Page 1

T

T

g

T

p

p

p

p

g)

TO PREVENT THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER (OR

)

q

BACK

QUALIFIED SERVICE PERSONNEL.

IMPORTAN

The lightning flash with arrowhead symbol, within an equilateral triangle, is

intended to alert the user to the

within the

a risk of electric shock to

NOTICE

The exclamation point within an equilateral triangle is intended to alert the user

to the

instructions in the literature accompanying the appliance.

NOTICE

The apparatus shall not be exposed to dripping or splashing and that no objects

filled with li

CAUTION!

. NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING TO

roduct's enclosure that may be of sufficient magnitude to constitute

resence of important operating and maintenance (servicin

uids, such as vases, shall be placed on the apparatus.

resence of un-insulated "dangerous voltage"

ersons.

OPERATING INSTRUCTIONS

CONTENTS

Safety Precautions

Setup & Installation

Controls

Cable Setup

Platter Setup

Interchanging Tonearm Tubes

one Arm Setup

Cartridge Setup

Important Notes & Operation

Specifications

rouble Shootin

1

3

4

7

8

9

10

11

12

13

14

Page 2

Thank you for purchasing this Numark product.

Please read these operating instructions so you will know how to operate this equipment properly.

After you have finished reading these instructions, keep them for future reference.

WARNING: TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS APPLIANCE TO RAIN OR

MOISTURE.

CAUTION:

This product satisfies FCC regulations when shielded cables and connectors are used to connect the unit to

other equipment. To prevent electromagnetic interference with electric appliances such as radios and

televisions, use shielded cables and connectors for connections.

IMPORTANT NOTICE:

RECORD THE MODEL NUMBER AND SERIAL NUMBER OF THIS EQUIPMENT BELOW.

MODEL NO:

SERIAL NO:

SAFETY PRECAUTIONS

READ INSTRUCTIONS

All the safety and operating instructions should be read before the product is operated.

RETAIN INSTRUCTIONS

The safety and operating instructions should be retained for future reference.

HEED WARNINGS

All warnings on the product and in the operating instructions should be adhered to.

FOLLOW INSTRUCTIONS

All operating and use instructions should be followed.

CLEANING

Unplug this product from the wall outlet before cleaning. The product should be cleaned only with a polishing

cloth or a soft dry cloth. Never clean with furniture wax, benzene, insecticides or other volatile liquids since

they may corrode the cabinet.

ATTACHMENTS

Do not use attachments not recommended by the product manufacturer as they may cause hazards.

WATER AND MOISTURE

Do not use this product near water - for example, near a bathtub, washbowl, kitchen sink, or laundry tub; in a

wet basement; or near a swimming pool; and the like.

ACCESSORIES

Do not place this product on an unstable cart, stand, tripod, bracket, or table. The product may fall, causing

serious injury to a child or adult and serious damage to the product. Use only with a cart, stand, tripod,

bracket, or table recommended by the manufacturer, or sold with the product. Any mounting of the product

should follow the manufacturer's instructions, and s hould use a mounting accessory recommended by the

manufacturer.

CART

A product and cart combination should be moved with care. Quick stops, excessive force, and uneven surfaces

may cause the product and cart combination to overturn.

POWER SOURCES

This product should be operated only from the type of power source indicated on the marking label. If you are

not sure of the type of power supply to your home, consult your product dealer or local power company.

LOCATION

The appliance should be installed in a stable location.

NONUSE PERIODS

The power cord of the appliance should be unplugged from the outlet when left unused for a long period.

GROUNDING OR POLARIZATION

If this product is equipped with a polarized alternating current line plug (a plug having one blade wider than

the other), it will fit into the outlet only one way. This is a safety feature. If you are unable to insert the plug

fully into the outlet, try reversing the plug. If the plug should still fail to fit, contact your electrician to replace

your obsolete outlet. Do not defeat the safety purpose of the polarized plug. If this product is equipped with a

three-wire grounding type plug, a plug having a third (grounding) pin, it will only fit into a grounding type

power outlet. This is a safety feature. If you are unable to insert the plug into the outlet, contact your

electrician to replace your obsolete outlet. Do not defeat the safety purpose of the grounding type plug.

PAGE 1 SAFETY PRECAUTIONS

Page 3

POWER-CORD PROTECTION

Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed

upon or against them, paying particular attention to cords at plugs, convenience receptacles, and the point

where they exit from the product.

OUTDOORS ANTENNA GROUNDING

If an outside antenna or cable system is connected to the product, be sure the antenna or cable system is

grounded to provide some protection against voltage surges and built-up static charges. Article 810 of the

National Electrical Code, ANSI/NFPA 70, provides information with regard to proper grounding of the mast and

supporting structure, grounding of the lead-in wire to an antenna discharge unit, size of grounding conductors,

location of antenna-discharge unit, connection to grounding electrodes, and requirements for the grounding

electrode.

LIGHTNING

For added protection for this product during a lightning storm, or when it is left unattended and unused for

long periods, unplug it from the wall outlet and disconnect the antenna or cable system. This will prevent

damage to the product due to lightning and power-line surges.

POWER LINES

An outside antenna system should not be located in the vicinity of overhead power lines or other electric light

or power circuits, or where it can fall into such power lines or circuits. When installing an outside antenna

system, extreme care should be taken to keep from touching such power lines or circuits, as contact with them

might be fatal.

OVERLOADING

Do not overload wall outlets, extension cords, or integral convenience receptacles as this can result in a risk of

fire or electric shock.

OBJECT AND LIQUID ENTRY - Never push objects of any kind into this product through openings as they

may touch dangerous voltage points or short-out parts that could result in a fire or electric shock. Never spill

liquid of any kind on the product.

SERVICING

Do not attempt to service this product yourself as opening or removing covers may expose you to dangerous

voltage or other hazards. Refer all servicing to qualified service personnel.

DAMAGE REQUIRING SERVICE

Unplug this product from the wall outlet and refer servicing to qualified service personnel under the following

conditions:

When the power-supply cord or plug is damaged.

If liquid has been spilled, or objects have fallen into the product.

If the product has been exposed to rain or water.

If the product does not operate normally by following the operating instructions. Adjust only those controls that

are covered by the operating instructions as an improper adjustment of other controls may result in damage

and will often require extensive work by a qualified technician to restore the product to its normal operation.

If the product has been dropped or damaged in any way.

When the product exhibits a distinct change in performance - this indicates a need for service.

REPLACEMENT PARTS

When replacement parts are required, be sure the service technician has used replacement parts specified by

the manufacturer or have the same characteristics as the original part. Unauthorized substitutions may result

in fire, electric shock, or other hazards.

SAFETY CHECK

Upon completion of any service or repairs to this product, ask the service technician to perform safety checks

to determine that the product is in proper operating condition.

HEAT

The product should be situated away from heat sources such as radiators, heat registers, stoves, or other

products (including amplifiers) that produce heat.

SAFETY PRECAUTIONS PAGE 2

Page 4

SETUP & INSTALLATION

This turntable has been designed exclusively for DJ use and can be setup in a variety of different ways depending on

your mixing style. The turntable should rest on a level and stable surface that is clear of obstructions. If a mixer is

placed between two turntables make sure that there is at least ¼" (7mm) between the mixer and the turntables to

prevent damage to the turntables and to reduce unwanted system noise.

Mixer

Mixer

85 mm

¼" ¼"

Mixer

¼" ¼"

Mixer

Setup Style 1 (traditional)

Best For:

Long mixes and blending

techniques

Setup Style 2 (battle style, scratching)

Best For:

Scratching, cutting, and aggressive

mixing techniques

There are many variations of these setups. Find the best setup that works for your mixing style by experimenting with

different turntable and mixer placements. It is strongly recommended that the top mixer surface and the top flat surface

of the turntable be at the same level.

PAGE 3 SETUP AND INSTALLATION

Page 5

CONTROLS

General Controls

1. Power Button

This button turns on the turntable when pressed. It illuminates blue when the turntable is switched on.

2. Platter

This turntable has a special edge design that has been optimized for "dragged" platter slow downs. (NOTE: The pattern

will appear to stand still when the Pitch Range is set to 0% and the Target Light is being used.)

3. Start/Stop Buttons

These buttons start and stop the turntable motor. Both buttons have the same function.

4. Reverse Button

Pushing this button down will reverse the rotation direction of the turntable platter.

5. Strobe Target Light and Power Jack

This aluminum light can be rotated depending on the head shell position and the amount of light required on the v inyl

record surface. The light also strobes against the platter edge making the pattern appear to stand still when the Pitch

Range is at 0%.

6. 33 and 45 RPM Buttons

These buttons control the RPM of the turntable platter. When both of the 33 and 45 RPM buttons are pressed, the 78 RPM

mode will engage.

7. Start Time Adjuster

This control can be rotated to increase or decrease the startup time of the motor.

8. Braking Time Adjuster

This control can be rotated to increase or decrease the stopping time of the motor.

28

1

3 4

CONTROLS

9

1110657

PAGE 4

Page 6

CONTROLS continued

9. Pitch Fader

This slide co ntrol allow s the pitch of the playba ck source to be changed. In the center position the pitch is at 0%. Moving

the fader knob closer to you will increase the pitch. The Pitch Slider is enclosed in an Interchangeable/Replaceable

Cartridge.

10. Pitch Button

This button allows the turntable pitch range of the pitch fader to be adjusted.

11. Quartz Button

This button locks the pitch at 0% usin g Quartz Mot or Control wh en it is pre ssed.

Tone Arm Parts

12. Counterweight and Scale Ring and S-Weight

The Counterweight is used to balance the head shell and

cartridge assembly so that the proper amount of stylus

pressure is applied to the record. The S-Weight s hould be used

in most cases when the S-Shaped tube is used. It is fastened to

the tonearm by threading it into the rear weight balance shaft.

The S-weight can be stored below the counterweight in the top

cabinet while not in use.

13. Height Adjust Ring

Turning this r ing counte r-clockwise raises the tonearm up to

6mm to accommodate for different Slipmat thicknesses. This

ring can not be adjusted unless the Height Lock Lever (12) is

unlocked.

14. Height Lock Lever

Turning this lever towards the direction of the arrow (clockwise)

unlocks the Height Adjust Ring (11) so that the tonearm height

can be adjusted.

15. Anti-Skate Adjustment

This knob is used to compensate for inward tracking forces. See

tonearm setup for more details on its settings.

16. Secondary Tube Lock Collar

This collar is used to secure the tonearm tubes (straight or sshaped) to the tonearm assembly.

WARNING:

DO NOT OVERTIGHTEN THIS LOCK COLLAR!

WARNING:

CONNECTING HEADSHELLS TO THIS COLLAR MAY DAMAGE

THE INTERNAL PIN HEIGHTS OF THE CONTACTS! ONLY

CONNECT NUMARK TUBES TO THE SECONDARY TUBE LOCK

COLLAR.

17. Arm Clip

This specially designed arm clip secures the tone arm while it is

being transported or not in use. The arm clip has been designed

to remain in the up position while unlocked.

18. Tonearm Cue System

This cueing system allows the tone arm to be positioned at a

certain point above the record and slowly engaged. When the

lift lever is in the up position the tone arm should rest on the

armrest. When the lift lever is lowered, the tone arm is slowly

lowered until the stylus is resting on the record.

19. Tone Arm Lock Nut

This Aluminum nut is used to secure the

head shell and cartridge assembly to the

tone arm tube. See cartridge setup for more

details.

13

16

17

12

14

15

18

19

CONTROLSPAGE 5

Page 7

CONTROLS continued

Bottom Parts

20. Adjustable Rubber Dampening Feet

When all of the feet of the turntable are completely tightened, the top flat surface of the turntable will be at

85mm. Unscrewing these feet raises the turntable up to compensate for unleveled surfaces.

21. Carrying Handles

These handles provide a secure grip so that the turntable may be comfortably transported.

22. Voltage Selector

This switches the internal voltage transformer between 115V, 230V and 240V. The turntable should be shipped

with the proper voltage setting for your region. Check that the switch is in the proper voltage before

connecting the IEC power cord to prevent damage to the turntable.

23. IEC Power Terminal

This IEC Power Terminal can be used with any IEC power cable, but it is recommended that the supplied IEC

power cable be used.

24. RCA Output

These stereo output jacks allow the turntable to be connected to a compatible device with a PHONO level input.

25. Ground Terminal

This ground terminal is used to run a ground line between the turntable and the device it is connected to.

20

x4

21

x4

24

22 23

25

PAGE 6 CONTROLS

Page 8

CABLE SETUP

This turntable is shipped with two sets of special cables:

(1) Right Angle IEC Power Cord

(1) Right Angle RCA cord

NOTE: Before connecting any cables, make sure that the voltage selector switch is set to the proper setting!

Making the power and audio connections:

1. Begin by lifting the turntable up from the rear handle and resting it on its side. (NOTE: The turntable must

be supported because it is not stable in this position!)

2. Next connect the Red Right Angle RCA Plug to the Red RCA jack with the "R" indication.

3. Then connect the White Right Angle RCA Plug to the White RCA jack with the "L" indication.

4. Finally connect the IEC power cord to the IEC Power terminal. It should only fit in the Terminal one way.

5. Rest the turntable back down on a level surface and route the cables to nearby power and audio accessories.

1. 2.

3. 4.

CABLE SETUPPAGE 7

Page 9

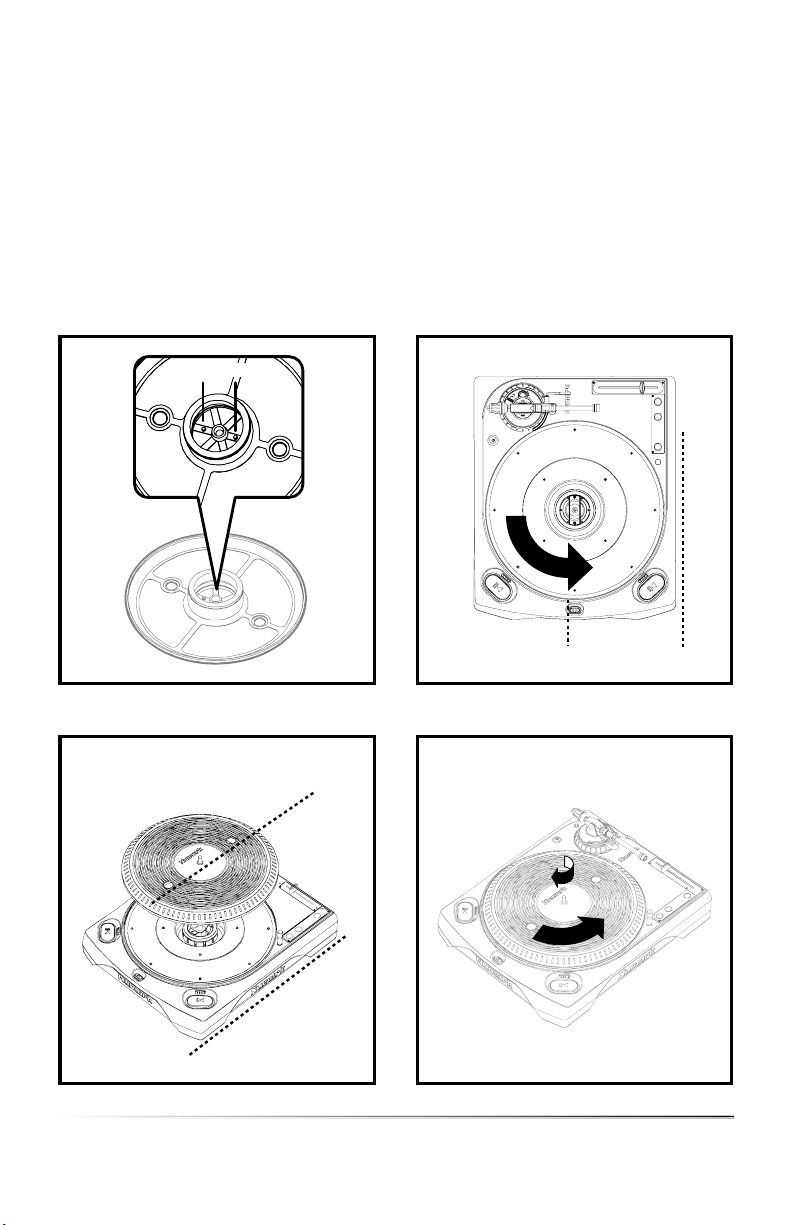

PLATTER SETUP

WARNING: Incorrect Platter setup can lead to poor turntable performance, platter instability, or permanent

motor damage.

1. Start by inspecting the bottom of the aluminum platter to check that both locking pins have rubber fittings

on them.

2. Next, rotate the platter spindle so that two holes are aligned parallel with the front of the turntable.

3. Carefully install the platter onto the center spindle and motor assembly making sure that the Numark logo

and the two holes are aligned parallel with the front of the turntable.

4. The two locking pins should drop into the top of the spindle assembly for a stable and secure fit. If they do

not, grasp the center spindle with one hand while rotating the platter with the other until the locking pins drop

into place. If the platter is properly installed, it should not wobble and should rotate smoothly without any

noise.

1.

Locking Pins

2.

ALIGNED

3.

D

E

N

G

I

L

A

4.

PAGE 8 PLATTER SETUP

Page 10

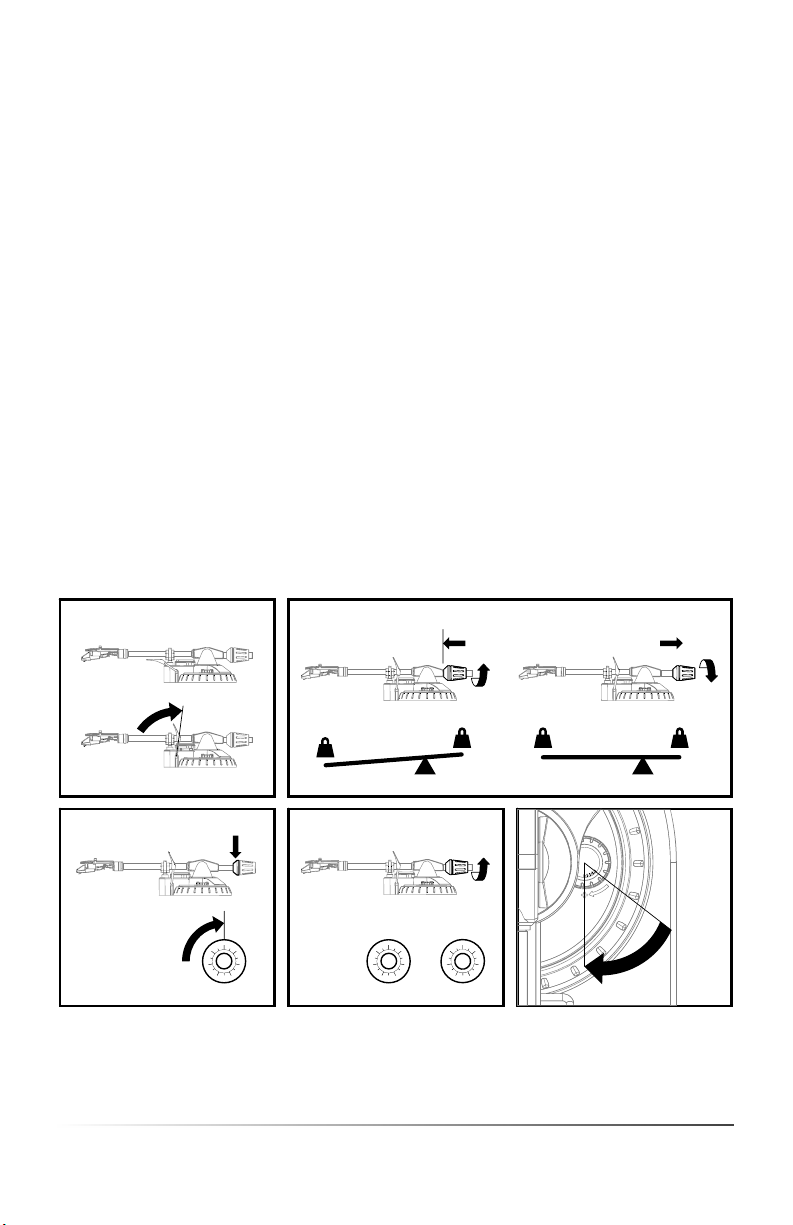

INTERCHANGING TONEARM TUBES

WARNING: An incomplete understanding of this procedure could lead to permanent damage to the headshell,

your records, or the tonearm assembly.

NOTICE: Interchanging tonearm tubes unnecessarily may shorten the life of the tonearm tubes and/or

tonearm components.

This turntable features the world's only tonearm assembly capable of accommodating two different tonearm

tube styles: S-Shaped and Straight. The S-Shaped tube produces a higher signal to noise ratio with most

cartridge assemblies. The Straight tube is ideal for heavy back-cueing or scratching. Decide which tube to use

based on your mixing style.

1. Power off the turntable and any connected mixers, amplifiers or monitoring devices.

2. Remove the Cartridge from the tonearm tube that is currently installed on the tonearm tube by rotating the

locking collar counter clockwise.

3. Unclip the tonearm tube from the armrest.

4. Remove the tonearm tube by rotating the locking collar counter clockwise.

5. Insert the desired tonearm into the tonearm assembly with the screws FACING TOWARDS THE TURNTABLE

BODY.

6. Tighten the tonearm tube in place by rotating the inner collar clockwise.

WARNING: It is only necessary to tighten the tonearm tube lock collar until resistance is felt. Over tightening

the tonearm tube lock collar will damage the tonearm tube.

7. Reinstall the headshell and proceed to TONEARM SETUP.

2. 3. 4.

5.

PAGE 9 INTERCHANGING TONEARM TUBES

7.

6.

DO NOT OVERTIGHTEN!

Page 11

TONE ARM SETUP

g

T

A properly adjusted tone arm and cartridge setup will minimize vinyl record wear and optimize the

performance of the turntable. Follow these simple steps for setting the tone arm on the turntable:

NOTE: In most cases, when using the S-Shaped tonearm tube, the additional S-Weight must be fastened to

the tonearm to achieve proper stylus pressure.Balancing the Tone Arm

1. Begin the balancing process by lifting the cue lever to the up position (or make sure that the stylus protector

is on the cartridge.)

2. Next, rotate the counterweight clockwise until it is in the complete forward position (NOTE: this is also the

maximum amount of pressure that can be applied to the cartridge.)

3. Now there should be a feeling of weight and resistance when the head shell is raised and lowered. Begin

rotating the counterweight counter-clockwise (away from the pivot point) until this weight and resistance

feeling is gone. If done properly, the tone arm will pivot with very little resistance back and forth indicating

that there is exactly 0 grams of stylus pressure.

4. With the counterweight in its new position further away from tone arm pivot point, grasp the scale ring of

the counter weight and rotate it until "0" is in the vertical position.

5. Finally, rotate the counterweight (and scale ring) clockwise (towards the pivot point) until the desired

amount of weight is reached. If the scale rotates 360 degrees beyond the zero point, the new scale ring

reading should be added to 3.5.

*The included head shell and cartridge assembly requires a minimum of 3 grams and no more than 5 grams

for optimum performance.

Setting the Anti-Skate Adjustment

In most cases, the Anti-Skate should be set to its minimum setting. Anti-Skate compensates for inward

tracking forces that occur with certain cartridges when the stylus nears the center of the record. If the

turntable is experiencing excessive skipping during back-cueing and scratching while nearing the center

spindle, try increasing the Anti-Skate in the increments indicated on the dial. Start by adding an increment of

1, test its performance, than increase it more, and so on.

1. 2. 3.

+

4.

0

0.5

Only Rotate

Scale Rin

!

3

2.5

1.5

2

5.

o

360

0

0.5

1

4.5 grams =

3

2.5

1.5

2

ONE ARM SETUP

- = =

1

1.5

0.5

1

+

2

0

2.5

3

MIN

MAX

PAGE 10

Page 12

CARTRIDGE SETUP

For Head Shell Mounted Cartridges:

The cartridge that comes with this turntable should be preinstalled on the head shell. If it isn't, please follow

the below instructions for installing a cartridge onto the head shell.

1. Position the head shell and the cartridge so that the four connector pins are visible. Make sure that the

stylus cover is installed to prevent damage to the stylus during installation.

2. Prepare to connect the cartridge to the head shell using the green, red, blue and white connector wires.

3. Starting with the upper left pin and going clockwise install the white, the red, the green and finally the blue

wires to the connector pins. Be careful not to bend the metal clips on the end of the wires. These metal

connectors should never make contact with one another.

4. Using the screws and bolts that are included with the cartridge, loosely fasten the cartridge to the head shell

body.

5. Once temporarily fastened, position the cartridge so that both screws are aligned with the optimum position

mark on the Head shell (Numark HS 1 Head shell and Numark Cartridges only.) Moving the both screws to a

mark away from the optimum position indicated on the head shell may increase or decrease performance

depending on the cartridge used. For safe vinyl record treatment, the screws should always be aligned

perpendicular to the head shell (any angle may increase "record burn.")

6. Once the cartridge is positioned correctly, secure the cartridge to the head shell by tightening the mounting

screws.

For Integrated Head Shell Cartridges (Numark CS-1, CC-1, CX-1, etc.)

7. Align the pin on the rear of the Cartridge Assembly so that it is in a vertical position and insert it into the

tone arm lock nut.

8. Secure the cartridge to the tone arm by turning the tone arm lock nut clockwise until the head shell feels

secure and does not wobble to the left or right. WARNING: Over tightening the tone arm lock nut may result in

permanent damage to the tone arm or the cartridge.

9. Remove the stylus protector before playback.

1.

Headshell

2.

Cartridge Headshell

3.

White

Blue

Red

Green

4.

W

R

Cartridge

5.

PAGE 11 CARTRIDGE SETUP

Connector

Pins

ALIGNED

6. 7. 8.

G

B

DO NOT TIGHTEN!

DO NOT OVERTIGHTEN!

Page 13

OTHER IMPORTANT NOTES

Please read these precautionary notes to insure a complete understanding and long life of this DJ turntable.

1. Unnecessarily removing the platter may cause damage to the magnet mounting structure, the motor or the

platter resulting in undesired performance. The turntable should ALWAYS be powered off before the turntable

platter is removed for any reason.

2. Repeatedly "interchanging" tonearm tubes may cause premature wear to components of the tonearm

assembly or the tonearm tubes. Interchange tubes only on an "as needed" basis.

3. Turning off the turntable while the output is set to LINE level or while the SPDIF output is in use will result in

an absence of audio. Keep this in mind during use - if the "motor off" effect is desired effect, it is

recommended that the BRAKE MOTOR CONTROL be adjusted.

4. Do not attempt to adjust or tighten any tonearm components. Undesirable performance may be a result of

an improperly adjusted tonearm or worn cartridge.

5. Never interchange tonearm tubes or the PITCH FADER and BUTTON CARTRIDGES while the turntable is

powered on.

6. Any attempt to "customize" the TT500 turntable beyond interchanging the tonearm tubes and fader/button

cartridges is not recommended and may result in PERMENANT DAMAGE to the turntable or a VOIDED

WARRANTY.

OPERATION

This turntable was designed to accommodate a variety of different mixing styles. Here are some general

operation guidelines to optimize the performance of the turntable.

1. Do not place the turntable on or near a speaker or subwoofer. This may cause unwanted noise depending on

the environment conditions.

2. ALWAYS use the included Slip Mat during record playback. This Slip Mat was designed to reduce friction

between the platter and the record to allow for rapid back cueing and efficient scratch play.

3. Using the tone arm Cue System may prevent damage to your stylus. First lift the Cue Lever, then position

the tone arm over the desired groove of the record, and finally lower the Cue Lever to slowly drop the tone

arm onto the record.

4. Always secure the tone arm using the Arm Clip when not in use. This can prevent stylus damage and

accidental tone arm engagement.

5. To reduce needle skipping, follow the guidelines in the Tone Arm Setup section of this manual. Too much

weight on a cartridge may cause erratic skipping or stylus damage.

Another guideline that may reduce skipping is back cueing and adjusting playback tempo by applying pressure

towards the center of the record near the spindle as indicated below.

Skipping induce by rapid cueing or scratching may be reduce by applying inward pressure to the side of the

record instead of applying pressure down on the record (see diagram below.)

PAGE 12 IMPORTANT NOTES & OPERATION

Page 14

SPECIFICATIONS

Turntable:

Torque (transient): 4.5kgf.cm

Torque (stable): 3.5kgf.cm

Motor: Brushless DC motor

Brake: Electronic braking system

Platter: Dampened aluminum diecast, low friction design

Pitch: +/-8%, 10%, 25%, 50%

Speeds: 33 1/3RPM, 45RPM, 78RPM

Wow/flutter: <0.15% max, <0.10% typical

Tonearm: Patented locking collar-based interchangeable tube system

Diecast aluminum

3-bearing construction

Height range: 0-6mm

Cue System: Dampened lift lever

Arm rest and arm clip

Balance Weight: 7 gram S-weight

Aluminum plated w/0-3.5gram range

Dimensions: 370mm x 460mmx 135mm

Weight: 19 lbs

Target light: High-intensity LED

Note, other manufacturers may claim lower wow/flutter specs by using different testing methods. We've

tested the competitors and found that our wow/flutter performance is equal to or superior to theirs.

PAGE 13 SPECIFICAT IONS

Page 15

T

T

Problem Cause? Solution

T

T

T

T

T

T

T

f

r

T

T

T

T

T

T

f

Turntable does not turn on. Disconnected Power Cord? Connect Power Cord.

The sound level is very low.

he Turntable is not connected to a

device with a PHONO preamp.

Connect the device to a preamp DJ

mixer or an AV receiver that has an

input labeled PHONO.

The sound is on one side only. The Cartridge is not properly wired. Reconnect the wires from the

NOTE:

Static electricity and/or other external

interference may cause this unit to

malfunction. To reset the unit to its

normal condition, turn the power of

and then on again. If the problem

continues to persist, ref er to the

connected component's

troubleshooting guides. If the

problem is not resolved afte

checking these items, contact the

nearest authorized Numark dealer.

The output sound is very distorted.The Cartridge is not properly wired.

The Target Light glows

inconsistently, flickers, or doesn't

work at all.

he Stylus is worn out. Replace the stylus on the cartridge.

he RCA audio cord is damaged.

he Cartridge is not making a

proper connection.

he Tonearm Tube is not making a

proper connection.

he Stylus is worn out. Replace the stylus on the cartridge.

he Target Light Lamp is burning

or burned out.

headshell to the cartridge. See the

"Cartridge Setup" section for more

detail.

Replacement styli are available

from most Numark Retailers.

If the RCA cord is frequently

connected and disconnected, it

may have become damaged and

needs to be replaced.

Remove the cartridge, clean the

contacts on the back with Isopropyl

Alcohol, and reinsert it.

Remove the tube, clean the

contacts on the back with Rubbing

Alcohol, and reinsert it.

he Tonearm Tube may be

damaged. Replace the Tonearm

ube.

Reconnect the wires from the

headshell to the cartridge. See the

"Cartridge Setup" section for more

detail.

Replacement styli are available

from most Numark Retailers.

Replace the entire target light with

a compatible part like the Numark

L-1.

The turntable skips like crazy.

he Turntable is on an unstable

surface.

he Tone Arm is not balanced

properly.

he Stylus is worn out. Replace the stylus on the cartridge.

Excessive force is being applied

directly down on the platter.

he record is warped. Buy new records.

Follow the guidelines for installation

in the "Setup & Installation"

Section.

Follow the guidelines for optimum

setup in the "Tone Arm Setup"

Section.

Replacement styli are available

from most Numark Retailers.

Reread the "Operation" section o

this manual.

ROUBLE SHOOTING PAGE 14

Page 16

t

A

r

t

l

d

t

INSIDE THE BOX:

l

t

t

r

(1) Turntable w/Straigh

Tonearm

(1) Headshel

(1) S-Shaped Tonearm

Tube

(1) IEC Power Cable

(1) Counter Weigh

(1) Anti-Drag

luminum Platte

(1) Target Ligh

(1) S-Tube Tonearm

Weigh

(1) RCA Cor

(1) Slipma

(1) 45 RPM Adapte

(1) Service Too

Loading...

Loading...