Page 1

USER GUIDE

CENTRAL VACUUM

POWER UNITS

PP500, PP600 & PP650

AB0039

FOR RESIDENTIAL USE ONLY

30042509E

! !

MODELS SFDB-DQ, SFDB-DR AND SFDB-DS

PUREPOWER SERIES

Page 2

SAVE THESE INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE

WARNING

To reduce the risk of fire, electric

shock or injury:

1. Do not use on wet surfaces or outdoors.

2. Do not vacuum liquids or fine powders

(such as drywall dust).

3. Do not use to pick up flammable or

combustible liquids such as gasoline or

use in areas where they may be present.

4. Do not pick up anything that is burning or

smoking, such as cigarettes, matches, or

hot ashes.

5. Do not allow to be used as a toy. Close

attention is necessary when used by or

near children.

6. Use only as described in this manual.

Use only manufacturer's recommended

attachments.

7. Keep hair, loose clothing, fingers and all

parts of body away from openings and

moving parts.

8. Turn off all controls before unplugging.

9. Use extra care when cleaning on stairs.

10. Do not handle plug or appliance with wet

hands.

11. Do not use with damaged cord or plug.

If appliance is not working as it should,

if it has been dropped, damaged, left

outdoors, or dropped into water, return it

to a Service Center.

12. Keep your work area well lighted.

13. Connect to a properly grounded outlet

only. See grounding instructions shown

on page 3.

14. When performing installation, servicing

or cleaning the unit, it is recommended

to wear safety glasses and gloves.

CAUTION

1. Do not put any object into openings. Do

not use with any opening blocked; keep

free of dust, lint, hair and anything that

may reduce air flow.

2. Ensure air flows freely and exhausts

unobstructed from top or side outlet.

3. Do not use without filter (or filters,

according to the model) in place.

4. Do not use to blow leaves or debris.

5. Do not place any object on top of the unit.

6. Do not install the unit horizontally.

7. Do not use the pail as a wash bucket.

8. Do not use the pail as a stool.

9. Avoid picking up sharp objects.

10. This appliance is for use on a standard

120 VAC, dedicated 20-amp minimum

branch circuit.

11. Do not unplug the unit by pulling on cord.

To unplug, grasp the plug, not the cord.

12. Store your vacuum cleaner indoors in

a clean, dry area, away from extreme

temperatures.

13. Any servicing other than that

recommended in this manual should

be performed by an authorized service

facility.

14. We recommend that your unit be

inspected by a specialized technician

once a year.

!

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should always be

followed, including the following:

2

GROUNDING INSTRUCTIONS . . . . 3

OPERATION & MAINTENANCE . .4-7

WHEN TO CHANGE BAG

OR EMPTY DEBRIS PAIL . . . . . . . . . . . . . . . 4

HOW TO EMPTY DEBRIS PAIL (PP600 AND

PP650 POWER UNITS ONLY) . . . . . . . . . . . 4

DISPOSABLE BAG REPLACEMENT

(MODEL 395) . . . . . . . . . . . . . . . . . . . . . 4

SEALED HEPA PERMANENT FILTER

(PP600 AND PP650 POWER UNITS ONLY) . 5

R

EMOVAL & INSTALLATION OF PERMANENT FILTER

(PP600 & PP650 POWER UNITS ONLY) . . . 5

MOTOR FOAM FILTER (ALL UNITS) . . . . . . . . 6

REMOVAL & INSTALLATION OF SECONDARY

HEPA FILTER (PP650 POWER UNIT ONLY) 7

SERVICE PARTS . . . . . . . . . . . . . .8-9

TROUBLESHOOTING GUIDE . . 10-11

TABLE OF CONTENTS

Page 3

3

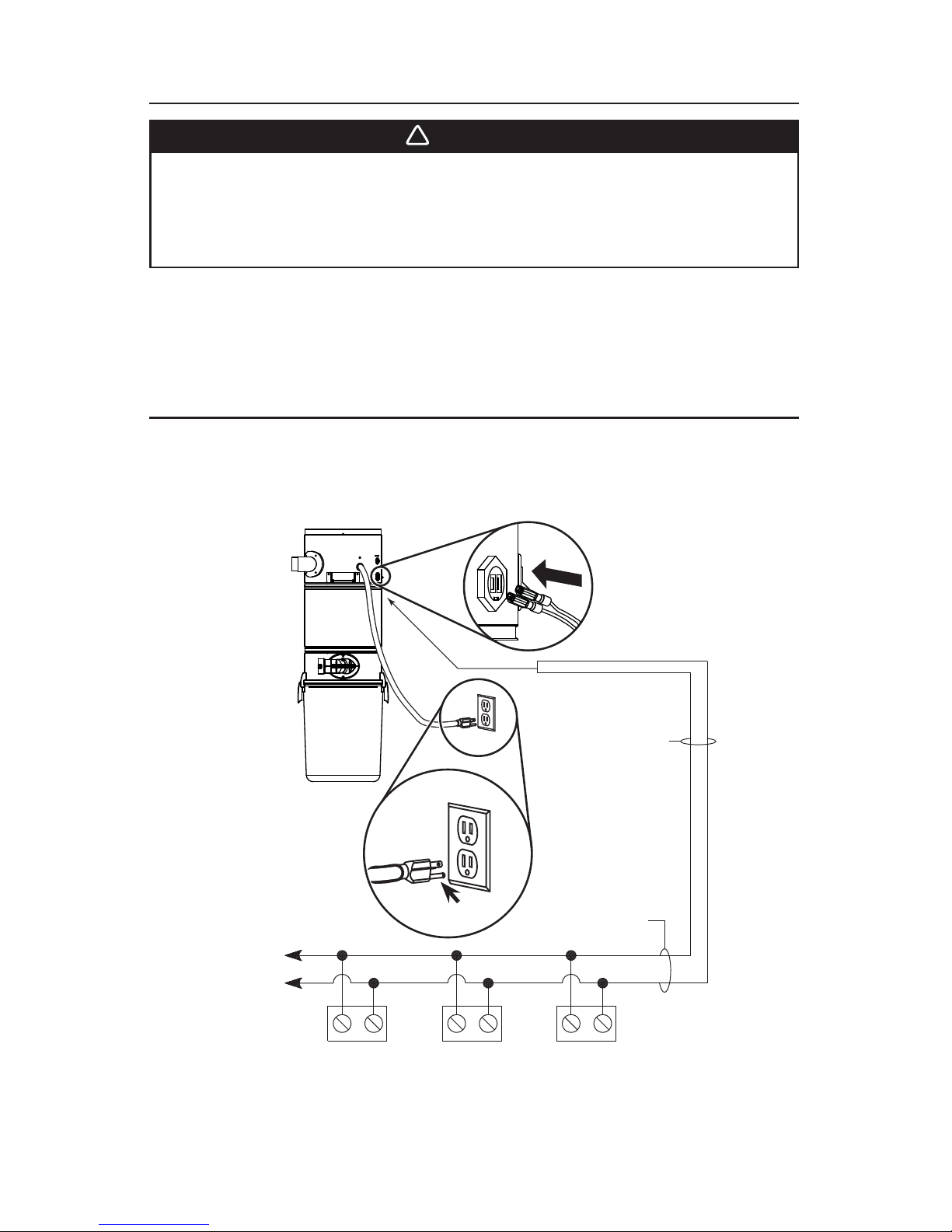

Grounding Instructions – This appliance must be grounded. If it should malfunction or break

down, grounding provides a path of least resistance for electric current, to reduce the risk

of electric shock. This appliance is equipped with a cord having an equipment-grounding

conductor and grounding plug. The plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

WIRING

This appliance is for use on a standard 120 VAC, minimum dedicated 20-amp branch circuit

with a NEMA 5-15R receptacle. Make sure that the power unit is connected to an outlet

and has a grounding attachment plug that looks like the plug shown in illustration below. No

adapter should be used with this power unit.

NOTE: Inlet leads to be connected to power unit low voltage tabs using crimp connectors

(included in parts bag) and low voltage harness.

GROUNDING INSTRUCTIONS

WARNING

!

Improper connection of the equipment-grounding conductor can result in

a risk of electric shock. Check with a qualified electrician or service person

if you are in doubt as to whether the outlet is properly grounded. Do not

modify the plug provided with the appliance – if it will not fit the outlet, have

a proper outlet installed by a qualified electrician.

AE0044

INLET

CRIMP

CONNECTORS TO

BE

CONNECTED

IN

LOW VOLTAG E

TABS

INLET INLET

TO

OTHER

INLETS

MODEL 376-UL

(18/2) LOW VO LTAGE

WIRE

INLET LEADS

GROUNDED OUTLETS

GROUNDING PIN

Page 4

Open the inlet cover and insert the end of the hose into the inlet to turn on the vacuum.

For non-switched hoses, inserting the hose automatically turns on the power unit; removing

the hose shuts off the power unit. Some hoses have switches which can be used to activate

power unit. Unless using the utility valve (PP650 unit only) the ON/OFF switch located on the

power unit needs to be kept in the OFF position.

As you vacuum, dirt and dust are carried to the power unit where they remain in a bag or in

the debris pail (according to the power unit model).

Use the cleaning tools as you would for any other vacuum cleaner. Avoid picking up very large

debris or lengthy as these kinds of objects may become lodged in the hose or tubing.

WHEN TO CHANGE BAG OR EMPTY DEBRIS PAIL

With a 6 U.S. gallons capacity, under normal conditions the bag/debris pail requires changing/

emptying approximately twice a year. If the bag/debris pail is full, you will notice a reduced

suction from the system. Unless this loss of suction is caused by a blockage in the system,

changing the bag or emptying the debris pail will solve the problem.

NOTE: Even if not filled to capacity, if the bag seems tightly stretched when removing the

debris pail, changing the bag will prevent it from tearing.

HOW TO EMPTY DEBRIS PAIL

(PP600 AND PP650 POWER UNITS ONLY)

To empty the debris pail, release both latches on sides of the unit by pulling out and then

pushing up. Holding the pail by the latches, lower it from unit. Carry pail to trash receptacle

and dispose of debris. Put the pail back in its place.

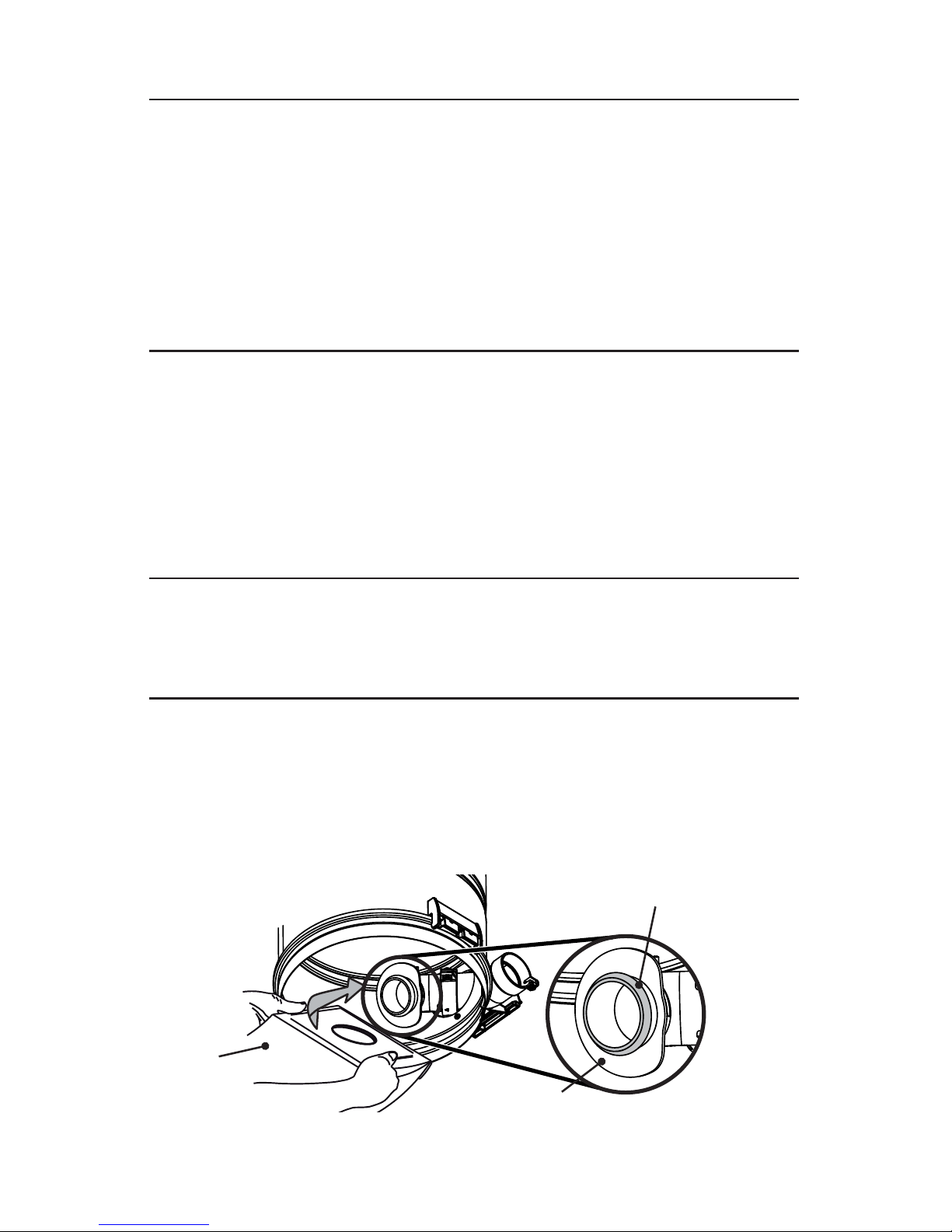

DISPOSABLE BAG REPLACEMENT (MODEL 391)

To remove the disposable bag, release both latches on sides of the unit by pulling out and

then pushing up. Remove the pail from unit. Grasp the edges of the bag collar and pull

down. The bag will slide off easily. Do not pull on the bag.

Unfold the new bag.

Grasp collar where indicated on the new bag and insert over bag adapter. Be careful not

to tear the bag. Ensure the collar is positioned between the taper ring and the bag stopper

on the bag adapter (see illustration below). Put the pail back in its place.

OPERATION AND MAINTENANCE

AO0081

TAPER RING

BAG STOPPER

4

DISPOSABLE BAG

MODEL 391

Page 5

5

OPERATION AND MAINTENANCE (CONT’D)

SEALED HEPA PERMANENT FILTER

(PP600 AND PP650 POWER UNITS ONLY)

This filter protects the motor and stops small particles from escaping to the outside of the

power unit without the need to replace it. The filter cleans itself by moving up when the power

unit starts, and dropping down when the unit is turned off. Under normal use, there is no need

to maintain this filter. It is possible to remove it to inspect the foam motor filter, or to replace it

if ever it has been damaged (by sharp debris, for example).

REMOVAL AND INSTALLATION OF SEALED HEPA PERMANENT

FILTER (PP600 AND PP650 POWER UNITS ONLY)

To remove:

Remove the pail from the unit. To remove the

permanent filter, use pull tab (A) located on edge of

filter to pull and loosen filter from inlet chamber wall.

Squeeze from both sides of the filter to the center of

the housing (see illustration at right). Then, carefully

remove it from the unit.

To reinstall:

Squeeze the filter in order to move it past the inlet

opening (B) (see illustration at right). Let the filter bear

against the unit wall by releasing the pressure. Make

sure to place the rigid ring in its groove to ensure

proper sealing.

NOTE: Make sure the filter is installed so that the

pull tab (A) is accessible for future filter removal.

AD0084

A

AA0005

A

CAUTION

Be sure to reinstall filter properly. Appropriate location is critical to insure

proper protection of the motor.

AD0085

B

Page 6

OPERATION AND MAINTENANCE (CONT’D)

FOAM MOTOR FILTER (ALL UNITS)

A foam motor safety filter, located at the top of the vacuum chamber provides protection

against dirt being pulled into the motor if the disposable bag or sealed HEPA permanent filter

should accidentally be torn. This filter should be checked and cleaned if necessary when

replacement bag is installed, or when sealed HEPA permanent filter is removed (PP600 and

PP650 units only). Simply brush filter clean. If the filter is excessively soiled, hand wash in

a water and mild detergent solution, rinse and let it dry completely on a flat surface before

reinstalling.

REMOVING FOAM MOTOR FILTER

Remove the debris pail and disposable bag or

permanent filter. Lift the center of the wire retaining the

foam motor filter and slide the filter out of its location.

REINSTALLING FOAM MOTOR FILTER

To reinstall the foam motor filter, reverse the steps

described above.

CAUTION

Operating the power unit without the foam motor filter will void the warranty.

AD0086

6

Page 7

7

REMOVAL AND INSTALLATION OF SECONDARY HEPA FILTER

(PP650 POWER UNIT ONLY)

NOTE: This is a disposable HEPA filter; do not attempt to wash it since this will damage it.

This HEPA filter should be replaced every 5 years. Proceed as follow:

If installed, detach the exhaust line from the top of the unit.

Disassemble upper part from lower part top cap assembly by pushing on the 4 retaining

tabs (one by one) located on the lower part and pulling on upper part to disengage it.

NOTE: A small flat blade screwdriver can also be used to pry on the 4 retaining tabs, as

shown in illustration A at the bottom of the page.

Discard the used filter and replace with a new one (part no. S10941416). Be sure to install

it with the gasket on top as shown in illustration B (at the bottom of the page), then snap in

place the upper part of the top cap. If need be, reconnect the exhaust line to the top cap.

OPERATION AND MAINTENANCE (CONT’D)

WARNING

!

Risk of warm surfaces and sharp edges. It is recommended to wear safety

gloves while handling this HEPA filter.

4 X

AR0053

AB

Page 8

SERVICE PARTS

PP650 UNIT

PP500 AND

PP600 UNITS

8

AL0021

7

15

10

17

8

9

11

1

3

12

13

14

1

2

4

5

6

16

Page 9

REPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains in good working

condition, you must use NuTone genuine replacement

parts only. NuTone genuine replacement parts are specially

designed for each unit and are manufactured to comply

with all the applicable certification standards and maintain

a high standard of safety. Any third party replacement part

used may cause serious damage and drastically reduce

the performance level of your unit, which will result in

premature failing. NuTone also recommends to contact a

NuTone authorized service center for all replacement parts

and repairs.

SERVICE PARTS (CONT’D)

KEY NO.PART NO.DESCRIPTION PP500 PP600 PP650

1

S10941409

PP650 T

OP CAP ASSEMBLY

(INCLUDING ITEM 5) (UPPER PA RT )

1

S10941424 PP600 T

OP CAP ASSEMBLY 1

S10941411 PP500 TOP CAP ASSEMBLY 1

2 S10941416 PP650 EXHAUST HEPA FILTER 1

3 S10941413

PP650 T

OP CAP ASSEMBLY

(INCLUDING ITEM 5) (LOWER PAR T)

1

4

S10941419

M

OTOR WITH UPPER AND LOWER

FOAMS AND NUTS

11

S10941418

M

OTOR WITH UPPER AND LOWER

FOAMS AND NUTS

1

5 S10941420

E

LECTRONIC BOARD WITH BOTTOM

AND SIDE FOAMS

111

6 S99670649 R

OCKER SWITCH 111

7 S10941399 MOTOR FOAM FILTER WITH FASTENER 111

8 S10941400 GASKET 113

9 S10941415 SEALED HEPA PERMANENT FILTER 11

10 S99670648 DEBRIS PAIL (INCLUDING KEY NO. 11)111

11 S10941199 LATCH AND SCREWS 222

12 S10941404 LATCH KEEPER WITH SCREWS 222

13 S10941405 BAG ADAPTER WITH NUT AND SCREW 111

14 S10941408 U

TILITY VALVE 111

15 S10941406

I

NTAKE ELBOW WITH GASKET,

SCREWS, AND NUTS

111

16 S99670650

E

XHAUST PORT WITH GASKET AND

SCREWS

11

17 S30390555 U

NIT SUPPORT BRACKET 111

18 391

D

ISPOSABLE BAG

(SET OF 3, NOT SHOWN)

111

NOTE: Order service parts by “Part No.” — not by “Key No.”

9

Page 10

TROUBLESHOOTING GUIDE

PROBLEMS POSSIBLE CAUSES POSSIBLE REMEDY

1. Loss or

decrease

of suction

occurs.

• Debris pail or disposable

bag is completely full.

• Debris pail gasket

damaged or missing.

• Obstruction in the hose.

A blockage in the hose

can be determined by

inserting the hose into

any wall inlet and, while

power unit is running,

check each additional

inlet for normal suction by

holding the palm of your

hand over the open inlet.

If normal suction is felt at

all other inlets, insert the

hose into a second inlet.

If the blockage still exists

it is located in the hose.

However, if the blockage

does not occur when

the hose is changed,

the blockage is probably

located in the tubing

system leading to the

original inlet.

• Obstruction in the tubing

system inside the walls.

• Sealed HEPA permanent

filter or disposable bag torn.

• Wall inlet cover not

properly sealed.

• Exhaust tubing or vent

clogged.

• Change the disposable bag or empty

debris pail as described on page 5.

• Replace the debris pail gasket.

• Disconnect the hose from the wall inlet

and insert a blunt instrument into the hose

— slightly smaller in diameter — such as

a flexible garden hose. Push the garden

hose through the cleaning system hose

until the obstruction has been cleared.

• Insert hose end into any inlet to make

power unit running, then place the palm

of your hand over the opposite end of

the hose. When you can feel the suction

increase, hold your hand over the hose

end for a few seconds and then quickly

remove your hand. This procedure

repeated several times should clear the

obstruction. If the blockage is not cleared,

contact your nearest Service Center.

• Clean the interior or the unit and install a

new permanent filter (or disposable bag).

• Check all wall inlet covers to be sure they

are closed and sealed tightly.

• Inspect and remove any blockages.

10

Page 11

TROUBLESHOOTING GUIDE (CONT’D)

PROBLEMS POSSIBLE CAUSES POSSIBLE REMEDY

2. Power

unit does

not start

or stops

suddenly.

• Defective inlet. Check

other wall inlets.

• Power unit internal

circuit breaker has been

activated (the reset button

is popped up).

• Blown fuse or tripped

circuit breaker on house

electrical panel.

• Defective hose.

• Power unit overcurrent

protector has been

activated.

3. Power

unit runs

continuously

when the

hose is

removed.

• The unit power switch is in

ON position.

• An electrical short has

occured somewhere in the

system.

• Set the unit power switch to OFF position.

• Perform a complete check of all wall inlets

and power unit low voltage control leads

connections. Contact your authorized

Service Center.

• Replace defective wall inlet.

• Push on

the circuit

breaker

reset button

located on

the left side

of the power

unit. If this

button pops

up again,

contact your

authorized

Service

Center.

• Replace fuse or reset circuit breaker on

house electrical panel.

• Replace hose as required.

• Unplug the power unit, wait at least 15

minutes and plug back the power unit.

AC0003

POWER

SWITCH

RESET

BUTTON

11

Discover a comprehensive collection of vacuums & floor care products on our website.

Loading...

Loading...