Page 1

Yellow Box User Manual

Yellow Box

z

Issue Number:

1.14

Issue Date:

29/01/2018

V.1.1

The

General Short Form User Manual

Portable Oxygen Analyser

Part Number.: 05-674

Page 2

Yellow Box User Manual

Contents

1. Introduction .................................................................................... 3

1.1 SPECIFICATIONS .................................................................. 3

2. Warnings ! ....................................................................................... 4

3. Start up ............................................................................................ 4

4. Operation ......................................................................................... 5

5. Calibration ....................................................................................... 6

MENU 1 – CALIBRATE SENSOR .......................................................... 7

MENU 8 - DIAGNOSTICS .................................................................... 8

The Yellow Box Analyser ................................................................... 9

Frontplate Description ....................................................................... 9

6. Maintenance .................................................................................. 10

Page 3

Yellow Box User Manual

V.1.1

Issue:

1.14

Page 3

1. INTRODUCTION

The Yellow Box Portable Oxygen Analyser is based on the Microx range of

Oxygen Analysers and incorporates two selectable Microx Analysers which

are application dependant to the end users requirements.

Typical measurement ranges are 0-25% and 0-1000ppm, and these will be

taken as a basis for the instructions that follow in this manual. For Yellow Box

models with different measurement ranges, the same operational principles

apply but calibration gases will differ. (Details available from Ntron when

required)

The Instrument is powered by connection to a main AC power supply as given

in the specification table below but is also available with an optional internal

Battery offering remote operation where no mains power outlet is available

and power back-up in case of a mains power failure. This option, if required,

must be specified at time of order.

The Yellow Box contains a flow indicator and flow adjustment to enable the

correct amount of sample gas to be presented to the internal Zirconia Oxygen

Sensors.

The Yellow Box is presented in a robust carry-case with Lid which provides

protection during transportation and use.

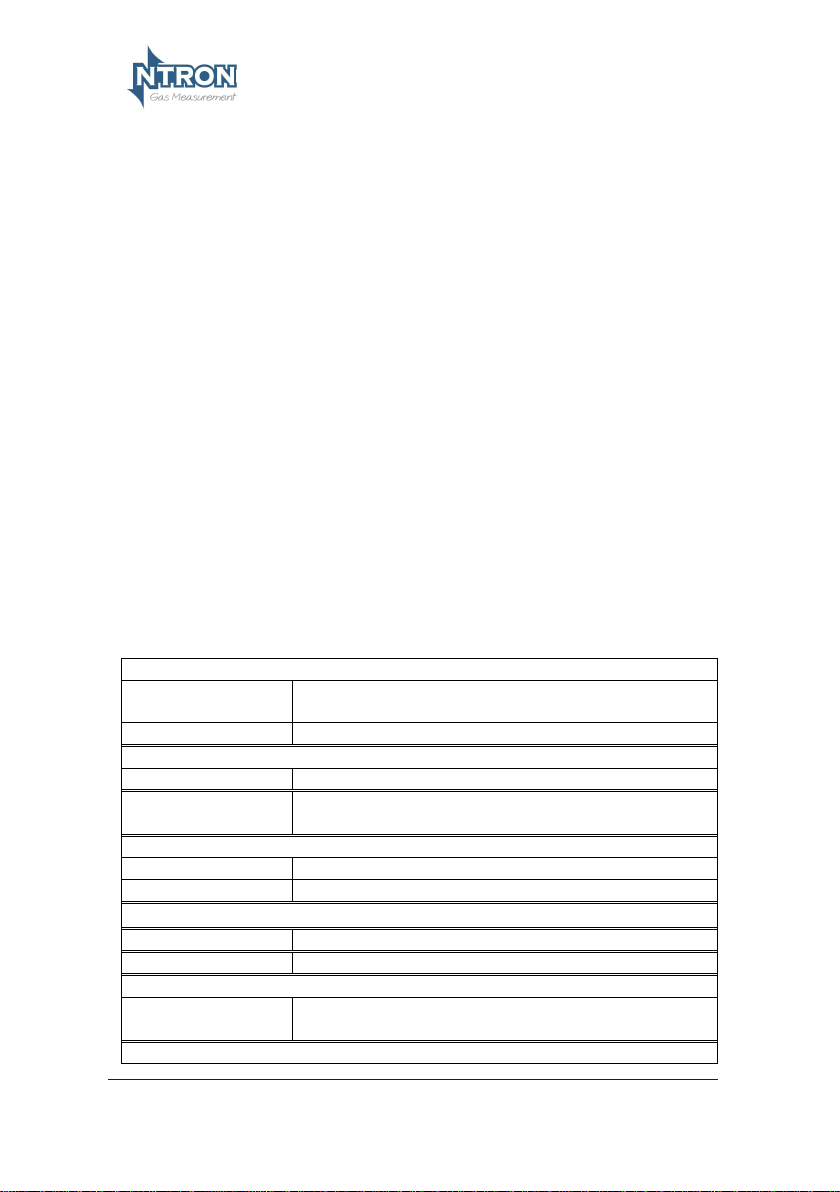

1.1 Specifications

Supply

Mains Input

Voltage

85-264VAC ; 47-63Hz; 0.1-0.15A

Battery Option:

Backup battery @ 12VDC , 2.3AH

Sensor

Type:

ppm and % Zirconia Oxide

Life:

5 years (Depending on Air exposure and other

gases)

Typical Range

%

0.1-25 Oxygen; Accuracy 2% of FSD

ppm

1-1000 Oxygen; Accuracy 2% of FSD

Sample Gas Input/Output

Pressure:

</= 2 Barg

Flow:

300-500 cc/minute (Typically 250cc/minute)

Fuses

Main Fuse

500mA anti-surge front panel fuse for input

protection.

Additional Features (microx analysers)

Page 4

Yellow Box User Manual

V.1.1

Issue:

1.14

Page 4

Display:

4 Digit, 7 Segment Display.

Keypad:

4-Button Keypad

Weight:

Typically 8Kg but dependant on model type.

Operating Temp.

+5 to +45 Degrees Centigrade

2. WARNINGS !

Over pressure at the sample gas input to the Yellow Box can damage the

internal Sensors.

Moisture or other liquid with the sample gas stream can damage the

internal Sensors particularly if applied when the internal Sensors are in

their un-powered/un-heated state.

3. START UP

.

Switch-on the Yellow Box by operating the %-On/Off-ppm 3 –position switch

on the front plate of the Yellow Box.

(Select % or ppm )

(For units with optional internal Battery, ensure that the battery is charged

sufficiently for operation or that the yellow Box is connected to the mains

electrical supply)

Choose the Microx module for the correct range of sample gas to be

measured.

When power is then first applied to the Microx module (% or ppm) an

initialisation procedure is performed as follows:

• All the display segments are displayed

• The software version number is displayed

• The company name is displayed

• The sensor type is displayed

• The display then shows the gas level.

The module is now operational

Page 5

Yellow Box User Manual

V.1.1

Issue:

1.14

Page 5

4. OPERATION

Note: A series of instruction labels are affixed to the front plate of the

Yellow Box and these can be followed for quick reference. Please see

the photograph of the front plate following the written instructions

below.

1. When the Yellow Box is first switched-on, do not use it for at least 15

minutes to allow the internal Zirconia Sensors to reach correct

operating temperature.

2. Connect a Rotameter (flowmeter) to the sample gas exhaust outlet of

the Yellow Box.

3. Ensure that at this time, the gas flow regulator valve on the Yellow

Box front plate is closed.

4. Measure or otherwise confirm the pressure of the sample gas to be

supplied to the Yellow Box before connection to the Yellow Box. If it

is in excess of 2 Barg, then the pressure must be reduced using

external components. (e.g. Pressure relief valve to line. Relief to

ambient air may result in sample contamination)

5. Connect the sample gas source to the Yellow Box Sample gas input

connection. This should be less than or equal to 2Barg.

6. Open the gas flow regulator valve and set the flow rate to between

300 and 500 cc per minute.(Visible on the Rotameter connected to

the sample gas outlet) At the same time the gas flow should be

indicated to be within the green section of the in-built flow indicator

on the Yellow Box frontplate.

7. Wait until all air is purged from the sample line and a stable reading

is obtained. For ppm measurement, this will take much longer

especially if the sample pipework within the yellow Box has been

exposed to ambient air.

8. Measurements can now be observed.

Page 6

Yellow Box User Manual

V.1.1

Issue:

1.14

Page 6

5. CALIBRATION

This is done by using the Menu functions on the Microx modules.

A Zero point calibration is not normally required after the initial setting when

manufactured, so calibration consists of a Span calibration for both the ppm

and % Microx modules.

Normal calibration gas used:

Certified gas 100ppm for the ppm Microx module.

Certified gas 20.9% for the % Microx module.

These gases should be applied individually after selecting the appropriate

Microx module to be calibrated. (It may be better to first calibrate the ppm

Microx module )

For a calibration to be performed, it is necessary to use the Menu system of

the Microx module. here are a range of Menus visible to the user but only

small number are required or should be entered by the user of the yellow Box.

Menu

option

Function

E:1

Calibrate Sensor

E:2

Analogue output FSD Not used/Do Not Use

E:3

Set 4 mA Not used/Do Not Use

E:4

Set 20 mA Not used/Do Not Use

E:5

Sensor simulation Not used/Do Not Use

E:6

Set sensor type Not used/Do Not Use

E:7

Not used/Do Not Use

E:8

Diagnostics Observation only.

E:9

Set Sensor type Not used/Do Not Use

Page 7

Yellow Box User Manual

V.1.1

Issue:

1.14

Page 7

1. Follow the start up procedures as detailed previously.

2. If required, fit the Rotameter to the sample outlet of the Yellow Box.

3. Ensure the gas pressure from the calibration gas source is within the

2 Barg pressure rating.

4. The required sample gas should be connected to the Yellow Box

sample input and allowed to flow sufficiently to purge the system.

5. When the reading on the Microx module is steady, compare it to the

value of the calibration gas. If correction is required, follow the

calibration procedure which follows.

Menu 1 – Calibrate sensor

• Press the MENU button to open the menu system.

• Using the NEXT and PREVIOUS buttons select menu option:

E:1

• Press ENTER.

• Apply a known concentration of gas (applicable to sensor type)

at a flow rate of between 100 to 500 ml/m. Allow time for the

sensor to respond. (see diagram on page 8)

• Using the INC and DEC buttons set the reading to that of the

calibration gas level.

• Press ENTER to span the sensor, ‘– – – –‘will be displayed to

confirm the sensor span has been performed.

Note: Pressing the MENU button rather than the ENTER

button exits the span feature without performing the

calibration.

Wait until the reading is stable, if not press the ENTER

button to span the sensor.

• Press the MENU button to close the menu system.

Note: The sensor span setting will be displayed ( as a

percentage value) on exit while the MENU key is pressed.

Note that this value is a percentage of the initial calibration

value .

• Turn off and disconnect the calibration gas.

Repeat the procedure for the second Microx module.

Page 8

Yellow Box User Manual

V.1.1

Issue:

1.14

Page 8

Microx module

The keypad has the following functionality:

Button

Function

Alternate Function

A

Menu Open/Close

B

Enter

C

Next (Increment)

D

Previous (Decrement)

Menu 8 - Diagnostics

This feature is a view-only feature. No configuration changes are possible

from within this menu.

• Press the MENU button to open the menu system.

• Using the NEXT and PREVIOUS buttons select menu option:

E:8

• Press ENTER.

• The display will alternate between the current value and

diagnostic code E:8x: where x is:

0 Sensor signal, A to D counts low ppm range.

1 Sensor signal, A to D counts high ppm range.

2 Sensor signal, A to D counts %vol range.

3 Firmware version.

• The diagnostic code can be selected by pressing the UP button.

• Press MENU to return the instrument to its standard mode of

operation.

20.9

Page 9

Yellow Box User Manual

V.1.1

Issue:

1.14

Page 9

The Yellow Box Analyser

Frontplate Description

*Battery Charge

Indicator

On/Off %/ppm

Selector Switch

Flow control/adjust

Mains power connection

Fuse

Sample gas

exhaust

Sample gas

input

Sample Gas Flowmeter

Brief Instructions:

1. Power up the unit by selecting % or PPM with the 3 position switch.

2. Close the flow adjust valve by turning it fully clockwise

3. Turn the flow indicator to its vertical position.

4. Connect a gas sample via the sample inlet port

5. Gradually open the flow adjust valve to achieve a flow in the green sector of

the flow indicator.

6. Allow the oxygen reading to stabilise and thereafter a reading can be taken.

*Models with optional internal Battery only.

✓

Page 10

Yellow Box User Manual

V.1.1

Issue:

1.14

Page 10

6. MAINTENANCE

Ensure that the Yellow Box faceplate is kept clean at all times.

Do not use chemical or abrasive cleaners on the Yellow Box case or

frontplate.

Perform annual calibration or as required.

When not in use, cover or plug the sample gas inlet and outlet ports of the

yellow box to minimise air intake and contaminants/ particulates.

Keep the cover of the Yellow Box closed when not in use.

The internal Sensors should provide a long life of operation but will require

replacement as some point. Contact the manufacturer when this is required.

Sensor replacement required may be indicated by a difficulty to calibrate the

Microx modules.

Note: some gases may be damaging to the Zirconia Sensor such as

Halogens or organic vapours. When the yellow Box is not under power,

water, condensed humidity and gases such as H2S and SOx should not be

allowed to flow into the yellow Box.

Optional Battery Unit.

The optional internal battery should provide a long life of operation but will

require replacement at some point. Contact the manufacturer when this is

required.

This will be indicated when the operating period of the Battery reduces

dramatically.

Page 11

Yellow Box User Manual

V.1.1

Issue:

1.14

Page 11

Mullaghboy Industrial Park

Navan, Co. Meath, Ireland

Phone: 00-353-46-9071333 • FAX: 00-353-46-9071331

E-Mail: info@ntron.com

Web: www.ntron.com

Loading...

Loading...