Page 1

NUM 1060

PC

MODULE

0101938928/2

09-97 en-938928/2

Page 2

Despite the care taken in the preparation of this document, NUM cannot guarantee the accuracy of the information it contains and cannot be held

responsible for any errors therein, nor for any damage which might result from the use or application of the document.

The physical, technical and functional characteristics of the hardware and software products and the services described in this document are subject

to modification and cannot under any circumstances be regarded as contractual.

The programming examples described in this manual are intended for guidance only. They must be specially adapted before they can be used in

programs with an industrial application, according to the automated system used and the safety levels required.

© Copyright NUM 1997.

All rights reserved. No part of this manual may be copied or reproduced in any form or by any means whatsoever, including photographic or magnetic

processes. The transcription on an electronic machine of all or part of the contents is forbidden.

© Copyright NUM 1997 software NUM 1060.

This software is the property of NUM. Each memorized copy of this software sold confers upon the purchaser a non-exclusive licence strictly limited

to the use of the said copy. No copy or other form of duplication of this product is authorized.

2 en-938928/2

Page 3

Table of Contents

1 General 7

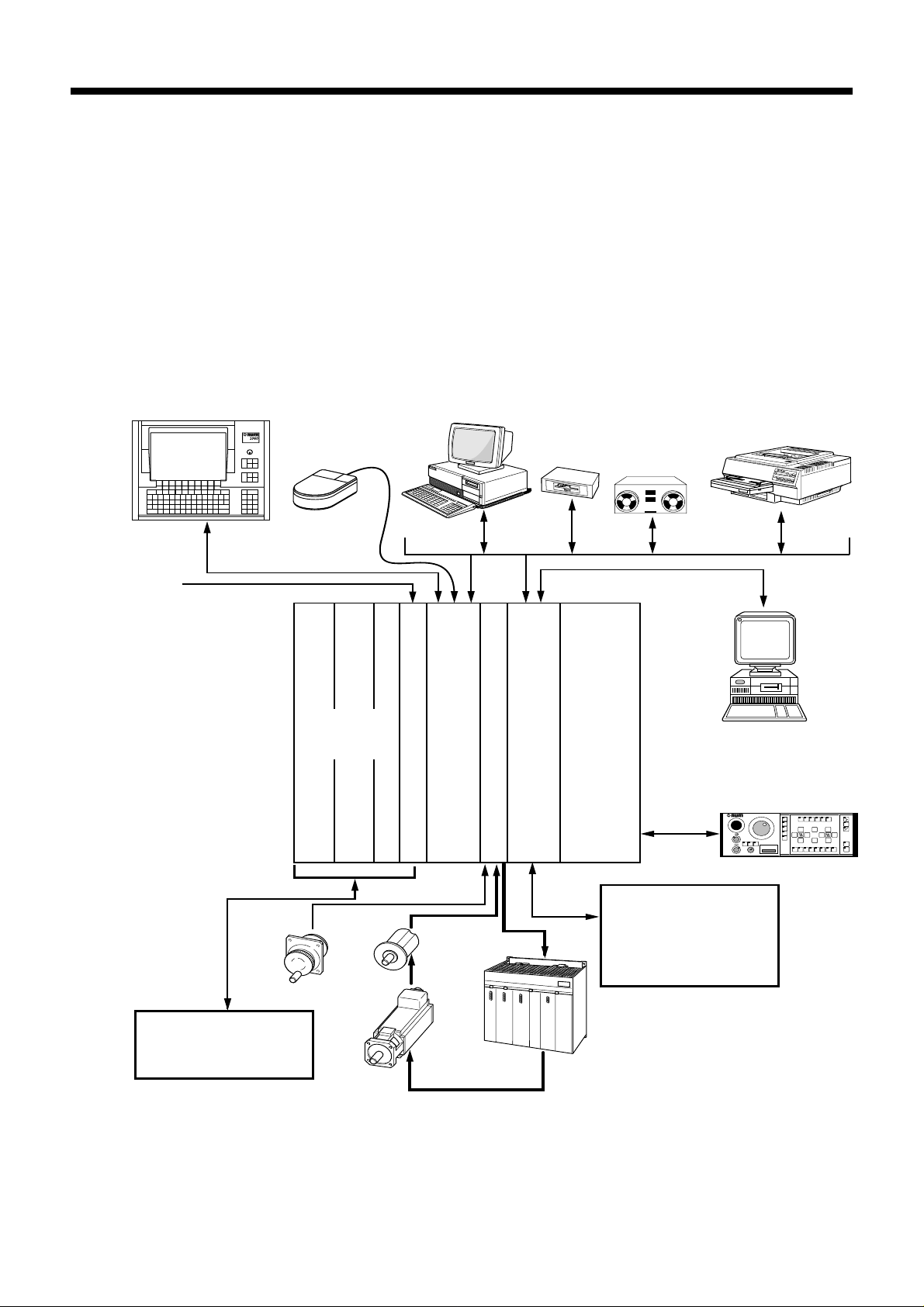

2 System Architecture 9

2.1 PCNC 1060 Series II System Architecture 9

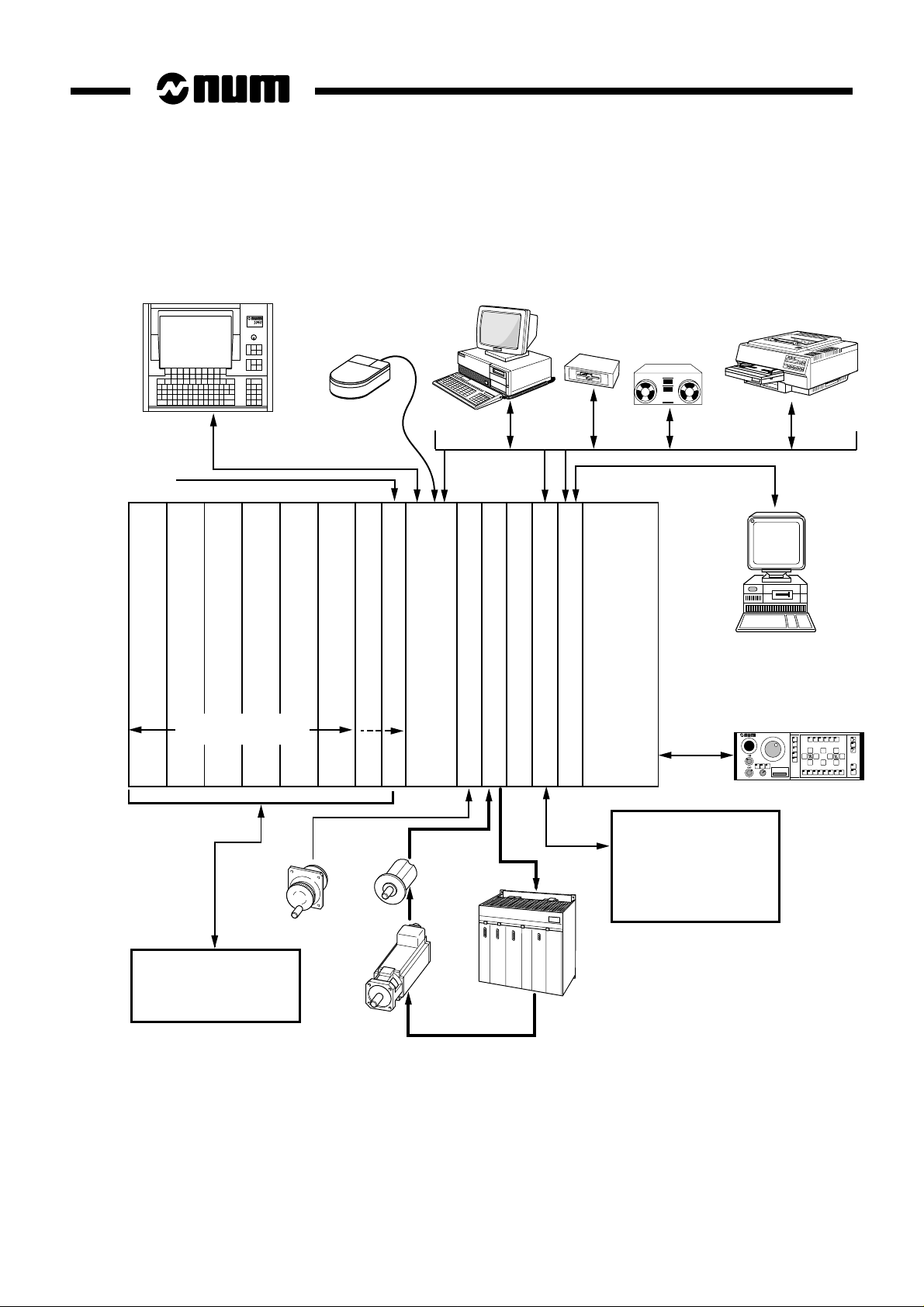

2.2 PCNC 1060 System Architecture 10

3 Card Layout in the Rack 11

3.1 Card Layout in the 1060 Series II Rack 11

3.2 Card Layout in the 1060 Rack 12

4 PCNC Configurations 13

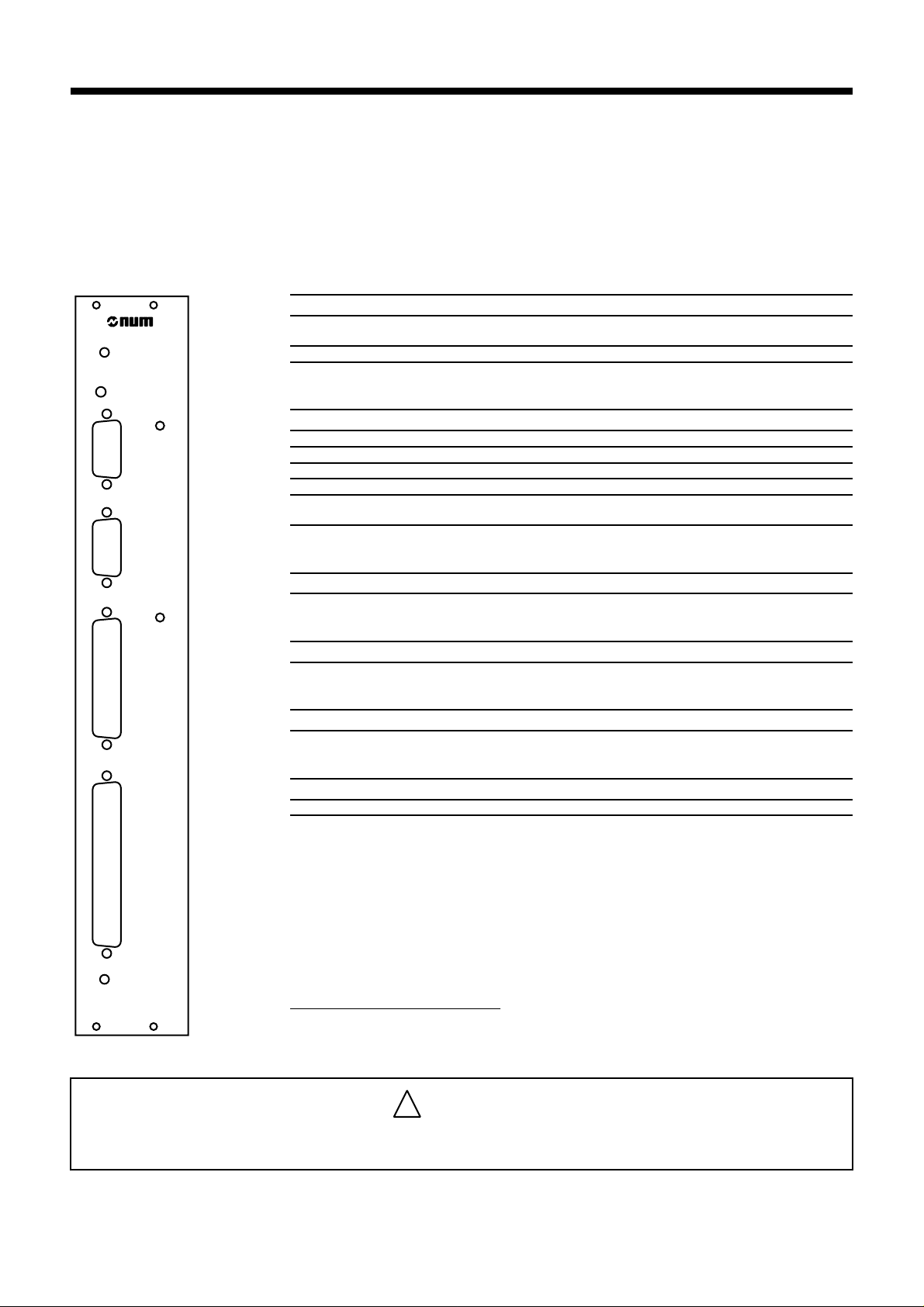

4.1 PCNC 1060 Series II Configuration 13

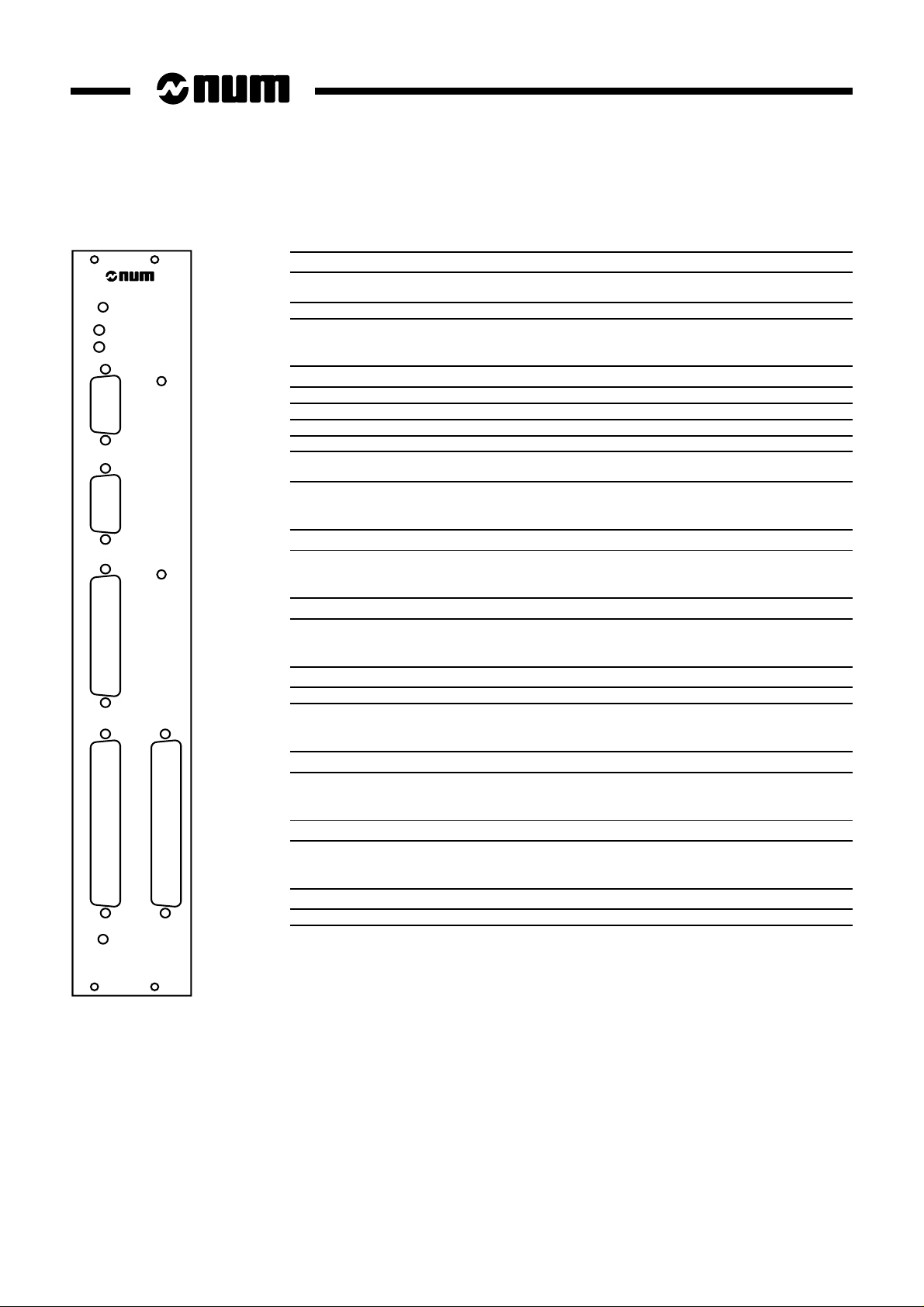

4.2 PCNC 1060 Configuration 14

5 PC Module Characteristics 15

5.1 PC Module Version 1 Characteristics 15

5.2 PC Module Version 2 Characteristics 16

6 PC Module Connection Wiring Diagram 18

6.1 PC Module Version 1 Connection 18

6.2 PC Module Version 2 Connection 19

7 PCMCIA Module Characteristics 20

8 Cables 21

8.1 Video Cable 21

8.2 Diskette Drive Cable 23

8.2.1 PC Version 1 Module 23

8.2.2 PC Version 2 Module 24

9 Work on the PC Module 25

9.1 Replacing the Battery 26

9.2 Adding a DRAM Memory Module 26

9.3 Adding the PCMCIA Module 27

10 Using the PC 28

10.1 Applications Which Can Be Used by the PC 28

10.2 Using the PC 28

10.2.1 Config.sys 28

10.2.2 NUM Shutdown 29

10.2.3 Opening a User Application at Startup 31

10.2.4 NUM Task/User Task Toggle 31

10.2.5 Creating System Diskettes 32

10.2.6 Regenerating the Initial Configuration 32

10.2.7 Reinstalling the NUM Application 32

10.2.8 Backing up the NUM Application 32

10.2.9 Restoring a Disk: CHKDSK 32

10.2.10 Modifying the NUM Application Task

Priorities 33

10.2.10.1Description of the Threads 33

10.2.10.2Modifying the Priorities 33

10.2.10.3Entering the Parameters 34

10.2.11 Modifying the Colour Palette 34

en-938928/2 3

Page 4

10.3 Development of Specific Applications 35

10.3.1 UNI-TE Primitives 35

10.3.1.1 Accessing UNI-TE: Open_Unite() Function 35

10.3.1.2 Opening Logic Ports: Get_Port() Function 36

10.3.1.3 Freeing Logic Ports: Free_Port Function 36

10.3.1.4 Sending a Request : Unito() Function 37

10.3.1.5 Receiving an Answer: Uniti() Function 38

10.3.1.6 Example of Use of UNI-TE Primitives in an

Application 39

10.3.2 Requests Accessible to the PC 40

10.3.2.1 List of CNC Requests 40

10.3.2.2 List of PLC Requests 42

10.3.2.3 Reading Part Programme Blocks 43

10.3.2.4 Writing Part Programme Blocks 44

10.3.2.5 Reserving Memory Space 45

10.4 Functional Description of the PCNC Server 46

10.4.1 OPEN-DOWNLOAD-SEQUENCE Request 46

10.4.2 WRITE-DOWNLOAD-SEGMENT Request 47

10.4.3 CLOSE-DOWNLOAD-SEQUENCE Request 48

10.4.4 OPEN-UPLOAD-SEQUENCE Request 48

10.4.5 READ-UPLOAD-SEGMENT 49

10.4.6 CLOSE-UPLOAD-SEQUENCE 50

10.4.7 "ICONIFICATION" (Minimise) Request 51

10.4.8 "RESTITUTION" (Restore) Request 51

10.4.9 "VERROUILLAGE/DEVERROUILLAGE"

(Lock/Unlock) Request 52

10.4.10 SHUTDOWN Request 53

10.4.11 START-APPLI Request 54

10.4.12 DELETE-FILE Request 54

10.4.13 READ-MEMORY-FREE 55

10.4.14 UNSOLICITED-DATA Request 56

4 en-938928/2

Page 5

Record of Revisions

Date Revision Pages revised Pages added Pages deleted

02 - 96 1 Document rewrite

09 - 97 2 Document rewrite

DOCUMENT REVISION

Date Revision Reason for revisions

08 - 94 0 Document creation

02 - 96 1 Conforming to NUM 1060 software - index J

Diskette contents

Added PC module, version 2

Added PCMCIA module

Added use of the PC

Added functional description of the PCNC server

09 - 97 2 Conforming to NUM 1060 software - index L

en-938928/2 5

Page 6

6 en-938928/2

Page 7

PC Module

1 General

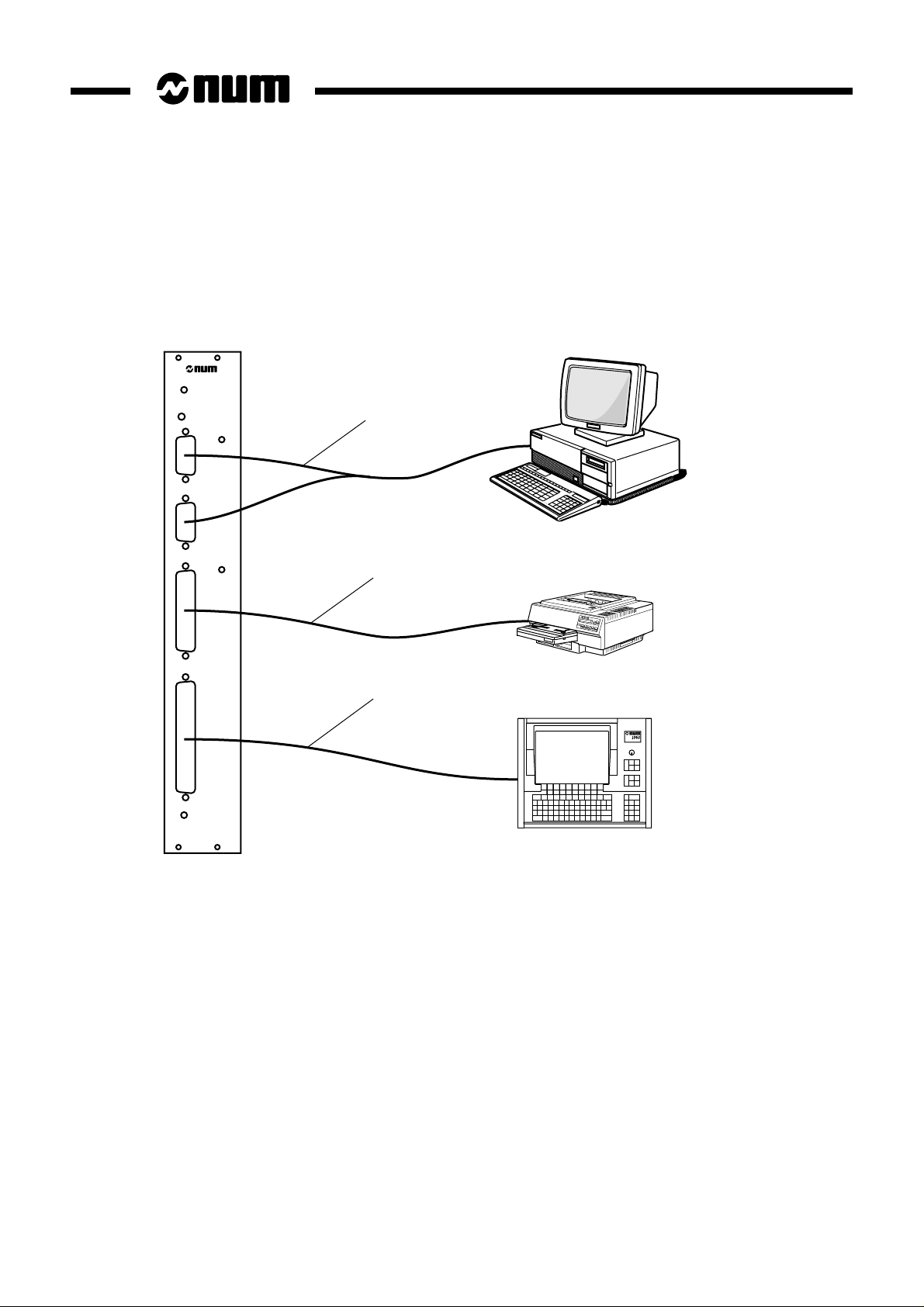

The PC module is designed for integration in the PCNC 1060 architecture.

If provides the following functions:

- conventional functions of a PC operating under OS/2,

- functions associated with the operation of the CNC through specific applications.

The present document covers only the specific features regarding the integration and operation of the PC module.

The integration of a system including a PC module involves concepts developed in the following manuals:

- NUM 1060 Installation and Commissioning Manual (938816),

- UC SII Central Processing Unit Manual (938922) when a Series II PCNC 1060 is involved,

- Automatic Control Function Programming Manual in Ladder Language (938846) or Assembler (938817),

- UNI-TE Protocol Utilization Manual (938914),

- Parameter Manual (938818).

The following are supplied with the PC module

The IBM documentation for the OS/2 operating system.

A NUM diskette.

REMARK The files on the NUM diskette are listed in file Readme.TXT, which also

contains information supplementing that below.

The NUM diskette includes:

- directory DEFINE containing file SAMPLES.DEF listing all the functions that can be imported from LIB_UNIT.DLL

and DNC.DLL,

- directory DOC containing the documentation of the functions included in the DLLs, in a document in WORD format

(DNC.DOC) and the same document in Text format (DNC.TXT). This directory also contains a file briefly describing

the examples of use of the queries supplied with the diskette (SAMPLES),

- directory INCLUDE containing the .h files required for the various compilations:

* compilation under DOS of the programmes using the pipe: conf_dos.h, dnc.h, lib_dll.h, uniosdos.h and

specific.h,

* compilation under OS/2 of the task managing the pipe: conf_OS2 and uniosdos.h,

* compilation under OS/2 of the examples: conf_OS2.h, dnc.h and lib_dll.h,

- directory LIBRARY containing the two DLLs to be loaded into directory C:\OS2\DLL

- directory OS2PIPE containing the files required to allow a DOS application to send DNC queries via a pipe to a task

running under OS/2. This directory contains:

* subdirectory DOSSRC containing library lib_dnc.lib to be compiled with the other files of the customer

application. This library was compiled and tested with a Microsoft compiler,

* subdirectory OS2PIPE containing the source and executable files of the task running under OS/2 as

well as the MAKEFILE using the IBM CSET/2 compiler,

- directory SAMPLES containing examples of use of the DNC queries under OS/2. This directory contains source

programmes and executable programmes. Compilation file CSET/2.CMD is used to compile the sample files using

IBM CSET/2,

- directory WINDOWS containing a sample programme running under Windows and using the PIPE. The

executable, the INI programme and the three DLLs must be copied into the same directory,

en-938928/2 7

Page 8

CAUTION

!

Up to version C2, the DNC library included only one file, LIB_UNIT.DLL.

It now includes two files (DNC.DLL and LIB_UNIT.DLL)

which must be loaded into directory C:\OS2\DLL.

The old file LIB_UNIT.DLL is now replaced by the new ones.

Installing the Diskette

To decompress the software, create a directory on the hard disk and transfer file ZIP.EXE into this directory. Go into

this directory and type ZIP.EXE -d.

8 en-938928/2

Page 9

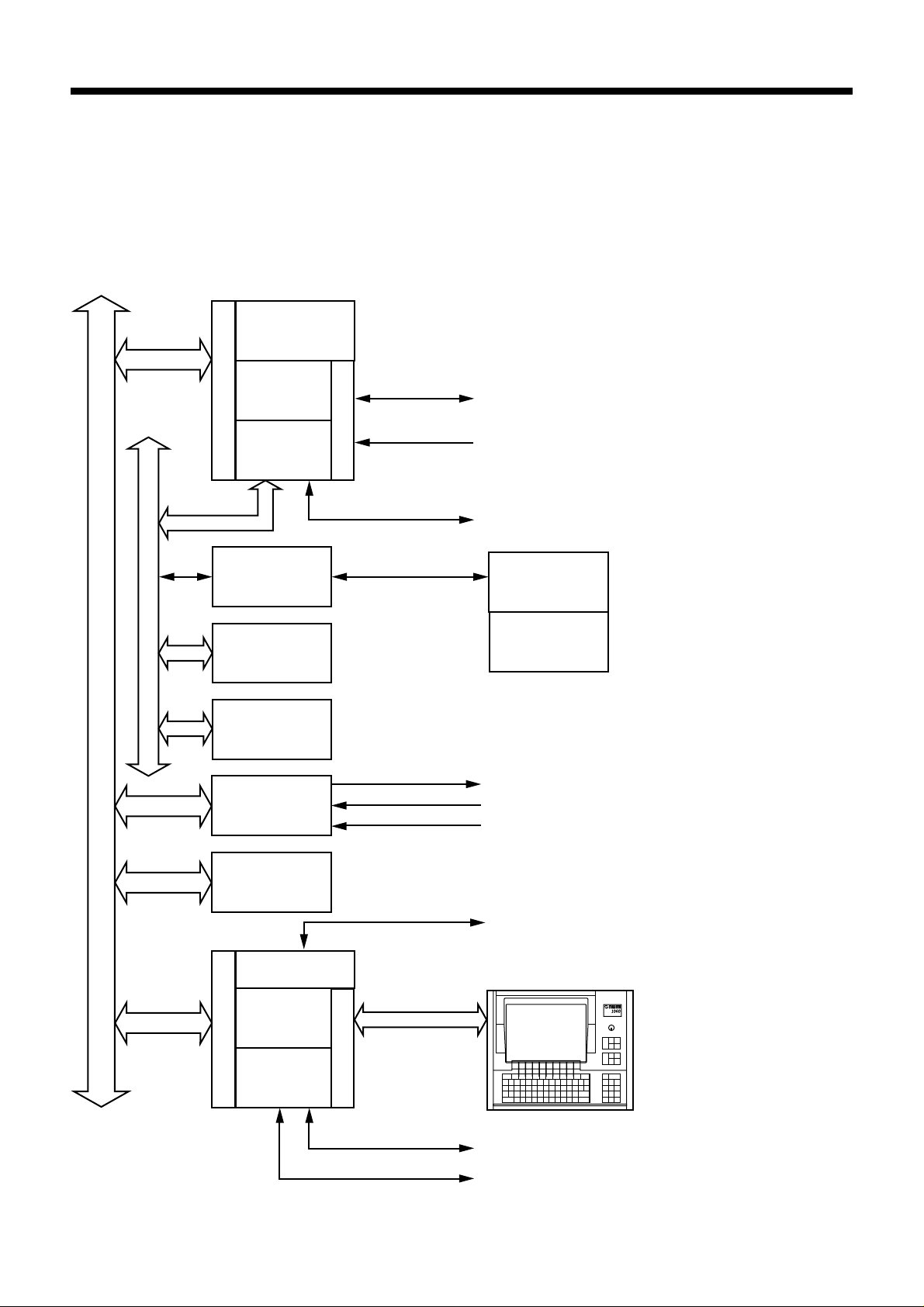

2 System Architecture

2.1 PCNC 1060 Series II System Architecture

Memory

S

II

CNC function

C

P

U

PLC function

RS 232 serial links

Interrupt

Analogue inputs/outputs

PC Module

Serial bus

System bus

P

C

Serial bus /

optical fibre

adaptation

Inputs

Outputs

Axes

Dedicated

interfaces

PCMCIA

Graphic

function

Machine

panel

Machine

panel

extension (I/O)

Speed reference

Measurement

Origin switch

Type 2 network links

Operator panel

PC

function

RS 232 serial links

Parallel link

en-938928/2 9

Page 10

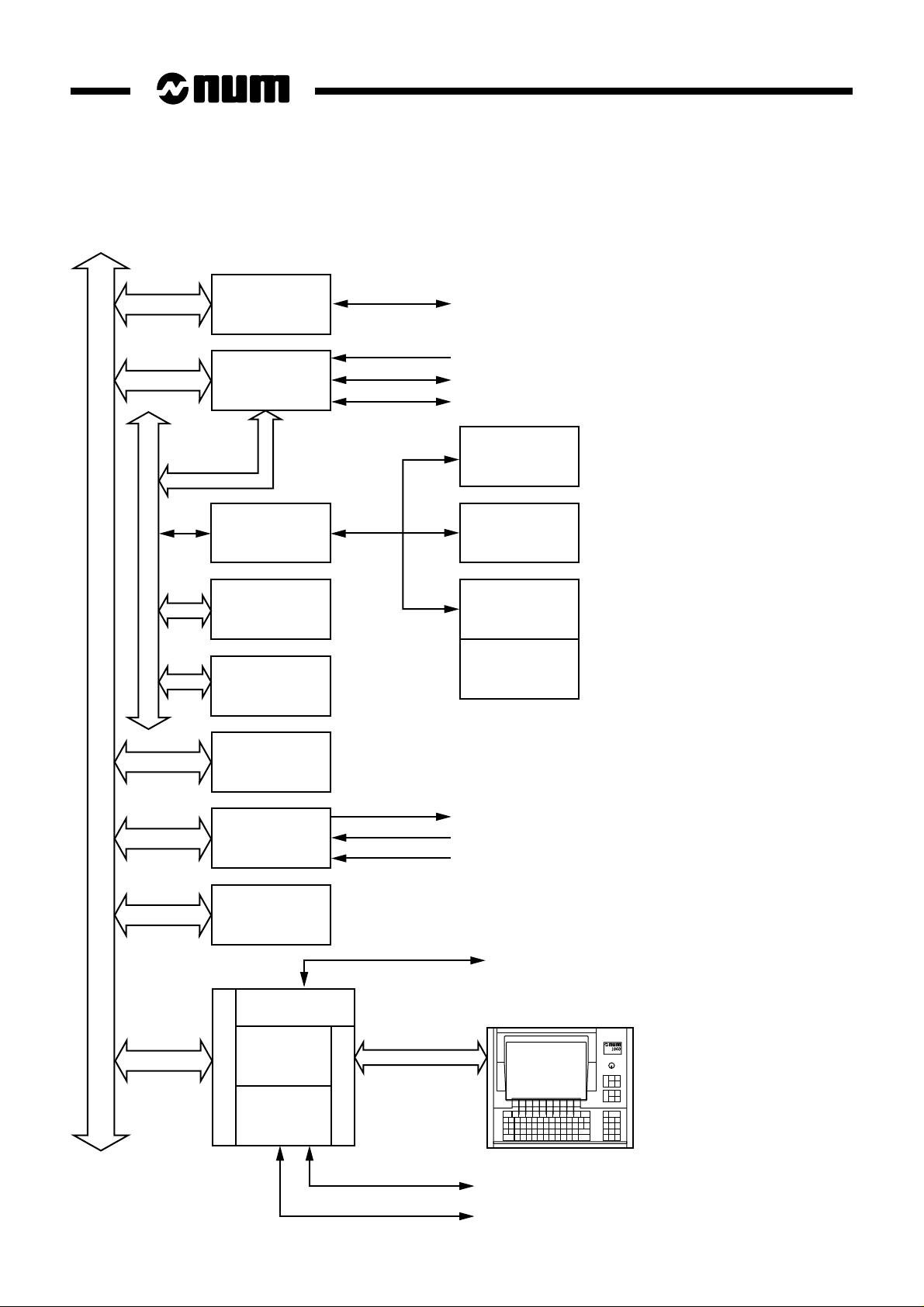

2.2 PCNC 1060 System Architecture

processor

Machine

processor

Serial bus /

optical fibre

adaptation

Inputs

Serial bus

Outputs

CNC

Serial links

Interrupts

Analogue inputs/outputs

Serial links

Remote

inputs

Remote

outputs

Machine

panel

Machine

panel

extension (I/O)

System bus

P

C

Memory

Axes

Dedicated

interfaces

PCMCIA

Graphic

function

PC

function

Speed reference

Measurement

Origin switch

Type 2 network links

Operator panel

RS 232 serial links

10 en-938928/2

Parallel link

Page 11

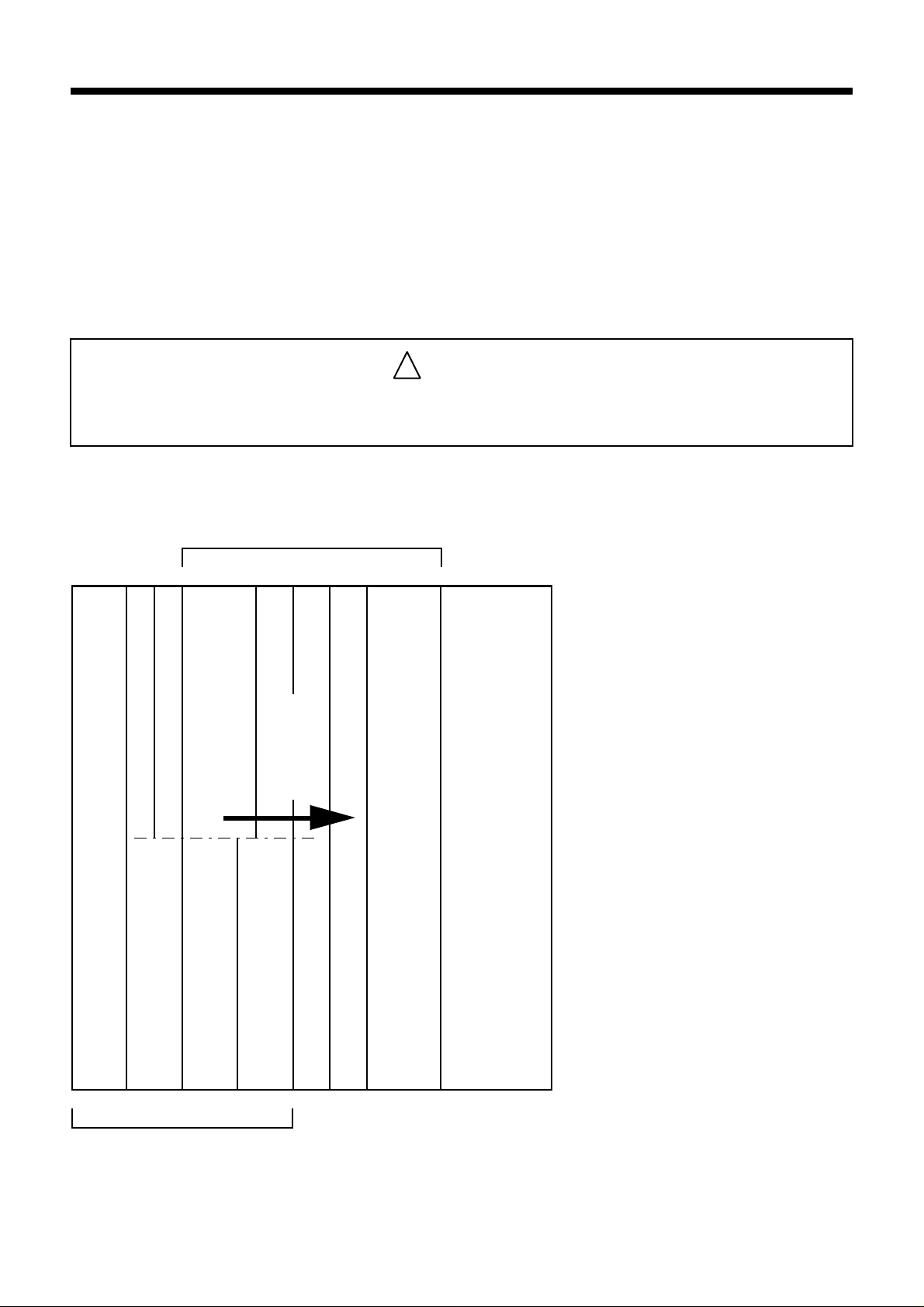

PC Module

3 Card Layout in the Rack

The CNC cards are installed one after the other starting from the right.

The input/output cards are installed leftward from the first available slot after the CNC cards.

Install blanking covers in the empty slots (10, 20 and 30 mm).

!

The PC module occupies the two slots immediately to the left of the last CNC card installed,

or three slots if the PCMCIA card is connected to it.

3.1 Card Layout in the 1060 Series II Rack

CAUTION

PCMCIA

Slots for CNC cards

452076

To left

of last

PC module

CNC

card

13

Power supply

UC SII Central Processing Unit

8

Slots for input/output cards

765

en-938928/2 11

Page 12

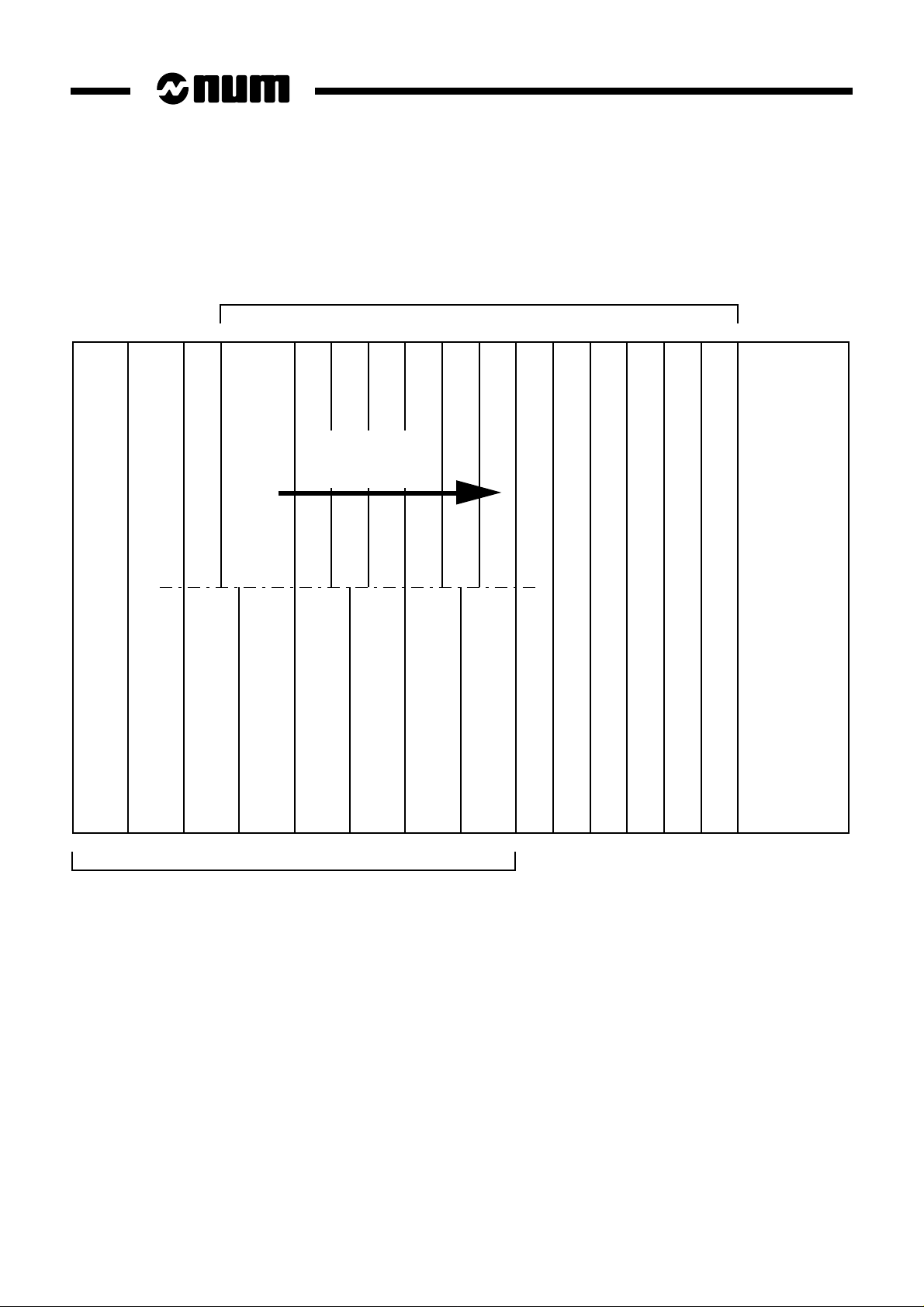

3.2 Card Layout in the 1060 Rack

Slots for CNC cards

11

121314 109876543210

To left of last

CNC card

PCMCIA

12 11 10 8 7 6 5

Slots for input/output cards

PC module

9

Memory card

CNC processor

Machine processor

Power supply

12 en-938928/2

Page 13

4 PCNC Configurations

4.1 PCNC 1060 Series II Configuration

PC Module

Operator panel

Support for

type 1 and 2

PCMCIA cards

Mouse

Input/

output

cards

PC

PCMCIA

PC module

Peripherals

Diskette

drive

Axis card

Tape read

punch unit

Power supply

UC SII Central processing unit

Printer

DNC computer

1 or 2 machine

panels

X

M01

CYCLE

START

CYCLE

STOP

Machine tool

Power cabinet

Automatic controls

Handwheel

Sensor or

rule

Motor

Analogue inputs/outputs

External interrupts

NUM and Customer

applications

Servo-drive

en-938928/2 13

Page 14

4.2 PCNC 1060 Configuration

Operator panel

Support for

type 1 and 2

PCMCIA cards

Input/output cards

Mouse

PCMCIA

PC module

PC

Axis card

Axis card

Memory card

Peripherals

Diskette

drive

CNC processor

Machine processor

Tape read

punch unit

Power supply

Printer

DNC computer

1 to 4 machine

panels

X

M01

CYCLE

START

CYCLE

STOP

Machine tool

Power cabinet

Automatic controls

14 en-938928/2

Sensor or

Handwheel

rule

Motor

Analogue

inputs/outputs

External interrupts

NUM and Customer

applications

Servo-drive

Page 15

5 PC Module Characteristics

5.1 PC Module Version 1 Characteristics

Power consumption 11 W maximum

Location Last two CNC board slots

External temperature 40 °C maximum

PC Module

(See Chapter 3)

Def.

C

O

M

1

Serial lines

Two RS 232 serial lines (9-pin male connectors)

Maximum input voltage ± 30 V

VOL typical - 9 V

VOH typical + 9 V

Extreme loads 2000 pF, 5kΩ (about 10 m of cable)

Data rate 110 to 9600 bauds with the possibility of

C

O

M

2

Parallel line

increasing to 115 kbauds for local applications

1 parallel line (25-contact female connector)

Mass MB

L

P

T

1

Hard disk

Local memory

8 or 16 MB DRAM

Software programs loaded on hard disk

P

A

N

E

L

L

I

N

K

OS/2 operating system

NUM graphic application

PC module version 1 is a 32-bit processor card with a 486 SX or 486 DX 20 MHz

microprocessor.

It communicates via the system bus with:

- the CNC and machine processors (in the 1060 system)

- the UC SII Central Processing Unit (in the 1060 Series II system)

It can communicate with peripheral equipment via the RS 232 COM1 and COM2

serial lines and a parallel line.

PC Proc.

Console management function

The PC module manages the display and the keyboard via the video link.

The PC data are backed up by a battery with a service life of 36 months.

!

CAUTION

The battery must be replaced after 36 months of use (connected)

en-938928/2 15

Page 16

5.2 PC Module Version 2 Characteristics

Power consumption 11 W maximum

Location Last two CNC board slots

External temperature 40 °C maximum

HD

Def.

Serial lines

(See Chapter 3)

C

O

M

1

Two RS 232 serial lines (9-pin male connectors)

Maximum input voltage ± 30 V

VOL typical - 9 V

VOH typical + 9 V

Extreme loads 2000 pF, 5kΩ (about 10 m of cable)

Data rate 110 to 9600 bauds with the possibility of

C

O

M

2

Parallel line

increasing to 115 kbauds for local applications

1 parallel line (25-contact female connector)

Floppy

L

P

T

1

1 floppy drive connector (37-contact female connector)

LEDs

Def Card fault

HD Lit to indicate read/write accesses to the hard disk

Mass MB

P

A

N

E

L

L

I

N

K

F

L

O

P

P

Y

Hard disk

Local memory

8 or 16 MB DRAM

Software programs loaded on hard disk

OS/2 operating system

NUM graphic application

Proc. PC

16 en-938928/2

PC module version 1 is a 32-bit processor card with a 486 SX or 486 DX 20 MHz

microprocessor.

It communicates via the system bus with:

- the CNC and machine processors (in the 1060 system)

- the UC SII Central Processing Unit (in the 1060 Series II system)

It can communicate with peripheral equipment via the RS 232 COM1 and COM2

serial lines and a parallel line as well as with a diskette drive via the floppy disk

connector.

Page 17

Console management function

The PC module manages the display and the keyboard via the video link.

The PC data are backed up by a battery with a service life of 5 years.

!

CAUTION

The battery must be replaced after 5 years of use (connected)

PC Module

en-938928/2 17

Page 18

6 PC Module Connection Wiring Diagram

6.1 PC Module Version 1 Connection

M

M

P

A

N

E

N

K

C

O

1

C

O

2

L

P

T

1

L

L

I

Déf.

. PC Proc

1

or

Peripherals

2

Printer

3

Operator panel

1 - Standard RS 232 serial cable

2 - Standard parallel cable

3 - Video cable (see 8.1)

REMARK Card connector J7 can be connected to a standard 3 1/2", 1.44 MB floppy disk

drive (see Secs. 8.2 and 9).

18 en-938928/2

Page 19

6.2 PC Module Version 2 Connection

HD

1

or

Def.

C

O

M

1

C

O

M

2

PC Module

2

Printer

Peripherals

Operator panel

L

P

T

1

3

P

A

N

F

E

L

L

O

P

L

P

I

Y

N

K

Proc. PC

1 - Standard RS 232 serial cable

2 - Standard parallel cable

3 - Video cable (see 8.1)

4 - Diskette drive cable (see 8.2.2)

4

Floppy disk

drive

en-938928/2 19

Page 20

7 PCMCIA Module Characteristics

Location To the left of the PC card, assembled with it

External temperature 40°C maximum

This module can only be connected to the PC version 2 card. The PC and PCMCIA

cards must be inserted together in the rack.

Network Cards Approved by NUM

IBM Ethernet 10DB2 PCMCIA card

National Semiconductor Ethernet NE4100 PCMCIA Infomover

3Com ETHERLINK III 10 base-T card

Installing the Network Card

The card is provided with a polarising (foolproofing) device so that

it can only be inserted in one direction. The polarising slot must

be at the bottom.

Position and insert the card in the slot and press it home. In case

of resistance, do not force. Make sure the card is right side up.

(width 24 mm)

LA CARTE PROC. PC

DO NOT REMOVE THIS CARD

WITHOUT THE PROC. PC CARD

NE RETIRER LA CARTE QU' AVEC

PCMCIA

PC

20 en-938928/2

Polarising slot

Extracting the Network Card

Insert a small screwdriver into the bottom of the PCMCIA module

slot and press gently on the button.

The card is ejected by approximately 1/2 cm from its slot.

Interface socket: The Compaq Concerto software interface is used for the above

network cards (in the system configuration - selective installation of PCMCIA card

socket).

Page 21

8 Cables

8.1 Video Cable

PC Module

Solder side

19

37

20

1

12

1 - 37-contact male sub-D plug

2 - Video cable (see table for cable lengths)

3 - 37-contact female sub-D plug

Solder side

3

19

37

20

1

Video cables:

Length Part Number Length Part Number

5 m 206203222 20 m 206203228

10 m 206203224 30 m 206203230

15 m 206203226 40 m 206203232

en-938928/2 21

Page 22

Red (white wire)

RGround (black wire)

Green (white wire)

GGround (black wire)

Blue (white wire)

BGround (black wire)

HSync (white wire)

HSGround (black wiire)

VSync (white wire)

VSGround (black wire)

VDC

VDC

GND

GND

DATA

GND

CLOCK

Red

7

8

27

28

10

11

30

31

13

14

1

2

20

21 21

Red (0.22)

17

White (0.22)

Blue (0.22)

22

Black (0.22)

35 35

Green

Blue

White

Black

Blue (0.6)

Red (0.6)

White (0.6)

Black (0.6)

Red (0.22)

White (0.22)

Blue (0.22)

Black (0.22)

Red (white wire)

7

RGround (black wire)

8

Green (white wire)

27

GGround (black wire)

28

Blue (white wire)

10

BGround (black wire)

11

HSync (white wire)

30

HSGround (black wire)

31

VSync (white wire)

13

VSGround (black wire)

14

VDC

1

VDC

2

GND

20

GND

DATA

17

GND

22

CLOCK

PROTECTIVE

EARTH

CON-

NECTOR

SHELL

NECTOR

SHELL

CON-

PROTECTIVE

EARTH

Wiring recommendations:

- clamp the cable on a half-cover,

- solder the pins on the other side,

- clamp the other side of the cable on a half-cover,

- solder the pins on the other side.

CAUTION

!

For correct interference suppression of the system, the cable screening must be earthed

(on 360 degrees) in accordance with the instructions of Installation and Commissioning

Manual 938816.

The two clamps must be used to clamp the cable on the cover

22 en-938928/2

Page 23

8.2 Diskette Drive Cable

8.2.1 PC Version 1 Module

J7

3536

PC Module

21

Edge connector to

PC version 1 card

Pinout for connecting a 3 1/2" diskette drive (type TEAFC FD-235HF) to the PC V1 module

Maximum length: 1 metre

GND

RPM/LC

GND

nc

GND

nc

GND

INDEX#

GND

DRV0#

GND

DRV1#

GND

nc

GND

MTRON#

GND

DIR

GND

STEP#

GND

WDATA#

GND

WGATE#

GND

TRK0#

GND

WRPRT#

GND

RDATA#

GND

HDSEL

GND

DSKCHG

GND

VCC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

GND

2

RPM/LC

3

GND

4

nc

5

GND

6

nc

7

GND

8

INDEX#

9

GND

10

DRV0#

11

GND

12

DRV1#

13

GND

14

nc

15

GND

16

MTRON#

17

GND

18

DIR

19

GND

20

STEP#

21

GND

22

WDATA#

23

GND

24

WGATE#

25

GND

26

TRK0#

27

GND

28

WRPRT#

29

GND

30

RDATA#

31

GND

32

HDSEL

33

GND

34

DSKCHG

24GND

VCC

Protective

earth

en-938928/2 23

Page 24

8.2.2 PC Version 2 Module

Solder side

37

20

19

1

37-contact male

connector

Pinout for connecting a 3 1/2" diskette drive (type TEAFC FD-235HF) to the PC V2 module

Maximum length: 1 metre. For wiring recommendations, see Sec. 8.1.

GND

RPM/LC

GND

nc

GND

nc

GND

INDEX#

GND

DRV0#

GND

DRV1#

GND

nc

GND

MTRON#

GND

DIR

GND

STEP#

GND

WDATA#

GND

WGATE#

GND

TRK0#

GND

WRPRT#

GND

RDATA#

GND

HDSEL

GND

DSKCHG

GND

VCC

GND

Protective

earth

1

20

2

21

3

22

4

23

5

24

6

25

7

26

8

27

9

28

10

29

11

30

12

31

13

32

14

33

15

34

16

35

17

35

18

37

19

COVER

1

GND

2

RPM/LC

3

GND

4

nc

5

GND

6

nc

7

GND

8

INDEX#

9

GND

10

DRV0#

11

GND

12

DRV1#

13

GND

14

nc

15

GND

16

MTRON#

17

GND

18

DIR

19

GND

20

STEP#

21

GND

22

WDATA#

23

GND

24

WGATE#

25

GND

26

TRK0#

27

GND

28

WRPRT#

29

GND

30

RDATA#

31

GND

32

HDSEL

33

GND

34

DSKCHG

24GND

VCC

Protective

earth

24 en-938928/2

Page 25

9 Work on the PC Module

Work is required on the PC module under the following circumstances:

- to replace the battery after 36 months of use for version 1 or 5 years for version 2,

- to extend the memory by adding a DRAM memory module,

- to add the PCMCIA module (PC version 2 module only).

The following diagram shows the locations involved by these operations.

PC Module

14

2

3

1 - Battery connector

2 - Battery

3 - Slot for DRAM memory module

4 - Edge connector for diskette drive (PC version 1 module only)

en-938928/2 25

Page 26

9.1 Replacing the Battery

Refer to the diagram showing the locations on the PC module (see previous page).

!

CAUTION

The battery must be replaced within 15 minutes at most so as not to lose the data backed

up in the PC CMOS RAM. A special capacitor replaces the battery to supply the memories

during replacement.

1 - Disconnect the old battery (1) and remove it (2) from its housing.

2 - Insert the new battery (2) in its housing and connect it (1), ensuring the connector is in the right direction.

9.2 Adding a DRAM Memory Module

The memory module slot is identified (3) in the diagram showing the locations on the PC module.

1 - Push the module into the connector, with the polarizing notch on the left.

2 - Tilt the module towards the vertical until it snaps into place.

Added memory does not have to be declared to the system since it is automatically recognised when power is applied.

Notch

2

1

26 en-938928/2

Page 27

9.3 Adding the PCMCIA Module

The PC card solder side is shown.

Post locations

PC Module

PCMCIA module

connection zone

Screw the three posts in place.

Plug the module into the location provided. The front panel must be in contact with that of the PC module.

Install the three screws.

Plug the PC module in its slot in the rack.

en-938928/2 27

Page 28

10 Using the PC

10.1 Applications Which Can Be Used by the PC

The PC must have OS/2 operating system in version 2.1 or above.

This operating system allows the following types of applications to be executed:

- DOS applications in full screen mode or in a window of the Presentation Manager desktop,

- Windows applications in version 3 and 3.11 for OS2/Warp in a full screen session or a Desktop window of

Presentation Manager

- OS/2 16-bit applications developed under OS/2 versions 1.x,

- OS/2 32-bit applications developed under OS/2 versions 2.x.

All the applications are executed in protected mode. OS/2 is a multitasking pre-emptive shared time system affording

full memory protection between each application.

For more details on the OS/2 operating system, refer to the IBM documentation, especially as regards DOS and

Windows compatibility.

10.2 Using the PC

10.2.1 Config.sys

- The 1060 system can be accessed by a driver which gives access to both the NUM application and the customer

application(s) using the UNI-TE library. The command:

DEVICE=C:\NUM\DRIVER\MEM_GLB.SYS is used to install the driver

- An image of the NUM application (GR_PC.EXE) is contained in the OS/2 STARTUP directory. This directory

is hidden in the STARTUP folder of OS/2. This folder is hidden and is therefore inaccessible to the customer.

CAUTION

!

The following command must mandatorily be included in config.sys:

SETRESTARTOBJECTS=STARTUPFOLDERSONLY, to guarantee that only the NUM

application contained in the STARTUP folder is started at system startup.

- Installation of a mouse. The user can connect a mouse to serial port 1 so that it is recognised by OS/2. The

config.sys file must be modified by deleting the letters REM at the beginning of certain lines:

DEVICE=C:\OS2\MDOS\VMOUSE.SYS

DEVICE=C:\OS2\MOUSE.SYS SERIAL=COM1

- To enable diskette drive a:

Delete the letters REM from the beginning of the following line in config.sys:

REM BASE DEV=IBM1FLPY.ADD

REMARK It is strongly recommended to copy the config.sys file into another directory

before making any changes to it.

The changes made to config.sys are not applied until the system is rebooted

(reset the system).

28 en-938928/2

Page 29

PC Module

10.2.2 NUM Shutdown

Shutdown can be accessed in two ways:

- Access from the NUM application

- Access from the user application.

Access from the NUM Application

Pressing keys Alt and F12 in the NUM application shuts down the PCNC, i.e. all the open applications are closed,

including the NUM application. Shutdown is indicated to the other processors which are then stopped. To be run, this

procedure requires confirmation from the operator in a message box.

Reset after Setting Machine Parameters

In earlier versions, all the applications running on the PCNC were killed by a reset, because it was not possible to tell

which ones accessed the system resources (by requests), made unavailable by a reset.

A new file, REINIT.CFG, is read in the event of a reset:

- If this file is not present or is empty, operation is the same as before, i.e. all the applications are killed.

- If this file contains the name of an application, only this application is killed, but the other applications continue to

run.

The REINIT.CFG file must be located in directory C:\NUM\GRAPHIC.

This file can contain a maximum of 16 application names.

All the applications dialoguing with the system by requests must be included in this file.

If an application is started by the NUM_CLIENT object, it must be included in this file.

The REINIT.CFG file can be edited while the NUM application is running, but a reset is required to take into account

any changes made to it.

Important remark:

- If several instances of the same application are running simultaneously (e.g. C:\OS2\CMD.EXE corresponding

to an OS/2 session window), they are all killed.

- For Windows sessions, if several Windows applications are running in the same session, they are all killed,

since there is no way of identifying a given executable, and the entire session is therefore killed.

The NAMEAPP.EXE utility located in C:\NUM\GRAPHIC is used to identify the applications running when it is started.

It is necessary to use this utility to determine the exact names of the applications (especially for Windows applications).

If several Windows applications are running in the same DOS machine (Virtual DOS Machine), the only way of

identifying the VDM is by the name of the first Windows application started. This is the name which must be stored

in REINIT.CFG (to be checked with NAMEAPP.EXE). The complete VDM is killed.

en-938928/2 29

Page 30

Shutdown

The SHUTDOWN.EXE Num executable was initially run from the NUM application by pressing keys Alt+F12. It killed

all the applications running in the system and started the OS/2 shutdown procedure. This was mainly for the purpose

of requiring the operator to confirm only the shutdown request. In addition, the server and pipeline also invoked

SHUTDOWN.EXE.

Now, pressing the same keys also runs SHUTDOWN.EXE, but this file kills the applications declared in REINIT.CFG,

stops the NUM graphic application, indicates to the other processors that the PCNC is stopping and runs the

SHUT.CMD file. SHUT.CMD contains the default command line START/N C:\NUM\GRAPHIC\KILLAPPS.EXE 6 in

which KILLAPPS.EXE is the executable that performs the final shutdown and stops the system.

It is necessary to specify a parameter when using KILLAPPS.EXE (6 in the above case). This parameter corresponds

to the process ID of the Num application. It can be obtained by running the NAMEAPP.EXE utility in directory

C:\NUM\GRAPHIC. This utility gives the name and ID of each process. In particular, when a network is loaded on

a PCNC under Warp before the NUM application, the parameter specified in SHUT.CMD is no longer 6, but the value

of the GR_PC.EXE process ID obtained from NAMEAPP.EXE.

This method preserves compatibility for the server and pipeline, since the same filename is always invoked. In addition,

it allows the user to edit the SHUT.CMD file, replacing the default line by a line with the format START/N pathname\user

_filename, where user_filename is the name of the user executable used to cleanly shut down the applications (e.g.

networks) and run either KILLAPS.EXE or the OS/2 SHUTDOWN.EXE located in C:\OS2\INSTALL. The main

difference between these two files is that the OS/2 SHUTDOWN.EXE file displays a confirm dialogue box for windowed

applications before proceeding to shutdown.

To summarise:

- If REINIT.CFG is empty, all the applications are killed by a reset (machine parameter modification, etc.)

- If REINIT.CFG is not empty, it should contain the names of all the applications (maximum 16) using 1060 system

resources (UNI-OS2, EDIT-PP, NUM-Bu, etc.).

Access from a User Application

OS/2 Type User Application

The executable running the shutdown procedure is located on the hard disk so that it can be used by an OS/2 type

user application. This executable is called SHUTDOWN.EXE and is located in directory C:\NUM\GRAPHIC.

In this case, no confirmation is requested of the operator.

Application Using the Pipe

For user applications using the pipe, the pipe source code is modified and includes the possibility of requesting

shutdown from a DOS application. The OS/2 pipe code is modified in the same way.

The shutdown is carried out by calling function SHUT_DOWN_PCNC() supplied in library lib_dnc.lib from a DOS or

WINDOWS application. OS/2 is closed without requesting confirmation.

The pipe is a communication facility supplied by NUM between Windows and OS/2 applications. It is used for issuing

DNC1000 requests and receiving replies to these requests. The pipe is created and managed by programme

UNI_OS2.EXE.

WINDOWS applications can send and receive information to and from the pipe using LIB_INIT.DLL.

30 en-938928/2

Page 31

PC Module

In this case, no confirmation is requested of the operator.

!

CAUTION

So as not to corrupt the hard disk, it is recommended to carry out a shutdown procedure

before turning off power.

During the shutdown, all the applications are closed without warning.

If an editor was open, any modifications made are lost. This is also the case for a reset

after modifying machine parameters.

10.2.3 Opening a User Application at Startup

The PCNC can open a user application during system startup. To do so, the user must configure his system by creating

a programme object on the OS/2 desktop whose identifier is known to the NUM application. Use the CREATPRG.CMD

programme supplied on the hard disk in directory C:\NUM.

In an OS/2 session, go into directory C:\NUM and run CREATPRG. The programme creates four programme objects:

“NUM client”, “START Appli”, “NUM Backup” and “EDIT-PP”. The last two are Windows utilities used for saving

machine data and managing files (START Appli is used by the server). Configure the "NUM client" programme object

created on the desktop by modifying its parameters so that it calls the required user application. The user application

can be an OS/2, DOS or WINDOWS executable.

Only the application associated with the "NUM client" object is automatically opened when the NUM application is

started, contrary to the one that can be associated with the "START Appli" object accessible by the PCNC server.

REMARK The user can also run a .CMD command file to start several applications.

After completing the configuration, shut down the system by an OS/2 shutdown accessible from the context-sensitive

menu of the desktop (do not use the NUM shutdown procedure) then reset the system.

The NUM application is started automatically and handles synchronisation with the other microprocessors.

After initialisation, the NUM application detects whether a user application is present on the system. If so, the NUM

application is minimised to an icon and the user application is automatically started. If not, the NUM application

continues to occupy the full screen.

The user can return to the NUM application from his application by displaying the list of active tasks by "Ctrl and Esc"

and selecting the NUM task.

10.2.4 NUM Task/User Task Toggle

The NUM application run when the PCNC is started can be minimised to an icon by simultaneously pressing Alt and

F9, which causes a return to the desktop if no other application is running.

When minimised, the icon is placed in the folder of minimised windows. The operator is on the OS/2 desktop and can

run OS/2 applications.

When the NUM application occupies the full screen, OS/2 controls the actions initiated by simultaneously pressing the

following keys:

- Ctrl and Esc to access the list of tasks

- Alt and Tab to display another open application

- Ctrl, Alt, Del are inoperative.

Two other ways of toggling are available:

- "Iconification" (minimise) (see Sec. 10.4.7)

- "Restitution" (restore) (see Sec. 10.4.8).

en-938928/2 31

Page 32

10.2.5 Creating System Diskettes

Available in OS/2 version 3 and above.

Since the PCNC is supplied with the software already installed and without installation diskettes, it is recommended

to created your own installation diskettes, in particular OS/2.

Use the following procedure:

- On the desktop, double-click the "Diskette Factory" icon

- In the window that opens, select the name of the product for which the installation diskettes are to be created

- Click "Create" and follow the instructions.

10.2.6 Regenerating the Initial Configuration

If a problem occurs, an archive containing the initial system desktop configuration can be restored (but not the NUM

application).

Reboot the system. When a white rectangle appears in the upper left-hand corner of the screen, press ALT+F1.

A utility menu is displayed. Item “X” allows you to regenerate the initial desktop configuration.

10.2.7 Reinstalling the NUM Application

You can reinstall the NUM application and the initial system configuration (except screen drivers - original config.sys

restored) as follows.

Reboot the system. When a white rectangle appears in the upper left-hand corner of the screen, press ALT+F1.

A utility menu is displayed. Item “R” allows you to completely reinstall the NUM application and the initial configuration

delivered. The procedure is started by confirming this selection. The files are restored, the system is booted and an

OS/2 session window is opened. Confirm when requested. At the end of the procedure, a shutdown is executed and

installation is completed.

10.2.8 Backing up the NUM Application

You can create a backup diskette for the NUM application. To do so, return to the desktop (by pressing ALT+F9 when

in the NUM 1060 graphic user interface). Run the Diskette Factory utility and select Num appli to generate the backup

diskette with the NUM application.

To restore the NUM application from the backup diskette, run Install from the diskette (the graphic configuration in

mode SVGA 256c with CL5428 or CL5429 drivers is not restored).

10.2.9 Restoring a Disk: CHKDSK

Exceptionally, the system may be blocked in the case of a general power failure when it was not possible to shut it down

first.

When turned back on, the system refuses to boot and displays the message:

- "Impossible to find PCSHELL.EXE. The system is stopped".

Use the following procedure to correct this problem. It is necessary to have a diskette drive connected to the PC card

and an OS/2 system diskette in HPFS format.

- Insert the diskette in the drive and boot from the diskette

- When the prompt A:> is displayed, enter CHKDSK C:/F.

This starts restoring of the diskette. When it is completed, remove the diskette from the drive and reset.

32 en-938928/2

Page 33

PC Module

10.2.10 Modifying the NUM Application Task Priorities

The task priorities of the GR_PC.EXE application can be modified. Version C3 of the PCNC software allows the

priorities of the four threads of the NUM graphic application to be modified.

10.2.10.1 Description of the Threads

NumExcep

This thread scans the global system memory to check for:

- Reboot requests from other processors,

- Exceptions from the other processors.

It is always active, even when the application is minimised.

Its default priority is Class=2 and Delta=20:

DosSetPriority(2, 2, 20, NumExcep).

NumSelect

This thread reads the graphic command blocks placed in the global memory by the CNC processor, performs INTEL/

MOTOROLA conversion and handles display.

It is suspended when the application is minimised.

Its default priority is Class=2 and Delta=20:

DosSetPriority(2, 2, 20, NumSelect).

NumStat

This thread manages display in the STATUS window.

It is suspended when the application is minimised.

Its default priority is Class=2 and Delta=20:

DosSetPriority(2, 2, 20, NumStat).

NumThread

This thread manages Presentation Manager messages such as the window minimisation command and keyboard

entries transmitted to other processors.

It is always active, even when the application is minimised.

Its default priority is Class=3 and Delta=20:

DosSetPriority(2, 3, 20, NumThread).

10.2.10.2 Modifying the Priorities

The priorities (Class and Delta) of the four threads are set by sending parameters to the GR_PC.EXE executable.

Eight parameters must be passed:

- NumExcep Class

- NumExcep Delta

- NumSelect Class

- NumSelect Delta

en-938928/2 33

Page 34

- NumStat Class

- NumStat Delta

- NumThread Class

- NumThread Delta.

If one of these parameters is missing or a ninth is added, the default priority definitions are applied.

The Class parameters must have a value ≥ 1 and ≤ 4 and the Delta parameters must have a value ≥ -31 and ≤ +31;

otherwise, the default values are applied.

10.2.10.3 Entering the Parameters

To enter the parameters, call the context-sensitive menu of the GR_PC.EXE programme object under C:\NUM\GRAPHIC

and select "Parameters". On the "Programme" page, enter the 8 numerical values separated by spaces in the

"Parameters" field.

Then shut down OS/2 and reset the system.

The modifications are not applied until after the system reset.

10.2.11 Modifying the Colour Palette

Starting with version C3 of the PCNC software, the NUM graphic application colour palette can be edited.

The colour palette is edited using the values entered in file GR_USER.PAL in C:\NUM\GRAPHIC.

This file contains the values corresponding to the basic colours defined by their R, G and B components.

The values are entered hexadecimally in lower case. The modified colours are applied after a system reset.

File of Basic Colours

The basic colours contained in the file are in lower case

{ /* R G B */

{ 0x00 0x00 0x80 }, /*0 : dark blue */

{ 0xff 0xff 0xff }, /*8 : white */

{ 0x00 0xff 0x00 }, /*4 : green */

{ 0x54 0x54 0x54 }, /*12 : dark grey */

{ 0x3c 0xbc 0xff }, /*2 : blue */

{ 0x7c 0xbc 0xff }, /*10 : light blue */

{ 0x00 0xff 0xff }, /*6 : cyan */

{ 0xff 0x3c 0x00 }, /*14 : flashing colour 1: red */

{ 0xff 0x00 0x00 }, /*1 : red */

{ 0x7c 0x3c 0x00 }, /*9 : brown */

{ 0xff 0xff 0x00 }, /*5 : yellow */

{ 0xff 0xbc 0x00 }, /*13 : orange */

{ 0xff 0x80 0xff }, /*3 : pink */

34 en-938928/2

Page 35

PC Module

{ 0xbc 0xbc 0xbc }, /*11 : light grey */

{ 0x00 0x00 0x00 }, /*7 : black */

{ 0xbb 0xbc 0xbc }, /*15 : flashing colour 2: light grey */

{ 0xfe 0xff 0xff }, /*16 : flashing colour 1: white */

{ 0xff 0xfe 0xff }, /*17 : flashing colour 2: white */

};

10.3 Development of Specific Applications

The PC integrated in the CNC allows the use of specific applications:

- customised interface,

- read/write access to the CNC and PLC data (e.g. possibility of modifying the tool dimensions table),

- large volume of mass storage provided by the hard disk for storing the part or PLC programmes and transferring them

to the CNC or PLC memory when required,

- use of a simplified part programming language suited to the application (e.g. language using graphic display) which

is then converted into ISO blocks and can be transmitted on request to the CNC for immediate (drip feed mode) or

deferred use (storage).

The applications running under OS/2 can be developed using IBM C Set/2 including:

- C/C++ tools,

- WorkFrame,

- ToolKit for OS/2.

The applications communicate with the CNC and the PLC through UNI-TE protocol. They use UNI-TE primitives (see

Sec. 10.3.1) to set up all calls and send requests (see Sec. 10.3.2).

The primitive files on the diskette (.obj, .h and .dll files) must be linked with the application to obtain an executable.

10.3.1 UNI-TE Primitives

10.3.1.1 Accessing UNI-TE: Open_Unite() Function

Syntax

USHORT Open_Unite (void)

Description

This primitive lets the application communicate with the 1060 system in requester mode and access requests.

It must always be called at the start of the application before any requests are used.

Answer code

Code Meaning Code Meaning

0 OK other bus access invalid

en-938928/2 35

Page 36

Example

if { (error = Open_Unite ())

printf (("\n %d unite opening error", error);}

10.3.1.2 Opening Logic Ports: Get_Port() Function

Syntax

USHORT Get_Port (UCHAR *port)

&port: address to which the system returns the port number

Description

This primitive is used to allocate a logic port (number 0x70 to 0x7F) through which the requests are sent.

It returns a free logic port number which can be used by the application.

A port has to be opened in order to transmit requests.

Returned code

Code Meaning Code Meaning

0 OK 2 UNI-TE invalid: Open_Unite not executed

1 no port available 3 system error (when OS/2 system

functions were called)

Example

for (i = 0 ; i < 15 ; i++)

{ if ( (error = Get_Port (&port[i])) !=0)

{ printf ("\n error %d opening port[%d]", error, i); }

else

{ printf ("\n OK port[%] =%x", i, port[i]); }

}

10.3.1.3 Freeing Logic Ports: Free_Port Function

Syntax

USHORT Free_Port (UCHAR port)

port: port number to free (0x70 to 0x7F)

Description

This primitive frees the port whose number is given as argument.

A port must not be freed until all the answers awaited have been received.

36 en-938928/2

Page 37

PC Module

Returned code

Code Meaning Code Meaning

0 OK 2 UNI-TE invalid: Open_Unite not executed

1 task does not own the port 3 system error (when searching for the

calling process identifier)

Example

for (i = 0 ; i < 15 ; i++)

{ if ( (error = Free_Port (port[i])) !=0)

{ printf ("\n error %d freeing port[%]", error, i); }

}

10.3.1.4 Sending a Request : Unito() Function

Syntax

UCHAR Unito (UCHAR port, void *adr_buf)

port: source port number (0x70 to 0x7F)

&adr_buf: address of the buffer to be sent

Description

This primitive allows a request to be sent to a server on one of the 16 source ports addressed by Get_Port.

The answer to a request must be requested before sending another request to the same port.

Returned code

Code Meaning Code Meaning

0 send OK 4 port number invalid or not owned

1 buffer too long 5 no server for this request

2 buffer length zero 6 system 1060 access error

3 queue full: Unito not followed by Uniti

Send buffer structure

Buffer start @

(1 word, maximum value 128)

Buffer size

(1 word, not significant)

Request size

Request

(128 bytes maximum)

Written by the

user programme

1 word

en-938928/2 37

Page 38

Example

BufferReq . ReqSize = yy ; /* size of request in bytes */

BufferReq . RequestCode = 0xnn ; /* Request code */

BufferReq . CategoryCode = mm ; /* Category code */

BufferReq . Segment = (UCHAR) Segment ;

BufferReq . Specific = (UCHAR) Specific ;

BufferReq . ObjectAddress = ObjectAddress ;

BufferReq . Quantity = Quantity ;

error = Unito (port[i], &BufferReq);

10.3.1.5 Receiving an Answer: Uniti() Function

Syntax

UCHAR Uniti (UCHAR port, void *adr_buf)

port: source port number (0x70 to 0x7F)

&adr_buf: address of the buffer which will receive the response

Description

This primitive is used to receive an answer to a request sent from the same source port.

As long as code 0x08 is returned (processing of request by server not completed), the function must be repeated

periodically until the answer is obtained.

Returned code

Code Meaning Code Meaning

0 read OK 7 buffer too small to contain the answer

4 port number invalid or not owned 8 no message at this port number

6 system 1060 access error

Receive buffer structure

Buffer start @

(1 word, answer size + 2)

(1 word, maximum value 128)

Buffer size

Answer size

Answer

(128 bytes maximum)

1 word

Written by the

user programme

Written by the

NUM software

38 en-938928/2

Page 39

Example

BufferResp . BufferSize = xx ;

BufferResp . ReqSize = 0 ;

do { error = Uniti (port[i], &BufferResp);

} while (error == NO_MESSAGE);

10.3.1.6 Example of Use of UNI-TE Primitives in an Application

{ /* declaration of variables */

USHORT error = 0;

UCHAR port[16];

#define NO_MESSAGE 0x08;

typedef struct { USHORT BufferSize;

USHORT ReqSize;

UCHAR RequestCode;

UCHAR CategoryCode;

UCHAR Segment;

UCHAR Specific;

USHORT ObjectAdress;

USHORT Quantity;

} Buf_req_client;

typedef struct { USHORT BufferSize;

USHORT ReqSize;

UCHAR ResponseCode;

UCHAR Specific;

UCHAR Data [126];

} Buf_resp_client;

Buf_req_client BufferReq;

Buf_resp_client BufferResp;

...

...

/* unite access */

if { (error = Open_Unite ())

printf ("\n unite %d opening error, error);}

...

/* opening of 16 ports */

for (i = 0 ; i < 15 ; i++)

{ if ( (error = Get_Port (&port[i])) != 0)

{ printf ("\n error %d opening port[%d]", error, i); }

else

{ printf ("\n OK port[%d] = %x", i, port[i]); }

}

...

/* sending a request */

BufferReq . ReqSize = yy ; /* size of request in bytes */

BufferReq . RequestCode = 0xnn ; /* Request code */

BufferReq . CategoryCode = mm ; /* Category code */

BufferReq . Segment = (UCHAR) Segment ;

BufferReq . Specific = (UCHAR) Specific ;

BufferReq . ObjectAddress = ObjectAddress ;

BufferReq . Quantity = Quantity ;

error = Unito (port[i], &BufferReq);

PC Module

en-938928/2 39

Page 40

...

/* receiving a response */

BufferResp . BufferSize = xx ;

BufferResp . ReqSize = 0 ;

do { error = Uniti (port[i], &BufferResp);

} while (error == NO_MESSAGE);

...

/* closing of 16 ports */

for (i = 0 ; i < 15 ; i++)

{ if ( (error = Free_Port (port[i])) != 0)

{ printf ("\n error %d freeing port[%d]", error, i); }

}

...

}

10.3.2 Requests Accessible to the PC

The requests listed below can be accessed by the PC. The requests are detailed in the UNI-TE Protocol Utilization

Manual 938914.

The "Read-Block", "Write-Block" and "Reserve-Memory" requests are described in Sections 10.3.2.3 to 10.3.2.5.

10.3.2.1 List of CNC Requests

Requests Request code Additional request code

Identification 0x0F

Run 0x24

Stop 0x25

Init 0x33

Read-Object 0x36 Segment (list below: code and meaning)

0x80 position reference

0x81 position measurement

0x82 DAT1

0x83 DAT2

0x84 DAT3

0x85 minimum machining limits

0x86 maximum machining limits

0x87 axis inclination

0x88 machine origin

0x89 minimum machine travels

0x8A maximum machine travels

0x8B position reference correction

0x8C axis position reference

0x8D axis position measurement

0x8F servo-controlled axes

0x90 spindle speed measurement

0x91 spindle position measurement

0x92 tool correctors

0x93 H variables

40 en-938928/2

Page 41

Requests Request code Additional request code

0x36 0x95 initialised axes

0x96 E80000 parameters

0x97 E81000 parameters

0x98 E82000 parameters

0x99 program status

0x9D end-of-block dimensions

0xB4 mode

0xB5 current part programme

Write-Object 0x37 Segment (list below: code and meaning)

0x82 DAT1

0x83 DAT2

0x84 DAT3

0x85 minimum machining limits

0x86 maximum machining limits

0x87 axis inclination

0x88 machine origin

0x89 minimum machine travels

0x8A maximum machine travels

0x92 tool correctors

0x93 H variables

0x95 initialized axes

0x96 E80000 parameters

0x97 E81000 parameters

0x98 E82000 parameters

0xB4 mode

0xB5 current part programme

Open-DownLoad-Sequence 0x3A File identification (list below: code and meaning)

0x02 axis calibration

0x05 machine parameters

0x0C part programmes in drip feed mode

0x12 part programmes for storage

Write-DownLoad-Segment 0x3B

Close-DownLoad-Sequence 0x3C

Open-UpLoad-Sequence 0x3D File identification (list below: code and meaning)

0x02 axis calibration

0x05 machine parameters

0x12 part programmes for storage

Read-UpLoad-Segment 0x3E

Close-UpLoad-Sequence 0x3F

Delete-File 0xF5 0x46

Read-Memory-Free 0xF5 0x47

Open-Directory 0xF5 0x48

Directory 0xF5 0x49

Close-Directory 0xF5 0x4A

Read-Block 0xF5 0x50

PC Module

en-938928/2 41

Page 42

Requests Request code Additional request code

Write-Block 0xF5 0x51

Reserve-Memory 0xF5 0x52

10.3.2.2 List of PLC Requests

Requests Request code Additional request code

Status 0x31

Read-Object 0x36 Segment (list below: code and meaning)

0xA0 internal Boolean variables (assembler)

non-saved variables (Ladder)

0xA1 internal numerical variables (assembler)

saved variables (Ladder)

0xA2 double numerical variables (assembler)

common word variables (Ladder)

0xA4 numerical inputs (assembler)

inputs from CNC (Ladder)

0xA5 numerical outputs (assembler)

outputs to CNC (Ladder)

0xA8 Boolean inputs (assembler)

inputs from terminal strip (Ladder)

0xA9 Boolean outputs (assembler)

outputs to terminal strip (Ladder)

0xAC counters (assembler)

0xAE timers (assembler)

Write-Object 0x37 Segment (list below: code and meaning)

0xA0 internal boolean variables (assembler)

non-saved variables (Ladder)

0xA1 internal numerical variables (assembler)

saved variables (Ladder)

0xA2 double numerical variables (assembler)

common word variables (Ladder)

0xA5 numerical outputs (assembler)

outputs to CNC (Ladder)

0xA9 Boolean outputs (assembler)

outputs to terminal strip (Ladder)

0xAC counters (assembler)

0xAE timers (assembler)

0xAF decoded M functions

0xB0 coded M functions

0xB1 T functions

0xB7 handwheels (assembler)

0xB8 counter output (assembler)

0xB9 timer output (assembler)

0xBA background task (assembler)

42 en-938928/2

Page 43

Requests Request code Aditional request code

Open-DownLoad-Sequence 0x3A File identification (list below: code and meaning)

0x0701 %TSi module (Ladder)

0x0702 %TFi module (Ladder)

0x0703 %SPi module (Ladder)

0x0704 %THi module (Ladder)

0x0705 %INI module (Ladder)

0x0710 any module (Ladder)

0x0741 C file

0x0761 text file

Write-DownLoad-Segment 0x3B

Close-DownLoad-Sequence 0x3C

Open-UpLoad-Sequence 0x3D File identification (list below: code and meaning)

0x0701 %TSi module (Ladder)

0x0702 %TFi module (Ladder)

0x0703 %SPi module (Ladder)

0x0704 %THi module (Ladder)

0x0705 %INI module (Ladder)

0x0710 any module (Ladder)

0x0740 C file directory

0x0741 C file

0x0760 text file directory

0x0761 text file

Read-UpLoad-Segment 0x3E

Close-UpLoad-Sequence 0x3F

Delete-File 0xF5 0x46

Stop 0xF5 0x4C

Init 0xF5 0x4D

Run 0xF5 0x4F

PC Module

10.3.2.3 Reading Part Programme Blocks

Description

The Read-Block request is used to read a part programme block.

Transmission

Request code / Additional request code / Programme number / Block number / Block offset

Request code 1 byte: 0xF5

Additional request code 1 byte: 0x50

Programme number 1 long word: indexed programme number (programme number x 10 + axis group

number)

Block number 1 word: block number pointed to

Block offset 1 word: rank of block to be read after the previously selected block (0 to read this

block)

en-938928/2 43

Page 44

Reception

Positive Answer

Answer code / Additional answer code / Block length / Data

Answer code 1 byte: 0xF5

Additional answer code 1 byte: 0x80

Block length 1 word: number of data bytes (maximum 119 including the

LF which ends the block)

Data Character string (ASCII codes) forming the block.

Negative answer

Answer code / Additional answer code

Answer code 1 byte: 0xF5

Additional answer code 1 byte: 0x80

10.3.2.4 Writing Part Programme Blocks

Description

The Write-Block request is used to add, modify or delete a part programme block.

REMARK Unlike the other requests, the Write-Block request can contain up to 132 bytes

Transmission

Request code / Additional request code / Programme number / Block number / Block Offset /

Block length / Data

Request code 1 byte: 0xF5

Additional request code 1 byte: 0x51

Programme number 1 long word: indexed programme number (program number x 10 +

axis group number)

Block number 1 word: block number pointed to

Block offset 1 word: rank of unnumbered block pointed to after the previously

selected block (0 to stay on this block)

Block length 1 word: number of data bytes (120 maximum)

Data Character string (ASCII codes) forming the block to be sent

(the block must end with LF : ASCII code 0x0A)

- "-LF" to delete the block selected

- "+[block]LF" to insert the block after the block selected

- "#[block]LF" to substitute the block for the block selected

REMARK The block writing method is similar to the block modification method (see

Operator Manual).

44 en-938928/2

Page 45

PC Module

Reception

Answer code / Additional answer code

Answer code 1 byte: 0xF5

Additional answer code 1 byte: 0x81

The answer code and the additional answer code are not significant: it is the code returned by the Uniti() function that

gives the request execution report.

10.3.2.5 Reserving Memory Space

Description

The Reserve-Memory request is used to reserve memory space for making modifications to an existing programme

without being in reset status.

Transmission

Request code / Additional request code / Programme number / Memory size

Request code 1 byte: 0xF5

Additional request code 1 byte: 0x52

Programme number 1 long word: indexed programme number (programme number x 10 + axis group

number)

Memory size 1 long word: size in bytes to be reserved for the program (0 to keep the program

at its present size)

Reception

Answer code / Additional answer code

Answer code 1 byte: 0xF5

Additional answer code 1 byte: 0x82

The answer code and additional answer code are not significant: it is the code returned by the Uniti() function that gives

the request execution report.

en-938928/2 45

Page 46

10.4 Functional Description of the PCNC Server

The CNC can send requests to the PC module. In this case, the PC module is the server.

Whenever a request is sent to the PC, it is received by the driver, which wakes up the server task. This task recovers

the data, decodes the request, performs the necessary processing and acknowledges the request by updating the

control data.

10.4.1 OPEN-DOWNLOAD-SEQUENCE Request

Description

This request starts loading a file on the PCNC HD (hard disk).

Request Format

Request code/Category/File identifier/Extension code/Filename

Request code: 1 byte: 0x3A

Category: 1 byte

File identifier: 2 long words (long word 1 at the low address, long word 2 at the high address)

long word 1: file identifier

long word 2: not significant

REMARK The high byte of this long word gives the file type; type 9 corresponds to the

PCNC; the next three bytes are not significant.

Extension code: 1 byte: 0x01

Optional field (see next field)

Filename: table of bytes (ASCII character string beginning with a length byte)

Optional field present only if the Extension code is present and equal to 0x01

Syntax: "C:\filename" or "C:\path\filename"

REMARK The Filename field gives the filename and possibly also the pathname of the

files to be downloaded. It must always be specified in the case of the PCNC.

Answer Format

Answer code/Status

Positive Answer

Answer code: 1 byte: 0x6A

Status: 1 byte: 0x00

46 en-938928/2

Page 47

Negative Answer

Answer code: 1 byte: 0x6A

Status: 1 byte: 0x01: file already exists

0x02: other download in progress

0x03: memory full

0x08: error in filename/header

0x1C: system error

10.4.2 WRITE-DOWNLOAD-SEGMENT Request

Description

This request is used to write data in a file that is already open.

PC Module

Request Format

Request code/Category/Segment number/Segment length/Data

Request code: 1 byte: 0x3B

Category: 1 byte

Segment number: word

Segment length: word

Data: table of bytes

Answer Format

Answer code/Status/Segment number

Positive Answer

Answer code: 1 byte: 0x6B

Status: 1 byte: 0x00

Segment number: word

Negative Answer

Answer code: 1 byte: 0x6B

Status: 1 byte: 0x03: Memory full

0x04: no file open

0x08: download already in progress

0x09: data length inconsistent with request received

0x0B: a block has more than 120 characters

0x0D: incoherent data

en-938928/2 47

Page 48

0x19: sequence error

0x1C: system error

Segment number: word

10.4.3 CLOSE-DOWNLOAD-SEQUENCE Request

Definition

This request is used to close download of a file already open.

Request Format

Request code/Category

Request code: 1 byte: 0x3C

Category: 1 byte

Answer Format

Answer code/Status

Positive Answer

Answer code: 1 byte: 0x6C

Status: 1 byte: 0x00

Negative Answer

Answer code: 1 byte: 0x6C

Status: 1 byte: 0x04: file already closed

0x08: other download in progress

0x0B: the last block loaded does not end with "LF": file deleted

0x1C: system error

10.4.4 OPEN-UPLOAD-SEQUENCE Request

Definition

This request is used to start upload of a file from the PCNC.

Request Format

Request code/Category/File identifier/Extension code/Filename

Request code: 1 byte: 0x3D

Category: 1 byte

File identifier: 2 long words (long word 1 at the low address, long word 2 at the high address)

long word 1: file identifier

long word 2: not significant

48 en-938928/2

Page 49

PC Module

REMARK The high byte of long word 1 specifies the file type. Type 9 corresponds to the

PCNC.

Byte 2 gives the subtype:

- value 0: file directory on the disk according to the pathname given in

Filename, syntax: "C:\*.*" or "C:\pathname\*.extension"

The data Read format is 8.3 (operates only on 8.3 format files in HPFS

mode) : a filename is encoded on 3 long words

- value 1: file stored on the disk.

The next two bytes are not significant.

Extension code: 1 byte: 0x01

Optional field (see next field)

Filename: table of bytes (ASCII character string beginning with a length byte)

Optional field present only if the Extension code is present and equal to 0x01

Answer Format

Answer code/Status

Positive Answer

Answer code: 1 byte: 0x6D

Status: 1 byte: 0x00

Negative Answer

Answer code: 1 byte: 0x6D

Status: 1 byte: 0x02: other download in progress

0x05: no such file

0x08: error in filename/header

0x1C: system error

10.4.5 READ-UPLOAD-SEGMENT

Definition

This request is used to upload data from a file that is already open.

Request Format

Request code/Category/Segment number

Request code: 1 byte: 0x3E

Category: 1 byte

Segment number: word

Answer Format

Answer code/Status/Segment number/Segment length/Data

en-938928/2 49

Page 50

Positive Answer

Answer code: 1 byte: 0x6E

Status: 1 byte: 0x00: OK, more data to be transmitted

0x0F: OK, end of file (automatic close)

Segment number: word

Segment length: word

Data: table of bytes

Negative Answer

Answer code: 1 byte: 0x6E

Status: 1 byte: 0x04: no download in progress

0x08: other download in progress

0x09: buffer too small for the answer

0x19: sequence error

0x1C: system error

Segment number: word

Segment length: word

Data: table of bytes

10.4.6 CLOSE-UPLOAD-SEQUENCE

Definition

This request is used to close the upload of a file already open.

Request Format

Request code/Category

Request code: 1 byte: 0x3F

Category: 1 byte

Answer Format

Answer code/Status

Positive Answer

Answer code: 1 byte: 0x6F

Status: 1 byte: 0x00

50 en-938928/2

Page 51

PC Module

Negative Answer

Answer code: 1 byte: 0x6F

Status: 1 byte: 0x04: file already closed

0x08: other download in progress

0x1C: system error

10.4.7 "ICONIFICATION" (Minimise) Request

Definition

This request minimises the NUM application icon on the PCNC. After reception of this request, the icon associated

with the NUM application is placed in the "Minimised windows" folder.

Request Format

Request code/Category/Additional request code/Reserved

Request code: 1 byte: 0xF5

Category: 1 byte

Additional request code: 1 byte: 0x62

Reserved: 1 byte: 0x00

Answer Format

Answer code/Additional answer or request code/Status

Positive Answer

Answer code: 1 byte: 0xF5

Additional answer code: 1 byte: 0x92

Status: 1 byte: 0x00

Negative Answer

Answer code: 1 byte: 0xF5

Additional request code: 1 byte: 0x92

Status: 1 byte: 0x04: application already minimised

0x1C: system error

10.4.8 "RESTITUTION" (Restore) Request

Definition

This request restores the NUM application on the PCNC screen.

Request Format

Request code/Category/Additional request code/Reserved

en-938928/2 51

Page 52

Request code: 1 byte: 0xF5

Category: 1 byte

Additional request code: 1 byte: 0x63

Reserved: 1 byte: 0x00

Answer Format

Answer code/Additional answer or request code/Status

Positive Answer

Answer code: 1 byte: 0xF5

Additional answer code: 1 byte: 0x93

Status: 1 byte: 0x00

Negative Answer

Answer code: 1 byte: 0xF5

Additional request code: 1 byte: 0x93

Status: 1 byte: 0x04: application already restored to full screen

0x1C: system error

10.4.9 "VERROUILLAGE/DEVERROUILLAGE" (Lock/Unlock) Request

Definition

This request is used to inhibit access to the OS/2 desktop (the PCNC is locked on the application in the foreground).

Calling this request toggles the system status from locked to unlocked or vice versa.

Format Request

Request code/Category/Additional request code/Reserved

Request code: 1 byte: 0xF5

Category: 1 byte

Additional request code: 1 byte: 0x64

Reserved: 1 byte: 0x00

Answer Format

Answer code/Additional answer or request code/Status

Positive Answer

Answer code: 1 byte: 0xF5

Additional answer code: 1 byte: 0x94

Status: 1 byte: 0x00: OK, locked

0x01: OK, unlocked

52 en-938928/2

Page 53

PC Module

Negative Answer

Answer code: 1 byte: 0xF5

Additional request code: 1 byte: 0x94

Status: 1 byte: 0x1C: system error

A second request of this type returns the system to its initial state.

REMARK Only operates for a full screen OS/2 application, but not for a DOS or Win/OS2

application.

10.4.10 SHUTDOWN Request

Request Format

Request code/Category/Additional request code/Reserved

Request code: 1 byte: 0xF5

Category: 1 byte

Additional request code: 1 byte: 0x66

Reserved: 1 byte: 0x00

Answer Format

Answer code/Additional answer or request code/Status

Positive Answer

Answer code: 1 byte: 0xF5

Additional answer code: 1 byte: 0x96

Status: 1 byte: 0x00

Negative Answer

Answer code: 1 byte: 0xF5

Additional request code: 1 byte: 0x96

Status: 1 byte: 0x1C

Reception of this request runs an executable that shuts down the PCNC and reports shutdown to the other processors.

REMARK Any changes made at OS/2 level (icon moved, session parameters changed)

are lost with this type of shutdown. To save them, the system must be shut

down using the conventional OS/2 shutdown procedure (accessible on the OS/

2 desktop context-sensitive menu).

en-938928/2 53

Page 54

10.4.11 START-APPLI Request

Definition

This request is used to run an application (executable) present on the hard disk, and associated with the START-APPLI

file. This object must first be created by running the creatprg.cmd file from C:\num.

Request Format

Request code/Category/Additional request code/Reserved

Request code: 1 byte: 0xF5

Category: 1 byte

Additional request code: 1 byte: 0x65

Reserved: 1 byte: 0x00

Answer Format

Answer code/Additional answer or request code/Status

Positive Answer

Answer code: 1 byte: 0xF5

Additional answer code: 1 byte: 0x95

Status: 1 byte: 0x00

Negative Answer

Answer code: 1 byte: 0xF5

Additional request code: 1 byte: 0x95

Status: 1 byte: 0x05: no such application

0x1C: system error

10.4.12 DELETE-FILE Request

Definition

This request deletes a file from the PCNC hard disk.

Request Format

Request code/Category/Additional request code/File identifier/Extension code/Filename

Request code: 1 byte: 0xF5

Category: 1 byte

Additional request code: 1 byte: 0x46

File identifier: long word

Extension code: 1 byte: 0x01: Optional field (see next field)

54 en-938928/2

Page 55

Filename: table of bytes (ASCII character string beginning with a length byte)

Optional field present only if Extension code is present and equal to 0x01

Syntax: "C:\filename" or "C:\path\filename"

Answer Format

Answer code/Additional answer or request code/Status

Positive Answer

Answer code: 1 byte: 0xF5

Additional answer code: 1 byte: 0x76

Status: 1 byte: 0x00

Negative Answer

Answer code: 1 byte: 0xF5

PC Module

Additional request code: 1 byte: 0x76

Status: 1 byte: 0x05: no such file

0x06: file protected

0x1C: system error

Example

Request: 245/0/70/9/01/H'08-43-3A-5C-41-4C-50-48-41

Answer: 245/118/06

245 = DELETE-FILE Request

0 = Category

70 = Additional request code

9 = File identifier

01 = Optional field

H'08 = Filename length (80 bytes)

H'43-3A-5C .... = C:\alpha (filename)

118 = Additional answer code

06 = Protected file

10.4.13 READ-MEMORY-FREE

Definition

This request returns the number of bytes available in the following memory areas:

- User programmes: areas 0, 1, 2 and 3,

- PLC programme (Ladder and C),

- MMI memory area,

- PC module hard disk

en-938928/2 55

Page 56

Request Format

Request code/Category/Additional request code/Area

Request code: 1 byte: 0xF5

Category: 1 byte

Additional request code: 1 byte: 0x47

Area: 1 byte: 0 to 3: User programmes

7: PLC programme (Ladder or C)

8: MMI memory area

9: PC Module hard disk

Answer Format

Answer code/Additional answer or request code/Status/Value

Positive Answer

Answer code: 1 byte: 0xF5

Additional answer code: 1 byte: 0x77

Status: 1 byte: 0x00

Value: long word

Negative Answer

Answer code: 1 byte: 0xF5

Additional request code: 1 byte: 0x77

Status: 1 byte: 0x1C: system error

10.4.14 UNSOLICITED-DATA Request

Definition

This request allows a server to send information without having first received a request. No answer is required of the

receiver.

The PLC sends this request by function Uneto.

The CNC server sends this request when it encounters instruction $9 in the programme being executed.

In the case of the PLC, no report is possible so there is no guarantee that the data were correctly received.

Description of Instruction $i in the Part Programme

In this instruction, the character $ is followed by number i then a character string. This string is the message to be sent.

For the PCNC, i = 9 for unsolicited data sent to the PCNC user programme.

This message is of the nonblocking type. Execution of the part programme continues without waiting for an answer.

56 en-938928/2

Page 57

PC Module

Request Format

Request code/Category/Object-address/Data-length/Data-specific

Request code: 1 byte: 0xFc

Category: 1 byte: 0x06

Object-address: 1 byte: (code giving the origin of the unsolicited data; optional except on a

network)

Index of the axis group

Data-length: 1 byte: number of bytes contained in the Data-specific field

Data-specific: table of bytes

Message contained in the part programme after $9

The message sent by the CNC is accessible via a port. Eight ports are available. Each port is assigned to an axis group:

- $90 for group 1,

- $91 for group 2,

- • • • • •

- $97 for group 8

$98 : unsolicited PLC data.

Answer Format