NStor Technologies CR8e, Disk Array Enclosure User Manual

nStor Corporation, Inc.

© 1996-1998 nStor Corporation, Inc., All Rights Reserved.

3rd Edition

nStor Corporation, Inc. shall not be liable for any damages or for the loss of any information resulting from the

performance or use of the information contained herein. Your rights to the software are governed by the license

agreement included with any accompanying software. nStor Corporation reserves the right to periodically revise this

manual without notice.

Product features and specifications described are subject to change without notice.

This manual may not be reproduced in whole or part, without prior written permission from nStor Corporation, Inc.

nStor Corporation, Inc.

450 Technology Park

Lake Mary, Florida 32746

nStor, A dminiStor, Smart Cabinet, and the nStor logo are trademarks or r egister ed tr ademarks of nStor Corpor ation, Inc.

Other company and product names herein may be trademarks or registered trademarks of their respective

companies.

CAUTION:

ATTENTION:

NOTE:

Drives and controller/adapter cards described in this manual should only be installed in UL-listed

and CSA certified computers that give specific instructions on the installation and removal of

accessory cards (refer to your computer installation manual for proper instructions).

Les lecteurs et cartes contrôleurs décrits ici ne doivent être montés que sur des ordinateurs

homologués (UL et CSA) et livrés avec des manuels contenant les instructions d’installation et de

retrait des accessoires. Reportez-vous au manuel d’installation de votre ordinateur.

Only drives supplied by nStor Corporation are approved for use in this pr oduct. Use of other driv es

could affect the safety and/or radio frequency interference characteristics of the product.

Regulatory Information

FCC Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy, and if not installed and used in

accordance with the instructions, may cause harmful interference to radio or tele vision communications. However , there is

no guarantee that the interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

■

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

■

Connect the equipment to an outlet on a circuit other than that to which the receiver is connected.

■

■

Consult the dealer or an experienced radio/TV technician for help.

nStor Corporation, Inc. is not r esponsible for any interfer ence caused b y unauthorized modifications to this equipment. It is

the user’s responsibility to correct such interference. You are also warned, that any changes to this certified device will void

your legal right to operate it.

CAUTION:

ATTENTION:

Drives and controller/adapter cards described in this manual should only be installed in UL-listed and CSA

certified computers that give specific instructions on the installation and removal of accessory cards (refer

to your computer installation manual for proper instructions).

Les lecteurs et cartes contrôleurs décrits ici ne doivent être montés que sur des ordinateurs homologués (UL

et CSA) et livrés avec des manuels contenant les instructions d’installation et de retrait des accessoires.

Reportez-vous au manuel d’installation de votre ordinateur.

Compliance Information Statement

We

,

nStor Corporation, Inc.

450 Technology Park

Lake Mary, Florida 32746

(407) 829-3500

declare under our sole responsibility that the product,

Type of Equipment: Disk Array Enclosure

Model Number: CR8e

to which this declaration relates is in conformity with the Title 47 o f the US Code o f Federal Regulations, P art 15 co v ering Class B

personal computers and peripherals.

Operation is subject to the following two conditions:

1

This device may not cause harmful interference, and

2

This device must accept any interference received, including interference that may cause undesired operation.

Power Cord Selection

■

This subsystem is intended for indoor use only.

This subsystem is intended to be plugged into a 6A branch circuit in Europe.

■

To select the proper power cord:

■

For 110 Volt Operation

– Use a UL Listed/CSA Labeled cord set consisting of a minimum 18 AWG, type SVT or

SJT three conductor cord, terminating in a molded connector body having an IEC CEE-22 female configuration on

one end and a molded-on parallel blade grounding type attachment plug rated 15A, 125V configuration (5 - 15P) at

the other end.

For 230 Volt Operation (North America)

– Use a UL Listed/CSA Labeled cord set consisting of a minimum 18

AWG, type SVT or SJT three conductor cord, terminating in a molded connector body having an IEC CEE-22

female configuration on one end and a molded-on tandem blade grounding type attachment plug rated 15A, 250V

configuration (6 - 15P) at the other end.

For 230 Volt Operation (Europe)

– Use a cord set marked “HAR”, consisting of a H05VV-F cord that has a

minimum 0.75 square mm diameter conductors provided with an IEC 320 receptacle and a male plug for the

country of installation rated 6A, 250V.

NOTE:

The subsystem automatically selects the proper settings for the input voltage. Therefore, no additional adjustments

are necessary to connect the unit to any input voltage within the range marked on the drive.

Das Laufwerk sollte nicht im Freien verwendet werden.

■

■

In Europa, sollte das Laufwerk an einen 6A-Stromkreis angeschlossen werden.

Zur Wahl des korrekten Netzkabels beachten Sie bitte folgendes:

■

230V-Betrieb (Europa)

– Verwenden Sie Netzkabel der Bezeichnung “HAR” die H05VV-F-Kabel und einen

Leitungsdurchmesser von mindestens 0,75 mm2 aufweisen. Ver Wenden Sie eine IEC 320-Buchse und einen für das

Installationsland passenden Stecker, der auf 6A und 250V gesichert ist.

Contents

Preface

Welcome v

Features vi

Where to Find Answers vii

Registering Your Product vii

1 Getting Started

CR8e Subsystem at a Glance 2

Components 4

Hot Swap Disk Drives 4

Hot Swap Cooling Fans 4

Hot Swap Power Supplies 5

Power Switch 5

Door Lock 5

I/O Interface Card 6

Power Cord Connector and Fuse 6

Configuration Modules 7

Controlling and Monitoring 8

Operator Control Panel 8

LEDs 9

Alarm Speaker 11

Fault LEDs 11

SAF-TE Card 11

v

1

i

2 Installation

Setup 13

System Requirements 14

Guidelines 14

Rack-Mount Subsystem Assembly 15

Component Installation 17

Cabling Configuration 20

General 20

Ultra Wide SCSI Mode 22

Fast Wide SCSI Mode 26

Other Configurations 36

13

3 Using the CR8e

Notifications and Error Conditions 37

Power-On Self Test 37

Firmware Error Conditions 38

LED Descriptions 39

Operator Control Panel 40

Startup Screens 40

Power Supply Error Conditions 41

Subsystem Status Icon 41

Main Menu 42

Options Menu 46

Heat Threshold 49

SAFTE CHAIN ID 50

Change Passcode 51

Unlock Options 52

4 Troubleshooting

Common Enclosure Problems 53

Common SCSI Bus Problems 54

Common Problems and Interpreting the LED Indications 56

37

53

5 Maintenance

Replacing a Disk Drive 57

Replacing a Power Supply 58

Replacing the Cooling Fans 60

Replacing an I/O Interface Card 61

ii

Contents

57

Replacing a Fuse 62

Replacing the CR8e Cabinet 63

A Glossary

B Technical Information

Specifications 69

Connectors and Jumpers 70

Connectors 70

Jumpers 72

Index

65

69

77

Contents

iii

iv

Contents

Preface

Welcome

Congratulations on the purchase of your new CR8e from nStor Corporation.

The nStor CR8e provides a superior fault-tolerant network storage solution in a

subsystem-based SAF-TE compliant RAID enclosure.

The CR8e is an eight drive enclosure designed to support Ultra Wide SCSI

(Fast-20) and Fast Wide SCSI protocols. The Ultra Wide SCSI (Fast-20) support

maintains SCSI bus data transfer rates up to 40 Mbytes/sec. The subsystem

supports both host system based RAID controllers, as well as an option for an

onboard Ultra SCSI-to-SCSI RAID controller.

The CR8e also provides an upgrade path to Ultra2 Low Voltage Differential

(LVD) SCSI technology and easily connects to the network attach storage module

to maintain its total cost of ownership.

The intelligent enclosure is compliant with SAF-TE version 1.0, an industry

standard, non-proprietary means to automatically integrate with peripheral

packaging that supports status signals, hot swapping drives and enclosure

monitoring. Combined with the enterprise-wide storage management software

from nStor, additional levels of fault tolerance can be maintained.

v

Preface

Features

The following are major features of the nStor CR8e disk array subsystem:

RAID Level Support

Configuration

Drive Support

Interface

Scalable Capacities

Hot Swap Power Supplies

Cooling

Notifications

Front Panel

RAID levels 0, 1, 3, 5, 10

Deskside tower-based subsystem or rack-mount

subsystem.

Up to eight 3.5-inch, half-height form factor, hot

swappable high performance 7,200 and 10,000 RPM

Ultra SCSI disk drives using SC A-II technology (4.2, 9.1,

or 18.2 gigabyte capacities).

Ultra SCSI (Fast 20)/SCSI.

Drive capacities are expandable to 145 GB using 18 GB

disk drives and further expansion through

daisy-chaining of multiple cabinets.

Dual hot swap power supplies expandable to three, all

with current sharing circuitry.

Dual high capacity hot swap cooling fans.

LEDs and audible alarms provide failure notifications.

A password protected Oper ator Control Panel (OCP) for

administration control and monitoring functions.

(1 + 0)

, 30, and 50.

SCSI-to-SCSI Support

Termination

Locking Door

SAF-TE

Cluster-Ready

Storage Management Solution

vi

Features

Provides on-board Ultra SCSI-to-Ultra SCSI RAID

processing via the Ultra S2S RAID Controller.

Automatic SCSI-bus termination.

A key-locking front door.

SAF-TE v1.0 compliant enclosure.

Cluster-ready subsystem.

Enterprise-wide managing and monitoring using

AdminiStor Manager and AdminiStor Agent software.

Preface

Where to Find Answers

When you have questions about your nStor products there are several places you

can look to find answers. Refer to the following:

In this guide

Resource Guide

AdminiStor Manager User’s Guide

AdminiStor Agent User’s Guide

On the software diskettes

Via email

This user’s guide provides detailed information for

installing and using the CR8e

manual assumes that the reader is already familiar with the

operating system environments where the CR8e will be

installed.

Use this manual to locate telephone numbers for customer

service and technical support, technical support email

address, instructions to obtain an RMA number, and

conditions of the limited warranty.

Use this manual to install and use the nStor Java-based

management and monitoring software.

Use one of these manuals to install and use the nStor

SNMP-based network RAID subsystem management

software.

Review the README files for last minute information

about the release of the software products.

You may email questions and comments to

support@nstor.com.

disk array subsystem. The

Registering Your Product

Registering your product allows nStor to continue providing the highest quality

technical support while keeping you informed about product developments.

To register your product, complete and fax the Plan Registration/Upgrade Form

found in the Product Registration kit.

Where to Find Answers

vii

Preface

viii

Registering Your Product

1

Getting Started

In this chapter we will provide a description of the components, and the control

and onboard monitoring systems found in the CR8e enclosure.

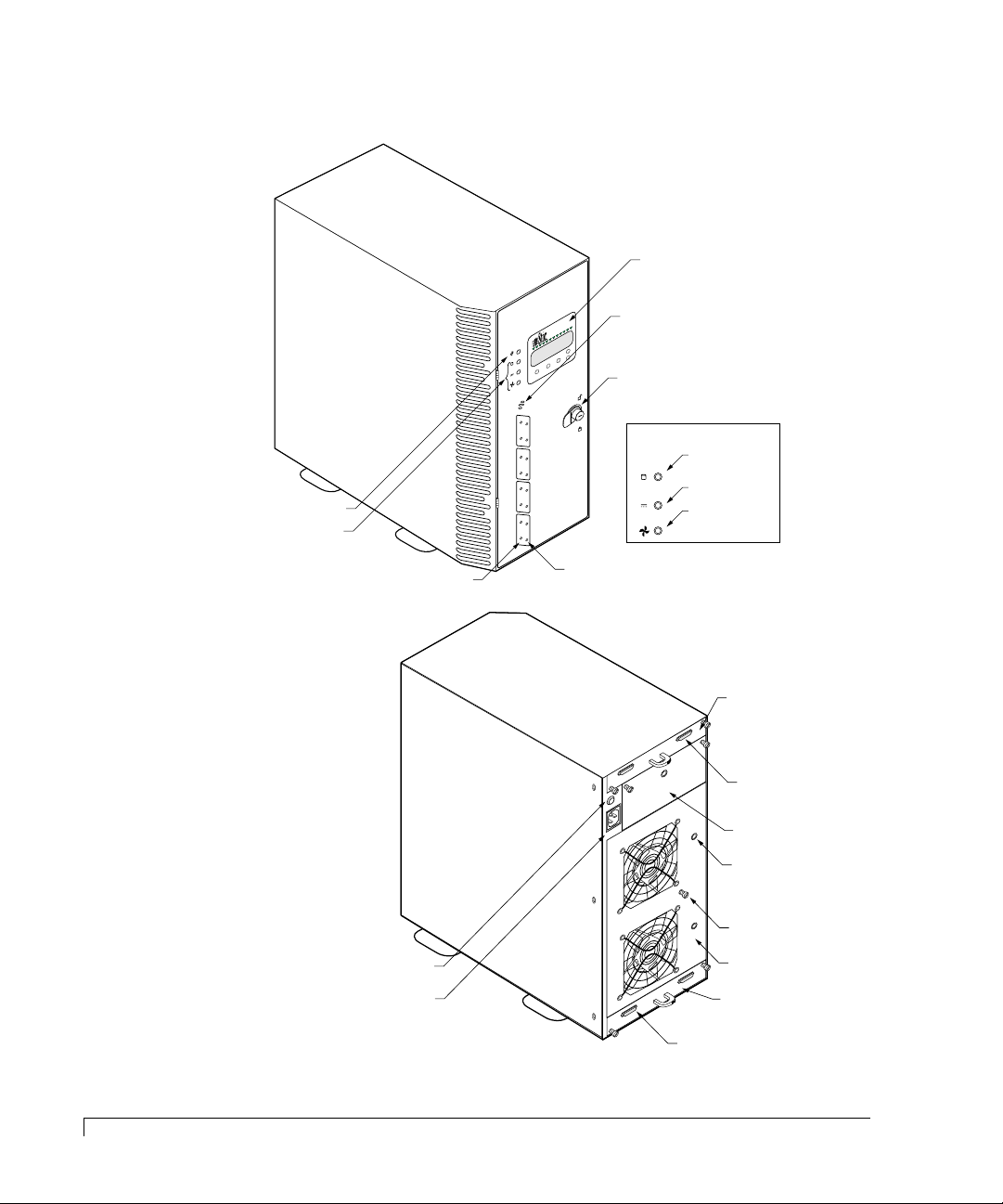

On the next two pages are illustrations that depicts the location of featured

components of the CR8e. Familiarize yourself with the subsystem’s components

and their descriptions prior to beginning the installation and using the CR8e.

Following the Components section, a Control and Monitoring section describes

the subsystem’s LEDs provides an explanation of the manner in which the CR8e

presents normal and abnormal conditions. The Operator Control Panel (OCP)

section describes in the general the features of the LCD panel and an illustration

pictorially describes items found on the display. In chapter 3 a more detailed

functional description of each OCP menu option is provided.

1

Getting Started

Channel Mode LED

Power Supply LED

Fan Status LED

Status Indicator LEDs

Note: LEDs normally visible

only when illuminated,

shown here for identification.

Activity LEDs

Operator Control

Panel (OCP)

Speaker

Door Lock

Power-On LED

Status Indicator LEDs

Status LEDs

Rear Door Fastener

Rear Door Panel

AC Power Cord

Connector Module

I/O Interface Card

I/O Interface Card

VHD SCSI Connectors

VHD SCSI Connectors

Power Supply #3

with PSU Cover Plate

PSU “DC Good” LED

Fuse

CR8e Subsystem at a Glance

2

CR8e Subsystem at a Glance

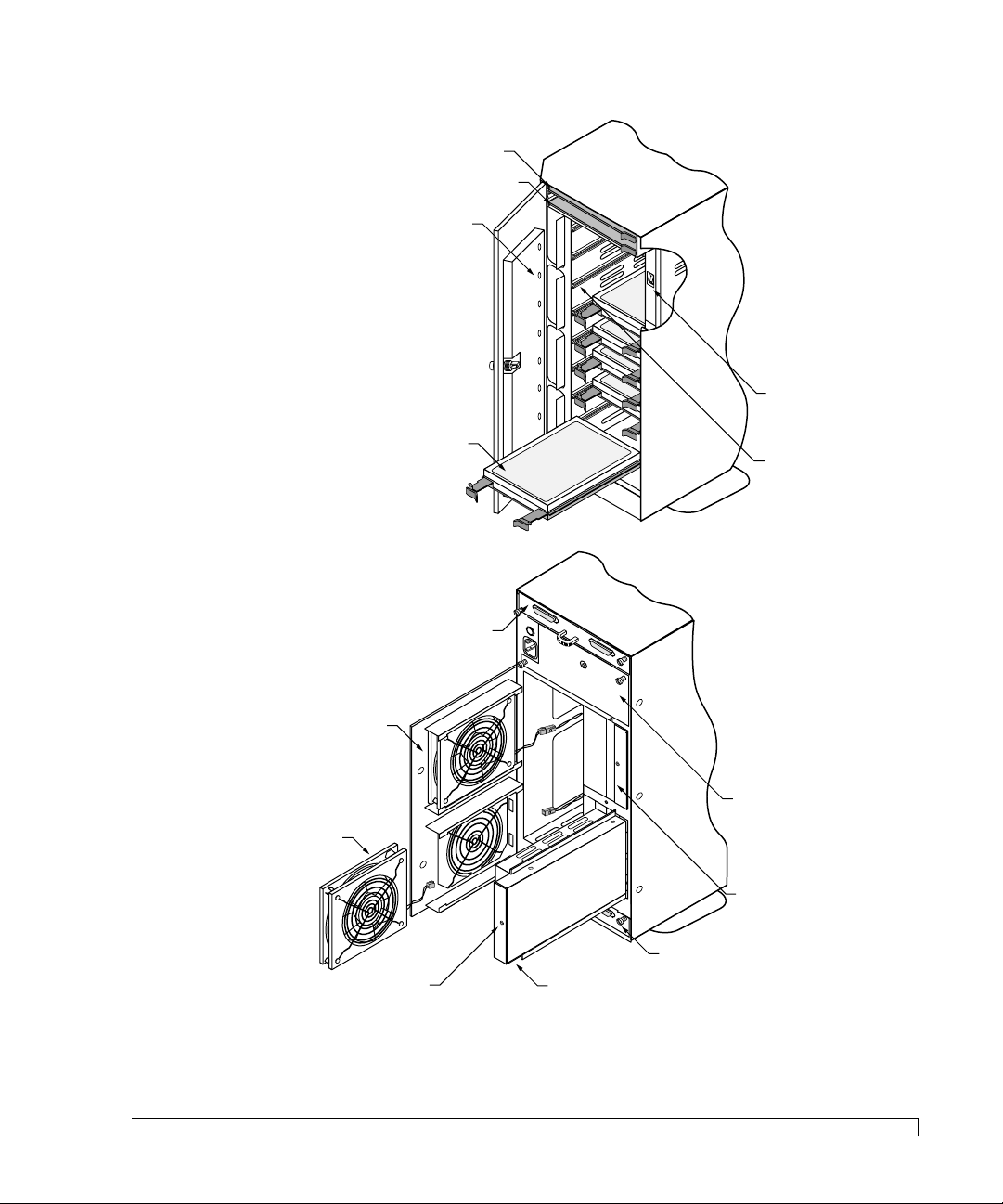

Bay for optional

Ultra S2S RAID Controller

SAF-TE Card

Fault LEDs

Getting Started

Power On/Off

Switch

Cooling Fan #2

Cooling Fan #1

Hard Disk Drive

I/O Interface Card

*

*

“DC Good” LED

Power Supply #1

Drive Rails

Note: Cover shown cut-away

to illustrate recessed power switch.

Power Supply #3

with PSU Cover Plate

Power Supply #2

I/O Interface Card

*

*

*

* Power supplies and cooling fans must be replaced by qualified service personnel only.

CR8e Subsystem at a Glance

3

Getting Started

Components

This section provides a descriptive overview of each of the major components

that comprise the CR8e subsystem.

Hot Swap Disk Drives

The CR8e uses either 4.2 gigabyte , 9.1 gigab yte , or 18.2 gigab yte high performance,

3.5-inch form factor hot swap disk drives. The drives are designed to operate on

the Small Computer System Interface (SCSI) and are Ultra SCSI as well as SCSI-2

command compatible.

Each drive has an 80-pin Wide Single Connector Attachment (SCA-II) interface,

designed to allow the drive to be inserted directly into the backplane thus making

it possible to “hot swap” the drive without shutting down the subsystem.

The drive mounting design uses a rail system with built-in connectors which

allows for easy installation with minimal force. Latching clips ensure that the

drive is secured once it is installed.

4

Components

Hot Swap Cooling Fans

CAUTION:

The cooling system consists of two high-performance fans fitted to the rear panel.

These fans draw air from a high pressure plenum, across the drives and

electronics of the system and exhaust out through the rear door panel.

The fan speed is thermally controlled to provide r educed operating noise le vels. In

the event of a fan failure or the cabinet temperature approaches the threshold

limit, the remaining fan will switch to maximum operating speed.

Cabinet temperature is measured within the drive bay area between drive slots 2

and 3, and slots 7 and 8. The fan’s speed and alarm are key ed to the higher of the

two temperatures. The SAF-TE processor monitors the performance of each of

the fans via tach pulses which track the speed (RPM) of each fan impeller.

The fans can be replaced during normal operation without having to po wer do wn

the CR8e. In the event of a fan failure, the Fan Status LED will illuminate amber

and an alarm will sound.

Cooling fans must be replaced by qualified service personnel only.

Getting Started

If an error occurs, access the Operator Control Panel to determine the cause and

locate the failed component. For more information, see

page 40. The fans are identified on the rear door panel using a placard for “FAN 1”

and “FAN 2.” For more information on changing a cooling fan, see

Cooling Fans

on page 60.

Operator Control Panel

Replacing the

on

Hot Swap Power Supplies

CAUTION:

Up to three 150 watt hot swap power supplies are incorporated as part of a

fault-tolerant design (N+1 power system). Each power supply unit (PSU) has

current share circuitry which balances the load between the installed power

supplies. In the event of a power supply failure, the load is transferred to the

remaining power supplies without interruption to the CR8e’s normal operation.

If a failure occurs, the Power Supply Status LED will illuminate amber and an

alarm will sound. The user can identify the failed component by accessing the OCP

and viewing the “Hardware Status.” The PSU “DC Good” LED will not be

illuminated on the failed power supply. For more information, see

Power Supply

Power supplies must be replaced by qualified service personnel only.

Replacing a

on page 58.

Power Switch

The power switch is located inside the locking fr ont door and controls AC po w er to

all of the power supplies. This positioning of the switch deters unauthorized users

from powering down the CR8e provided the door is locked. The switch is recessed

to prevent inadvertent activation during service activities.

The switch is labeled with a “I” for the ON condition and “O” for the OFF condition

and is illuminated when the power is on for easy identification. Depending on the

orientation of the subsystem (i.e., in the rack configuration) the “I” label will appear

as a “—” and should be interpreted as the ON condition.

Door Lock

The front door has an integral lock that also serves as a door handle. In addition,

the door lock provides security to deter unauthorized access to the disk drives and

SAF-TE card. Two keys are provided with the system.

To unlock the door, insert the key and turn it in a counterclockwise dir ection. To

lock the door, turn the key in a clockwise direction.

Hot Swap Power Supplies

5

Getting Started

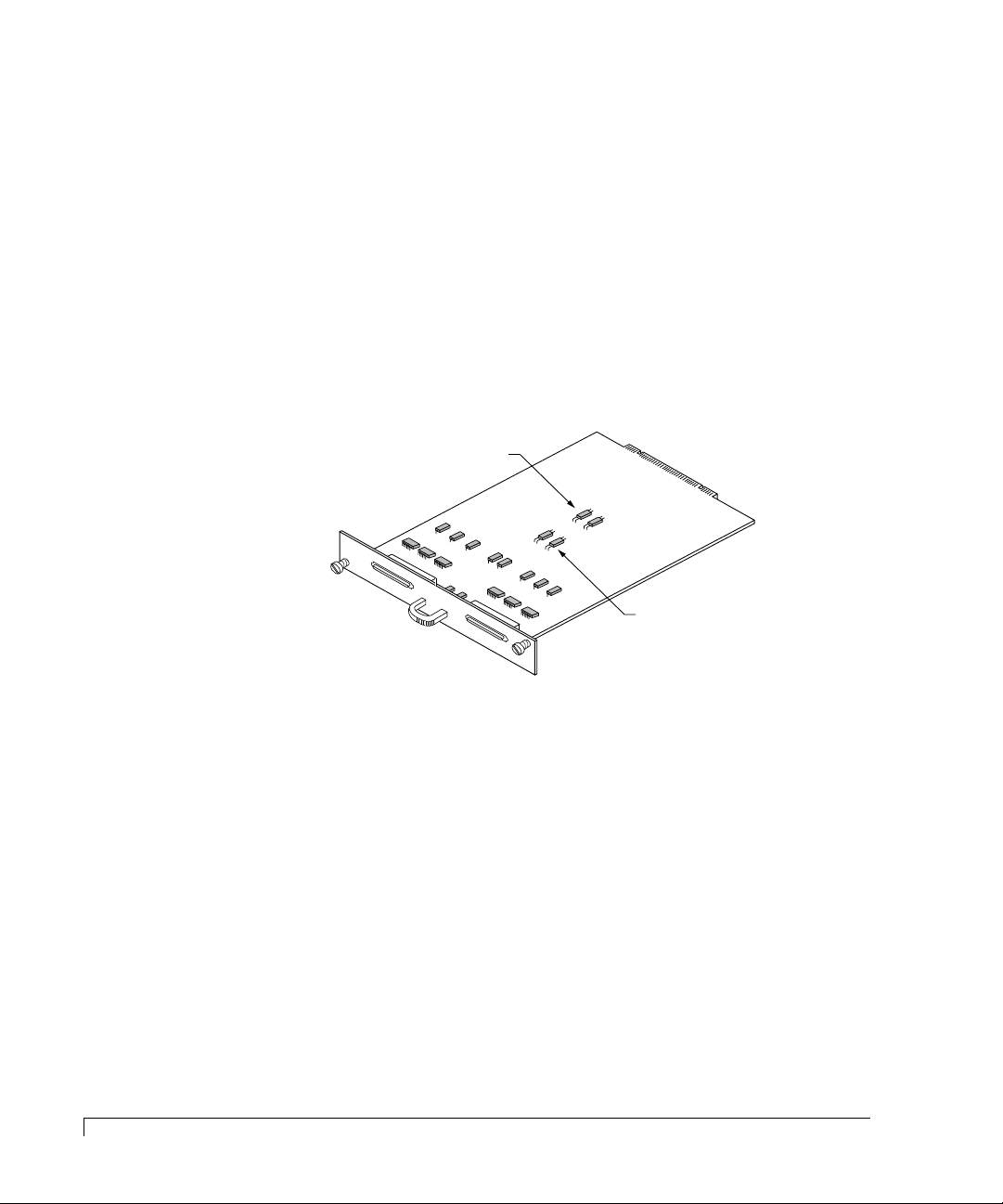

Channel 0

Channel 1

JP3 and JP4

Fault Bus Protocol

Jumpers (Add to

disable termination)

JP1 and JP2

Channel 0 and 1

Term Power Jumpers

I/O Interface Card

The I/O Interface card provides the connection from the subsystem’s bus to the

host adapter. Located on the I/O Interface card are two 68-pin very high density

(VHD) SCSI connectors. The connectors are labeled Channel 0 and Channel 1.

The I/O Interface card incorporates built-in automatic SCSI termination. When a

data cable is plugged in, the system automatically senses the connection and

provides the required SCSI termination.

Two sets of jumpers are provided on the card. One set of jumpers (JP1 and JP2)

routes Term Power in the event that the host controller does not provide it. The

default setting is the unjumpered condition (jumper offset on one pin only).

6

I/O Interface Card

The next set of jumpers, JP3 and JP4, addresses termination protocol for a specific

set of controllers that use the DEC Fault Bus. If you are using a DEC system

where the controller uses this protocol, y ou will need to jumper locations (jumper

on both pins) JP3 and JP4 for each channel that has an external SCSI cable

connected. This will disable termination at that point.

If you are using a standard host adapter that provides Term Power, no change is

required and SCSI bus termination will occur automatically.

Power Cord Connector and Fuse

The power cord connector supplies the AC power to the CR8e through a power

cord connected to a conventional three-hole grounded outlet or power strip. A

250V 10 amp fuse is provided to protect the system from any electrical fault.

Configuration Modules

Getting Started

CAUTION:

Configuration modules must be installed or replaced by qualified

service personnel only.

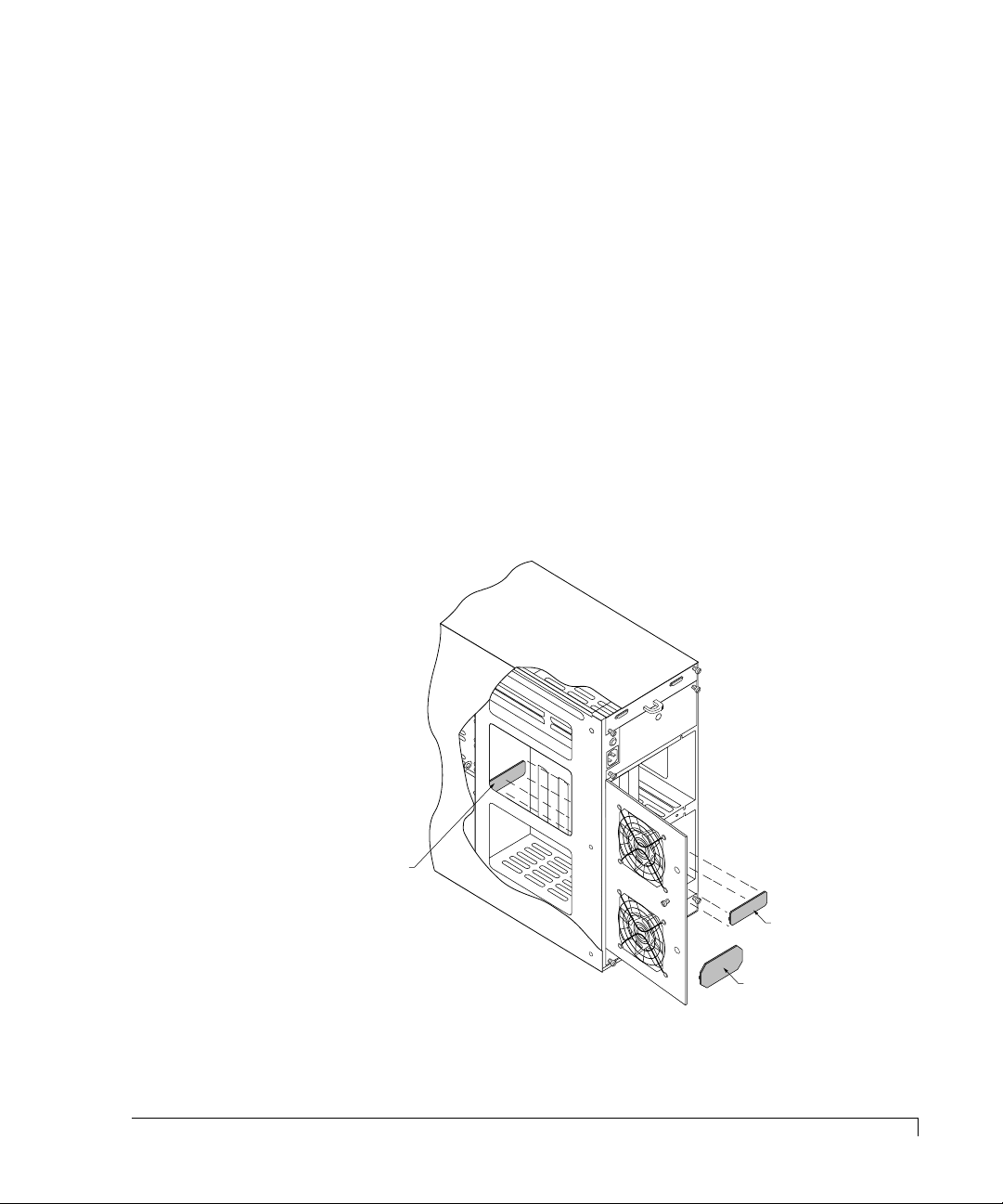

The CR8e’s SCSI bus design provides either of two bus configurations which is

determined by the configuration module installed. The Dual-Bus module pro vides

a split bus configuration where the enclosure’s top four drive slots and the lower

four drive slots are on two independent SCSI buses. The Single-Bus module

connects both SCSI buses together tying all drive slots to one SCSI bus.

The Single-Bus module is larger in physical size than the Dual-Bus module and is

easily identified by its description silkscreened on the module card. It is installed

on the backplane printed circuit board, at location JP1, and is accessed from the

rear door panel.

The connector is keyed and the module will only install in one direction. For

illustration purposes, the tower system is used to depict the location of the

modules.

Backplane PCB

(JP1)

NOTE: The cover is cut

away to demonstrate

the location of the installed

configuration module.

Dual-Bus Module

Single-Bus Module

Configuration Modules

7

Getting Started

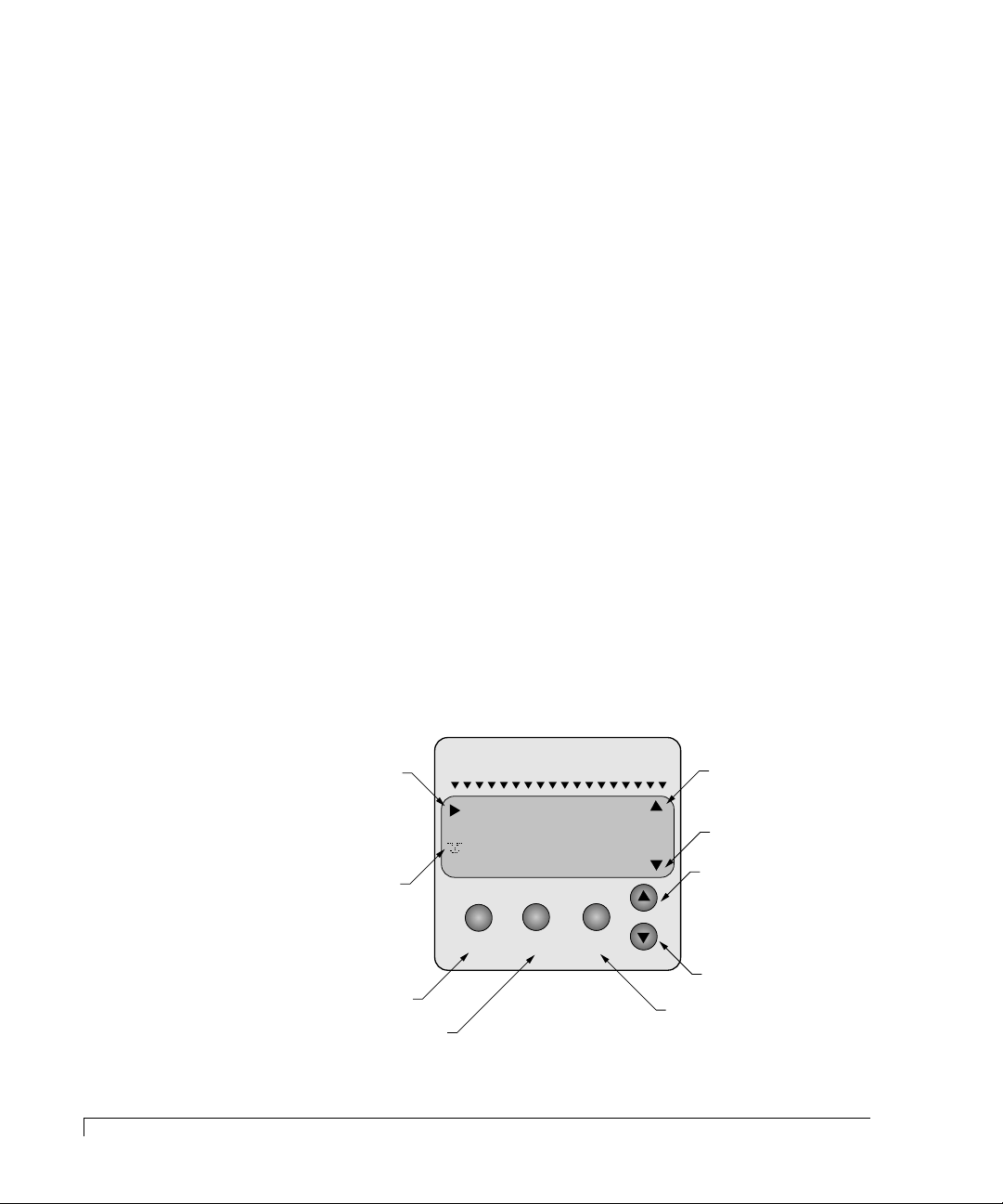

MENU ENTER ESCAPE

HARDWARE MENU

OPTIONS MENU

TURN OFF ALARM

Moves Menu

Selector Up

Appears When

More Options are

Available Above

Appears When

More Options are

Available Below

Moves Menu

Selector Down

Menu

Selector

firmware by lyle

Animated

Icon

Selects Menus Option or

Returns to Main Menu

Selects the Option

Indicated by Selector

Backs Up One Level

or Cancels Action

nStor

Controlling and Monitoring

An integral part of the CR8e is its control and monitor capabilities. The subsystem

enclosure contains a series of redundant alert notifications in the form of LEDs,

alarms, and an LCD Operator Control Panel. Each of these components are discuss

in the following topics.

Operator Control Panel

The Operator Control Panel (OCP) provides control and monitoring capabilities

through an LCD panel located on the front door of the CR8e. The disk drives,

power supplies, fans, and processor can be monitor ed for their status by using the

menu drive OCP interface. Also the user can maintain control of the subsystem

components by providing the capability to change to the disk drive SCSI IDs and

SAF-TE processor ID, and making changes to the temperature threshold for the

thermal monitoring system.

Other menu functions provide for viewing subsystem component status, silencing

the audible alarm, establishing a password to protect the subsystem OCP access,

establishing intra-cabinet communications (master/slave), and reading firmware

information.

8

Controlling and Monitoring

The OCP uses a four line by twenty character LCD display. There are five

function keys that define the menu driven interface.

Getting Started

An animated icon will appear on the display after 30 seconds of no OCP input

activity and provides an “at-a-glance” look at system status. When a “happy”

animated face appears, all systems are indicating a nominal state. When the

animated face changes to a “sad” face, the system indicates that a problem has

been detected and requires attention.

The “power system” status will display the total power available per drive slot in

redundant and non-redundant mode. A maximum supported value of 30 watts

per drive bay is av ailable in either mode. Also the user can view individual power

supply status and configurations.

The OCP displays information on each cooling fan’s speed. Each fan’s speed

(RPM) is controlled via the internal cabinet thermal monitoring system,

referenced from a user-established temper atur e thr eshold. Cabinet temper ature is

measured within the drive bay ar ea between driv e slots 2 and 3, and between slots

7 and 8. By sensing cabinet temperature in these locations, the system provides

the most sensitive measurement for maximum protection. The temperature is

displayed in both Celsius and Fahrenheit. The SAF-TE processor monitors the

performance of each fan via tach pulses which track the speed (RPM) of each fan

impeller.

LEDs

Power-On LED

The Power-On LED signifies that the CR8e system has power applied.

Status Indicator LEDs

There are three Status Indicator LEDs to assist the user in determining the current

state of the CR8e subsystem. The following subsections describe each LED.

Channel Mode

The Channel Mode LED indicates the status of the subsystem array by changes in

its color and state. Steady green indicates normal array activities.

When the LED changes to amber (flashing or steady) it indicates abnormal

activities. For more information see LED Descriptions on page 39.

LEDs

9

Getting Started

Power Supply Status

The Po wer Supply Status LED indicates the condition of the power supplies. The

LED will illuminate steady green when all the power supplies are functioning

normally and will change to amber if one of the power supplies should fail. The

LED will also switch to amber if the power system is in a non-redundant state. A

failed component can be identified via the Operator Control Panel and the lack of

an illuminated “DC Good” LED located on each power supply unit.

Fan Status

The Fan Status LED indicates the condition of the cooling fans by changes in its

color. The LED will illuminate green when all of the fans are functioning normally

and will change to amber if any of the fans fail.

When a failed component is present, use the Operator Control Panel to identify

the failed fan. The fans are identified on the rear door panel via placarded

markings. For more information see Hardware Menu on page 42.

Status LEDs

10

There are eight Status LEDs located in windows on the front panel (for the

rack-mount system they are the lo wer set of LEDs and for the to w er-based system

they will be the set on the left hand side).

These LEDs, in conjunction with an approved RAID controller, will indicate the

status of a specific disk drive by their state (flashing or steady) and/or color

(amber or green).

For more information on interpreting these indications, see LED Descriptions on

page 39.

Activity LEDs

There are eight Activity LEDs located in windows on the front panel (for the

rack-mount system they are the upper set of LEDs and for the to wer-based system

they will be the set on the right hand side). These LEDs will flash indicating a

specific drive is being accessed, either as reads or writes.

LEDs

Getting Started

Alarm Speaker

An audible alarm will sound when any component’s condition changes to an

abnormal state. The Status Indicator LEDs conditions (color and/or state) will

provide a general area of failure, and the failed component can then be identified

using the Operator Control Panel.

To silence the alarm, access the control panel and select “Turn Off Alarm.” For

more information see Main Menu on page 42.

Fault LEDs

When a disk drive is installed in a drive slot, it has a corresponding Drive Fault

LED that will illuminate to aide in identifying a failed or problem disk drive.

These LEDs are located on the inside front door panel and are aligned with their

respective drive slot. If the LED is illuminated (amber), the condition indicates a

failed or problem drive found in that drive slot.

SAF-TE Card

The SAF-TE card contains the control and monitoring electronics for the

subsystem cabinet. It provides the central data link betw een the enclosure and the

host system.

Located in the tower-based systems’ top bay (the r ack-mount systems’ far left bay)

are two card slots. The SAF-TE card is installed in the lower (furthest right) of

the two slots. The upper slot (furthest left slot) is not used.

SAF-TE

The CR8e is designed to be compliant with version 1.0 of the SAF-TE (SCSI

Accessed Fault-Tolerant Enclosure) specification. Under this specification, the

enclosure is implemented as an assignable SCSI target ID. This allows

standardized alert detection and status reporting using the SCSI bus as the

underlying transport mechanism.

Alarm Speaker

11

Getting Started

Disk drives, power supplies, cooling fans and temperature are continually

monitored and these conditions are then reported over the SCSI bus to the host

system.

When used in conjunction with the A dminiStor Stor age Management software , the

CR8e can alert the user or LAN administrator of conditions requiring their

attention. These alert notifications can be made via network br oadcast or electr onic

pages, in addition to the LEDs and Operator Control Panel alerts found on the

CR8e subsystem. This allows the administrator to receive remote notification of

conditions that require corrective action to prevent data loss.

12

SAF-TE Card

2

Installation

Setup

The installation of your nStor CR8e disk array subsystem is essentially a

three-step process: the subsystem is setup and its components installed, the

cabling is completed based on the supported configurations, and the array is then

configured.

This chapter is divided into two sections: Setup and Cabling Configuration. The

Setup section provides the instructions for assembling the rack-mount subsystem,

and installing the hardware components (contr ollers, disk driv es, pow er supplies,

etc.,) for both rack-mount and deskside tower-based subsystems.

The Cabling Configuration section contains samples of cabling schemes and

configurations. If your desired configur ation is not shown in the samples, refer to

the example most similar and follow the cabling topology scheme expanding the

configuration example to fit your needs while conforming to the specific SCSI

specification.

The CR8e is designed with an open architecture that allows for many possible

combinations of cabling schemes. Because of these possible combinations, we will

provide a sampling of configurations in this chapter.

Additional configurations are available through the use of nStor’s Ultra Extender

or Differential Converter Feature cards. Refer to the nStor Feature Card User’s

Guide for information specific to each card and configuration. When configuring

the array, refer to the user’s guide provided with your RAID controller.

13

Installation

System Requirements

The nStor CR8e disk subsystem is based on an open architecture design and can

be connected to any host-based SCSI system. R efer to your adapter/contr oller and

host system user’s manuals for information about the system requirements for

the host system where the controller will be installed.

Guidelines

Before installation, you will need to consider the following:

■ When referencing a component on the rear panel it is assumed the user is

facing the rear panel and when referencing the fr ont panel components the

assumption is that the user is facing the front panel.

■ Interior temperature of the rack cabinet should be maintained at ambient

temperatures but must not exceed 117°F (47°C) during normal operation.

■ Remove each piece from the shipping carton, leaving the disk drives in

their anti-static protective packaging until you are ready to install them.

■ Save the packing materials in case you need to ship the CR8e.

■ Secure all cable connectors using the thumb screws (finger tight only).

■ When connecting the data cable VHD connectors, be sure to exercise

caution that the connector is inserted carefully and correctly. Otherwise it

is very likely to bend the pins inside the connector.

14

System Requirements

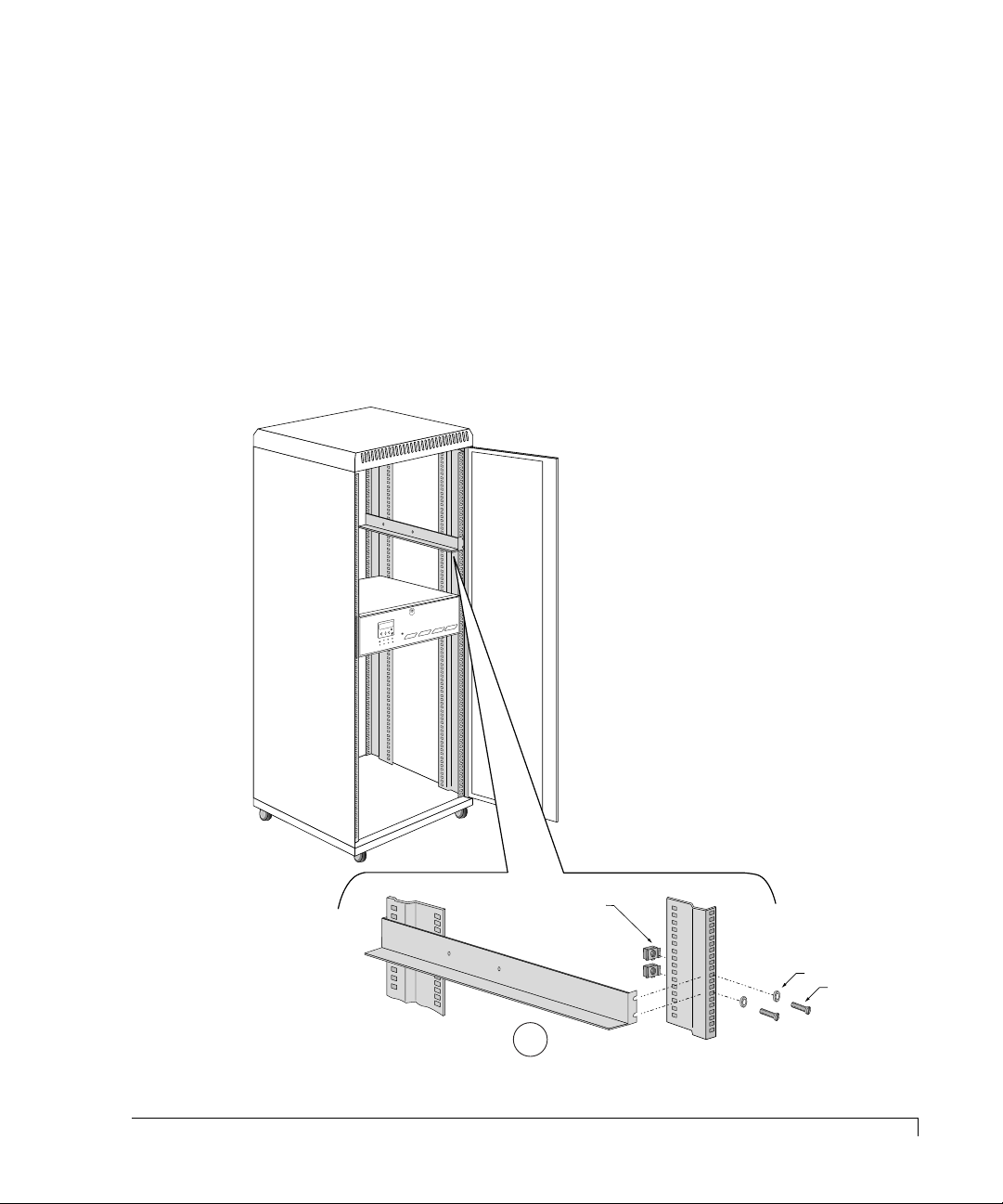

Installation

A

8-32 Pan Head

Screws

8-32 Caged

Nuts

Washers

Front Rack Vertical

Rear Rack Vertical

Rack-Mount Subsystem Assembly

You can install the CR8e into any standard IAE 19" rack cabinet.

CAUTION: Ensure that the location of the CR8e does not create an unstable

condition when installed in the rack cabinet enclosure.

NOTE: Mount the subsystem into the rack enclosure before installing the disk

drives. This will reduce the weight r equired to support during installation.

1 Select an appropriate location in your rack cabinet for the CR8e. If you are

installing multiple systems, review the cabling configuration section later in

this chapter for your cable scheme to determine the optimum locations.

Rack-Mount Subsystem Assembly

15

Installation

Rail is installed to

the front and rear

rack cabinet verticals.

8-32 Pan

Head Screws

2 To aide in support bracket installation, remove the rack cabinet side panels.

3 Locate the two support brackets. Mount the two brackets to the rack cabinet

verticals using the four screws, four washers, and four caged nuts provided

for each bracket. Refer to detail “A” in the illustration on the previous page.

NOTE: The caged nuts are secured into the r ack cabinet v ertical slots by inserting

one side of the nut into the slot and squeezing while pressing the opposite

side in until it snaps into place.

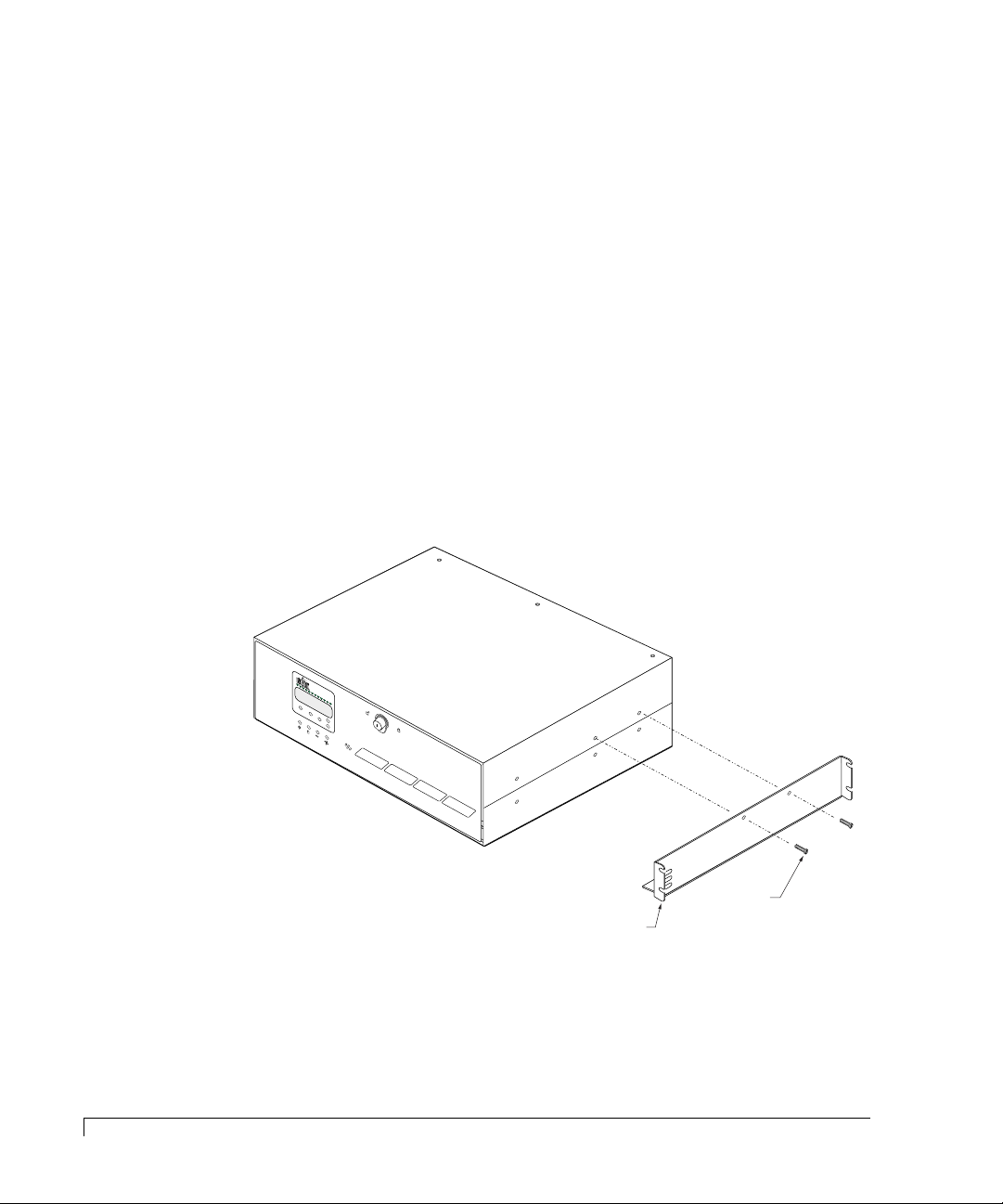

4 Remove the two (2) upper enclosure case screws as depicted below on the

right side of the subsystem cabinet.

NOTE: The enclosure is attached to the support bracket only on the right side.

5 Slide the subsystem cabinet into the cabinet with the subsystem riding on top

of the support brackets.

6 Align the two upper case screw holes with those provided in the support

bracket on the right side.

16

Rack-Mount Subsystem Assembly

7 Secure the subsystem cabinet to the right hand rail using the two (2) screws

previously removed.

8 Continue with the component installation on the next page.

Loading...

Loading...