Page 1

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

Rev. 08 — 22 October 2009 Product data sheet

1. General description

The PCA9555 is a 24-pin CMOS device that provides 16 bits of General Purpose parallel

Input/Output (GPIO) expansion for I2C-bus/SMBus applications and was developed to

enhance the NXP Semiconductors family of I2C-bus I/O expanders. The improvements

include higher drive capability, 5 V I/O tolerance, lower supply current, individual I/O

configuration, and smaller packaging. I/O expanders provide a simple solution when

additional I/O is needed for ACPI power switches, sensors, push buttons, LEDs, fans, etc.

The PCA9555consists of two 8-bit Configuration (Input or Output selection); Input, Output

and Polarity Inversion (active HIGH or active LOW operation) registers. The system

master can enable the I/Os as either inputs or outputs by writing to the I/O configuration

bits. The data for each Input or Output is kept in the corresponding Input or Output

register. The polarity of the read register can be inverted with the Polarity Inversion

register. All registers can be read by the system master. Although pin-to-pin and I2C-bus

address compatible with the PCF8575, software changes are required due to the

enhancements, and are discussed in

Application Note AN469

.

2. Features

The PCA9555 open-drain interrupt output is activated when any input state differs from its

corresponding input port register state and is used to indicate to the system master that

an input state has changed. The power-on reset sets the registers to their default values

and initializes the device state machine.

Three hardware pins (A0, A1, A2) vary the fixed I2C-bus address and allow up to eight

devices to share the same I2C-bus/SMBus. The fixed I2C-bus address of the PCA9555 is

the same as the PCA9554, allowing up to eight of these devices in any combination to

share the same I2C-bus/SMBus.

n Operating power supply voltage range of 2.3 V to 5.5 V

n 5 V tolerant I/Os

n Polarity Inversion register

n Active LOW interrupt output

n Low standby current

n Noise filter on SCL/SDA inputs

n No glitch on power-up

n Internal power-on reset

n 16 I/O pins which default to 16 inputs

n 0 Hz to 400 kHz clock frequency

n ESD protection exceeds 2000 V HBM per JESD22-A114, 200 V MM per

JESD22-A115, and 1000 V CDM per JESD22-C101

Page 2

NXP Semiconductors

n Latch-up testing is done to JEDEC Standard JESD78 which exceeds 100 mA

n Six packages offered: DIP24, SO24, SSOP24, TSSOP24, HVQFN24 and HWQFN24

3. Ordering information

Table 1. Ordering information

Type number Package

PCA9555N DIP24 plastic dual in-line package; 24 leads (600 mil) SOT101-1

PCA9555D SO24 plastic small outline package; 24 leads;

PCA9555DB SSOP24 plastic shrink small outline package; 24 leads;

PCA9555PW TSSOP24 plastic thin shrink small outline package; 24 leads;

PCA9555BS HVQFN24 plastic thermal enhanced very thin quad flat package;

PCA9555HF HWQFN24 plastic thermal enhanced very very thin quad flat

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

Name Description Version

SOT137-1

body width 7.5 mm

SOT340-1

body width 5.3 mm

SOT355-1

body width 4.4 mm

SOT616-1

no leads; 24 terminals; body 4 × 4 × 0.85 mm

SOT994-1

package; no leads; 24 terminals; body 4 × 4 × 0.75 mm

3.1 Ordering options

Table 2. Ordering options

Type number Topside mark Temperature range

PCA9555N PCA9555 −40 °C to +85 °C

PCA9555D PCA9555D −40 °C to +85 °C

PCA9555DB PCA9555 −40 °C to +85 °C

PCA9555PW PCA9555 −40 °C to +85 °C

PCA9555BS 9555 −40 °C to +85 °C

PCA9555HF P55H −40 °C to +85 °C

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 2 of 34

Page 3

NXP Semiconductors

4. Block diagram

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

PCA9555

A0

A1

A2

SCL

SDA

V

DD

V

SS

INPUT

FILTER

POWER-ON

RESET

Remark: All I/Os are set to inputs at reset.

Fig 1. Block diagram of PCA9555

I2C-BUS/SMBus

CONTROL

8-bit

write pulse

read pulse

8-bit

write pulse

read pulse

INPUT/

OUTPUT

PORTS

INPUT/

OUTPUT

PORTS

LP filter

002aac702

IO1_0

IO1_1

IO1_2

IO1_3

IO1_4

IO1_5

IO1_6

IO1_7

IO0_0

IO0_1

IO0_2

IO0_3

IO0_4

IO0_5

IO0_6

IO0_7

V

DD

INT

5. Pinning information

5.1 Pinning

INT

IO0_0

IO0_1

IO0_2

IO0_3

IO0_4

IO0_5

IO0_6

IO0_7

V

A1

A2

SS

1

2

3

4

5

6

7

8

9

10

11

12

PCA9555N

002aac697

24

V

DD

23

SDA

22

SCL

21

A0

20

IO1_7

19

IO1_6

18

IO1_5

17

IO1_4

16

IO1_3

15

IO1_2

14

IO1_1

13

IO1_0

1

INT V

2

A1 SDA

3

A2 SCL

4

IO0_0 A0

5

IO0_1 IO1_7

6

IO0_2 IO1_6

IO0_3 IO1_5

IO0_4 IO1_4

IO0_5 IO1_3

IO0_6 IO1_2

IO0_7 IO1_1

V

SS

7

8

9

10

11

12

PCA9555D

002aac698

Fig 2. Pin configuration for DIP24 Fig 3. Pin configuration for SO24

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 3 of 34

24

DD

23

22

21

20

19

18

17

16

15

14

13

IO1_0

Page 4

NXP Semiconductors

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

INT

A1

A2

IO0_0

IO0_1

IO0_2

IO0_3

IO0_4

IO0_5

IO0_6

IO0_7

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

PCA9555DB

002aac699

24

V

DD

23

SDA

22

SCL

21

A0

20

IO1_7

19

IO1_6

18

IO1_5

17

IO1_4

16

IO1_3

15

IO1_2

14

IO1_1

13

IO1_0

INT

A1

A2

IO0_0

IO0_1

IO0_2

IO0_3

IO0_4

IO0_5

IO0_6

IO0_7

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

PCA9555PW

002aac700

24

V

DD

23

SDA

22

SCL

21

A0

20

IO1_7

19

IO1_6

18

IO1_5

17

IO1_4

16

IO1_3

15

IO1_2

14

IO1_1

13

IO1_0

Fig 4. Pin configuration for SSOP24 Fig 5. Pin configuration for TSSOP24

8

IO0_7

9

SS

V

DD

SDA

V

101112

IO1_0

IO1_1

SCL

19

18

14

13

IO1_2

IO1_4

IO1_3

002aac881

terminal 1

index area

IO0_0 A0

IO0_1 IO1_7

IO0_2 IO1_6

IO0_3 IO1_5

IO0_4

IO0_5

A2

2423222120

1

2 17

3 16

PCA9555BS

4 15

5

6

789

IO0_6

Transparent top view

A1

IO0_7

INT

SS

V

DD

SDA

V

101112

IO1_0

IO1_1

SCL

19

18

14

13

IO1_2

IO1_4

IO1_3

002aac701

terminal 1

index area

IO0_0 A0

IO0_1 IO1_7

IO0_2 IO1_6

IO0_3 IO1_5

IO0_4

IO0_5

A2A1INT

2423222120

1

2 17

3 16

PCA9555HF

4 15

5

6

7

IO0_6

Transparent top view

Fig 6. Pin configuration for HVQFN24 Fig 7. Pin configuration for HWQFN24

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 4 of 34

Page 5

NXP Semiconductors

5.2 Pin description

Table 3. Pin description

Symbol Pin Description

INT 1 22 interrupt output (open-drain)

A1 2 23 address input 1

A2 3 24 address input 2

IO0_0 4 1 port 0 input/output

IO0_1 5 2

IO0_2 6 3

IO0_3 7 4

IO0_4 8 5

IO0_5 9 6

IO0_6 10 7

IO0_7 11 8

V

SS

IO1_0 13 10 port 1 input/output

IO1_1 14 11

IO1_2 15 12

IO1_3 16 13

IO1_4 17 14

IO1_5 18 15

IO1_6 19 16

IO1_7 20 17

A0 21 18 address input 0

SCL 22 19 serial clock line

SDA 23 20 serial data line

V

DD

[1] HVQFN and HWQFN package die supply ground is connected to both the VSSpin and the exposed center

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

DIP24, SO24,

SSOP24, TSSOP24

12 9

24 21 supply voltage

pad. The VSS pin must be connected to supply ground for proper device operation. For enhanced thermal,

electrical, and board-level performance, the exposed pad needs to be soldered to the board using a

corresponding thermal pad on the board, and for proper heat conduction through the board thermal vias

need to be incorporated in the PCB in the thermal pad region.

HVQFN24,

HWQFN24

[1]

supply ground

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 5 of 34

Page 6

NXP Semiconductors

6. Functional description

Refer to Figure 1 “Block diagram of PCA9555”.

6.1 Device address

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

slave address

Fig 8. PCA9555 device address

6.2 Registers

6.2.1 Command byte

The command byte is the first byte to follow the address byte during a write transmission.

It is used as a pointer to determine which of the following registers will be written or read.

Table 4. Command byte

Command Register

0 Input port 0

1 Input port 1

2 Output port 0

3 Output port 1

4 Polarity Inversion port 0

5 Polarity Inversion port 1

6 Configuration port 0

7 Configuration port 1

0 1 0 0 A2 A1 A0

fixed

programmable

002aac219

R/W

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 6 of 34

Page 7

NXP Semiconductors

6.2.2 Registers 0 and 1: Input port registers

This register is an input-only port. It reflects the incoming logic levels of the pins,

regardless of whether the pin is defined as an input or an output by Register 3. Writes to

this register have no effect.

The default value ‘X’ is determined by the externally applied logic level.

Table 5. Input port 0 Register

Bit 7 6 5 4 3 2 1 0

Symbol I0.7 I0.6 I0.5 I0.4 I0.3 I0.2 I0.1 I0.0

Default XXXXXXXX

Table 6. Input port 1 register

Bit 7 6 5 4 3 2 1 0

Symbol I1.7 I1.6 I1.5 I1.4 I1.3 I1.2 I1.1 I1.0

Default XXXXXXXX

6.2.3 Registers 2 and 3: Output port registers

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

This register is an output-only port. It reflects the outgoing logic levels of the pins defined

as outputs by Registers 6 and 7. Bit values in this register have no effect on pins defined

as inputs. In turn, reads from this register reflect the value that is in the flip-flop controlling

the output selection, not the actual pin value.

Table 7. Output port 0 register

Bit 7 6 5 4 3 2 1 0

Symbol O0.7 O0.6 O0.5 O0.4 O0.3 O0.2 O0.1 O0.0

Default 11111111

Table 8. Output port 1 register

Bit 7 6 5 4 3 2 1 0

Symbol O1.7 O1.6 O1.5 O1.4 O1.3 O1.2 O1.1 O1.0

Default 11111111

6.2.4 Registers 4 and 5: Polarity Inversion registers

This register allows the user to invert the polarity of the Input port register data. If a bit in

this register is set (written with ‘1’), the Input port data polarity is inverted. If a bit in this

register is cleared (written with a ‘0’), the Input port data polarity is retained.

Table 9. Polarity Inversion port 0 register

Bit 7 6 5 4 3 2 1 0

Symbol N0.7 N0.6 N0.5 N0.4 N0.3 N0.2 N0.1 N0.0

Default 00000000

Table 10. Polarity Inversion port 1 register

Bit 7 6 5 4 3 2 1 0

Symbol N1.7 N1.6 N1.5 N1.4 N1.3 N1.2 N1.1 N1.0

Default 00000000

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 7 of 34

Page 8

NXP Semiconductors

6.2.5 Registers 6 and 7: Configuration registers

This register configures the directions of the I/O pins. If a bit in this register is set (written

with ‘1’), the corresponding port pin is enabled as an input with high-impedance output

driver. If a bit in this register is cleared (written with ‘0’), the corresponding port pin is

enabled as an output. Note that there is a high value resistor tied to VDD at each pin. At

reset, the device's ports are inputs with a pull-up to VDD.

Table 11. Configuration port 0 register

Bit 7 6 5 4 3 2 1 0

Symbol C0.7 C0.6 C0.5 C0.4 C0.3 C0.2 C0.1 C0.0

Default 11111111

Table 12. Configuration port 1 register

Bit 7 6 5 4 3 2 1 0

Symbol C1.7 C1.6 C1.5 C1.4 C1.3 C1.2 C1.1 C1.0

Default 11111111

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

6.3 Power-on reset

When power is applied to VDD, an internal power-on reset holds the PCA9555 in a reset

condition until VDDhas reached V

. At that point, the reset condition is released and the

POR

PCA9555 registers and SMBus state machine will initialize to their default states. The

power-on reset typically completes the reset and enables the part by the time the power

supply is above V

. However, when it is required to reset the part by lowering the power

POR

supply, it is necessary to lower it below 0.2 V.

6.4 I/O port

When an I/O is configured as an input, FETs Q1 and Q2 are off, creating a

high-impedance input with a weak pull-up to VDD. The input voltage may be raised above

VDD to a maximum of 5.5 V.

If the I/O is configured as an output, then either Q1 or Q2 is on, depending on the state of

the Output Port register. Care should be exercised if an external voltage is applied to an

I/O configured as an output because of the low-impedance path that exists between the

pin and either VDD or VSS.

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 8 of 34

Page 9

NXP Semiconductors

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

data from

shift register

data from

shift register

configuration

write pulse

read pulse

data from

shift register

write polarity

write

pulse

pulse

configuration

register

DQ

FF

CK Q

DQ

FF

CK

output port

register

At power-on reset, all registers return to default values.

Fig 9. Simplified schematic of I/Os

input port

register

DQ

FF

CK

polarity inversion

register

DQ

FF

CK

Q1

100 kΩ

Q2

output port

register data

V

DD

I/O pin

V

SS

input port

register data

to INT

polarity

inversion

register data

002aac703

6.5 Bus transactions

6.5.1 Writing to the port registers

Data is transmitted to the PCA9555 by sending the device address and setting the least

significant bit to a logic 0 (see Figure 8 “PCA9555 device address”). The command byte is

sent after the address and determines which register will receive the data following the

command byte.

The eight registers within the PCA9555 are configured to operate as four register pairs.

The four pairs are Input Ports, Output Ports, Polarity Inversion Ports, and Configuration

Ports. After sending data to one register, the next data byte will be sent to the other

register in the pair (see Figure 10 and Figure 11). For example, if the first byte is sent to

Output Port 1 (register 3), then the next byte will be stored in Output Port 0 (register 2).

There is no limitation on the number of data bytes sent in one write transmission. In this

way, each 8-bit register may be updated independently of the other registers.

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 9 of 34

Page 10

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 10 of 34

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

NXP Semiconductors

SCL

slave address

SDA A

write to port

data out

from port 0

data out

from port 1

1 0 0 A2 A1 A0 0 AS0

START condition R/W acknowledge

Fig 10. Write to Output port registers

SCL

slave address

SDA A P

1 0 0 A2 A1 A0 0 AS0

987654321

987654321

from slave

00001100

command byte

00000100

command byte

A

acknowledge

from slave

A

data to port 0

DATA 0

data to register

DATA 0

t

v(Q)

LSBMSB

0.00.7

acknowledge

from slave

data to register

data to port 1

DATA 1 1.01.7

DATA VALID

DATA 1

t

LSBMSB

v(Q)

A

P

A

STOP

condition

002aac220

16-bit I

2

C-bus and SMBus I/O port with interrupt

START condition R/W acknowledge

Fig 11. Write to Configuration registers

from slave

acknowledge

from slave

acknowledge

from slave

STOP

condition

002aac221

PCA9555

Page 11

NXP Semiconductors

6.5.2 Reading the port registers

In order to read data from the PCA9555, the bus master must first send the PCA9555

address with the least significant bit set to a logic 0 (see Figure 8 “PCA9555 device

address”). The command byte is sent after the address and determines which register will

be accessed. After a restart, the device address is sent again, but this time the least

significant bit is set to a logic 1. Data from the register defined by the command byte will

then be sent by the PCA9555 (see Figure 12, Figure 13 and Figure 14). Data is clocked

into the register on the falling edge of the acknowledge clock pulse. After the first byte is

read, additional bytes may be read but the data will now reflect the information in the other

register in the pair. For example, if you read Input Port 1, then the next byte read would be

Input Port 0. There is no limitation on the number of data bytes received in one read

transmission but the final byte received, the bus master must not acknowledge the data.

slave address

SDA

1 0 0 A2 A1 A00 0

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

AS

COMMAND BYTE

(cont.)

A

START condition R/W

slave address

(cont.)

S

1 0 0 A2 A1 A0 1 A0

(repeated)

START condition

Remark: Transfer can be stopped at any time by a STOP condition.

Fig 12. Read from register

acknowledge

from slave

R/W

acknowledge

from slave

acknowledge

from slave

data from lower or

upper byte of register

LSBMSB

DATA (first byte)

at this moment master-transmitter becomes master-receiver

and slave-receiver becomes slave-transmitter

A P

acknowledge

from master

data from upper or

lower byte of register

DATA (last byte)

no acknowledge

LSBMSB

from master

NA

STOP

condition

002aac222

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 11 of 34

Page 12

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 12 of 34

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

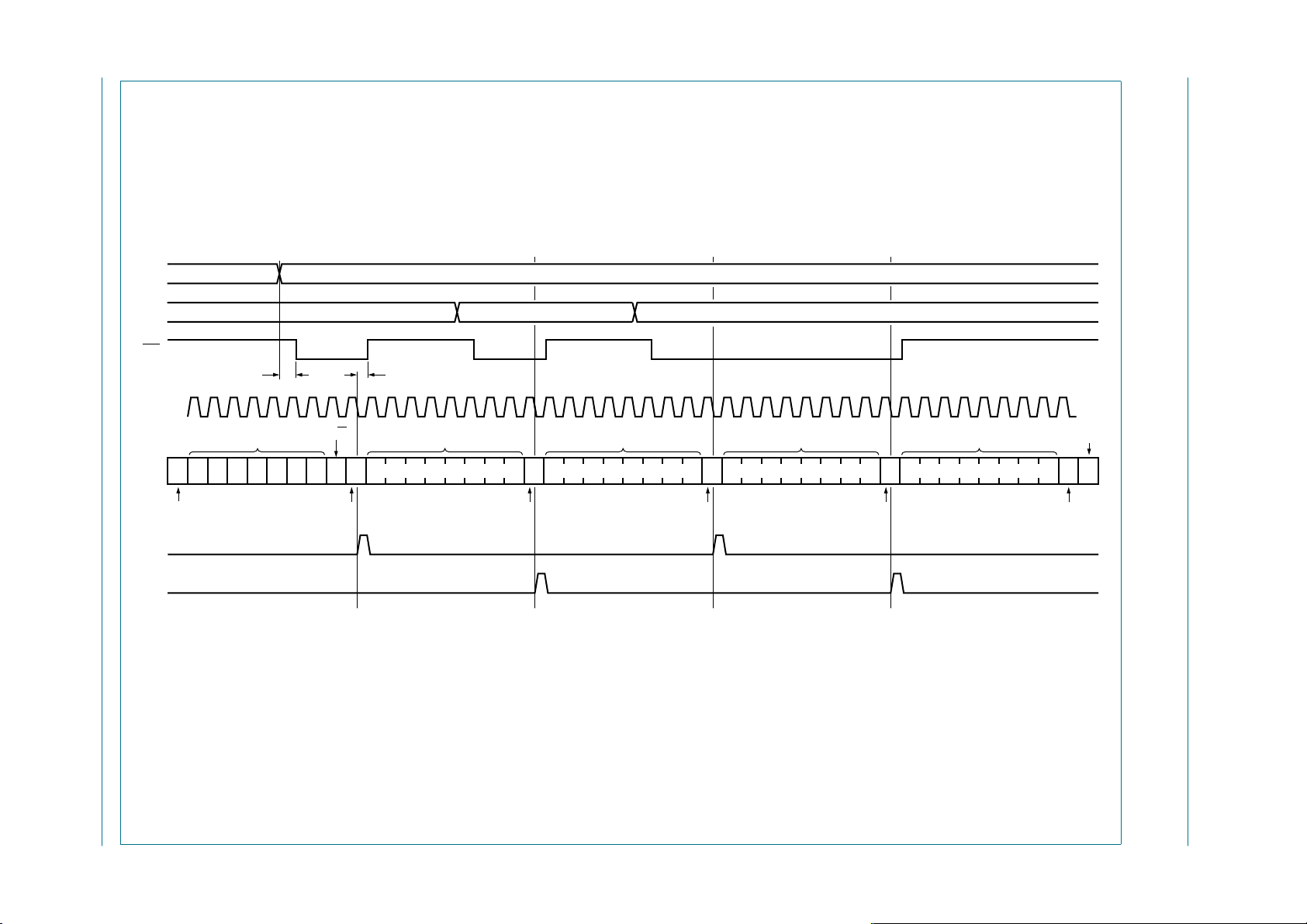

data into port 0

data into port 1

INT

INT

t

v(INT_N)

t

rst(INT_N)

NXP Semiconductors

SCL

SDA A

read from port 0

read from port 1

1 0 0 A2 A1 A0 1 AS0

START condition

acknowledge

R/W

from slave

987654321

I0.xslave address

65432107 65432107 65432107 65432107

acknowledge

from master

A

I1.x

acknowledge

from master

Remark: Transfer of data can be stopped at any moment by a STOP condition. When this occurs, data present at the latest acknowledge phase is valid (output mode). It

is assumed that the command byte has previously been set to ‘00’ (read Input Port register).

Fig 13. Read Input port register, scenario 1

I0.x

A

A

I1.x

STOP condition

1

P

16-bit I

acknowledge

from master

non acknowledge

from master

002aac223

2

C-bus and SMBus I/O port with interrupt

PCA9555

Page 13

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 13 of 34

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

NXP Semiconductors

data into port 0

data into port 1

INT

t

v(INT_N)

SCL

SDA A

read from port 0

read from port 1

1 0 0 A2 A1 A0 1 AS0

START condition

DATA 00 DATA 01

t

h(D)

DATA 10 DATA 11 DATA 12

t

rst(INT_N)

987654321

R/W

acknowledge

from slave

I0.xslave address

DATA 00 DATA 10 DATA 03 DATA 12

acknowledge

from master

DATA 02

t

su(D)

t

h(D)

I1.x

A

acknowledge

from master

DATA 03

t

su(D)

I0.x

A

A

I1.x

STOP condition

1

P

16-bit I

acknowledge

from master

non acknowledge

from master

002aac224

2

C-bus and SMBus I/O port with interrupt

PCA9555

Remark: Transfer of data can be stopped at any moment by a STOP condition. When this occurs, data present at the latest acknowledge phase is valid (output mode). It

is assumed that the command byte has previously been set to ‘00’ (read Input Port register).

Fig 14. Read Input port register, scenario 2

Page 14

NXP Semiconductors

6.5.3 Interrupt output

The open-drain interrupt output is activated when one of the port pins changes state and

the pin is configured as an input. The interrupt is deactivated when the input returns to its

previous state or the Input Port register is read (see Figure 13). A pin configured as an

output cannot cause an interrupt. Since each 8-bit port is read independently,the interrupt

caused by Port 0 will not be cleared by a read of Port 1 or the other way around.

Remark: Changing an I/O from an output to an input may cause a false interrupt to occur

if the state of the pin does not match the contents of the Input Port register.

7. Characteristics of the I2C-bus

The I2C-bus is for 2-way, 2-line communication between different ICs or modules. The two

lines are a serial data line (SDA) and a serial clock line (SCL). Both lines must be

connected to a positive supply via a pull-up resistor when connected to the output stages

of a device. Data transfer may be initiated only when the bus is not busy.

7.1 Bit transfer

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

One data bit is transferred during each clock pulse. The data on the SDA line must remain

stable during the HIGH period of the clock pulse as changes in the data line at this time

will be interpreted as control signals (see Figure 15).

SDA

SCL

Fig 15. Bit transfer

7.1.1 START and STOP conditions

Both data and clock lines remain HIGH when the bus is not busy. A HIGH-to-LOW

transition of the data line while the clock is HIGH is defined as the START condition (S). A

LOW-to-HIGH transition of the data line while the clock is HIGH is defined as the STOP

condition (P) (see Figure 16).

SDA

data line

stable;

data valid

change

of data

allowed

mba607

SCL

S

START condition

Fig 16. Definition of START and STOP conditions

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 14 of 34

P

STOP condition

mba608

Page 15

NXP Semiconductors

7.2 System configuration

A device generating a message is a ‘transmitter’; a device receiving is the ‘receiver’. The

device that controls the message is the ‘master’ and the devices which are controlled by

the master are the ‘slaves’ (see Figure 17).

SDA

SCL

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

MASTER

TRANSMITTER/

RECEIVER

Fig 17. System configuration

7.3 Acknowledge

The number of data bytes transferred between the START and the STOP conditions from

transmitter to receiver is not limited. Each byte of eight bits is followed by one

acknowledge bit. The acknowledge bit is a HIGH level put on the bus by the transmitter,

whereas the master generates an extra acknowledge related clock pulse.

A slave receiver which is addressed must generate an acknowledge after the reception of

each byte. Also a master must generate an acknowledge after the reception of each byte

that has been clocked out of the slave transmitter. The device that acknowledges has to

pull down the SDA line during the acknowledge clock pulse, so that the SDA line is stable

LOWduring the HIGH period of the acknowledge related clock pulse; set-up time and hold

time must be taken into account.

A master receiver must signal an end of data to the transmitter by not generating an

acknowledge on the last byte that has been clocked out of the slave. In this event, the

transmitter must leave the data line HIGH to enable the master to generate a STOP

condition.

SLAVE

RECEIVER

SLAVE

TRANSMITTER/

RECEIVER

MASTER

TRANSMITTER

MASTER

TRANSMITTER/

RECEIVER

SLAVE

I2C-BUS

MULTIPLEXER

002aaa966

data output

by transmitter

not acknowledge

data output

by receiver

acknowledge

SCL from master

S

START

condition

clock pulse for

acknowledgement

9821

002aaa987

Fig 18. Acknowledgement on the I2C-bus

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 15 of 34

Page 16

NXP Semiconductors

8. Application design-in information

V

DD

(5 V)

V

DD

MASTER

CONTROLLER

SCL

SDA

GND

INT

10 kΩ

10 kΩ10 kΩ 2 kΩ

V

DD

PCA9555

SCL

SDA

INT

A2

A1

A0

IO0_0

IO0_1

IO0_2

IO0_3

IO0_4

IO0_5

IO0_6

IO0_7

IO1_0

IO1_1

IO1_2

IO1_3

IO1_4

IO1_5

IO1_6

IO1_7

V

SS

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

SUB-SYSTEM 1

(e.g., temp sensor)

INT

SUB-SYSTEM 2

(e.g., counter)

RESET

A

ENABLE

10 DIGIT

NUMERIC

KEYPAD

controlled

switch

(e.g., CBT device)

B

SUB-SYSTEM 3

(e.g., alarm system)

ALARM

V

DD

Device address configured as 0100 000xb for this example.

IO0_0, IO0_2, IO0_3 configured as outputs.

IO0_1, IO0_4, IO0_5 configured as inputs.

IO0_6, IO0_7, and IO1_0 to IO1_7 configured as inputs.

Fig 19. Typical application

002aac704

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 16 of 34

Page 17

NXP Semiconductors

9. Limiting values

Table 13. Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

DD

V

I/O

I

O

I

I

I

DD

I

SS

P

tot

T

stg

T

amb

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

supply voltage −0.5 +6.0 V

voltage on an input/output pin VSS− 0.5 6 V

output current on an I/O pin - ±50 mA

input current - ±20 mA

supply current - 160 mA

ground supply current - 200 mA

total power dissipation - 200 mW

storage temperature −65 +150 °C

ambient temperature operating −40 +85 °C

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 17 of 34

Page 18

NXP Semiconductors

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

10. Static characteristics

Table 14. Static characteristics

VDD= 2.3 V to 5.5 V; VSS=0V; T

Symbol Parameter Conditions Min Typ Max Unit

Supplies

V

I

I

V

DD

DD

stb

POR

supply voltage 2.3 - 5.5 V

supply current Operating mode; VDD= 5.5 V; no load;

standby current Standby mode; VDD= 5.5 V; no load;

power-on reset voltage

Input SCL; input/output SDA

V

IL

V

IH

I

OL

I

L

C

i

LOW-level input voltage −0.5 - +0.3VDDV

HIGH-level input voltage 0.7V

LOW-level output current VOL= 0.4 V 3 - - mA

leakage current VI=VDD=V

input capacitance VI=V

I/Os

V

V

I

V

I

IL

IH

OL

OH

LIH

LOW-level input voltage −0.5 - +0.3VDDV

HIGH-level input voltage 0.7V

LOW-level output current VDD= 2.3 V to 5.5 V; VOL= 0.5 V

HIGH-level output voltage IOH= −8 mA; VDD= 2.3 V

HIGH-level input leakage

current

I

LIL

LOW-level input leakage

current

C

i

C

o

Interrupt

I

OL

input capacitance - 3.7 5 pF

output capacitance - 3.7 5 pF

INT

LOW-level output current VOL= 0.4 V 3 - - mA

Select inputs A0, A1, A2

V

IL

V

IH

I

LI

LOW-level input voltage −0.5 - +0.3VDDV

HIGH-level input voltage 0.7V

input leakage current −1- +1µA

=−40°C to +85°C; unless otherwise specified.

amb

f

= 100 kHz

SCL

V

Standby mode; V

V

[1]

no load; VI=VDD or V

V

I

OH

I

OH

I

OH

I

OH

I

OH

VDD= 5.5 V; VI=V

VDD= 5.5 V; VI=V

; f

I=VSS

I=VDD

SS

= 2.3 V to 5.5 V; VOL= 0.7 V

DD

= 0 kHz; I/O = inputs

SCL

= 5.5 V; no load;

; f

DD

= 0 kHz; I/O = inputs

SCL

SS

SS

= −10 mA; VDD= 2.3 V

= −8 mA; VDD= 3.0 V

= −10 mA; VDD= 3.0 V

= −8 mA; VDD= 4.75 V

= −10 mA; VDD= 4.75 V

DD

SS

- 135 200 µA

- 1.1 1.5 mA

- 0.25 1 µA

- 1.5 1.65 V

- 5.5 V

DD

−1- +1µA

- 6 10 pF

- 5.5 V

DD

[2]

8 (8 to 20) - mA

[2]

10 (10 to 24) - mA

[3]

1.8 - - V

[3]

1.7 - - V

[3]

2.6 - - V

[3]

2.5 - - V

[3]

4.1 - - V

[3]

4.0 - - V

-- 1µA

-- −100 µA

- 5.5 V

DD

[1] VDD must be lowered to 0.2 V for at least 5 µs in order to reset part.

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 18 of 34

Page 19

NXP Semiconductors

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

[2] Each I/O must be externally limited to a maximum of 25 mA and each octal (IO0_0 to IO0_7 and IO1_0 to IO1_7) must be limited to a

maximum current of 100 mA for a device total of 200 mA.

[3] The total current sourced by all I/Os must be limited to 160 mA.

6.0

V

OH

(V)

5.0

4.0

3.0

2.0

2.7 5.53.6

(1) IOH= −8mA

(2) IOH= −10 mA

002aac706

(1)

(2)

V

(V)

DD

4.5

V

OH

(V)

3.5

2.5

1.5

2.3 4.753.0

(1) IOH= −8mA

(2) IOH= −10 mA

Fig 20. VOH maximum Fig 21. VOH minimum

002aac705

(1)

(2)

(3)

I

DD

(mA)

1.6

1.2

0.8

002aac707

(1)

(2)

V

(V)

DD

0.4

0

VDD= 5.5 V; V

(1) T

amb

(2) T

amb

(3) T

amb

= −40 °C

= +25 °C

= +85 °C

all 1s all 0sone 0 three 0s

= 5.5 V; A2, A1, A0 set to logic 0.

I/O

number of I/Os

Fig 22. IDD versus number of I/Os held LOW

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 19 of 34

Page 20

NXP Semiconductors

16-bit I2C-bus and SMBus I/O port with interrupt

11. Dynamic characteristics

Table 15. Dynamic characteristics

Symbol Parameter Conditions Standard-mode

f

SCL

t

BUF

SCL clock frequency 0 100 0 400 kHz

bus free time between a STOP and

START condition

t

HD;STA

t

SU;STA

hold time (repeated) START condition 4.0 - 0.6 - µs

set-up time for a repeated START

condition

t

SU;STO

t

VD;ACK

t

HD;DAT

t

VD;DAT

t

SU;DAT

t

LOW

t

HIGH

t

f

t

r

t

SP

set-up time for STOP condition 4.0 - 0.6 - µs

data valid acknowledge time

[1]

data hold time 0 - 0 - ns

data valid time

[2]

data set-up time 250 - 100 - ns

LOW period of the SCL clock 4.7 - 1.3 - µs

HIGH period of the SCL clock 4.0 - 0.6 - µs

fall time of both SDA and SCL signals - 300 20 + 0.1C

rise time of both SDA and SCL signals - 1000 20 + 0.1C

pulse width of spikes that must be

suppressed by the input filter

Port timing

t

v(Q)

t

su(D)

t

h(D)

data output valid time - 200 - 200 ns

data input set-up time 150 - 150 - ns

data input hold time 1 - 1 - µs

Interrupt timing

t

v(INT_N)

t

rst(INT_N)

valid time on pin INT - 4 - 4 µs

reset time on pin INT - 4 - 4 µs

2

I

C-bus

Min Max Min Max

4.7 - 1.3 - µs

4.7 - 0.6 - µs

0.3 3.45 0.1 0.9 µs

300 - 50 - ns

- 50 - 50 ns

PCA9555

Fast-mode I2C-bus Unit

[3]

300 ns

b

[3]

300 ns

b

[1] t

[2] t

[3] Cb= total capacitance of one bus line in pF.

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 20 of 34

= time for acknowledgement signal from SCL LOW to SDA (out) LOW.

VD;ACK

= minimum time for SDA data out to be valid following SCL LOW.

VD;DAT

Page 21

NXP Semiconductors

SDA

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

t

BUF

t

LOW

t

r

SCL

t

HD;STA

t

HD;DAT

Fig 23. Definition of timing on the I2C-bus

12. Test information

RL= load resistor.

CL = load capacitance includes jig and probe capacitance.

RT= termination resistance should be equal to the output impedance of Zoof the pulse generators.

Fig 24. Test circuitry for switching times

t

HIGH

PULSE

GENERATOR

t

f

t

SU;DAT

V

t

HD;STA

t

SU;STA

Sr

V

DD

I

V

O

R

500 Ω

t

SP

t

SU;STO

PP S

002aaa986

V

DD

open

GND

L

DUT

C

R

T

L

50 pF

002aab284

from output under test

50 pF

R

L

500 Ω

C

L

R

L

500 Ω

S1

002aac226

2V

open

GND

DD

Fig 25. Load circuit

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 21 of 34

Page 22

NXP Semiconductors

13. Package outline

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

DIP24: plastic dual in-line package; 24 leads (600 mil)

D

seating plane

L

Z

24

pin 1 index

e

b

SOT101-1

M

E

A

2

A

A

1

w M

b

1

13

E

c

(e )

1

M

H

1

0 5 10 mm

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

A

UNIT

inches

Note

1. Plastic or metal protrusions of 0.25 mm (0.01 inch) maximum per side are not included.

max.

mm

OUTLINE

VERSION

SOT101-1

1 2

min.

max.

1.7

1.3

0.066

0.051

IEC JEDEC JEITA

051G02 MO-015 SC-509-24

b

b

0.53

0.38

0.021

0.015

cD E e M

1

0.32

0.23

0.013

0.009

REFERENCES

32.0

31.4

1.26

1.24

scale

12

14.1

13.7

0.56

0.54

(1)(1)

e

L

3.9

3.4

0.15

0.13

EUROPEAN

PROJECTION

M

15.80

15.24

0.62

0.60

E

17.15

15.90

0.68

0.63

1

H

w

0.252.54 15.24

0.010.1 0.6

ISSUE DATE

99-12-27

03-02-13

Z

max.

2.25.1 0.51 4

0.0870.2 0.02 0.16

(1)

Fig 26. Package outline SOT101-1 (DIP24)

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 22 of 34

Page 23

NXP Semiconductors

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

SO24: plastic small outline package; 24 leads; body width 7.5 mm

D

c

y

Z

24

pin 1 index

1

e

13

12

w M

b

p

SOT137-1

E

H

E

Q

A

2

A

1

L

p

L

detail X

(A )

A

X

v M

A

A

3

θ

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT137-1

A

A1A2A3b

max.

0.3

2.65

0.1

0.012

0.1

0.004

p

2.45

2.25

0.096

0.089

IEC JEDEC JEITA

075E05 MS-013

0.25

0.01

0.49

0.36

0.019

0.014

0.32

0.23

0.013

0.009

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm (0.006 inch) maximum per side are not included.

(1)E(1) (1)

cD

15.6

15.2

0.61

0.60

REFERENCES

eHELLpQ

7.6

7.4

0.30

0.29

1.27

0.05

10.65

10.00

0.419

0.394

1.4

0.055

1.1

0.4

0.043

0.016

1.1

1.0

0.043

0.039

0.25

0.01

EUROPEAN

PROJECTION

0.25 0.1

0.01

0.004

ywv θ

Z

0.9

0.4

0.035

0.016

ISSUE DATE

99-12-27

03-02-19

o

8

o

0

Fig 27. Package outline SOT137-1 (SO24)

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 23 of 34

Page 24

NXP Semiconductors

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

SSOP24: plastic shrink small outline package; 24 leads; body width 5.3 mm

D

c

y

Z

24 13

A

2

A

pin 1 index

1

SOT340-1

E

H

E

Q

L

p

L

(A )

A

X

v M

A

A

3

θ

112

w M

b

e

DIMENSIONS (mm are the original dimensions)

UNIT A1A2A3b

Note

1. Plastic or metal protrusions of 0.2 mm maximum per side are not included.

A

max.

0.21

mm

2

OUTLINE

VERSION

SOT340-1 MO-150

0.05

1.80

0.25

1.65

IEC JEDEC JEITA

p

0.38

0.25

p

0 2.5 5 mm

scale

(1)E(1) (1)

cD

0.20

8.4

5.4

0.09

REFERENCES

8.0

0.65 1.25

5.2

eHELLpQZywv θ

7.9

7.6

1.03

0.63

detail X

0.9

0.7

EUROPEAN

PROJECTION

0.13 0.10.2

0.8

0.4

ISSUE DATE

99-12-27

03-02-19

o

8

o

0

Fig 28. Package outline SOT340-1 (SSOP24)

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 24 of 34

Page 25

NXP Semiconductors

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

TSSOP24: plastic thin shrink small outline package; 24 leads; body width 4.4 mm

D

c

y

Z

24

pin 1 index

13

A

2

A

1

112

w M

b

e

p

E

H

E

detail X

SOT355-1

A

X

v M

A

Q

(A )

3

A

θ

L

p

L

0 2.5 5 mm

scale

DIMENSIONS (mm are the original dimensions)

UNIT A1A2A3b

Notes

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

2. Plastic interlead protrusions of 0.25 mm maximum per side are not included.

A

max.

0.15

mm

1.1

OUTLINE

VERSION

SOT355-1 MO-153

0.05

0.95

0.25

0.80

IEC JEDEC JEITA

p

0.30

0.19

(1)E(2) (1)

cD

0.2

7.9

0.1

7.7

REFERENCES

eHELLpQZywv θ

4.5

4.3

0.65

6.6

6.2

0.75

0.50

0.4

0.3

EUROPEAN

PROJECTION

o

0.5

0.13 0.10.21

ISSUE DATE

99-12-27

03-02-19

0.2

8

o

0

Fig 29. Package outline SOT355-1 (TSSOP24)

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 25 of 34

Page 26

NXP Semiconductors

16-bit I2C-bus and SMBus I/O port with interrupt

HVQFN24: plastic thermal enhanced very thin quad flat package; no leads;

24 terminals; body 4 x 4 x 0.85 mm

A

D

terminal 1

index area

B

E

PCA9555

SOT616-1

A

A

1

detail X

c

e

1

e

712

L

6

E

h

1

terminal 1

index area

DIMENSIONS (mm are the original dimensions)

(1)

A

UNIT

mm

Note

1. Plastic or metal protrusions of 0.075 mm maximum per side are not included.

OUTLINE

VERSION

SOT616-1 MO-220 - - -- - -

max.

A

0.05

0.00

1

0.30

0.18

24

(1)

c

b

IEC JEDEC JEITA

D

4.1

3.9

1/2 e

b

13

e

1/2 e

18

D

h

0 2.5 5 mm

D

h

2.25

1.95

19

(1)

E

E

h

4.1

2.25

3.9

1.95

REFERENCES

scale

0.51 0.2

w

v

e

2.5

C

y

C

L

1

w

0.1v0.05

ye

0.05 0.1

EUROPEAN

PROJECTION

M

ACCB

M

e

2

e

1

2

0.5

2.5

0.3

y

X

y

1

ISSUE DATE

01-08-08

02-10-22

Fig 30. Package outline SOT616-1 (HVQFN24)

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 26 of 34

Page 27

NXP Semiconductors

16-bit I2C-bus and SMBus I/O port with interrupt

HWQFN24: plastic thermal enhanced very very thin quad flat package; no leads;

24 terminals; body 4 x 4 x 0.75 mm

PCA9555

SOT994-1

terminal 1

index area

L

E

D

e

1

1/2 e

e

6

h

b

B A

E

M

∅ v

127

M

13

e

1/2 e

A

A

1

detail X

B

AC

C∅ w

e

2

y

C

1

C

y

c

1

terminal 1

index area

DIMENSIONS (mm are the original dimensions)

(1)

A

UNIT

mm 0.8

Note

1. Plastic or metal protrusions of 0.075 mm maximum per side are not included.

OUTLINE

VERSION

SOT994-1 - - -

max

A

0.05

0.00

1

24 19

D

h

0 2.5 5 mm

0.2

D

4.1

3.9

(1)

DhE

2.25

4.1

1.95

3.9

REFERENCES

MO-220

b c

0.30

0.18

IEC JEDEC JEITA

- - -

18

X

scale

(1)

E

e

2.25

1.95

h

e1e

0.5

2.5 2.5 0.1

L

0.5

0.3

v w

0.05y0.05

EUROPEAN

PROJECTION

2

y

0.1

1

ISSUE DATE

07-02-07

07-03-03

Fig 31. Package outline SOT994-1 (HWQFN24)

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 27 of 34

Page 28

NXP Semiconductors

14. Handling information

All input and output pins are protected against ElectroStatic Discharge (ESD) under

normal handling. When handling ensure that the appropriate precautions are taken as

described in

JESD625-A

15. Soldering of SMD packages

This text provides a very brief insight into a complex technology. A more in-depth account

of soldering ICs can be found in Application Note

soldering description”

15.1 Introduction to soldering

Soldering is one of the most common methods through which packages are attached to

Printed Circuit Boards (PCBs), to form electrical circuits. The soldered joint provides both

the mechanical and the electrical connection. There is no single soldering method that is

ideal for all IC packages. Wave soldering is often preferred when through-hole and

Surface Mount Devices (SMDs) are mixed on one printed wiring board; however, it is not

suitable for fine pitch SMDs. Reflow soldering is ideal for the small pitches and high

densities that come with increased miniaturization.

.

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

or equivalent standards.

AN10365 “Surface mount reflow

15.2 Wave and reflow soldering

Wave soldering is a joining technology in which the joints are made by solder coming from

a standing wave of liquid solder. The wave soldering process is suitable for the following:

• Through-hole components

• Leaded or leadless SMDs, which are glued to the surface of the printed circuit board

Not all SMDs can be wave soldered. Packages with solder balls, and some leadless

packages which have solder lands underneath the body, cannot be wave soldered. Also,

leaded SMDs with leads having a pitch smaller than ~0.6 mm cannot be wave soldered,

due to an increased probability of bridging.

The reflow soldering process involves applying solder paste to a board, followed by

component placement and exposure to a temperature profile. Leaded packages,

packages with solder balls, and leadless packages are all reflow solderable.

Key characteristics in both wave and reflow soldering are:

• Board specifications, including the board finish, solder masks and vias

• Package footprints, including solder thieves and orientation

• The moisture sensitivity level of the packages

• Package placement

• Inspection and repair

• Lead-free soldering versus SnPb soldering

15.3 Wave soldering

Key characteristics in wave soldering are:

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 28 of 34

Page 29

NXP Semiconductors

• Process issues, such as application of adhesive and flux, clinching of leads, board

• Solder bath specifications, including temperature and impurities

15.4 Reflow soldering

Key characteristics in reflow soldering are:

• Lead-free versus SnPb soldering; note that a lead-free reflow process usually leads to

• Solder paste printing issues including smearing, release, and adjusting the process

• Reflow temperature profile; this profile includes preheat, reflow (in which the board is

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

transport, the solder wave parameters, and the time during which components are

exposed to the wave

higher minimum peak temperatures (see Figure 32) than a SnPb process, thus

reducing the process window

window for a mix of large and small components on one board

heated to the peak temperature) and cooling down. It is imperative that the peak

temperature is high enough for the solder to make reliable solder joints (a solder paste

characteristic). In addition, the peak temperature must be low enough that the

packages and/or boards are not damaged. The peak temperature of the package

depends on package thickness and volume and is classified in accordance with

Table 16 and 17

Table 16. SnPb eutectic process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (°C)

Volume (mm3)

< 350 ≥ 350

< 2.5 235 220

≥ 2.5 220 220

Table 17. Lead-free process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (°C)

Volume (mm3)

< 350 350 to 2000 > 2000

< 1.6 260 260 260

1.6 to 2.5 260 250 245

> 2.5 250 245 245

Moisture sensitivity precautions, as indicated on the packing, must be respected at all

times.

Studies have shown that small packages reach higher temperatures during reflow

soldering, see Figure 32.

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 29 of 34

Page 30

NXP Semiconductors

Fig 32. Temperature profiles for large and small components

maximum peak temperature

temperature

MSL: Moisture Sensitivity Level

= MSL limit, damage level

minimum peak temperature

= minimum soldering temperature

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

peak

temperature

time

001aac844

For further information on temperature profiles, refer to Application Note

“Surface mount reflow soldering description”

.

16. Soldering of through-hole mount packages

16.1 Introduction to soldering through-hole mount packages

This text gives a very brief insight into wave, dip and manual soldering.

Wave soldering is the preferred method for mounting of through-hole mount IC packages

on a printed-circuit board.

16.2 Soldering by dipping or by solder wave

Driven by legislation and environmental forces the worldwide use of lead-free solder

pastes is increasing. Typical dwell time of the leads in the wave ranges from

3 seconds to 4 seconds at 250 °C or 265 °C, depending on solder material applied, SnPb

or Pb-free respectively.

The total contact time of successive solder waves must not exceed 5 seconds.

The device may be mounted up to the seating plane, but the temperature of the plastic

body must not exceed the specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling may be necessary immediately

after soldering to keep the temperature within the permissible limit.

AN10365

stg(max)

). If the

16.3 Manual soldering

Apply the soldering iron (24 V or less) to the lead(s) of the package, either below the

seating plane or not more than 2 mm above it. If the temperature of the soldering iron bit is

less than 300 °C it may remain in contact for up to 10 seconds. If the bit temperature is

between 300 °C and 400 °C, contact may be up to 5 seconds.

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 30 of 34

Page 31

NXP Semiconductors

16.4 Package related soldering information

Table 18. Suitability of through-hole mount IC packages for dipping and wave soldering

Package Soldering method

CPGA, HCPGA - suitable

DBS, DIP, HDIP, RDBS, SDIP, SIL suitable suitable

PMFP

[1] For SDIP packages, the longitudinal axis must be parallel to the transport direction of the printed-circuit

[2] For PMFP packages hot bar soldering or manual soldering is suitable.

17. Abbreviations

Table 19. Abbreviations

Acronym Description

CMOS Complementary Metal Oxide Semiconductor

GPIO General Purpose Input/Output

2

C-bus Inter-Integrated Circuit bus

I

SMBus System Management Bus

I/O Input/Output

ACPI Advanced Configuration and Power Interface

LED Light Emitting Diode

ESD ElectroStatic Discharge

HBM Human Body Model

MM Machine Model

CDM Charged Device Model

PCB Printed-Circuit Board

FET Field-Effect Transistor

MSB Most Significant Bit

LSB Least Significant Bit

[2]

board.

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

Dipping Wave

[1]

- not suitable

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 31 of 34

Page 32

NXP Semiconductors

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

18. Revision history

Table 20. Revision history

Document ID Release date Data sheet status Change notice Supersedes

PCA9555_8 20091022 Product data sheet - PCA9555_7

Modifications:

PCA9555_7 20070605 Product data sheet - PCA9555_6

PCA9555_6 20060825 Product data sheet - PCA9555_5

PCA9555_5

(9397 750 14125)

PCA9555_4

(9397 750 13271)

PCA9555_3

(9397 750 10164)

PCA9555_2

(9397 750 09818)

PCA9555_1

(9397 750 08343)

• Table 2 “Ordering options”, Topside mark for TSSOP24 package, PCA9555PW, is changed from

“PCA9555PW” to “PCA9555”

• Figure 13 “Read Input port register, scenario 1” modified

• Figure 14 “Read Input port register, scenario 2” modified

• Table 14 “Static characteristics”, Table note [1] modified (added phrase “for at least 5 µs”)

• updated soldering information

20040930 Product data sheet - PCA9555_4

20040727 Product data sheet - PCA9555_3

20020726 Product data 853-2252 28672 of

2002 July 26

20020513 Product data - PCA9555_1

20010507 Product data - -

PCA9555_2

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 32 of 34

Page 33

NXP Semiconductors

19. Legal information

19.1 Data sheet status

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

Document status

Objective [short] data sheet Development This document contains data from the objective specification for product development.

Preliminary [short] data sheet Qualification This document contains data from the preliminary specification.

Product [short] data sheet Production This document contains the product specification.

[1] Please consult the most recently issued document before initiating or completing a design.

[2] The term ‘short data sheet’ is explained in section “Definitions”.

[3] The product status of device(s)described in this document mayhave changedsince thisdocument was published and maydiffer incase ofmultiple devices.The latest productstatus

information is available on the Internet at URL

[1][2]

Product status

19.2 Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. NXP Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information includedherein and shallhave no liabilityfor the consequencesof

use of such information.

Short data sheet — A short data sheet is an extract from a full data sheet

with thesame product typenumber(s) and title.A short data sheetis intended

for quickreference only and shouldnot be relied upon tocontain detailed and

full information. For detailed and full information see the relevant full data

sheet, which is available on request via the local NXP Semiconductors sales

office. In case of any inconsistency or conflict with the short data sheet, the

full data sheet shall prevail.

19.3 Disclaimers

General — Information in this document is believed to be accurate and

reliable. However,NXP Semiconductors does notgive any representationsor

warranties, expressed or implied,as to the accuracyorcompleteness of such

information and shall have no liability for the consequences of use of such

information.

Right to make changes — NXP Semiconductors reserves theright to make

changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. Thisdocumentsupersedes and replaces all information supplied prior

to the publication hereof.

Suitability for use — NXP Semiconductors products are not designed,

authorized or warranted to be suitable for use in medical, military, aircraft,

space or life support equipment, nor in applications where failure or

malfunction of an NXP Semiconductors product can reasonably be expected

to result in personal injury, death or severe property or environmental

[3]

http://www.nxp.com.

Definition

damage. NXP Semiconductors accepts no liability for inclusion and/or use of

NXP Semiconductors products in such equipment or applications and

therefore such inclusion and/or use is at the customer’s own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. NXP Semiconductors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

Limiting values — Stress above one or more limiting values (as defined in

the AbsoluteMaximumRatings System of IEC 60134)may cause permanent

damage tothe device. Limitingvalues are stress ratingsonly and operationof

the device at these or any other conditions above those given in the

Characteristics sections of this document is not implied. Exposure to limiting

values for extended periods may affect device reliability.

Terms and conditions of sale — NXP Semiconductors products are sold

subject to the general terms andconditionsof commercial sale, as published

at

http://www.nxp.com/profile/terms, including those pertaining to warranty,

intellectual property rights infringement and limitation of liability, unless

explicitly otherwise agreed to in writing by NXP Semiconductors. In case of

any inconsistency or conflict between information in this document and such

terms and conditions, the latter will prevail.

No offer to sell or license — Nothing in this document may be interpreted

or construed as an offer to sell products that is open for acceptance or the

grant, conveyance or implicationof any license under anycopyrights, patents

or other industrial or intellectual property rights.

Export control — This document as well as the item(s) described herein

may be subject to export control regulations. Export might require a prior

authorization from national authorities.

19.4 Trademarks

Notice: Allreferenced brands,product names, servicenames and trademarks

are the property of their respective owners.

I2C-bus — logo is a trademark of NXP B.V.

20. Contact information

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

PCA9555_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 22 October 2009 33 of 34

Page 34

NXP Semiconductors

21. Contents

PCA9555

16-bit I2C-bus and SMBus I/O port with interrupt

1 General description. . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Ordering information. . . . . . . . . . . . . . . . . . . . . 2

3.1 Ordering options . . . . . . . . . . . . . . . . . . . . . . . . 2

4 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5 Pinning information. . . . . . . . . . . . . . . . . . . . . . 3

5.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 5

6 Functional description . . . . . . . . . . . . . . . . . . . 6

6.1 Device address. . . . . . . . . . . . . . . . . . . . . . . . . 6

6.2 Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.2.1 Command byte . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.2.2 Registers 0 and 1: Input port registers . . . . . . . 7

6.2.3 Registers 2 and 3: Output port registers. . . . . . 7

6.2.4 Registers 4 and 5: Polarity Inversion registers . 7

6.2.5 Registers 6 and 7: Configuration registers . . . . 8

6.3 Power-on reset . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.4 I/O port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.5 Bus transactions . . . . . . . . . . . . . . . . . . . . . . . . 9

6.5.1 Writing to the port registers . . . . . . . . . . . . . . . 9

6.5.2 Reading the port registers . . . . . . . . . . . . . . . 11

6.5.3 Interrupt output . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Characteristics of the I

2

C-bus. . . . . . . . . . . . . 14

7.1 Bit transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.1.1 START and STOP conditions . . . . . . . . . . . . . 14

7.2 System configuration . . . . . . . . . . . . . . . . . . . 15

7.3 Acknowledge . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Application design-in information . . . . . . . . . 16

9 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . 17

10 Static characteristics. . . . . . . . . . . . . . . . . . . . 18

11 Dynamic characteristics . . . . . . . . . . . . . . . . . 20

12 Test information. . . . . . . . . . . . . . . . . . . . . . . . 21

13 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 22

14 Handling information. . . . . . . . . . . . . . . . . . . . 28

15 Soldering of SMD packages . . . . . . . . . . . . . . 28

15.1 Introduction to soldering . . . . . . . . . . . . . . . . . 28

15.2 Wave and reflow soldering . . . . . . . . . . . . . . . 28

15.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 28

15.4 Reflow soldering . . . . . . . . . . . . . . . . . . . . . . . 29

16 Soldering of through-hole mount packages . 30

16.1 Introduction to soldering through-hole mount

packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

16.2 Soldering by dipping or by solder wave . . . . . 30

16.3 Manual soldering . . . . . . . . . . . . . . . . . . . . . . 30

16.4 Package related soldering information . . . . . . 31

17 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . 31

18 Revision history . . . . . . . . . . . . . . . . . . . . . . . 32

19 Legal information . . . . . . . . . . . . . . . . . . . . . . 33

19.1 Data sheet status . . . . . . . . . . . . . . . . . . . . . . 33

19.2 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

19.3 Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . 33

19.4 Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . 33

20 Contact information . . . . . . . . . . . . . . . . . . . . 33

21 Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section ‘Legal information’.

© NXP B.V. 2009. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: 22 October 2009

Document identifier: PCA9555_8

Loading...

Loading...