Page 1

NUM

1020/1040/1050/1060

T and G

OPERATOR

MANUAL

0101938822/2

06-98 en-938822/2

Page 2

Despite the care taken in the preparation of this document, NUM cannot guarantee the accuracy of the information it contains and cannot be held

responsible for any errors therein, nor for any damage which might result from the use or application of the document.

The physical, technical and functional characteristics of the hardware and software products and the services described in this document are subject

to modification and cannot under any circumstances be regarded as contractual.

The programming examples described in this manual are intended for guidance only. They must be specially adapted before they can be used in

programs with an industrial application, according to the automated system used and the safety levels required.

© Copyright NUM 1998.

All rights reserved. No part of this manual may be copied or reproduced in any form or by any means whatsoever, including photographic or magnetic

processes. The transcription on an electronic machine of all or part of the contents is forbidden.

© Copyright NUM 1998 NUM 1000 range software.

This software is the property of NUM. Each memorized copy of this software sold confers upon the purchaser a non-exclusive licence strictly limited

to the use of the said copy. No copy or other form of duplication of this product is authorized.

2 en-938822/2

Page 3

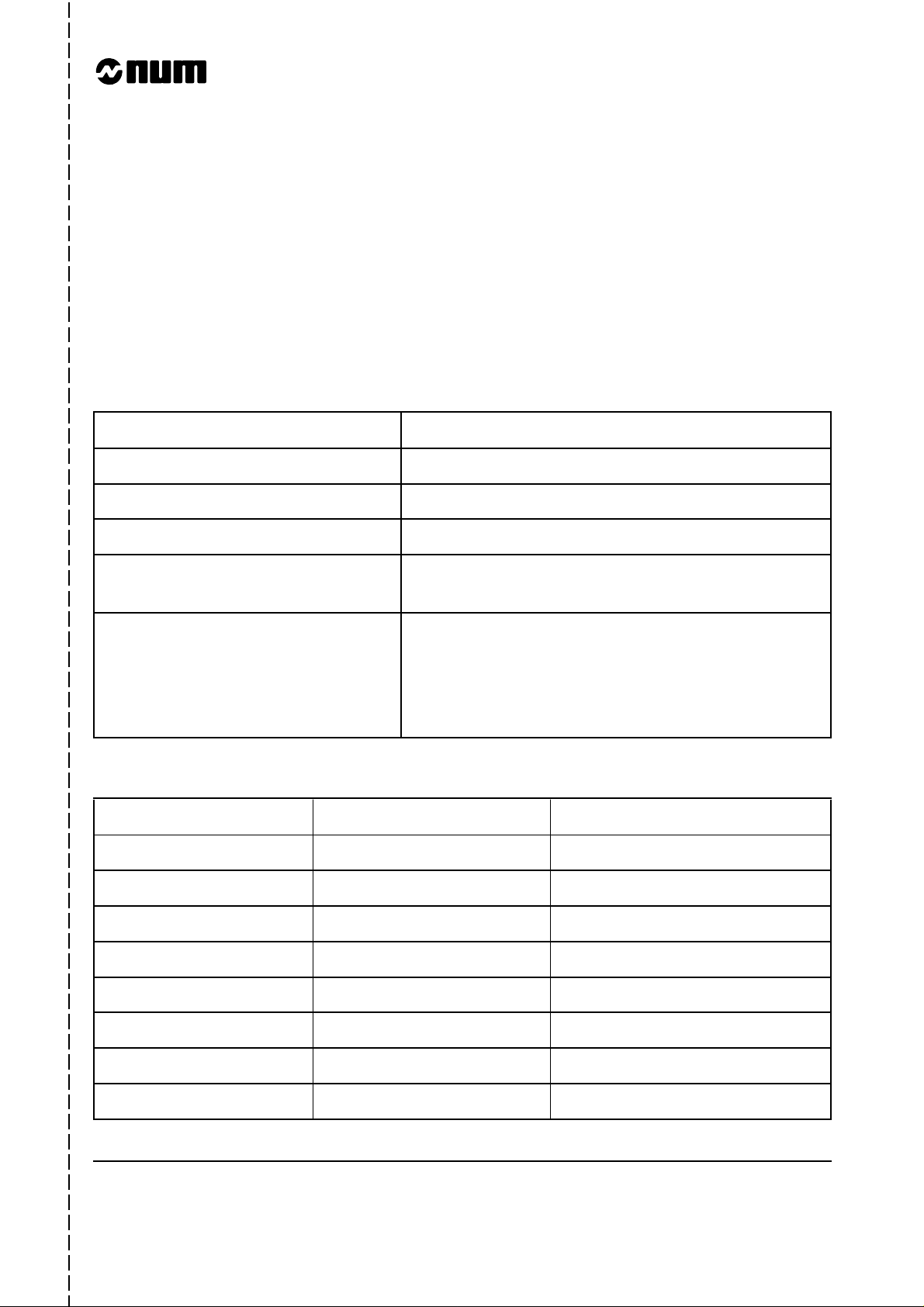

COMMISSIONING AND

WARRANTY CARD

The products whose part numbers are given below are covered by the “parts” warranty provided for by the

generation conditions of sale subject to return of this warranty card, duly filled in, to the NUM SA Service Centre

(by mail or fax) within one week at most after commissioning in the end user’s plant.

NUM S.A. Tel: 33(0)1.34.23.66.66

Service Clients Telex: 609 611 F

21, Avenue du Maréchal Foch Fax: 33(0)1.39.47.25.19

BP 68 - 95101 Argenteuil Cedex

MANUFACTURER

MACHINE

CNC TYPE

JOB REFERENCE

DATE OF COMMISSIONING

(see note)

USER

Name

Address

Phone

Fax

Fill in the table below only for NUM supplies.

Item Part Number Serial Number

Spindle servo-drive

Spindle motor

Axis servo-drive

Axis motor

Axis servo-drive

Axis motor

Axis servo-drive

Axis motor

NOTE: The date of commissioning corresponds to the date of installation in the user’s plant, which is not

necessarily the date of acceptance of the machine.

✄

Page 4

Table of Contents

Table of Contents

1 Review 1 - 1

1.1 System Overview 1 - 3

1.2 Machine Overview 1 - 5

2 Product Presentation 2 - 1

2.1 Environment 2 - 3

2.2 Switching on/off 2 - 6

2.3 System Identification 2 - 7

3 Operator Panel Description 3 - 1

3.1 NUM Panels and Sub-Assemblies 3 - 3

3.2 Interactions Between Mode Selections

and Display Pages 3 - 12

3.3 Available Controls and Indicators 3 - 13

3.4 Special Keyboard Operations 3 - 20

3.5 Use of a 102/105-Key Keyboard with the

Compact Panel 3 - 24

4 Display System Utilization 4 - 1

4.1 Inch/Metric Unit Conventions 4 - 3

4.2 Display of Tool Position 4 - 3

4.3 Display of Shifts 4 - 5

4.4 Display of Tool Dimensions, Corrections

and Wear Offsets 4 - 6

4.5 Display of Programmes 4 - 9

4.6 Display of a Programme in Graphic Mode 4 - 13

4.7 Display of Active Data 4 - 43

4.8 Display of Programme-Being Executed 4 - 45

4.9 Display of Programme Variables and

Equivalent Address Table 4 - 47

4.10 Display of Inputs/Outputs 4 - 49

4.11 Access to Maintenance Functions 4 - 57

5 CNC Operation 5-1

5.1 Preliminary Operations 5 - 5

5.2 Preparation for Machining 5 - 10

5.3 Manual Data Input 5 - 22

5.4 Automatic Programme Execution 5 - 23

5.5 Operator Interventions 5 - 47

5.6 CNC Information Archiving 5 - 60

5.7 Creation of a Part Programme 5 - 64

5.8 Inch/Metric Unit Selection 5 - 67

5.9 Part Programme Operations in Background

Mode 5 - 69

en-938822/2 3

Page 5

6 Operational Problems 6 - 1

6.1 Indicator "FDHLD" Displayed 6 - 5

6.2 No Movement in Manual Mode 6 - 6

6.3 No Movement in Automatic Mode 6 - 8

6.4 No Cycle Start 6 - 11

6.5 No Block Sequencing 6 - 12

6.6 Faults Detected by the System 6 - 17

6.7 Data Modification 6 - 17

6.8 Failure on Analogue Input/Output Cards 6 - 17

6.9 Power Failures 6 - 18

7 System Faults 7 - 1

7.1 Hardware Fault 7 - 5

7.2 Customisation Error 7 - 5

7.3 Temporary Customisation 7 - 6

7.4 Customisation Overrun 7 - 6

7.5 Sampling Period Too Small 7 - 7

7.6 Parameter Table Not Conforming to

Software Version 7 - 8

7.7 A Declared Axis Missing 7 - 9

7.8 Not Enough Memory to Execute the

Pocket Module 7 - 10

7.9 Wrong Number of PLC Axes 7 - 10

7.10 Incorrect Sampling Period with

UC SII CPU 7 - 11

7.11 Sensor Declared Connected Several

Times to the QVN Card 7 - 11

7.12 Incoherent QVN Sensor Address 7 - 12

7.13 Sensor Declared on QVN Card but

Detected on an Axis Card 7 - 12

7.14 Undeclared Speed Sensor Connected

to the QVN Card 7 - 13

7.15 Speed Sensor Declared Several Times 7 - 13

7.16 Speed and Position Sensor Declared

on Several Axes 7 - 14

7.17 Position Sensor Not Found on Axis Card

and Not Declared as QVN Sensor 7 - 14

7.18 Several Axis Drive Sensors Have the

Same Address 7 - 15

7.19 List of Drives Different from the List of

QVN Axes 7 - 15

7.20 QVN Axes Missing 7 - 16

7.21 Missing QVN Measured-Only Axes 7 - 16

7.22 Sampling Period Not Within the

Authorised Values 7 - 17

7.23 Editing Parameter P98 7 - 17

4 en-938822/2

Page 6

Table of Contents

8 Operator-Accessible Maintenance 8 - 1

8.1 Hardware Maintenance 8 - 3

8.2 Accessing the Utilities 8 - 10

8.3 Serial Line Parameters 8 - 12

8.4 Customising the Colour Palette 8 - 16

8.5 Backing up Machine Data 8 - 19

8.6 Setting the Date and Time 8 - 22

8.7 Battery Management Update 8 - 24

8.8 Protected Memory Area Management 8 - 25

8.9 Customisation of the System 8 - 50

Appendix A Function Summary Tables A - 1

A.1 ISO Programming Syntax A - 3

A.2 Parametric Programming Syntax A - 18

A.3 Profile Geometry Programming (PGP)

Syntax A - 25

Appendix B List of Errors B - 1

B.1 Miscellaneous Errors and Machine Errors B - 3

B.2 Parametric Programming Errors B - 4

B.3 Profile Geometry Programming (PGP)

Errors B - 5

B.4 Miscellaneous Errors B - 6

B.5 Request for Movements Outside the

Machine Travel Limits B - 6

B.6 Structured Programming Errors B - 7

B.7 Axis Errors B - 7

B.8 Errors in Pocket Cycles B - 8

B.9 Axes Not Identified on the Bus B - 8

B.10 Dynamic Operators in C B - 9

B.11 Spline Curve Interpolation Errors B - 9

B.12 Errors in Numaform B - 9

B.13 Cycle Programming Errors B - 10

Appendix C Use of Peripherals C - 1

C.1 CNC / Peripheral Interconnection C - 3

C.2 Connection to a Peripheral Device C - 21

C.3 Connection to a Computer C - 27

Appendix D Information Concerning the Exchange Area Bit D - 1

en-938822/2 5

Page 7

6 en-938822/2

Page 8

Record of Revisions

Date index Document revisions

07-92 0 Document creation (conforming to software at index C)

02-95 1 Revised to conform to software at index G

06-98 2 Revised to conform to software at index L

Table of Contents

en-938822/2 7

Page 9

8 en-938822/2

Page 10

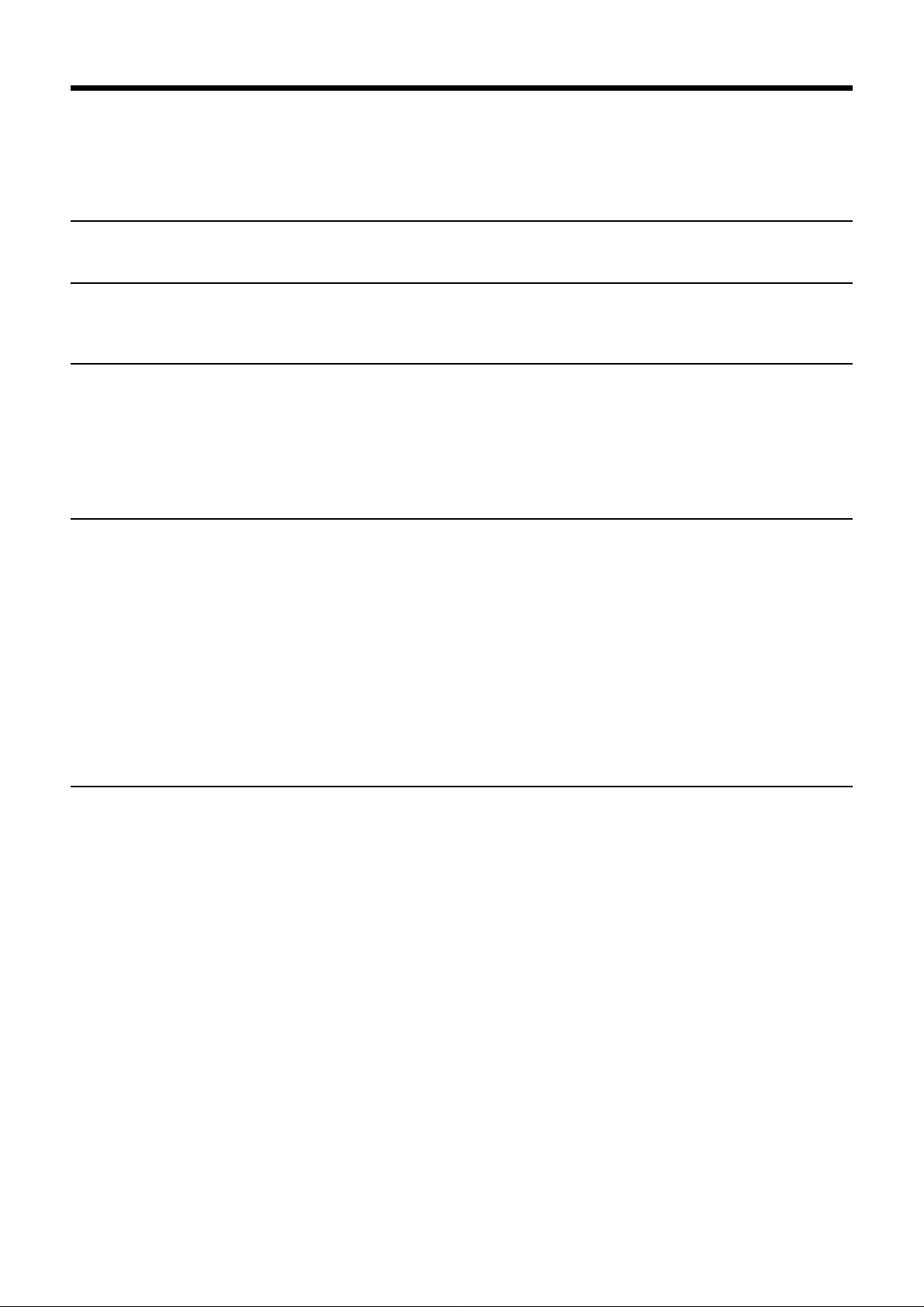

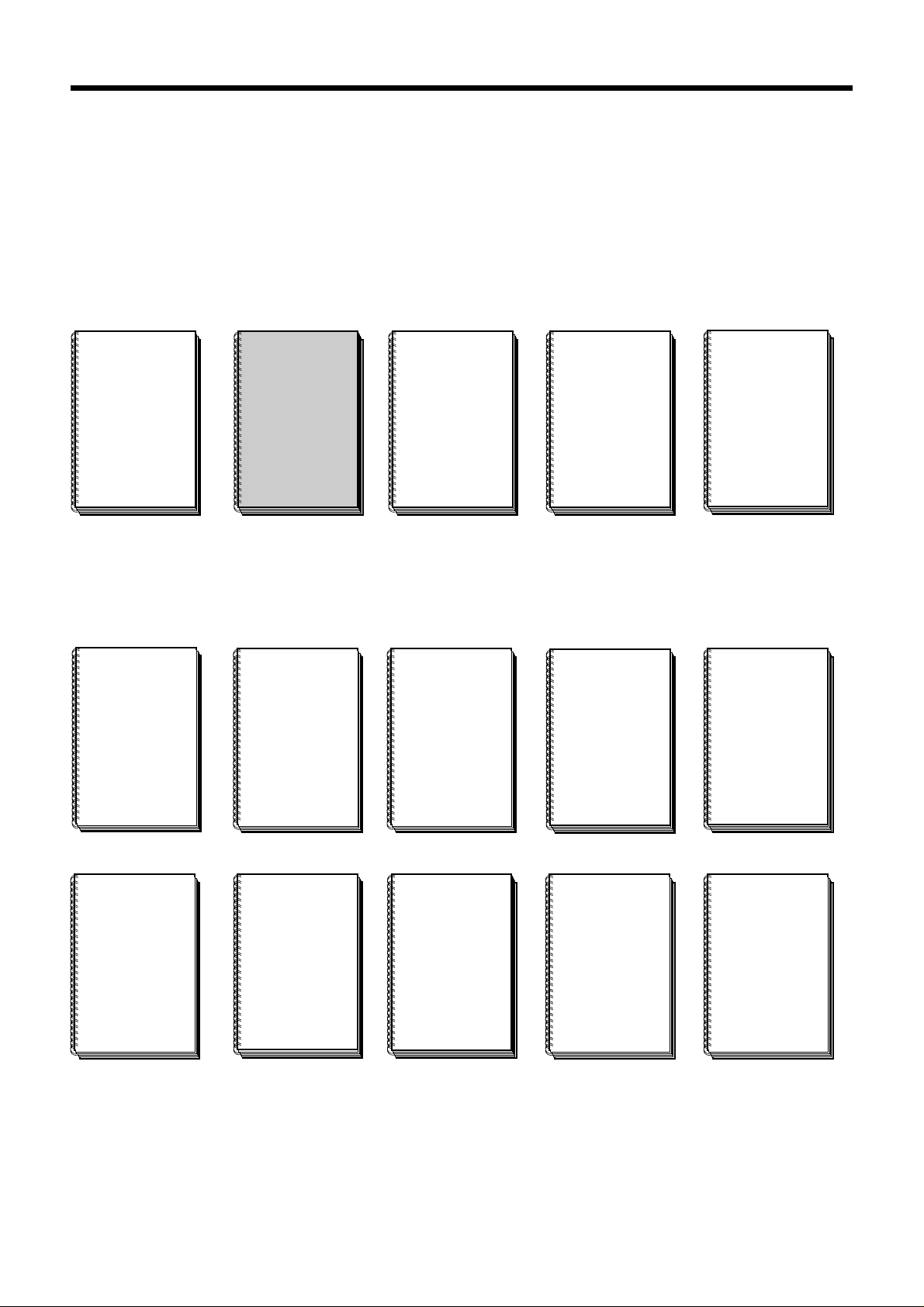

NUM 1020/1040/1050/1060 Documentation Structure

NUM T

PROGRAMMING

MANUAL

938820

NUM

PARAMETER

MANUAL

938818

User Documents

These documents are designed for use of the CNC.

Foreword

Foreword

NUM M/W

OPERATOR

MANUAL

938821

NUM T/G

OPERATOR

MANUAL

938822

NUM M

PROGRAMMING

MANUAL

938819

Integrator Documents

These documents are designed for setting up the CNC on a machine.

NUM 1060

INSTALLATION

AND

COMMISSIONING

MANUAL

938816

NUM 1020-1040

INSTALLATION

AND

COMMISSIONING

MANUAL

938938

NUM 1050

INSTALLATION

AND

COMMISSIONING

MANUAL

938977

NUM G

CYLINDRICAL

GRINDING

PROGRAMMING

MANUAL

938930

NUM

AUTOMATIC

CONTROL

FUNCTION

PROGRAMMING

MANUAL

LADDER

LANGUAGE

938846

MAN/MACHINE

INTERFACE

CUSTOMISATION

NUM

MMITOOL

TOOL

938946

NUM G

CYLINDRICAL

GRINDING

COMMISSIONING

MANUAL

938929

NUM

FTP40

PC PANEL

938967

NUM

SETTOOL

PARAMETER

INTEGRATION

TOOL

938924

NUM

PLCTOOL

LADDER

LANGUAGE

PROGRAMMING

TOOL

938859

en-938822/2 9

Page 11

List of NUM Utilities

A series of utilities are available for products of the NUM 10xx range for integration and use of the system.

These utilities may be included in the basic version or available as options.

Depending on the function performed by each utility, its use is described in the integration manual or operator manual,

as appropriate.

The table below lists the utilities and gives the references of the document describing them:

Utility Name Manual

UT2 axis calibration installation and commissioning

manuals

UT3 resident macros operator manuals

UT5 parameter integration parameter manual

UT7 programme debugging machine processor programming

manual - ladder language

UT12 option locking operator manuals

UT20 interaxis calibration installation and commissioning

manual

UT22 parameter integration SETTOOL manual

10 en-938822/2

Page 12

Operator Manual

CHAPTER 1

REVIEW

Foreword

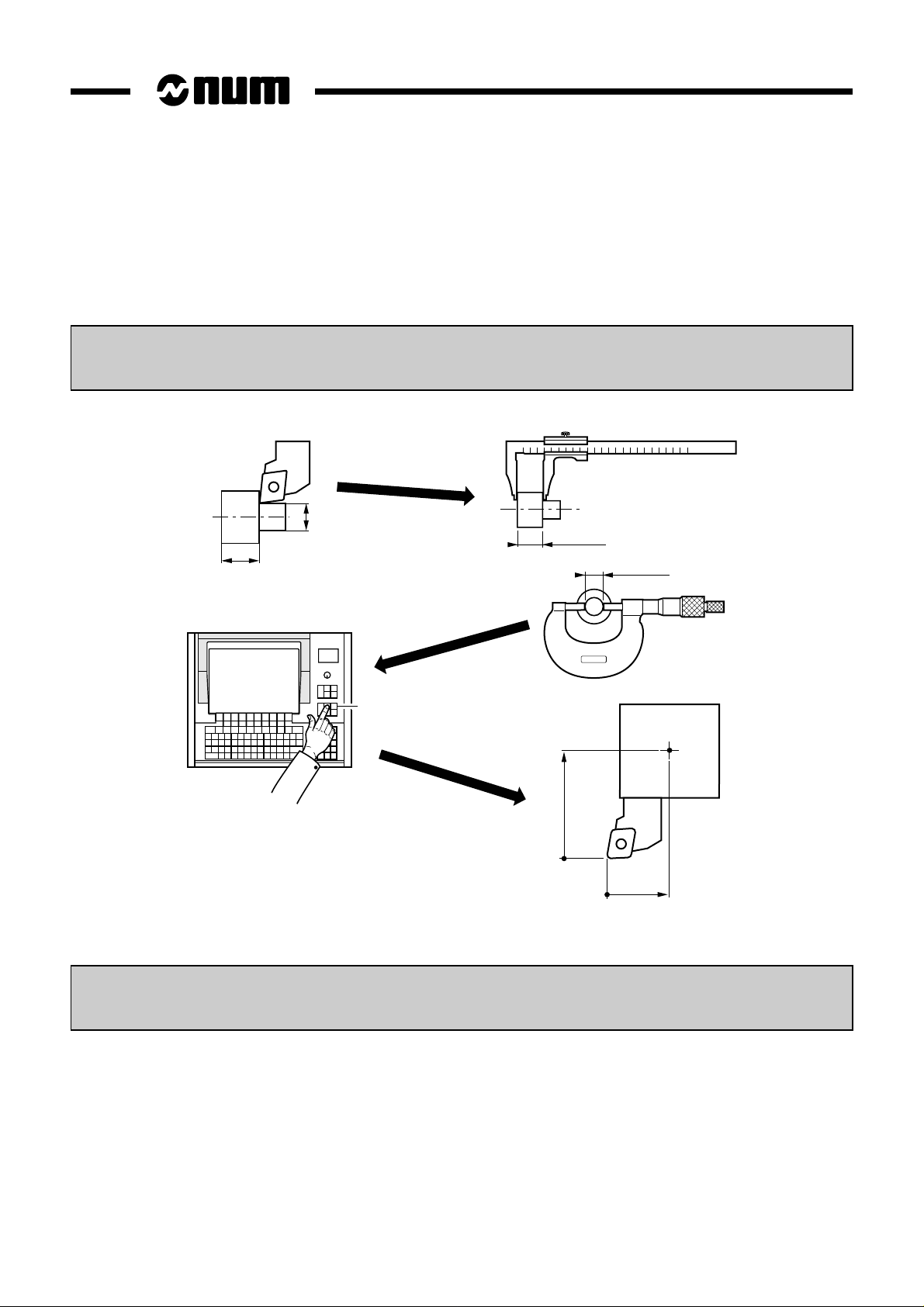

Presentation of the CNC and its role in relation to the machine tool.

Reminder of the rules and standards associated with CNC and machines.

Overview of the relationship between the CNC and its environment.

CHAPTER 2

PRODUCT

PRESENTATION

CHAPTER 3

OPERATOR

PANEL

DESCRIPTION

Procedures for switching on and re-starting following an emergency stop.

Access to information about the system (job reference, customisation, etc.).

Detailed presentation of the operator panel and screen.

Use of special keyboard functions.

Detailed presentation of the CNC display pages.

CHAPTER 4

DISPLAY

SYSTEM

UTILIZATION

en-938822/2 11

Page 13

CHAPTER 5

CNC

OPERATION

CHAPTER 6

OPERATIONAL

PROBLEMS

Description of machining preparation phases:

- axis jogs,

- machine-specific settings on the CNC,

- part programme processing.

Part programme automatic execution procedures.

Description of operator interventions during part machining.

Operations in background mode on part programmes.

Presentation of the incidents which occur most frequently on the CNC and flowcharts

indicating the most suitable action to be taken in each case.

Presentation of the system faults which can occur on power up and action to be taken.

CHAPTER 7

SYSTEM

FAULTS

CHAPTER 8

OPERATOR-

ACCESSIBLE

MAINTENANCE

Description of simple maintenance operations.

Presentation of user-accessible system management utilities.

12 en-938822/2

Page 14

APPENDIX A

FUNCTION

SUMMARY

TABLES

APPENDIX B

Foreword

Introduction to part programming and tables summarising the programming functions

(all these notions are explained in detail in the Programming Manual).

List of CNC error numbers and descriptions.

LIST OF

ERRORS

APPENDIX C

USE OF

PERIPHERALS

APPENDIX D

INFORMATION

CONCERNING THE

EXCHANGE

AREA BIT

Presentation of peripheral commissioning operations prior to data exchanges.

Addresses of the exchange area bits mentioned in this manual.

en-938822/2 13

Page 15

Using the Operator Manual

Procedures

This manual includes procedures.

The actions required are presented as follows:

Reset the system. ☞

The keys to be pressed are indicated on the right. They can have two forms:

Square keys: correspond to keys on the operator panel.

UTIL

Rectangular keys: correspond to softkeys located in the block at the bottom of the screen and activated

by function keys (F2-F11) located under the screen.

Y

Dealers

The list of NUM dealers is given at the end of the manual.

Questionnaire

To help us improve the quality of our documentation, we ask you to return the questionnaire at the end of this manual.

14 en-938822/2

Page 16

Review

1 Review

1.1 System Overview 1 - 3

1.1.1 Overview of Modes 1 - 3

1.1.2 Defining a Programme 1 - 3

1.1.3 Preparing a Programme 1 - 4

1.2 Machine Overview 1 - 5

1.2.1 Review of Axis Definition and Direction 1 - 5

1.2.2 Machine Overview 1 - 6

1.2.3 Definition of Travels and Origins 1 - 7

1.2.4 Definition of Shifts 1 - 9

1.2.5 Definition of Tool Dimensions 1 - 12

1.2.5.1 Definition of Tool Reference Dimension 1 - 12

1.2.5.2 Definition of Tool Tip Radius and

Orientation 1 - 13

1.2.6 Definition of Tool Wear Offsets 1 - 14

1

en-938822/2 1 - 1

Page 17

1 - 2 en-938822/2

Page 18

Review

This chapter does not aim to reflect the way an operator actually uses his machine. Rather, it attempts to explain certain

basic notions which will be referred to in this manual.

For example, in paragraph 1.2.4 (definition of shifts), the aim is not to impose a method of measuring shifts, but simply

to provide a definition of shifts and the corresponding zero points.

1.1 System Overview

1.1.1 Overview of Modes

The operator uses the numerical control (NC) in various operating modes

accessible from the operator panel.

Each mode corresponds to a particular use of the numerical control

(continuous machining, programme loading, tool setting, etc.).

MODE

1

1.1.2 Defining a Programme

A programme is a sequence of instructions written in a programming language specific to the numerical control (the

most widely used is ISO code: International Standards Organization).

The numerical control interprets the programme to control actions on a machine-tool.

The most widespread storage media for programmes are punched tape and diskettes.

en-938822/2 1 - 3

Page 19

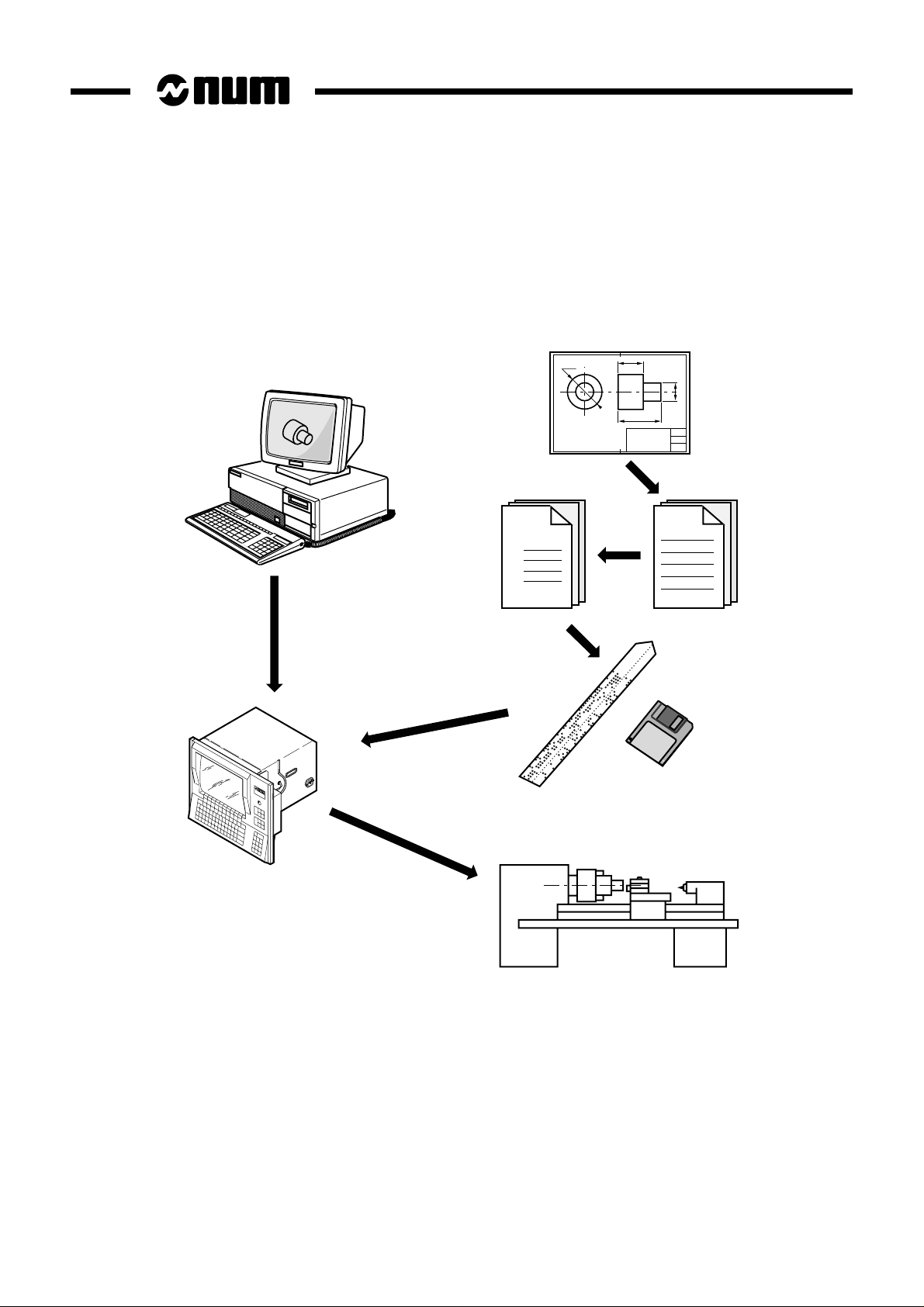

1.1.3 Preparing a Programme

A part programme can be created by traditional programming or using a CAD/CAM system.

CAD/CAM

Part

Programme

% 1

N10

N20

N30

Machining

instructions

1 - 4 en-938822/2

Page 20

1.2 Machine Overview

1.2.1 Review of Axis Definition and Direction

A coordinate system is used to identify the positions and movements of an

object with respect to an origin or zero point.

A rectangular cartesian coordinate system is a right-handed three-axis

system of three linear axes, X, Y and Z, with which are associated three

rotary axes, A, B and C.

Review

1

Z

C

Y

B

The direction of axes X, Y and Z is easily remembered by the right-hand

rule.

The positive direction of rotation of a rotary axis corresponds to the

direction of screwing of a right-hand screw on the associated axis.

0

Z

X

A

Y

X

en-938822/2 1 - 5

Page 21

1.2.2 Machine Overview

The manufacturer defines the coordinate system associated with the machine in accordance with standard ISO 841

(or NF Z68-020).

The X, Y and Z axes, parallel to the machine slideways, form a right-handed rectangular cartesian coordinate system.

The coordinate system measures tool movements with respect to the part to be machined, assumed fixed.

REMARK When it is the part that moves, it may be more convenient to identify its

movements. In this case, axes X’, Y’ and Z’, pointing in opposite directions from

axes X, Y and Z, are used.

The direction of the axis of a machine depends on the type of machine and the layout of its components.

For a lathe:

- the Z axis coincides with the spindle axis,

- the X axis is perpendicular to the Z axis and corresponds to radial movement of the tool-holder turret,

- the Y axis (generally fictional) forms a right-handed coordinate system with the X and Z axes.

Movement in the positive Z or X direction increases the distance between the part and the tool.

Rotary axes A, B and C define rotations around axes parallel to X, Y and Z.

Secondary linear axes U, V and W may or may not be parallel to primary axes X, Y and Z.

For more details, refer to the above-mentioned standard.

+ X

+ C'

+ Z

1 - 6 en-938822/2

Page 22

Review

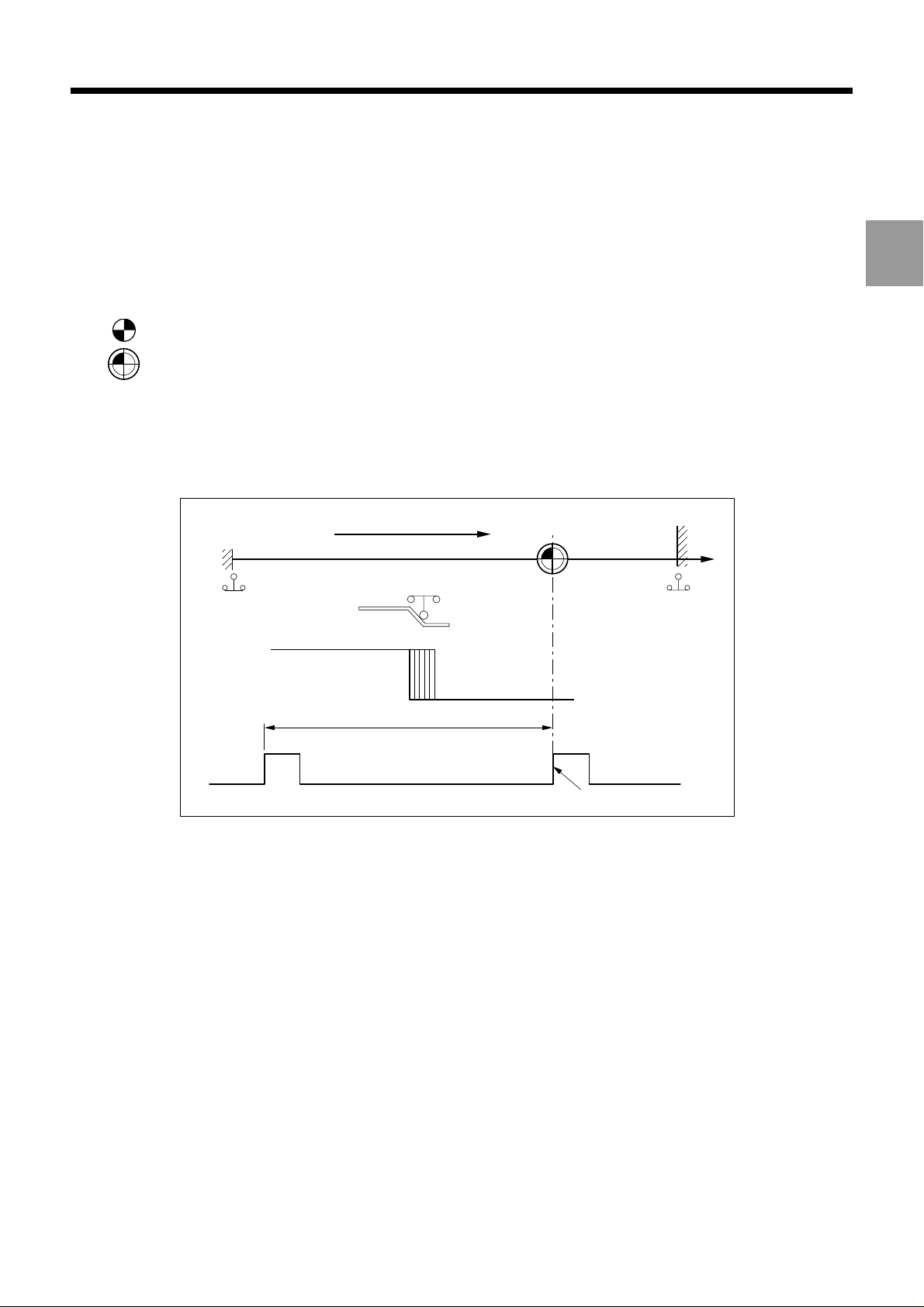

1.2.3 Definition of Travels and Origins

The NC processor computes all movements with respect to the measurement origin or zero point of the machine.

When the system is turned on, it does not know the measurement origin. The mechanical travel on each machine axis

is limited by maximum and minimum limit switches.

1

OM :

Om :

The homing procedure is completed for each of the axes when:

- the origin limit switch is actuated in the direction of movement specified by the m/c manufacturer (MOS direction),

- the encoder which measures axis movement outputs its marker pulse.

The system establishes the measurement origin (OM) via a homing procedure (MOS).

The home switch is set in a specific physical location: the machine zero point (Om) may or may not be the

same as the measurement origin (OM).

MOS direction

Om

Min. limit

switch

Contact closed Contact open

One encoder revolution

Max. limit

switch

Encoder marker pulse

en-938822/2 1 - 7

Page 23

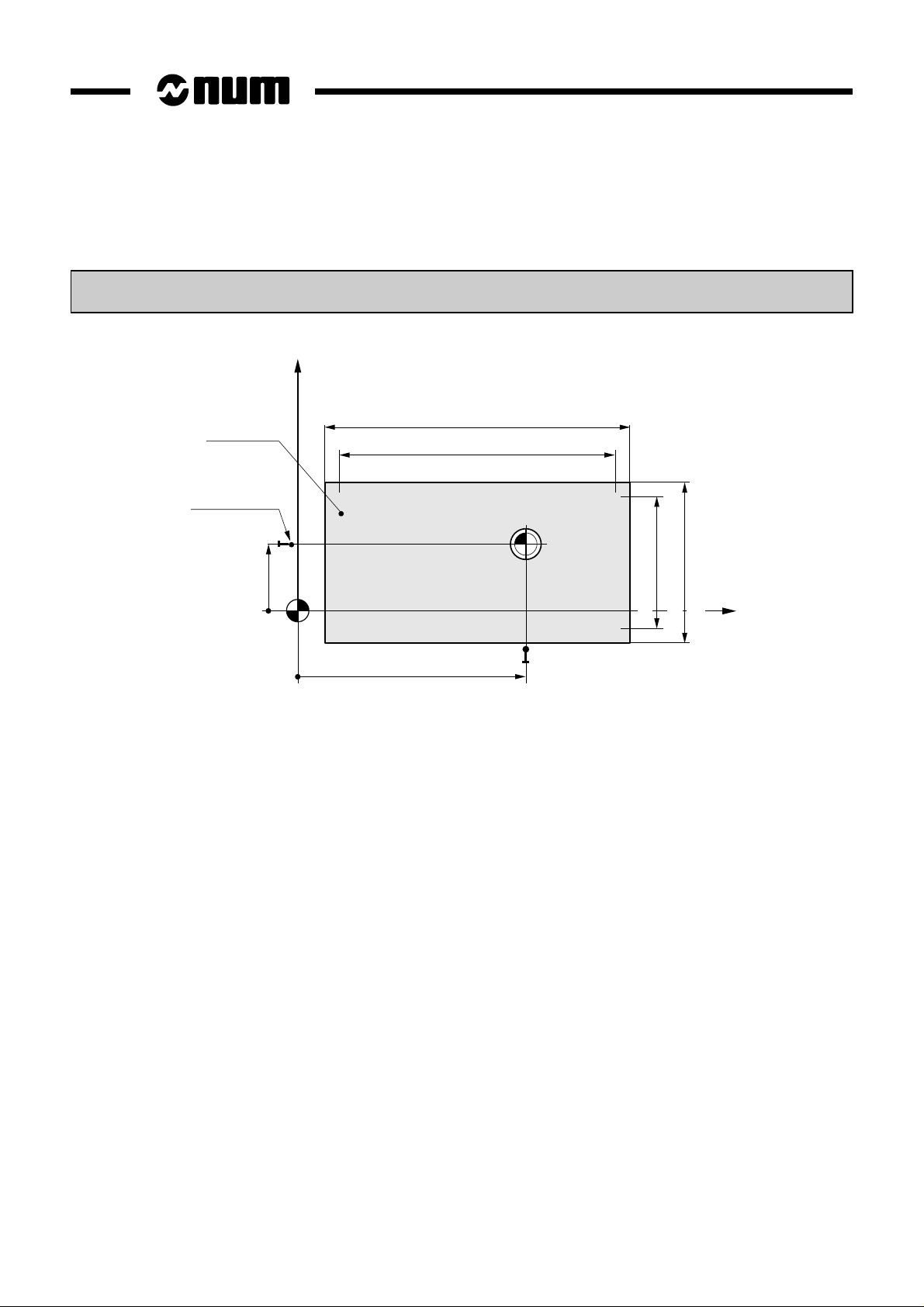

When homing (MOS) is completed, the system applies the shift defined by the manufacturer to each of the axes to

establish the measurement origin (OM).

Measurement origin shift (OM/Om) = ORPOM

The useful travel on each axis is established by software limits whose values are defined by the manufacturer.

X

Accessible

area

Origin switch

+ encoder

zero pulse

ORPOM X

OM

Mechanical travel on Z (limit switches)

Useful travel on Z

Om

ORPOM Z

Useful travel on X

Mechanical travel

Z

on X (limit switches)

1 - 8 en-938822/2

Page 24

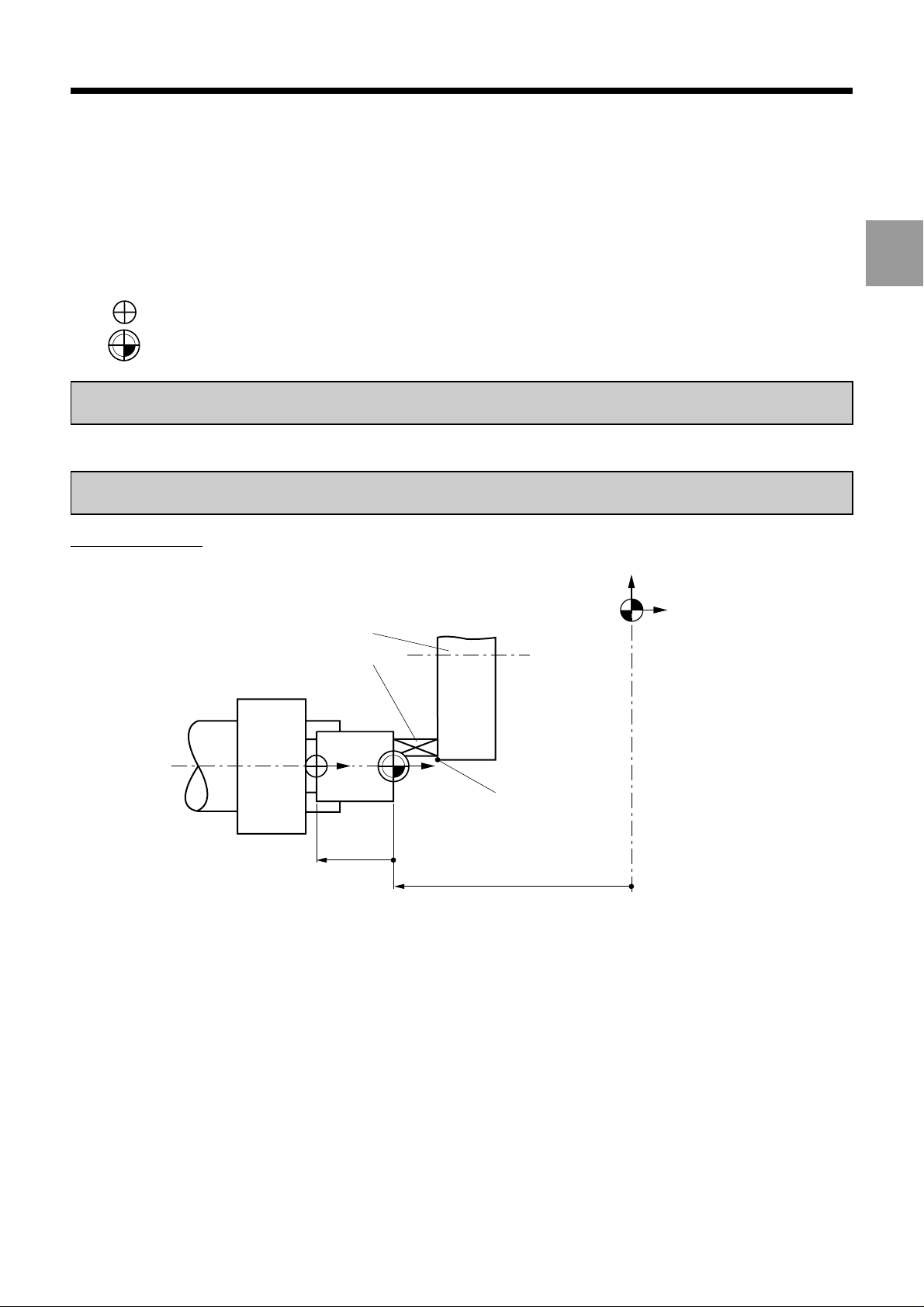

1.2.4 Definition of Shifts

To write a part programme, the programmer chooses a programme origin.

The programme origin is generally a starting point for dimensional measurements on the part drawing.

Review

1

OP :

Op :

It is possible to set the DAT1 and DAT2 values from the part programme.

Shifts on the Z axis

The operator sets the programme origin (OP) as shown below:

He sets (for each axis) a known, accessible point on the part, called the part origin (Op). This may be the

same point as the programme origin.

Part datum shift (Op/OM) = DAT1

Programme datum shift (OP/Op) = DAT2

Turret

Setting equipment

Z

Z

Measurement

origin

(OM)

OP

Z DAT2

Op

Turret

datum

Z DAT1

en-938822/2 1 - 9

Page 25

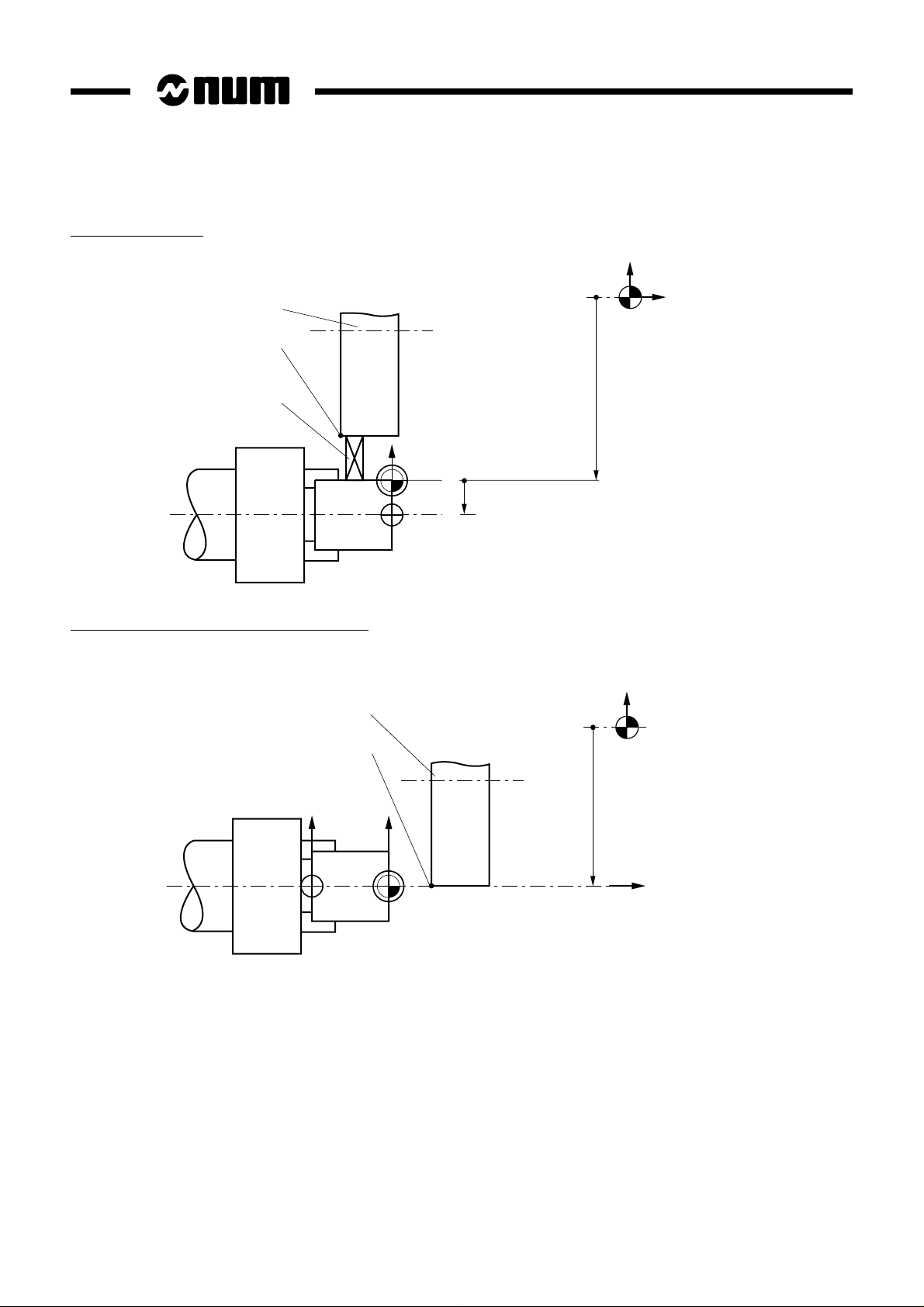

Shifts on the X axis

X

Turret

Turret

datum

Setting

equipment

X

Op

OP

Shifts on the X axis (solution without DAT2)

XDAT1: Fixed value measured between OM and the spindle axis.

Turret

Turret

datum

X DAT2

X DAT1

X

Measurement

origin

(OM)

Measurement

origin

(OM)

1 - 10 en-938822/2

X

OP

X

X DAT1

Op

Z

Page 26

Review

The coordinates of any point (A) defined with respect to the programme origin (OP) are converted by the CNC into

coordinates with respect to the measurement origin (OM) :

1

X

OP

PART

Z DAT1

Z DAT2

Z

PA

Z

MA

Op

A

X

OM

MA

X

X

PA

Z

X DAT1

X DAT2

Z

Programme dimensions (with respect to OP) Measurement dimensions (with respect to OM)

X

PA

Z

PA

The dimensions are algebraic values.

Programmed shifts can be added to the programme dimensions.

XMA = XPA + X DAT1 + X DAT2

ZMA = ZPA + Z DAT1 + Z DAT2

en-938822/2 1 - 11

Page 27

1.2.5 Definition of Tool Dimensions

1.2.5.1 Definition of Tool Reference Dimension

Tool reference dimension = distance from tool cutting edge to turret datum

X

OP

Turret datum

Part/tool

contact

diameter

X

Z

Tool axis orientation

OP

Z

Z dimension

Part/tool contact

surface

Turret datum

X dimension

1 - 12 en-938822/2

Tool X dimension = X

Tool Z dimension = Z

Page 28

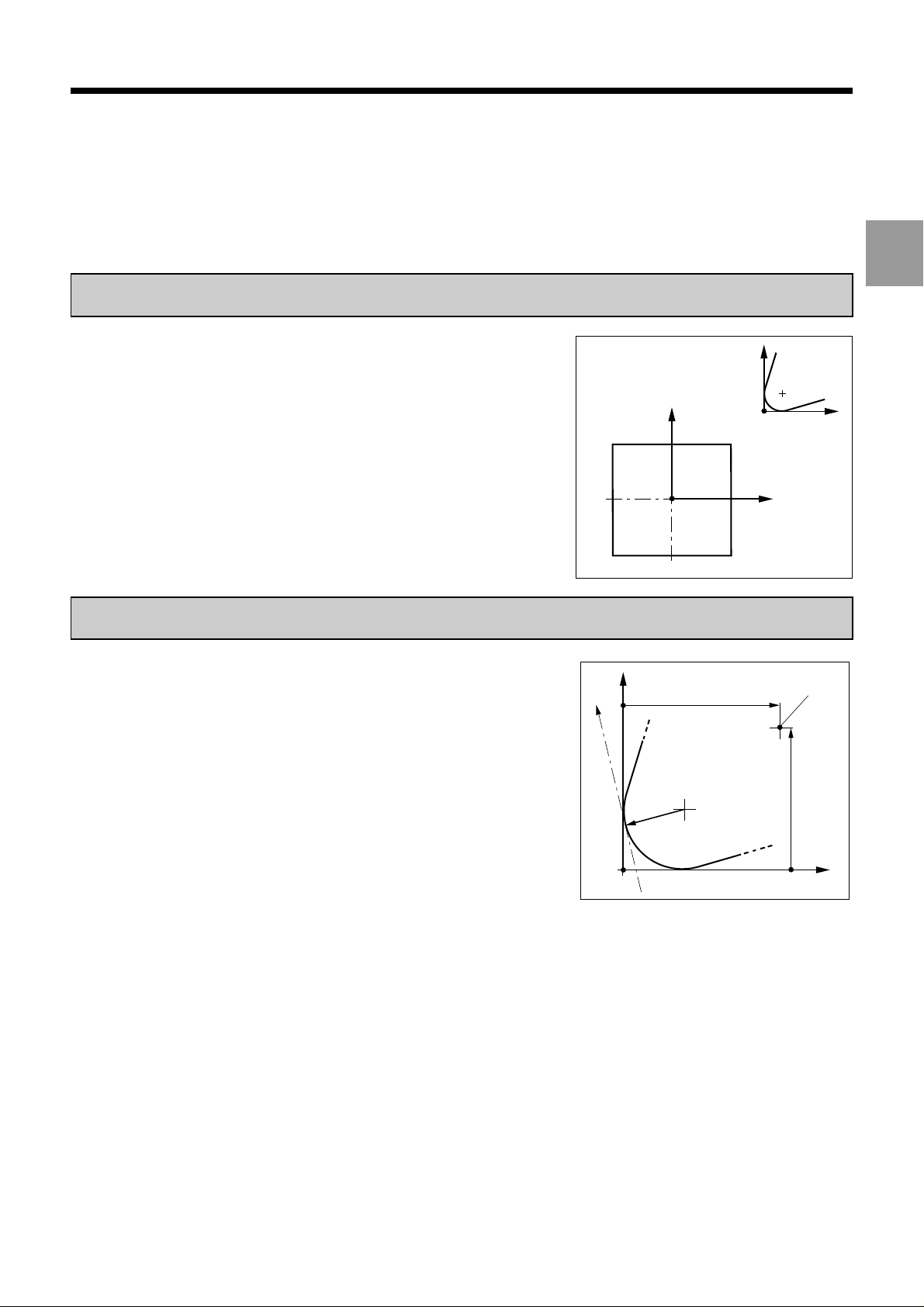

1.2.5.2 Definition of Tool Tip Radius and Orientation

Z

Z

X

P

P

C1

X

C4

Example:

C0 C8

C3 C2 C1

C5 C6 C7

The description of a tool is completed by:

Tool tip orientation = code C0 to C8

The tool tip orientation code allows the system to identify the location of

the tool cutting part centre (C) from the theoretical cutting point (P).

Review

1

Radius of tool cutting part = R

The real tool cutting point is obtained by applying a vector with length «R»

perpendicular to the direction of movement starting from «C».

X

R

movement

Direction of

P

Z dimension

C

Turret

datum

X dimension

Z

en-938822/2 1 - 13

Page 29

1.2.6 Definition of Tool Wear Offsets

At any time (even during machining), the operator can enter tool wear offsets when he observes a difference between

the expected and the actual results on a part.

The offsets (positive or negative) compensate for slight dimensional variations of the tool or part (wear, expansion).

Tool wear offset on X = DX (to the diameter)

D

L

Tool wear offset on Z = DZ

L + ∆L

D + ∆D

TOOL

DX = -∆D

DZ = -∆L

The system takes into account the corrected tool dimensions as quickly as possible:

Corrected length on X = X dimension + DX/2

Corrected length on Z = Z dimension + DZ

X + DX/2

Z + DZ

1 - 14 en-938822/2

Page 30

Product Presentation

2 Product Presentation

2.1 Environment 2 - 3

2.1.1 NUM 1060 Series I or NUM 1060 Series II 2 - 3

2.1.2 NUM 1020, 1040 and 1050 2 - 4

2.1.2.1 NUM 1020, 1040 and 1050 with CNC Panel

or Compact Panel 2 - 4

2.1.2.2 NUM 1020, 1040 and 1050 with FTP40

PC Panel 2 - 5

2.2 Switching on/off 2 - 6

2.2.1 Switching on 2 - 6

2.2.2 Restart Following an Emergency Stop 2 - 6

2.3 System Identification 2 - 7

2.3.1 Access to System Customisation

Attributes 2 - 7

2.3.2 System Customization Information Grid 2 - 17

2

en-938822/2 2 - 1

Page 31

2 - 2 en-938822/2

Page 32

Product Presentation

2.1 Environment

2.1.1 NUM 1060 Series I or NUM 1060 Series II

The following diagram illustrates the links between the CNC, the machine and the peripherals for NUM 1060 Series

I and NUM 1060 Series II systems with CNC panel or LCD panel or compact panel.

2

Panel

or

or

NUM 1060 Series I

or Series II CNC

ou

Compact panel

Optional keyboard

SERIAL LINES

∗

INDUSTRIAL NETWORKS

• UNI-TELWAY

• MAP

• MAPWAY

Machine panel

Movement

sensor

MACHINE

Motor

Sensors

Actuators

Axes

Additional

handwheels

Servo-drive

External

interrupts

(measurement

probes)

PC or PS

Diskette drive

Printer

PERIPHERALS

∗ The compact panel is incompatible with the machine panel. An optional keyboard can be connected to the compact

panel.

en-938822/2 2 - 3

Page 33

2.1.2 NUM 1020, 1040 and 1050

2.1.2.1 NUM 1020, 1040 and 1050 with CNC Panel or Compact Panel

The following diagram illustrates the links between the CNC, the machine and the peripherals for a NUM 1020, 1040

or 1050 system with CNC panel or LCD panel or compact panel.

INDUSTRIAL NETWORKS

• UNI-TELWAY

• FIPWAY

Motor

External

interrupts

(measurement

probes)

Actuators

Sensors

Movement

sensor

Diskette

drive

PERIPHERALS

Axes

PC or PS

Printer

Panel

Serial line

or

50-key LCD panel

MACHINE

Additional

handwheels

Servo-drive

Compact panel

Optional keyboard

NUM 1020, 1040

or 1050 CNC

∗

∗ The compact panel is incompatible with the machine panel. An optional keyboard can be connected to the compact

panel.

2 - 4 en-938822/2

Page 34

Product Presentation

2.1.2.2 NUM 1020, 1040 and 1050 with FTP40 PC Panel

The following diagram illustrates the links between the CNC, the machine and the peripherals for a NUM 1020, 1040

or 1050 system with FTP40 PC panel.

2

Motor

External

interrupts

(measurement

probes)

Actuators

Sensors

Movement

sensor

INDUSTRIAL NETWORKS

• UNI-TELWAY

• FIPWAY

FTP40 PC panel

and keyboard

Serial line

Axes

MACHINE

NUM 1020, 1040

or 1050 CNC

Additional

handwheels

Servo-drive

en-938822/2 2 - 5

Page 35

2.2 Switching on/off

2.2.1 Switching on

Switch on the machine using the procedure defined by the OEM

Example of equipment power up sequence:

- general switching on (the CNC and the peripherals),

- switching on the power systems (with conditions related to the CNC).

When the CNC is switched on, a status window displays the following type of information:

12345

HOME

FREE M02 CN1

1 Increment indicator: "FREE" is the default setting (another

increment can be selected by the PLC)

2 "HOME" indicator: the measurement origin settings still to be

performed on the declared axes

3 "M02" indicator: normal status of the system when not machining

(the "RESET" indicator is displayed if there is no PLC programme

or the PLC is faulty)

4 "CN1" indicator: in single-panel configuration (single or multiple

CNC), the first CNC is the default CNC

5 "OVER" and "CAPS" indicators: text editor is set to overtype

mode and upper case letters when the system is switched on

If one of these indicators is missing, a fault may be present on the system.

Notes

If the power to the CNC is switched off and back on, all the machining parameters (shifts, tool offsets, etc.) remain

stored; only the measurement origin is lost.

Incidents

Any message displayed when the CNC is switched on (See chapter 7) is linked to a system fault.

OVER

CAPS

2.2.2 Restart Following an Emergency Stop

An emergency stop automatically switches off the power to the machine actuators. The CNC remains energised and

retains all the machining data including movement commands.

Reset all the current movement commands. ☞

Restart the machine using the procedure defined by the OEM.

2 - 6 en-938822/2

Page 36

Product Presentation

2.3 System Identification

2.3.1 Access to System Customisation Attributes

The user can consult the pages indicating the customisation attributes which have been set for his system.

Requirements

Basic softkeys (See 3.1.4.2).

Actions

Select the "CNC COMMUNICATION DISPLAY" menu. ☞

Display of the "CNC COMMUNICATION DISPLAY" menu (See 4.10).

Select the first system identification page (after themenu). ☞

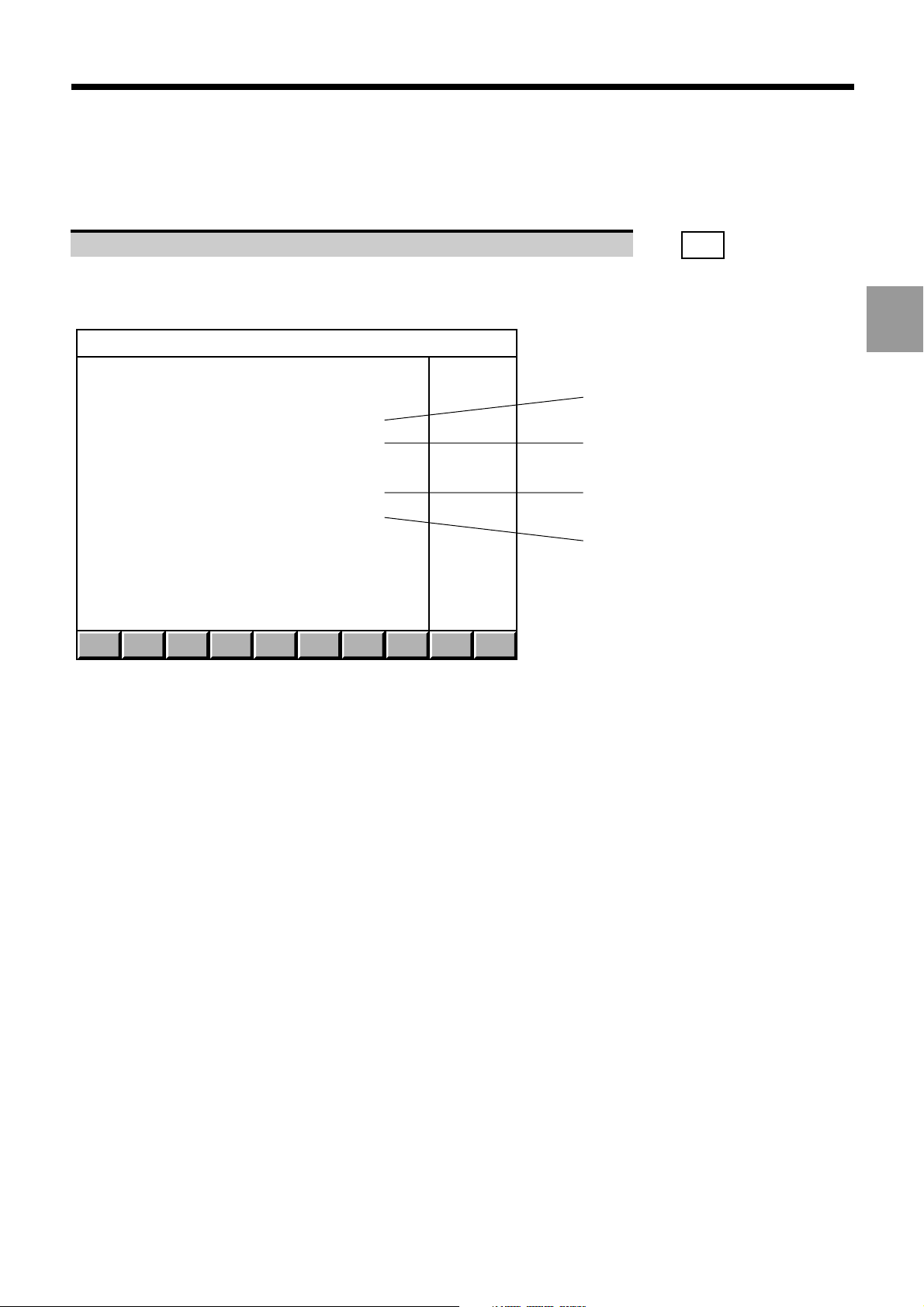

Display of the "AFFAIR AND SOFTWARE VERSIONS" page, e.g.:

AFFAIR AND SOFTWARE VERSIONS

1

JOB REFERENCE : XXXXXX 00

CNC SOFTWARE # : 202606G1

2

2

PLC

I / O

*

8

1 - Job reference

2 - Software version and index

en-938822/2 2 - 7

Page 37

Select the next page. ☞

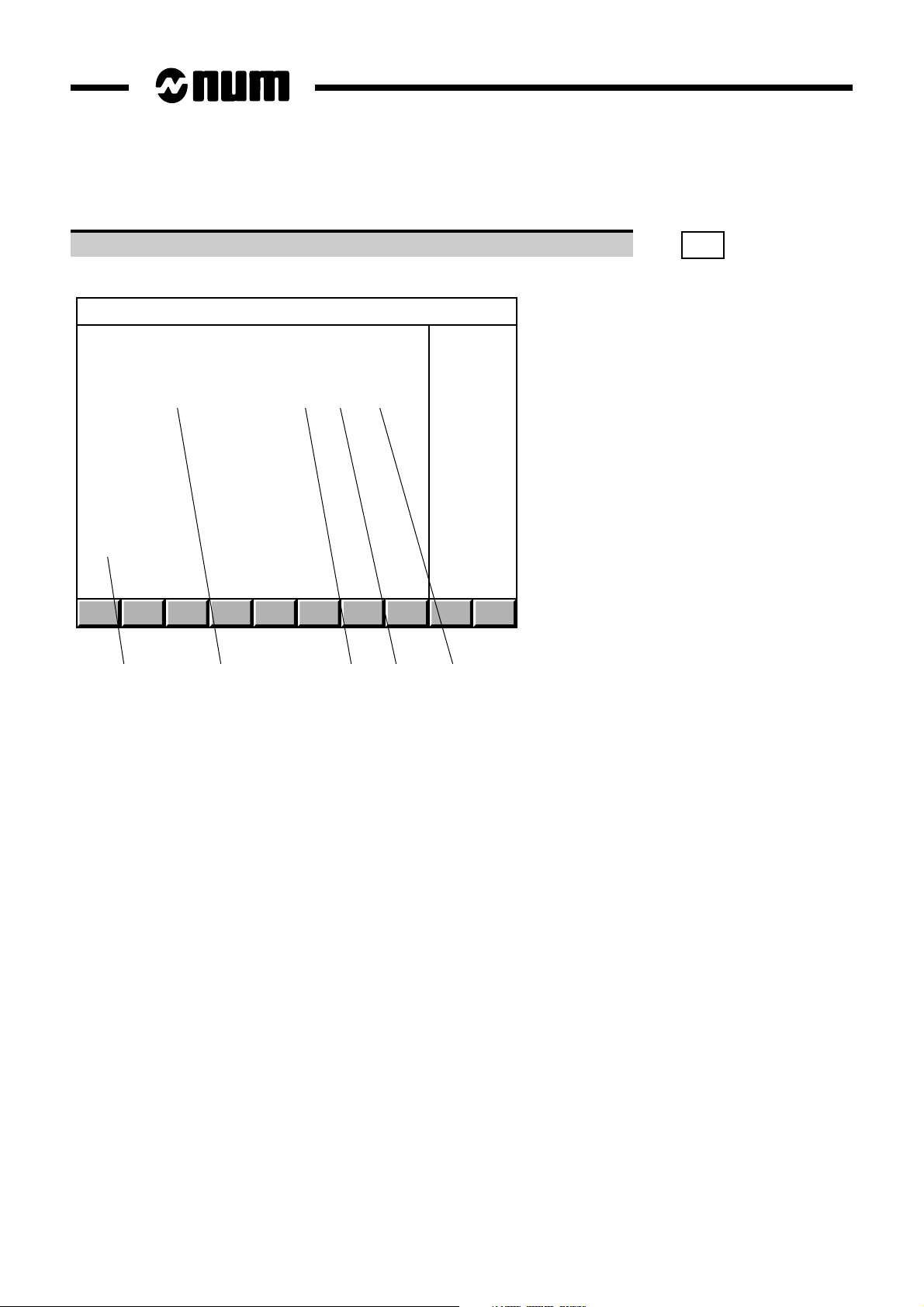

Display of "OPTIONS" page, e.g.:

. . / . .

DAT

0 1 2 3 4 5 6 7 8 9 10 11 12

X X 0

X x 1

X 2

X X 3

O

4

5

P

6

7

T

8

9

I

13 14 15 16 17 18 19 20 21 22 23 24 25

0

O

1

2

N

3

4

S

5

6

7

8

9

1 - Tens

2 - Units

3 - "X" indicates that the corresponding function is available

1

2

3

2 - 8 en-938822/2

Page 38

The table below lists the functions available.

Number Function

0 3D display

1 Double windowing graphics

2 Hard copy

3 Additional language for CNC software

4 Program display/edit for NUM Tplus

5 Program load/unload and graphic simulation for NUM Tplus

10 Axis calibration: access to Utility 2, axis Calibration

access to Utility 20, Interaxis Calibration

11 Dynamic operators

12 Synchronised and duplicated axes

13 Multigroup function

14 Inclined axes

15 Inclined plane

16 N/M auto function

17 RTCP (Rotation around Tool Centre Point)

18 High speed machining of precision contours

19 Dynamic operators in C

20 Rigid tapping

21 Slaving of axes to spindle (G31, G33, G38)

22 Integrated spindle synchro

30 3D tool radius offset

31 Extension of number of corrections to 255

32 Tool wear offset control by the PLC

33 5-axis tool dimension

40 PROCAM interpreter

41 Accuracy setting

42 PGP (Profile geometry programming)

43 Resident macros: Access to Utility 3

44 Scaling factor

45 Programmable angular shift

46 Structured programming

47 Transfer of active parametric values into the part programme

48 Radial axis (boring function)

49 Irregular pockets and islands

50 Cartesian, polar and cylindrical conversion

51 Spline curve

52 Smooth polynomial interpolation

53 Creation of profile storage table

55 2D circular interpolation

Product Presentation

2

en-938822/2 2 - 9

Page 39

Number Function

60 Turning functions

61 Milling functions

62 Mixed machine functions

63 Selection of 1020 (=0) or 1040 (=1)

64 NUM 1040 GP: four axis groups (=1)

65 NUM Tplus (=1)

70 Emergency retraction

71 On-the-fly measurement acquisition

72 Backtrack along path

80 Coprocessor interchange protocol

81 UNI-TELWAY

82 Telemaintenance

83 DNC1

84 3-layer network

85 7-layer network

86 High speed console line

87 FIPWAY

90 PLC programming in C

91 Gear grinding

92 Automatic gear alignment

93 Access to utility 6 (=1)

100 Application development software tool

101 NUMAFORM

103 PROCAM TURN or MILL

104 PROCAM MULTITURN

105 PROCAM MX (mixed machine)

106 PROCAM Grinding

107 Rigid tapping (on diskette)

108 Spindle synchronisation (on diskette)

109 RTCP (Rotation around Tool Centre Point) on diskette

127 Servo-control simulation

200 Milling package for DIDACNUM turning

201 Turning package for DIDACNUM milling

202 WOODplus

203 PCToolKit

210 MMITool interpreter

211 Package of basic options for NUM subsidiaries

2 - 10 en-938822/2

Page 40

Product Presentation

Select the next page. ☞

Display of the "AXES NUMBER" page (the numbers displayed on this page are set during the customization

procedure), e.g.:

. . / . .

DAT

AXES NUMBER

1

NUMBER OF CNC OR PLC AXES : 7

NUMBER OF SPINDLES : 2

NUMBER OF INTERPOLATED AXES : 5

2

3

NUMBER OF PLC ONLY AXES : 2

4

1 - Total number of axes authorized on the system (CNC axes +

PLC axes)

2 - Total number of spindles authorized

3 - Number of simultaneous interpolated axes

4 - Number of axes exclusively controlled by the PLC

2

en-938822/2 2 - 11

Page 41

Select the next page. ☞

Display of the "MEMORY SIZES" page (these sizes are set during the customization procedure), e.g.:

. . / . .

DAT

MEMORY SIZES

1

PART PROGRAMME STORAGE : 1024

PLC PROGRAMME STORAGE : 256

MMI PROGRAMME STORAGE : 800

1 - RAM size assigned to part programmes

2 - RAM size assigned to the PLC

3 - RAM size assigned to MMITool

(man/machine interface customisation tool)

2

3

2 - 12 en-938822/2

Page 42

Product Presentation

Select the next page. ☞

Display of the "HISTORY" page, e.g.:

HISTORY

1

FACTORY OUT :

26 / 2 / 92 15:20:65 CABE-EF

2

LAST MODIFIED ON :

8 / 6 / 94 10:37:23 D2R2

1 - Date, time and identification of the first person to customize the

system

2 - Date, time and identification of the last user to customize the

system using utility 12

. . / . .

DAT

2

en-938822/2 2 - 13

Page 43

Select the next page. ☞

Display of the "SYSTEM BUS HARDWARE CONFIGURATION" page for instance:

SYSTEM BUS HARDWARE CONFIGURATION

Address Designation File number Vers. Ident.

Unknown card 000 000 000 8 $0007F8

0 4M V2 graphic processor 204 202 778 0 $005340

1 1M PLC 204 201 935 0 $004B00

2 V2 1,7/2M memory board 204 202 301 0 $008D80

3 4 V1 14b encoder axes 204 201 982 0 $000E00

4

5

6

7

8

9

10

11

12

13

.../...

1 2 3 4 5

. . / . .

DAT

1 - Card address on the system bus (the addresses are numbered

from 0 to 13 starting from the right end of the rack)

2 - Card description

3 - Part number of each card

4 - Card functionality index (decimal conversion of the last character

of the identifier. For instance, if the last character is D, the

functionality index is 13)

5 - Electronic identifier of each card (this number is used to ensure

card interchangeability).

Each line of the "SYSTEM BUS HARDWARE CONFIGURATION" page gives information on a card installed on the

system bus.

The first line corresponds to the system bus backplane card.

Blank lines correspond to empty card slots.

If the card identifier is unknown, the message "card unknown" is displayed in the "Description" column.

2 - 14 en-938822/2

Page 44

Product Presentation

Select the next page. ☞

Display of the "PLC BUS HARDWARE CONFIGURATION (RACK 0)" page, for instance:

PLC BUS HARDWARE CONFIGURATION (RACK 0)

Address Designation File number Vers. Ident.

0 Main serial bus 204 201 857 0 $000000

0 130W power supply with optic F. 204 201 950 0 $000000

1

2

3

4

5 32 inputs board 204 201 926 0 $000A00

6 32 relayed outputs board 204 201 746 0 $000100

7

8

9

10

11

12

13

1 2 3 4 5

. . / . .

DAT

2

1 - Address on the serial bus:

- address 0 corresponds to the serial bus and the fibre-optic

interface on the power supply card

- addresses 1 to 4 are reserved for the machine panels

- addresses 5 to 12 are reserved for the input/output cards

2 - Card description

3 - Part number of each card

4 - Card functionality index (decimal conversion of the last character

of the identifier. For instance, if the last character is D, the

functionality index is 13)

5 - Electronic identifier of each card (this number is used to ensure

card interchangeability)

Each line of the "PLC BUS HARDWARE CONFIGURATION (RACK 0)" page gives information on a module installed

on the serial bus.

Blank lines correspond to empty slots.

When the system includes extension racks, the sign ".../..." is displayed in the bottom right-hand corner of the page.

en-938822/2 2 - 15

Page 45

To display the contents of the extension racks:

Select the next page as many times as necessary. ☞

. . / . .

DAT

The "PLC BUS HARDWARE CONFIGURATION (RACK X)" page is displayed.

It contains the same type of information as the "PLC BUS HARDWARE CONFIGURATION (RACK 0)" page; the input/

output cards occupy slots 1 and 2 (two-card extension racks) or 1 to 12 (12-card extension racks).

Notes

If no PLC is present, the message "PLC MISSING" is displayed in the "PLC BUS HARDWARE CONFIGURATION"

page.

If a CL7 controller card (link with a TSX series 7 PLC) is present, no PLC bus configuration page is displayed.

Exit from the procedure

Select a display page.

2 - 16 en-938822/2

Page 46

Product Presentation

2.3.2 System Customization Information Grid

The system customization parameters can only be consulted when the system is operational.

It is recommended to write this information down for communication to the OEM or NUM customer support in case of

a failure preventing consultation.

MACHINE IDENTIFICATION

Machine No.: Shop:

CUSTOMISATION

2

Job reference:

Options present:

0 1 2 3 4 5 6 7 8 9 10 11 12

0

1

2

3

4

5

6

7

8

9

Total number of axes:

Number of interpolated axes:

Part programme RAM size:

CNC software #:

Number of measured splindles:

Number of machine proc. axes:

Machine processor RAM size:

Date factory out:

Date last modified on:

HISTORY

Identification:

Identification:

en-938822/2 2 - 17

Page 47

The following table can be reproduced as many times as there are "BUS XXX HARDWARE CONFIGURATION" pages.

HARDWARE CONFIGURATION OF BUS ____________

Address Description Part Number Index Identifier

0

1

2

3

4

5

6

7

8

9

10

11

12

13

2 - 18 en-938822/2

Page 48

Operator Panel Description

3 Operator Panel Description

3.1 NUM Panels and Sub-Assemblies 3 - 3

3.1.1 NUM Panels 3 - 3

3.1.1.1 QWERTY Panel and CRT 3 - 3

3.1.1.2 50-Key Panels with CRT 3 - 4

3.1.1.3 50-Key Panel with LCD 3 - 4

3.1.1.4 Compact Panel 3 - 5

3.1.2 Display Screen 3 - 6

3.1.3 Status Window 3 - 7

3.1.4 Softkeys 3 - 8

3.1.4.1 Root Softkey Bar (Compact Panel) 3 - 8

3.1.4.2 Basic Softkeys 3 - 8

3.1.4.3 Mode Softkeys 3 - 8

3.1.4.4 JOG Softkeys 3 - 9

3.1.4.5 Tool Softkeys 3 - 10

3.1.4.6 Character Softkeys of the Compact Panel 3 - 10

3.1.5 Modal Data Window 3 - 11

3.2 Interactions Between Mode Selections and Display Pages 3 - 12

3.2.1 Neutral Mode 3 - 12

3.2.2 Interactions between Modes 3 - 12

3.2.3 Interactions between Modes and

Display Pages 3 - 12

3.3 Available Controls and Indicators 3 - 13

3.3.1 Keyboard Keys 3 - 13

3.3.1.1 Special Features of the 50-Key

Panel Keyboard 3 - 13

3.3.1.2 Special Features of the Compact

Panel Keyboard 3 - 13

3.3.1.3 Special Keyboard Keys 3 - 14

3.3.1.4 Special Control keys 3 - 15

3.3.1.5 Mode Selection Keys 3 - 16

3.3.1.6 Reset Key 3 - 16

3.3.1.7 Machine Panel Function Keys on the

Compact Panel 3 - 16

3.3.2 Softkeys 3 - 17

3.3.2.1 Root Softkeys (Compact Panel) 3 - 17

3.3.2.2 Basic Softkey Functions 3 - 17

3.3.2.3 Mode Softkey Functions 3 - 18

3.3.2.4 JOG Softkey Functions 3 - 19

3.3.2.5 Tool Softkey Functions 3 - 19

3.4 Special Keyboard Operations 3 - 20

3.4.1 Hardcopy 3 - 20

3.4.1.1 Hardcopy on Printer 3 - 20

3.4.1.2 Hardcopy in File 3 - 21

3.4.2 Keyboard Sound 3 - 22

3.4.3 Switching between Operator Panels 3 - 22

3.4.4 Switching between CNCs 3 - 23

3.5 Use of a 102/105-Key Keyboard with the Compact Panel 3 - 24

3

en-938822/2 3 - 1

Page 49

3 - 2 en-938822/2

Page 50

3.1 NUM Panel and Sub-Assemblies

3.1.1 NUM Panels

3.1.1.1 QWERTY Panel and CRT

Operator Panel Description

5

4

3

6

3

2 4

1

3

7

8

MODE

JOGTOOL

M01

2

9

F10

F9

{

[}]

";:

`

,<.>/

F11 F12

`

?

CAPS

ALL

J

F8F7F6F5F4

KL

MNBVCXZSHIFT SPACE

F1

!1@2#3$4%

ESC Q W E R T Y U I O P

1

CTRL A D F G H

F3F2

5^6&7*8(9)0_-+=+

S

x off

/

HELP

line

line

DEL

INS

char

char

home Pg Up

VALID

Pg Dnend

10

1 - QWERTY alphanumeric keyboard

2 - Key to access previous softkeys

3 - Function keys

4 - Colour CRT

5 - Brightness control

6 - Context selection keys

7 - Reset key

8 - Mode selection keys

9 - Key to access next "Mode" softkey

10 - Cursor control keys

en-938822/2 3 - 3

Page 51

3.1.1.2 50-Key Panels with CRT

4

1 2 3

3

N GHF

A

2

YBV(J)T

C

PDQ

SHIFT

1

F10F9F8F7F6F5F4F3F2F1 F11 F12

HELP

R

CTRL

MODE

'

M

_

?

S

I;U:X

{

x off

L

TOOL

]

E

SPACE

,

+K[WZ

JOG

}

"

\ ~0

7&8 9

S

4 5 6

!

∗0= /

INS/

OVER

ENTER

line

DEL

char

3#2@1

home

PgUp

end

PgDn

5

6

7

8

9

10

1 - Key to access previous softkeys

2 - Function keys

3 - Key to access next "Mode" softkeys

4 - 9" Monochrome or 10" colour screen

5 - Context selection keys

6 - RESET key

7 - Compact alphanumeric keyboard

8 - Brightness control

9 - Mode selection keys

10 - Cursor control keys

3.1.1.3 50-Key Panel with LCD

This assembly includes a 50-key panel and a separate LCD. It has the same functions as the 50-key panel with CRT

(see 3.1.1.2).

1 2 3

F10F9F8F7F6F5F4F3F2F1 F12F11

N GHF

A

I;U:X

{

YBV(J)T

}

C

"

PDQ

L

R

SHIFT

CTRL

HELP

MODE

TOOL

'

_

]

E

SPACE

M

?

S

x off

,

+K[WZ

JOG

7&8 9

S

4 5 6

!

∗0= /

INS/

OVER

ENTER

line

DEL

char

\ ~0

3#2@1

home

PgUp

end

PgDn

3 - 4 en-938822/2

Page 52

Operator Panel Description

3.1.1.4 Compact Panel

The compact panel is used for production and settings. It combines the functions of a CNC panel and a machine panel.

It can be used for ISO programming and maintenance by connecting a standard 102/105-key PC keyboard.

2

34

1

F

H

x

T-=

Z+!

C

Q.R

16

G%ME/

7N8S9

4X5Y6

1A2B3

DP0

a

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12

15 14 13 12 11

1 - 9" monochrome or 10" colour CRT 10 - DIN connector for additional standard 102/

2 - Data entry keys 105-key PC keyboard (this connector can

3 - Special keys be moved to the rear of the panel; see 3.5)

4 - Programmable keys (two functions per 11 - Reset key

key: key alone and Shift + key) ∗ 12 - Lighted CYCLE key ∗

5 - Emergency stop switch 13 - Lighted FEED STOP key ∗

6 - Lighted on/off switch 14 - Special cursor control keys and Shift key

7 - Feed rate override potentiometer 15 - Cursor control keys

8 - Axis jogs ∗ 16 - Function keys

9 - Serial port

10

3

5

6

7

8

9

∗ These machine keys remain active when the screen saver is on (the other keys merely turn the screen back on).

en-938822/2 3 - 5

Page 53

3.1.2 Display Screen

1 - Status window

2 - Main window (20 lines of small characters)

3 - Modal data window

4 - Dialogue window (3 dialogue lines)

5 - Softkey bar

1

2

3

4

5

Certain screens do not have a dialogue window. In this case, 11 lines of large characters are displayed.

3 - 6 en-938822/2

Page 54

Operator Panel Description

3.1.3 Status Window

The status window shows the status of the CNC at any given time via indicators displayed in 17 fields.

When no indicators are required in a field, it is not displayed.

18234567

LOAD

TLCOMP

MDI

.1

17 916 15 14 13 11 10

/

NC ?? CYHLD

AXRCL

M01 INCYC CN1

MSGFDHLD

mm

12

N_POS

OVER

LCASE

1 - Current mode (See list of modes: 3.3.2.2)

2 - Entry of tool dimensions (TLCOMP), entry of tool wear offsets

(WEAR +) or cancellation of tool wear offsets (WEAR 0)

3 - Block skip (/) enabled

4 - Fault (NC ?? flashing) or MOS not performed (HOME flashing)

5 - Machining stop (CYHLD)

6 - Feed interruption (FDHLD)

7 - Message present (MSG)

8 - Overtype text mode (OVER) or insert mode (INSRT)

9 - Upper case letters (CAPS) or lower case letters (LCASE)

10 - Axis not in position (N_POS) or hardcopy in progress (HCOPY)

or hardcopy fault (HCDEF)

11 - Panel number (KBD1 or KBD2) in multi-panel configuration,

number of active CNC (between CN1 and CN4) in multi-CNC

configuration or system fault (PRSOV)

12 - Display unit: millimetres (mm) or inches (inch)

13 - End of part programme (M02), programmed stop (M00),

reset (momentary display of RESET) or current cycle (INCYC)

14 - Axis recall (AXRCL flashing) or manual override (INTER

flashing)

15 - Optional stop (M01) enabled

16 - Selected JOG increment (.001 to 10000, FREE or HANDWH)

17 - Standby mode

3

Special Case of the Compact Panel

The status window displayed on a compact panel is somewhat different from the standard status window:

- It includes a field indicating the name of the axis controlled by the jogs, followed by the group number in multigroup

systems

- It includes fields with indicators for the programmable function keys (lit if the function is active).

1

LOAD

TLCOMP

MDI

X1 FCT

/

NC?? CYHLD

100

AXRCL

M01 INCYC CN1

MSGFDHLD

mm

3

N POS

OVER

SFCT

1 2 3 4 5 6

1 2 3 4 5 6

2

1 - LEDs for the shifted programmable function keys

2 - LEDs for the programmable function keys

3 - Axis name followed by group number

en-938822/2 3 - 7

Page 55

3.1.4 Softkeys

The softkeys of the compact panel differ from those of the other CNC panels. Since the compact panel has fewer keys,

certain keys of the CNC panels are replaced by softkeys (see the sections “Special Case of the Compact Panel”).

These softkeys are accessible in special softkey bars of the compact panel:

- The root softkey bar gives access to the Mode, Jog, Tool and Character softkeys

- The first Jog softkey bar is used to select the axis controlled by the jogs

- The two Mode softkey bars, the Tool softkey bar and the second Jog softkey bar (only Jog softkey bar on CNC

panels) are different

- The Character softkey bars allow entry of characters not available on the compact panel keyboard.

3.1.4.1 Root Softkey Bar (Compact Panel)

MODE

The Root softkey bar on the compact panel provides the functions accessible on other CNC panels by the

JOG

and

keys as well as giving access to the character keybars.

To display the Root softkeys, press the context key .

TOOL JOGMODE SYMBOL

To return to the basic softkeys, press again.

3.1.4.2 Basic Softkeys

TOOL

,

. . / . .

DAT

DIR. PROG. INFO. L / @ AXIS TOOLS BKGND

PLC

I / O

UTIL

These softkeys are displayed when none of the following softkeys have been selected:

- Mode softkeys,

- JOG softkeys,

- Tool softkeys.

To return to the basic softkeys, press the selection key of the softkey bar displayed (Mode, Jog or Tool) or, with the

QWERTY keyboard, press the key.

3.1.4.3 Mode Softkeys

Access the start of these softkeys by pressing

SINGLE MDI DRYRUN SEARCH EDIT TEST MANUAL HOMEAUTO

Access the following functions by pressing or

TL SET LOAD UNLOADSHIFTS

MODE

.

MODE

.

Once a mode has been selected, the basic softkeys are redisplayed.

REMARK The modes can be cancelled individually by PLC programming (see Automatic

Control Function Programming Manuals). In this case, the corresponding

softkeys are not displayed.

3 - 8 en-938822/2

Page 56

Special case of the Compact Panel: Mode Softkeys

Access the first Mode softkeys by pressing the

SINGLE MDI DRYRUN SEARCH EDIT TEST MANUAL HOMEAUTO

MODE

Operator Panel Description

key of the Root softkey bar.

Access the second Mode softkeys by pressing the key (F12) or the Next key

TL SET LOAD UNLOADSHIFTS

Return to the first Mode softkeys by pressing (F12) or the Next key

. . / . . .

. . / . . .

.

.

Return to the Root softkeys by pressing (F1).

3.1.4.4 JOG Softkeys

Access these softkeys by pressing

.1 1 10 100 1000 10000 FREEHANDW .01.001

JOG

.

REMARK The increments can be cancelled individually by PLC programming (see Automatic

Control Function Programming Manuals). In this case, the corresponding

softkeys are not displayed.

Special Case of the Compact Panel: Jog Softkeys

Access the first Jog softkeys by pressing the

Z A B C HANDWYX

Names of the axes declared in P9

JOG

key of the Root softkey bar.

3

The first Jog softkeys contain the names of the first axes (maximum 6) declared in machine parameter P9. They are

used to select the axis to be controlled by the jogs.

In multigroup systems, the axis name is followed by the group number declared in P9:

X

GR1

GR1XGR2ZGR2

GR1

Access the second Jog softkeys by pressing (F12) or the Next key

.1 1 10 100 1000 10000 FREE.01.001

Return to the first Jog softkeys by pressing (F12) or the Next key

HANDW

. . / . . .

. . / . . .

.

.

Z

Y

Return to the Root softkeys by pressing (F1).

en-938822/2 3 - 9

Page 57

3.1.4.5 Tool Softkeys

Access these softkeys by pressing

TOOL

.

TLCOMP

WEAR + L or X R or Z WEAR 0

Special Case of the Compact Panel: Tool Softkeys

Access the Tool softkeys by pressing the

TLCOMP

LR@

WEAR + L or X R or Z WEAR 0

TOOL

key of the Root softkey bar.

The tool softkeys contain the characters L, R and @.

Return to the Root softkeys by pressing (F1).

3.1.4.6 Character Softkeys of the Compact Panel

Use of these softkeys on the compact panel should be exceptional. It is preferable to connect a standard PC keyboard.

Access the first Character softkeys by pressing the

;|JKLOUV#W

SYMBOL

key of the Root softkey bar.

Access the second softkeys by pressing (F12).

()[]<>&:$?

Access the third softkeys by pressing (F12).

"

`'

\ ↑ _{}

|

~

The symbol Î represents a caret.

Return to the first softkeys by pressing (F12). Return to the Root softkeys by pressing (F1).

3 - 10 en-938822/2

Page 58

Operator Panel Description

3.1.5 Modal Data Window

The modal data window displays information concerning the programme being executed:

6

5

4

3

2

1

%20 . 0

N150

H6558 . 2

G40G2

G94G90

G83

M9M3

T12 D12

Sp: 600

S%: 75%

Fp: 1000

F%: 100

7

8

9

10

11

12

13

14

15

16

1 - Tool number

2 - Spindle rotation direction (M3 or M4), spindle off (M5) or

spindle indexing (M19)

3 - Current cycle (G31, G45, G81 to G89)

4 - Programming of movements in absolute (G90) or relative

(G91) dimensions

5 - Programmed interpolation function (G0 to G3)

6 - Current programme

7 - Current block

8 - Active subroutine

9 - Radius offset (G41 or G42) or radius offset cancel (G40)

10 - Feed rate in V/D (G93), in mm/min (G94) or mm/rev (G95)

11 - Programmed coolant (M7, M8 or M7M8) or coolant off (M9)

12 - Tool correction

13 - Programmed spindle speed

14 - Spindle speed override percentage set on the spindle speed

potentiometer

15 - Programmed feed rate

16 - Feed rate override percentage set on the feed rate

potentiometer

3

On certain screens, the modal data window may include different data. This is the case for simulated machining (see

4.6.2) and use of the PROFIL function (see 5.7.2).

en-938822/2 3 - 11

Page 59

3.2 Interactions Between Mode Selections and Display Pages

3.2.1 Neutral Mode

When the CNC is switched on, no mode is active and the "current mode" field of the status window is not displayed:

the CNC is in neutral mode.

The alphanumeric keyboard is inactivated.

3.2.2 Interactions between Modes

When a mode is selected from the Mode softkeys, its name is automatically displayed in the "current mode" field of

the status window (assuming that the selection is authorised by the machine processor).

Two modes cannot be active at the same time:

- when no cycle is in progress (indicator "M02" displayed in the status window), each time a mode is selected, it

replaces the previous selection,

- when a cycle is in progress (indicator "INCYC" displayed in the status window), each time a new mode is selected,

its name is displayed in the "standby mode" field.

When a mode is on standby, it is activated:

- at the end of a cycle for all modes except automatic mode,

- at the end of a block for automatic mode (or at the end of a cycle if the block being executed comprises a canned

machining cycle such as G31 or G81).

3.2.3 Interactions between Modes and Display Pages

When a display page is selected from the basic softkeys, this page is displayed in the main window.

Changing pages returns the CNC to neutral mode in the following cases:

- if the CNC is in edit or origin shift mode (SHIFTS)

- if the CNC is in loading or unloading mode but not in progress

When the system is in edit mode and a new mode (other than homing, loading and unloading) is selected, the "current

position" page is displayed.

Irrrespective of which mode is active, when the:

- edit mode is selected, the active programme is displayed,

- homing mode is selected, the SHIFTS page is displayed,

- loading mode is selected, the "FILE LOADING" menu is displayed,

- unloading mode is selected, the "FILE UNLOADING" menu is displayed unless the CNC is in graphic display mode.

3 - 12 en-938822/2

Page 60

Operator Panel Description

3.3 Available Controls and Indicators

3.3.1 Keyboard Keys

3.3.1.1 Special Features of the 50-Key Panel Keyboard

On the alphanumeric keyboard of the 50-key panel:

- the main character on the key can be accessed directly,

- the character in the top right-hand corner of the key is accessed by pressing the shift key together with the key,

- the character in the bottom right-hand corner of the key is accessed by pressing the control key together with the

key.

3

SHIFT

CTRL

+ key

+ key

S

x off

Accessed by

?

Main character accessed by key alone

Accessed by

Adaptation of the Procedures

The procedures described herein are based on the use of the QWERTY panel.

When using the 50-key panels, these procedures should be adapted by using the shift or control key combinations

where necessary.

Example

The following line of a procedure:

Confirm password removal. ☞

Y

Adapted as follows for use on the 50-key panel:

Confirm password removal. ☞

SHIFT

+

O

ENTER

M

Deleting the dialogue line

line

On 50-key panels, the dialogue line is deleted by the key combination

SHIFT

+

DEL

.

char

3.3.1.2 Special Features of the Compact Panel Keyboard

The compact panel keys are different from those of the other CNC panels. They include keys corresponding to machine

panel functions. In addition to the 12 horizontal function keys, there are four vertical function keys.

For the machine panel keys, five programmable keys are assigned to functions managed by the PLC programme (see

3.3.1.7).

Substitution of Characters Not Available on the Compact Panel

To make a positive answer to a question:

Answer Y(es).

When an action requires the use of the Xoff character,

On the 102-key keyboard, enter the key combination Ctrl + S,

en-938822/2 3 - 13

Page 61

3.3.1.3 Special Keyboard Keys

ESC

F1

F12

CTRL

SHIFT

ENTER

ALL

CAPS

Escape key (QWERTY panel, not used).

Key to access previous softkeys (50-key panel).

Key to access next softkeys (only used for the Mode softkeys which are displayed in two parts).

Control key: access to special characters (Xoff) and, on 50-key panels, to the characters engraved in the

bottom right-hand corner of the keys.

SHIFT key, held depressed to:

- access upper case characters and the second character on certain keys (QWERTY panel),

- access the characters in the top right-hand corner of the keys (50-key panel).

Enter key of the QWERTY panel (equivalent to the Valid key): confirms the dialogue line or selection in a

menu.

Enter key of the 50-key panel: confirms the dialogue line or selection in a menu.

Upper/lower case key (QWERTY panel).

Key used to delete current line (QWERTY panel).

Key used to delete previous character.

ALT

Alt key used on the PCNC (QWERTY panel).

Tab key used on the PCNC (QWERTY panel).

Shift key: hold this key depressed to use the characters engraved in the top right-hand corner of the character

keys and the second function of the programmable function keys (compact panel).

Escape key (compact panel).

Help key: press to display the remaining error messages (compact panel).

Context key, used to:

- Return to the basic softkeys (QWERTY panel)

- Toggle between contexts (50-key panel)

- Return to the Root softkeys (compact panel).

2

Context selection keys: gives access to the contexts defined with MMITool.

Key to access previous softkeys (compact panel).

Key to access next softkeys (compact panel).

3 - 14 en-938822/2

Page 62

3.3.1.4 Special Control keys

Operator Panel Description

Pg Dn

end

Pg Dn

Pg Up

home

Pg Up

Home

End

➞

VALID

Page Down key (equivalent to the software "page down" key): used to display the next part of the page on

screen (QWERTY panel).

PageDown key (equivalent to the "../..." softkey): used to display the next part of the page (50-key panel).

Page Up key (QWERTY panel).

Page Up key (50-key panel).

Start of file key (QWERTY panel, not used).

End of file key (QWERTY panel, not used).

Cursor key used to move up one line.

➞

➞

Cursor key used to move down one line.

Cursor key used to move one character to the right.

➞

Cursor key used to move one character to the left.

Validation key (QWERTY panel, equivalent to the Enter key).

3

HELP

INS/

OVER

line

DEL

char

a

Help key gives access to the other error messages.

Overtype/insert text mode key.

Delete selected character key.

Key to delete the character selected (compact panel).

Insert/overwrite toggle key (compact panel).

Start of file key (compact panel).

End of file key (compact panel).

Page up key (compact panel).

Page down key (compact panel).

en-938822/2 3 - 15

Page 63

3.3.1.5 Mode Selection Keys

MODE

TOOL

JOG

Mode key: used to display the "Mode" softkeys and then exit.

Tool key: used to display the "Tool" softkeys and then exit (See 5.2.2).

JOG key: used to display the "JOG" softkeys and then exit (See 5.1.1).

Block skip: enables block skips "/" (QWERTY panel, See 5.4.3.1).

M01

Optional stop key: enables "M01" optional stops (QWERTY panel, See 5.4.3.1).

3.3.1.6 Reset Key

Reset key (See 5.5.1.8).

3.3.1.7 Machine Panel Function Keys on the Compact Panel

These five keys are specific to the compact panel. They are programmable and can be assigned to functions managed

by the PLC programme.

Rapid jog key: When this key is depressed, the jog keys move the axis selected at high speed.

Negative jog key: When this key is depressed, the jog keys move the axis selected in the negative direction.

Positive jog key: When this key is depressed, the jog keys move the axis selected in the positive direction.

Cycle key: This key starts execution of the active programme or a block in MDI mode.

Feed stop key: This key suspends execution of the active programme.

3 - 16 en-938822/2

Page 64

3.3.2 Softkeys

The softkeys are activated using function keys F2 to F11 located below them.

3.3.2.1 Root Softkeys (Compact Panel)

Compact panel selection keys:

Operator Panel Description

MODE

TOOL

JOG

MODE key: gives access to the first Mode softkeys.

TOOL key: gives access to the Tool softkeys.

JOG key: gives access to the first Jog softkeys.

3.3.2.2 Basic Softkey Functions

Display page selection:

. . / . .

DAT

DIR.

PROG.

INFO.

L / @

AXIS

- Page down (equivalent to the "Pg Dn" key on the keyboard).

- Shifts page (option available by pressing Shift): shift display page (See 4.3).

List of stored programmes (See 4.5).

Programme being executed (See 4.8).

Summary of information on block (See 4.7).

List of programme variables (See 4.9.1) and equivalent addresses (See 4.9.2).

Current point coordinates (See 4.2).

3

TOOLS

BKGND

PLC

I / O

UTIL

List of tool dimensions and wear offsets (See 4.4).

Graphic display (See 4.6), PROCAM (See 5.7.1) and background programme operations (See 5.9).

Machine and PLC data: inputs/outputs (See 4.10).

Access to utilities (See 8.2.2).

en-938822/2 3 - 17

Page 65

3.3.2.3 Mode Softkey Functions

Mode selection:

AUTO

MODE

Automatic mode: execution of part programme with automatic sequencing of blocks (See 5.4.3.5).

SINGLE

MDI

DRYRUN

SEARCH

MODIFY

TEST

MANUAL

HOME

SHIFTS

TL SET

LOAD

Single step mode: execution of part programme block by block (See 5.4.3.3).

Manual Data Input mode: manual input of a block without it being stored (See 5.3).

Dry run mode: execution of part programme in dry run mode (See 5.4.3.4).

Sequence Number Search mode: the programme restarts at block N.. (See 5.5.1.3).

Edit mode: modification of part programme (See 5.4.2).

Test mode: test of part programme under the operating conditions of the machine and system assembly

(See 5.4.2.6).

Manual mode: axes moved using axis jogs or handwheels selected by the PLC (See 5.1.1.2).

Measurement origin setting mode: acquisition of measurement origins by the system (See 5.1.2).

Origin shift mode: entry of origin shifts (DAT1, DAT2 and DAT3) and scaling factor (See 5.2.1).

Automatic tool setting mode: acquisition of tool dimensions by the system (See 5.2.2).

Load mode: loading of part programmes (See 5.4.1) or tool dimensions (See 5.2.2.3) and selection of active

programme (See 5.4.1.2).

UNLOAD

Unload mode: unloading of part programmes or tool dimensions (See 5.6).

3 - 18 en-938822/2

Page 66

3.3.2.4 JOG Softkey Functions

Selection of jog type:

Operator Panel Description

HANDW

Axis jog using handwheel.

.001

.01

.1

1

10

100

1000

10000

Jog in increments of 0.001 to 10,000 µm.

FREE

Continuous axis jog using push-buttons.

3.3.2.5 Tool Softkey Functions

Modification of tool dimensions and wear offsets:

TLCOMP

WEAR +

L or X

R or Z

WEAR 0

Input of tool dimensions via the keyboard (See 5.2.2.2).

Input of tool wear offsets (See 5.2.2.4).

Wear offset on length L (milling) or on the dimension along the X axis (turning).

Wear offset on radius R (milling) or on the dimension along the Z axis (turning).

Wear offset cancel (See 5.2.2.4).

Special Case of the Compact Panel: Functions of the Tool Softkeys

3

The Tool softkeys contain the symbols L, R and @ for entry of tool offsets.

en-938822/2 3 - 19

Page 67

3.4 Special Keyboard Operations

3.4.1 Hardcopy

The contents of the CNC screen can be output on a printer or in a file according to the parameter settings of the CNC.

3.4.1.1 Hardcopy on Printer

This function allows output on a printer at any time of the contents of the CNC screen.

Requirements

Connecting cable connected between the printer and a configured serial port of the CNC (see C.2.4).

On the printer side

Printer configured and ready to receive data (see printer manual).

On the CNC side

CNC on.

Machine parameter P59 (word N0) set for the type of print (see Parameter Manual): black and white print N0=1, printing

with grey levels N0=2, colour print N0=3.

REMARK It is necessary to reboot the system after modifying machine parameter P59.

Image to be hardcopied displayed on the screen.

Actions

On the CNC side

Print screen contents. ☞

CTRL

+

P

The current screen page is stored and the hardcopy indicator is displayed in the status window (See 3.1.3).

The screen page is printed.

REMARK This printing function does not prevent normal operation of the CNC.

Incidents

When a printing fault occurs (printer incorrectly configured, faulty connection, etc.), the hardcopy indicator is replaced

by the hardcopy fault indicator and data transmission is interrupted.

Correct the printing fault.

Display of the hardcopy indicator in place of the hardcopy fault indicator.

The page is printed.

Exit from the procedure

Cancel the hardcopy. ☞

The hardcopy (or hardcopy fault) indicator disappears from the screen.

CTRL

+

C

3 - 20 en-938822/2

Page 68

Operator Panel Description

3.4.1.2 Hardcopy in File

This function outputs all or part of the image displayed on the screen into a bitmap file (HARDCOPY.BMP). This type

of hardcopy requires availability of NUM software tools for PC.

Requirements

Connecting cable connected between the PC serial port and a serial port of the CNC.

On the PC side

Line configured (see PLCTool - Ladder Language Programming Tool manual).

PLCTool running, presence of a group designed to receive the hardcopies and a bitmap file called HARDCOPY.BMP.

On the CNC side

System on.

Machine parameter P59 set for output of the hardcopy into a file (word N0=0) (see Parameter Manual).

3

Machine parameter P112 set to assign the CNC serial line to the PLCTool link (see Parameter Manual).

REMARK It is necessary to reboot the system after modifying the machine parameter

settings.

PLCTool line selected (see Machine Processor Programming in Ladder Language manual).

Image to be hardcopied displayed on the screen.

Actions

On the CNC side

➞

CTRL

or

Select hardcopy. ☞

Display of the full screen selection area and summary of the main functions at the bottom of the area: HARDCOPY.BMP:

(DIM=F1, Sav=CR, Abort=ESC).

Change the selection if required (see table below).

Operations Key

Select reduced area or full screen

Reduced area = 120x80 pixels; full screen = 640x480 pixels ☞

Move the selection: left, right, up, down

☞

Enlarge the selection: left, right, up, down

☞

Cancel hardcopy

☞

End

SHIFT

ESC

Home

or

➞

or ➞ or

+

➞

or ➞ or

+

P

➞

➞

➞

or

Save the selection. ☞

REMARK The hardcopy is saved until it is retrieved via the PLCTool link.

en-938822/2 3 - 21

Page 69

On the PC side

Select the HARDCOPY.BMP target file.

Select the direction of transfer by the command NC -> PC.

Display of the dialogue box Download PC -> NC-PLC.

The hardcopy is downloaded by action on the Transmit key.

If the file already contains data, a message requests confirmation of overwrite of the old data.

If overwrite is accepted, the file is downloaded. Duplicate the file created by a copy/paste operation to avoid overwriting

it by the next file sent.

3.4.2 Keyboard Sound

The operator panel keyboard beeps each time a key is pressed.

This sound function can be activated or deactivated.

Actions

Activate or deactivate the keyboard sound function. ☞

CTRL

+

G

3.4.3 Switching between Operator Panels

On CNCs with two to four panels, only one panel is active at a time (at power on, it is panel 1).

A switch can be made to another panel.

To prevent a panel from being accidently deactivated from the inactive panel, the active panel can be locked by a

password.

Requirements

Active panel indicated by panel number indicator (KBD1 or KBD2) in the status window (See 3.1.3).

Actions

Locking the active panel

Lock the active panel. ☞

Enter a password (four characters maximum). ☞

The active panel is locked and can only be deactivated by using the password.

Switching to an inactive panel

Request switchover at the inactive panel. ☞

CTRL

CTRL

+

+

I

I

Enter the password (if any). ☞

The switchover is executed. The panel number indicator is displayed in the status window of the newly activated panel

and disappears from the other. The newly activated panel «beeps».

3 - 22 en-938822/2

Page 70

Notes

The password can be changed each time the active panel is locked.

Switchover cannot take place if dialogue is in progress on the active panel.

Incidents

Error in password entered on the inactive panel.

Operator Panel Description

Repeat the switchover operations on the inactive panel.

3.4.4 Switching between CNCs

On multi-CNC (two to four) systems, it must be possible to interrogate any one of the CNCs from the single operator

panel.

Requirements

Active CNC indicated by the CNC number indicator (CN1 to CN4) in the status window (See 3.1.3).

Actions

Request CNC switching. ☞

Enter the number of the CNC to be activated. ☞

The switchover is executed. The active CNC number indicator is displayed in the status window of the operator panel

and the panel beeps.

Notes

When the system is switched on, there is no password.

Switchover cannot take place if dialogue is in progress on the active CNC.

Incidents

Incorrect CNC number (exceeding the number of CNCs)

CTRL

+

I

3

Repeat the switchover operations.

en-938822/2 3 - 23

Page 71

3.5 Use of a 102/105-Key Keyboard with the Compact Panel

A standard 102/105-key PC keyboard can be connected to the front of the compact panel (see 3.1.1.4) after removing

the dust cap (or to the rear if the DIN connector was moved to the rear of the panel), for instance to enter or edit part

programmes.

This keyboard should also be used for accessing the utilities. Press Ctrl + S to exit from the utilities.

!

CAUTION

A keyboard should only be connected exceptionally to the front panel, because removal of

the dust cap breaks the panel seal. Move the connector to the rear of the panel if the

keyboard is to remain permanently connected.

Three types of standard 102/105-key PC keyboards can be connected

AZERTY French keyboard

Specify the use of an AZERTY keyboard on the keyboard. ☞

The configuration with AZERTY keyboard is saved in the system memory.

QWERTY English keyboard

Specify the use of a QWERTY keyboard on the keyboard. ☞

The configuration with QWERTY keyboard is saved in the system memory.

QWERTZ German keyboard

Specify the use of a QWERTZ keyboard on the keyboard. ☞

The configuration with QWERTZ keyboard is saved in the system memory.

!

CAUTION

The PC keyboard must have the following characteristics:

- Standard keyboard with 102 or 105 keys (excluding Compaq),

- Maximum power consumption: 150 mA,

- 5-contact DIN connector.

Arrêt

Défil

Scroll

Scroll

Lock

Lock

+

+

+

1

0

2

3 - 24 en-938822/2

Page 72

Display System Utilization

4 Display System Utilization

4.1 Inch/Metric Unit Conventions 4 - 3

4.2 Display of Tool Position 4 - 3

4.3 Display of Shifts 4 - 5

4.4 Display of Tool Dimensions, Corrections and Wear Offsets 4 - 6

4.5 Display of Programmes 4 - 9

4.5.1 Access to the List of Programmes 4 - 10

4.5.2 Access to the Listing of a Programme 4 - 11

4.5.3 Access to a Programme Listing at a Given

Sequence 4 - 12

4.6 Display of a Programme in Graphic Mode 4 - 13

4.6.1 Selection of Graphic Display Parameters

and Part Contour Trace 4 - 14

4.6.1.1 Selection of Graphic Display Parameters 4 - 14

4.6.1.2 Part Contour Trace 4 - 16

4.6.1.3 Scaling of Display Planes 4 - 18

4.6.2 Machining Simulation 4 - 19

4.6.3 Machining Simulation by Material Removal 4 - 21

4.6.4 Defining the Blank 4 - 24

4.6.4.1 Creating the Blank 4 - 25

4.6.4.2 Editing the Blank 4 - 26

4.6.4.3 Defining the Blank 4 - 28

4.6.5 Defining the Tool Geometries 4 - 30

4.6.5.1 Editing a Tool Geometry File 4 - 31

4.6.5.2 Defining a Tool Geometry Step by Step 4 - 35

4.6.5.3 Defining a Tool Geometry from Typical

Forms 4 - 36

4.6.5.4 Definition of the Tool Geometry Unit 4 - 39

4.6.6 Trace during Cutting 4 - 40

4.7 Display of Active Data 4 - 43

4.8 Display of Programme-Being Executed 4 - 45

4.9 Display of Programme Variables and Equivalent Address Table 4 - 47

4.9.1 Display of Programme Variables 4 - 47

4.9.2 Display of Equivalent Address Table 4 - 48

4.10 Display of Inputs/Outputs 4 - 49