Page 1

NUM

1020/1040/1060

SUPPLEMENTARY

PROGRAMMING

MANUAL

0101938872/2

06-97 en-938872/2

Page 2

Despite the care taken in the preparation of this document, NUM cannot guarantee the accuracy of the information it contains and cannot be held

responsible for any errors therein, nor for any damage which might result from the use or application of the document.

The physical, technical and functional characteristics of the hardware and software products and the services described in this document are subject

to modification and cannot under any circumstances be regarded as contractual.

The programming examples described in this manual are intended for guidance only. They must be specially adapted before they can be used in

programs with an industrial application, according to the automated system used and the safety levels required.

© Copyright NUM 1997.

All rights reserved. No part of this manual may be copied or reproduced in any form or by any means whatsoever, including photographic or magnetic

processes. The transcription on an electronic machine of all or part of the contents is forbidden.

© Copyright NUM 1997 software NUM 1000 line.

This software is the property of NUM. Each memorized copy of this software sold confers upon the purchaser a non-exclusive licence strictly limited

to the use of the said copy. No copy or other form of duplication of this product is authorized.

2 en-938872/2

Page 3

Table of Contents

Table of Contents

1 Structured Programming 1 - 1

1.1 General 1 - 3

1.2 Structured Programming Commands 1 - 6

1.3 Example of Structured Programming 1 - 13

2 Reading the Programme Status Access Symbols 2 - 1

2.1 General 2 - 3

2.2 Symbols for Accessing the Data of the

Current Block 2 - 3

2.3 Symbols Accessing the Data of the

Previous Block 2 - 11

3 Storing Data in Variables L900 to L951 3 - 1

3.1 General 3 - 3

3.2 Storing F, S, T, H and N in Variables L900

to L925 3 - 3

3.3 Storing EA to EZ in Variables L926 to L951 3 - 4

3.4 Symbolic Addressing of Variables L900

to L951 3 - 4

4 Creating and Managing Symbolic Variable Tables 4 - 1

4.1 Creating Symbolic Variable Tables 4 - 3

4.2 Symbolic Variable Management Commands 4 - 8

5 Creating Subroutines Called by G Functions 5 - 1

5.1 Calling Subroutines by G Functions 5 - 3

5.2 Inhibiting Display of Subroutines Being

Executed 5 - 5

5.3 Programming Examples 5 - 6

6 Polynomial Interpolation 6 - 1

6.1 General 6 - 3

6.2 Programming Segmented Polynomial

Interpolation 6 - 3

6.3 Programming Smooth Polynomial

Interpolation 6 - 7

7 Coordinate Conversions 7 - 1

7.1 General 7 - 3

7.2 Using the Coordinate Conversion Matrix 7 - 3

7.3 Application of Coordinate Conversion 7 - 5

7.4 Example of Application Subroutine 7 - 6

en-938872/2 3

Page 4

8 RTCP Function 8 - 1

8.1 General 8 - 3

8.2 Using the RTCP Function 8 - 4

8.3 Description of Movements 8 - 6

8.4 Processing Related to the RTCP Function 8 - 9

8.5 Use in JOG and INTERV Modes 8 - 11

8.6 Restrictions and Conditions of Use 8 - 11

9 N/M AUTO Function 9 - 1

9.1 General 9 - 3

9.2 Using the N/M AUTO Function 9 - 7

9.3 Procedure After Enabling the N/M AUTO

Function 9 - 8

9.4 Stopping and Restarting in N/M AUTO Mode 9 - 11

9.5 Checks Included in N/M AUTO 9 - 12

Appendix A Table of Structured Programming Commands A - 1

Appendix B Table of Symbolic Variable Management Commands B - 1

Appendix C Table of Programme Status Access Symbols C - 1

C.1 Addressing G and M Functions C - 3

C.2 Addressing a List of Bits C - 3

C.3 Addressing a Value C - 3

C.4 Addressing a List of Values C - 4

Appendix D Table of Symbols Stored in Variables L900 to L951 D - 1

D.1 Symbols Stored in Variables L900 to L925 D - 3

D.2 Symbols Stored in Variables L926 to L951 D - 3

4 en-938872/2

Page 5

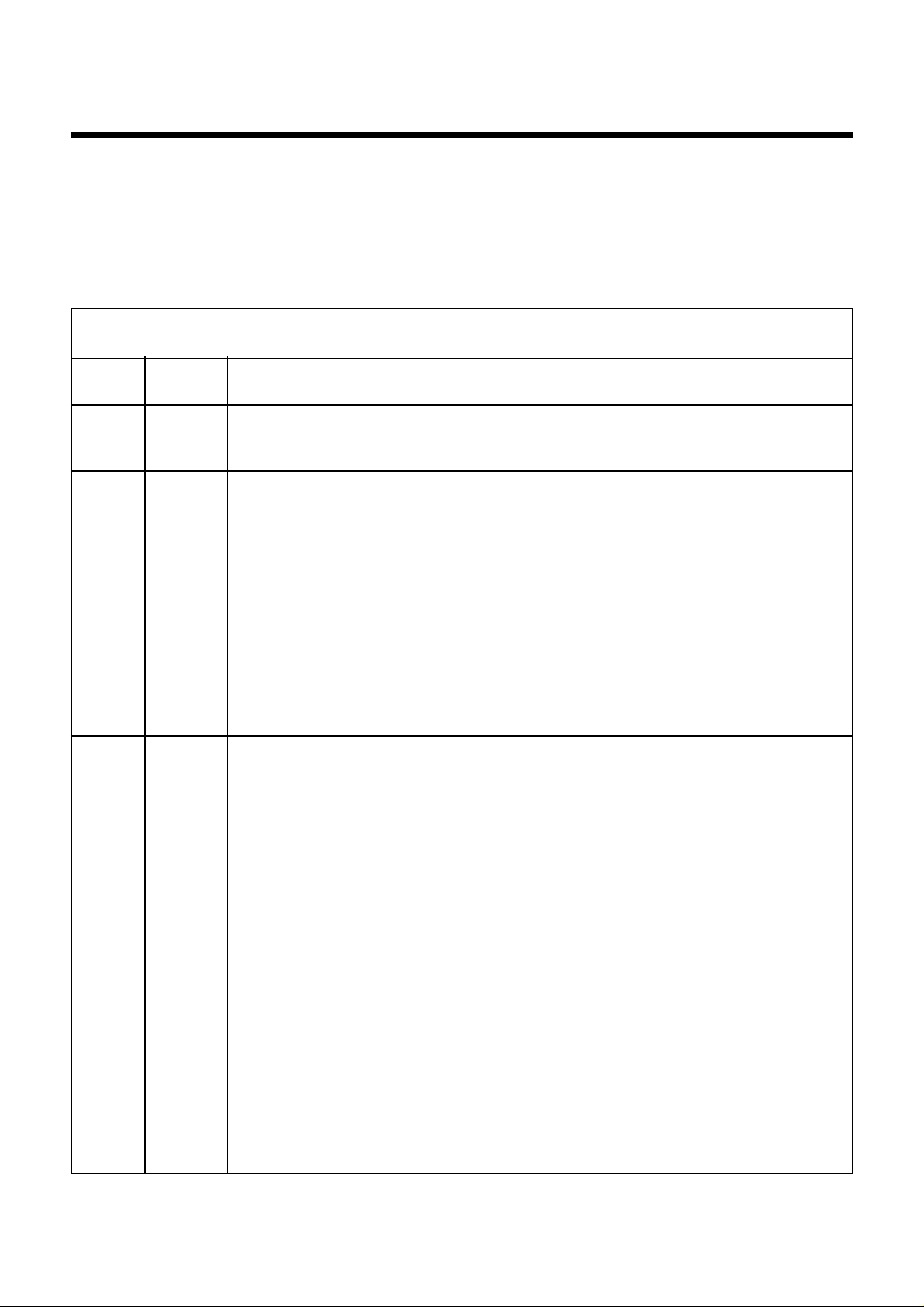

Record of Revisions

DOCUMENT REVISIONS

Date Revision Reason for revisions

02-93 0 Document creation (conforming to software at index D)

01-95 1 Conforming to software at index G

Additions to the manual

- RTCP function

- N/M AUTO function

Table of Contents

Inclusion of changes

Software at index E:

- Addressing of the calling function by [.RG80] in a subroutine called by a G function

- Addressing by [.IRDI(i)] defining the origin of angular offsets

Software at index F:

- Coordinate conversions

06-97 2 Conforming to software at index K

Additions to the manual:

- Smooth polynomial interpolation

- For addressing by [.IBX(i)], [.IRX(i)] and [.IBI(i)], [.IRI(i)], added indexes 10, 11, 4

and 5 related to G21 and G22.

Inclusion of changes

Software at indexes H and J:

- Update of N/M AUTO function

en-938872/2 5

Page 6

6 en-938872/2

Page 7

NUM 1020/1040/1060 Documentation Structure

NUM

T

PROGRAMMING

MANUAL

Volume 1

Volume 2

938820

NUM

AUTOMATIC

CONTROL

FUNCTION

PROGRAMMING

MANUAL LADDER

LANGUAGE

938846

NUM

SYNCHRONISATION

OF TWO SPINDLES

938854

User Documents

These documents are designed for use of the CNC.

Forword

Foreword

NUM

M/W

OPERATOR

MANUAL

938821

OPERATOR

Integrator Documents

NUM

1060

INSTALLATION

AND

COMMISSIONING

MANUAL

938816

INSTALLATION

COMMISSIONING

NUM

T

MANUAL

938822

NUM

M

PROGRAMMING

MANUAL

Volume 1

Volume 2

938819

These documents are designed for setting up the CNC on a machine.

NUM

1020/1040

AND

MANUAL

938938

NUM

PARAMETER

MANUAL

938818

NUM

G

CYLINDRICAL

GRINDING

PROGRAMMING

MANUAL

938930

NUM

DYNAMIC

OPERATORS

938871

NUM

PROCAM

DESCRIPTION

LANGUAGE

938904

NUM

G

CYLINDRICAL

GRINDING

COMMISSIONING

MANUAL

938929

NUM

H/HG

GEAR

CUTTING AND

GRINDING

MANUAL

938932

NUM

GS

SURFACE

GRINDING

MANUAL

938945

en-938872/2 7

Page 8

Special Programming Documents

NUM

PROFIL

FUNCTION

OPERATING

MANUAL

938937

These documents concern special numerical control programming applications.

NUM

SUPPLEMENTARY

PROGRAMMING

MANUAL

938872

NUM

GS

PROCAM GRIND

INTERACTIVE

PROGRAMMING

938953

NUM

M

PROCAM MILL

INTERACTIVE

PROGRAMMING

MANUAL

938873

NUM

G

PROCAM GRIND

INTERACTIVE

PROGRAMMING

938931

NUM

T

PROCAM TURN

INTERACTIVE

PROGRAMMING

MANUAL

938874

NUM

DUPLICATED

AND

SYNCHRONISED

AXES

938875

8 en-938872/2

Page 9

Supplementary Programming Manual

Manual Contents

Presentation of the commands used for structured programming of branches and

loops.

CHAPTER 1

STRUCTURED

PROGRAMMING

Forword

CHAPTER 2

READING THE

PROGRAMME

STATUS ACCESS

SYMBOLS

CHAPTER 3

STORING

DATA IN

VARIABLES

L900 TO L951

Presentation of the symbols giving visibility into the programmed functions and

programme context during call of a cycle by a G function.

How to store values related to the arguments or functions programmed in variables

L900 to L951 when calling a cycle by a G function.

en-938872/2 9

Page 10

CHAPTER 4

CREATING AND

MANAGING

SYMBOLIC

VARIABLE TABLES

CHAPTER 5

CREATING

SUBROUTINES

CALLED BY

G FUNCTIONS

How to create and manage symbolic variable tables for storing functions and cutting

paths.

How to create subroutines called by G functions.

How to specify tool paths by polynomials.

CHAPTER 6

POLYNOMIAL

INTERPOLATION

CHAPTER 7

COORDINATE

CONVERSIONS

10 en-938872/2

Coordinate conversions using a square matrix.

Page 11

CHAPTER 8

RTCP

FUNCTION

Forword

Possibility of controlling the movements of a machine to position the tool with respect

to the part and pivot it around its centre.

Possibility of controlling the N/M AUTO axes while the other machine axes follow a

programmed path.

CHAPTER 9

N/M AUTO

FUNCTION

APPENDIX A

TABLE OF

STRUCTURED

PROGRAMMING

COMMANDS

APPENDIX B

Presents the structured programming commands in table form.

Presents the symbolic variable management commands in table form.

TABLE OF

SYMBOLIC

VARIABLE

MANAGEMENT

COMMANDS

en-938872/2 11

Page 12

APPENDIX C

TABLE OF

PROGRAMME

STATUS ACCESS

SYMBOLS

APPENDIX D

TABLE OF

SYMBOLS

STORED IN

VARIABLES

L900 TO L951

Presents the programme status access symbols in table form:

- G function addressing,

- M function addressing,

- addressing a list of bits,

- addressing a value,

- addressing a list of values.

Presents lists of symbols stores in variables L900 to L951 in table form.

- Symbols stored in variables L900 to L925.

- Symbols stored in variables L926 to L951.

12 en-938872/2

Page 13

Using the Supplementary Programming Manual

Syntax Conventions

The command lines (blocks) used in programming include commands, symbols,

variables, functions and/or arguments.

A particular syntax is used for each of the elements described herein. The applicable

syntax rules describe how to write the programme blocks.

Certain syntaxes are given on one or more lines. Writing is simplified by use of the

following conventions:

- the functionality(ies) to which the syntax relates is (are) highlighted by the use of

bold face characters,

- «..» or lower case letters after one or more capital letters, addresses or signs

replace a numerical value (e.g. N..),

- the ellipsis «...» replaces a character or address string similar to that preceding it

in the block (e.g. [Symb1]/[Symb2]...),

- «xx» after one or more address letters replaces alphanumeric characters (e.g.

[.IBxx(i)]),

- «xxx» after an address letter replaces numerical values (e.g. Gxxx).

Forword

Examples

Syntax for creating a symbolic variable table

P.BUILD [TAB(7,NB)] H.. N.. +n N..+n

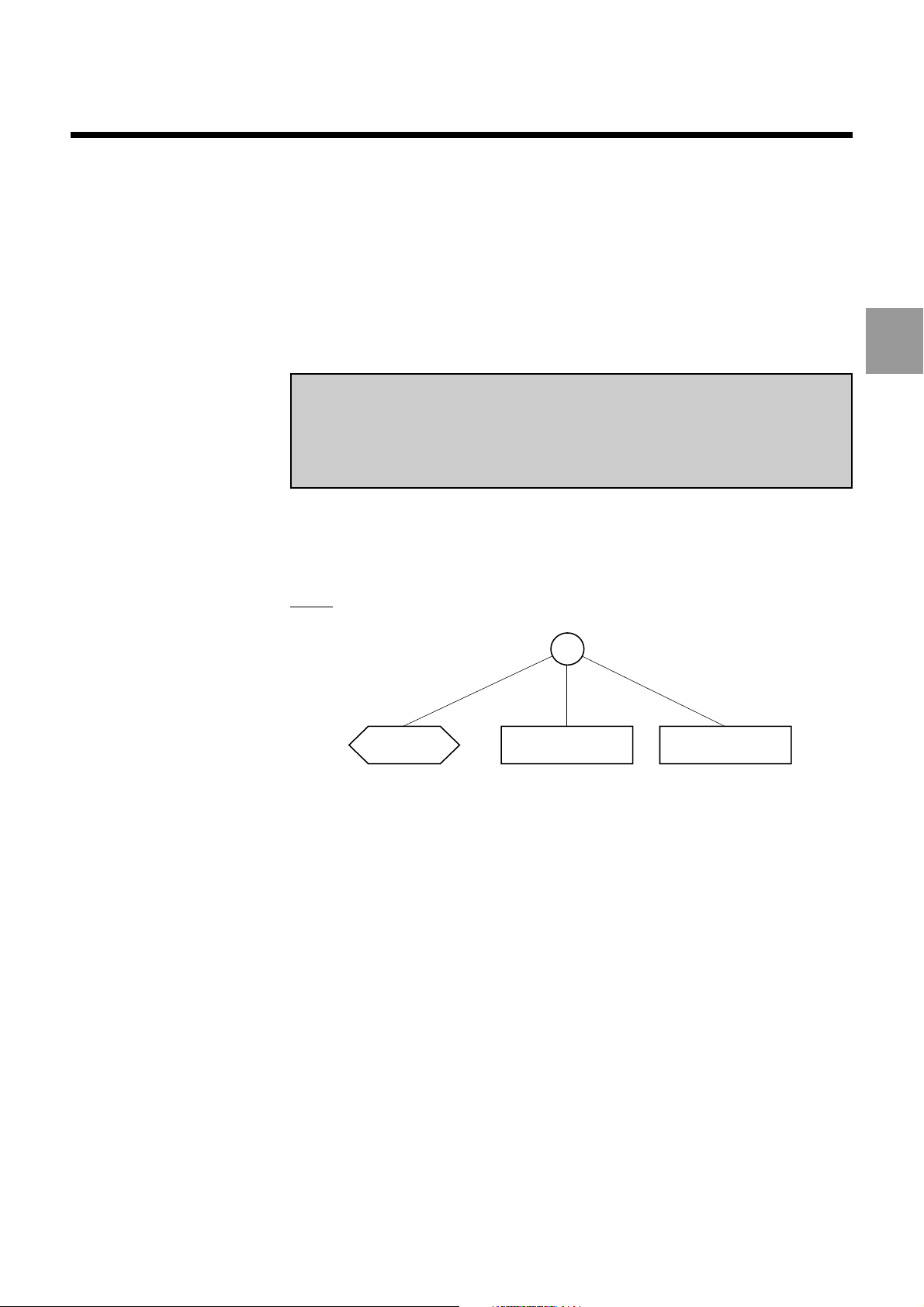

Syntax of a «repeat until» loop and its graphic representation

REPEAT

(instructions)

UNTIL (condition)

Repeat

Instructions

Until

condition

en-938872/2 13

Page 14

Index

Questionnaire

Agencies

The index at the end of the volume gives access to information by keywords.

To help us improve the quality of our documentation, we request you to return the

questionnaire at the end of the volume.

The list of NUM agencies is given at the end of the volume.

14 en-938872/2

Page 15

Structured Programming

1 Structured Programming

1.1 General 1 - 3

1.1.1 Commands Used in Structured Sequences 1 - 3

1.1.2 General Syntax Rules 1 - 3

1.1.3 Nesting and Branches 1 - 5

1.2 Structured Programming Commands 1 - 6

1.2.1 Condition Graph 1 - 6

1.2.2 Instruction Execution Conditions 1 - 7

1.2.3 REPEAT UNTIL Loops 1 - 8

1.2.4 WHILE Loops 1 - 9

1.2.5 Loops with Control Variable 1 - 10

1.2.6 Exiting the Loop 1 - 12

1.3 Example of Structured Programming 1 - 13

1

en-938872/2 1 - 1

Page 16

1 - 2 en-938872/2

Page 17

1.1 General

Structured Programming

The system provides the possibility of programming structured branches and loops,

making the programmes easier to read and simplifying the programming of complex

part programmes.

The programming tools described in this chapter are used to create subroutines

called by G functions (see Chapter 5).

A structured sequence always begins and ends with keywords.

It begins with one of the following keywords:

IF

REPEAT

WHILE

FOR

1

It ends with:

ENDI for IF

UNTIL for REPEAT

ENDW for WHILE

ENDF for FOR

The word ELSE can be interposed between the words IF and ENDI.

1.1.1 Commands Used in Structured Sequences

- Conditional execution of instructions: IF, THEN, ELSE, ENDI

- Repeat until loops: REPEAT, UNTIL

- While loops: WHILE, DO, ENDW

- Loops with control variables: FOR, TO, DOWNTO, BY, DO, ENDF

- Exit from a loop: EXIT

1.1.2 General Syntax Rules

The words IF, REPEAT, WHILE, FOR, ENDI, UNTIL, ENDW and ENDF must be the

first words in a block (no sequence number).

The words IF, REPEAT, THEN, ELSE, UNTIL, WHILE, DO and DOWNTO must

always be followed by a space, e.g.:

WHILEL0 <3 is not recognised by the system. The required syntax is WHILE L0 <3.

The words DO and THEN must immediately follow the condition. Alternately, if these

two words are not located on the same line as the words IF, WHILE and FOR, they

must be the first words on the next line.

en-938872/2 1 - 3

Page 18

Blocks with sequence numbers (N..) are allowed in loops.

Blocks beginning with the words ENDI, ENDW, ENDF, EXIT or UNTIL must not

include ISO programming functions.

One of words DO, THEN or ELSE can be followed by ISO programming functions in

a same block.

Example:

WHILE L1 < 3 DO G91 X12

or

WHILE L1 < 3

DO G91 X12

The following sequence is refused:

WHILE L0 < 3 G91 X10

DO

Not allowed in a

conditional instruction

1 - 4 en-938872/2

Page 19

1.1.3 Nesting and Branches

Structured Programming

Nesting

Fifteen structured nesting levels are possible independently of subroutine calls by

function G77 ...

Example:

First nesting level Second nesting level Third nesting level

IF

IF

REPEAT

UNTIL

ENDI

ENDI

Branches

Programming of a conditional or unconditional branch by G79 ... is allowed in a

structured sequence, but must branch to the lowest nesting level of the current

programme or subroutine.

Example:

1

%1 %2

IF G79 N100

WHILE REPEAT

G79 N100

good

IF

G77 H2 G79 N100

G79 N50

G79 N30

bad

bad

G79 N50

ENDI

N30 N50

ENDW UNTIL

N50 N100

ENDI

N100

M02

good

good

bad

en-938872/2 1 - 5

Page 20

1.2 Structured Programming Commands

1.2.1 Condition Graph

A condition must follow one of words IF, WHILE or UNTIL and must be located in the

same block. If the block contains limits and a possible increment, they must follow

the word FOR.

Condition Graph

<

>

Parameters

Variables

Variables: All the variables used in parametric programming:

L variables, E parameters and symbolic variables.

Expression: Sequence of parameters and immediate values connected by symbols

+, -, *, /, !, & (see Chapter 6 of the Programming Manual). The operations

are calculated in sequence from left to right.

=

(Expression)

and

or

1 - 6 en-938872/2

Page 21

1.2.2 Instruction Execution Conditions

Structured Programming

Syntax

IF(condition) THEN

(instructions 1)

ELSE

(instructions 2)

ENDI

If the condition is true, «instructions 1» are executed. Else, «instructions 2» are

executed.

The word ELSE is optional.

Graph

IF

Condition

THEN

instructions 1

ELSE

instructions 2

1

Example

IF E70000> 100 AND E70000 <200 THEN

G77 H100

ELSE

G77 H500

ENDI

The word THEN may be programmed at the beginning of the next block and followed

by the functions to be executed.

Example:

IF L4 < 8

THEN L6 = L2+1 XL6

ENDI

en-938872/2 1 - 7

Page 22

1.2.3 REPEAT UNTIL Loops

Syntax

The instructions are executed repetitively until the condition becomes true.

Even if the condition is true at the beginning, the instructions are executed once.

Graph

Example

Wait for a correct answer

REPEAT

(instructions)

UNTIL (condition)

Repeat

Untilinstructions

REPEAT

$ EXIT FROM THE PROGRAMME (Y/N) ?

[ANSWER]= $

UNTIL [ANSWER] = 14 OR [ANSWER] = 25

The answer «Y» returns the value 25

and the answer «N» returns the value

14 (ranks of the letters Y and N in the

alphabet)

1 - 8 en-938872/2

Page 23

1.2.4 WHILE Loops

Structured Programming

Syntax

WHILE (condition) DO

(instructions)

ENDW

The instructions are executed while the condition remains true. Unlike REPEAT

UNTIL loops, the instructions are not executed if the condition is false at the

beginning.

Graph

While

condition

The word DO may be programmed at the beginning of the next block and followed

by the functions to be executed.

Example:

instructions

1

WHILE (condition)

DO XL6

ENDW

en-938872/2 1 - 9

Page 24

1.2.5 Loops with Control Variable

Syntax

FOR (variable) = (expression 1) TO/DOWNTO (expression 2) BY (value) DO

(instructions)

ENDF

The instructions are executed for «variable = expression 1». Then «variable» is

incremented (TO) or decremented (DOWNTO) by «value» before the «instructions»

are executed again, and the process is continued until «variable» is equal to

«expression 2».

The word «BY» is optional.

Graph

Variable = expression 1

to expression 2

by ± value

For

instructions

1 - 10 en-938872/2

The variable can be:

- an L programme variable,

- a symbolic variable,

- a parameter E80000, E81000 or E82000 (be careful about stopping computations

for L100 to L199, Exxxxx and the symbolic variables).

The expressions are positive or negative integers. The system rounds them off (down

to 0.5 and up above 0.5).

Page 25

Structured Programming

With TO, the loop continues to be executed as long the current value of the variable

is less than or equal to the final value (incrementing of the variable).

With DOWNTO, the loop continues to be executed as long the current value is higher

than or equal to the final value (decrementing of the variable).

The value of BY is incremented or decremented from the variable each cycle (the

default value of Y is equal to 1).

BY must always have a positive value. If the value of BY is negative, functions TO

and DOWNTO are reversed.

Example

Resetting the tool data

FOR L1=1 TO 20

DO

L2=56000+L1

EL2=0

ENDF

1

en-938872/2 1 - 11

Page 26

1.2.6 Exiting the Loop

Syntax

The EXIT instruction is used to exit from an iteration loop (FOR, WHILE or REPEAT)

and go to the next higher nesting level, ignoring any subsequent IF functions.

The word EXIT is used only in IF loops.

Example

Current

loop

EXIT

REPEAT

(instructions)

IF (condition) THEN

(instructions)

ELSE

EXIT

ENDI

UNTIL (condition)

(continued)

WHILE (condition) DO

REPEAT

IF (condition) THEN

(instructions)

IF (condition) THEN

Current

loop

EXIT

ENDI

(instructions)

ENDI

UNTIL (condition)

(instructions)

ENDW

1 - 12 en-938872/2

Page 27

1.3 Example of Structured Programming

L10

L11

L1

Y

L0

Pattern

start point

X

Hole drilling pattern

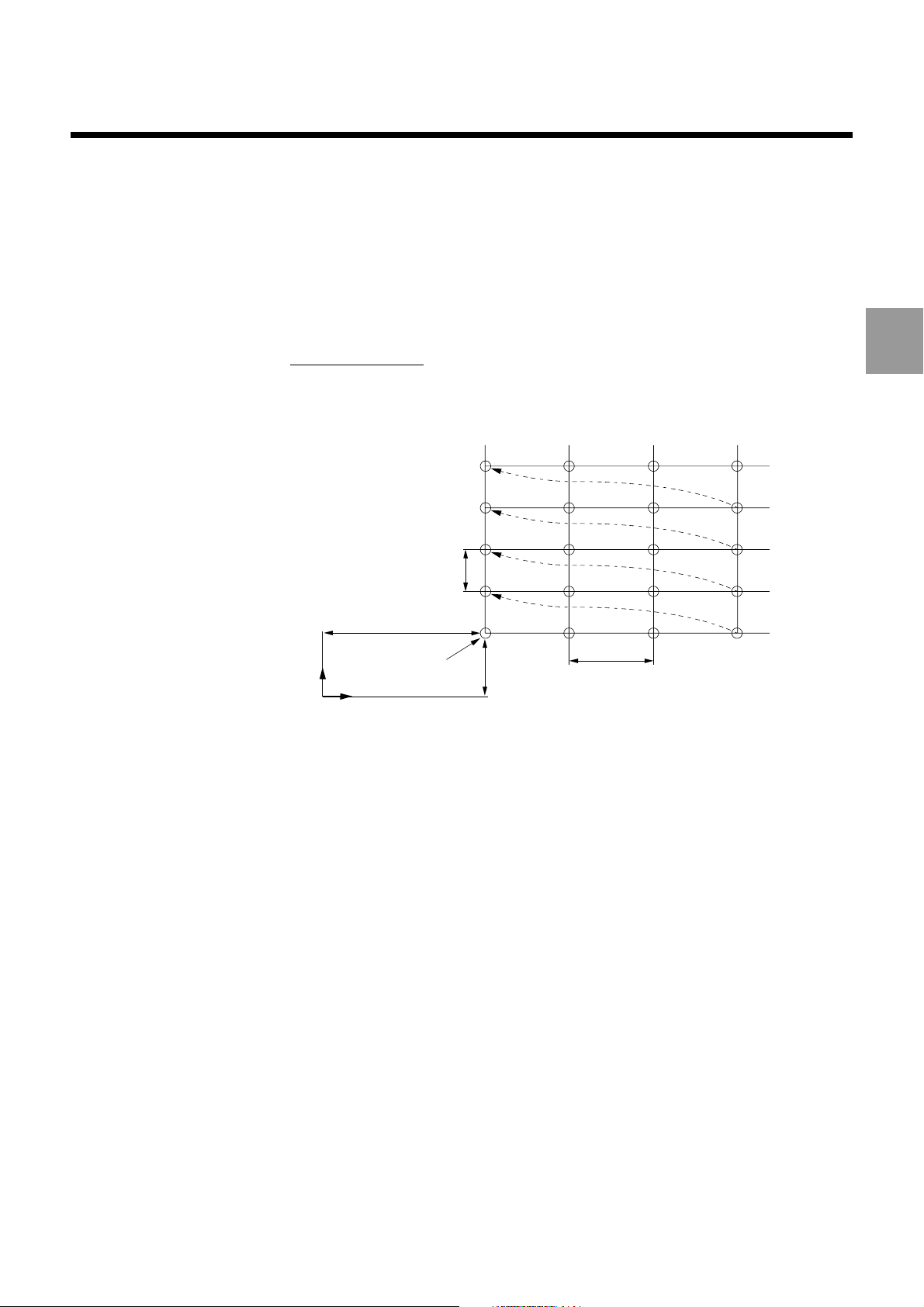

L2 = number of holes in X

L3 = number of holes in Y

Structured Programming

1

en-938872/2 1 - 13

Page 28

%20

$ X START:

L0=$

$ Y START:

L1=$

$ X STEP:

L10=$

$ Y STEP:

L11=$

L4=0

WHILE L4 <> 25 DO

Test for answer yes: Y

REPEAT $ NUMBER OF POINTS IN X:

L2=$

UNTIL L2>0

Test for number of columns greater

than 0

REPEAT $ NUMBER OF POINTS IN Y:

L3=$

UNTIL L3>0

Test for number of rows greater than 0

REPEAT $ PATTERN OF POINTS IN X:

$=L2

$+ /Y:

$=L3

$+ OK (Y/N) :

L4=$

UNTIL L4=14 OR L4=25

Wait for answer: N (no) or Y (yes)

ENDW

$

N.. G00 G52 XO Z0

N.. T1 D1 M06

N..

FOR L5=1 TO L3 DO

Loop on rows

$ ROW POSITION:

$=L5

XL0 L6=L5-1

L11+L1 YL6

*

G00 Z0

FOR L4=1 TO L2 DO

Loop on columns

$ DRILL THE ROW POINT:

$=L5

$+COLUMN:

$=L4

L6=L4-1*L10+L0 XL6

G01 Z-10 F50

G00 Z0

ENDF

ENDF

N..

M02

1 - 14 en-938872/2

Page 29

Reading the Programme Status Access Symbols

2 Reading the Programme Status Access Symbols

2.1 General 2 - 3

2.2 Symbols for Accessing the Data of the Current Block 2 - 3

2.2.1 Symbols Addressing Boolean Values 2 - 3

2.2.1.1 Addressing G Functions 2 - 4

2.2.1.2 Addressing of M Functions 2 - 4

2.2.1.3 Addressing a List of Bits 2 - 6

2.2.2 Symbols Addressing Numerical Values 2 - 8

2.2.2.1 Addressing a Value 2 - 8

2.2.2.2 Addressing a List of Values 2 - 9

2.3 Symbols Accessing the Data of the Previous Block 2 - 11

2

en-938872/2 2 - 1

Page 30

2 - 2 en-938872/2

Page 31

2.1 General

Reading the Programme Status Access Symbols

The programming tools described in this chapter are required for creating subroutines

called by G functions (see Chapter 5).

The programme status access symbols give visibility into the functions programmed

in a block used to call a machining cycle by a G function. They also give information

on the part programme context when the call is made.

These symbols are used to read the modal data in the current block.

These read-only symbols are accessible by parametric programming.

These symbols can be:

- symbols to access the data in the current block,

- symbols to access the data in the previous block.

Each symbol addresses a data item or list of data items with the form of a one-

dimensional array or table.

2.2 Symbols for Accessing the Data of the Current Block

The symbols can be:

- symbols addressing Boolean values,

- symbols addressing numerical values.

General Syntax

Variable = [•symbol(i)]

Variable L programme variable, symbolic variable [symb], E

parameter.

2

[•symbol(i)] Symbol between square brackets, preceded by a

decimal point, possibly followed by an index (i).

2.2.1 Symbols Addressing Boolean Values

The symbols addressing Boolean values associated with programmed functions are

used to determine whether the functions are active or not.

The Boolean values are defined by 0 or 1.

en-938872/2 2 - 3

Page 32

2.2.1.1 Addressing G Functions

[•BGxx] G function addressing.

The symbol [•BGxx] is used to determine whether the G functions specified by xx are

enabled or inhibited, e.g.:

[•BGxx]=0: function Gxx inhibited

[•BGxx]=1: function Gxx enabled

List of G Functions

[•BG00] [•BG01] [•BG02] [•BG03] [•BG17] [•BG18] [•BG19]

[•BG20] [•BG21] [•BG22] [•BG29] [•BG40] [•BG41] [•BG42]

[•BG70] [•BG71] [•BG80] [•BG81] [•BG82] [•BG83] [•BG84]

[•BG85] [•BG86] [•BG87] [•BG88] [•BG89] [•BG90] [•BG91]

[•BG93] [•BG94] [•BG95] [•BG96] [•BG97]

2.2.1.2 Addressing of M Functions

[•BMxx] M functions addressing.

The symbol [•BMxx] is used to determine whether the M functions specified by xx are

enabled or inhibited, e.g.:

[•BMxx]=0: function Mxx inhibited

[•BMxx]=1: function Mxx enabled

2 - 4 en-938872/2

List of M Functions

[•BM03] [•BM04] [•BM05] [•BM07] [•BM08] [•BM09] [•BM10] [•BM11]

[•BM19] [•BM40] [•BM41] [•BM42] [•BM43] [•BM44] [•BM45] [•BM48]

[•BM49] [•BM62] [•BM63] [•BM64] [•BM65] [•BM66] [•BM67] [•BM68]

[•BM69] [•BM997] [•BM998] [•BM999]

Page 33

Reading the Programme Status Access Symbols

Example

%100

N10 G00 G52 Z0 G71

N..

N40 G97 S1000 M03 M41

N50 M60 G77 H9000

N..

N350 M02

%9000

VAR

[GPLAN] [MGAMME] [MSENS] [GINCH] [GABS]

[XRETOUR] [YRETOUR] [ZRETOUR]

ENDV

Tool check subroutine call

2

$ CONTEXT SAVE

N10 [GPLAN]=17

[GPLAN]=18

[GPLAN]=19

N20 [MGAMME]=40

[MGAMME]=41

N30 [MSENS]=03

[MSENS]=04

[MENS]=05

N40 [GINCH]=70

[GINCH]=71

N50 [GABS]=90

[GABS]=91

[XRETOUR]=E70000

[YRETOUR]=E71000

[ZRETOUR]=E72000

N60 G90 G70 G00 G52 Z0

N70 G52 X100 Y100 M05

N80 G52 G10 Z-500

N90 G52 Z0

N100 G52 Z [ZRETOUR]

N110 G52 X [XRETOUR]

N120 G52 Y [YRETOUR]

G[GPLAN] M[MGAMME]

M[MSENS] G[GINCH] G[GABS]

[•BG17]

*

[•BG18]+[GPLAN]

*

[•BG19]+[GPLAN]

*

[•BM40]

*

[•BM41]+[MGAMME]

*

[•BM03]

*

[•BM04]+[MSENS]

*

[•BM05]+[MSENS]

*

[•BG70]

*

[•BG71]+[GINCH]

*

[•BG90]

*

[•BG91]+[GABS]

*

Interpolation plane

Speed range

Direction of rotation

Inches

Absolute

Tool check position

Return to Z position

Restore context

en-938872/2 2 - 5

Page 34

2.2.1.3 Addressing a List of Bits

[•IBxx(i)] Addressing a list of bits.

The symbol [•IBxx(i)] addresses a list of bits corresponding to the items specified by

xx.

The values are Boolean, i.e. 0 or 1.

The index (i) defines the rank of the element in the list.

[•IBX(i)] List of axes programmed in the current block.

Index i = 1 to 11.

This nonmodal list can remain stored and be read by parametric

programming if the system is in state G999.

i = 1: X axis

i = 2: Y axis

i = 3: Z axis

i = 4: U axis

i = 5: V axis

i = 6: W axis

i = 7: A axis

i = 8: B axis

i = 9: C axis

i = 10: in G21: Y axis address index 10

in G22: Z axis address index 10

i = 11: in G21: X axis address index 11

in G22: Y axis address index 11

2 - 6 en-938872/2

[•IBX1(i)] List of axes programmed from the beginning of the programme to

the current block.

Index i = 1 to 9: Same as list of axes programmed in the current

block (see [•IBX(i)]).

The axes programmed with respect to the measurement origin

(G52) are cancelled in this list, but are included in it again if

programming is resumed with respect to the programme origin.

[•IBX2(i)] List containing the last axes programmed (primary axes X Y Z or

secondary axes U V W).

Index i = 1 to 6. Except for axes A, B and C, the list is the same

as for the axes programmed in the current block (see [•IBX(i)]).

Programming an axis in a group cancels the equivalent axis in

other group. For instance, programming axis V resets the bit

relative to X and sets the bit for V.

Page 35

Reading the Programme Status Access Symbols

[•IBXM(i)] Mirroring of the axes. The bit is set to indicate mirroring and is

reset to indicate no mirroring.

Index i = 1 to 9: same as the list of axes programmed in the

current block (see [•IBX(i)]).

[•IBI(i)] List of arguments I, J and K programmed in the current block.

Index i = 1 to 5.

List modal only in state G999.

i = 1: argument I

i = 2: argument J

i = 3: argument K

i = 4: in G21: J component address index 4

in G22: K component address index 4

i = 5: in G21: I component address index 5

in G22: J component address index 5

[•IBP(i)] List of arguments P, Q and R programmed in the current block.

Index i = 1 to 3.

List modal only in state G999.

i = 1: argument P

i = 2: argument Q

i = 3: argument R

2

en-938872/2 2 - 7

Page 36

2.2.2 Symbols Addressing Numerical Values

The symbols addressing numerical values are used to read the modal data of the

current block.

2.2.2.1 Addressing a Value

[•Rxx] Addressing a value.

The symbol [•Rxx] is used to address a value corresponding to the elements specified

by xx.

[•RF] Feed rate

(units as programmed by G93, G94 or G95).

[•RS] Spindle speed

(G97: format according the spindle characteristics declared in

machine parameter P7).

[•RT] Tool number.

[•RD] Tool correction number.

[•RN] Number of the last sequence (block) encountered.

If the block number is not specified, the last numbered block is

analysed.

[•RED] Angular offset.

[•REC] Spindle orientation (milling).

[•RG4] Dwell time programmed (G04 F..).

This nonmodal function may however remain stored. Its value

can therefore be read if the system is in state G999 or G998.

[.RG80] Number of the calling function in a subroutine called by G

function.

In a subroutine called by G function, the number of the calling

function is addressed by [.RG80] (in state G80, its value is zero).

[•RNC] Value of NC (spline curve number).

[•RDX] Tool axis orientation.

Defined by the following signs and values:

+1 for G16 P+ +2 for G16 Q+ +3 for G16 R+

-1 for G16 P- -2 for G16 Q- -3 for G16 R-

[•RXH] Nesting level of the current subroutine.

1: main programme

2: first nesting level

3: second nesting level, etc. (8 possible nesting levels)

2 - 8 en-938872/2

Page 37

2.2.2.2 Addressing a List of Values

[•IRxx(i)] Addressing a list of values.

Reading the Programme Status Access Symbols

The symbol [•IRxx(i)] is used to address a list of values corresponding to the elements

specified by xx.

Index (i) defines the rank of the element in the list.

[•IRX(i)] Values of the dimensions programmed on the axes.

Index i = 1 to 11.

i = 1: value of X

i = 2: value of Y

i = 3: value of Z

i = 4: value of U

i = 5: value of V

i = 6: value of W

i = 7: value of A

i = 8: value of B

i = 9: value of C

i = 10: in G21: Y axis address index 10

in G22: Z axis address index 10

i = 11: in G21: X axis address index 11

in G22: Y axis address index 11

[•IRTX(i)] Values of the offsets programmed on the axes.

Index i = 1 to 9, same as the values of the dimensions

programmed on the axes (see [•IRX(i)]).

[•IRI(i)] Values of arguments I, J and K. Index i = 1 to 5.

i = 1: value of I

i = 2: value of J

i = 3: value of K

i = 4: in G21: J component address index 4

in G22: K component address index 4

i = 5: in G21: I component address index 5

in G22: J component address index 5

2

[•IRP(i)] Values of arguments P, Q and R. Index i = 1 to 3.

i = 1: value of P

i = 2: value of Q

i = 3: value of R

[•IRH(i)] Numbers of current programmes or subroutines or lower nesting

levels.

Index i = 1 to n subroutine.

i = 1: addresses the main programme

i = 2: addresses the subroutine called by the main programme

i = 3: addresses the next subroutine, etc. (8 possible nesting

levels)

en-938872/2 2 - 9

Page 38

[•IRDI(i)] Values defining the origin of the programmed angular offsets

(G59 I.. J.. K..). Index i = 1 to 3.

i = 1: value of I

i = 2: value of J

i = 3: value of K

2 - 10 en-938872/2

Page 39

Reading the Programme Status Access Symbols

2.3 Symbols Accessing the Data of the Previous Block

The same data can be accessed in the previous block as in the current block (see 2.2).

The same symbols are used, but are preceded by two decimal points (instead of one).

The symbols can be:

- symbols addressing Boolean values, or

- symbols addressing numerical values.

The symbols are used to read the modal data of the previous block.

These data are those of the last executable previous block (or possibly the last block

executed).

This addressing is used only when execution of the current block is suspended by

programming function G999.

2

General Syntax

Variable = [••symbol(i)]

Variable L programme variable, symbolic variable [symb], E

parameter.

[••symbol(i)] Symbol between square brackets, preceded by two

decimal points, possibly followed by an index (i).

en-938872/2 2 - 11

Page 40

2 - 12 en-938872/2

Page 41

Storing Data in Variables L900 to L951

3 Storing Data in Variables L900 to L951

3.1 General 3 - 3

3.2 Storing F, S, T, H and N in Variables L900 to L925 3 - 3

3.3 Storing EA to EZ in Variables L926 to L951 3 - 4

3.4 Symbolic Addressing of Variables L900 to L951 3 - 4

3

en-938872/2 3 - 1

Page 42

3 - 2 en-938872/2

Page 43

3.1 General

Storing Data in Variables L900 to L951

The programming tools described in this chapter are necessary for creating subroutines

called by G functions (see Chapter 5).

Certain arguments or functions may have different meanings in the machining cycles

programmed. Status symbols [•IBE0(i)] and [•IBE1(i)] are used to detect their

presence in blocks including a G function calling a subroutine.

It is up to the subroutine to correctly address these arguments or functions according

to their meanings and to store their values in variables L900 to L951.

The bits of [•IBE0(i)] and [•IBE1(i)] (each equal to 0 or 1) are accessible for read by

parametric programming.

3.2 Storing F, S, T, H and N in Variables L900 to L925

Storing F, S and T

Status symbol [•IBE0(i)] consisting of a list of bits is used to detect programming of

F, S or T in blocks including a function Gxxx.

Index (i): from 1 to 26 for addresses A to Z.

Addressing the status symbol:

- bit [•IBE0(6)] is set if F is programmed,

- bit [•IBE0(19)] is set if S is programmed,

- bit [•IBE0(20)] is set if T is programmed.

The values of F, S and T are stored in the following variables (L900 to L925):

- F in L905,

- S in L918,

- T in L919.

Storing H and N

H and N can only be stored when not preceded by functions G75, G76, G77 or G79

related to them for ISO programming.

3

A second N (following the first N and defining the last call sequence of a subroutine

N.. to N..) is stored in variable L914 (this N can in no case be the block number

programmed at the start of the sequence).

Addressing the status symbol:

- bit [•IBE0(8)] is set if H is programmed,

- bit [•IBE0(14)] is set if the first N is programmed,

- bit [•IBE0(15)] is set if the second N is programmed.

en-938872/2 3 - 3

Page 44

The values of H and N are stored in the following variables:

- H in L907,

- first N in L913,

- second N in L914.

3.3 Storing EA to EZ in Variables L926 to L951

The values of EA to EZ to be stored in variables L926 to L951 are defined by two

alphabetic characters:

- the first is the letter E,

- the second is a letter between A and Z.

Status symbol [•IBE1(i)] consisting of a list of 26 bits is used to detect the presence

of functions EA to EZ in blocks including a function Gxxx (i = alphabetic index of the

second letter after E).

Addressing the status symbol:

- bit [•IBE1(1)] addresses the bit corresponding to EA,

- bit [•IBE1(2)] addresses the bit corresponding to EB, and so forth down to ...,

- bit [•IBE1(26)] addresses the bit corresponding to EZ.

The values are stored in the following variables (L926 to L951):

- EA in L926,

- EB in L927, and so forth down to ...,

- EZ in L951.

3.4 Symbolic Addressing of Variables L900 to L951

Variables L900 to L925 and L926 to L951 in either the left-hand or right-hand side of

an expression can be addressed by alphabetic symbols preceded by the character

«‘» (apostrophe).

Variables L900 to L925

L900 to L925 can be addressed by symbols ‘A to ‘Z.

Example:

‘C = ‘A + ‘B is equivalent to L902 = L900 + L901

Variables L926 to L951

L926 to L951 can be addressed by symbols ‘EA to ‘EZ respectively.

(‘EA = L926, ‘EB = L927, etc. up to ‘EZ = L951).

Example:

‘A = ‘B - ‘EA / ’EZ is equivalent to L900 = L901 - L926 / L951.

3 - 4 en-938872/2

Page 45

Creating and Managing Symbolic Variable Tables

4 Creating and Managing Symbolic Variable Tables

4.1 Creating Symbolic Variable Tables 4 - 3

4.1.1 Defining a Table 4 - 3

4.1.2 Table Dimensions 4 - 3

4.1.3 Initialising Variables and Tables 4 - 5

4.1.4 Creating Tables for Storing Profiles 4 - 6

4.1.5 Data That Can Be Stored in a Table 4 - 7

4.2 Symbolic Variable Management Commands 4 - 8

4.2.1 Storing a Profile 4 - 8

4.2.2 Storing a Profile Interpolated in the Plane 4 - 11

4.2.3 Offsetting an Open Profile and Updating

the Table 4 - 13

4.2.4 Redefining a Profile According to the Tool

Relief Angle 4 - 15

4.2.5 M Functions and/or Axes Enabled or

Inhibited. Setting or Resetting Bits 4 - 18

4.2.6 Searching the Stack for Symbolic

Variables 4 - 20

4.2.7 Providing a List of Symbolic Variables 4 - 21

4.2.8 Copying Blocks or Entries from One Table

into Another Table 4 - 22

4.2.9 Indirect Addressing of Symbolic Variables 4 - 27

4.2.10 Programming Examples 4 - 28

4

en-938872/2 4 - 1

Page 46

4 - 2 en-938872/2

Page 47

Creating and Managing Symbolic Variable Tables

The programming tools described in this chapter are used to create subroutines

called by G functions (see Chapter 5).

4.1 Creating Symbolic Variable Tables

The rules for writing symbolic variables used when creating tables are the same as

those defined for parametric programming (see Chapter 7 of the Programming

Manual).

4.1.1 Defining a Table

A table is declared as a symbolic variable between the words VAR and ENDV.

A table is defined by including its dimensions between brackets after the last

character of the symbolic variable.

For tables with several dimensions, the dimensions are separated by commas «,» or

semicolons «;».

Syntax

VAR

[TABLn(a,b,c ...)]

ENDV

VAR Declaration of symbolic variables.

[TABLn(a,b,c...)] TABLn: table name in the stack.

(a,b,c ...) : table dimensions.

ENDV End of symbolic variable declaration.

Example of table definitions

VAR

[TABL1(10)] [TABL2(2,5,3)]

ENDV

For table 2 [TABL2] above, the number of entries reserved equals:

2 x 5 x 3 = 30 entries, i.e. 5 groups of 2 then 3 groups of 10.

4

4.1.2 Table Dimensions

Tables can have from one to four dimensions.

For tables with one dimension:

- the value of a dimension must be between 1 and 65535.

en-938872/2 4 - 3

Page 48

For tables with 2, 3 or 4 dimensions:

- the value of a dimension must be between 1 and 255.

The dimensions must be declared as immediate values or declared symbolic

variables.

Example:

[VAR1] = 10

[VAR] = [TAB1 (VAR1,5)]

Symbolic variables are real values.

Table indexes are immediate values or symbolic variables.

A dimension cannot be defined using:

- L programme variables,

- E external parameters.

Example:

If symbolic variable [TAB(L0,3)] is programmed, it is not programme variable L0 but

symbolic variable [L0] that is searched for.

The table indexes can be additions or subtractions of values or symbolic variables.

Example:

is equivalent to:

[TAB1 (10,5)]

VAR [IX] [COSX] [SINX] [NBT] = 4

[TABL(2,NBT)] = 0, 0, 10, 5, 20, 8, 30, -2

ENDV

FOR [IX] = 1 TO [NBT] -1 DO

[COSX] = [TABL(1,IX+1)] - [TABL(1,IX)]

[SINX] = [TABL(2,IX+1)] - [TABL(2,IX)]

L0 = [COSX]

[COSX] L0 = [SINX]

*

[SINX] + L0

*

[COSX] = [COSX] / RL0 [SINX] = [SINX] / RL0

X [TABL(1,IX+1)] Y [TABL(2,IX+1)]

ENDF

4 - 4 en-938872/2

Structure of tables with several dimensions

The entries for the first dimension are located first in the declaration, then multiplied

by the number of entries of the second dimension. The result is then multiplied by the

number of entries of the following dimension and so forth.

Page 49

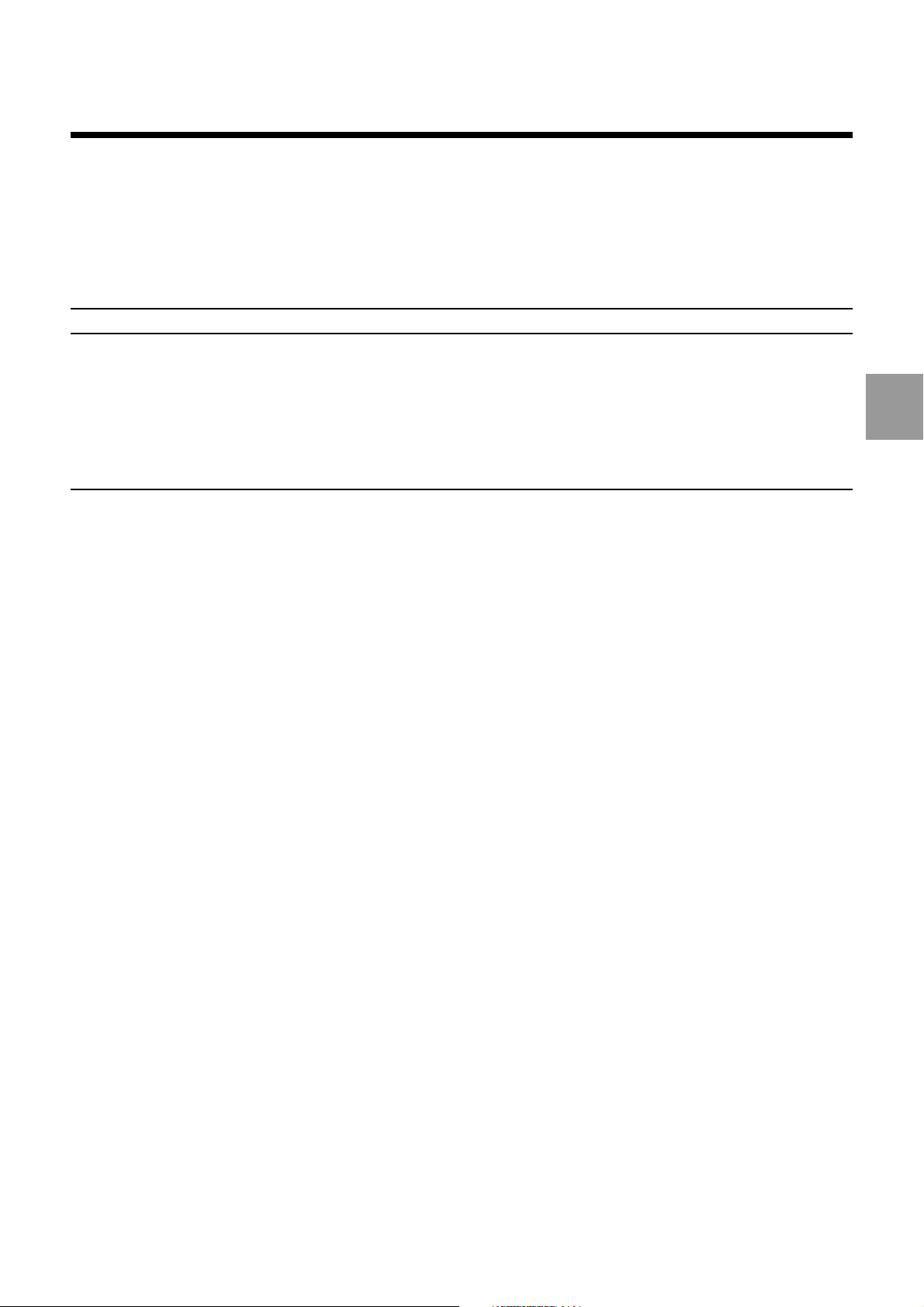

4.1.3 Initialising Variables and Tables

The values are initialised with a default value of zero.

Initialising with other values is made by declaring the character = followed by the initial

value(s) separated by commas «,».

The initial values can be declared in several blocks. In this case, the character = is

repeated before the value(s) defined in the next block.

Example:

VAR [NTB] = 4 [TABLE(2,NTB)] = 3,6

= 10,1,8,2,6,6

ENDV

Creating and Managing Symbolic Variable Tables

4

If

L0= [TABLE(2,3)]

L0= 2 (ie. the loth digit)

Storage in the memory

TABLE (1.1) = 3

TABLE (2.1) = 6

TABLE (1.2) = 10

4 x

Second

dimension

2

2

2

2

First

dimension

NBT = 4

(2.2) = 1

(1.3) = 8

(2.3) = 2

(1.4) = 6

(2.4) = 6

en-938872/2 4 - 5

Page 50

4.1.4 Creating Tables for Storing Profiles

Entry 1 Entry 2 Entry 3 Entry 4 Entry 5 etc.

First dimension

Second

dimension

(blocks)

The system offers the possibility of storing a profile written in ISO or PGP in a table

of the programme stack. The table is created as the profile blocks are read.

The programmed blocks are stored in a table with two dimensions:

- the first dimension includes all the functions to be saved in a block,

- the second dimension corresponds to the number of blocks in the profile.

The data in the table are then accessed by parametric programming.

Example:

4 - 6 en-938872/2

Page 51

Creating and Managing Symbolic Variable Tables

4.1.5 Data That Can Be Stored in a Table

The following ISO programming data can be stored in tables.

G Functions

Only one G function per block can be stored.

After a change of interpolation plane in a block, the new function is stored (G17, G18

or G19 for milling, G20, G21 or G22 for turning). Otherwise, one of modal functions

G00, G01, G02 or G03 is stored.

Values of the Programmed Axes

X, Y, Z, U, V, W, A, B, C (depending on the axes declared in machine parameter P0).

The modal values programmed with the axes are stored.

Values of I, J, K, P, Q, R

The values of the functions are stored only if the functions are present in the block.

Otherwise, the value zero is stored in the corresponding entries.

Feed Rate F

The modal value related to function F is stored.

Spindle Speed S

The value of S is not stored in the table unless it is present in the block. Otherwise,

a value of zero is stored.

Tool Call T

Function T is not stored in the table unless it is present in the block. Otherwise, a value

of zero is stored.

4

en-938872/2 4 - 7

Page 52

4.2 Symbolic Variable Management Commands

4.2.1 Storing a Profile

BUILD Creates a table for storing profile paths.

The BUILD function is used to store the profile in a two-dimensional table:

- the first dimension is limited to 16 entries,

- the second dimension is limited to 255 entries.

Syntax

BUILD [TAB(G / X / Y / I / J,NB)] H.. N..+n N..+n

BUILD Creation of a table for storing a profile.

TAB Table name in the stack.

G / X / Y / I / J Data types whose values are stored in the entries of the

first table dimension (16 entries maximum).

NB Name of the variable containing the number of blocks of

the second table dimension (maximum 255 blocks).

H.. Definition of the limits of the profile.

N.. N..

H.. N.. N..

N..+n N..+n

H N..+n N..+n

4 - 8 en-938872/2

Note

The BUILD function must be the first word in the block and the table name TAB must

be the second. They must be separated by at least one space.

Page 53

Creating and Managing Symbolic Variable Tables

Programming the table name TAB and variable NB automatically creates a twodimensional table.

Example:

%555 %55

N10 ... G.. ...

First block of the profile

N.. G.. ...

N.. G.. ...

BUILD [TAB(G/X/Y/I/J,NB)] H55 G.. ...

Last block of the profile

N..

Two-dimensional table created by the above programme:

- first dimension: 5 entries,

- second dimension: 4 entries (blocks).

(blocks)

NB

TAB

Allocation of Additional Entries in a Field of the BUILD Function

Additional entries can be allocated in the first table dimension if they are not initialised

by data in the blocks. In this case, the entries are declared by «0s» separated by the

character /.

Example:

..

..

..

..

4

..

..

..

..

...

...

...

...

..

..

..

..

..

..

..

..

%55

N10 ...

N..

N110

First block of the profile

N..

N..

N220

Last block of the profile

N..

BUILD [PROF1(G/X/Y/Z/0/0,NB)] N110 N220

The first table dimension includes

6 entries

4

en-938872/2 4 - 9

Page 54

Declaring Entries as a List of Bits in a Field of the BUILD Function

In a symbolic variable, some of the following axes and arguments can be declared

as a list of bits:

- axes X, Y, Z, etc.,

- arguments I, J, K,

- arguments P, Q, R.

The list of bits is declared by programming one of addresses X, I or P followed by a

decimal point and the symbolic variable name in a field of BUILD.

Example:

BUILD [TAB1(G/I.Symb/R,NB)] H..

Symbolic variable [Symb] contains a sum of values. This sum is defined from the

indexes of the addressing symbols [••IBX(i)], [••IBI(i)] and [••IBP(i)], i.e.:

- 1 for index i = 1

- 2 for index i = 2

- 4 for index i = 3

- 8 for index i = 4, etc.

Therefore, the value of the variable including I, J and K of [••IBI(i)] is equal to

I-1

J-1

2

+ 2

Example:

+ 2

K-1

.

Declaration of I.Symb

VAR [LIST] = 6

ENDV

BUILD [PROF(G/X.LIST/R,NB)] N.. N..

is equivalent to the following block:

BUILD [PROF(G/Y/Z/R,NB)] N.. N..

4 - 10 en-938872/2

Page 55

Creating and Managing Symbolic Variable Tables

4.2.2 Storing a Profile Interpolated in the Plane

P.BUILD Creates a table for storing the dimensions of the profile

interpolation plane.

The P.BUILD function is used to store the profile in a two-dimensional table:

- the first dimension is limited to 7 entries,

- the second dimension is limited to 255 entries.

Syntax

P.BUILD [TAB(7,NB)] H.. N..+n N..+n

BUILD Creation of a table for storing a profile.

TAB Table name in the stack.

7 Number of entries in the first dimension (maximum 7).

NB Name of the variable containing the number of blocks

(maximum 255 blocks).

H.. Definition of the limits of the profile.

N.. N..

H.. N.. N..

N..+n N..+n

H.. N..+n N..+n

Note

The P.BUILD function must be the first word in the block and the table name TAB must

be the second. They must be separated by at least one space.

4

en-938872/2 4 - 11

Page 56

Defining the Seven Entries of the First Dimension with the P.BUILD Function

0

+1

0

20

20

10

10

50

20

0

20

0

0

30

0

10

20

20

10

10

50

3

NB

(blocks)

TAB

- entry 1: Type of interpolation:

value = 0 for linear interpolation,

value = -1 for clockwise circular interpolation,

value = +1 for anticlockwise circular interpolation.

- entry 2: End point, value of the dimension on the X axis.

- entry 3: End point, value of the dimension on the Y axis.

- entry 4: Position of the centre:

value on the X axis for circular interpolation, else value = 0.

- entry 5: Position of the centre:

value on the Y axis for circular interpolation, else value = 0.

- entry 6: Start point, value of the dimension on the X axis.

- entry 7: Start point, value of the dimension on the Y axis.

Example:

%70 %80

N10 G17 X10 Y10 N10 ...

P.BUILD [TAB(7,NB] H80 N110 N130 N..

N.. N..

N110 G01 X20

N120 G03 X20 Y50 I20 J30

N130 G01 X10 Y20

N.. ...

4 - 12 en-938872/2

Table TAB and variable NB create the following table with 7 entries:

Page 57

Creating and Managing Symbolic Variable Tables

4.2.3 Offsetting an Open Profile and Updating the Table

R.OFF Normal offset of an open profile.

The R.OFF function is used for normal offset of a profile initially created in a table by

the P.BUILD function or a table with the same format, i.e. [Pa(7,Nb)].

After execution of the R.OFF function, the offset profile is contained in the same table

and the variable specifying the number of blocks is updated since intermediate blocks

may have been created (see Fig. 1).

Syntax

R.OFF [Pa(7,Nb)] / ±1 / R

4

R.OFF Normal offset of a profile.

Pa Table name.

7 Number of table entries.

Nb Name of the variable containing the number of blocks in

table Pa.

±1 Value = +1: right offset of the profile,

value = -1: left offset of the profile.

R Radius expressed in the same units as the dimensions.

Note

The R.OFF function must be the first word in a block.

The profile executed with the R.OFF function must be an open profile, i.e. the start

point of the profile must be different from the end point (see Fig. 2).

The R.OFF function can only operate on profiles contained in P.BUILD that do not

include alternating left and right offsets during execution.

en-938872/2 4 - 13

Page 58

Creation of an Intermediate Block by the System

When the profile includes particular

paths, the system may create a

connection block.

Open contour

When the profile includes a narrowed

section, it must be sufficiently large to

allow passage of the tool. Otherwise,

the system considers the profile to be

closed.

Figure 1

R

-1 offset

Figure 2

Narrowed section > tool

Intermediate

block

4 - 14 en-938872/2

Example

%92

N..

P.BUILD [P(7,NB)] N110 N200

...

...

R.OFF [PA(7,NB)] /-1 /10

Profile offset by 10 to the left

Page 59

Creating and Managing Symbolic Variable Tables

4.2.4 Redefining a Profile According to the Tool Relief Angle

CUT Elimination of the grooves or parts of groove located inside the tool

relief angle.

The CUT function applies to grooves located in the path of a plane profile created in

a table by the P.BUILD function or a table with the same format, i.e. [Pa(7,Nb)].

After execution of the CUT function, the new profile is contained in the same table and

the variable specifying the number of blocks is updated.

Syntax

CUT * [Pa(7,Nb)] / Angle

4

CUT Eliminates the grooves or parts of grooves located

within the tool relief angle.

*

Pa Table name.

7 Number of table entries.

Nb Name of the variable containing the number of blocks in

Angle Angle Relief angle in degrees.

Note

The CUT function must be the first word in the block (no sequence number).

When the character * precedes the table name, all the

grooves located within the tool relief angle are

processed.

When the character * is missing in front the table name,

only the first groove located within the tool relief angle is

processed.

table Pa.

en-938872/2 4 - 15

Page 60

Review of the Angles of a Cutting Tool Defined in Plane ZX

Charac teristic angles:

- Kr: approach angle,

- εr : tool nose angle,

- a : clearance angle.

Processing of the table

The table analysis begins on the first block and ends:

- on the last block with CUT * ...,

- on the first cut with CUT ...

In the table, the profile must always be defined so that the profile start dimension on

the X axis (first block) is less than the profile end X dimension (last block).

Example:

Profile correctly defined Profile incorrectly defined

εr

Kr

a

Feed direction

4 - 16 en-938872/2

First

block

Last

block

Last

block

First

block

Page 61

Creating and Managing Symbolic Variable Tables

a

,,,,,

,,,,,

,,,,,

,,,,,

a

a

When the clearance angle is negative or zero (between 0 degrees and -180 degrees),

the profile areas located below this angle are eliminated.

When the relief angle is positive (between 0 degrees and +180 degrees), the profile

areas above the angle are eliminated.

Examples:

«a» shows the areas that are eliminated.

Example 1:

Elimination of the first groove in the profile (no * in front of the variable).

CUT [PA(7,NB)] / -95

Example 2:

Elimination of the grooves or parts of grooves located on the profile (* in front of the

variable).

CUT * [PA(7,NB)] / -50

4

en-938872/2 4 - 17

Page 62

4.2.5 M Functions and/or Axes Enabled or Inhibited. Setting or Resetting Bits

BSET Programming of M functions and/or one or more axes enabled.

Setting of the bits of [•IBE0(i)] and [•IBE1(i)].

BCLR Programming of M functions and/or one or more axes inhibited.

Resetting of the bits of [•IBE0(i)] and [•IBE1(i)].

Syntax

BSET [•BMxx] / [•IBX(i)] / [•IBE0(i)] / [•IBE1(i)]

BSET Enabling the programming of M functions and/or one or

more axes.

[•BMxx] / [•IBX(i)] When the system is in state G999, enabling by BSET

sets the bits of [•BMxx] and/or [•IBX(i)].

[•IBE0(i)] / [•IBE1(i)] When a subroutine is called by function Gxx, BSET also

sets the bits of [•IBE0(i)] and [•IBE1(i)].

Syntax

BCLR [•BMxx] / [•IBX(i)] / [•IBE0(i)] / [•IBE1(i)]

BCLR Inhibiting the programming of M functions and/or one or

more axes.

[•BMxx] / [•IBX(i)] When the system is in state G999, inhibiting by BCLR

resets the bits of [•BMxx] and/or [•IBX(i)].

[•IBE0(i)] / [•IBE1(i)] When a subroutine is called by function Gxx, BCLR also

resets the bits of [•IBE0(i)] and [•IBE1(i)].

4 - 18 en-938872/2

Page 63

Creating and Managing Symbolic Variable Tables

Note

Functions BSET and BCLR:

- must be the first words in the block (no sequence number),

- must be separated from the list of symbols by at least one space. However, there

must be no spaces in the list of symbols,

- are followed by the list of symbols to be enabled or inhibited. The symbols are

separated by «/».

Example

In block N120, only movements X10 and Z10 are executed. The movements on the

Y and B axes and the "post M" function M05 are inhibited (see Chapter 2 for indexes

(2) and (8) corresponding to Y and B respectively).

N..

N..

N.. G999 X10 Y10 Z10 B30 M05

BCLR [•IBX(2)] / [

IBX(8)] / [

•

BM05]

•

Disabled

N120 G997

4

en-938872/2 4 - 19

Page 64

4.2.6 Searching the Stack for Symbolic Variables

SEARCH Searches the stack for a symbolic variable.

Syntax

SEARCH [Symb] N..

SEARCH Searches the stack for a symbolic variable.

[Symb] Name of the symbolic variable.

When the variable searched for is found, analysis of the

block is continued.

N.. Block number to which a branch is made when the

symbolic variable is not found.

Example

%30

N..

VAR [Symb]

ENDV

N..

4 - 20 en-938872/2

%35

N..

N90 ...

SEARCH [Symb] N100

N..

N100

N..

Page 65

Creating and Managing Symbolic Variable Tables

4.2.7 Providing a List of Symbolic Variables

SAVE Provides the main programme and subroutines with a list of the

symbolic variables declared in any subroutine.

Syntax

SAVE [Symb1] / [Symb2] ...

SAVE Provides the main programme and subroutines with a

list of the symbolic variables declared in any subroutine.

[Symb1] / [Symb2] ... List of symbolic variables.

4

Notes

The symbolic variables provided may be declared within subroutines at any nesting

levels.

The variables declared after SAVE must be separated by the character «/».

Example

After a return from subroutine %30, programme %10 and subroutine %20 as well as

any new subroutines can use symbolic variables [V1] and [TB(4)].

%10

N..

N.. G77 H20

N..

%20

N..

N.. G77 H30

N..

%30

N..

VAR [V1] / [TB(4)]

ENDV

N..

SAVE [V1] / [TB(4)]

N..

en-938872/2 4 - 21

Page 66

4.2.8 Copying Blocks or Entries from One Table into Another Table

MOVE Copies all or part of a table into another table.

The MOVE function is used to copy tables with the following formats:

- [P(m)] : m blocks of an entry,

- [P(n,m)] : m blocks of n entries.

General Syntax

MOVE [Pj(nj,mj)],mj1,mj2 = [Pi(ni,mi)],mi1,mi2 / j1=i1 / j2=i2 /jn=in

The MOVE function provides several possibilities for copying:

- simple copying of blocks,

- partial copying of blocks,

- specification of the entries to be copied.

Syntax for Simple Copying of Blocks

MOVE [Pj(nj,mj)] = [Pi(ni,mi)]

MOVE Copies the contents of one table into another table.

During a simple copy, the two tables must have the

same format, i.e.: nj = ni and mj = mi.

4 - 22 en-938872/2

Pj Target table name.

nj,mj Entries and blocks of the target table.

Pi Source table name.

ni,mi Entries and blocks of the source table.

Page 67

Creating and Managing Symbolic Variable Tables

Syntax for Partially Copying Blocks

MOVE [Pj(nj,mj)],mj1,mj2 = [Pi(ni,mi)],mi1,mi2

MOVE Copies the contents of one table into another table.

Pj Target table name.

nj,mj Entries and blocks of the target table.

mj1,mj2 Limits of target table Pj between which are copied the

blocks indexed mi1 to mi2 of the source table Pi. The

other blocks of Pj are not modified.

Pi Source table name.

4

ni,mi Entries and blocks of the source table.

mi1,mi2 Indexed limits of source table Pi.

These limits and the blocks between these two limits

are copied into table Pj between limits mj1 and mj2.

Syntax for Specifying Entries to Be Copied

MOVE [Pj(nj,mj)] = [Pi(ni,mi)] / j1=i1 / j2=i2 / jn=in

MOVE Copies the contents of one table into another table.

Pj Target table name.

nj,mj Entries and blocks of the target table.

Pi Source table name.

ni,mi Entries and blocks of the source table.

/ j1=i1 / j2=i2 / jn=in When certain entries of a table are not to be copied,

each entry to be copied must be specified with, after the

character «/», the target entry index followed by the

character «=» and the source entry index.

The value of an entry copied in the target table can be

inverted by preceding the source entry index by the sign

«-» (minus).

en-938872/2 4 - 23

Page 68

Notes

The MOVE function must be the first word in the block (no sequence number).

The maximum number of blocks in a finished profile is limited to 95.

It is possible to reverse the order of a copy by reversing the start and end limit indexes

in one of the tables.

The indexes can be specified in symbolic variables.

In case of a programming error, the system returns the following error numbers:

ERROR 196 (inconsistency in index declaration),

ERROR 199 (syntax error).

Examples

MOVE simple copy of blocks

Example: Copying the contents of one table into another table.

MOVE [PB(2,3)] = [PA(2,3)]

Entries 1

Block 1

Block 2

Block 3

Target table

212

Source table

1

2

3

4 - 24 en-938872/2

Page 69

Creating and Managing Symbolic Variable Tables

MOVE partial copy of blocks

Example 1: Copying part of a table into another table.

MOVE [PB(2,5)],2,5 = [PA(2,6)],1,4

4

Example 2: Copying part of a table into another table.

MOVE [PB(2,5)],2,4 = [PA(2,6)],3,5

Example 3: Reversal of the limit and block indexes when copying part of a table into

another table.

MOVE [PB(2,5)],2,5 = [PA(2,6)],4,1

en-938872/2 4 - 25

Page 70

MOVE: Partial copying of blocks and specification of the entries to be copied

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,

,,

,,

,,

,,,,,

,

,

,

,

,

,

,

,

,

,

,

,,

,,

,,

,,

,,,,,

,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

,,

,,

,,

,,

,,,,,

Example: Inversion of the values of the entries when copying part of a table into

another table.

Only the first and third entries are copied into the target table PB, and the values of

the first entries are inverted.

MOVE [PB(3,6)] = [PA(3,6)] / 1=-1 / 3=3

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

,,,,,,,,

Reminder

DELETE Function

The DELETE (or DELE) function can be used to programme deletion of the symbolic

variables (see Chapter 7 of the Programming Manual).

4 - 26 en-938872/2

Page 71

Creating and Managing Symbolic Variable Tables

4.2.9 Indirect Addressing of Symbolic Variables

A variable or a table of symbolic variables can be referenced by a value.

This addressing mode simplifies linking tables by using numbers instead of the

names of the symbolic variables.

This symbolic variable addressing mode is indirect, since it is via another address

vector variable whose value is the reference of another symbolic variable or table of

symbolic variables.

Numerical addressing is symbolised by the character @ followed by the address

vector name.

The variables addressed by negative numbers are automatically deleted by function

G80.

Example

VAR [no] = 7 [@no(10)]

[Symb]

The table with 10 entries is referenced

by the value 7

ENDV

[Symb] = 7 L0 = [@Symb(2)]

«@Symb» addresses the same

table declared as «@no»

4

en-938872/2 4 - 27

Page 72

4.2.10 Programming Examples

1 0 0 0 0

2 22.268 8.104 0 0

3 28.243 14.081 18.846 17.501

1 35.905 35.13 0 0

2 65 30 50 30

1 65 20 0 0

1

GXY I J

Points

2

3

4

5

6

Values stored in

the table when

BUILD is executed

[NB] -1

G[TAB(1,I)]

X[TAB(2,I)]

Example 1

Use of BUILD for milling (XY plane). With radius correction, path from 1 to 6 then back

from 6 to 1.

Representation of machining

G2

Y

G3

4

5

1

Table built by the programme

G3

3

2

G2

6

X

4 - 28 en-938872/2

Page 73

Creating and Managing Symbolic Variable Tables

%350

Z0

M999 G79 N100

N10 G1 X Y

EA20 ES EB10

EA70

Definition (points 1 to 6)

G2 I50 J30 R15

N40 G1 Y20

N100

BUILD [TAB(G/X/Y/I/J,NB)]N10 N40

VAR [I]

4

ENDV

FOR [I]=1 T0 [NB] D0 G41 D1

Path from 1 to 6

G[TAB(1,I)] X[TAB(2,I)] Y[TAB(3,I)] I[TAB(4,I)] J[TAB(5,I)]

ENDF

FOR [I]=[NB] -1 DOWNT0 1 D0

Path back from 6 to 1

L0=[TAB(1,I+1)]

IF L0>1 THEN L0=L0

3+1&3

*

Reversal of G2 and G3 for the return

ENDI

GLO X[TAB(2,I)] Y[TAB(3,I)] I[TAB(4,I+1)] J[TAB(5,I+1)]

ENDF

G40 X Y

M2

en-938872/2 4 - 29

Page 74

Example 2

Use of P.BUILD for turning. Execution of a profile with offset and use of the MOVE

and R.OFF functions

Representation of machining

X

Z

4 - 30 en-938872/2

Page 75

Creating and Managing Symbolic Variable Tables

%46

P.BUILD [C(7,N)] N100 N110

Creation of a table to store the profile

VAR [R][G(3)]=2,1,3 [I] [V]

ENDV

...

FOR [R]= 30 DOWNTO 2 BY 2 DO

VAR [M]=[N]-1 [P(7,M)]

ENDV

MOVE [P(7,M)] = [C(7,N)],2,[N]

R.OFF [P((7,M)] / + 1 / [R]

Copy the table into another table

Offset the profile to the right

G X60 Z110

X[P(7,1)] Z[P(6,1)]

FOR [I] = 1 TO [M] DO [V] = [P(1,I)]+2

G[G(V)] X[P(3,I)] Z[P(2,I)] I[P(5,I)] K[P(4,I)]

ENDF

DELE [P]/[M]

ENDF

M02

N100 X0 Z100

G3 I0 K20 ESG1 EA180 X20 Z85 EB2

X12

Z75

X20

Z70

X15

Profile definition

Z60

G2 X15 Z50 I15 K55

G1 X25 EB-4

Z40

G2 I30 K30 ES+

G1 EA90 X50 Z25 EB3

N110 Z10

4

en-938872/2 4 - 31

Page 76

4 - 32 en-938872/2

Page 77

Creating Subroutines Called by G Functions

5 Creating Subroutines Called by G Functions

5.1 Calling Subroutines by G Functions 5 - 3

5.2 Inhibiting Display of Subroutines Being Executed 5 - 5

5.3 Programming Examples 5 - 6

5

en-938872/2 5 - 1

Page 78

5 - 2 en-938872/2

Page 79

5.1 Calling Subroutines by G Functions

Gxxx Subroutine call by a G function.

Function Gxxx is used to call and execute a subroutine.

Function Gxxx is used for execution of machining cycles. The cycles created can be

customised. This functionality is also used to create special functions.

Syntax

N.. Gxxx Parameters specific to each machining cycle.

Creating Subroutines Called by G Functions

Gxxx This function forces a call to subroutine %10xxx whose

number corresponds to the machining cycle.

Example:

- G81 calls subroutine %10081,

- G199 calls subroutine %10199.

Parameters The parameters (or arguments) specific to the

machining cycle must be specified after Gxxx.

Properties of the Functions

Functions Gxxx calling subroutines are modal.

A function Gxxx is nonmodal when the cancellation function G80 is included in the

subroutine called by the cycle.

Cancellation

Modal functions Gxxx are cancelled by function G80 (this function does not call a

subroutine).

Notes

CAUTION

!

Since functions G200 to G255 may be used for NUM applications, it is recommended to use

only functions G100 to G199.

5

List of G functions forcing a call to a subroutine:

- G06, G31, G33, G38, G45, G46, G48, G49, G63, G64, G65, G66, G81-G89,

- G100 to G255 (reminder: G200 to G255 reserved for NUM).

en-938872/2 5 - 3

Page 80

A subroutine call by a Gxxx function without arguments is ignored by the system. The

arguments are interpreted by the %10xxx subroutine called.

The subroutines called by G functions must therefore have visibility into the programme context and all the functions programmed in the calling block.

Execution of a subroutine called by a G function cannot be interrupted by an

«immediate» request in the edit mode (EDIT).

A subroutine called by a G function cannot itself call another subroutine by a G

function. However, nesting with another type of call is possible (call by M function or

machine processor), but two calls of the same type can in no case be nested.

Functionalities Used in %10xxx Subroutines

- Functions G997, G998 and G999,

- Programme variables L900 to L925 and L926 to L951,

- External parameters E,

- Symbolic variables,

- Programme status access symbols.

A call to a subroutine by a G function implicitly sets function G999 (execution

suspended and block concatenation forced). This function has to be cancelled by

programming functions G998 and/or G997 set in the subroutine.

During the return to the part programme, state G999 is systematically reset as long

as the subroutine calling function (Gxxx) remains present and active (no G80).

For additional information on functions G997, G998 and G999, refer to the programming

manuals for:

- Milling (938819),

- Turning (938820).

5 - 4 en-938872/2

Page 81

Creating Subroutines Called by G Functions

5.2 Inhibiting Display of Subroutines Being Executed

Display on the programme page (PROG) of a subroutine and its internal subroutines

during execution can be inhibited.

The character «:» after the subroutine number inhibits display. In this case, only the

subroutine call block is displayed.

Example:

Only block N150 including function G108 is displayed during execution of subroutines

%10108 and %118.

%10 %10108: %118

N10 N10 N10

N.. N.. N..

N150 G108 ... N80 G77 H118 N..

N.. N.. N..

5

en-938872/2 5 - 5

Page 82

5.3 Programming Examples

Example 1

Creating a particular cycle with function G199 (subroutine %10199).

The cycle below is given only for guidance.

It allows execution of several drilling or punching operations «P» distributed on a

circle with radius «R» centred on XY (G17).

Cycle syntax and parameters

G199 Cycle for drilling equally spaced holes on a circle.

X.. Y.. Circle centre position.

ER.. Approach and clearance position.

Z.. Machining end point.

P.. Number of equally spaced holes.

R.. Radius of the hole circle.

F.. Feed rate.

N.. G199 X.. Y.. ER.. Z.. P.. R.. F..

5 - 6 en-938872/2

Main machining programme

%20

N10 G0 G52 Z0

N20 T1 D1 M06 (DRILL)

N30 S1000 M40 M03

N40 X0 Y0 Z5

N50 G199 X50 Y50 ER2 Z-10 P6 R20 F90

N60 X100 Z-5 P4 R10

N70 X150 Y150 Z-15 P6 R25

N80 X200 Y50 Z-5 P4 R10

N90 X250 Z-10 P6 R20

N100 G80 G0 G52 M05

Circle 1 cycle

Circle 2 cycle

Circle 3 cycle

Circle 4 cycle

Circle 5 cycle

Cycle cancelled

N110 M02

Page 83

Representation of machining

X

Y

1 (6 holes)

2 (4 holes) 4 (4 holes)

5 (6 holes)

3 (6 holes)

Creating Subroutines Called by G Functions

Cycle subroutine

%10199: (Equally spaced holes on the circle)

VAR

[G0/1] [RETURN] [FEED] [G94/5]

ENDV

[G0/1]=3

[G0/1]=1

[..BG03] [G0/1]=2

*

[..BG01] + [G0/1]

*

[FEED]=[.RF]

[G94/5]= 94

[G94/5]= 95

*

[.BG95] + [G94/5]

*

PUSH L0 - L7

(Test whether P and R are programmed in the call block)

IF [..G80]= 1 THEN

L0= [.IBP(1)]

G79 L0= 0 N100

ENDI

IF [.IBP(1)] = 1 THEN

L100= [.IRP(1)]

ENDI

L100= [.IRP(1)]

G79 L100 < 1 N101

IF [.IBX(3)] = 1 THEN L925 = [.IRX(3)]

ENDI

[.BG94]

[.IBP(3)]

*

[..BG02] + [G0/1]

*

Store G0, G1, G2 or G3

Store G94 or G95

First block in the cycle?

Error if P or R is missing

Read next P if any

Store P

Error if P is not a positive integer

Hole bottom dimension

5

en-938872/2 5 - 7

Page 84

[RETURN]= 'ER

BCLR [.IBX(3)]

Return dimension

Z axis disabled

L0= [.IRX(1)]

L1= [.IRX(2)]

L2= L0 + [.IRP(3)]

XL2

G997

X dimension

Y dimension

Cycle start dimension

Hole bottom dimension modified

XY movements enabled

FOR L4= 1 TO L100

L5= L4

L6= CL5

L7= SL5

360 / L100

*

[.IRP(3)] + L0

*

[.IRP(3)] + L1

*

G3 G94 F5000 XL6 YL7 IL0 JL1

M997

IF [.IBE0(6)]= 1 THEN

Current angle

X dimension

Y dimension

Circular positioning

Forced concatenation

Feed rate

G94 FL905

ENDI

G1 Z L925

G4 F1

G0 Z [RETURN]

Hole drilled

Dwell in bottom of hole

Return in Z

M999

ENDF

G [G94/5] F [FEED]

End of cycle

Return to initial conditions

PULL L0 - L7

G79 N9999

End of cycle

5 - 8 en-938872/2

N100 E.500

N101 E.501

Error number (see %20500)

Error number (see %20500)

N9999

Error message programme

%20500 (Error messages of cycle G199)

N500 $ P AND R MANDATORY IN G199

N501 $ P MUST BE A POSITIVE INTEGER IN G199

Page 85

Creating Subroutines Called by G Functions

Example 2

Creating a special cycle with function G177 (subroutine %10177).

The cycle below is given only for guidance.

It is used to execute a profile by back and forth passes with the possibility of radius

correction if required.

Cycle syntax and parameters

G177 N.. N.. ER..

G177 Machining by back and forth passes.

N.. N.. Numbers of the first and last blocks defining the profile