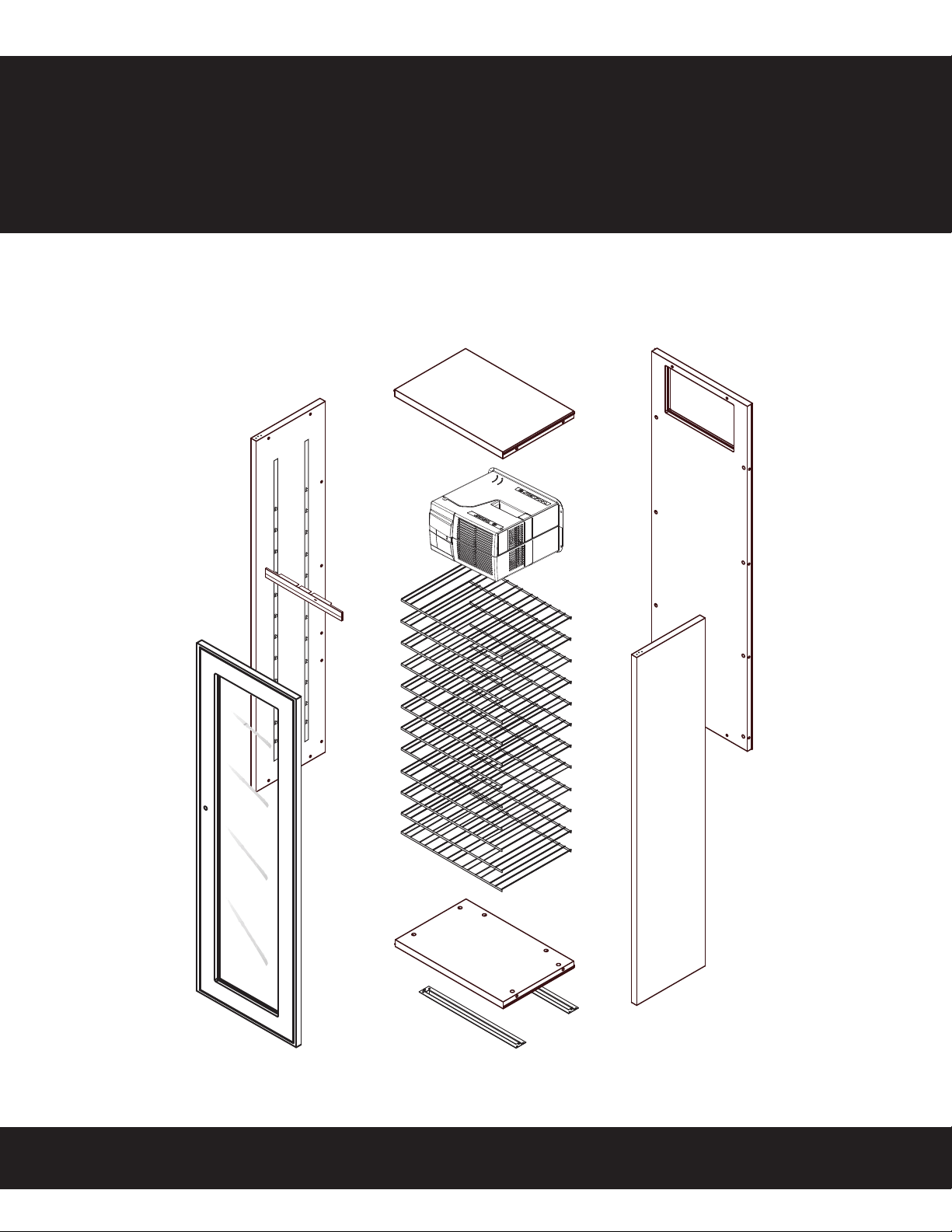

Nuvo 220, 110 User Manual

C E L L A R nuvo

1 1 0 / 2 2 0

k o o l s pac e

TM

ASSEMBLY & OPERATION MANUAL

~ 3 ~

READ BEFORE YOU START

1. LOCATING YOUR WINE CELLAR - Remember, it is not an appliance, it is a piece of furniture

A. Provide 4” minimum clearance for both sides and back, keep the top completely clear.

Under no circumstances should the unit be “built-in” in any way.

B. Never locate your wine cellar outdoors or in an area with extremes of temperature and

humidity.

Garages, attics, unnished basements, laundry rooms, breezeways, closets, bedrooms or

any unventilated room. In other words these units must be installed in air-conditioned

environments which do not “trap” the warm air being exhausted.

C. Temperatures in surrounding area must not exceed 80 °F (25 °C) with humidity levels not

to exceed 70% R.H. (Relative Humidity). Never set your temperatures below default (57ºF)

whenever ambient conditions are warm (above 75ºF) or humid (above 50%R.H.).

D. Outlet power must be a DEDICATED separately fused, grounded, 15 Amp 110 - 120 V line or

7.5 Amp - 240 V line rated for your unit (CHECK BOX OR SERIAL NUMBER LABEL ON UNIT

FOR YOUR LINE VOLTAGE REQUIREMENTS).

E. You must monitor your unit DAILY. If unit is in “Alarm”, unplug the unit inmediately. Always

check for any water (condensate) leaks.

Vintage Keeper will not be liable or responsible for incidental or consequential damages.

(See Warranty).

F. Place unit in a clean area and allow access to the exterior surfaces for periodic vacuuming

of the condensor coil. (See troubleshooting for details.)

G. Always remove all bottles before relocating your wine cellar.

2. AREA FOR ASSEMBLING YOUR WINE CELLAR

Choose a clear 12’ by 12’ area with a level oor and carpeting to help reduce scratching of surfaces.

3. TOOLS

* Hex wrench (included)

* Phillips screwdriver

* Carpenter’s level

* Helper or two is strongly recommended

4. TEST THE COOLING UNIT

Plug it in for a few minutes on a table top, to verify that controls and display are functional, and that

the unit is producing cool air after a few minutes of operation.

Note that the electronic controller has a one-minute cautionary delay between initial plug-in and

start-up of the compressor.

BEFORE YOU START !

NOTE: Fill out the WARRANTY REGISTRATION FORM with the serial number located on the LEFT

SIDE of unit.

~ 2 ~

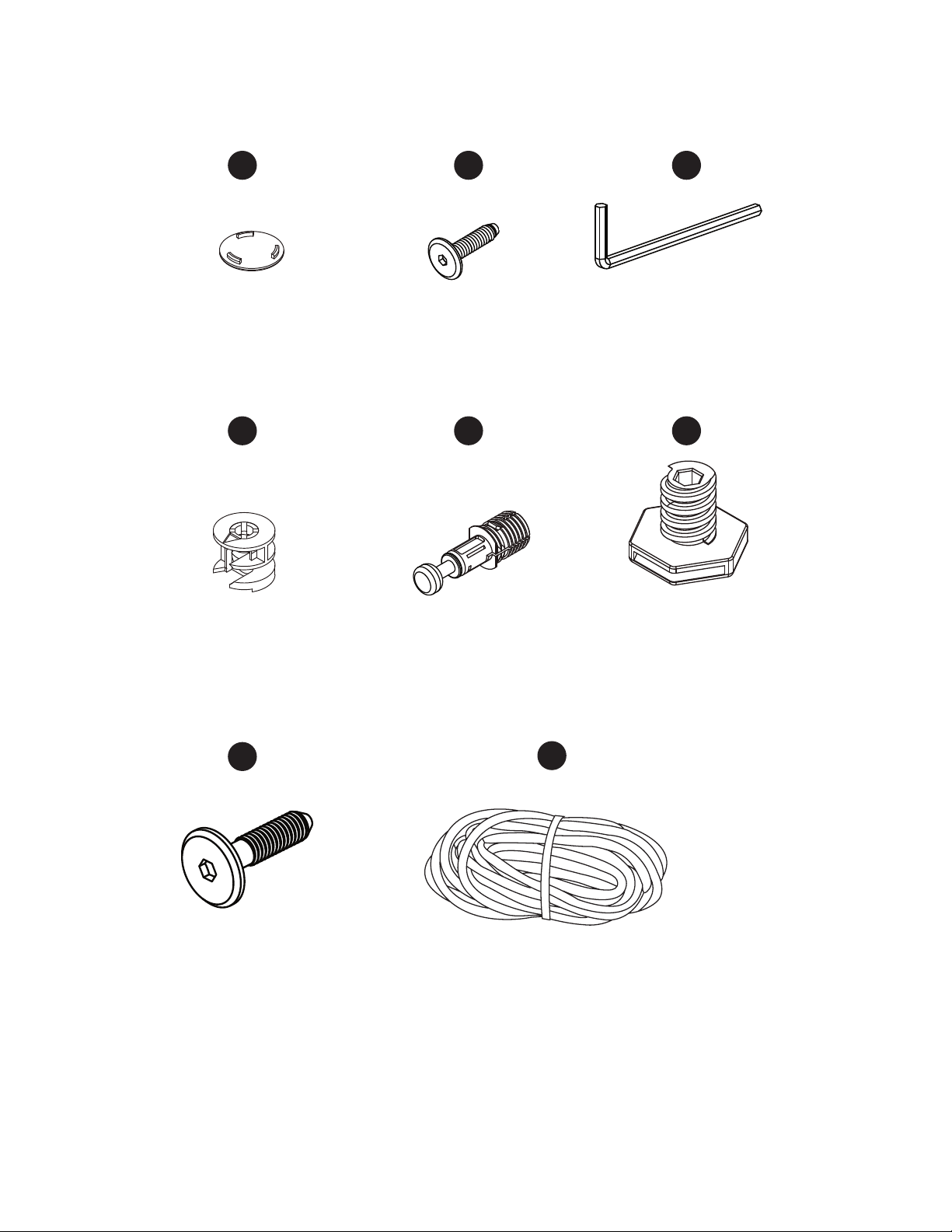

HARDWARE KIT

A

Cam Cap

x 20 (x24)*

D

B

Hex Bolt

x 14

E

C

Hex Wrench

x 1

F

Cam

x 20 (x24)*

G

In Cooling Unit Box

Hex Bolt (Flange)

x 2

Cam Pin

x 20 (x24)*

Panel Insulation Strip

Leg

x 4

H

x 1

*NOTE : Hardware quantities for Model 220 are indicated in parenthesis.

~ 3 ~

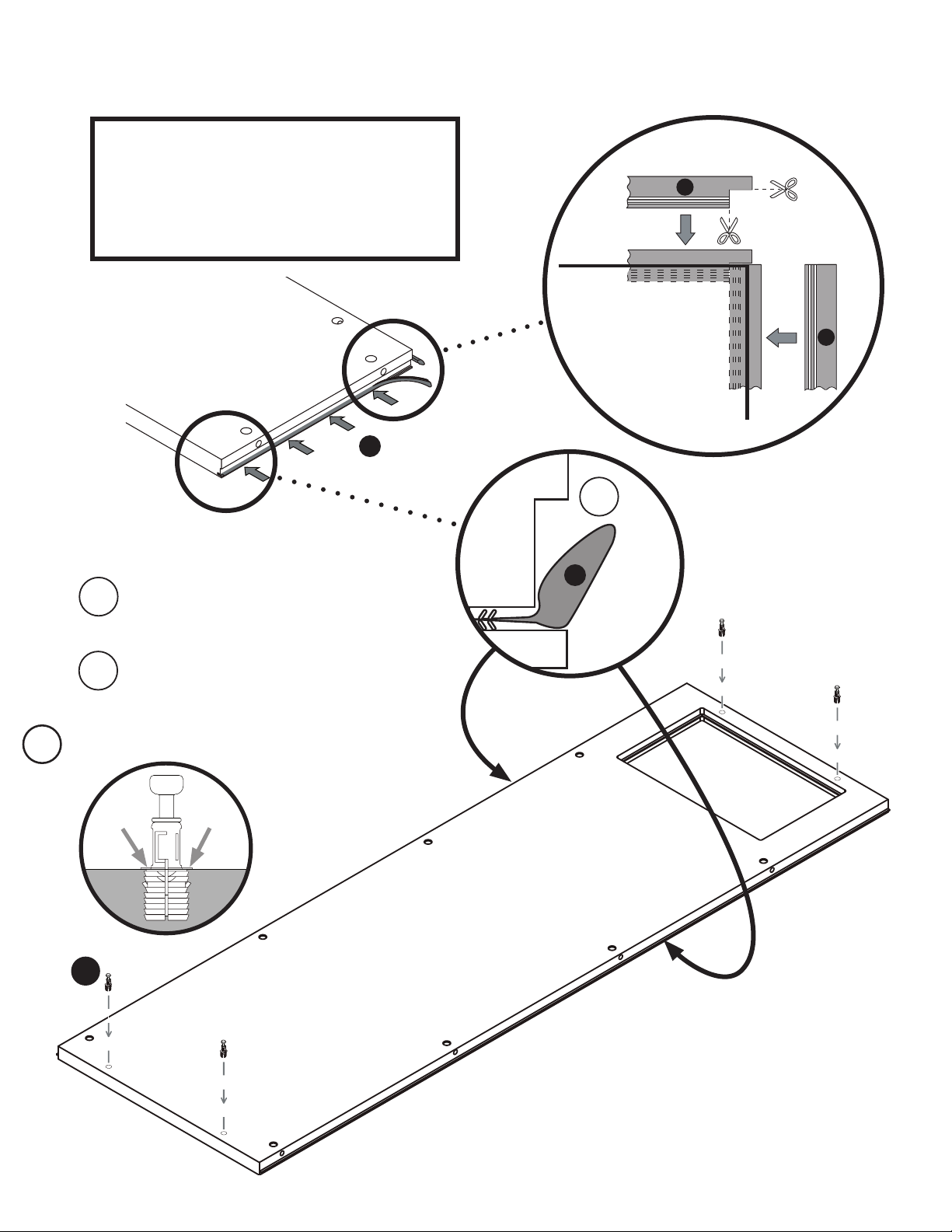

~ 5 ~

PANEL EDGE

CAUTION :

STEP 1 : PANEL PREPARATION

1. Watch for sharp staples on boxes.

2. DO NOT STEP ON PANELS

3. The manual will give a recommended

order to open boxes, it saves space and time.

H

Open Box VP1.

Install INSULATION STRIP (H) to Back,

1

Top, and Bottom Panels. PUSH IN

FULLY!

H

H

1

H

Insert Cam Pins (E) by hand in BACK

2

PANEL’S predrilled holes down to

TAB.(May require some force)

CAUTION : DO NOT BREAK CAM PIN TABS!

!

DO NOT HAMMER!

TAB

TAB

BACK PANEL

E

~ 4 ~

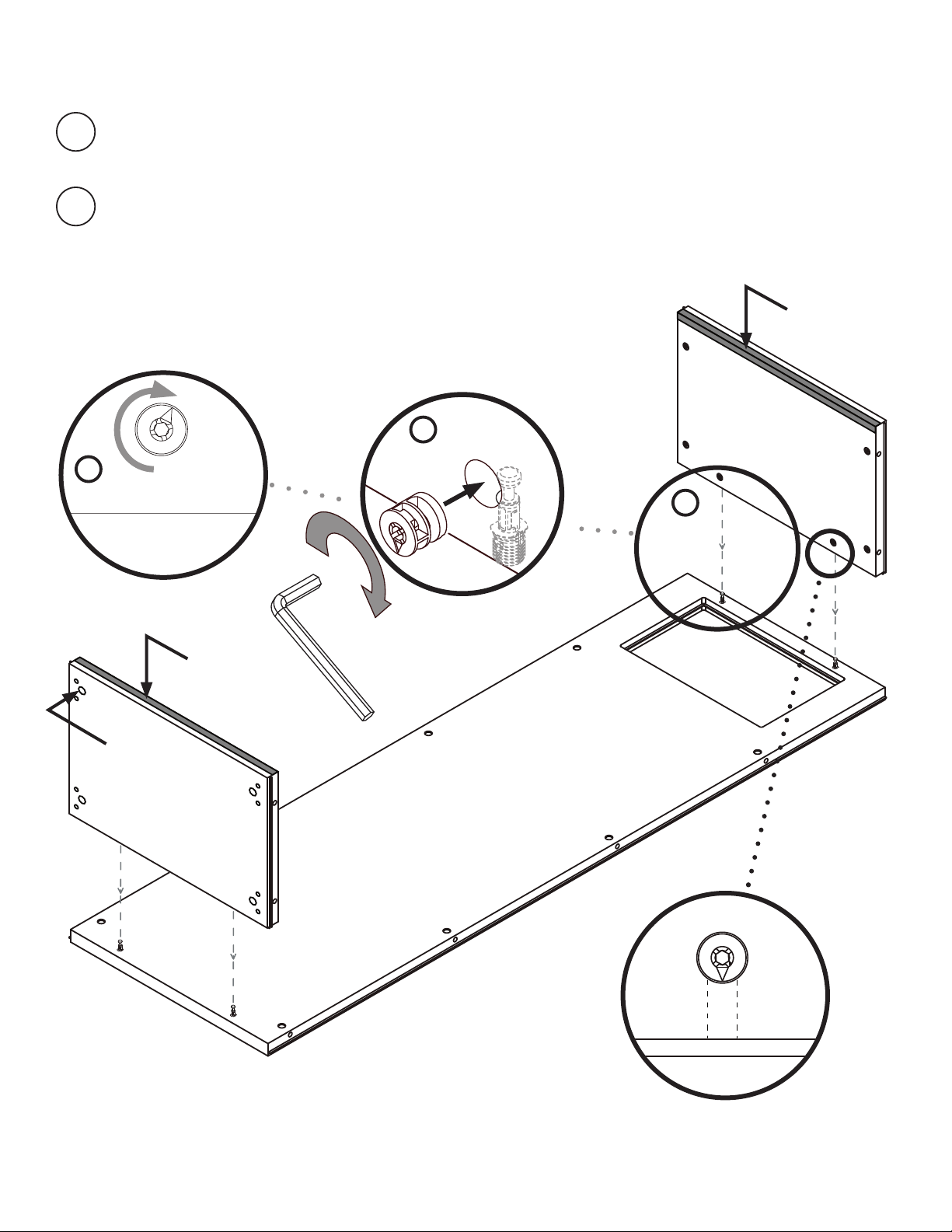

STEP 2 : CABINET ASSEMBLY

1

2

Attach Top and Bottom to Back by CAREFULLY aligning edge holes

over Cam Pins and gently push together to avoid damaging cam

pins. DO NOT BANG OR SLAP PANELS TOGETHER!!!

Insert Cam, push all the way in under panel level (may require

some force) and make sure Arrow points to outside edge, use

allen key provided or #3 phillips screwdriver.

Cam Arrow faces away from outside edge when tightened

2

CAM in LOCKED

PANEL EDGE

POSITION

METAL

2

1

METAL

BOTTOM

PANEL

~ 5 ~

Loading...

Loading...