Page 1

PCA9533

4-bit I2C-bus LED dimmer

Rev. 03 — 27 April 2009 Product data sheet

1. General description

The PCA9533 is a 4-bit I2C-bus and SMBus I/O expander optimized for dimming LEDs in

256 discrete steps for Red/Green/Blue (RGB) color mixing and back light applications.

The PCA9533 contains an internal oscillator with two user programmable blink rates and

duty cycles coupled to the output PWM. The LED brightness is controlled by setting the

blink rate high enough(> 100 Hz) that the blinking cannot be seen and then using the duty

cycle to vary the amount of time the LED is on and thus the average current through the

LED.

The initial setup sequence programs the two blink rates/duty cycles for each individual

PWM. From then on, only one command from the bus master is required to turn individual

LEDs ON, OFF, BLINK RATE 1 or BLINK RATE 2. Based on the programmed frequency

and duty cycle, BLINK RATE 1 and BLINK RATE 2 will cause the LEDs to appear at a

different brightness or blink at periods up to 1.69 second. The open-drain outputs directly

drive the LEDs with maximum output sink current of 25 mA per bit and 100 mA per

package.

2. Features

To blink LEDs at periods greater than 1.69 second the bus master (MCU, MPU, DSP,

chip set, etc.) must send repeated commands to turn the LED on and off as is currently

done when using normal I/O expanders like the NXP Semiconductors PCF8574 or

PCA9554. Any bits not used for controlling the LEDs can be used for General Purpose

parallel Input/Output (GPIO) expansion, which provides a simple solution when additional

I/O is needed for ACPI power switches, sensors, push-buttons, alarm monitoring, fans,

etc.

The Power-On Reset (POR) initializes the registers to their default state, causing the bits

to be set HIGH (LED off).

Due to pin limitations, the PCA9533 is not featured with hardware address pins. The

PCA9533/01 and the PCA9533/02 have different fixed I2C-bus addresses allowing

operation of both on the same bus.

n 4 LED drivers (on, off, flashing at a programmable rate)

n Two selectable, fully programmable blink rates (frequency and duty cycle) between

0.591 Hz and 152 Hz (1.69 second and 6.58 milliseconds)

n 256 brightness steps

n Input/outputs not used as LED drivers can be used as regular GPIOs

n Internal oscillator requires no external components

n I2C-bus interface logic compatible with SMBus

Page 2

NXP Semiconductors

n Internal power-on reset

n Noise filter on SCL/SDA inputs

n 4 open-drain outputs directly drive LEDs to 25 mA

n Edge rate control on outputs

n No glitch on power-up

n Supports hot insertion

n Low standby current

n Operating power supply voltage range of 2.3 V to 5.5 V

n 0 Hz to 400 kHz clock frequency

n ESD protection exceeds 2000 V HBM per JESD22-A114, 150 V MM per

JESD22-A115 and 1000 V CDM per JESD22-C101

n Latch-up testing is done to JEDEC Standard JESD78 which exceeds 100 mA

n Packages offered: SO8, TSSOP8 (MSOP8)

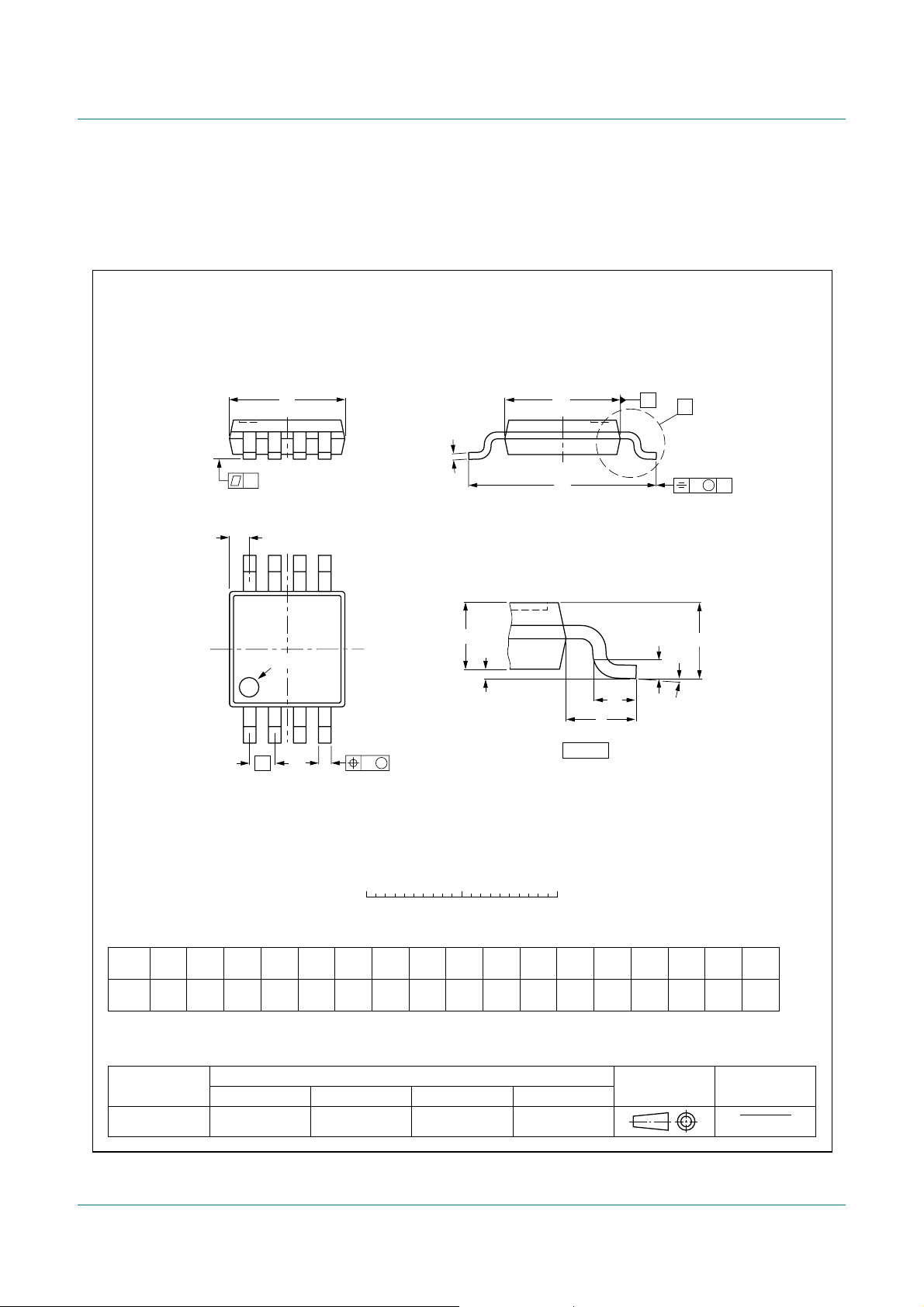

3. Ordering information

Table 1. Ordering information

Type number Package

PCA9533D/01 SO8 plastic small outline package; 8 leads;

PCA9533D/02

PCA9533DP/01 TSSOP8 plastic thin shrink small outline package; 8 leads;

PCA9533DP/02

PCA9533

4-bit I2C-bus LED dimmer

Name Description Version

SOT96-1

body width 3.9 mm

SOT505-1

body width 3 mm

3.1 Ordering options

Table 2. Ordering options

Type number Topside mark Temperature range

PCA9533D/01 P9533/1 T

PCA9533D/02 P9533/2 T

PCA9533DP/01 P33/1 T

PCA9533DP/02 P33/2 T

amb

amb

amb

amb

= −40 °C to +85 °C

= −40 °C to +85 °C

= −40 °C to +85 °C

= −40 °C to +85 °C

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 2 of 24

Page 3

NXP Semiconductors

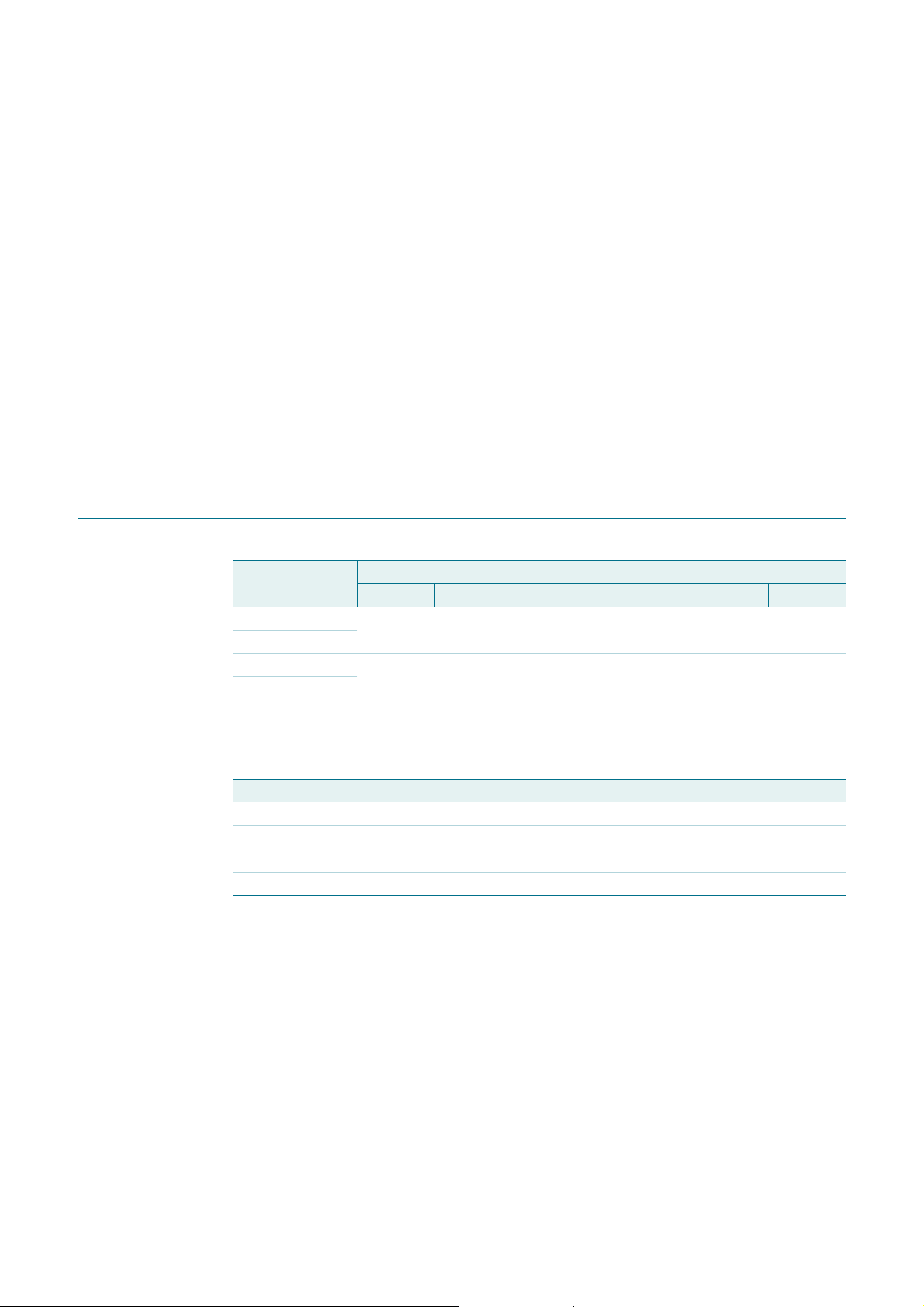

4. Block diagram

PCA9533

4-bit I2C-bus LED dimmer

PCA9533

SCL

SDA

V

DD

V

SS

INPUT

FILTERS

POWER-ON

RESET

OSCILLATOR

Remark: Only one I/O shown for clarity.

Fig 1. Block diagram of PCA9533

5. Pinning information

5.1 Pinning

I2C-BUS

CONTROL

PRESCALER 0

REGISTER

PRESCALER 1

REGISTER

PWM0

REGISTER

PWM1

REGISTER

REGISTER

LED SELECT (LSn)

REGISTER

0

1

BLINK0

BLINK1

INPUT

LEDn

002aae626

PCA9533D/01

PCA9533D/02

1

LED0 V

2

LED1 SDA

3

LED2 SCL

4

V

SS

002aae624

Fig 2. Pin configuration for SO8 Fig 3. Pin configuration for TSSOP8

5.2 Pin description

Table 3. Pin description

Symbol Pin Description

LED0 1 LED driver 0

LED1 2 LED driver 1

LED2 3 LED driver 2

V

SS

LED3 5 LED driver 3

4 supply ground

PCA9533DP/01

PCA9533DP/02

8

DD

7

6

5

LED3

1

LED0 V

2

LED1 SDA

3

LED2 SCL

4

V

SS

002aae625

8

DD

7

6

5

LED3

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 3 of 24

Page 4

NXP Semiconductors

PCA9533

4-bit I2C-bus LED dimmer

Table 3. Pin description

Symbol Pin Description

SCL 6 serial clock line

SDA 7 serial data line

V

DD

6. Functional description

Refer to Figure 1 “Block diagram of PCA9533”.

6.1 Device address

Following a START condition, the bus master must output the address of the slave it is

accessing. The address of the PCA9533/01 is shown in Figure 4 and the address of

PCA9533/02 is shown in Figure 5.

1 1 0 0 0 1 0 R/W

Fig 4. PCA9533/01 slave address Fig 5. PCA9533/02 slave address

…continued

8 supply voltage

slave address

002aae627

slave address

1 1 0 0 0 1 1 R/W

002aae628

The last bit of the address byte defines the operation to be performed. When set to logic 1

a read is selected, while a logic 0 selects a write operation.

6.2 Control register

Followingthe successful acknowledgement of the slave address, the bus master will send

a byte to the PCA9533, which will be stored in the Control register.

0 0 0 AI 0 B2 B1

register address

Reset state: 00h

Fig 6. Control register

Auto-Increment

flag

The lowest 3 bits are used as a pointer to determine which register will be accessed.

If the Auto-Increment (AI) flag is set, the three low order bits of the Control register are

automatically incremented after a read or write. This allows the user to program the

registers sequentially. The contents of these bits will rolloverto ‘000’ after the last register

is accessed.

When Auto-Increment flag is set (AI = 1) and a read sequence is initiated, the sequence

must start by reading a register different from the INPUT register (B2 B1 B0 ≠ 0 0 0).

B0

002aad744

Only the 3 least significant bits are affected by the AI flag. Unused bits must be

programmed with zeroes.

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 4 of 24

Page 5

NXP Semiconductors

6.2.1 Control register definition

Table 4. Register summary

B2 B1 B0 Symbol Access Description

0 0 0 INPUT read only input register

0 0 1 PSC0 read/write frequency prescaler 0

0 1 0 PWM0 read/write PWM register 0

0 1 1 PSC1 read/write frequency prescaler 1

1 0 0 PWM1 read/write PWM register 1

1 0 1 LS0 read/write LED selector

6.3 Register descriptions

6.3.1 INPUT - Input register

The INPUTregister reflects the state of the device pins. Writes to this register will be

acknowledged but will have no effect.

Table 5. INPUT - Input register description

Bit 7 6 5 4 3 2 1 0

Symbol ----LED3 LED2 LED1 LED0

Default 0000XXXX

PCA9533

4-bit I2C-bus LED dimmer

Remark: The default value ‘X’ is determined by the externally applied logic level(normally

logic 1) when used for directly driving LED with pull-up to VDD.

6.3.2 PCS0 - Frequency Prescaler 0

PSC0 is used to program the period of the PWM output.

The period of BLINK0 = (PSC0 + 1) / 152.

Table 6. PSC0 - Frequency Prescaler 0 register description

Bit 7 6 5 4 3 2 1 0

Symbol PSC0[7] PSC0[6] PSC0[5] PSC0[4] PSC0[3] PSC0[2] PSC0[1] PSC0[0]

Default 00000000

6.3.3 PWM0 - Pulse Width Modulation 0

The PWM0 register determines the duty cycle of BLINK0. The outputs are LOW (LED on)

when the count is less than the value in PWM0 and HIGH (LED off) when it is greater. If

PWM0 is programmed with 00h, then the PWM0 output is always HIGH (LED off).

The duty cycle of BLINK0 = PWM0 / 256.

Table 7. PWM0 - Pulse Width Modulation 0 register description

Bit 7 6 5 4 3 2 1 0

Symbol PWM0

[7]

Default 10000000

PWM0

[6]

PWM0

[5]

PWM0

[4]

PWM0

[3]

PWM0

[2]

PWM0

[1]

PWM0

[0]

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 5 of 24

Page 6

NXP Semiconductors

6.3.4 PCS1 - Frequency Prescaler 1

PSC1 is used to program the period of the PWM output.

The period of BLINK1 = (PSC1 + 1) / 152.

Table 8. PSC1 - Frequency Prescaler 1 register description

Bit 7 6 5 4 3 2 1 0

Symbol PSC1[7] PSC1[6] PSC1[5] PSC1[4] PSC1[3] PSC1[2] PSC1[1] PSC1[0]

Default 00000000

6.3.5 PWM1 - Pulse Width Modulation 1

The PWM1 register determines the duty cycle of BLINK1. The outputs are LOW (LED on)

when the count is less than the value in PWM1 and HIGH (LED off) when it is greater. If

PWM1 is programmed with 00h, then the PWM1 output is always HIGH (LED off).

The duty cycle of BLINK1 = PWM1 / 256.

Table 9. PWM1 - Pulse Width Modulation 1 register description

Bit 7 6 5 4 3 2 1 0

Symbol PWM1

Default 10000000

[7]

PWM1

[6]

PWM1

[5]

PWM1

[4]

PWM1

[3]

PCA9533

4-bit I2C-bus LED dimmer

PWM1

[2]

PWM1

[1]

PWM1

[0]

6.3.6 LS0 - LED selector

The LSn LED selector register determines the source of the LED data.

00 = output is set high-impedance (LED off; default)

01 = output is set LOW (LED on)

10 = output blinks at PWM0 rate

11 = output blinks at PWM1 rate

Table 10. LS0 - LED selector register bit description

Legend: * default value.

Register Bit Value Description

LS0 7:6 00* LED3 selected

5:4 00* LED2 selected

3:2 00* LED1 selected

1:0 00* LED0 selected

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 6 of 24

Page 7

NXP Semiconductors

6.4 Pins used as GPIOs

LEDn pins not used to control LEDs can be used as General Purpose I/Os (GPIOs).

For use as input, set LEDn to high-impedance (00) and then read the pin state via the

INPUT register.

For use as output, connect external pull-up resistor to the pin and size it according to the

DC recommended operating characteristics. LEDn output pin is HIGH when the output is

programmed as high-impedance, and LOW when the output is programmedLOW through

the ‘LED selector’ register. The output can be pulse-width controlled when PWM0 or

PWM1 are used.

6.5 Power-on reset

When power is applied to VDD, an internal Power-On Reset (POR) holds the PCA9533 in

a reset condition until VDDhas reached V

and the PCA9533 registers are initialized to their default states, all the outputs in the

OFF state. Thereafter, VDD must be lowered below 0.2 V to reset the device.

PCA9533

4-bit I2C-bus LED dimmer

. At that point, the reset condition is released

POR

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 7 of 24

Page 8

NXP Semiconductors

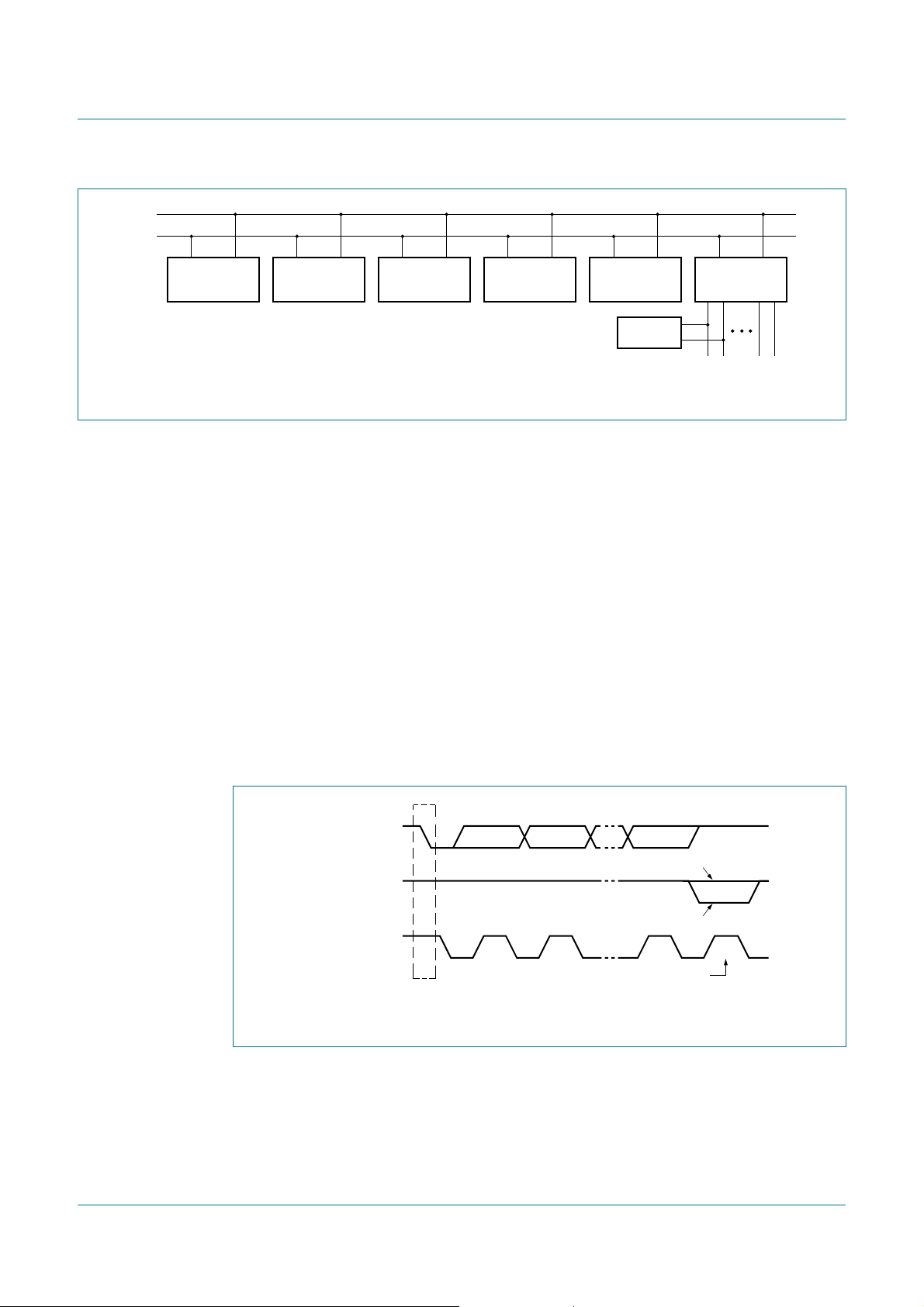

7. Characteristics of the I2C-bus

The I2C-bus is for 2-way, 2-line communication between different ICs or modules. The two

lines are a serial data line (SDA) and a serial clock line (SCL). Both lines must be

connected to a positive supply via a pull-up resistor when connected to the output stages

of a device. Data transfer may be initiated only when the bus is not busy.

7.1 Bit transfer

One data bit is transferred during each clock pulse. The data on the SDA line must remain

stable during the HIGH period of the clock pulse as changes in the data line at this time

will be interpreted as control signals (see Figure 7).

SDA

SCL

PCA9533

4-bit I2C-bus LED dimmer

Fig 7. Bit transfer

7.1.1 START and STOP conditions

Both data and clock lines remain HIGH when the bus is not busy. A HIGH-to-LOW

transition of the data line while the clock is HIGH is defined as the START condition (S).

A LOW-to-HIGH transition of the data line while the clock is HIGH is defined as the STOP

condition (P) (see Figure 8).

SDA

SCL

S

START condition

Fig 8. Definition of START and STOP conditions

7.2 System configuration

data line

stable;

data valid

change

of data

allowed

mba607

P

STOP condition

mba608

A device generating a message is a ‘transmitter’; a device receiving is the ‘receiver’. The

device that controls the message is the ‘master’ and the devices which are controlled by

the master are the ‘slaves’ (see Figure 9).

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 8 of 24

Page 9

NXP Semiconductors

SDA

SCL

PCA9533

4-bit I2C-bus LED dimmer

MASTER

TRANSMITTER/

RECEIVER

Fig 9. System configuration

7.3 Acknowledge

The number of data bytes transferred between the START and the STOP conditions from

transmitter to receiver is not limited. Each byte of eight bits is followed by one

acknowledge bit. The acknowledge bit is a HIGH level put on the bus by the transmitter,

whereas the master generates an extra acknowledge related clock pulse.

A slavereceiver which is addressed must generate an acknowledge after the reception of

each byte. Also a master must generate an acknowledge after the reception of each byte

that has been clocked out of the slave transmitter. The device that acknowledges has to

pull down the SDA line during the acknowledge clock pulse, so that the SDA line is stable

LOW during the HIGH period of the acknowledge related clock pulse; set-up and hold

times must be taken into account.

A master receiver must signal an end of data to the transmitter by not generating an

acknowledge on the last byte that has been clocked out of the slave. In this event, the

transmitter must leave the data line HIGH to enable the master to generate a STOP

condition.

SLAVE

RECEIVER

SLAVE

TRANSMITTER/

RECEIVER

MASTER

TRANSMITTER

MASTER

TRANSMITTER/

RECEIVER

SLAVE

I2C-BUS

MULTIPLEXER

002aaa966

data output

by transmitter

not acknowledge

data output

by receiver

acknowledge

SCL from master

S

START

condition

clock pulse for

acknowledgement

9821

002aaa987

Fig 10. Acknowledgement on the I2C-bus

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 9 of 24

Page 10

NXP Semiconductors

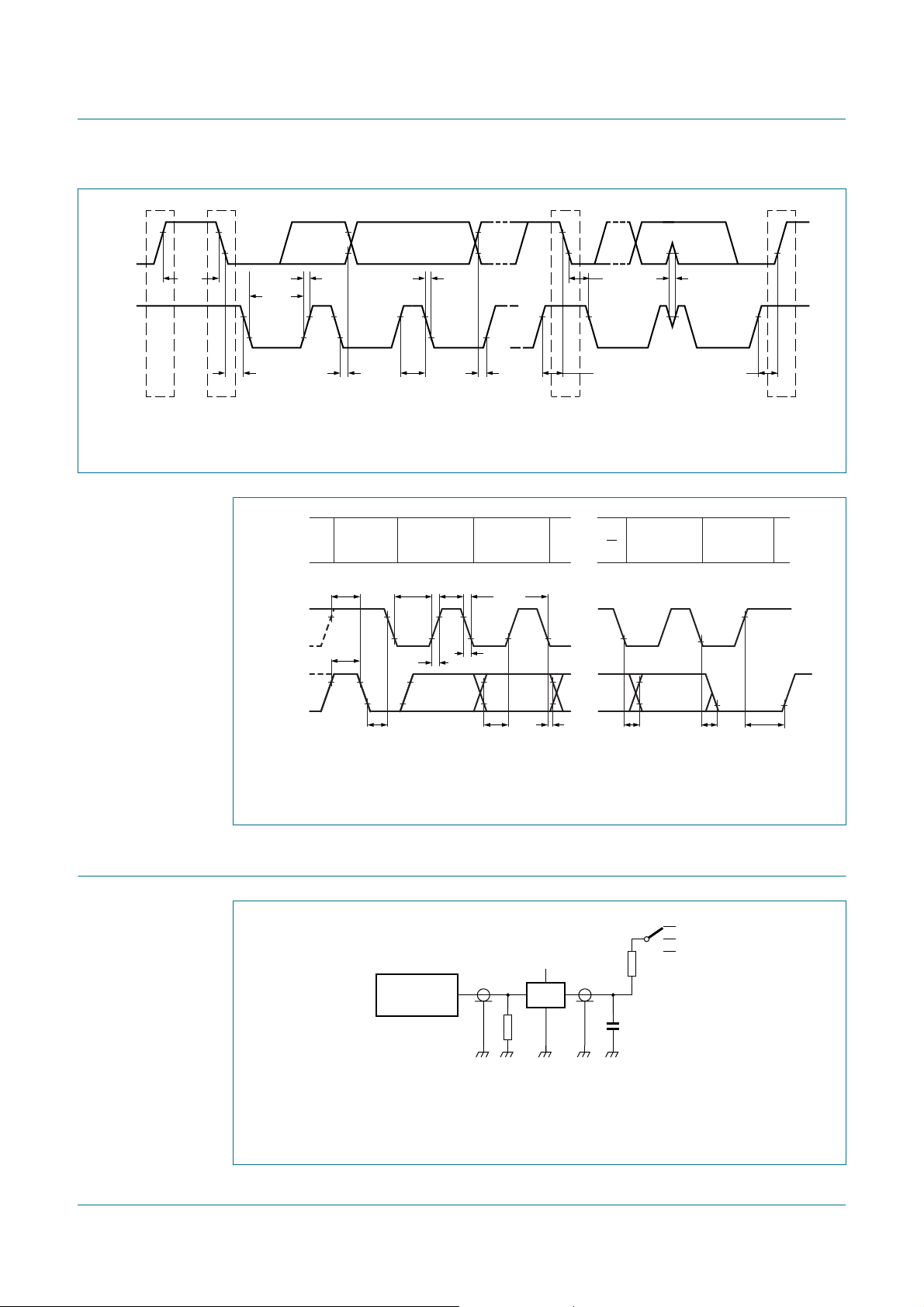

7.4 Bus transactions

12345678SCL 9

PCA9533

4-bit I2C-bus LED dimmer

slave address (PCA9533/01)

SDA DATA 1 A

write to register

data out from port

1000101

START condition R/W acknowledge

Fig 11. Write to register

slave address (PCA9533/01)

SDA

(cont.)

1000100AS1

START condition R/W

slave address (PCA9533/01)

S

1000101

(repeated)

START condition

0 AS

acknowledge

from slave

R/W

acknowledge

from slave

command byte

0 0 AI 0 B2B1B00

from slave

command byte

0 0 AI 0 B2 B10B0

acknowledge

from slave

data from register

1 A

DATA (first byte)

Auto-Increment

register address

if AI = 1

at this moment master-transmitter becomes master-receiver

and slave-receiver becomes slave-transmitter

A

acknowledge

from slave

A

A P

data to register

(cont.)

acknowledge

from master

t

v(Q)

data from register

DATA (last byte)

no acknowledge

acknowledge

from slave

DATA 1 VALID

from master

002aae629

NA

STOP

condition

002aae630

Fig 12. Read from register

no acknowledge

from master

slave address (PCA9533/01)

SDA NA

read from

port

data into

port

1000101AS1

START condition R/W acknowledge

DATA 1

t

h(D)

from slave

data from port

t

su(D)

A

acknowledge

from master

DATA 1

DATA 2 DATA 3 DATA 4

data from port

DATA 4

P

STOP

condition

002aae631

Remark: This figure assumes the command byte has previously been programmed with 00h.

Fig 13. Read input port register

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 10 of 24

Page 11

NXP Semiconductors

8. Application design-in information

PCA9533

4-bit I2C-bus LED dimmer

5 V

2

C-BUS/SMBus

I

MASTER

SDA

SCL

10 kΩ10 kΩ

V

DD

SDA

SCL

LED0

LED1

LED2

LED3

5 V

PCA9533

V

SS

002aae632

Fig 14. Typical application

8.1 Minimizing IDD when the I/Os are used to control LEDs

When the I/Os are used to control LEDs, they are normally connected to VDD through a

resistor as shown in Figure 14. Since the LED acts as a diode, when the LED is off the

I/O VI is about 1.2 V less than VDD. The supply current, IDD, increases as VI becomes

lower than VDD and is specified as ∆IDD in Table 13 “Static characteristics”.

Designs needing to minimize current consumption, such as battery power applications,

should consider maintaining the I/O pins greater than or equal to VDDwhen the LED is off.

Figure 15 shows a high value resistor in parallel with the LED. Figure 16 shows VDD less

than the LED supply voltage by at least 1.2 V. Both of these methods maintain the I/O V

at or above VDD and prevents additional supply current consumption when the LED is off.

I

V

DD

V

DD

LEDn

LED

100 kΩ

002aac189

Fig 15. High value resistor in parallel with

Fig 16. Device supplied by a lower voltage

3.3 V 5 V

V

DD

LEDn

002aac190

LED

the LED

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 11 of 24

Page 12

NXP Semiconductors

8.2 Programming example

The followingexample will show how to set LED0 and LED1 off. It will set LED2 to blink at

1 Hz at a 50 % duty cycle. LED3 will be set to be dimmed at 25 % of their maximum

brightness (duty cycle = 25 %). PCA9533/01 is used in this example.

Table 11. Programming PCA9533

Program sequence I2C-bus

START S

PCA9533 address C4h

PSC0 subaddress + Auto-Increment 11h

Set prescaler PSC0 to achieve a period of 1 second:

Blink period 1

PSC0 = 151

Set PWM0 duty cycle to 50 %:

PWM0

-----------------

PWM0 = 128

Set prescaler PCS1 to dim at maximum frequency:

256

0.5=

PSC0 1+

==

----------------------- -

PCA9533

4-bit I2C-bus LED dimmer

97h

152

80h

00h

Blink period max=

PSC1 = 0

Set PWM1 output duty cycle to 25 %:

PWM1

-----------------

PWM1 = 64

Set LED0 on, LED1 off; LED2 set to blink at PSC0, PWM0; LED3 set to blink at

PSC1, PWM1

STOP P

9. Limiting values

Table 12. Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

DD

V

I/O

I

O(LEDn)

I

SS

P

tot

T

stg

T

amb

256

40h

0.25=

E1h

supply voltage −0.5 +6.0 V

voltage on an input/output pin VSS− 0.5 5.5 V

output current on pin LEDn - 25 mA

ground supply current - 100 mA

total power dissipation - 400 mW

storage temperature −65 +150 °C

ambient temperature operating −40 +85 °C

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 12 of 24

Page 13

NXP Semiconductors

4-bit I2C-bus LED dimmer

10. Static characteristics

Table 13. Static characteristics

VDD= 2.3 V to 5.5 V; VSS=0V; T

Symbol Parameter Conditions Min Typ

Supplies

V

I

I

∆I

DD

DD

stb

DD

supply voltage 2.3 - 5.5 V

supply current operating mode; VDD= 5.5 V; no load;

standby current Standby mode; VDD= 5.5 V; no load;

additional quiescent supply

current

V

POR

power-on reset voltage no load; VI=VDD or V

Input SCL; input/output SDA

V

IL

V

IH

I

OL

I

L

C

i

LOW-level input voltage −0.5 - +0.3V

HIGH-level input voltage 0.7V

LOW-level output current VOL= 0.4 V 3 6.5 - mA

leakage current VI=VDD=V

input capacitance VI=V

I/Os

V

IL

V

IH

I

OL

I

LI

C

io

LOW-level input voltage −0.5 - +0.8 V

HIGH-level input voltage 2.0 - 5.5 V

LOW-level output current VOL= 0.4 V

input leakage current VDD= 3.6 V; VI= 0 V or V

input/output capacitance - 2.1 5 pF

=−40°C to +85°C; unless otherwise specified.

amb

V

V

I=VDD

I=VDD

or VSS; f

or VSS; f

= 100 kHz

SCL

= 0 kHz

SCL

Standby mode; VDD= 5.5 V;

every LED I/O at V

f

= 0 kHz

SCL

SS

= 2.3 V

V

DD

= 3.0 V

V

DD

= 5.0 V

V

DD

= 0.7 V

V

OL

= 2.3 V

V

DD

= 3.0 V

V

DD

= 5.0 V

V

DD

SS

= 4.3 V;

I

SS

DD

- 350 550 µA

- 1.9 3.0 µA

- - 325 µA

[2]

- 1.7 2.2 V

- 5.5 V

DD

−1- +1 µA

- 3.7 5 pF

[3]

9-- mA

[3]

12 - - mA

[3]

15 - - mA

[3]

15 - - mA

[3]

20 - - mA

[3]

25 - - mA

−1- +1 µA

PCA9533

[1]

Max Unit

DD

V

[1] Typical limits at VDD= 3.3 V, T

[2] VDD must be lowered to 0.2 V in order to reset part.

[3] Each I/O must be externally limited to a maximum of 25 mA and the device must be limited to a maximum current of 100 mA.

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 13 of 24

amb

=25°C.

Page 14

NXP Semiconductors

PCA9533

4-bit I2C-bus LED dimmer

20 %

percent

variation

0 %

−20 %

−40 %

(1)

(2)

(3)

−40 100−20

0 20406080

002aac191

T

amb

(°C)

(1) maximum

(2) average

(3) minimum

Fig 17. Typical frequency variation over process at

V

= 2.3 V to 3.0 V

DD

20 %

percent

variation

0 %

−20 %

−40 %

(1)

(2)

(3)

−40 100−20

0 20406080

002aac192

T

(°C)

amb

(1) maximum

(2) average

(3) minimum

Fig 18. Typical frequency variation over process at

VDD= 3.0 V to 5.5 V

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 14 of 24

Page 15

NXP Semiconductors

11. Dynamic characteristics

Table 14. Dynamic characteristics

Symbol Parameter Conditions Standard-mode

f

SCL

t

BUF

SCL clock frequency 0 100 0 400 kHz

bus free time between a STOP and

START condition

t

HD;STA

t

SU;STA

hold time (repeated) START condition 4.0 - 0.6 - µs

set-up time for a repeated START

condition

t

SU;STO

t

HD;DAT

t

VD;ACK

t

VD;DAT

t

SU;DAT

t

LOW

t

HIGH

t

r

t

f

t

SP

set-up time for STOP condition 4.0 - 0.6 - µs

data hold time 0 - 0 - ns

data valid acknowledge time

data valid time LOW-level

HIGH-level

[1]

[2]

[2]

data set-up time 250 - 100 - ns

LOW period of the SCL clock 4.7 - 1.3 - µs

HIGH period of the SCL clock 4.0 - 0.6 - µs

rise time of both SDA and SCL signals - 1000 20 + 0.1C

fall time of both SDA and SCL signals - 300 20 + 0.1C

pulse width of spikes that must be

suppressed by the input filter

Port timing

t

v(Q)

t

su(D)

t

h(D)

data output valid time - 200 - 200 ns

data input set-up time 100 - 100 - ns

data input hold time 1 - 1 - µs

2

I

C-bus

Min Max Min Max

4.7 - 1.3 - µs

4.7 - 0.6 - µs

- 600 - 600 ns

- 600 - 600 ns

- 1500 - 600 ns

- 50 - 50 ns

PCA9533

4-bit I2C-bus LED dimmer

Fast-mode I2C-bus Unit

[3]

300 ns

b

[3]

300 ns

b

[1] t

[2] t

[3] Cb= total capacitance of one bus line in pF.

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 15 of 24

= time for Acknowledgement signal from SCL LOW to SDA (out) LOW.

VD;ACK

= minimum time for SDA data output to be valid following SCL LOW.

VD;DAT

Page 16

NXP Semiconductors

SDA

PCA9533

4-bit I2C-bus LED dimmer

t

BUF

SCL

t

Fig 19. Definition of timing

t

LOW

HD;STA

protocol

SCL

SDA

t

r

t

HD;DAT

condition

t

SU;STA

t

BUF

START

(S)

t

HIGH

bit 7

MSB

(A7)

t

LOWtHIGH

t

r

t

f

t

SU;DAT

(A)

t

SP

t

SU;STO

STOP

condition

PP S

002aaa986

(P)

t

HD;STA

t

SU;STA

Sr

bit 6

(A6)

1

/f

SCL

t

f

bit 0

(R/W)

acknowledge

Fig 20. I2C-bus timing diagram

12. Test information

Fig 21. Test circuitry for switching times

t

HD;STA

t

SU;DAT

t

HD;DAT

t

VD;DAT

t

VD;ACK

t

SU;STO

002aab175

Rise and fall times refer to VIL and VIH.

V

DD

open

V

L

002aab880

SS

PULSE

GENERATOR

V

DD

V

I

V

O

R

500 Ω

DUT

C

R

T

L

50 pF

RL = load resistor for LEDn. RL for SDA and SCL > 1kΩ (3 mA or less current).

CL = load capacitance includes jig and probe capacitance.

RT = termination resistance should be equal to the output impedance Zo of the pulse generators.

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 16 of 24

Page 17

NXP Semiconductors

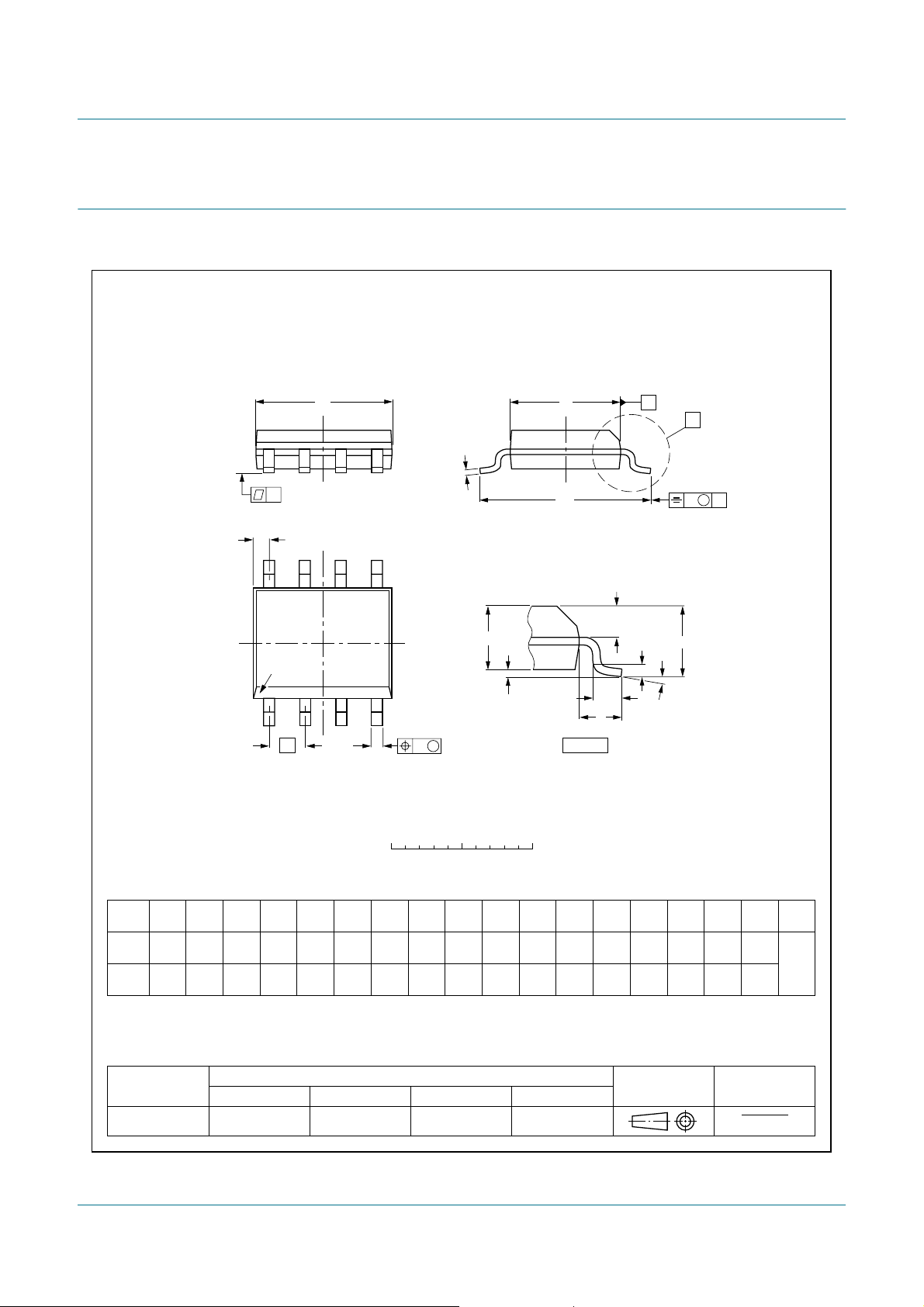

13. Package outline

PCA9533

4-bit I2C-bus LED dimmer

SO8: plastic small outline package; 8 leads; body width 3.9 mm

D

c

y

Z

8

pin 1 index

1

e

5

A

2

A

4

w M

b

p

SOT96-1

E

H

E

1

detail X

A

X

v M

A

Q

A

(A )

3

θ

L

p

L

0 2.5 5 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT96-1

A

A1A2A3b

max.

0.25

1.75

0.10

0.010

0.069

0.004

p

1.45

1.25

0.057

0.049

IEC JEDEC JEITA

076E03 MS-012

0.25

0.01

0.49

0.36

0.019

0.014

0.25

0.19

0.0100

0.0075

UNIT

inches

Notes

1. Plastic or metal protrusions of 0.15 mm (0.006 inch) maximum per side are not included.

2. Plastic or metal protrusions of 0.25 mm (0.01 inch) maximum per side are not included.

(1)E(2)

cD

5.0

4.8

0.20

0.19

REFERENCES

eHELLpQZywv θ

4.0

3.8

0.16

0.15

1.27

0.05

6.2

5.8

0.244

0.228

1.05

1.0

0.4

0.039

0.016

0.7

0.6

0.028

0.024

0.25 0.10.25

0.010.010.041 0.004

EUROPEAN

PROJECTION

(1)

0.7

0.3

0.028

0.012

ISSUE DATE

99-12-27

03-02-18

o

8

o

0

Fig 22. Package outline SOT96-1 (SO8)

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 17 of 24

Page 18

NXP Semiconductors

PCA9533

4-bit I2C-bus LED dimmer

TSSOP8: plastic thin shrink small outline package; 8 leads; body width 3 mm

D

y

Z

8

pin 1 index

5

14

e

w M

b

p

c

A

2

A

1

E

H

E

detail X

SOT505-1

A

X

v M

A

(A3)

L

p

L

A

θ

2.5 5 mm0

scale

DIMENSIONS (mm are the original dimensions)

A

A

UNIT

max.

mm

1.1

Notes

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

2. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

OUTLINE

VERSION

SOT505-1

1

0.15

0.05

A2A3b

0.95

0.25

0.80

IEC JEDEC JEITA

p

0.45

0.25

ceD

0.28

0.15

REFERENCES

(1)E(2)

3.1

2.9

3.1

2.9

0.65

5.1

4.7

LH

E

L

0.7

0.4

p

wyv

0.1 0.10.10.94

EUROPEAN

PROJECTION

(1)

Z

0.70

0.35

ISSUE DATE

99-04-09

03-02-18

θ

6°

0°

Fig 23. Package outline SOT505-1 (TSSOP8)

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 18 of 24

Page 19

NXP Semiconductors

14. Handling information

All input and output pins are protected against ElectroStatic Discharge (ESD) under

normal handling. When handling ensure that the appropriate precautions are taken as

described in

JESD625-A

15. Soldering of SMD packages

This text provides a very brief insight into a complex technology. A more in-depth account

of soldering ICs can be found in Application Note

soldering description”

15.1 Introduction to soldering

Soldering is one of the most common methods through which packages are attached to

Printed Circuit Boards (PCBs), to form electrical circuits. The soldered joint provides both

the mechanical and the electrical connection. There is no single soldering method that is

ideal for all IC packages. Wave soldering is often preferred when through-hole and

Surface Mount Devices (SMDs) are mixed on one printed wiring board; however, it is not

suitable for fine pitch SMDs. Reflow soldering is ideal for the small pitches and high

densities that come with increased miniaturization.

.

PCA9533

4-bit I2C-bus LED dimmer

or equivalent standards.

AN10365 “Surface mount reflow

15.2 Wave and reflow soldering

Wave soldering is a joining technology in which the joints are made by solder coming from

a standing wave of liquid solder. The wave soldering process is suitable for the following:

• Through-hole components

• Leaded or leadless SMDs, which are glued to the surface of the printed circuit board

Not all SMDs can be wave soldered. Packages with solder balls, and some leadless

packages which have solder lands underneath the body, cannot be wave soldered. Also,

leaded SMDs with leads having a pitch smaller than ~0.6 mm cannot be wave soldered,

due to an increased probability of bridging.

The reflow soldering process involves applying solder paste to a board, followed by

component placement and exposure to a temperature profile. Leaded packages,

packages with solder balls, and leadless packages are all reflow solderable.

Key characteristics in both wave and reflow soldering are:

• Board specifications, including the board finish, solder masks and vias

• Package footprints, including solder thieves and orientation

• The moisture sensitivity level of the packages

• Package placement

• Inspection and repair

• Lead-free soldering versus SnPb soldering

15.3 Wave soldering

Key characteristics in wave soldering are:

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 19 of 24

Page 20

NXP Semiconductors

• Process issues, such as application of adhesive and flux, clinching of leads, board

• Solder bath specifications, including temperature and impurities

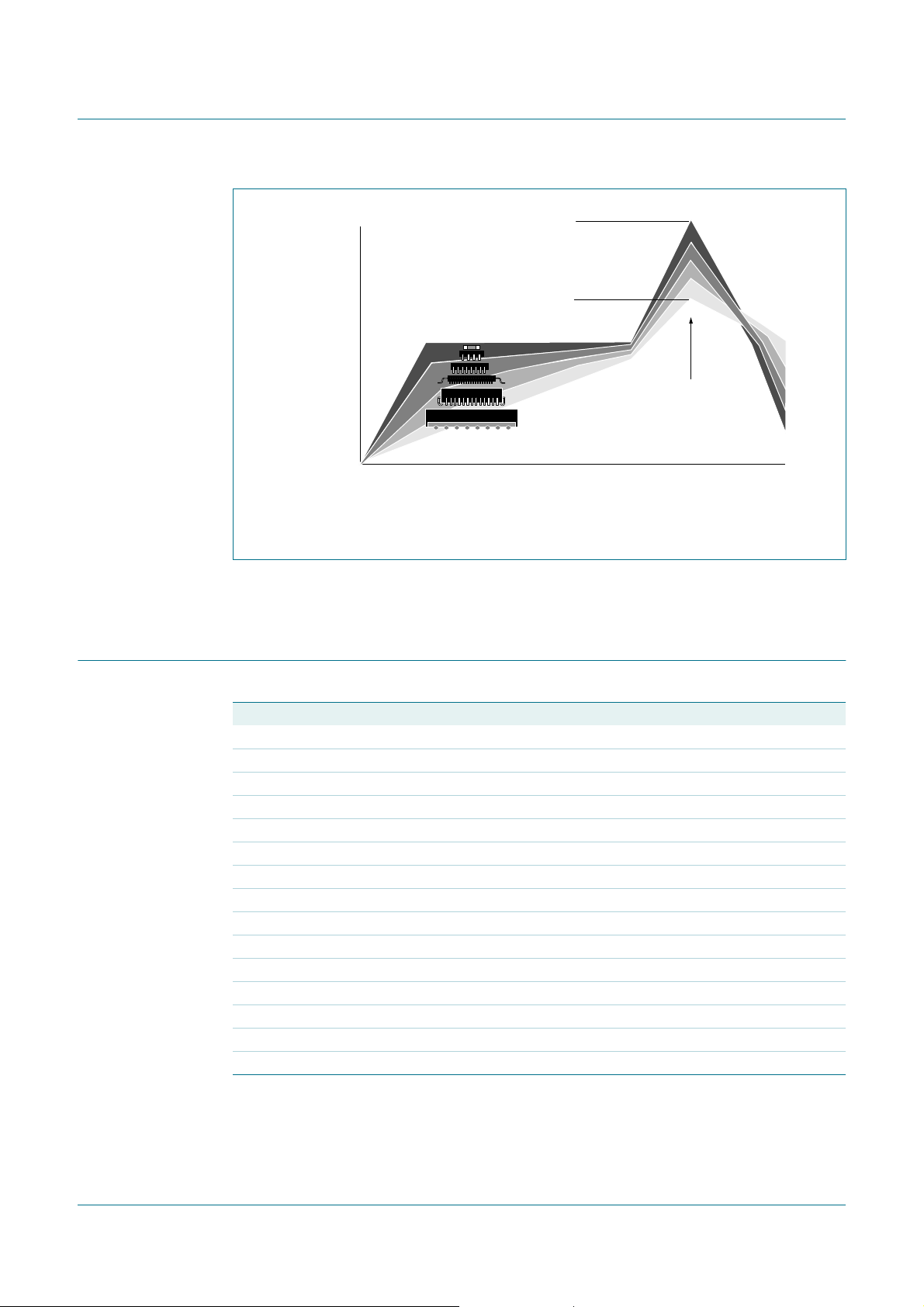

15.4 Reflow soldering

Key characteristics in reflow soldering are:

• Lead-freeversusSnPb soldering; note that a lead-free reflow process usually leads to

• Solder paste printing issues including smearing, release, and adjusting the process

• Reflow temperature profile; this profile includes preheat, reflow (in which the board is

PCA9533

4-bit I2C-bus LED dimmer

transport, the solder wave parameters, and the time during which components are

exposed to the wave

higher minimum peak temperatures (see Figure 24) than a SnPb process, thus

reducing the process window

window for a mix of large and small components on one board

heated to the peak temperature) and cooling down. It is imperative that the peak

temperature is high enough forthe solder to make reliable solder joints (a solder paste

characteristic). In addition, the peak temperature must be low enough that the

packages and/or boards are not damaged. The peak temperature of the package

depends on package thickness and volume and is classified in accordance with

Table 15 and 16

Table 15. SnPb eutectic process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (°C)

Volume (mm3)

< 350 ≥ 350

< 2.5 235 220

≥ 2.5 220 220

Table 16. Lead-free process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (°C)

Volume (mm3)

< 350 350 to 2000 > 2000

< 1.6 260 260 260

1.6 to 2.5 260 250 245

> 2.5 250 245 245

Moisture sensitivity precautions, as indicated on the packing, must be respected at all

times.

Studies have shown that small packages reach higher temperatures during reflow

soldering, see Figure 24.

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 20 of 24

Page 21

NXP Semiconductors

Fig 24. Temperature profiles for large and small components

maximum peak temperature

temperature

MSL: Moisture Sensitivity Level

= MSL limit, damage level

minimum peak temperature

= minimum soldering temperature

PCA9533

4-bit I2C-bus LED dimmer

peak

temperature

time

001aac844

For further information on temperature profiles, refer to Application Note

“Surface mount reflow soldering description”

16. Abbreviations

Table 17. Abbreviations

Acronym Description

ACPI Advanced Configuration and Power Interface

CDM Charged Device Model

DSP Digital Signal Processor

DUT Device Under Test

ESD ElectroStatic Discharge

GPIO General Purpose Input/Output

HBM Human Body Model

2

C-bus Inter-Integrated Circuit bus

I

LED Light Emitting Diode

MCU MicroController Unit

MM Machine Model

MPU MicroProcessor Unit

POR Power-On Reset

RC Resistor-Capacitor network

SMBus System Management Bus

AN10365

.

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 21 of 24

Page 22

NXP Semiconductors

PCA9533

4-bit I2C-bus LED dimmer

17. Revision history

Table 18. Revision history

Document ID Release date Data sheet status Change notice Supersedes

PCA9533_3 20090427 Product data sheet - PCA9533_2

Modifications:

PCA9533_2

(9397 750 13692)

PCA9533_1

(9397 750 12061)

• The format of this data sheet has been redesigned to comply with the new identity guidelines of

NXP Semiconductors.

• Legal texts have been adapted to the new company name where appropriate.

• Figure 11 “Write to register”: changed symbol from “t

pv

” to “t

v(Q)

”

• Figure 13 “Read input port register”:

– changed symbol from “t

– changed symbol from “t

ph

ps

” to “t

” to “t

• Table 11 “Programming PCA9533”,6

at maximum frequency” to “Set prescaler PSC1 to dim at maximum frequency”

• Table 12 “Limiting values”: changed symbol/parameter from “I

to “I

, output current on pin LEDn”

O(LEDn)

”

h(D)

”

su(D)

th

table body row: changed from “Set prescaler PWM1 to dim

, DC output current on an I/O”

I/O

• Table 13 “Static characteristics”:

– descriptive line below table title: phrase “TYP at 3.3 V and 25 °C” is re-written as

with reference to it at column heading “Typ”

– sub-section “I/Os”: symbol for parameter “input leakage current” changed from “I

Table note [1],

” to “ILI”

L

• Table 14 “Dynamic characteristics”:

– symbols t

Conditions

– symbol/parameter changed from “t

– symbol/parameter changed from “t

– symbol/parameter changed from “t

VD;DAT

(L) and t

(H) are merged as “t

VD;DAT

, Output data valid” to “t

PV

, Input data setup time” to “t

PS

, Input data hold time” to “t

PH

”; LOW and HIGH levels noted under

VD;DAT

, data output valid time”

v(Q)

, data input set-up time”

su(D)

, data input hold time”

h(D)

• Added soldering information

• Added Section 16 “Abbreviations”

20041001 Product data sheet - PCA9533_1

20030919 Product data ECN 853-2404 30307

dated 08 Sep 2003

-

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 22 of 24

Page 23

NXP Semiconductors

18. Legal information

18.1 Data sheet status

PCA9533

4-bit I2C-bus LED dimmer

Document status

Objective [short] data sheet Development This document contains data from the objective specification for product development.

Preliminary [short] data sheet Qualification This document contains data from the preliminary specification.

Product [short] data sheet Production This document contains the product specification.

[1] Please consult the most recently issued document before initiating or completing a design.

[2] The term ‘short data sheet’ is explained in section “Definitions”.

[3] Theproduct status of device(s) describedin this documentmay havechanged since thisdocument was publishedand maydiffer in caseof multiple devices. The latestproduct status

information is available on the Internet at URL

[1][2]

Product status

18.2 Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. NXP Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information includedherein and shall haveno liability fortheconsequences of

use of such information.

Short data sheet — A short data sheet is an extract from a full data sheet

with thesame product type number(s) andtitle. A short data sheetis intended

for quickreference only and should not be reliedupon to contain detailed and

full information. For detailed and full information see the relevant full data

sheet, which is available on request via the local NXP Semiconductors sales

office. In case of any inconsistency or conflict with the short data sheet, the

full data sheet shall prevail.

18.3 Disclaimers

General — Information in this document is believed to be accurate and

reliable. However,NXPSemiconductors does not give any representationsor

warranties, expressedor implied, as to the accuracyor completeness of such

information and shall have no liability for the consequences of use of such

information.

Right to make changes — NXP Semiconductors reserves the right to make

changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This documentsupersedesand replaces all information supplied prior

to the publication hereof.

Suitability for use — NXP Semiconductors products are not designed,

authorized or warranted to be suitable for use in medical, military, aircraft,

space or life support equipment, nor in applications where failure or

malfunction of an NXP Semiconductors product can reasonably be expected

to result in personal injury, death or severe property or environmental

[3]

http://www.nxp.com.

Definition

damage. NXP Semiconductors accepts no liability for inclusion and/or use of

NXP Semiconductors products in such equipment or applications and

therefore such inclusion and/or use is at the customer’s own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. NXP Semiconductors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

Limiting values — Stress above one or more limiting values (as defined in

the Absolute MaximumRatings System of IEC 60134) may cause permanent

damage to thedevice. Limiting valuesarestress ratings only and operationof

the device at these or any other conditions above those given in the

Characteristics sections of this document is not implied. Exposure to limiting

values for extended periods may affect device reliability.

Terms and conditions of sale — NXP Semiconductors products are sold

subject to the general terms and conditions of commercial sale, as published

at

http://www.nxp.com/profile/terms, including those pertaining to warranty,

intellectual property rights infringement and limitation of liability, unless

explicitly otherwise agreed to in writing by NXP Semiconductors. In case of

any inconsistency or conflict between information in this document and such

terms and conditions, the latter will prevail.

No offer to sell or license — Nothing in this document may be interpreted

or construed as an offer to sell products that is open for acceptance or the

grant, conveyance or implication of any license underanycopyrights, patents

or other industrial or intellectual property rights.

Export control — This document as well as the item(s) described herein

may be subject to export control regulations. Export might require a prior

authorization from national authorities.

18.4 Trademarks

Notice: Allreferenced brands, productnames, service names andtrademarks

are the property of their respective owners.

I2C-bus — logo is a trademark of NXP B.V.

19. Contact information

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

PCA9533_3 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 03 — 27 April 2009 23 of 24

Page 24

NXP Semiconductors

20. Contents

PCA9533

4-bit I2C-bus LED dimmer

1 General description. . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Ordering information. . . . . . . . . . . . . . . . . . . . . 2

3.1 Ordering options . . . . . . . . . . . . . . . . . . . . . . . . 2

4 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5 Pinning information. . . . . . . . . . . . . . . . . . . . . . 3

5.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 3

6 Functional description . . . . . . . . . . . . . . . . . . . 4

6.1 Device address. . . . . . . . . . . . . . . . . . . . . . . . . 4

6.2 Control register . . . . . . . . . . . . . . . . . . . . . . . . . 4

6.2.1 Control register definition . . . . . . . . . . . . . . . . . 5

6.3 Register descriptions . . . . . . . . . . . . . . . . . . . . 5

6.3.1 INPUT - Input register. . . . . . . . . . . . . . . . . . . . 5

6.3.2 PCS0 - Frequency Prescaler 0. . . . . . . . . . . . . 5

6.3.3 PWM0 - Pulse Width Modulation 0. . . . . . . . . . 5

6.3.4 PCS1 - Frequency Prescaler 1. . . . . . . . . . . . . 6

6.3.5 PWM1 - Pulse Width Modulation 1. . . . . . . . . . 6

6.3.6 LS0 - LED selector . . . . . . . . . . . . . . . . . . . . . . 6

6.4 Pins used as GPIOs . . . . . . . . . . . . . . . . . . . . . 7

6.5 Power-on reset . . . . . . . . . . . . . . . . . . . . . . . . . 7

7 Characteristics of the I

2

C-bus. . . . . . . . . . . . . . 8

7.1 Bit transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.1.1 START and STOP conditions . . . . . . . . . . . . . . 8

7.2 System configuration . . . . . . . . . . . . . . . . . . . . 8

7.3 Acknowledge . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.4 Bus transactions . . . . . . . . . . . . . . . . . . . . . . . 10

8 Application design-in information . . . . . . . . . 11

8.1 Minimizing I

when the I/Os are used to

DD

control LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.2 Programming example . . . . . . . . . . . . . . . . . . 12

9 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . 12

10 Static characteristics. . . . . . . . . . . . . . . . . . . . 13

11 Dynamic characteristics . . . . . . . . . . . . . . . . . 15

12 Test information. . . . . . . . . . . . . . . . . . . . . . . . 16

13 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 17

14 Handling information. . . . . . . . . . . . . . . . . . . . 19

15 Soldering of SMD packages . . . . . . . . . . . . . . 19

15.1 Introduction to soldering. . . . . . . . . . . . . . . . . 19

15.2 Wave and reflow soldering . . . . . . . . . . . . . . . 19

15.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 19

15.4 Reflow soldering. . . . . . . . . . . . . . . . . . . . . . . 20

16 Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . 21

17 Revision history. . . . . . . . . . . . . . . . . . . . . . . . 22

18 Legal information . . . . . . . . . . . . . . . . . . . . . . 23

18.1 Data sheet status. . . . . . . . . . . . . . . . . . . . . . 23

18.2 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

18.3 Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

18.4 Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . 23

19 Contact information . . . . . . . . . . . . . . . . . . . . 23

20 Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section ‘Legal information’.

© NXP B.V. 2009. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: 27 April 2009

Document identifier: PCA9533_3

Loading...

Loading...