Page 1

POWER

MODULE

READ AND SAVE THESE INSTRUCTIONS

MODEL

PM44

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If

you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel

and lock the service disconnecting means to prevent power from

being switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified

person(s) in accordance with all applicable codes and standards,

including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer’s

guideline and safety standards such as those published by the

National Fire Protection Association (NFPA), and the American

Society of Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. To reduce the risk of fire or electric shock, do not use this range

hood with an additional speed control device.

7. Ducted fans must always be vented to the outdoors.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or when cooking

flaming foods.

3. Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate for the

size of the surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal

tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately, EVACUATE AND CALL

THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent

steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you al-

ready know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

3. For best capture of cooking impurities, your range hood should

be mounted so that the top of the hood is 24-30” above the cooking surface.

4. Please read specification label on product for further information and requirements.

!

Installer: Leave this manual with the homeowner.

Homeowner: Operating and Cleaning information on page 3.

Page 2

VENTILATING AND WIRING

INSTALLATION

CUTOUTS

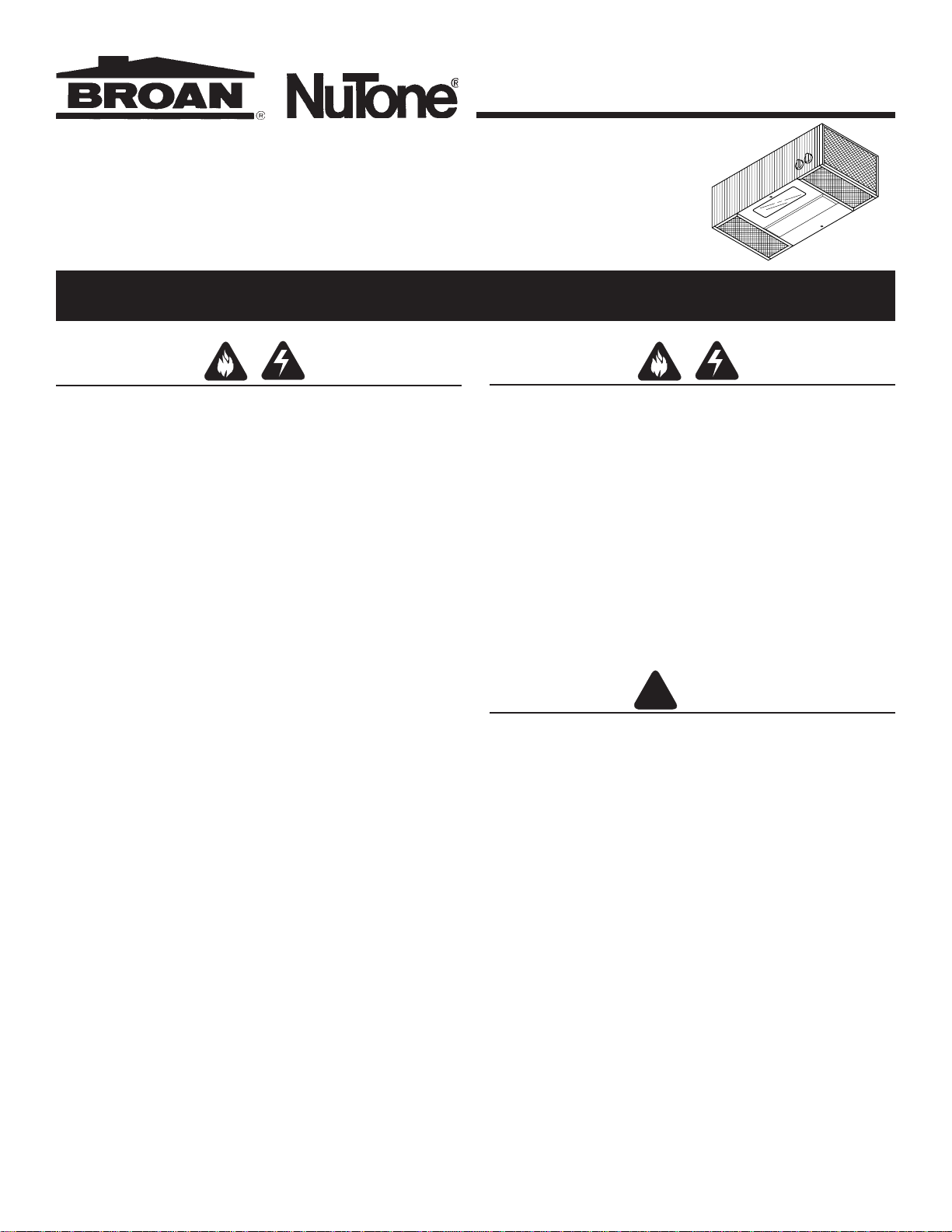

1. Mark locations on cabinet for ventilating duct and electrical wiring from the dimensions given (FIGURE 1).

2. Cut holes at the marked locations to accommodate the ventilating duct and electrical wiring. Allow 3/4” extra on the ventilating opening toward the front of the cabinet. Be sure to minimize

openings, these will have to be sealed later (FIGURE 2).

3. Run house wiring through 1-1/2” diameter hole in cabinet or

wall. Be sure all wiring is in accordance with the National Electrical Code and local ordinances.

FIGURE 1

1. Remove blower housing and filters for easier installation. See

exhaust unit assembly illustration used for “Replacement Parts

List.”

2. Lift the exhaust unit into position and mark the hole locations

on the cabinet for each of the four keyhole mounting slots.

NOTE: REMOVE FASTENERS FROM PLASTIC BAG.

3. Remove the unit. Start all four screws (#10 x 5/8 slotted) in

center of the narrow neck of the keyhole slots previously marked

on the cabinet bottom (FIGURE 3).

FIGURE 3

(IN INSTALLATION PARTS BAG)

4. There are predrilled holes on each side of the 3-1/2 x 10 hole in

exhaust unit for damper attachment. Use the small sheet metal

screws included (#8 x 1/4).

5. Remove junction box cover and appropriate knockout in exhaust unit for access to wiring.

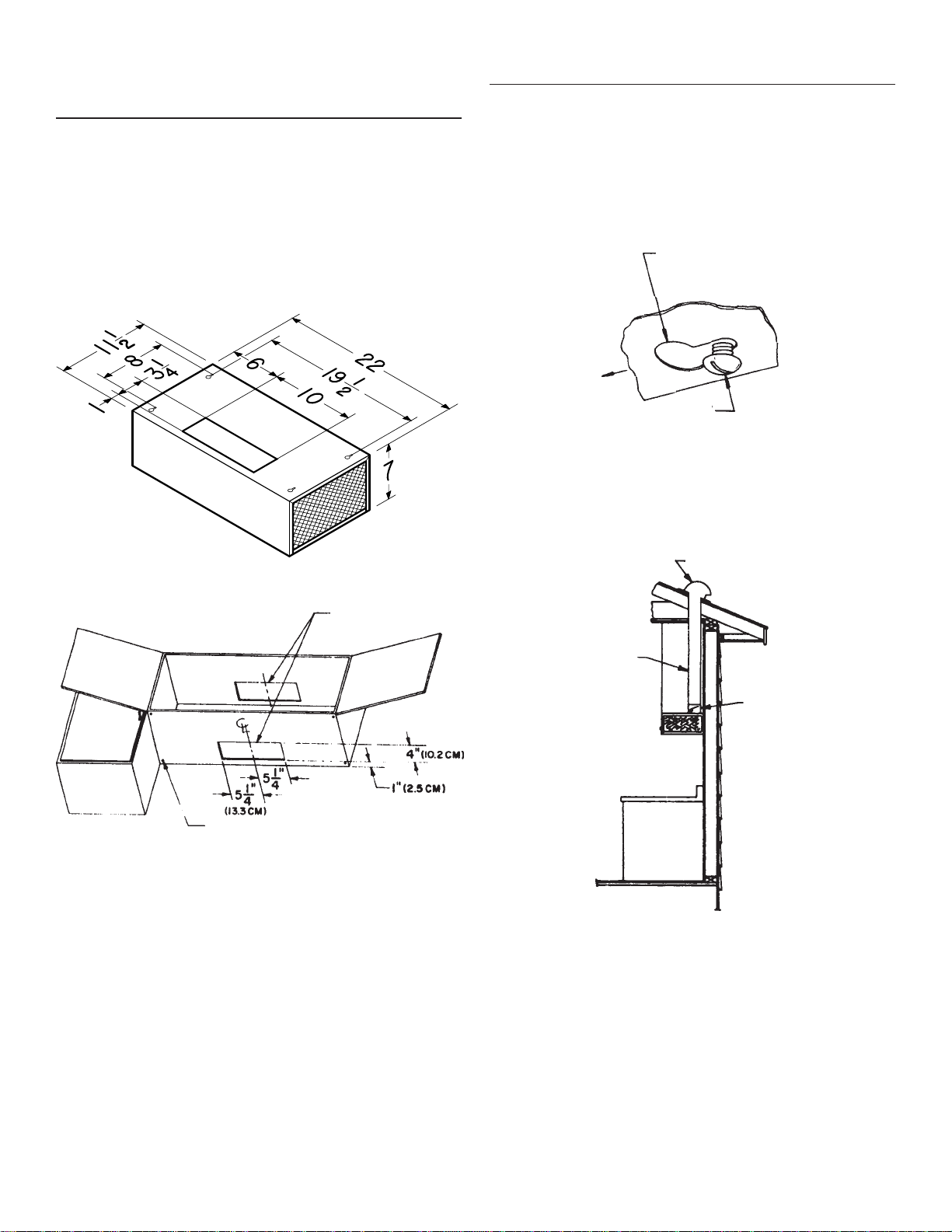

6. Install proper ductwork (FIGURE 4).

KEYHOLE SLOT IN CANOPY

SCREW

FIGURE 2

STARTER HOLES

CABINET CUTOUTS

FIGURE 4

3-1/4” x 10”

DUCT

7. Lift the exhaust unit into position simultaneously feeding house

wiring through exhaust unit knockout.

8. Tighten the four mounting screws to secure the exhaust unit to

the cabinet. Be sure the screw heads are in the narrow neck of

the keyhole slots (FIGURE 3).

9. Complete electrical wiring in junction box according to the National Electrical Code and local ordinances.

10. Replace junction box cover.

11. Seal holes around ventilating pipe and wiring passing through

ceiling or walls with caulking or insulation to prevent heat loss.

12. Replace blower housing and filters.

RAIN CAP

DAMPER

IF RAIN CAP HAS A

DAMPER, REMOVE

DAMPER BLADE

2

Page 3

BLOWER ORIENTATION

REPLACEMENT PARTS LIST

IMPORTANT: Be sure the blower is correctly orientated. Note ar-

row on the side of the blower housing indicating the correct air flow

direction (FIGURE 5).

FIGURE 5 – VERTICAL DISCHARGE

VERTICAL

DISCHARGE

VENT

(TOP OF HOOD)

BLOWER

DISCHARGE –

LOCATE AT

DISCHARGE

VENT IN TOP

OF HOOD

THIS

SURFACE

TO REAR

Part No. Description

R561107 3-Pos. Rotary Light Switch

R567073 Motor, Speed Control

R730079 Blower Assembly

R610038 Filter

R566066 Lampholder

R520098 Motor

R531041 Blower Wheel CW

R531042 Blower Wheel CCW

MOTOR

CONTROL

LIGHT SWITCH

JUNCTION

BOX

CLEANING INFORMATION

FILTER

For greatest efficiency, the aluminum filters should be removed and

cleaned periodically.

To clean, the filter should be soaked in hot water and detergent

then thoroughly rinsed. The aluminum filter can be cleaned in a

dishwasher.

EXTERIOR SURFACE

To preserve its lasting beauty, clean with a mild detergent. DO NOT

use abrasive cleaners.

MOTOR SPEED

TROUBLESHOOTING

If you have a motor speed problem, please check the following list

for possible troubles.

1. Knockouts not removed from hood.

2. Blower assembly installed wrong – intended for vertical discharge but installed for horizontal discharge and vice versa

(FIGURE 5).

3. Damper blade not opening.

4. Duct undersized – reduced airflow because duct too small or

too long.

5. Restriction in duct from foreign materials or debris.

6. Undersized or restrictive wall or roof cap.

7. Damper blade in wall or roof cap not opening.

8. Wait for 20 - 30 seconds between speed changes for RPM to

adjust.

By removing or correcting these adverse factors, the motor speed

control will be able to decrease from maximum RPM.

BLOWER

ASSEMBLY

THUMB

SCREW

BLOWER

COVER

FILTER

3

Page 4

WARRANTY

Broan-NuTone warrants to the original consumer purchaser of its products that such

products will be free from defects in materials or workmanship for a period of one year

from the date of original purchase. THERE ARE NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace,

without charge, any product or part which is found to be defective under normal use

and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS

AND TUBES. This warranty does not cover (a) normal maintenance and service or

(b) any products or parts which have been subject to misuse, negligence, accident,

improper maintenance or repair (other than by Broan-NuTone), faulty installation or

installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for

the express warranty. Some states do not allow limitation on how long an implied

warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROANNUTONE’S OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE

REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE

FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT

OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some

states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights,

which vary from state to state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or

phone number below, (b) give the model number and part identification and (c)

describe the nature of any defect in the product or part. At the time of requesting

warranty service, you must present evidence of the original purchase date.

In the United States, contact:

Broan-NuTone LLC,

926 West State Street

Hartford, WI 53027

(1-800-637-1453)

In Canada, contact:

Broan-NuTone Canada, Inc.

1140 Tristar Drive

Mississauga, Ontario, L5T 1H9

(1-888-882-7626)

BROAN-NUTONE ONE YEAR LIMITED WARRANTY

NuTone, Inc.

4820 Red Bank Road

Cincinnati, Ohio 45227

(1-800-543-8687)

626844B

Loading...

Loading...