semiconductor products for any such

unintended or unauthorized application, Buyer shall indemnify and hold

Freescale Semiconductor and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses,

and reasonable attorney fees arising out of, directly or indirectly, any claim o

personal injury or death associated with such unintended or unauthorized

use, even if such claim alleges that Freescale Semiconductor was negligent

regarding the design or manufacture of the part.

Freescale™ and the Freescale logo are trademarks of Freescale

Semiconductor, Inc.

ll other product or service names are the property of their respective

owners.

© Freescale Semiconductor, Inc. 2006. All rights reserved.

SLK0101UG

Rev. 0

09/2006

Loading...

Loading...