Page 1

DB, DBQ, DGV, DW, OR PW PACKAGE

(TOP VIEW)

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

A0

A1

RESET

P0

P1

P2

P3

GND

V

CC

SDA

SCL

INT

P7

P6

P5

P4

RGV PACKAGE

(TOP VIEW)

16

6 8

2

10

P7

P5

V

CC

4

3

1

75

12

11

9

131415

SDA

A0

A1

P6

INT

SCL

P3

GND

P4

RESET

P0

P1

P2

RGT PACKAGE

(TOP VIEW)

16

6 8

2

10

P7

P5

V

CC

4

3

1

75

12

11

9

131415

SDA

A0

A1

P6

INT

SCL

P3

GND

P4

RESET

P0

P1

P2

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

PCA9538 Remote 8-Bit I2C AND SMBus Low-power I/O Expander With Interrupt Output,

Reset, and Configuration Registers

1 Features 2 Description

1

• Low Standby Current Consumption of 1 μA Max

• I2C to Parallel Port Expander

• Open-Drain Active-Low Interrupt Output

• Active-Low Reset Input

• Operating Power-Supply Voltage Range of 2.3 V

to 5.5 V

• 5-V Tolerant I/O Ports

• 400-kHz Fast I2C Bus

• Two Hardware Address Pins Allow up to Four

Devices on the I2C/SMBus

• Input/Output Configuration Register

• Polarity Inversion Register

• Power-Up With All Channels Configured as Inputs

• No Glitch on Power Up

• Noise Filter on SCL/SDA Inputs

• Latched Outputs With High-Current Drive

Maximum Capability for Directly Driving LEDs

• Latch-Up Performance Exceeds 100 mA Per

JESD 78, Class II

• ESD Protection Exceeds JESD 22

– 2000-V Human-Body Model (A114-A)

– 200-V Machine Model (A115-A)

– 1000-V Charged-Device Model (C101)

This 8-bit I/O expander for the two-line bidirectional

bus (I2C) is designed for 2.3-V to 5.5-V V

operation. It provides general-purpose remote I/O

expansion for most microcontroller families via the I2C

interface [serial clock (SCL), serial data (SDA)].

The PCA9538 consists of one 8-bit Configuration

(input or output selection), Input Port, Output Port,

and Polarity Inversion (active high or active low)

registers. At power on, the I/Os are configured as

inputs. However, the system master can enable the

I/Os as either inputs or outputs by writing to the I/O

configuration bits. The data for each input or output is

kept in the corresponding Input Port or Output Port

register. The polarity of the Input Port register can be

inverted with the Polarity Inversion register. All

registers can be read by the system master.

The system master can reset the PCA9538 in the

event of a timeout or other improper operation by

asserting a low in the RESET input. The power-on

reset puts the registers in their default state and

initializes the I2C/SMBus state machine. The RESET

pin causes the same reset/initialization to occur

without powering down the part.

The PCA9538 open-drain interrupt (INT) output is

activated when any input state differs from its

corresponding Input Port register state and is used to

indicate to the system master that an input state has

changed.

CC

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

SSOP (16) 6.20 mm × 5.30 mm

TCA6424

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

TVSOP (16) 3.60 mm × 4.40 mm

SOIC (16) 10.30 mm 7.50 mm

TSSOP (16) 5.00 mm × 4.40 mm

(1)

Page 2

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

www.ti.com

Table of Contents

1 Features.................................................................. 1 7 Parameter Measurement Information ................ 10

2 Description ............................................................. 1 8 Detailed Description............................................ 14

3 Revision History..................................................... 2

4 Description (Continued)........................................ 3

5 Pin Configuration and Functions......................... 3

6 Specifications......................................................... 4

6.1 Absolute Maximum Ratings ..................................... 4

6.2 Handling Ratings....................................................... 4

6.3 Recommended Operating Conditions....................... 4

6.4 Electrical Characteristics........................................... 5

6.5 I2C Interface Timing Requirements........................... 6

6.6 RESET Timing Requirements................................... 6

6.7 Switching Characteristics.......................................... 6

6.8 Typical Characteristics.............................................. 7 12 Mechanical, Packaging, and Orderable

8.1 Functional Block Diagram ....................................... 14

8.2 Device Functional Modes........................................ 16

8.3 Programming........................................................... 17

9 Application And Implementation........................ 24

9.1 Typical Application ................................................. 24

10 Power Supply Recommendations ..................... 26

10.1 Power-On Reset Errata......................................... 26

11 Device and Documentation Support................. 27

11.1 Trademarks........................................................... 27

11.2 Electrostatic Discharge Caution............................ 27

11.3 Glossary................................................................ 27

Information........................................................... 27

3 Revision History

Changes from Revision E (September 2008) to Revision F Page

• Added RESET Errata section............................................................................................................................................... 16

• Added Interrupt Errata section ............................................................................................................................................. 17

• Power-On Reset Errata section............................................................................................................................................ 26

2 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 3

DB, DBQ, DGV, DW, OR PW PACKAGE

(TOP VIEW)

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

A0

A1

RESET

P0

P1

P2

P3

GND

V

CC

SDA

SCL

INT

P7

P6

P5

P4

RGV PACKAGE

(TOP VIEW)

16

6 8

2

10

P7

P5

V

CC

4

3

1

75

12

11

9

131415

SDA

A0

A1

P6

INT

SCL

P3

GND

P4

RESET

P0

P1

P2

RGT PACKAGE

(TOP VIEW)

16

6 8

2

10

P7

P5

V

CC

4

3

1

75

12

11

9

131415

SDA

A0

A1

P6

INT

SCL

P3

GND

P4

RESET

P0

P1

P2

PCA9538

www.ti.com

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

4 Description (Continued)

INT can be connected to the interrupt input of a microcontroller. By sending an interrupt signal on this line, the

remote I/O can inform the microcontroller if there is incoming data on its ports without having to communicate via

the I2C bus. Thus, the PCA9538 can remain a simple slave device.

The device outputs (latched) have high-current drive capability for directly driving LEDs. It has low current

consumption.

Two hardware pins (A0 and A1) are used to program and vary the fixed I2C address and allow up to four devices

to share the same I2C bus or SMBus.

5 Pin Configuration and Functions

NAME

A0 1 15 Address input. Connect directly to VCCor ground.

A1 2 16 Address input. Connect directly to VCCor ground.

RESET 3 1

P0 4 2 P-port input/output. Push-pull design structure.

P1 5 3 P-port input/output. Push-pull design structure.

P2 6 4 P-port input/output. Push-pull design structure.

P3 7 5 P-port input/output. Push-pull design structure.

GND 8 6 Ground

P4 9 7 P-port input/output. Push-pull design structure.

P5 10 8 P-port input/output. Push-pull design structure.

P6 11 9 P-port input/output. Push-pull design structure.

P7 12 10 P-port input/output. Push-pull design structure.

INT 13 11 Interrupt output. Connect to VCCthrough a pullup resistor.

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 3

SCL 14 12 Serial clock bus. Connect to VCCthrough a pullup resistor.

SDA 15 13 Serial data bus. Connect to VCCthrough a pullup resistor.

V

CC

PIN

Pin Functions

NO.

QSOP (DBQ),

SSOP (DB),

TSSOP (PW),

OR

TVSOP (DGV)

16 14 Supply voltage

QFN (RGT) OR

QFN (RGV)

Product Folder Links: PCA9538

Active-low reset input. Connect to VCCthrough a pullup resistor if no

active connection is used.

DESCRIPTION

Page 4

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

6 Specifications

www.ti.com

6.1 Absolute Maximum Ratings

(1)

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

V

CC

V

I

V

O

I

IK

I

OK

I

IOK

I

OL

I

OH

I

CC

θ

JA

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

(2) The input negative-voltage and output voltage ratings may be exceeded if the input and output current ratings are observed.

(3) The package thermal impedance is calculated in accordance with JESD 51-7.

Supply voltage range –0.5 6 V

Input voltage range

Output voltage range

(2)

(2)

–0.5 6 V

–0.5 6 V

Input clamp current VI< 0 –20 mA

Output clamp current VO< 0 –20 mA

Input/output clamp current VO< 0 or VO> V

Continuous output low current VO= 0 to V

Continuous output high current VO= 0 to V

CC

CC

CC

±20 mA

50 mA

–50 mA

Continuous current through GND –250

Continuous current through V

CC

160

DB package 82

DBQ package 90

DGV package 86

Package thermal impedance

(3)

DW package 46 °C/W

PW package 88

RGT package TBD

RGV package TBD

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

mA

6.2 Handling Ratings

MIN MAX UNIT

T

stg

V

Storage temperature range –65 150 °C

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all

(1)

Electrostatic discharge V

(ESD)

pins

Charged device model (CDM), per JEDEC specification

JESD22-C101, all pins

(2)

0 2000

0 1000

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

V

CC

V

IH

V

IL

I

OH

I

OL

T

A

Supply voltage 2.3 5.5 V

High-level input voltage V

Low-level input voltage V

SCL, SDA 0.7 × V

A0, A1, RESET, P7–P0 2 5.5

SCL, SDA –0.5 0.3 × V

A0, A1, RESET, P7–P0 –0.5 0.8

CC

High-level output current P7–P0 –10 mA

Low-level output current P7–P0 25 mA

Operating free-air temperature –40 85 °C

5.5

CC

4 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 5

PCA9538

www.ti.com

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

6.4 Electrical Characteristics

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS V

V

Input diode clamp voltage II= –18 mA 2.3 V to 5.5 V –1.2 V

IK

V

Power-on reset voltage VI= VCCor GND, IO= 0 V

POR

CC

POR

MIN TYP

2.3 V 1.8

3 V 2.6

4.5 V 4.1

4.75 V 4.1

2.3 V 1.7

3 V 2.5

4.5 V 4

V

P-port high-level output voltage

OH

IOH= –8 mA

(2)

IOH= –10 mA

4.75 V 4

SDA VOL= 0.4 V 2.3 V to 5.5 V 3 8

2.3 V 8 10

VOL= 0.5 V

P port

(3)

I

OL

VOL= 0.7 V

3 V 8 14

4.5 V 8 17

4.75 V 8 35

2.3 V 10 13

3 V 10 19

4.5 V 10 24

4.75 V 10 45

INT VOL= 0.4 V 2.3 V to 5.5 V 3 10

SCL, SDA ±1

I

I

A0, A1, RESET ±1

I

P port VI= V

IH

I

P port VI= GND 2.3 V to 5.5 V –1 μA

IL

VI= VCCor GND 2.3 V to 5.5 V μA

CC

2.3 V to 5.5 V 1 μA

5.5 V 104 175

I

CC

Operating mode

VI= VCCor GND, IO= 0,

I/O = inputs, f

= 400 kHz, No load

scl

VI= VCCor GND, IO= 0,

I/O = inputs, f

= 100 kHz, No load

scl

3.6 V 50 90

2.7 V 20 65

5.5 V 60 150

3.6 V 15 40 μA

2.7 V 8 20

5.5 V 0.25 1

Standby mode 3.6 V 0.2 0.9

Additional current in standby

ΔI

CC

mode

C

SCL VI= VCCor GND 2.3 V to 5.5 V 4 5 pF

i

SDA 5.5 6.5

C

io

P port 8 9.5

VI= VCCor GND, IO= 0,

I/O = inputs, f

One input at VCC– 0.6 V,

Other inputs at VCCor GND

All LED I/Os at VI= 4.3 V,

f

= 0 kHz

scl

= 0 kHz, No load

scl

2.7 V 0.1 0.8

2.3 V to 5.5 V 1.5

5.5 V 1

VIO= VCCor GND 2.3 V to 5.5 V pF

(1) All typical values are at nominal supply voltage (2.5-V, 3.3-V, or 5-V VCC) and TA= 25°C.

(2) The total current sourced by all I/Os must be limited to 85 mA.

(3) Each I/O must be externally limited to a maximum of 25 mA, and the P port (P7–P0) must be limited to a maximum current of 200 mA.

(1)

MAX UNIT

1.5 1.65 V

mA

mA

V

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: PCA9538

Page 6

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

6.5 I2C Interface Timing Requirements

over operating free-air temperature range (unless otherwise noted) (see Figure 14)

STANDARD MODE FAST MODE

I2C BUS I2C BUS

MIN MAX MIN MAX

f

I2C clock frequency 0 100 0 400 kHz

scl

t

I2C clock high time 4 0.6 μs

sch

t

I2C clock low time 4.7 1.3 μs

scl

t

I2C spike time 50 50 ns

sp

t

I2C serial-data setup time 250 100 ns

sds

t

I2C serial-data hold time 0 0 ns

sdh

t

I2C input rise time 1000 20 + 0.1C

icr

t

I2C input fall time 300 20 + 0.1C

icf

t

I2C output fall time 10-pF to 400-pF bus 300 20 + 0.1C

ocf

t

I2C bus free time between Stop and Start 4.7 1.3 μs

buf

t

I2C Start or repeated Start condition setup 4.7 0.6 μs

sts

t

I2C Start or repeated Start condition hold 4 0.6 μs

sth

t

I2C Stop condition setup 4 0.6 μs

sps

t

Valid data time SCL low to SDA output valid 300 50 ns

vd(data)

t

Valid data time of ACK condition 0.3 3.45 0.1 0.9 μs

vd(ack)

C

I2C bus capacitive load 400 400 ns

b

(1) Cb= Total capacitance of one bus in pF

ACK signal from SCL low to

SDA (out) low

www.ti.com

UNIT

(1)

b

(1)

b

(1)

b

300 ns

300 ns

300 ns

6.6 RESET Timing Requirements

over operating free-air temperature range (unless otherwise noted)

STANDARD MODE FAST MODE

I2C BUS I2C BUS

MIN MAX MIN MAX

t

W

t

REC

t

RESET

PARAMETER UNIT

Reset pulse duration 4 4 ns

Reset recovery time 0 0 ns

Time to reset 400 400 ns

6.7 Switching Characteristics

over operating free-air temperature range (unless otherwise noted) (see Figure 15 and Figure 16)

PARAMETER UNIT

t

Interrupt valid time P port INT 4 4 μs

iv

t

Interrupt reset delay time SCL INT 4 4 μs

ir

t

Output data valid SCL P7–P0 200 200 ns

pv

t

Input data setup time P port SCL 100 100 ns

ps

t

Input data hold time P port SCL 1 1 μs

ph

FROM TO

(INPUT) (OUTPUT)

STANDARD MODE FAST MODE

I2C BUS I2C BUS

MIN MAX MIN MAX

6 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 7

0

25

50

75

100

125

150

175

200

225

250

275

-40 -15 10 35 60 85

TA– Free-Air Temperature – °C

(VCC – V OH) – Out put High Volt age – mV

VCC= 5 V, IOL= 10 mA

VCC= 2.5 V, IOL= 10 mA

VCC= 5 V, IOL= 1 mA

VCC= 2.5 V, IOL= 1 mA

0

5

10

15

20

25

30

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

VOL– Outpu t Low Volt age – V

ISINK – I/O Sink Current – mA

TA= –40°C

VCC= 2.5 V

TA= 25°C

TA= 85°C

0

10

20

30

40

50

60

70

2.3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

VCC– Supply Voltage – V

ICC – Supply Current – µ A

f

SCL

= 400 kHz

I/Os unloaded

0

50

100

150

200

250

300

350

400

450

500

550

600

0 1 2 3 4 5 6 7 8

Number of I/Os Held L ow

ICC – Supply Current – µ A

TA= –40°C

VCC= 5 V

TA= 25°C

TA= 85°C

0

5

10

15

20

25

30

35

40

45

50

55

-40 -15 10 35 60 85

TA– Free-Air Temperature – °C

ICC – Supply Current – µ A

VCC= 2.5 V

VCC= 3.3 V

VCC= 5 V

f

SCL

= 400 kHz

I/Os unloaded

0

5

10

15

20

25

30

35

-40 -15 10 35 60 85

TA– Free-Air Temperature – °C

ICC – Supply Current – nA

VCC= 2.5 V

VCC= 3.3 V

VCC= 5 V

SCL = V

CC

www.ti.com

6.8 Typical Characteristics

TA= 25°C (unless otherwise noted)

Figure 1. Supply Current vs Temperature Figure 2. Quiescent Supply Current vs Temperature

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Figure 3. Supply Current vs Supply Voltage

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 7

Figure 5. I/O Output Low Voltage vs Temperature

Figure 4. Supply Current vs Number Of I/Os Held Low

Figure 6. I/O Sink Current vs Output Low Voltage

Product Folder Links: PCA9538

Page 8

0

5

10

15

20

25

30

35

40

45

50

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

(VCC– VOH) – Outp ut High Voltag e – V

ISOURCE – I/O Source Current – mA

TA= –40°C

VCC= 3.3 V

TA= 25°C

TA= 85°C

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

(VCC– VOH) – Outp ut High Voltag e – V

ISOURCE – I/O Source Current – mA

TA= –40°C

VCC= 5 V

TA= 25°C

TA= 85°C

0

25

50

75

100

125

150

175

200

225

250

275

-40 -15 10 35 60 85

TA– Free-Air Temperature – °C

(VCC – V OH) – Out put High Volt age – mV

VCC= 5 V, IOL= 10 mA

VCC= 2.5 V, IOL= 10 mA

VCC= 5 V, IOL= 1 mA

VCC= 2.5 V, IOL= 1 mA

0

5

10

15

20

25

30

35

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

(VCC– VOH) – Outp ut High Voltag e – V

ISOURCE – I/O Source Current – mA

TA= –40°C

VCC= 2.5 V

TA= 25°C

TA= 85°C

0

5

10

15

20

25

30

35

40

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

VOL– Outpu t Low Volt age – V

ISINK – I/O Sink Current – mA

TA= –40°C

VCC= 3.3 V

TA= 25°C

TA= 85°C

0

5

10

15

20

25

30

35

40

45

50

55

60

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

VOL– Outpu t Low Volt age – V

ISINK – I/O Sink Current – mA

TA= –40°C

VCC= 5 V

TA= 25°C

TA= 85°C

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Typical Characteristics (continued)

TA= 25°C (unless otherwise noted)

Figure 7. I/O Sink Current vs Output Low Voltage Figure 8. I/O Sink Current vs Output Low Voltage

www.ti.com

Figure 9. I/O Output High Voltage vs Temperature

8 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Figure 11. I/O Source Current vs Output High Voltage Figure 12. I/O Source Current vs Output High Voltage

Figure 10. I/O Source Current vs Output High Voltage

Product Folder Links: PCA9538

Page 9

0

1

2

3

4

5

6

2.3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

VCC– Supply Voltage – V

VOH – O utput High Voltage – V

IOH= –10 mA

IOH= –8 mA

TA= 25°C

www.ti.com

Typical Characteristics (continued)

TA= 25°C (unless otherwise noted)

Figure 13. Output High Voltage vs Supply Voltage

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: PCA9538

Page 10

RL = 1 kΩ

V

CC

CL = 50 pF

(see Note A)

t

buf

t

icr

t

sth

t

sds

t

sdh

t

icf

t

icr

t

scl

t

sch

t

sts

t

PHL

t

PLH

0.3 × V

CC

Stop

Condition

t

sps

Repeat

Start

Condition

Start or

Repeat

Start

Condition

SCL

SDA

Start

Condition

(S)

Address

Bit 7

(MSB)

Data

Bit 10

(LSB)

Stop

Condition

(P)

Three Bytes for Complete

Device Programming

SDA LOAD CONFIGURATION

VOLTAGE WAVEFORMS

t

icf

Stop

Condition

(P)

t

sp

DUT

SDA

0.7 × V

CC

0.3 × V

CC

0.7 × V

CC

R/W

Bit 0

(LSB)

ACK

(A)

Data

Bit 07

(MSB)

Address

Bit 1

Address

Bit 6

BYTE DESCRIPTION

1 I2C address

2, 3 P-port data

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

7 Parameter Measurement Information

www.ti.com

A. CLincludes probe and jig capacitance.

B. All inputs are supplied by generators having the following characteristics: PRR ≤ 10 MHz, ZO= 50 Ω, tr/tf≤ 30 ns.

C. All parameters and waveforms are not applicable to all devices.

Figure 14. I2C Interface Load Circuit And Voltage Waveforms

10 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 11

A

A

A

A

S 1 1 1 0 A10 A0 1

Data 1 1 PData 2

Start

Condition

8 Bits

(One Data Byte)

From Port

Data From PortSlave Address

R/W

87654321

t

ir

t

ir

t

sps

t

iv

Address Data 1 Data 2

INT

Data

Into

Port

B

B

A

A

P

n

INT

R/W A

t

ir

0.7 × V

CC

0.3 × V

CC

0.7 × V

CC

0.3 × V

CC

0.7 × V

CC

0.3 × V

CC

0.7 × V

CC

0.3 × V

CC

INT

SCL

View B−BView A−A

t

iv

RL = 4.7 kΩ

V

CC

CL = 100 pF

(see Note A)

INTERRUPT LOAD CONFIGURATION

DUT

INT

ACK

From Slave

ACK

From Slave

www.ti.com

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Parameter Measurement Information (continued)

PCA9538

A. CLincludes probe and jig capacitance.

B. All inputs are supplied by generators having the following characteristics: PRR ≤ 10 MHz, ZO= 50 Ω, tr/tf≤ 30 ns.

C. All parameters and waveforms are not applicable to all devices.

Figure 15. Interrupt Load Circuit And Voltage Waveforms

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Links: PCA9538

Page 12

P0 A

0.7 × V

CC

0.3 × V

CC

SCL

P3

t

pv

(see Note B)

Slave

ACK

Unstable

Data

Last Stable Bit

SDA

P

n

P

n

WRITE MODE (R/W = 0)

P0 A

0.7 × V

CC

0.3 × V

CC

SCL

P3

0.7 × V

CC

0.3 × V

CC

t

ps

t

ph

READ MODE (R/W = 1)

DUT

CL = 50 pF

(see Note A)

P-PORT LOAD CONFIGURATION

Pn

2 × V

CC

500 W

500 W

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Parameter Measurement Information (continued)

www.ti.com

A. CLincludes probe and jig capacitance.

B. All inputs are supplied by generators having the following characteristics: PRR ≤ 10 MHz, ZO= 50 Ω, tr/tf≤ 30 ns.

C. The outputs are measured one at a time, with one transition per measurement.

D. All parameters and waveforms are not applicable to all devices.

Figure 16. P-Port Load Circuit And Voltage Waveforms

12 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 13

SDA

SCL

Start

ACK or Read Cycle

t

w

t

REC

RESET

0.3 y V

CC

VCC/2

t

RESET

Px

(see Note D)

RL = 1 kΩ

V

CC

CL = 50 pF

(see Note A)

SDA LOAD CONFIGURATION

DUT

SDA

P-PORT LOAD CONFIGURATION

VCC/2

t

RESET

DUT

CL = 50 pF

(see Note A)

Pn

2 × V

CC

500 W

500 W

www.ti.com

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Parameter Measurement Information (continued)

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 13

A. CLincludes probe and jig capacitance.

B. All inputs are supplied by generators having the following characteristics: PRR ≤ 10 MHz, ZO= 50 Ω, tr/tf≤ 30 ns.

C. The outputs are measured one at a time, with one transition per measurement.

D. I/Os are configured as inputs.

E. All parameters and waveforms are not applicable to all devices.

Figure 17. Reset Load Circuits And Voltage Waveforms

Product Folder Links: PCA9538

Page 14

14

I/O

Port

Shift

Register

8 Bits

LP Filter

Interrupt

Logic

Input

Filter

15

Power-On

Reset

Read Pulse

Write Pulse

2

1

13

16

8

GND

V

CC

SDA

SCL

A1

A0

INT

I2C Bus

Control

P7−P0

RESET

3

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

8 Detailed Description

8.1 Functional Block Diagram

www.ti.com

A. Pin numbers shown are for the DB, DBQ, DGV, DW, or PW package.

Figure 18. Functional Block Diagram

14 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 15

Data From

Shift Register

Data From

Shift Register

Write Configuration

Pulse

Write Pulse

Read Pulse

Write Polarity

Pulse

Data From

Shift Register

Output Port

Register

Configuration

Register

Input Port

Register

Polarity

Inversion

Register

Polarity

Register Data

Input Port

Register Data

GND

ESD Protection

Diode

P0 to P7

V

CC

Output Port

Register Data

Q1

Q2

D

C

K

FF

Q

Q

D

C

K

FF

Q

Q

D

C

K

FF

Q

Q

D

C

K

FF

Q

Q

To INT

www.ti.com

Functional Block Diagram (continued)

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 15

A. At power-on reset, all registers return to default values.

Figure 19. Simplified Schematic Of P0 To P7

Product Folder Links: PCA9538

Page 16

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

www.ti.com

8.2 Device Functional Modes

8.2.1 RESET Input

The RESET input can be asserted to reset the system while keeping the VCCat its operating level. A reset can

be accomplished by holding the RESET pin low for a minimum of tW. The PCA9538 registers and I2C/SMBus

state machine are changed to their default states once RESET is low (0). Once RESET is high (1), the I/O levels

at the P port can be changed externally or through the master. This input requires a pullup resistor to VCCif no

active connection is used.

8.2.1.1 RESET Errata

If RESET voltage set higher than VCC, current will flow from RESET pin to VCC pin.

System Impact

VCC will be pulled above its regular voltage level

System Workaround

Design such that RESET voltage is same or lower than VCC

8.2.2 Power-On Reset

When power (from 0 V) is applied to VCC, an internal power-on reset holds the PCA9538 in a reset condition until

VCChas reached V

state machine will initialize to their default states. After that, VCCmust be lowered to below 0.2 V and then back

up to the operating voltage for a power-reset cycle.

Please refer to the Power-On Reset Errata section.

. At that point, the reset condition is released and the PCA9538 registers and SMBus/I2C

POR

8.2.3 I/O Port

When an I/O is configured as an input, FETs Q1 and Q2 (in Figure 19) are off, creating a high-impedance input.

The input voltage may be raised above VCCto a maximum of 5.5 V.

If the I/O is configured as an output, Q1 or Q2 is enabled depending on the state of the output port register. In

this case, there are low impedance paths between the I/O pin and either VCCor GND. The external voltage

applied to this I/O pin should not exceed the recommended levels for proper operation.

16 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 17

PCA9538

www.ti.com

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Device Functional Modes (continued)

8.2.4 Interrupt Output (INT)

An interrupt is generated by any rising or falling edge of the port inputs in the input mode. After time, tiv, the

signal INT is valid. Resetting the interrupt circuit is achieved when data on the port is changed to the original

setting, data is read from the port that generated the interrupt. Resetting occurs in the read mode at the

acknowledge (ACK) or not acknowledge (NACK) bit after the rising edge of the SCL signal.

Interrupts that occur during the ACK or NACK clock pulse can be lost (or be very short) due to the resetting of

the interrupt during this pulse. Each change of the I/Os after resetting is detected and is transmitted as INT.

Writing to another device does not affect the interrupt circuit, and a pin configured as an output cannot cause an

interrupt. Changing an I/O from an output to an input may cause a false interrupt to occur, if the state of the pin

does not match the contents of the Input Port register. Because each 8-pin port is read independently, the

interrupt caused by port 0 is not cleared by a read of port 1 or vice versa.

The INT output has an open-drain structure and requires pullup resistor to VCC.

8.2.4.1 Interrupt Errata

The INT will be improperly de-asserted if the following two conditions occur:

1. The last I²C command byte (register pointer) written to the device was 00h.

NOTE

This generally means the last operation with the device was a Read of the input register.

However, the command byte may have been written with 00h without ever going on to

read the input register. After reading from the device, if no other command byte written, it

will remain 00h.

2. Any other slave device on the I²C bus acknowledges an address byte with the R/W bit set high

System Impact

Can cause improper interrupt handling as the Master will see the interrupt as being cleared.

System Workaround

Minor software change: User must change command byte to something besides 00h after a Read operation to

the PCA9538 device or before reading from another slave device.

NOTE

Software change will be compatible with other versions (competition and TI redesigns) of

this device.

8.3 Programming

8.3.1 I2C Interface

The bidirectional I2C bus consists of the serial clock (SCL) and serial data (SDA) lines. Both lines must be

connected to a positive supply through a pull-up resistor when connected to the output stages of a device. Data

transfer may be initiated only when the bus is not busy.

I2C communication with this device is initiated by a master sending a Start condition, a high-to-low transition on

the SDA input/output while the SCL input is high (see Figure 20). After the Start condition, the device address

byte is sent, most significant bit (MSB) first, including the data direction bit (R/W).

After receiving the valid address byte, this device responds with an acknowledge (ACK), a low on the SDA

input/output during the high of the ACK-related clock pulse. The address inputs (A0–A1) of the slave device must

not be changed between the Start and the Stop conditions.

On the I2C bus, only one data bit is transferred during each clock pulse. The data on the SDA line must remain

stable during the high pulse of the clock period, as changes in the data line at this time are interpreted as control

commands (Start or Stop) (see Figure 21).

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: PCA9538

Page 18

SDA

SCL

Data Line

Stable;

Data Valid

Change

of Data

Allowed

SDA

SCL

Start Condition

S

Stop Condition

P

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

www.ti.com

Programming (continued)

A Stop condition, a low-to-high transition on the SDA input/output while the SCL input is high, is sent by the

master (see Figure 20).

Any number of data bytes can be transferred from the transmitter to receiver between the Start and the Stop

conditions. Each byte of eight bits is followed by one ACK bit. The transmitter must release the SDA line before

the receiver can send an ACK bit. The device that acknowledges must pull down the SDA line during the ACK

clock pulse so that the SDA line is stable low during the high pulse of the ACK-related clock period (see

Figure 22). When a slave receiver is addressed, it must generate an ACK after each byte is received. Similarly,

the master must generate an ACK after each byte that it receives from the slave transmitter. Setup and hold

times must be met to ensure proper operation.

A master receiver will signal an end of data to the slave transmitter by not generating an acknowledge (NACK)

after the last byte has been clocked out of the slave. This is done by the master receiver by holding the SDA line

high. In this event, the transmitter must release the data line to enable the master to generate a Stop condition.

Figure 20. Definition Of Start And Stop Conditions

Figure 21. Bit Transfer

18 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 19

1 1 1 0 A10 A0

Slave Address

R/W

Fixed

Hardware

Selectable

Data Output

by Transmitter

SCL From

Master

Start

Condition

S

1 2 8 9

Data Output

by Receiver

Clock Pulse for

Acknowledgment

NACK

ACK

www.ti.com

Programming (continued)

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Figure 22. Acknowledgment On I2C Bus

8.3.2 Register Map Table 1. Interface Definition Table

BYTE

I2C slave address H H H L L A1 A0 R/W

Px I/O data bus P7 P6 P5 P4 P3 P2 P1 P0

7 (MSB) 6 5 4 3 2 1 0 (LSB)

BIT

8.3.2.1 Device Address

Figure 23 shows the address byte of the PCA9538.

Figure 23. PCA9538 Address

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Links: PCA9538

Page 20

0 0 0 0 B1 B000

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

www.ti.com

Table 2. Address Reference Table

INPUTS

A1 A0

L L 112 (decimal), 70 (hexadecimal)

L H 113 (decimal), 71 (hexadecimal)

H L 114 (decimal), 72 (hexadecimal)

H H 115 (decimal), 73 (hexadecimal)

I2C BUS SLAVE ADDRESS

The last bit of the slave address defines the operation (read or write) to be performed. When it is high (1), a read

is selected while a low (0) selects a write operation.

8.3.2.2 Control Register And Command Byte

Following the successful Acknowledgment of the address byte, the bus master sends a command byte that is

stored in the control register in the PCA9538 (see Figure 24). Two bits of this command byte state the operation

(read or write) and the internal register (input, output, polarity inversion or configuration) that will be affected. This

register can be written or read through the I2C bus. The command byte is sent only during a write transmission.

Once a command byte has been sent, the register that was addressed continues to be accessed by reads until a

new command byte has been sent.

Figure 24. Control Register Bits

Table 3. Command Byte Table

CONTROL REGISTER BITS

B1 B0

0 0 0x00 Input Port Read byte XXXX XXXX

0 1 0x01 Output Port Read/write byte 1111 1111

1 0 0x02 Polarity Inversion Read/write byte 0000 0000

1 1 0x03 Configuration Read/write byte 1111 1111

COMMAND BYTE

(HEX)

REGISTER PROTOCOL POWER-UP DEFAULT

20 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 21

PCA9538

www.ti.com

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

8.3.2.3 Register Descriptions

The Input Port register (register 0) reflects the incoming logic levels of the pins, regardless of whether the pin is

defined as an input or an output by the Configuration register. It only acts on read operation. Writes to these

registers have no effect. The default value, X, is determined by the externally applied logic level.

Before a read operation, a write transmission is sent with the command byte to indicate to the I2C device that the

Input Port register is accessed next.

Table 4. Register 0 (Input Port Register) Table

BIT I7 I6 I5 I4 I3 I2 I1 I0

DEFAULT X X X X X X X X

The Output Port register (register 1) shows the outgoing logic levels of the pins defined as outputs by the

Configuration register. Bit values in this register have no effect on pins defined as inputs. In turn, reads from this

register reflect the value that is in the flip-flop controlling the output selection, not the actual pin value.

Table 5. Register 1 (Output Port Register) Table

BIT O7 O6 O5 O4 O3 O2 O1 O0

DEFAULT 1 1 1 1 1 1 1 1

The Polarity Inversion register (register 2) allows polarity inversion of pins defined as inputs by the Configuration

register. If a bit in this register is set (written with 1), the corresponding port pin polarity is inverted. If a bit in this

register is cleared (written with a 0), the corresponding port pin original polarity is retained.

Table 6. Register 2 (Polarity Inversion Register) Table

BIT N7 N6 N5 N4 N3 N2 N1 N0

DEFAULT 0 0 0 0 0 0 0 0

The Configuration register (register 3) configures the directions of the I/O pins. If a bit in this register is set to 1,

the corresponding port pin is enabled as an input with a high-impedance output driver. If a bit in this register is

cleared to 0, the corresponding port pin is enabled as an output.

Table 7. Register 3 (Configuration Register) Table

BIT C7 C6 C5 C4 C3 C2 C1 C0

DEFAULT 1 1 1 1 1 1 1 1

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Links: PCA9538

Page 22

SCL

SDA

Data to

Register

Start Condition R/W ACK From Slave ACK From Slave ACK From Slave

1 98765432

Data1/001 1S 01 A1 A0 0 A 1000000 A A P

Data to RegisterCommand ByteSlave Address

SCL

Start Condition

Data 1 Valid

SDA

Write to Port

Data Out

From Port

R/W ACK From Slave

ACK From Slave

ACK From Slave

1 98765432

Data 1

101 1S 01 A1 A0 0 A 0000000 A A P

t

pv

Data to PortCommand ByteSlave Address

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

www.ti.com

8.3.2.4 Bus Transactions

Data is exchanged between the master and PCA9538 through write and read commands.

8.3.2.4.1 Writes

Data is transmitted to the PCA9538 by sending the device address and setting the least-significant bit (LSB) to a

logic 0 (see Figure 23 for device address). The command byte is sent after the address and determines which

register receives the data that follows the command byte (see Figure 25 and Figure 26). There is no limitation on

the number of data bytes sent in one write transmission.

Figure 25. Write To Output Port Register

<br/>

Figure 26. Write To Configuration Or Polarity Inversion Registers

8.3.2.4.2 Reads

The bus master first must send the PCA9538 address with the LSB set to a logic 0 (see Figure 23 for device

address). The command byte is sent after the address and determines which register is accessed. After a restart,

the device address is sent again but, this time, the LSB is set to a logic 1. Data from the register defined by the

command byte then is sent by the PCA9538 (see Figure 27 and Figure 28). After a restart, the value of the

register defined by the command byte matches the register being accessed when the restart occurred. Data is

clocked into the register on the rising edge of the ACK clock pulse. There is no limitation on the number of data

bytes received in one read transmission, but when the final byte is received, the bus master must not

acknowledge the data.

22 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 23

SCL

SDA

INT

Start

Condition

R/W

Read From

Port

Data Into

Port

Stop

Condition

ACK From

Master

NACK From

Master

ACK From

Slave

Data From Port

Slave Address Data From Port

1 98765432

01 1S 01 A1 A0

1

A

Data 1 Data 4

A NA

P

Data 2 Data 3 Data 4

t

iv

t

ph

t

ps

t

ir

Data 5

01 1S 01 A1 A0 0 A A

Data from Register

Slave Address

Slave Address

R/W

ACK From

Slave

Command Byte

ACK From

Slave

S 01 1 01 A1 A0

R/W

1 A Data

A

ACK From

Master

Data

Data from Register

NACK From

Master

NA

P

Last Byte

ACK From

Slave

www.ti.com

<br/>

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Figure 27. Read From Register

A. This figure assumes the command byte has previously been programmed with 00h.

B. Transfer of data can be stopped at any moment by a Stop condition.

C. This figure eliminates the command byte transfer, a restart, and slave address call between the initial slave address

call and actual data transfer from the P port. See Figure 27 for these details.

Figure 28. Read From Input Port Register

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Links: PCA9538

Page 24

A1

A0

SDA

SCL

INT

GND

P6

P0

P1

P2

P3

P4

P5

P7

INT

GND

V

CC

V

CC

(5 V)

V

CC

10 kW 10 kW

10 kW 10 kW

2 kW

100 kW

(y3)

Master

Controller

PCA9538

INT

RESET

Subsystem 2

(e.g., counter)

Subsystem 3

(e.g., alarm system)

ALARM

Controlled Device

(e.g., CBT device)

ENABLE

A

B

V

CC

RESET RESET

Subsystem 1

(e.g., temperature sensor)

SDA

SCL

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

9 Application And Implementation

9.1 Typical Application

Figure 29 shows an application in which the PCA9538 can be used.

www.ti.com

A. Device address is configured as 1110000 for this example.

B. P0, P2, and P3 are configured as outputs.

C. P1, P4, and P5 are configured as inputs.

D. P6 and P7 are not used and must be configured as outputs.

Figure 29. Typical Application

24 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 25

LED

3.3 V

5 V

LEDx

V

CC

LED

LEDx

V

CC

100 kW

V

CC

PCA9538

www.ti.com

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

Typical Application (continued)

9.1.1 Detailed Design Procedure

9.1.1.1 Minimizing ICCWhen I/Os Control Leds

When the I/Os are used to control LEDs, normally they are connected to VCCthrough a resistor as shown in

Figure 29. The LED acts as a diode, so when the LED is off, the I/O VINis about 1.2 V less than VCC. ICCin

Electrical Characteristics shows how ICCincreases as VINbecomes lower than VCC.

For battery-powered applications, it is essential that the voltage of I/O pins is greater than or equal to VCCwhen

the LED is off to minimize current consumption. Figure 30 shows a high-value resistor in parallel with the LED.

Figure 31 shows VCCless than the LED supply voltage by at least 1.2 V. Both of these methods maintain the I/O

VINat or above VCCand prevents additional supply current consumption when the LED is off.

Figure 30. High-Value Resistor In Parallel With Led

Figure 31. Device Supplied By A Lower Voltage

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Links: PCA9538

Page 26

PCA9538

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

www.ti.com

10 Power Supply Recommendations

10.1 Power-On Reset Errata

A power-on reset condition can be missed if the VCC ramps are outside specification listed below.

System Impact

If ramp conditions are outside timing allowances above, POR condition can be missed, causing the device to lock

up.

26 Submit Documentation Feedback Copyright © 2006–2014, Texas Instruments Incorporated

Product Folder Links: PCA9538

Page 27

PCA9538

www.ti.com

SCPS126F –SEPTEMBER 2006–REVISED JUNE 2014

11 Device and Documentation Support

11.1 Trademarks

All trademarks are the property of their respective owners.

11.2 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

11.3 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Copyright © 2006–2014, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Links: PCA9538

Page 28

PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device Status

PCA9538DB ACTIVE SSOP DB 16 80 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 PD538

PCA9538DBR ACTIVE SSOP DB 16 2000 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 PD538

PCA9538DGVR ACTIVE TVSOP DGV 16 2000 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 PD538

PCA9538DW ACTIVE SOIC DW 16 40 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 PCA9538

PCA9538DWR ACTIVE SOIC DW 16 2000 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 PCA9538

PCA9538PW ACTIVE TSSOP PW 16 90 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 PD538

PCA9538PWG4 ACTIVE TSSOP PW 16 90 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 PD538

PCA9538PWR ACTIVE TSSOP PW 16 2000 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 85 PD538

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead finish/

Ball material

(6)

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of <=1000ppm threshold. Antimony trioxide based

flame retardants must also meet the <=1000ppm threshold requirement.

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

Samples

Addendum-Page 1

Page 29

PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

(6)

Lead finish/Ball material - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead finish/Ball material values may wrap to two

lines if the finish value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Addendum-Page 2

Page 30

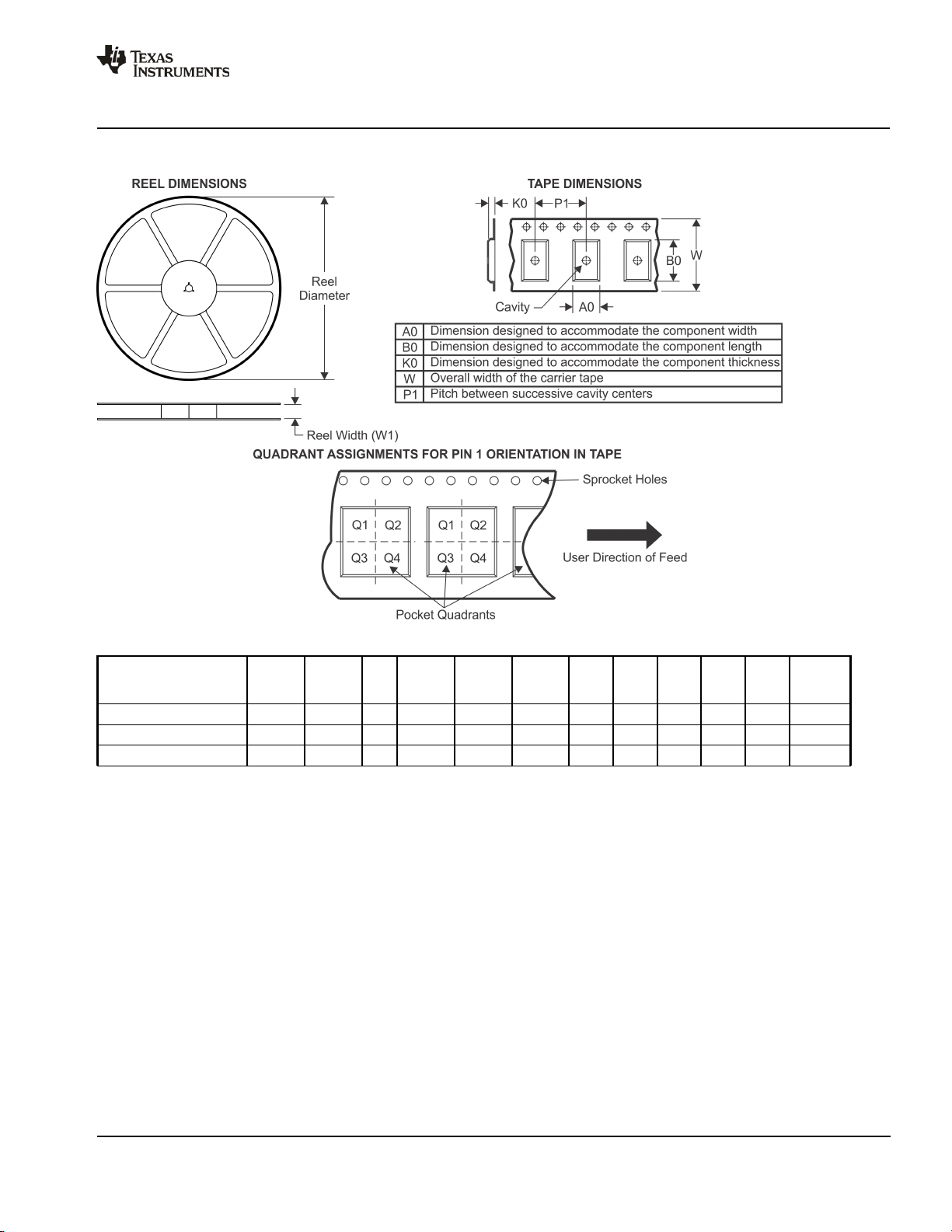

PACKAGE MATERIALS INFORMATION

www.ti.com 1-Nov-2020

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

PCA9538DGVR TVSOP DGV 16 2000 330.0 12.4 6.8 4.0 1.6 8.0 12.0 Q1

PCA9538DWR SOIC DW 16 2000 330.0 16.4 10.75 10.7 2.7 12.0 16.0 Q1

PCA9538PWR TSSOP PW 16 2000 330.0 12.4 6.9 5.6 1.6 8.0 12.0 Q1

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 31

PACKAGE MATERIALS INFORMATION

www.ti.com 1-Nov-2020

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

PCA9538DGVR TVSOP DGV 16 2000 853.0 449.0 35.0

PCA9538DWR SOIC DW 16 2000 350.0 350.0 43.0

PCA9538PWR TSSOP PW 16 2000 853.0 449.0 35.0

Pack Materials-Page 2

Page 32

PACKAGE OUTLINE

A

5.1

4.9

NOTE 3

SCALE 2.500

TSSOP - 1.2 mm max heightPW0016A

SMALL OUTLINE PACKAGE

SEATING

6.6

TYP

6.2

PIN 1 INDEX AREA

1

8

B

4.5

4.3

NOTE 4

16

9

14X 0.65

2X

4.55

0.30

16X

0.19

0.1 C A B

C

1.2 MAX

PLANE

0.1 C

(0.15) TYP

SEE DETAIL A

GAGE PLANE

0.25

0.75

-80

0.50

A 20

DETAIL A

TYPICAL

4220204/A 02/2017

NOTES:

1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

3. This dimension does not include mold flash, protrusions, or gate burrs. Mold flash, protrusions, or gate burrs shall not

exceed 0.15 mm per side.

4. This dimension does not include interlead flash. Interlead flash shall not exceed 0.25 mm per side.

5. Reference JEDEC registration MO-153.

0.15

0.05

www.ti.com

Page 33

EXAMPLE BOARD LAYOUT

TSSOP - 1.2 mm max heightPW0016A

SMALL OUTLINE PACKAGE

16X (0.45)

14X (0.65)

1

8

16X (1.5)

SYMM

(R0.05) TYP

16

SYMM

9

(5.8)

LAND PATTERN EXAMPLE

EXPOSED METAL SHOWN

SCALE: 10X

SOLDER MASK

OPENING

EXPOSED METAL

0.05 MAX

ALL AROUND

NON-SOLDER MASK

DEFINED

(PREFERRED)

METAL

15.000

SOLDER MASK DETAILS

METAL UNDER

SOLDER MASK

0.05 MIN

ALL AROUND

SOLDER MASK

DEFINED

NOTES: (continued)

6. Publication IPC-7351 may have alternate designs.

7. Solder mask tolerances between and around signal pads can vary based on board fabrication site.

SOLDER MASK

OPENING

EXPOSED METAL

4220204/A 02/2017

www.ti.com

Page 34

EXAMPLE STENCIL DESIGN

TSSOP - 1.2 mm max heightPW0016A

SMALL OUTLINE PACKAGE

16X (0.45)

14X (0.65)

1

8

16X (1.5)

SYMM

(5.8)

SOLDER PASTE EXAMPLE

BASED ON 0.125 mm THICK STENCIL

SCALE: 10X

(R0.05) TYP

16

SYMM

9

4220204/A 02/2017

NOTES: (continued)

8. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate

design recommendations.

9. Board assembly site may have different recommendations for stencil design.

www.ti.com

Page 35

GENERIC PACKAGE VIEW

SOIC - 2.65 mm max heightDW 16

7.5 x 10.3, 1.27 mm pitch

This image is a representation of the package family, actual package may vary.

SMALL OUTLINE INTEGRATED CIRCUIT

Refer to the product data sheet for package details.

www.ti.com

4224780/A

Page 36

PACKAGE OUTLINE

A

10.5

10.1

NOTE 3

SCALE 1.500

10.63

TYP

9.97

PIN 1 ID

AREA

1

8

B

7.6

7.4

NOTE 4

16

9

14X 1.27

2X

8.89

0.51

16X

0.31

0.25 C A B

SOIC - 2.65 mm max heightDW0016A

SOIC

C

SEATING PLANE

0.1 C

2.65 MAX

0.33

TYP

0.10

SEE DETAIL A

GAGE PLANE

0 - 8

0.25

1.27

0.40

(1.4)

DETAIL A

TYPICAL

4220721/A 07/2016

NOTES:

1. All linear dimensions are in millimeters. Dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

3. This dimension does not include mold flash, protrusions, or gate burrs. Mold flash, protrusions, or gate burrs shall not

exceed 0.15 mm, per side.

4. This dimension does not include interlead flash. Interlead flash shall not exceed 0.25 mm, per side.

5. Reference JEDEC registration MS-013.

0.3

0.1

www.ti.com

Page 37

EXAMPLE BOARD LAYOUT

SOIC - 2.65 mm max heightDW0016A

SOIC

16X (2)

16X (0.6)

14X (1.27)

R0.05 TYP

SYMM

1

8

(9.3)

SEE

DETAILS

16

SYMM

9

LAND PATTERN EXAMPLE

SCALE:7X

METAL

0.07 MAX

ALL AROUND

NON SOLDER MASK

DEFINED

SOLDER MASK

OPENING

SOLDER MASK

OPENING

0.07 MIN

ALL AROUND

SOLDER MASK

DEFINED

SOLDER MASK DETAILS

NOTES: (continued)

6. Publication IPC-7351 may have alternate designs.

7. Solder mask tolerances between and around signal pads can vary based on board fabrication site.

METAL

4220721/A 07/2016

www.ti.com

Page 38

EXAMPLE STENCIL DESIGN

SOIC - 2.65 mm max heightDW0016A

SOIC

16X (2)

16X (0.6)

14X (1.27)

R0.05 TYP

SYMM

1

8

(9.3)

16

SYMM

9

SOLDER PASTE EXAMPLE

BASED ON 0.125 mm THICK STENCIL

NOTES: (continued)

8. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate

design recommendations.

9. Board assembly site may have different recommendations for stencil design.

SCALE:7X

4220721/A 07/2016

www.ti.com

Page 39

MECHANICAL DATA

MSSO002E – JANUARY 1995 – REVISED DECEMBER 2001

DB (R-PDSO-G**) PLASTIC SMALL-OUTLINE

28 PINS SHOWN

0,65

28

1

2,00 MAX

0,38

0,22

15

14

A

0,05 MIN

0,15

5,60

5,00

M

8,20

7,40

Seating Plane

0,10

0,25

0,09

0°–ā8°

Gage Plane

0,25

0,95

0,55

PINS **

DIM

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-150

14

6,50

6,50

5,905,90

2016

7,50

6,90

24

8,50

28

10,50

9,907,90

30

10,50

9,90

38

12,90

12,30

4040065 /E 12/01

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 40

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2020, Texas Instruments Incorporated

Loading...

Loading...