Page 1

NUM

1020/1040/1060T

PROGRAMMING

MANUAL

VOLUME 1

0101938820/5

06-97 en-938820/5

Page 2

Despite the care taken in the preparation of this document, NUM cannot guarantee the accuracy of the information it contains and cannot be held

responsible for any errors therein, nor for any damage which might result from the use or application of the document.

The physical, technical and functional characteristics of the hardware and software products and the services described in this document are subject

to modification and cannot under any circumstances be regarded as contractual.

The programming examples described in this manual are intended for guidance only. They must be specially adapted before they can be used in

programs with an industrial application, according to the automated system used and the safety levels required.

© Copyright NUM 1997.

All rights reserved. No part of this manual may be copied or reproduced in any form or by any means whatsoever, including photographic or magnetic

processes. The transcription on an electronic machine of all or part of the contents is forbidden.

© Copyright NUM 1997 software NUM 1000 family.

This software is the property of NUM. Each memorized copy of this software sold confers upon the purchaser a non-exclusive licence strictly limited

to the use of the said copy. No copy or other form of duplication of this product is authorized.

2 en-938820/5

Page 3

Table of Contents

Table of Contents

1 Review 1 - 1

1.1 System Overview 1 - 3

1.2 Machine Overview 1 - 5

2 Structure of a Programme 2 - 1

2.1 Word Format 2 - 4

2.2 Block Format 2 - 7

2.3 General Structure of a Programme 2 - 9

2.4 Classification of Preparatory G Functions

and Miscellaneous M Functions 2 - 18

3 Axis Programming 3 - 1

3.1 General 3 - 3

3.2 Programming the Independent Secondary

Axes 3 - 4

3.3 Programming Carrier/Carried Parallel Axis

Pairs 3 - 5

3.4 Programming of Rotary Axes Modulo 360

Degrees 3 - 6

3.5 Programming of Slaved Rotary Axes with

Limited Travel 3 - 7

3.6 Programming of Axes A, B or C Declared as

Nonrotary 3 - 7

3.7 Features of Front Turret, Rear Turret 3 - 8

4 ISO Programming 4 - 1

4.1 Choice of the Programming System 4 - 5

4.2 Programming with Reference to Diameter

or Radius 4 - 9

4.3 Spindle Commands 4 - 11

4.4 Rapid Positioning 4 - 29

4.5 Programming of Movements 4 - 32

4.6 Path Sequencing Conditions 4 - 59

4.7 Feed Rate 4 - 61

4.8 Programming of Tools 4 - 70

4.9 Basic Cycles 4 - 91

4.10 Other Machining Cycles 4 - 128

4.11 Breaks in Sequence 4 - 165

4.12 Movement Origin Selection 4 - 203

4.13 Spline Curve Interpolation 4 - 216

4.14 Coordinates Systems with C Axis 4 - 226

4.15 Other Functions 4 - 238

4.16 «Inclined Axis» or «Inclined Wheel»

State on a Grinder 4 - 267

4.17 Special Programming for Multiple Axis

Groups 4 - 273

en-938820/5 3

Page 4

4.18 Special Programming of PLC Axes 4 - 283

4.19 Message Transmission 4 - 288

4.20 Spindle Synchronisation 4 - 293

5 Profile Geometry Programming 5 - 1

5.1 Profile Geometry Programming (PGP) 5 - 3

5.2 Profil Function 5 - 22

6 Parametric Programming 6 - 1

6.1 Programme L Variables 6 - 3

6.2 External E Parameters 6 - 16

6.3 Address Equivalences 6 - 54

6.4 Transfer of the Current Values of L

Variables and E Parameters into the Part

Programme 6 - 55

6.5 Message Display with Wait for an Operator

Response 6 - 57

6.6 Display of Messages with Parametric

Value 6 - 59

6.7 Reading the Programme Status Access

Symbols 6 - 60

6.8 General Diagrams of Parametric

Programming 6 - 64

7 Programme Stack - L Variables and Symbolic Variables 7 - 1

7.1 Programme Stack 7 - 3

7.2 Saving and Restoring L Variables 7 - 4

7.3 Symbolic Variables 7 - 7

8 Programming of Error Numbers and Messages 8 - 1

8.1 General 8 - 3

8.2 Creating Error Messages 8 - 3

Appendix A Function Summary Tables A - 1

A.1 G Function Summary Table A - 3

A.2 M Function Summary Table A - 17

A.3 Additional Function Summary Table A - 22

Appendix B External Parameter E Summary Tables B - 1

B.1 Parameters in the PLC Memory B - 3

B.2 Parameters in the NC Memory B - 3

Appendix C Word Format Summary Table C - 1

4 en-938820/5

Page 5

Table of Contents

Appendix D List of Errors D - 1

D.1 Miscellaneous Errors and Machine Errors D - 3

D.2 Parametric Programming Errors D - 5

D.3 Profile Geometry Programming (PGP)

Errors D - 6

D.4 Miscellaneous Errors D - 7

D.5 Request for Movements Outside the

Machine Travel Limits D - 8

D.6 Structured Programming Errors D - 8

D.7 Axis Errors D - 8

D.8 Errors in Pocket Cycles D - 9

D.9 Axes Not Identified on the Bus D - 10

D.10 Dynamic Operators in C D - 10

D.11 Spline Curve Interpolation Errors D - 10

D.12 Errors in Numaform D - 11

D.13 Cycle Programming Errors D - 12

en-938820/5 5

Page 6

6 en-938820/5

Page 7

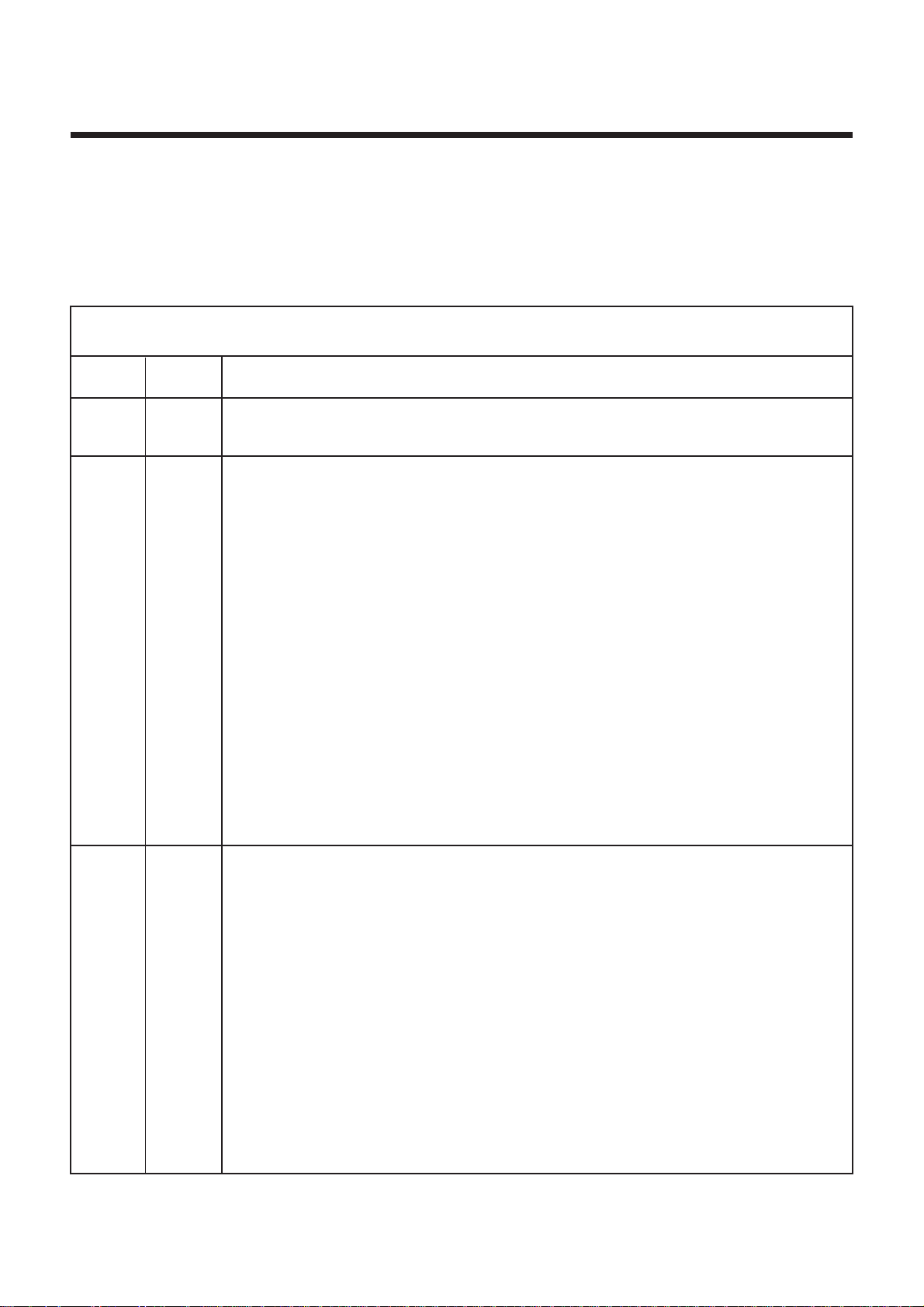

Record of Revisions

DOCUMENT REVISIONS

Date Revision Reason for revisions

04-92 0 Document creation (conforming to software index B)

11-93 1 Update to conform to software index D

Manual revisions:

- Classification of G preparatory functions and M miscellaneous functions.

- Processing of blocks and programmed G and M functions (with G997 to G999).

- Programming of error numbers and messages.

- Counterboring, boring and tapping cycles.

- The sections on structured programming and the use of table of variables are

transferred from this manual to the supplementary programming manual.

Table of Contents

Taking into account of upgrades

Software index C:

- Special programming of PLC axes.

- Creation of external parameter E41004.

Software index D:

- Spline curve interpolation.

- Rigid tapping.

- Creation of external parameters E42000 to E42127, E79003, E79004, E41005,

E941xx, E960xx, E961xx, E962xx, E963xx.

09-94 2 Update to conform to software index F

Manual revisions:

- Circular interpolation defined by three points (G23)

- Block sequencing without stopping movement, with sequence interruption and feed rate

limiting after interrupt by EF (changes to G10)

- Temporary suspension of next block preparation (G79+/-)

- Automatic homing subroutine branch

- Subroutine branch on reset

- Message transmission by $0 to $6 (formerly in Chapter 3, moved to the end of

Chapter 4)

- Added a paragraph concerning access to the Profil function (see Sec. 5.2)

- Unconditional call to a sequence by G77N..

en-938820/5 7

Page 8

Added changes

Software at index E:

- Polar programming

- Feed rate in fillets EB+ and chamfers EB-

- Movements parallel to inclined axes (G05 and G07)

- Extension of parameter E21000

- External parameters E49001 to E49128, E931xx, E932xx, E933xx, E7x100, E934xx,

E951xx, E952xx, E41102, E33xyz, E43xyz, E34xxy, E44xxy, E20100 to E20111,

E9030x, E9031x, E9032x, E9033x, E970xx, E971xx, E972xx, E11014, E11016 and

E32001

- Acquisition of variables in the stack of another axis group by function VAR H.. N.. N..

- Adressing by function [.RG80]

- Conversion of the internal unit to the programming unit by function U for linear axes.

02-95 3 Update to conform to software index G

Manual revisions:

- Spindle synchronisation

- External parameters E11013, E41006, E935xx, E980xx

05-96 4 Update to conform to software index J

Manual revisions:

- transmission of a message from CNC to PC ($9)

- call of a subroutine return block (G77 -i)

- tool number T defined by 8 digits

- inclined wheel p, grinding machine

- external parameters E32002, E32003, E32004, E32005, E69002, E9034x, E9035x,

E7x101, E913xx, E942xx, E973xx, E982xx and E983xx

8 en-938820/5

Inclusion of changes

Software index H

- external parameters E11008, E936xx

Page 9

DOCUMENT REVISIONS

Date Revision Reason for revisions

06-97 5 Update to conform to software index L

Manual revisions:

- ISO programme or block creation/deletion (G76+/-)

- Conversion of the internal unit to the programming unit by function M for rotary axes

Added changes:

Software index J and K

Table of Contents

en-938820/5 9

Page 10

10 en-938820/5

Page 11

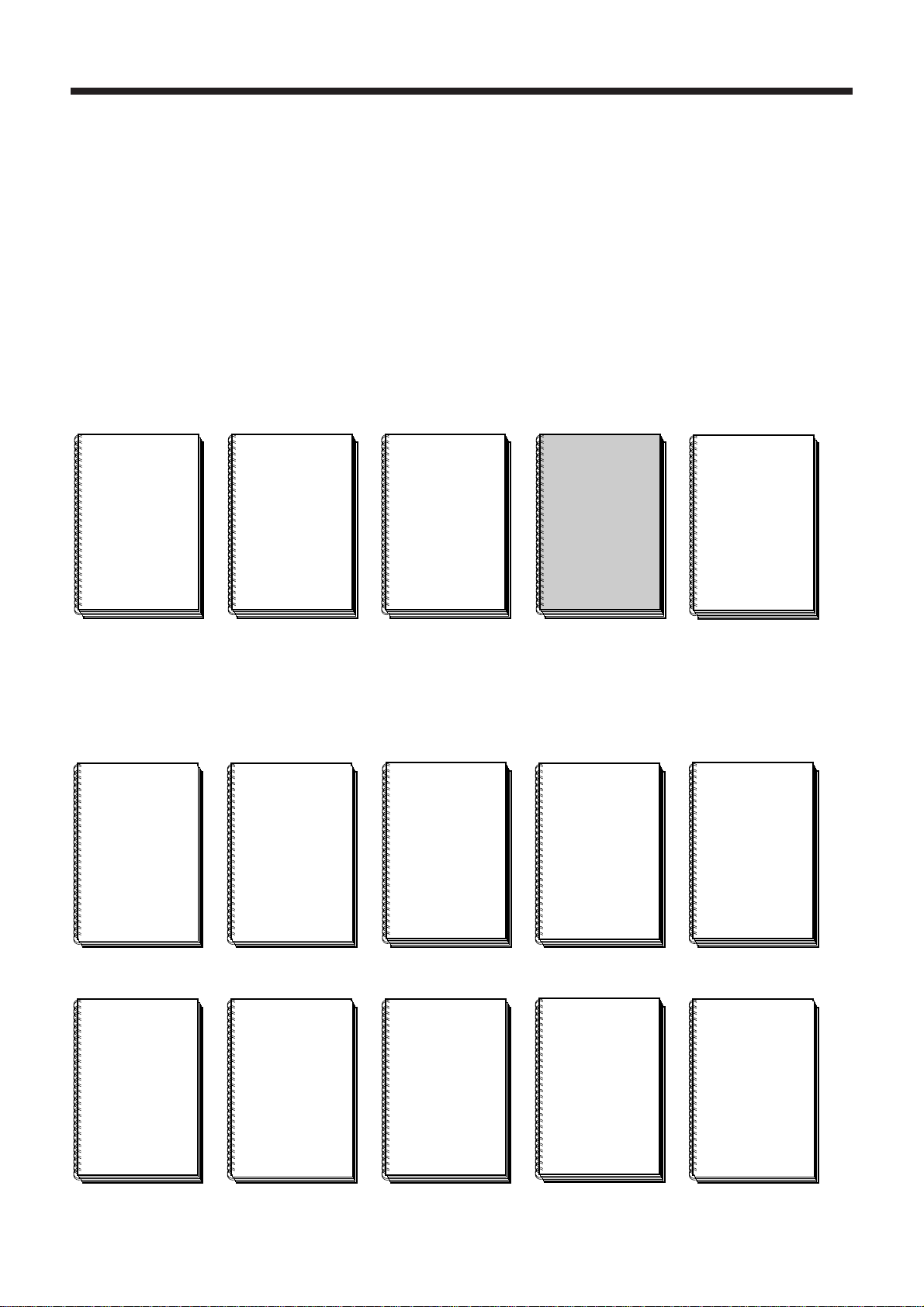

Structure of the NUM 1020/1040/1060 Documentation

User Documents

These documents are designed for the operator of the numerical control.

Foreword

Foreword

NUM

M/W

OPERATOR’S

MANUAL

938821

OEM Documents

NUM

1060

INSTALLATION

AND

COMMISSIONING

MANUAL

938816

NUM

T

OPERATOR’S

MANUAL

938822

These documents are designed for the OEM integrating the numerical control on a

machine.

NUM

1020/1040

INSTALLATION

AND

COMMISSIONING

MANUAL

938938

NUM

M

PROGRAMMING

MANUAL

V

OLUME

OLUME

938819

NUM

MANUAL

938818

1

2

V

PARAMETER

NUM

T

PROGRAMMING

MANUAL

V

OLUME

OLUME

938820

NUM

MANUAL

LADDER

938846

1

2

V

AUTOMATIC

CONTROL

FUNCTION

PROGRAMMING

LANGUAGE

NUM

G

CYLINDRICAL

GRINDING

PROGRAMMING

MANUAL

938930

NUM

DYNAMIC

OPERATORS

938871

NUM

PROCAM

DESCRIPTION

MANUAL

938904

NUM

G

CYLINDRICAL

GRINDING

COMMISSIONING

MANUAL

938929

NUM

H/HG

GEAR

CUTTING AND

GRINDING

MANUAL

938932

NUM

TWO-SPINDLE

SYNCHRONISATION

MANUAL

938854

NUM

GS

SURFACE

GRINDING

MANUAL

938945

en-938820/5 11

Page 12

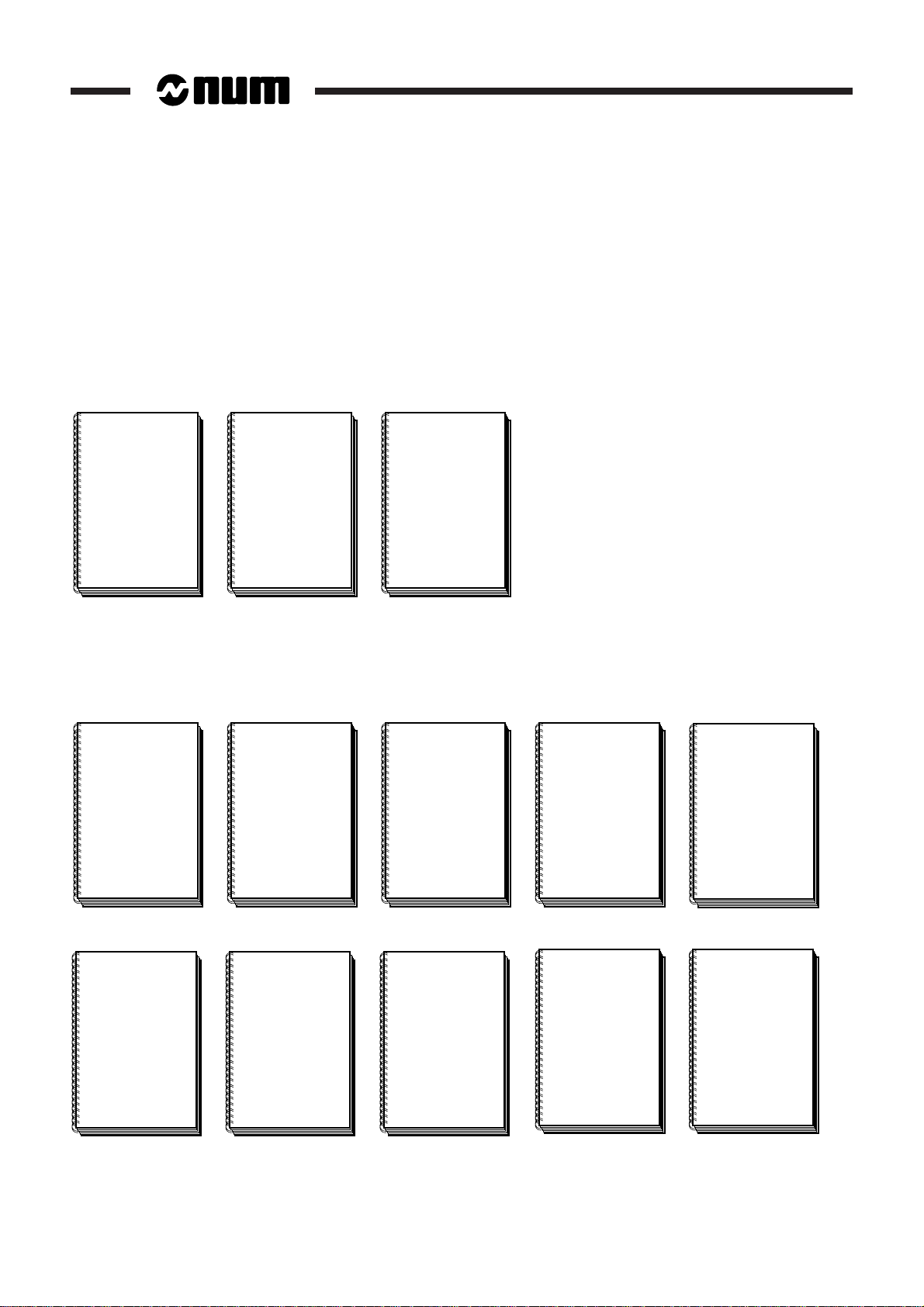

OEM Documents (cont’d)

These documents are designed for the OEM integrating the numerical control on a

machine.

NUM

SETTOOL

PARAMETER

INTEGRATION

TOOL

938924

NUM

PLCTOOL LADDER

LANGUAGE

PROGRAMMING

TOOL

938859

Special Programming Documents

These documents concern special numerical control programming applications.

NUM

SUPPLEMENTARY

PROGRAMMING

MANUAL

NUM

M

PROCAM MILL

INTERACTIVE

PROGRAMMING

MANUAL

NUM

MMITOOL

MAN/MACHINE

INTERFACE

CUSTOMISATION

TOOL

938946

NUM

T

PROCAM TURN

INTERACTIVE

PROGRAMMING

NUM

DUPLICATED

AND

SYNCHRONISED

AXES

NUM

PROFIL

FUNCTION

USER’S

MANUAL

938872

NUM

G

PROCAM GRIND

INTERACTIVE

PROGRAMMING

938931

12 en-938820/5

938873

NUM

POLYGON

CUTTING

MANUAL

938952

938874

NUM

GS

PROCAM GRIND

INTERACTIVE

PROGRAMMING

938953

938875

NUM

T

PROCAM

TURN

TECHNOLOGICAL

DATA

938959

938937

NUM

M

PROCAM

MILL

TECHNOLOGICAL

DATA

938958

Page 13

Programming Manual

CHAPTER 1

REVIEW

Foreword

General description of the NC and its use with the machine tool.

Review of the rules and standards related to the NC/machine-tool combination.

CHAPTER 2

STRUCTURE

OF A

PROGRAMME

CHAPTER 3

AXIS

PROGRAMMING

Rules for writing a part programme by assembling characters into words, words into

blocks and blocks into a complete programme.

Description of the features related to axis programming.

Detailed description of functions related to ISO programming.

CHAPTER 4

ISO

PROGRAMMING

en-938820/5 13

Page 14

CHAPTER 5

PROFILE

GEOMETRY

PROGRAMMING

CHAPTER 6

PARAMETRIC

PROGRAMMING

Detailed description of profile geometry programming (PGP).

Description of access to the Profil function and the contour call created by Profil.

PGP and Profil are used to define contours as a sequence of geometric elements,

with computation of intermediate points. PGP and Profil are extensions of ISO

programming.

Gives the possibility of assigning variables to NC functions. The values of the

variables can be obtained by computation or by reading machine data.

Possibility of saving or restoring a chain of L variables in a single instruction.

CHAPTER 7

PROGRAMME

STACK-

L VARIABLES

AND SYMBOLIC

VARIABLES

CHAPTER 8

PROGRAMMING

OF ERROR

NUMBERS AND

MESSAGES

14 en-938820/5

Possibility of naming the variables used in a part programme to make the programme

easier to read.

Gives the possibility of programming and displaying error numbers and messages.

Page 15

APPENDIX A

FUNCTION

SUMMARY

TABLES

Foreword

Tables given as lists of:

- G preparatory functions,

- M miscellaneous functions,

- other functions.

APPENDIX B

EXTERNAL

PARAMETER E

SUMMARY

TABLES

APPENDIX C

WORD

FORMAT

SUMMARY

TABLE

Tables given as lists of:

- exchange parameters with the PLC,

- parameters stored in the NC memory.

Table given as a list of words with their associated formats.

List of NC error numbers and definitions.

APPENDIX D

LIST OF

ERRORS

en-938820/5 15

Page 16

Use of this Programming Manual

(

)

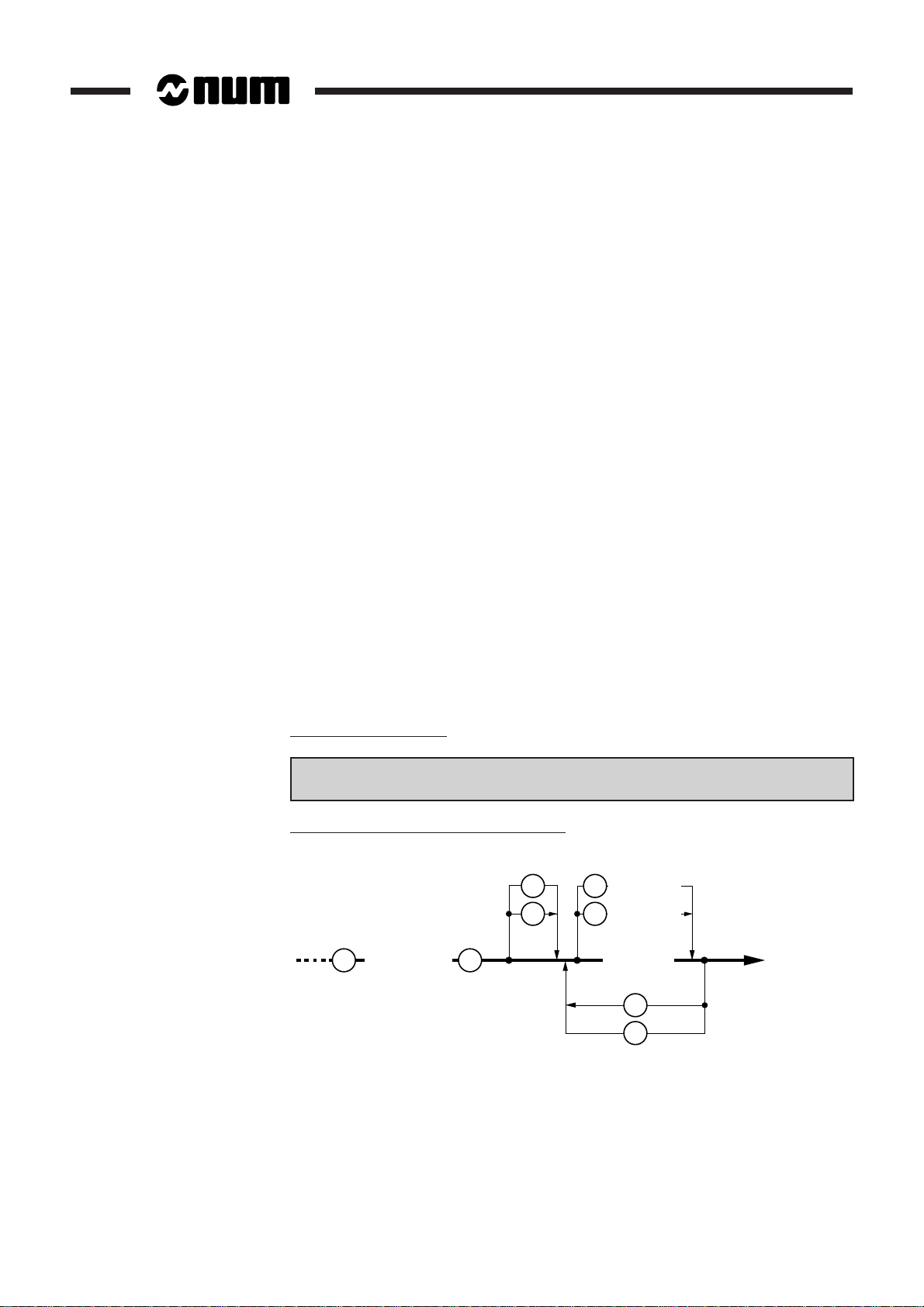

Function Syntax Entry Conventions

The lines (blocks) of a part programme include several functions and arguments.

Special syntax rules apply to each of the functions described herein. These syntax

rules specify how the programme blocks must be written.

Certain syntax formats are given as a line. The following conventions simplify writing

the line:

- the function to which the syntax format is related is highlighted by boldface type,

- terms between square brackets «[..]» are optional functions or arguments in the

block (or functions activated earlier, with values unchanged, etc.) (except Sec. 6.6

and Chapter 7),

- «/» indicates a choice between several terms (equivalent to «or») (except Sec. 6.6

and Chapter 7),

- «..» after a letter replaces a numerical value,

- «...» replaces a character string (for instance a message).

Examples

Syntax of function G12

NC Operating Modes

N.. [G01/G02/G03] G12 X.. Z.. [F..] [$0…]

Syntax in the form of a Conway diagram

+

–

1 to 3 digits

L

(

Certain NC operating modes are mentioned herein when they are directly related to

the use of ISO functions. For additional information on these modes, refer to the

Operator Manual.

=

)

E

L

Parameter

(

1 to 3 digits

Value

8 digits

(

5 digits

Variable

)

max

+

–

)

16 en-938820/5

Page 17

Optional Functionalities

The use of certain functionalities described herein requires validating the associated

options. The «OPTIONS» system page is used to check for the presence of these

functionalities (for access to the «OPTIONS» page and the list of functionalities, see

Chapter 2 of the Operator Manual).

List of G, M and Other Functions

The lists at the beginning of the manual indicate the pages where the G, M and other

functions are found (yellow pages).

Foreword

Index

Agencies

Questionnaire

The index at the end of the manual facilitates access to information by keywords.

The list of NUM agencies is given at the end of the manual.

To help us improve the quality of our documentation, we kindly request you to return

the questionnaire at the end of the manual.

en-938820/5 17

Page 18

18 en-938820/5

Page 19

G Functions

Lists of G, M and Other Functions

Lists of G, M and Other Functions

Code Description Page

G00 High-speed linear interpolation 4 - 29

G01 Linear interpolation at programmed feed rate 4 - 32

G02 Clockwise circular interpolation at programmed feed rate 4 - 36

G03 Counterclockwise circular interpolation at programmed

feed rate 4 - 36

G04 Programmable dwell 4 - 238

G05 Movement on an inclined axis 4 - 269

G06 Spline curve execution command 4 - 216

G07 Initial tool positioning before machining on an inclined axis 4 - 268

G09 Accurate stop at end of block before going to next block 4 - 59

G10 Interruptible block 4 - 180

G12 Overspeed by handwheel 4 - 242

G16 Definition of tool axis orientation with addresses P, R 4 - 72

G20 Programming in polar coordinates (X, Z, C) 4 - 226

G21 Programming in cartesian coordinates (X, Y, Z) 4 - 229

G22 Programming in cylindrical coordinates (X, Y, Z) 4 - 234

G23 Circular interpolation defined by three points 4 - 44

G33 Constant lead thread cutting 4 - 92

G38 Sequenced thread cutting 4 - 99

G40 Tool radius offset (cutter compensation) cancel 4 - 80

G41 Left tool radius offset (cutter compensation) 4 - 79

G42 Right tool radius offset (cutter compensation) 4 - 79

en-938820/5 19

Page 20

Code Description Page

G48 Spline curve definition 4 - 216

G49 Spline curve deletion 4 - 216

G51 Mirroring 4 - 261

G52 Programming of movements in absoluted dimensions

with reference to the measurement origin 4 - 203

G53 DAT1 and DAT2 offset cancel 4 - 206

G54 DAT1 and DAT2 offset enable 4 - 206

G59 Programme origin offset 4 - 209

G63 Roughing cycle with groove 4 - 151

G64 Turn/Face roughing cycle 4 - 128

G65 Groove roughing cycle 4 - 140

G66 Plunging cycle 4 - 146

G70 Inch data input 4 - 244

G71 Metric data input 4 - 244

G73 Scaling factor cancel 4 - 259

G74 Scaling factor enable 4 - 259

G75 Emergency retraction subroutine declaration 4 - 189

G76 Transfer of the current values of «L» and «E» parameters

into the part programme 6 - 55

G76+/- ISO programme or block creation/deletion 4 - 198

G77 Unconditional branch to a subroutine or block sequence

with return 4 - 165

G77 -i Call of a subroutine return block 4-196

G78 Axis group synchronisation 4 - 279

G79 Conditional or unconditional jump to a sequence without

return 4 - 174

G79 +/- Temporary suspension of next block preparation in a

sequence with movements 4 - 187

20 en-938820/5

Page 21

Lists of G, M and Other Functions

Code Description Page

G80 Canned cycle cancel 4 - 91

G81 Centre drilling cycle 4 - 104

G82 Counterboring cycle 4 - 106

G83 Peck drilling cycle 4 - 108

G84 Tapping cycle 4 - 113

G84 Rigid tapping cycle 4 - 111

G85 Boring cycle 4 - 117

G87 Drilling cycle with chip breaking 4 - 119

G89 Boring cycle with dwell at hole bottom 4 - 122

G90 Programming in absolute dimensions with respect to the

programme origin 4 - 5

G91 Programming in incremental dimensions with respect to the

start of the block 4 - 5

G92 Programme origin preset 4 - 207

G92 R.. Programming of the tangential feed rate 4 - 66

G92 S.. Spindle speed limiting 4 - 27

G94 Feed rate expressed in millimetres, inches or degrees

per minute 4 - 61

G95 Feed rate expressed in millimetres or inches per revolution 4 - 64

G96 Constant surface speed expressed in metres per minute 4 - 15

G97 Spindle speed expressed in revolutions per minute 4 - 13

G98 Definition of the start X for interpolation on the C axis 4 - 228

G997 Enabling and execution of all the functions stored in

state G999 4 - 264

G998 Enabling of execution of the blocks and part of the functions

processed in state G999 4 - 264

G999 Suspension of execution and forcing of block concatenation 4 - 264

en-938820/5 21

Page 22

M Fonctions

Code Description Page

M00 Programme stop 4 - 248

M01 Optional stop 4 - 250

M02 End of programme 2 - 9

M03 Clockwise spindle rotation 4 - 11

M04 Counterclockwise spindle rotation 4 - 11

M05 Spindle stop 4 - 11

M06 Tool change 4 - 70

M07 Coolant 2 on 4 - 247

M08 Coolant 1 on 4 - 247

M09 Coolant off 4 - 247

M10 Clamp 4 - 246

M11 Unclamp 4 - 246

M12 Programmed feed stop 4 - 240

M19 Spindle index 4 - 21

M40 to M45 Spindle speed ranges 4 - 20

M48 Enable overrides 4 - 255

M49 Disable overrides 4 - 255

M61 Release of current spindle in the axis group 4 - 278

M62 to M65 Control of spindles 1 to 4 4 - 23

M66 to M69 Measurement of spindles 1 to 4 4 - 25

M997 Forced block sequencing 4 - 254

M998 Reactivation of edit (EDIT) and manual data input (MDI)

modes and subroutine calls by the automatic control function 4 - 252

M999 Programmed cancellation of the edit (EDIT) and manual data

input (MDI) modes and subroutine calls by the automatic

control function 4 - 252

22 en-938820/5

Page 23

Other Functions

Lists of G, M and Other Functions

Code Description Page

$0 Message transmission to the display 4 - 288

$1 to $6 Message transmission to the PLC function or a remote

server or a peripheral 4 - 290

/ Block skip 4 - 256

D.. Call to tool correction 4 - 74

ED.. Programmed angular offset 4 - 215

EG.. Programmed acceleration modulation 4 - 258

T Tool number 4 - 70

M Conversion of the internal unit of rotary axes 6-6 and 6-19

U Conversion of the internal unit of linear axes 6-6 and 6-19

en-938820/5 23

Page 24

24 en-938820/5

Page 25

Review

1 Review

1.1 System Overview 1 - 3

1.1.1 Overview of Modes 1 - 3

1.1.2 Defining a Programme 1 - 3

1.1.3 Preparating a Programme 1 - 4

1.2 Machine Overview 1 - 5

1.2.1 Review of Axis Definition and Direction 1 - 5

1.2.2 Machine Overview 1 - 6

1.2.3 Definition of Travels and Origins 1 - 7

1.2.4 Offset Definitions 1 - 9

1.2.5 Definition of the Tool Dimensions 1 - 12

1.2.5.1 Definition of the Tool Dimensions 1 - 12

1.2.5.2 Definition of Tool Tip Radius and

Orientation 1 - 13

1.2.6 Definition of Dynamic Tool Corrections 1 - 14

1

en-938820/5 1 - 1

Page 26

1 - 2 en-938820/5

Page 27

The aim of this chapter is to introduce concepts that will be detailed in the rest of the

MODE

manual, rather than to reflect the way an operator works on the machine.

For instance, in Section 1.2.4 (Offset Definition), the aim is to define the offsets and

corresponding origins or zero points rather than give a method for measuring the

offsets.

1.1 System Overview

1.1.1 Overview of Modes

The operator uses the numerical control

(NC) in various operating modes accessible from the operator panel.

Review

1

Each mode corresponds to a particular

use of the numerical control (continuous-machining, programme loading, tool

setting, etc.).

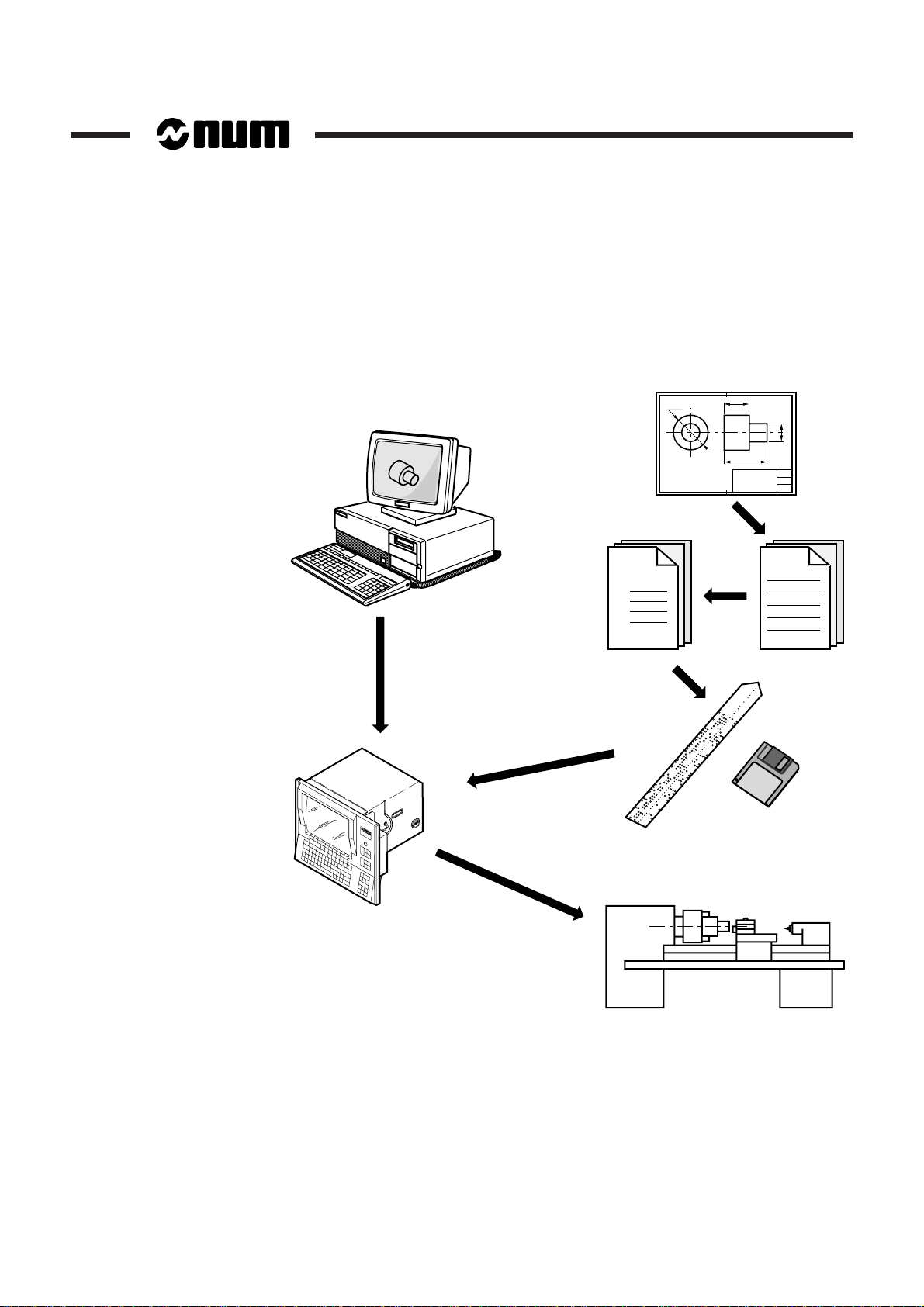

1.1.2 Defining a Programme

A programme is a sequence of instructions written in a programming language

specific to the numerical control (the most widely used is ISO code: International

Standards Organization).

The numerical control interprets the programme to control actions on a machine-tool.

The most widespread storage media for programmes are punched tape and

diskettes.

en-938820/5 1 - 3

Page 28

1.1.3 Preparating a Programme

A part programme can be created by traditional programming or using a CAD/CAM

system.

CAD/CAM

Part

Programme

% 1

N10

N20

N30

Machining

instructions

1 - 4 en-938820/5

Page 29

1.2 Machine Overview

Z

C

B

A

X

0

Y

X

Y

Z

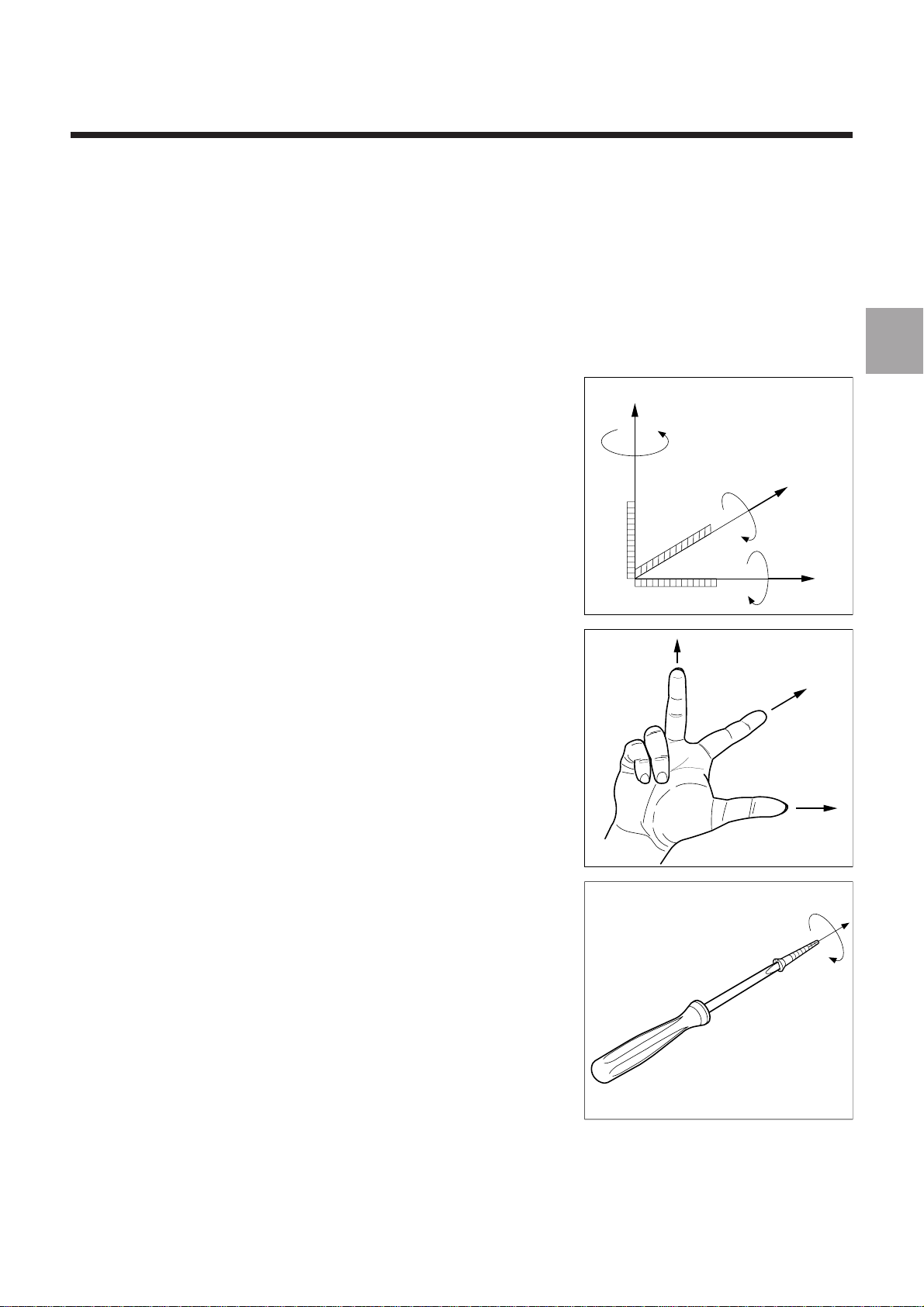

1.2.1 Review of Axis Definition and Direction

A coordinate system is used to identify

the positions and movements of an object

with respect to an origin or zero point.

A rectangular cartesian coordinate

system is a direct three-axis system of

three linear axes, X, Y and Z, with which

are associated three rotary axes, A, B

and C.

Review

1

The direction of axes X, Y and Z is easily

remembered by the right-hand rule.

The positive direction of rotation of a

rotary axis corresponds to the direction

of screwing of a right-hand screw on the

associated axis.

en-938820/5 1 - 5

Page 30

1.2.2 Machine Overview

The manufacturer defines the coordinate system associated with the machine in

accordance with standard ISO 841 (or NF Z68-020).

The X, Y and Z axes, parallel to the machine slideways, form a right-handed

rectangular cartesian coordinate system.

The coordinate system measures tool movements with respect to the part to be

machined, assumed fixed.

REMARK When it is the part that moves, it may be more convenient to identify its

movements. In this case, axes X’, Y’ and Z’, pointing in opposite

directions from axes X, Y and Z, are used.

The direction of the axis of a machine depends on the type of machine and the layout

of its components.

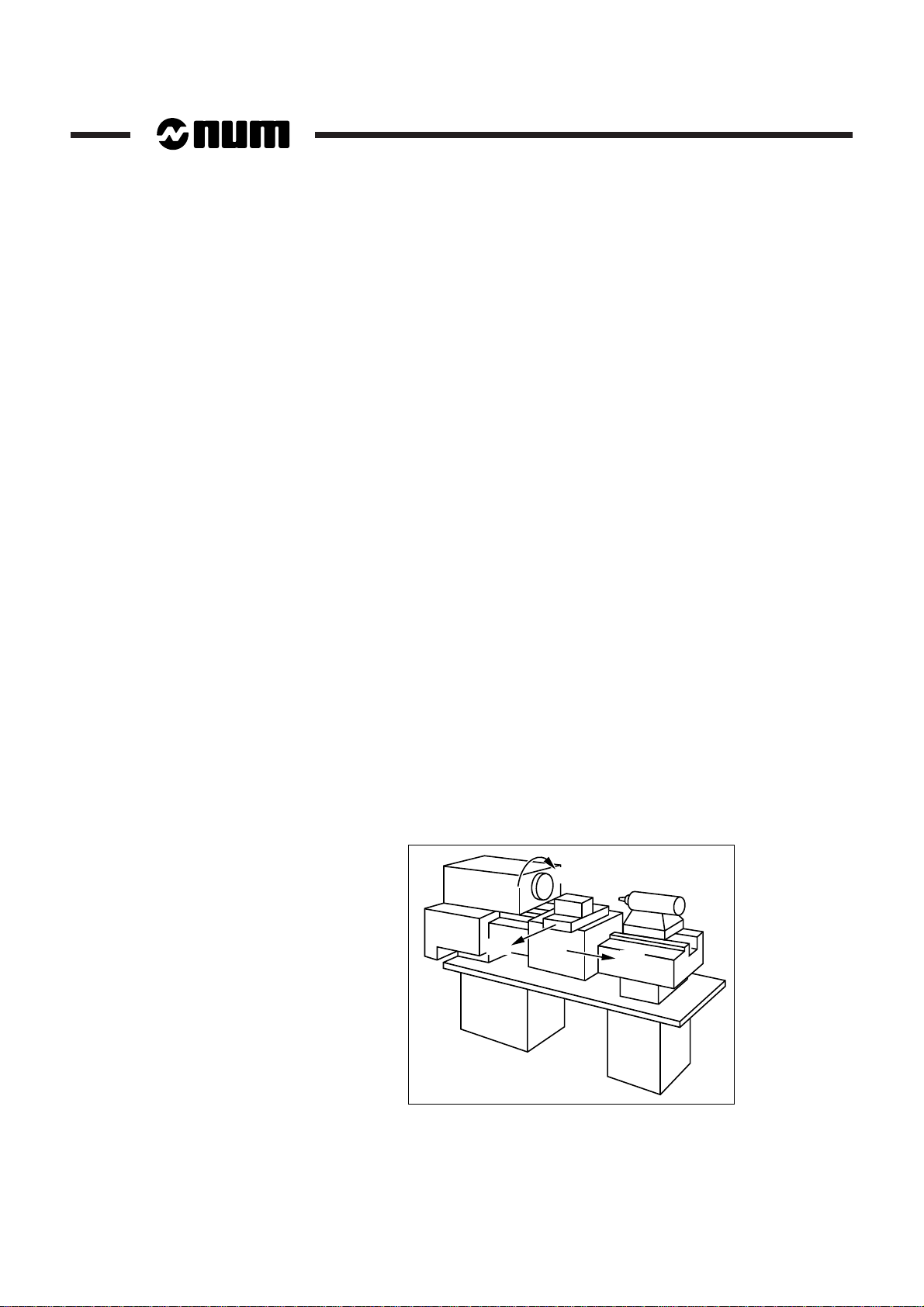

For a lathe:

- the Z axis is the same as the spindle axis,

- the X axis is perpendicular to the Z axis and corresponds to radial movement of

- the Y axis (generally a dummy axis) forms a right-handed coordinate system with

Positive movement along the Z or X axis increases the distance between the part and

the tool.

Rotary axes A, B and C define rotations around axes parallel to X, Y and Z.

the tool-holder turret,

the X and Z axes.

Secondary linear axes U, V and W may or may not be parallel to primary axes X, Y

and Z.

For more details, refer to the above-mentioned standard.

+ C'

+ X

+ Z

1 - 6 en-938820/5

Page 31

1.2.3 Definition of Travels and Origins

MOS direction

Om

Min. limite

switch

Max limit

switch

Contact closed Contact open

One encoder revolution

Encoder marker pulse

Review

OM :

Om :

The NC processor computes all movements with respect to the measurement origin

or zero point of the machine.

When the system is turned on, it does not know the measurement origin. The

mechanical travel on each machine axis is limited by maximum and minimum limit

switches.

The system establishes the measurement origin (OM) via a homing procedure

(MOS).

The home switch is set in a specific physical location: the machine zero point (Om)

may or may not be the same as the measurement origin (OM).

The homing procedure is completed for each of the axes when:

- the origin limit switch is actuated in the direction of movement specified by the

m/c manufacturer (MOS direction),

- the encoder which measures axis movement outputs its marker pulse.

1

en-938820/5 1 - 7

Page 32

When homing (MOS) is completed, the system applies the offset defined by the

X

Z

Mechanical travel on Z (limit switch)

Useful travel on Z

Accessible

area

Origin switch

encoder zero

Om

ORPOM Z

OM

ORPOM X

Useful travel on X

Mechanical travel

on X (limit switch)

manufacturer to each of the axes to establish the measurement origin (OM).

Measurement origin offset (OM/Om) = ORPOM

The useful travel on each of the axes is limited by software limits whose values are

defined by the machine parameters.

1 - 8 en-938820/5

Page 33

1.2.4 Offset Definitions

Review

OP :

Op :

To write a part programme, the programmer chooses a programme origin.

The programme origin is generally a starting point for dimensional measurements on

the part drawing.

The operator sets the programme origin (OP) as shown below:

He sets (for each axis) a known, accessible point on the part, called the part origin,

(Op). This may be the same point as the programme origin.

Part origin offset (Op/OM) = DAT1

It is possible to set the DAT1, DAT2 values from the part programme.

Programme origin offset (OP/Op) = DAT2

Offsets on the Z axis

Z

Turret

Setting block

Measurement

origin

(OM)

1

Z

OP

Z DAT2

Op

Turret

reference

Z DAT1

en-938820/5 1 - 9

Page 34

Offsets on the X axis (solution with DAT2)

X

Measurement

origin

(OM)

Setting

block

Turret

reference

X DAT1

Op

X DAT2

OP

X

Turret

X

Z

Measurement

origin

(OM)

Turret

reference

X DAT1

OP

X

Turret

Op

X

Offsets on the X axis (solution without DAT2)

X DAT1: Fixed value measured between OM and the spindle axis.

1 - 10 en-938820/5

Page 35

Review

OM

OP

Op

Z

X

Z

X

Z DAT1

Z DAT2

Z

PA

Z

MA

X

MA

X DAT1

X DAT2

X

PA

A

PART

The coordinates of a point (A) defined with respect to the programme origin (OP) are

converted by the NC to coordinates with respect to the measurement origin (OM):

1

Programme dimensions Measurement dimensions

(with respect to OP) (with respect to OM)

X

Z

PA

PA

Programmed shifts can be added to the programme dimensions.

XMA = XPA + X DAT1 + X DAT2

ZMA = ZPA + Z DAT1 + Z DAT2

en-938820/5 1 - 11

Page 36

1.2.5 Definition of the Tool Dimensions

1.2.5.1 Definition of the Tool Dimensions

Tool dimension = distance from tool cutting edge to turret reference point

X

Turret reference

point

OP

Part/tool

contact

diameter

X

Z

Tool axis orientation

OP

Z

Dimension Z

Part/tool contact

face

Turret reference

point

Dimension X

1 - 12 en-938820/5

Tool X dimension = X

Tool Z dimension = Z

Page 37

1.2.5.2 Definition of Tool Tip Radius and Orientation

Review

The description of a tool is shown below:

Tool tip orientation = codes C0-C8

The tool tip orientation code allows the

system to locate the centre (C) of the tool

tip from the theoretical cutting point (P).

Tool tip radius = R

Example :

X

C3 C2 C1

C4

C5 C6 C7

C0 C8

P

1

X

C1

P

Z

Z

The real cutting point of the tool is

obtained by applying a vector of length R

perpendicular to the direction of

movement from C.

X

Movement

R

P

Turret

Z dimension

C

en-938820/5 1 - 13

reference

X dimension

Z

Page 38

1.2.6 Definition of Dynamic Tool Corrections

At any time (even during machining), the operator can enter dynamic tool corrections

when he observes a difference between the expected and the actual results on a part.

The corrections (positive or negative) compensate for slight dimensional variations

of the tool or part (wear, expansion).

Dynamic tool correction on X = DX (diameter)

Dynamic tool correction on Z = DZ

D

L

L + ∆L

D + ∆D

TOOL

DX = -∆D

DZ = -∆L

The system takes into account the corrected tool dimensions:

Corrected length on X = X dimension + DX/2

Corrected length on Z = Z dimension + DZ

X + DX/2

Z + DZ

1 - 14 en-938820/5

Page 39

Structure of a Programme

2 Structure of a Programme

2.1 Word Format 2 - 4

2.1.1 General Word Format 2 - 4

2.1.2 Special Features of the Dimension Word

Format 2 - 4

2.1.2.1 Internal System Unit for Linear Axes 2 - 5

2.1.2.2 Internal System Unit for Rotary Axes 2 - 5

2.2 Block Format 2 - 7

2.3 General Structure of a Programme 2 - 9

2.3.1 General 2 - 9

2.3.2 Branches and Subroutine Calls 2 - 11

2.3.3 Programme Numbering 2 - 12

2.3.4 Characteristics of the ISO and EIA Codes 2 - 13

2.4 Classification of Preparatory G Functions and Miscellaneous M Functions 2 - 18

2.4.1 Classification of Preparatory G Functions 2 - 18

2.4.1.1 Modal G Functions 2 - 18

2.4.1.2 Nonmodal G Functions 2 - 18

2.4.1.3 G Functions Incompatible with the State

of the Programme 2 - 18

2.4.1.4 G Functions Associated with Arguments 2 - 19

2.4.2 Classification of Miscellaneous

M Functions 2 - 21

2.4.2.1 Modal M Functions 2 - 21

2.4.2.2 Nonmodal M Functions 2 - 21

2.4.2.3 «Pre» M Functions 2 - 21

2.4.2.4 «Post» M Functions 2 - 21

2.4.2.5 Encoded M Functions 2 - 22

2.4.2.6 Decoded M Functions 2 - 22

2

en-938820/5 2 - 1

Page 40

2 - 2 en-938820/5

Page 41

Structure of a Programme

A CNC part programme is a list of instructions and data to be transmitted to the control

system.

The creation of a programme consisting of blocks and words must obey structure,

syntax and format rules.

The programmes are variable in length with addresses as per the ISO and EIA codes

and standards.

Programming is possible in both codes:

- ISO (International Standards Organization) 6983-1 (NF Z 68-035), 6983-2

(NF Z 68 036) and 6983-3 (NF Z 68-037).

- EIA (Electronic Industries Association) Standards RS 244 A and 273 A.

PROGRAMME

%10

N10

N..

N..

N50 G01 X20.45 F0.15 M08

N..

N..

BLOCK

2

N250

XOFF

M02

WORD

en-938820/5 2 - 3

Page 42

2.1 Word Format

A word contains an instruction or data to be transmitted to the control system.

Word types:

- words defining dimensions

- words defining functions.

The word format defines the specific characteristics of each code word used in

programming (see table, Appendix C).

2.1.1 General Word Format

Address Algebraic sign Numerical data

WORD

Digits related to the address

Sign, possibly plus (+) or minus (-)

One or two letters or a digit

REMARK For words defining a dimension, the decimal point is generally explicit.

It separates the digits before and after the decimal point (it does not

appear in the definition of the word format).

The number of characters and spaces in a block must not exceed 118.

2.1.2 Special Features of the Dimension Word Format

The format of dimension words is determined by the choice of the internal system

units specified by the OEM when integrating the CNC.

Internal system units are specified for:

- Linear axes

- Rotary axes.

The internal units directly affect the machine travels and the dimension acquisition

and display formats for linear and rotary axes (modulo or not).

2 - 4 en-938820/5

Page 43

2.1.2.1 Internal System Unit for Linear Axes

The number of decimal digits available for programming the linear axes (where the

basic unit is the mm) is declared in machine parameter P4, word N2 (see Parameter

Manual).

Structure of a Programme

Correspondence between the word format and internal unit for linear axes

Internal unit Definition Word format

0.1 mm 1 decimal digit Format 071

0.01 mm 2 decimal digits Format 062

µm 3 decimal digits Format 053

0.1 µm 4 decimal digits Format 044

0.01 µm 5 decimal digits Format 035

2.1.2.2 Internal System Unit for Rotary Axes

The number of decimal digits available for programming the rotary axes (for which the

basic unit is the degree) is declared in machine parameter P4, word N4 (see

Parameter Manual).

Correspondence between the word format and the internal system unit for

rotary axes

2

Internal unit Definition Word format

0.1 degree 1 decimal digit Format 031

0.01 degree 2 decimal digits Format 032

0.001 degree 3 decimal digits Format 033

0.0001 degree 4 decimal digits Format 034

en-938820/5 2 - 5

Page 44

Examples of word formats:

X+053

Maximum number of digits

after the decimal point

Maximum number of digits

before the decimal point

Leading zeros are optional

The «+» sign is optional

Word address

Word defining a dimension, address X (internal unit in µm)

The dimension 0.450 mm in X+053 format (variable word format), can be written:

X+0.450 or X.45

Word defining a function, address G

G02

Word address

G function words in G02 format (variable word format).

Word G01 can be written: G1

Word G04 can be written: G4

Maximum number of digits

with the address

Leading zeros are optional

2 - 6 en-938820/5

Page 45

2.2 Block Format

Structure of a Programme

A block (or sequence) defines an instruction line of code words to be actioned by the

control system.

The block format defines the syntax of the function and dimension words in each

programming block.

BLOCK

N.. G.. X.. F.. M..

2

Miscellaneous function word

Technological function word

Dimension word

Preparatory function word

Block number

Examples of blocks

A block defining a tool change and calling up the tool correction

N20 T01 D01 M06

Tool change

Correction number

Tool number

Block number

en-938820/5 2 - 7

Page 46

A block defining spindle rotation

N30 S650 M41 M03

Spindle range

Speed of rotation

Block number

A block defining a move

Direction of rotation

N50 G01 X20.456 F150

End point

Linear interpolation

Block number

M08

Coolant

Feed rate

2 - 8 en-938820/5

Page 47

2.3 General Structure of a Programme

2.3.1 General

An NC programme must include start and end characters.

A programme is executed in the order in which the blocks are written between the

programme start and end characters.

A programme is executed in the order in which the blocks are written, and not in the

order of the block numbers. However, it is recommended to number the blocks in

ascending order (in increments of ten, for instance).

REMARK A programme can be written in ISO code or EIA code. The ISO or EIA

code is recognised by the system by reading the programme start

character.

Structure of a Programme

2

Structure of an ISO Programme

Programme start: % character

Programme end: code M02

Programme end of load: XOFF character

en-938820/5 2 - 9

Page 48

Programme start character

Programme number

%

1

N10

N20

N30

N..

N..

N..

N..

N250

XOFF

Programme end character

Structure of an EIA programme

An EIA programme has the same structure as an ISO programme except for the

programme start and end characters, which are different.

Programme start: EOR (End of Record) character

Programme end: BS (Back Space) character

M02

Programme

Miscellaneous programme

end function

REMARK For an EIA programme, a programme end character other than BS can

2 - 10 en-938820/5

be declared by machine parameter P80 (see Parameter Manual).

Page 49

2.3.2 Branches and Subroutine Calls

Particular instructions (branches and subroutine calls) can modify the order in which

a programme is executed.

A programme can be structured as follows:

Main programme Subroutine

Structure of a Programme

2

%10 (……)

$0…

N10 G .. G.. X.. Z..

N.. T.. D.. M.. (....)

N... ...

N50...

N... ...

N... ...

N100 Call to a sequence of blocks (N50...)

N... ...

N150 Call to a subroutine

N... ...

N200 Jump to a numbered block

N... ...

N250 M02

X OFF

%20

$0…

N10...

N... ...

N220...

X OFF

en-938820/5 2 - 11

Page 50

2.3.3 Programme Numbering

Programme number: The permissible format is %051.

The % character is followed by a programme number and possibly by a comment in

brackets.

Example:

%324 (PART No. 72 - PROG 3)

A programme number can be indexed (indices .1 to .8 with multiple axis group

programming, see Sec. 4.15).

Example:

%425.2 (PROG FOR GROUP 2)

!

CAUTION

Programmes with numbers above %9000 are reserved for NUM and the OEM integrating

the NC on the machine (check with NUM or the OEM for possible use of these numbers).

Programme Number and ISO Functions

When ISO functions are programmed after the programme (or subroutine) number

on the same line, they are ignored.

Example:

%99 G1 X80

Programme Load from a Peripheral

When loading a programme from a peripheral, if the programme number does not

comply with format %051, the excess digits are ignored.

Example:

%1234567.89 (comment)

%12345 .8 (comment)

Inhibiting display of subroutines being executed

Display on the programme page (PROG) of a subroutine and its internal subroutines

during execution can be inhibited.

Placing the character «:» after the subroutine number (e.g. %110:) inhibits display.

Only the subroutine call block is then displayed (for additional information, see Sec.

4.11.1).

Movement G1 X80 is ignored

Programme number received over the line

Number actually stored

2 - 12 en-938820/5

Page 51

2.3.4 Characteristics of the ISO and EIA Codes

10 digits

Letters of the alphabet

Programme start

Start of comment

End of comment

Plus sign

Minus sign

Decimal point

Greater than

Less than

Multiplied by

Equal to

Divided by

At sign

End of block

Skip block

Programme subdivision

Programme end

0-9

A-Z

%

(

)

+

-

.

>

<

*

=

/

@

LF

/

:

X OFF

0-9

A-Z

EOR

,

%

+

.

CR

/

letter O

BS

DESCRIPTION ISO EIA

List of characters recognised by the system in ISO and EIA codes:

Structure of a Programme

2

List of characters recognised by the system with no action on the machine:

DESCRIPTION ISO EIA

Tab

Carriage return

Space

Error

HT

CR

SP

DEL

RUB OUT

TAB

SP

DEL

RUB OUT

en-938820/5 2 - 13

Page 52

Structure of an ISO programme tape:

LEADER

8 7 6 5 4 3 2 1

8 6 3 1

8 4 3 1

4 2

6 4

8 6 4 1

8 4 3 1

4 2

7 4 3 2

8 6 5 1

6 5

7 4 3 1

8 6 5 2

8 4 3 1

4 2

8 5 2 1

Channel numbers as per standards

Sprocket holes

%

CR

LF

I

I

I

(

)

CR

LF

N

1

0

I

I

I

I

I

I

I

I

I

I

I

M

2

CR

LF

CTRL-X-OFF

Comments

Part programme

End of programme

- Start of

programme

- End of

rewind

- End of tape

- Start of

rewind

2 - 14 en-938820/5

TRAILER

Page 53

List of characters used in ISO code:

ISO CODE

Channel No.

Function

Programme start, rewind stop

Plus sign

Minus sign

Digits

Angular direction about X axis

Angular direction about Y axis

Angular direction about Z axis

Tool correction

Peripheral parameter

Feed rate. Dwell

Preparatory function

Subroutine No.

Interpolation address

Interpolation address

Interpolation address

Programmer parameter No.

Miscellaneous function

Sequence number

Miscellaneous parameters

Spindle speed function

Tool No.

Secondary dimension parallel to X axis

Secondary dimension parallel to Y axis

Secondary dimension parallel to Z axis

Primary X dimension

Primary Y dimension

Primary Z dimension

Programme subdivision

Optional block skip

Carriage return

End of block/line feed

Start of comment

End of comment

Space

End of tape

Horizontal tab

Delete

No punch

Charac-

ter

%

+

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

:

/

CR

LF

(

)

SP

X OFF

HT

DEL

NUL

Structure of a Programme

8 7 6 5 4 3 2 1

Tape punch

code

2

en-938820/5 2 - 15

Page 54

List of characters used in EIA code (RS.244.B):

EIA CODE

Channel No.

Function

Programme start, rewind stop

Plus sign

Minus sign

Digits

Angular direction about X axis

Angular direction about Y axis

Angular direction about Z axis

Tool correction

Peripheral parameter

Feed rate. Dwell

Preparatory function

Subroutine No.

Interpolation address

Interpolation address

Interpolation address

Programmer parameter No.

Miscellaneous function

Sequence number

Miscellaneous parameters

Spindle speed function

Tool No.

Secondary dimension parallel to X axis

Secondary dimension parallel to Y axis

Secondary dimension parallel to Z axis

Primary X dimension

Primary Y dimension

Primary Z dimension

Programme subdivision

Optional block skip

Carriage return

End of block/line feed

Start of comment

End of comment

Space

End of tape

Horizontal tab

Delete

No punch

Charac-

8 7 6 5 4 3 2 1

Tape punch

ter

EOR

+

0

1

2

3

4

5

6

7

8

9

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

s

t

u

v

w

x

y

z

o

/

EOB

?

%

SP

BS

TAB

DEL

NUL

code

2 - 16 en-938820/5

Page 55

Special ISO code characters:

8 7 6 5 4 3 2 1

Channel numbers

Charac-

ter

Description

Holes

punched

Less than

Greater than

Multiplied by

Equal to

Divided by or block skip

At sign

AND

OR

Dollar sign

Comma

Period

Single quote

Semicolon

Pound sign

Question mark

Double quote

<

>

*

=

/

@

&

!

$

,

.

'

;

#

?

"

Special characters

Structure of a Programme

2

The «$» character is used in a programme to send messages (see Sec. 4.19).

Most of the other characters are mainly used for parametric programming (see

Chapter 6).

Special characters of the EIA code:

As comments were not provided for by the EIA code, the characters «,» et «%» are

used and have the same meaning as round brackets «( )» in ISO code.

As there is no equivalence in EIA code for ISO characters «>», «<«, «*», «=» and

«@», parametric programming, tool data entry and tape punching are prohibited in

this code.

The absence of a character on an EIA tape is reported as a parity error.

en-938820/5 2 - 17

Page 56

2.4 Classification of Preparatory G Functions and Miscellaneous M Functions

2.4.1 Classification of Preparatory G Functions

Types of G functions:

- Modal G functions,

- Nonmodal G functions.

Certain G functions must be programmed with the associated arguments.

Programming of certain G functions may be incompatible with the state of the current

programme.

2.4.1.1 Modal G Functions

Functions belonging to a family of G functions that cancel one another.

Certain families of G functions include a default function that is initialised when power

is applied (see A.1).

These functions remain enabled until cancelled by another function of the same

family.

Example:

N.. G00 X.. Z..

N.. G01 Z..

High-speed linear interpolation

G00 cancelled by linear interpolation at

machining feed rate

2.4.1.2 Nonmodal G Functions

Functions enabled only in the block where they are programmed (cancelled at the end

of the block).

Example:

N.. G09 X..

2.4.1.3 G Functions Incompatible with the State of the Programme

Functions whose programming is enabled or not according to the state of the current

programme.

Example:

N.. G21 G42 X.. Y.. Z..

Accurate stop at end of block cancelled

at end of block.

Syntax correct, change of X Y Z

coordinate system (G21), followed by

radius offset (G42)

N..

N.. G42 G21 X.. Y.. Z..

Syntax incorrect, change of coordinate

system prohibited with radius offset

2 - 18 en-938820/5

Page 57

2.4.1.4 G Functions Associated with Arguments

Functions followed by one or more arguments that are specific to the G function

announcing them.

The argument(s) must immediately follow the function.

The analysis of the arguments of a G function is ended by reading a word that does

not belong to the list of arguments of this function.

Example:

N.. G04 F2 T03 F0.2

N.. G04 T03 F2 F0.2

When a G functions has several arguments, they can be programmed in any order

except for G functions that introduce breaks in the sequencing (G10, G76, G77 and

G79, see Sec. 4.11).

Structure of a Programme

2

Syntax correct

Syntax incorrect, argument F2 does not

immediately follow G04

The arguments associated with a function can be:

- compulsory,

- optional.

The argument of certain G functions can be programmed alone in a block.

Compulsory Arguments

The arguments are compulsory if:

- the G function serves only to announce arguments.

Example:

N.. G16 P+

- the G function cancels a former modal state and characterises its argument

differently.

Example:

N.. G94 F100

G function and its argument P+

Feed in mm/min

N..

N.. G95 F0.5

Optional Arguments

The arguments are optional if the G function allows them to be defined by default.

The change from feed in mm/min to

mm/revolution requires redefining

argument F

Example:

N.. G96 [X..] S150

Case where the X position (with respect

to OP) was specified by an earlier block

en-938820/5 2 - 19

Page 58

Arguments Programmed Alone

The argument can be programmed alone in a block when the associated G function

is still active.

Example:

N.. G94 F150 X.. Z..

Feed in mm/min

N..

N.. X.. Z.. F100

Function G94 is not compulsory with its

argument because the system is still in

state G94.

2 - 20 en-938820/5

Page 59

2.4.2 Classification of Miscellaneous M Functions

Type of M functions:

- Modal M functions,

- Nonmodal M functions.

Structure of a Programme

M functions can be:

- «pre» or «post» functions,

- encoded or decoded functions.

2.4.2.1 Modal M Functions

Functions belonging to a family of M functions that cancel one another.

Certain families of M functions include a default function that is initialised when power

is applied (see A.2).

These functions remain enabled until they are cancelled by another function of the

same family.

Example:

N.. S500 M03

N.. M05

2.4.2.2 Nonmodal M Functions

Enabled only in the block where they are programmed.

Example:

N.. M00

2.4.2.3 «Pre» M Functions

Functions executed before axis movements programmed in the block.

2

Start of spindle rotation

Spindle stop, cancels M03

Programme stop

Example:

N.. X100 Z50 M08

2.4.2.4 «Post» M Functions

Functions executed after the axis movements programmed in the block.

Example:

N.. X50 Z100 M09

Coolant function M08 is executed before

the movements on X and Z

The coolant off function (M09) is

executed after movements on X and Z

en-938820/5 2 - 21

Page 60

2.4.2.5 Encoded M Functions

The encoded functions are defined by the machine manufacturer and are specific to

the machine (see manufacturer’s technical data).

Encoded Functions M100 to M199

These functions with PLC handshake are generally nonmodal «post» functions, but

these features can be redefined by the machine manufacturer.

Only one of these functions is allowed in a part programme block.

Encoded Functions M200 to M899

These so-called on-the-fly functions are modal «pre» functions. The programme

continues without waiting for the execution report.

Only one of these functions is allowed in a part programme block.

REMARK An encoded nonmodal function (M100 to M199) can be programmed

in the same block with an encoded modal function (M200 to M899).

2.4.2.6 Decoded M Functions

The decoded M functions are the basic system functions whose meaning is known.

REMARK All these functions are acknowledged by a PLC handshake (CRM). The

acknowledgement enables continuation of the part programme.

2 - 22 en-938820/5

Example:

N.. T01 M06

Several decoded M functions can be programmed in the same block.

Example:

Tool change function M06

N.. G97 S500 M03 M40 M08

Page 61

Axis Programming

3 Axis Programming

3.1 General 3 - 3

3.2 Programming the Independent Secondary Axes 3 - 4

3.3 Programming Carrier/Carried Parallel Axis Pairs 3 - 5

3.4 Programming of Rotary Axes Modulo 360 Degrees 3 - 6

3.5 Programming of Slaved Rotary Axes with Limited Travel 3 - 7

3.6 Programming of Axes A, B or C Declared as Nonrotary 3 - 7

3.7 Features of Front Turret, Rear Turret 3 - 8

3

en-938820/5 3 - 1

Page 62

3 - 2 en-938820/5

Page 63

3.1 General

Axis Programming

Programmable axes:

- Primary axes X, (Y), Z,

- Secondary axes U, (V), W,

- Rotary axes (A), (B), C.

Primary and secondary axes:

- they can be independent or form carrier/carried axis pairs (see machine parameter

P64),

- they can be programmed in millimetres (basic unit) or inches.

Rotary axes:

- They can be modulo 360 degrees or have limited travel or be declared as nonrotary (see machine parameter P1),

- They are programmed in degrees (basic unit).

3

Reminder

Definition of the Internal System Measurement Units

The internal measurement unit is defined by the OEM when integrating the CNC. It

directly affects the machine travels on the linear axes and rotary axes (modulo or not).

The number of decimal digits is declared in machine parameter P4 and determines

the word formats (see Sec. 2.1 and Appendix C).

For linear axes, the internal unit can be 0.1 mm, 0.01 mm, µm, 0.1 µm or 0.01 µm.

For rotary axes, the internal unit can be 0.1 degree, 0.01 degree, 0.001 degree or

0.0001 degree.

REMARK For ISO functions and programming arguments defining angular va-

lues (EA.., EC.., ED.., etc.), the unit is always 0.0001 degree.

For additional information, refer to:

- The machine manufacturer’s manual

- The Parameter Manual.

en-938820/5 3 - 3

Page 64

3.2 Programming the Independent Secondary Axes

Programming the independent secondary axes U, (V), W is unrelated to the

programming of the primary axes X, (Y), Z.

For a primary axis, the machine dimension is expressed:

Mx (machine dimension) = Px (programmed dimension) + xDAT1 + xDAT2 + tool

offset x

In the above example, x is the primary axis X (the equation is the same for the Y and

Z axes).

For an independent secondary axis, the same machine dimension is expressed:

Mu (machine dimension) = Pu (programmed dimension) + uDAT1 + uDAT2

In the above example, u is the independent secondary axis U (the equation is the

same for the (V) and W axes).

It should be noted that the tool length correction is not applied to the independent

secondary axes.

3 - 4 en-938820/5

Page 65

3.3 Programming Carrier/Carried Parallel Axis Pairs

Movement of the axis pair with respect to the part.

The U axis is a large slide and the X axis is a small slide.

Representation of large slide approach programmed by UP2

Calculation of UM2, knowing that XP2 = UP2.

Axis Programming

UM2 = UP2 = (DAT1 + DAT2 + X dimension) - XM1

X DAT1 + U DAT1 + DAT2

UM2

OM U

Representation of the small slide approach programmed by XP3

Calculation of XM3, knowing that XP3 = UP3.

XM3 = XP3 = (DAT1 + DAT2 + X dimension) - UM2

OM X

UM2

XM1

X DAT1 + U DAT1 + DAT2

X

UP2

Part origin

(Op)

Part

Programme

origin (OP)

3

OM U

OM X

XM3

XP3

Part origin

(Op)

X

Part

Programme

origin (OP)

en-938820/5 3 - 5

Page 66

3.4 Programming of Rotary Axes Modulo 360 Degrees

Rotary axis C programmed in absolute dimensions (G90)

The angular value assigned to the axis is the position of the end point with reference

to the programme origin, value between 0 and 360 degrees, maximum one revolution

(see Sec. 4.1 for function G90).

The sign (+ or -) determines the direction of rotation to reach this point.

Example:

a: Start point

b: End point

Positive rotation

+ (Positive)

(30°)

a

N.. ...

N.. G90 C+270

C0

X

N..

– (Negative)

Negative rotation

N..

+ 270°

b

– 270°

N.. G90 C-270

N..

Rotary axis C programmed in incremental dimensions (G91)

The value assigned to the axis indicates the amplitude of rotation of the axis with

reference to the previous position (see Sec. 4.1 for function G91).

Example:

a: Start point

b: End point

Positive rotation

N.. ...

N.. G91 C+240

+ (Positive)

a

C0

(30°)

X

N..

– (Negative)

Negative rotation

N..

+ 240°

b

– 120°

N.. G91 C-120

N..

3 - 6 en-938820/5

Page 67

REMARK With incremental programming G91 (see Sec. 4.1 for function G91), a

+ 45

+

–

0

- 495

movement of more than one revolution is allowed on modulo rotary

axes A, B or C. It should be noted that a maximum of 15 revolutions

are allowed. If this value is exceeded, the system returns error

message 1.

3.5 Programming of Slaved Rotary Axes with Limited Travel

Axis Programming

Servoed rotary axes A, B or C with limited travel are defined by machine parameters

like linear axes and therefore follow the same programming rules.

This definition of a rotary axis can be used for axes with more than 360 degrees of

travel to be rotated by more than one revolution with respect to a preferential position.

Example:

Rotation greater than one revolution Rotation greater than one revolution

in absolute dimensions (G90). in incremental dimensions (G91).

+

–

0

- 405+ 405

3.6 Programming of Axes A, B or C Declared as Nonrotary

3

When axes A, (B) or C are declared as nonrotary (see machine parameter P1), they

are considered as linear axes (in particular in keyboard Homing mode and Shift

mode).

The speed of movement on axes A, B or C declared as nonrotary is expressed in

mm/min. However, if they are programmed in a block together with primary and

secondary axes X, (Y), Z, U, (V) or W, the programmed speed is assigned to the latter.

en-938820/5 3 - 7

Page 68

3.7 Features of Front Turret, Rear Turret

The front or rear position of the main turret defines the positive orientation of the X

axis.

Lathe with rear turret

Spindle

axis

Lathe with front turret

Spindle

axis

Turret

X

OP

OP

Z

Z

OM

OM

Measurement

origin

3 - 8 en-938820/5

X

Measurement

origin

Turret

OM

Page 69

ISO Programming

4 ISO Programming

4.1 Choice of the Programming System 4 - 5

4.1.1 Programming by Absolute or Incremental

Dimensions 4 - 5

4.2 Programming with Reference to Diameter or Radius 4 - 9

4.3 Spindle Commands 4 - 11

4.3.1 Notes on Axis Programming 4 - 11

4.3.2 Spindle Speed Control 4 - 13

4.3.2.1 Constant Surface Speed 4 - 15

4.3.3 Spindle Range 4 - 20

4.3.4 Indexed Spindle Stop 4 - 21

4.3.5 Spindle Control Selection 4 - 23

4.3.6 Spindle Measurement Selection 4 - 25

4.3.7 Spindle Speed Limiting 4 - 27

4.4 Rapid Positioning 4 - 29

4.5 Programming of Movements 4 - 32

4.5.1 Linear Interpolation 4 - 32

4.5.2 Circular Interpolation 4 - 36

4.5.3 Circular Interpolation Defined by Three

Points 4 - 44

4.5.4 Polar Programming 4 - 46

4.5.4.1 Polar Programming of a Line 4 - 47

4.5.4.2 Polar Programming of a Circle 4 - 49

4.5.4.3 Defining a Circle by the Arc Angle 4 - 53

4.5.5 Programming Fillets and Chamfers 4 - 57

4.5.5.1 Fillet Between Two Interpolations 4 - 57

4.5.5.2 Chamfer Between Two Linear I

nterpolations 4 - 58

4.6 Path Sequencing Conditions 4 - 59

4.7 Feed Rate 4 - 61

4.7.1 Feed Rate Expressed in Millimetres,

Inches or Degrees per Minute 4 - 61

4.7.2 Feed Rate Expressed in Millimetres or

Inches per Revolution 4 - 64

4.7.3 Tangential Feed Rate 4 - 66

4.7.4 Feed Rate Specific to Fillets EB+ and

Chamfers EB- 4 - 68

4.8 Programming of Tools 4 - 70

4.8.1 Tool Change 4 - 70

4.8.2 Tool Axis Orientation 4 - 72

4.8.3 Tool Correction Call 4 - 74

4.8.4 Positioning the Tool with Respect to the

Part 4 - 79

4

en-938820/5 4 - 1

Page 70

4.9 Basic Cycles 4 - 91

4.9.1 Cancellation of a Canned Cycle 4 - 91

4.9.2 Constant Pitch Thread Chasing Cycle 4 - 92

4.9.3 Sequenced Thread Cutting 4 - 99

4.9.4 Drilling, Boring and Tapping Cycles 4 - 101

4.9.4.1 General 4 - 101

4.9.4.2 Centre Drilling Cycle 4 - 104

4.9.4.3 Counterboring Cycle 4 - 106

4.9.4.4 Peck Drilling Cycle 4 - 108

4.9.4.5 Tapping Cycle 4 - 111

4.9.4.6 Rigid Tapping Cycle 4 - 113

4.9.4.7 Boring Cycle 4 - 117

4.9.4.8 Drilling Cycle with Chip Breaking 4 - 119

4.9.4.9 Boring Cycle with Dwell at the Bottom of

the Hole 4 - 122

4.9.4.10 Examples of Programming Cycles 4 - 124

4.9.4.11 Table Summarising Cycles G81 to G89 4 - 127

4.10 Other Machining Cycles 4 - 128

4.10.1 Rough Turning/Facing Cycle 4 - 128

4.10.2 Groove Roughing Cycle 4 - 140

4.10.3 Plunging Cycle 4 - 146

4.10.4 Roughing Cycle with Groove 4 - 151

4.11 Breaks in Sequence 4 - 165

4.11.1 Unconditional Branch to a Subroutine or

Sequence of Blocks with Return 4 - 165

4.11.2 Subroutine Branch by M Function 4 - 172

4.11.3 Branch to a Sequence without Return 4 - 175

4.11.4 Subroutine Call by Automatic Control

Function 4 - 178

4.11.5 Block Interrupt 4 - 181

4.11.5.1 Special Use of Sequence Interrupt 4 - 185

4.11.6 Temporary Suspension of Next Block

Preparation 4 - 187

4.11.7 Emergency Retract 4 - 189

4.11.8 Branch to Automatic Homing Subroutine 4 - 193

4.11.9 Subroutine Branch on a Reset 4 - 194

4.11.10 Restrictions Related to Drip Feed Mode 4 - 195

4.11.11 Call to Subroutine Return Block 4 - 196

4.11.12 ISO Programme or Block Creation/

Deletion 4 - 198

4 - 2 en-938820/5

Page 71

ISO Programming

4.11.12.1General 4 - 198

4.11.12.2Creating a Programme 4 - 198

4.11.12.3Deleting a Programme 4 - 199

4.11.12.4Inserting a Block 4 - 200

4.11.12.5Deleting a Block 4 - 202

4.12 Movement Origin Selection 4 - 203

4.12.1 Programming of Movements in Absolute

Coordinates Referenced to the

Measurement Origin 4 - 203

4.12.2 Datum Shift DAT1 and DAT2 Cancel/

Enable 4 - 206

4.12.3 Programme Origin Preset 4 - 207

4.12.4 Programme Origin Offset 4 - 209

4.12.5 Angular Offset 4 - 215

4.13 Spline Curve Interpolation 4 - 216

4.13.1 General 4 - 216

4.13.2 Programming 4 - 216

4.13.2.1 Spline Curve Interpolation 4 - 217

4.13.2.2 Spline Curve Execution Command 4 - 220

4.13.2.3 Programming Examples 4 - 221

4.13.2.4 Freeing Memory by Deleting a Spline

Curve 4 - 225

4.14 Coordinates Systems with C Axis 4 - 226

4.14.1 Programming in Polar Coordinates 4 - 226

4.14.2 Definition of the Start X for Interpolation

on the C Axis 4 - 228

4.14.3 Programming in Cartesian Coordinates 4 - 229

4.14.4 Programming in Cylindrical Coordinates 4 - 234

4.15 Other Functions 4 - 238

4.15.1 Dwell 4 - 238

4.15.2 Programmed Feed Stop 4 - 240

4.15.3 Feed Enhancement 4 - 242

4.15.4 Programming in Inches or Metric Data 4 - 244

4.15.5 Axis Clamping and Unclamping 4 - 246

4.15.6 Coolant 4 - 247

4.15.7 Programme Stop 4 - 248

4.15.8 Optional Stop 4 - 250

4.15.9 Cancellation of MDI and EDIT modes 4 - 252

4.15.10 Forced Block Continuation 4 - 254

4.15.11 Potentiometer Inhibit 4 - 255

4.15.12 Block Skip 4 - 256

4

en-938820/5 4 - 3

Page 72

4.15.13 Programmed Acceleration Reduction 4 - 258

4.15.14 Scaling Factor 4 - 259

4.15.15 Mirror Function 4 - 261

4.15.16 Processing of Blocks and Programmed G

and M Functions 4 - 264

4.16 «Inclined Axis» or «Inclined Wheel» State on a Grinder 4 - 267

4.16.1 «Inclined Axis» State 4 - 267

4.16.1.1 Initial Tool Positioning Before Machining

on an Inclined Axis 4 - 268

4.16.1.2 Movement Along the Inclined Axis 4 - 269

4.16.2 «Inclined Wheel» State 4 - 271

4.17 Special Programming for Multiple Axis Groups 4 - 273

4.17.1 Programme Declaration 4 - 273

4.17.2 Programming Notes 4 - 273

4.17.3 Subroutine branches for Multi-Axis

Groups 4 - 275

4.17.3.1 Branch to Automatic Homing Subroutine 4 - 275

4.17.3.2 Subroutine Call by a Reset 4 - 275

4.17.3.3 Subroutine Call by the Automatic Control

Function 4 - 276

4.17.3.4 Subroutine Call by M Function 4 - 276

4.17.4 Spindle Programming 4 - 277

4.17.5 Current Spindle Release by an Axis

Group 4 - 278

4.17.6 Axis Group Synchronisation 4 - 279

4.18 Special Programming of PLC Axes 4 - 283

4.18.1 Programme Declaration and Storage 4 - 283

4.18.2 Programming of the PLC Axes 4 - 285

4.18.2.1 Emergency Retraction on a PLC Axis

Group 4 - 285

4.18.3 Editing the Programmes 4 - 286

4.18.4 Exchanging Axes between Groups 4 - 286

4.18.5 Exchanging Spindles Between Groups 4 - 287

4.19 Message Transmission 4 - 288

4.19.1 Message Transmission to the Display 4 - 288

4.19.2 Transmission to Automatic Control

Function or Remote Server or Peripheral

or PC 4 - 290

4.20 Spindle Synchronisation 4 - 293

4.20.1 Spindle Acceleration Control 4 - 293

4.20.2 Servo-Controlled Spindles and

Synchronised Spindles 4 - 294

4.20.2.1 Servo-Controlled Spindles 4 - 294

4.20.2.2 Synchronised Spindles 4 - 295

4 - 4 en-938820/5

Page 73

4.1 Choice of the Programming System

4.1.1 Programming by Absolute or Incremental Dimensions

G90 Absolute dimensions with

respect to the programme

origin.

ISO Programming

X

Z

The value programmed on an axis is with

reference to the programme origin (OP).

G91 Incremental dimensions.

The value programmed on an axis is with

reference to the last programmed position.

The value is equal to the movement to be

performed.

Syntax

OP

OP

X

Z

4

X

Z

X

Z

N.. G90/G91 X.. Z.. C..

G90 Absolute dimensions.

G91 Incremental dimensions.

X.. Z.. C.. End point.

en-938820/5 4 - 5

Page 74

Properties of the Functions

Functions G90 and G91 are modal.

G90 is the default function.

Cancellation

Functions G90 and G91 cancel one another.

Notes

The first movement must be programmed:

- in absolute dimensions (G90),

- by manual data entry (MDI) or in a programme with respect to the programme

origin (OP) instead of with respect to the current position.

Incremental programming (G91) is prohibited for PGP (Profile Geometry Programming,

see Chapter 5).

Combined programming

Both types of programming (G90/G91) can be included in a programme and even in

a block. For instance:

N..

N.. G91 X.. Z..

N.. G90 X.. G91 Z..

X absolute, Z incremental

N.. G90 X.. Z..

N..

4 - 6 en-938820/5

Page 75

ISO Programming

Examples

Absolute programming (G90), (System programmed on radius)

Tool located at point a (starting point)

Absolute programming of point b

(coordinates of the end point).

Z

b

N.. (G90)...

N.. Xa Ya

N.. Xb Yb

N..

Xb

X

OP

Z

a

4

Incremental programming (G91), (System programmed on radius)

Tool located at point a (starting point)

Incremental programming of point b

(amount of movement to reach end point

b).

N.. (G90) ...

X

X

b

N.. Xa Za

N.. G91 Xb Zb

N..

OP

Z

Z

a

en-938820/5 4 - 7

Page 76

Absolute programming (G90), (System programmed on diameter)

Coordinates of points a, b, c, d, with

respect to the programme origin (OP).

N.. (G90) ...

N.. X20 Z5

N.. Z-10

N.. X30 Z-30

ø 50

d

c

b

ø 30

N.. X50

N..

30

Incremental programming (G91), (System programmed on diameter)

Absolute programming of point a,

incremental movement to points b, c, d.

N.. (G90) ...

N.. X20 Z5

N.. G91 Z-15

N.. X5 Z-20

N.. X10

ø 50

ø 30

20

d

c

b

N.. G90

N..

ø 20

10

15

ø 20

5

a

X

Z

OP

a

X

Z

OP

4 - 8 en-938820/5

Page 77

4.2 Programming with Reference to Diameter or Radius

X

OP

Point a

Xa

Xa

The part programme and certain data

related to machining along the X (or U)

axis are directly affected by whether

programming is with reference to

diameter or radius.

Programming of the system with

reference to the diameter or radius is

selected by machine parameter P4 (see

parameter manual).

ISO Programming

In both cases, certain functions are

always expressed with respect to the

diameter and others with respect to the

radius.

System Programmed with Reference to Diameter

Programmed values expressed with reference to diameter:

- values programmed in absolute dimensions (G90): coordinates of a movement

along X.. and position I.. of the centre of a circle,

- value of the starting diameter with constant surface speed (G96),

- value programmed with function G98.

Programmed values expressed with reference to radius:

- values programmed in incremental dimensions (G91): value of a movement along

X.. and position I.. of the centre of a circle,

- circle radius with circular interpolation (R),

- fillet or chamfer (EB+, EB-),

- pass depth for roughing cycle (P or R),

- machining allowance for roughing cycles (I or K), (ER),

- positioning clearance for roughing cycle (Q),

- minimum depth of cut for roughing cycle (EQ),

- thread depth (P) and last pass for thread cutting (Q),

- pass depth for drilling cycle (P and Q),

- offsets programmed with functions G59 and G52.

4

Tool dimensions:

- Entry of values with respect to radius.

Dynamic tool corrections:

- Entry of values with respect to diameter, but display of the radius changes on the

«DYNAMIC TOOL CORRECTIONS» page.

en-938820/5 4 - 9

Page 78

Value of offset DAT2:

- Entry of the value with reference to radius.

Movements related to the manual controls:

- Movements on the X axis with reference to radius, but display with reference to

diameter on the «AXES» page.

System Programmed with Reference to Radius

Values expressed with reference to radius:

- All the programmed movements applied to the X axis and all the values entered

related to machining along X.

Values expressed with reference to diameter:

- Only the dynamic tool corrections on X are entered with reference to diameter.

4 - 10 en-938820/5

Page 79

4.3 Spindle Commands

M03

M04

4.3.1 Notes on Axis Programming

M03 Spindle clockwise rotation.

This command starts spindle rotation at

the speed programmed.

ISO Programming

4

M04 Spindle counterclockwise

rotation.

This command starts spindle rotation at

the speed programmed.

M05 Spindle off.

This command stops spindle rotation.

en-938820/5 4 - 11

Page 80

Syntax

N.. M03/M04/M05

M03 Spindle clockwise rotation.

M04 Spindle counterclockwise rotation.

M05 Spindle off.

Properties of the Functions

Functions M03 and M04 are decoded modal «pre» functions.

Function M05 is a decoded modal «post» function. It is the default function.

Cancellation

Functions M03, M04 and M05 cancel one another.

Functions M00, M19 and M01 (enabled) cancel functions M03 or M04.

Example

N.. ...

N120 ...

N130 M03 ...

Tool call

Spindle clockwise rotation

N..

N..

N220 M05 ...

Spindle off

N..

4 - 12 en-938820/5

Page 81

4.3.2 Spindle Speed Control

S

G97 RPM spindle speed.

This function defines a fixed spindle

speed programmed with the S word.

ISO Programming

4

Syntax

N.. G97 S.. [M03/M04]

G97 Function setting the spindle speed in rpm.

S.. Mandatory argument associated with the function to

define the speed.

M03/M04 Spindle direction of rotation.