Page 1

Multi Function Ultrasonic Scaler

OPERATION MANUAL

Please read this Operation Manual carefully before use,

and file for future reference.

Varios 970

OM-E0847E 000

Page 2

Classifications of equipment

• Type of protection against electric shock:

– Class I equipment

• Degree of protection against electric shock:

– Type BF applied part:

• Method of sterilization or disinfection recommended by the manufacture:

– See 12. Sterilization

• Degree of protection against ingress of water as detailed in the current edition of IEC 60529:

– Foot Control: IPX1 (Protected against vertically falling water drops)

• Degree of safety of application in the presence of a flammable anesthetic mixture with air or with oxygen or nitrous oxide:

– EQUIPMENT not suitable for use in the presence of a flammable anesthetic mixture with air or with oxygen or nitrous

oxide.

• Mode of operation:

– Continuous operation

English

Intended to Use

This product is designed only for dental clinic /dental office use. This device generates ultrasonic waves intended for use in

dental applications such as scaling, root canal treatment, periodontal and cavity preparation.

1. Cautions for handling and operation

Read these cautions carefully and use only as intended or instructed.

Safety instructions are intended to avoid potential hazards that could result in personal injury or damage to the device.

Safety instructions are classified as follows in accordance with the seriousness of the risk.

Class Degree of Risk

WARNING

CAUTION

NOTICE

A hazard that could result in bodily injury or damage to the device if the safety instructions are not

followed.

A hazard that could result in light or moderate bodily injury or damage to the device if the safety

instructions are not followed.

General information needed to operate the device safely.

WARNING

• TO PREVENT ELECTRIC SHOCK Do not unplug the power cord with wet hands.

• TO PREVENT ELECTRIC SHOCK Be sure to prevent water on the Control Unit.

• TO PREVENT ELECTRIC SHOCK Do not touch the handpiece backend electrical connections.

• TO PREVENT ELECTRIC SHOCK Use an electrical outlet that is grounded.

• If you feel any abnormality such as vibration, heat generation, abnormal noise, etc., prior or during the use of the unit, stop

using it immediately.

• Do not turn the Power Switch without reason; it might blow out a fuse.

• This product is Medical Electrical equipment Electromagetic compatable (EMC).As described in the accompanying

documentation.

• Portable and mobile RF communications equipment can affect Electrical Medical equipment. Do not use RF equipment in

close proximity to the product.

• When installing the product, provide space of approximately 10cm around the Control Unit for easy access to the inlet and

the Power Cord.

• When operating the product always consider the safety of the patient.

• Use by medical professional, such as doctor or dental hygienist, is intended.

• Check the vibration outside the patient’s oral cavity before use. If any abnormalities are found, stop using immediately and

contact your dealer.

• Do not drop, hit, or subject to excessive shock to the Control Unit/Handpiece.

1

Page 3

• USE ONLY NSK genuine tips when using NSK Varios Ultrasonic Scaler (Varios 970 or Varios 970 LUX) problems such as

damage, failure and accident of Handpieces resulting from use of Non-NSK Tips are not included in the warranty. The

following are the possible failure that could happen when using the Non-NSK Tips;

· Vibration failure caused by using non conforming screws.

· Patients accidental ingestion of broken tips.

· Damage of thread ridge of handpiece.

· You must use the tip within the power range described on the Tip-Power Guide. If you use it out of the power

range, the tip might break or damage an operative site.

• To prevent possible tooth plane damage and handpiece overheating, Always use with sufficient water.

• Do not sterilize by ultraviolet light. Handpiece could discolor.

• Sterilize the Tip, Handpiece, and Tip Wrench by autoclaving. Wipe the Control Unit, AC Power Cord, Foot Control, and

Handpiece Cord including the cover.

• If chemical, solvent or antiseptic solution is deposited on this product, immediately wipe it away. Discoloration or

deformation may occur if left.

• Do not disassemble or alter the handpiece/Control Unit.

• Keep away from patients with cardiac pacemakers.

• Keep away from explosive substances and flammable materials. Do not use for patients anesthetized under laughter gas.

(Nitrous Oxide)

• Use the Fuse of specified rating. (120V: T630mAL 250V, 230V: T315mAL 250V)

• This product needs special precautions regarding EMC and needs to be installed and put into service according to the

EMC information.

• The use of ACCESSORIES, transducers and cables other than those specified, with the exception of transducers and

cables sold by the manufacturer of this product as replacement parts for internal components, may result in increased

EMISSIONS or decreased IMMUNITY of this product.

• This product should not be used adjacent to or stacked with other equipment and that if adjacent or stacked use is

necessary, this product should be observed to verify normal operation in the configuration in which it will be used.

• If any water drops remain on the handpiece after autoclaving, wipe them

off., Staining may result if left.

• There is the judgment that applies this product to a patient in the user side.

• Grounding reliability can only be achieved when the equipment is

connected to an equipment receptacle marked "Hospital Only" or "Hospital

Grade".

• Do not apply excessive power to the Tip. It may damage the teeth because

of the ultrasonic vibration.

Power plug below is used in N orth America area.

Plug Type NEMA 5-15P (Hospital Grade Type)

CAUTION

• During operation, high frequency oscillations in the handpiece and handpiece cord may affect computer and LAN Noise

may be heard during operation near a radio receiver.

• Be sure to turn off the Power Switch after use. Remove the power plug and water inside of the Control Unit before storage.

• Users are responsible for operational control, maintenance and inspection.

• Clean/sterilize the product immediately after using it. Then store it. Leaving it non-sterile might lead to failure.

• When cleaning, use MinutenWipes (ALPRO) to wipe the surface of the handpiece. Use of chemicals other than those may

cause the handpiece to discolor, crack, etc.

• When you have not used the product for long time and use it again, check the operation before use.

• Eye damage may result if the LED is stared directly into, Do not look into or turn it to the eyes of the patient.

• This product does not consider patient’s age (except infants), gender, weight or nationality.

• No special training is required for this device.

• Applied parts for patient and/or operator are/is tip and Handpiece.

• Surface temperature of tip shall be more than 50 degree without using a tap water or bottle. To avoid this event, be sure

to use a tap water or bottle.

NOTICE

• Repeated autoclaving may cause the handpiece to become discolored due to heat. However, this is due to properties of

the product and is not a problem in terms of quality.

2

Page 4

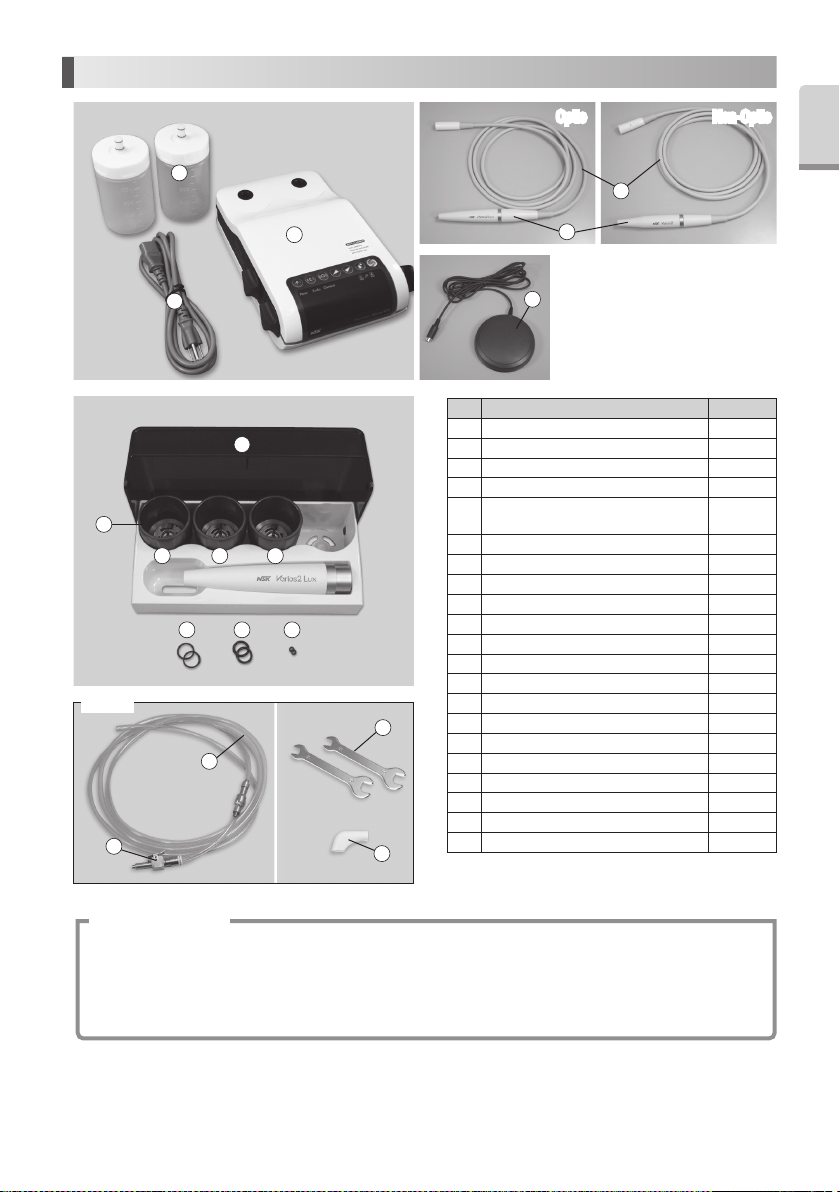

2. Component Names

2

Optic Non-OpticNon-OpticOptic

English

English

5

8

Option

15

3

7

12 13 14

16

1

4

6

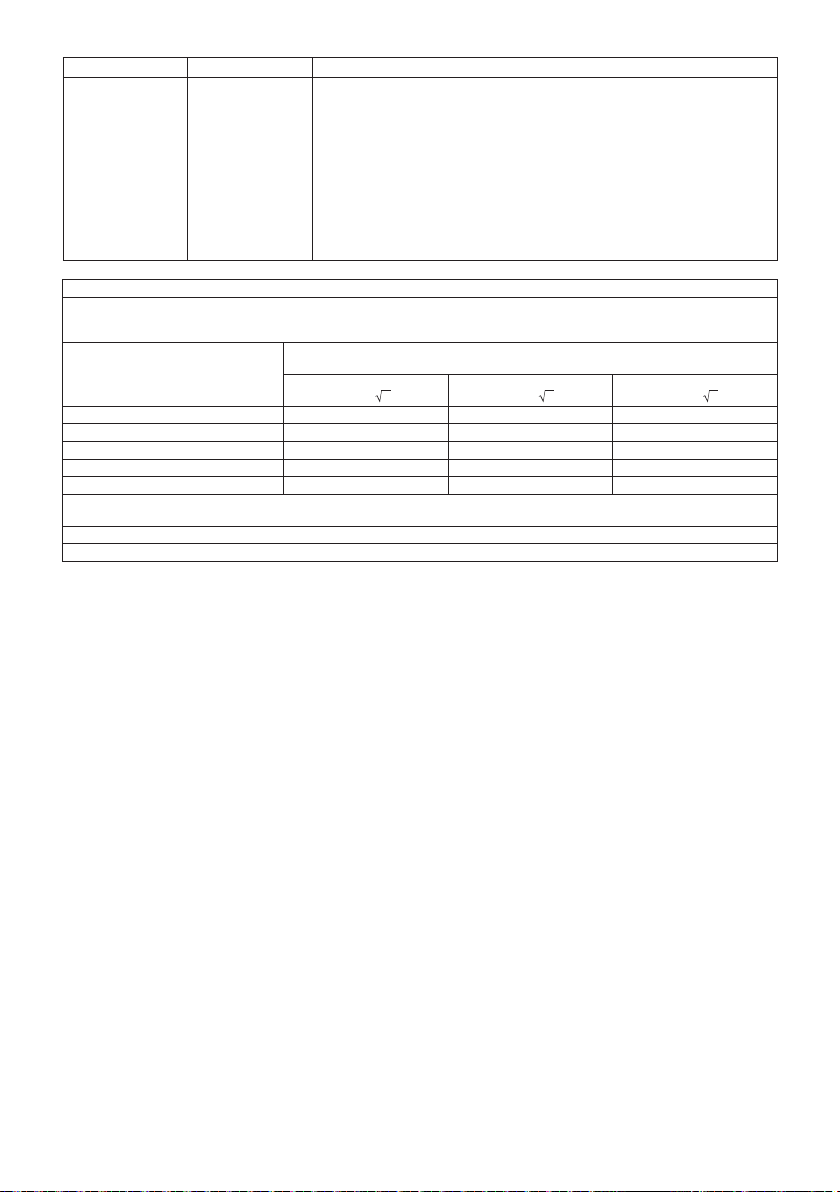

No. Parts Name Quantity

1 Control Unit 1

2 VA Bottle 2

3 AC Power Cord 1

4 Varios2 Handpiece (Optic or Non-Optic) 1

Handpiece Cord (Unshielded 2M)

5

119 10

17

18

6 Foot Control 1

7 Sterilization Case 1

8 Tip Wrench 3

9 Tip G4 1

10 Tip G8 1

11 Tip G16 1

12 O-Ring (Thin section) (For VA Bottle) 2

13 O-Ring (Thick section) (For VA Bottle) 2

14 O-Ring (For Handpiece Cord) 2

15 Water Connector (Option) 1

16 Water Tube (Option) 1

17 Spanner Wrench (5x8) (Option) 2

18 Tip Cover S (Option) 1

19 Tip-Power Guide 1*

20 Tip Card 1*

21 Operation Manual 1*

* These are not on photo above.

(Optic or Non-Optic)

1

* Operation Principle

A sinusoidal electrical signal, at ultrasonic frequency ( f > 20Khz ), is delivered by the generator. This signal is applied

to the ‘piezoelectric ceramic’ located inside the transducer. Piezoelectric ceramic converts this signal into mechanical

vibrations. These vibrations are at the same ultrasonic frequency as the electrical signal. The mechanical vibrations

are propagated towards the distal end of the transducer. The “TIP” insert, which is attached at the distal end of the

transducer, vibrates at ultrasonic frequencies and makes it possible to achieve the aimed purpose.

3

Page 5

3. Name and Function of each part

Left Bottle (L Bottle) Right Bottle (R Bottle)

* L and R bottle is common

Handpiece Holder

Bottle Selection Indicator L

Handpiece Cord Connector

Tap Water Adjustment Knob

(Left)

Bottle Selection Indicator R

(Right)

Bottle Water Adjustment Knob

Power Switch

Foot Control Connector Tap Water Connector

AC Power Cord Connection Jack

<Bottom>

4

Page 6

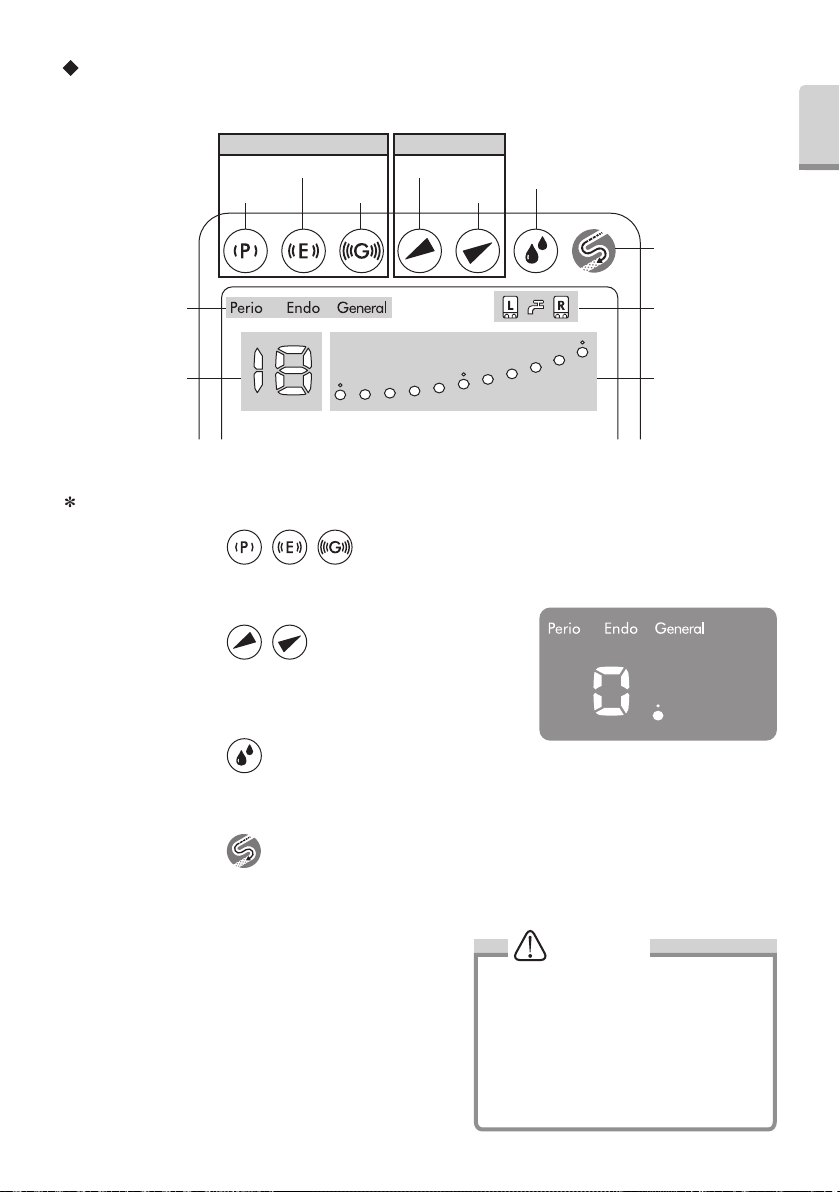

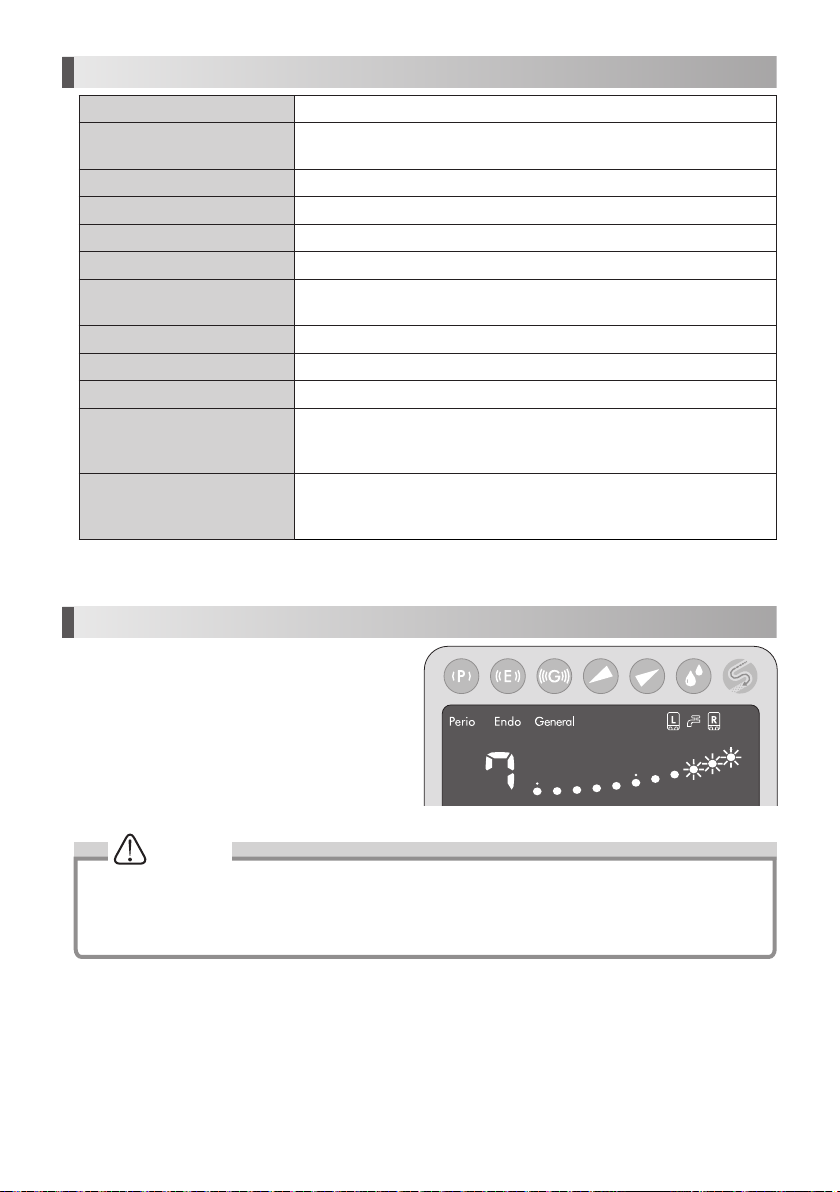

Operation Panel and Display

Mode Select Keys Power Level Keys

Endo Key

Perio Key General Key

Down Key

Up Key

Irrigation Select Key

Auto-cleaning Key

English

English

Operation Mode

Display

Numerical Display Bar Graph Indicator

If you purchase the Optional products such as Water Tube and Water Connector you can use Tap Water.

Irrigation Mode

Display

Mode Select Keys

You can select Operation Mode to pressing this key. (Perio, Endo and General) The Control Unit can resume power level,

water volume and irrigation mode for each Operation Mode.

Power Level Keys

Press key to select Power o/p Level . There are 11 levels (0 to 10). There

is no output vibration at level 0 (zero). (Fig.1). The Bar Graph Indicator and

Numerical Display will change simultaneously.

Irrigation Select Key

Press key to select ‘R’ or ‘L’ Bottle. Front panel display and Bottle Selection Indicator simultaneously change in position.

Pressing the Irrigation Select Key for more than one second will select Tap Water Mode.

Auto-Cleaning Key

Press key to select Auto Cleaning Mode, For detail refer to 11. (5).

Fig.1

Bottle Water Adjustment Knob

Water Volume Adjustment can be made prior to the tip vibrating

you can adjust the Water Volume during Bottle Irrigation or

during a wait before Tip vibration start. If the setting is not

applicable (too low or too high) for the Control Unit, it may beep.

During the operation, Front Panel displays the current Power

Level. However, keep turning the knob more than a second; it

may change the Water Volume.

CAUTION

• Do not turn the knob fast. It may not sense

the movement if it turn fast.

• Water Volume can set during 5ml/min to

45ml/min.

• Operation sound may different between

Right and Left Bottle.

• During adjustment of water volume,

Numerical Display indicate “–”.

5

Page 7

Tap Water Adjustment Knob

You can adjust tap water volume by this Knob. (Even the tip vibration).

4. Prior to Operating System

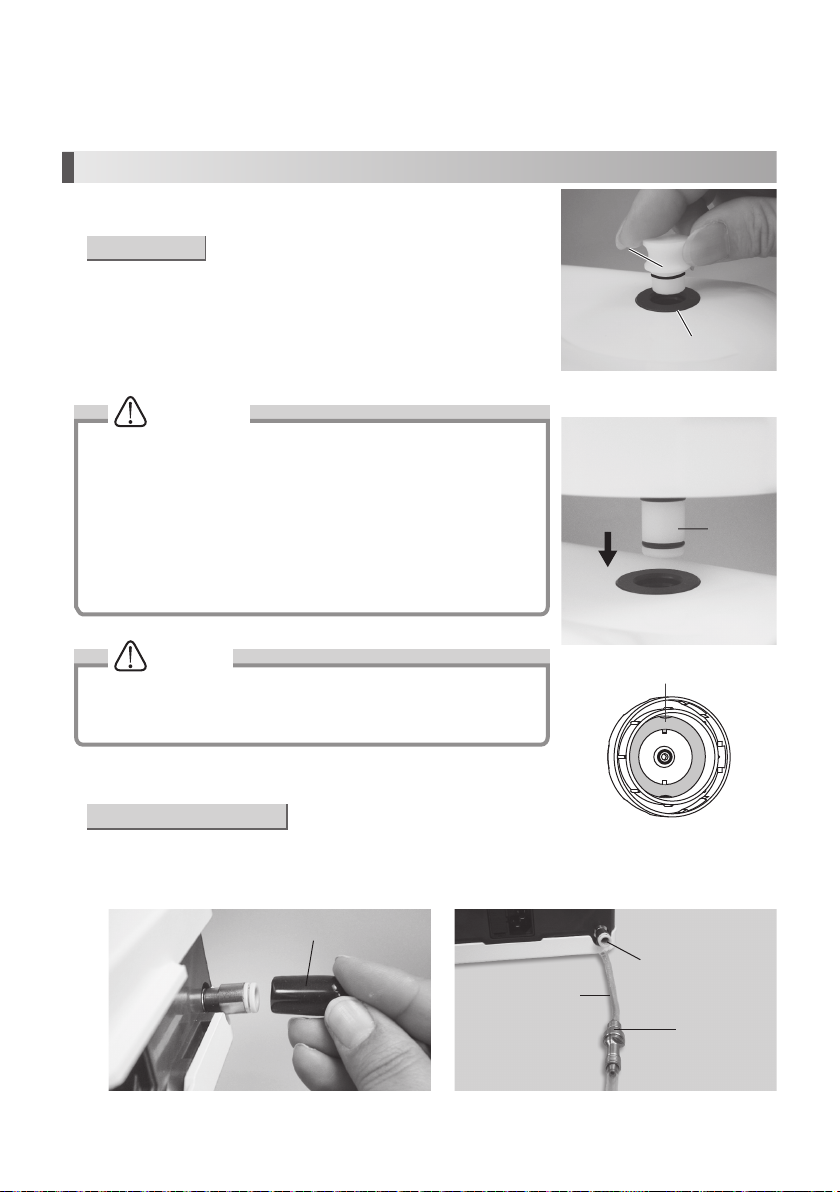

(1) Water System Setup

• Use of Bottle

1) Remove the Dust Cover from the Bottle Base Connector. (Fig. 2)

2) Remove the cap of the VA Bottle and fill solution to the desired level.

3) Close the cap of VA Bottle and insert the Bottle Joint into the Bottle Base

Connector until it clicks. (Fig. 3)

To remove the Bottle, pull it up.

CAUTION

• Use the VA Bottle Set 400 only for Varios 970.

• Before filling solution to the VA Bottle, check the Gasket inside the bottle

cap is clean. (Fig. 4)

• Do not use a sharp tool to clean the Gasket or do not allow any impact

on to the product. It may cause malfunction.

• Insert the Bottle straight. (Damage to seals may result).

• Keep the Gasket clean. When it becomes dirty by water or antiseptic

solution, wash by clean water it immediately.

• The Gasket is consumable. *Optional Gasket: Order Code Z1047350

Dust Cover

Bottle Base Connector

Fig.2

Bottle Joint

NOTICE

• The Bottle calibrations are printed on both sides of the Bottle and can be

read accurately from the fill position or mounted on the Control Unit.

• Mount the Dust Cover when not in use.

• Use of Tap Water (Option)

1) Remove the Cover from the Tap Water Connector. (Fig. 5)

2) Connect the filter side of the Water Tube deep into the Control Unit Tap Water Connector (Fig. 6).

3) Connect the water tube to the water outlet on the Dental Unit.

Cover

Water Tube

Fig.5

6

Gasket

Fig.3

Fig.4

Tap Water Connector

Water Filter Case

Fig.6

Page 8

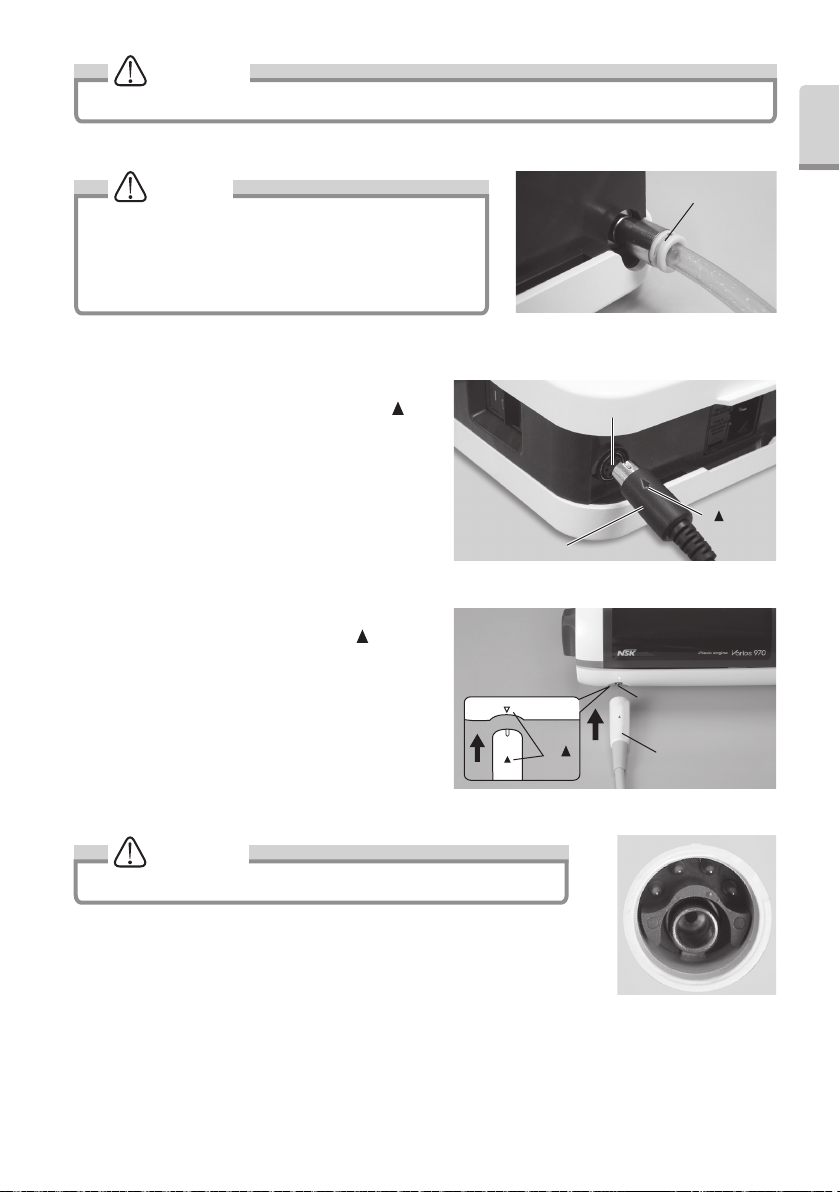

CAUTION

Ensure the water from the dental unit runs clear before connecting to the scalar.

English

NOTICE

• Insert the Water Tube firmly into Control Unit.

•

Pushing the White Ring, (the Quick Connector Release Ring) on

the Tap Water Connector, gently pull the tube to remove. (Fig. 7)

• When the water tube is not connected, mount the cover on the

Tap Water Connector.

(2) Foot Control Connection

Connect Foot Control Plug and the Control Unit with [ ]

mark on the upper surface of the plug. (Fig.8)

(3) Handpiece Cord Connection

Insert Handpiece Cord Plug into Control Unit. [ ] Mark side

is upper surface. Do not insert it up-side-down. (Fig.9)

Foot Control Plug

Foot Control Connector

Handpiece Cord Connector

[ ]

Mark

White Ring

Fig.7

[ ] Mark

Fig.8

Handpiece Cord Plug

CAUTION

Check that the Handpiece Cord Plug is clean & dry before connecting. (Fig.10)

7

Fig.9

Fig.10

Page 9

(4) Mounting Power Cord

Insert the Power Cord into the AC Power Cord Connection

Jack at the back of the Control Unit. (Fig. 11)

Power Cord

AC Power Cord Connection Jack

CAUTION

• Ensure Power is OFF on the Control Unit during the Power Cord Connection. It may cause Fuse to blow.

• Do not connect the cord in wall outlet before connecting AC Power Cord.

• Do not pull the AC Power Cord forcibly.

• Do not unplug the Power Cord or handpiece cord while pressing on the Foot Control.

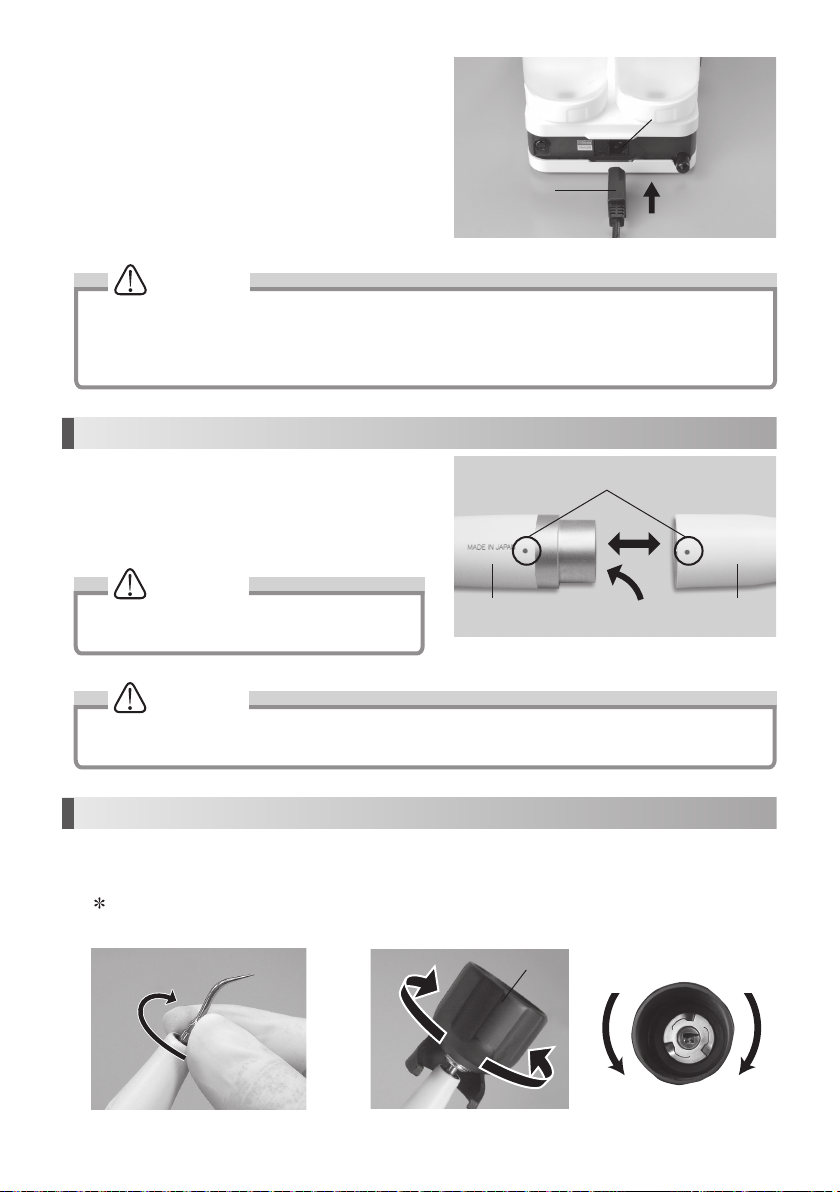

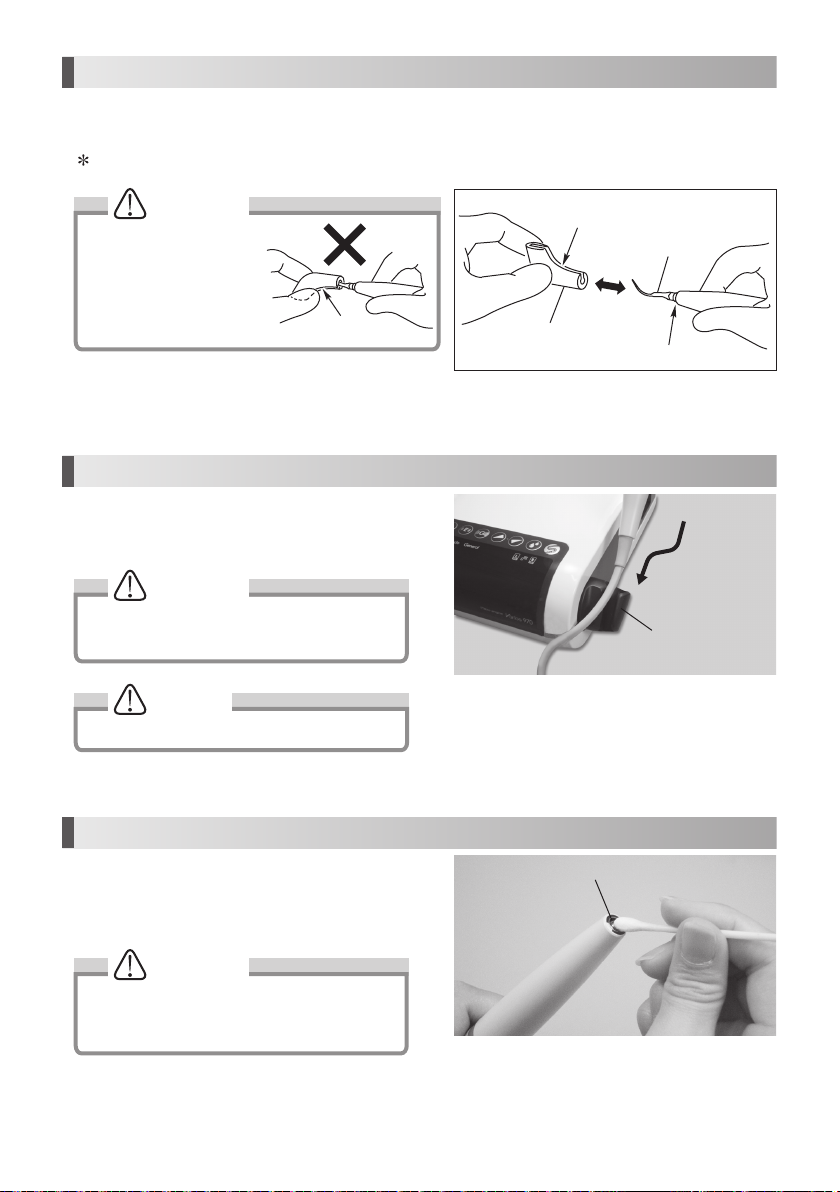

5. Mounting and Removing the Handpiece

Align the Dots on the Handpiece and the Handpiece Cord. Push

handpiece into connector.

To remove the handpiece, grip the Handpiece and Handpiece

Cord and pull to part handpiece and cord. (Fig. 12)

Dots

WARNING

To avoid Electrical Shock Do not touch the handpiece

backend electrical contacts.

Handpiece backendHandpiece Handpiece Cord

Fig.11

Fig.12

CAUTION

• Always confirm that the handpiece is correctly seated and locked into place.

• Do not connect or use Handpiece other than included one (Varios2 handpiece).

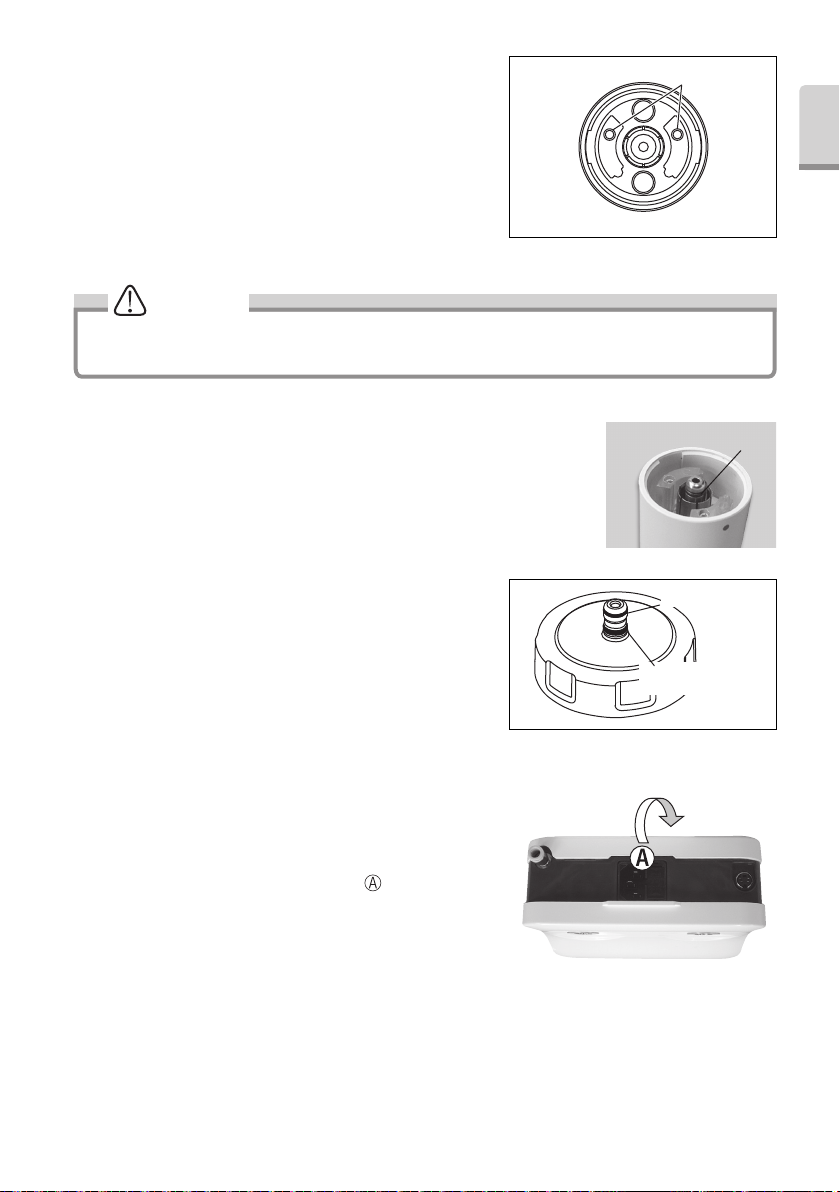

6. Mounting and Removing Tip

1) Turn Tip lightly by hand, and install it. (Fig. 13)

2) Tip will insert from the bottom hole of Tip Wrench. Align the four corner of the Tip base area into the four corner of Tip

Wrench. And turn it clockwise until it clicks. (Fig. 14)

Do not touch the top part of Tip to avoid an injury. (There is the case that is longer than height of TIP WRENCH)

To remove the Tip, turn it counterclockwise with the Tip Wrench.

Fig.13

Tip Wrench

Loosen

Tighten

Loosen

8

Tighten

Fig.14

Page 10

Caution for Tip Usage

• Check the Tip before use. (Flush, Damage, Bending or Rust)

• Do not exceed Maximum Power Level for Tip. Damage to tooth structure and Tip may result.

• Do not hit ceramic prosthesis with Tip during scaling. Tip Damage may result.

• Do not hit metal or prosthetic crown except for removing them. Tip could break and fall into mouth.

• Do not hit gingival, mucosa and/or skin. It could cause damage and/or burn injury.

• Do not sharpen and/or bend the Tip. Tip may damage and not generate enough vibration during scaling.

• During cutting, Tip will gradually wear away, as the Tip wears the stroke will get smaller and decrease cutting

efficiancy When level drops too far, change the Tip.(tip card check)

• DO ENSURE When securing tip to use the tip wrench as supplied, inefficient cutting will result.

• DO ENSURE before attaching Tip, Cleanliness of the tip screw, inefficient cutting will result.

• To avid personal injury DO ENSURE tip is removed prior to disconnecting the handpiece or the handpiece cord.

• If you feel the Tip is not vibrating, remove it from an operative site, and press the Foot Control again. If this does

not improve the condition, Ensure the tip is secure, turn the power off and restart it.

• When mounting the Tip, always use groves and Tip Wrench as supplied.

• Ensure that water volume must be “0”, when you use Tip which does not appear of water.

• Tip Wrench is consumable For reliable operation replace annually.

7. Operating Procedures

(1) Water System Setup

• Use of Bottle

1) Check that the VA Bottle is filled to the proper level.

2) Make sure that the cap of the Bottle is secure and not leaking.

CAUTION

• DO ENSURE liquid temperature is below 35°C.

• Do not put liquid such as high acid water in the Bottle.

English

• Use of Tap Water

1) Ensure water tube is firmly connected.

2) Open the dental unit's water valve. (Set water pressure between 0.1-0.5MPa (1-5 kgf/cm

(2) Power On

Connect the AC Power Cord to the wall outlet. Turn the Power

Switch on the Control Unit. Front Display will illuminate.

9

Power Switch

2

)).

Fig.15

Page 11

(3) Power Level Setting

DO ENSURE Power setting does not exceed the recommended Power Level (Tip-Power Guide included in the package.)

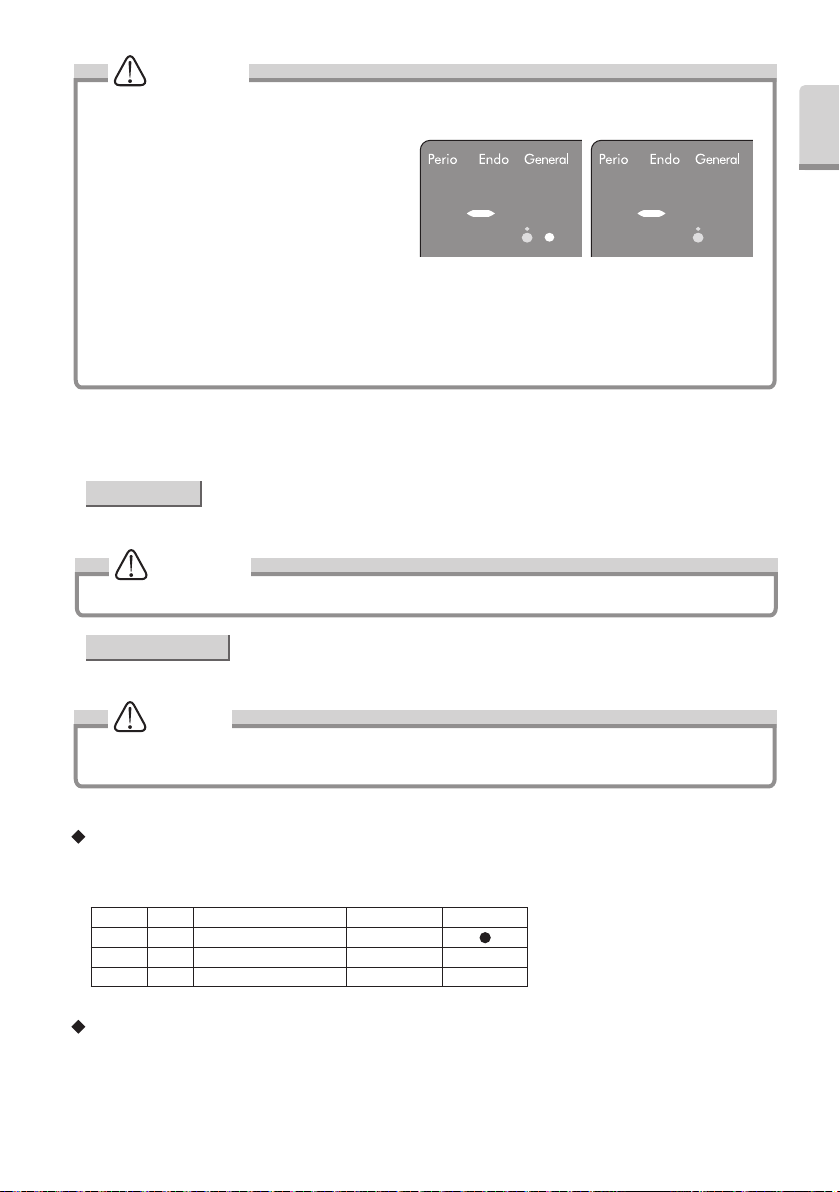

1) Select the Operating Mode with the Mode Select Keys on the Front Panel. The Indicator light over the selected mode

will illuminate. (Fig. 16)

Mode Select Keys

Power Level for each mode

Operating Mode Display

2) Set the power level with the Power Level Key on the

Front Panel. The Bar Graph Indicator and Numerical

Display will indicate the selected power level. (Fig. 17)

Make sure the power level is set in the appropriate

range for the attached Tip.

Fig.16

NOTICE

• Press & Hold the Power Level Key will increase or

decrease the Power Level.

• If the Power Level is 0 (zero) and set the water

volume, Tip will not oscillate but water comes out

from the handpiece.

(4) Irrigation setting

Select the Irrigation Mode (L Bottle, R Bottle or Tap Water) with

the Irrigation Select Key on the Front Panel. (Fig. 18)

The Indicator light over the selected mode will illuminate.

Press & Hold the Irrigation Select Key to select Tap Water Mode.

(5) Operate Varios 970 / 970 LUX

By stepping on the Foot Control, the tip vibrates and spraying

starts (except for tips that do not spray) and the handpiece

LED lamp lights up (Varios 970 LUX).

When you remove your foot from the foot control, tip vibration

and water spraying stop and the handpiece LED lamp turns

off. (Varios 970 LUX).

Power Level Key

Bar Graph IndicatorNumerical Display

Irrigation Select Key

L Bottle Tap Water R Bottle

Increase

Fig.17

Fig.18

Increase

• Water Supply Volume Adjustment

Turn the Water Adjustment Knob counterclockwise gradually

to increase the supply volume. (Fig. 19) For detail, refer to P5

Bottle Water Adjustment Knob or P6 Tap Water Adjustment

Knob.

10

Tap Water Adjustment Knob Bottle Water Adjustment Knob

Fig.19

Page 12

CAUTION

• While pressing the Foot Control and switching the power ‘ON’. The Control Unit will display "F" and sound a beep,

for your safety the Control Unit will not operate. Remove your foot from Foot Control to cancel and reset.

• Bar Graph Display (Fig.20)

Minimum Irrigation -> One white and blue LED.

No Irrigation -> Blue LED only

• Always use the water supply. If water supply is

insufficient, handpiece will overheat and patient’s

tooth surface can be injured.

• Verify that the water spray is clean and of

adequate volume before use.

• If irrigation volume set low, sometimes irrigation water is difficult to come out from the Tip.

When it happened, set volume again after setting up high volume.

• During Water Adjustment Knob operation;

Numerical Display: Display "-"

Bar Graph: Display current volume of water

Minimum irrigation No Irrigation

(6) After the treatment

Release the Foot Control and Power off the Control Unit.

• Use of Bottle

Thoroughly wash the Bottle (s) Water Supply system. Refer to 11. (5) Auto Cleaning (Cleaning of Irrigation Tube).

CAUTION

When using medicated solutions, clean the entire Irrigation System thoroughly.

• Use of Tap Water

Close the dental unit's water valve.

English

Fig.20

NOTICE

• LED of the handpiece will remain ‘On’ for approx 5 seconds after Foot Control is released. (Varios 970 LUX)

• When the Control Unit is Power off, the last mode settings in use are automatically retained in memory.

Initialized Program (Factory Setting)

Press both Auto-Cleaning and Power Key on the Control Unit to initialize the Factory memory Setting. Do not release

Auto-Cleaning Key until the beeping sound from the Control Unit. (Initial Mode is Perio)

Power Flow amount (L, R each) Irrigation Mode Initial Mode

Perio 1 10 L Bottle

Endo 1 10 L Bottle

General 1 10 L Bottle

During the Handpiece operation :

Possible: Power Level and Water Volume adjustment.

Impossible: Operation Mode and Irrigation Mode setting, Auto Cleaning.

11

Page 13

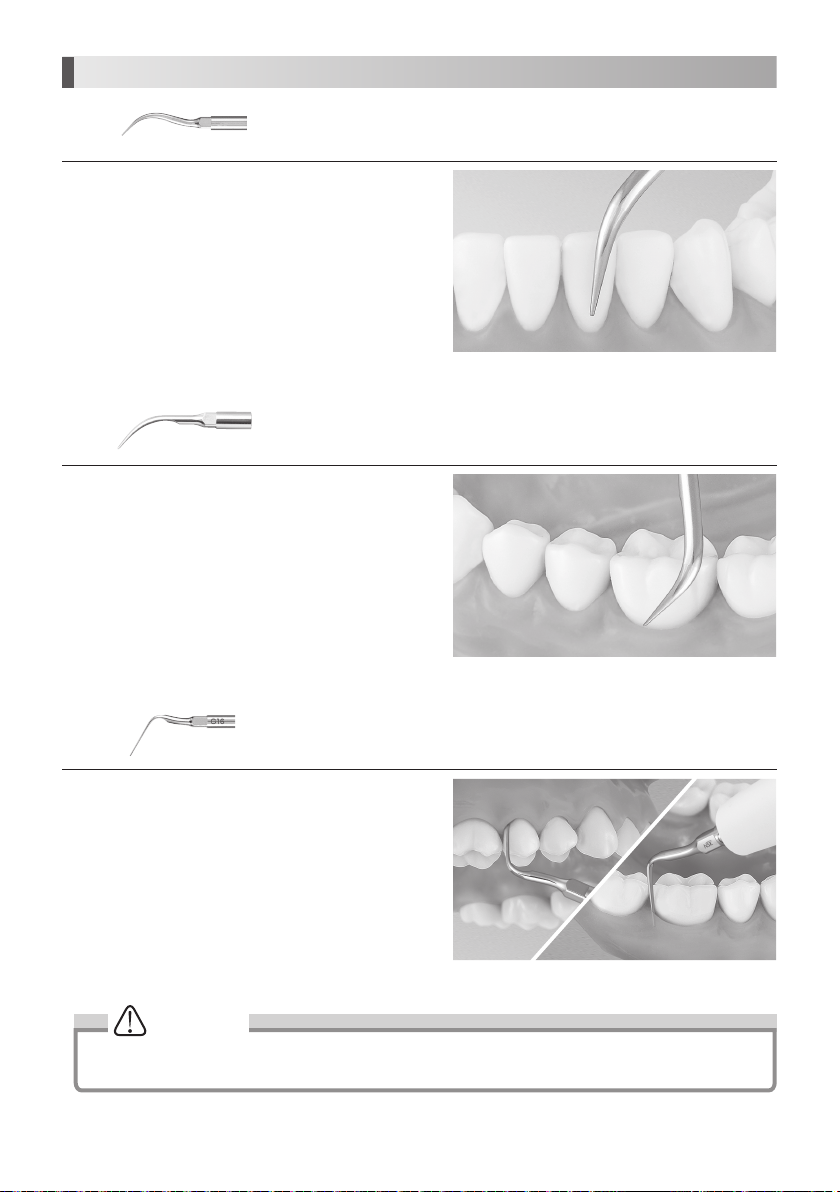

8. Provided Scaler Tips

G4

Apply the top of the Tip on the tooth plane and move it sideways

finely in the same way as G8 Tip. (Fig. 21)

The end of the Tip is thin and for supragingival fine scaling and interdental scaling. The

round cross-section allows tooth surfaces to be finished without causing damage.

Fig.21

G8

Apply the top of the Tip on the tooth plane and move it sideways

finely along the neck of tooth. (Fig. 22)

G16

Insert the top of the Tip into the periodontal pocket and move it

slowly. The top of the Tip is sharp so that it could remove tartar

on long coroner and retracted gingival. (Fig. 23)

Clean periodontal pocket at low power.

Removal of supragingival and interdental calculus. This Tip can be used in all

quadrants and is very useful for the removal of hard calculus.

Removal of supra and subgingival calculus. It provides easy access to interdental

spaces and narrow pockets.

Fig.22

Fig.23

CAUTION

Tip is article of consumption. We recommend periodical replacement. About time of replacement, check the Tip

Card.

12

Page 14

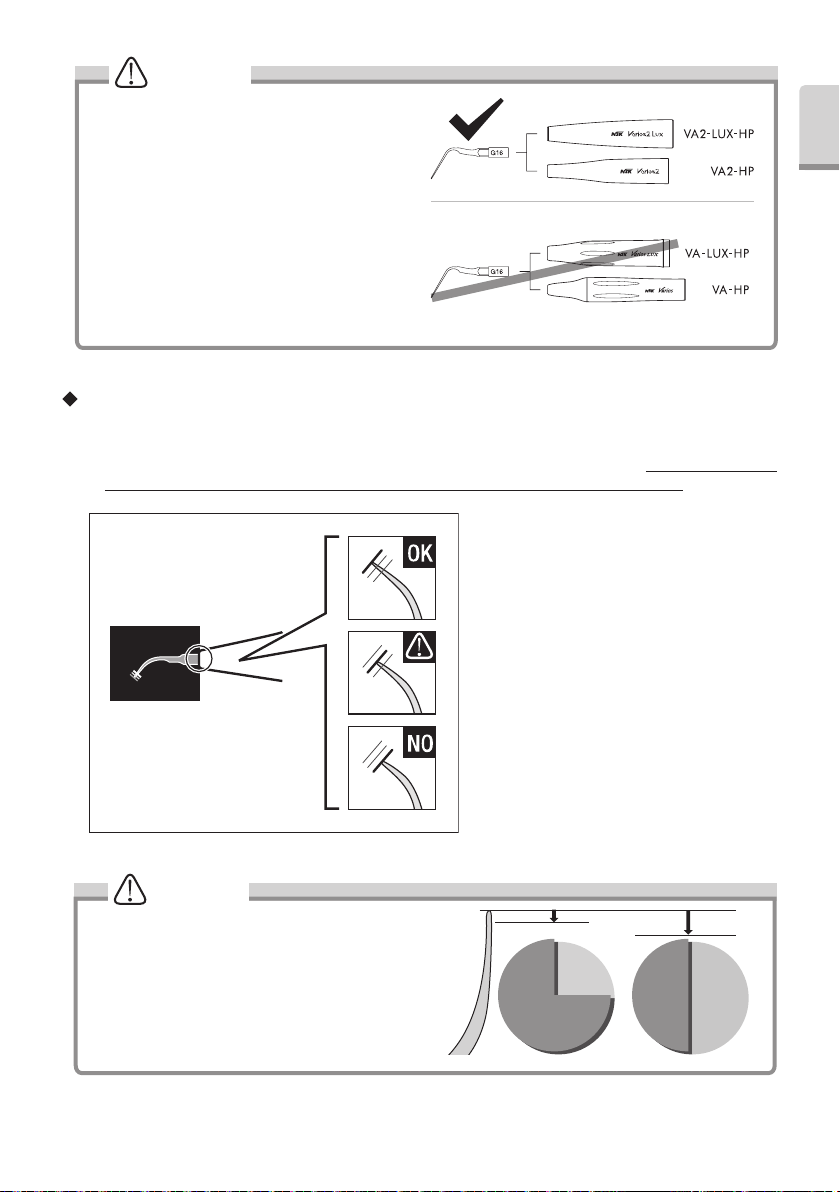

WARNING

Do not connect the supplied G16 Tip to a handpiece

other than a Varios2 handpiece (VA2-LUX-HP /

VA2-HP). Doing so may cause fracturing of the Tip or

scratches on the surface of the dentition, prosthesis,

etc. due to an increase in vibration amplitude (Fig. 24).

Fig.24

How to use the Tip Card

1) Place the neck of the Tip in the cut out.

2) Check wear of the Tip.

3) See the green, yellow and red line to check wear of the Tip. *See below what each color means. At NSK we recommend

to replace a Tip when the Tip meets the yellow line (wear of 1mm) to guarantee safe and effective use.

Tip Card

Green: No wear - Tip is OK

Tip replacement is not necessary.

English

CAUTION

Tips are consumables. The efficiency of dental scaling

decreases approximately 25% when the top of the Tip

wears 1 mm and approximately 50% when it wears 2 mm.

In addition, the vibration condition changes owing to the

wear, which may damage a patient’s tooth surface. Check

the Tip wear condition with the Tip Card periodically, and

replace the Tip with a new one in good time.

13

Yellow: Wear of 1mm - Tip is showing some wear

Tip replacement is recommended.

Red: Wear of 2mm - Tip is badly worn

Tip replacement is necessary.

Fig.25

1mm

25%

Decrease

Efficiency

2mm

50%

Decrease

Fig.26

Page 15

9. How to Use Tip Cover S (Option)

Grip the Tip Cover S and insert it to the Tip.

To remove, grip the Tip Cover S and the handpiece & pull. (Fig. 27)

The Tip Cover S is not designed for use as a Tip changing tool.

CAUTION

Carefully insert the Tip

into the Tip Cover S. Avoid

injuring the fingers.

Slit

10. Handpiece Holder

While the Handpiece is not in use, put the Handpiece in the

Handpiece Holder.

The Handpiece Holder is adjustable. (Fig. 28)

CAUTION

Do not put excessive load to the Handpiece Holder

to prevent from breaking down and deformation.

NOTICE

To prevent injury, always mount Scaler Tip Cover (S).

Slit

Tip

Tip Cover

Tip-Handpiece Joint

Fig.27

Handpiece Holder

Fig.28

11. Care and Maintenance

(1) Cleaning of Optic Fiber (Varios 970 LUX)

Wipe the debris off the end of the Optic Fibers at the

handpiece with alcohol soaked cotton swab. (Fig. 29)

CAUTION

Do not use any sharp pointed tools to clean the

Optic Fiber End Face. In case the light degridation,

contact your dealer.

Optic Fiber End Face

Fig.29

14

Page 16

(2) Cleaning the Handpiece cord

Remove the handpiece after use on each patient and clean it

as described below.

1) Wipe the surface of the handpiece cord with a cloth soaked

in alcohol.

2) Carefully wipe the handpiece cord plug with an

alcohol-immersed cotton swab. If it is difficult to use a

cotton swab, carefully wipe with a towelette wound around

a thin stick-shaped object.

CAUTION

Do not use a sharp pointed stick or push the terminal part when cleaning the handpiece cord plug. Doing so may

cause damage, resulting in contact failure (Fig. 30).

Terminal part

English

Fig.30

(3) Changing O-Ring

• Handpiece Cord

An O-Ring is located in the Handpiece Cord Connector. Use a pointed tool to remove,

and mount new O-Ring into the groove. (Fig. 31)

* Optional O-Ring: Order Code D0310020080

• VA Bottle

Remove two O-Rings at the Bottle Joint with a pointed tool, and

mount new O-Rings into the grooves. (Fig. 32)

* O-Ring (Thick section) : Order code D0310075150

O-Ring (Thin section) : Order code D0312090100

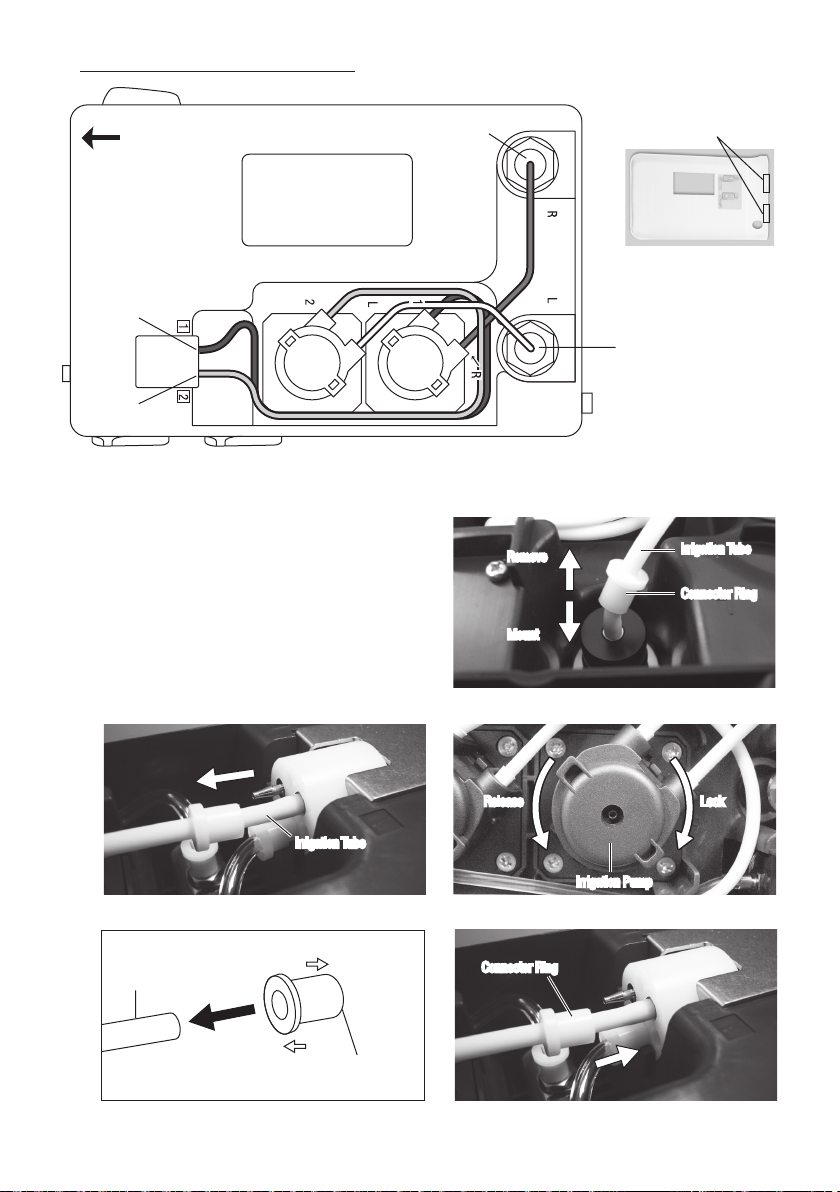

(4) Changing the Irrigation Pump

1) Remove the Bottle, the Power Cord, the Handpiece Cord and the

Foot Control from the Control Unit.

2) Turn back the Control Unit. Hang a finger on “

up the bottom cover to remove.

” point and pull

O-Ring

Fig.31

O-Ring (Thick section)

O-Ring (Thin section)

Fig.32

Fig.33

15

Page 17

Picture below is shows inside of the Control Unit.

Front Panel Side

R Pump Tube Joint

L Pump Tube Joint

R Bottle Bottle Joint

R PumpL Pump

Bottom Cover Hook

Bottom Cover (Back Side)

L Bottle Bottle Joint

3) Remove the Irrigation Tube from the Control Unit. (Bottle side and Front Panel side.) (Fig. 35, 36)

4) Remove the Connector Ring from the Irrigation Tube. Do not dispose it. You can use the Rings to the replacement

Irrigation Pump.

5) Turn the Irrigation Pump counterclockwise until it clicks

Irrigation Tube

and pull it out. (Fig. 37)

6) Mount the Connector Ring to the new Irrigation Pump.

Observing Ring direction. (Fig. 38)

7) Align the replacement Irrigation Pump with the Drive Shaft.

Turn clockwise until it clicks. (Fig. 37)

8) Mount the Irrigation Tube opposite procedure of removing

Remove

Remove

Mount

Mount

Irrigation Tube

Connector Ring

Connector Ring

(Fig.35). Connector Ring should firmly into the Control Unit

until it stops. (Fig.39)

* Bottle side

Fig.34

Fig.35

* Front Panel side

Irrigation Tube

L/R Pump side

Irrigation Tube

Irrigation Tube

Control Unit side

Connector Ring

Fig.36

Fig.38

16

Release LockRelease Lock

Irrigation Pump

Irrigation Pump

Connector RingConnector Ring

* Front Panel side

Fig.37

Fig.39

Page 18

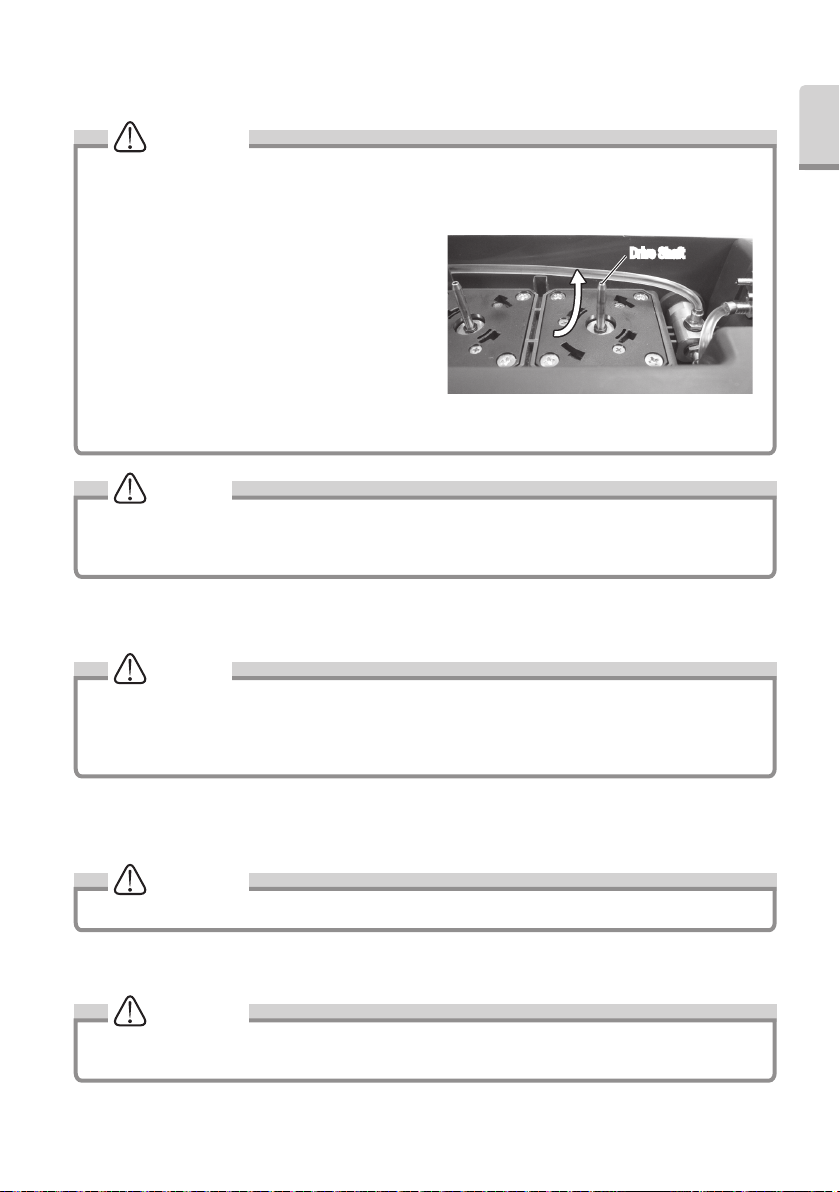

9) Align the Bottom Cover Hook and hole on the Control Unit. Mount the Bottom Cover.

* Optional Irrigation Pump: Order Code 10000643 (Not included the Connecter Ring.)

CAUTION

• If water is spilled out the irrigation pump, wipe it off and allow drying completely prior to use. If water gets inside

the irrigation pump the roller may slip and fail to pump.

• Before replacing the Irrigation Pump, wipe off excess water on pump and Drive Shaft. The wet drive shaft and

rollers can be slippery and cause improper operation.

• Wipe dirt and water off the Drive Shaft from bottom up.

(Fig.40)

• Insert the replacement Irrigation Pump into the Drive

Shaft straight (slow and soft) to prevent damaging rollers

in pump.

• Run the replaced Irrigation Pump about 10 seconds

on largest setting of Water Volume before operation to

adopt Irrigation Tube to new pump.

• Ensure Irrigation tube has no kink or twists If tube is set

incorrectly, Irrigation Water may not come out.

• Do not pull the tube when the bottom cover is closed.

Drive ShaftDrive Shaft

NOTICE

• Perform periodical cleaning for the Drive Shaft with socked alcohol cloth. Dirt on Drive Shaft may cause an

incorrect pump operation.

• The pump is consumable. If the irrigation volume decreases markedly, replace pump.

(5) Auto Cleaning (Cleaning of Irrigation Tube (Use of Bottle))

NOTICE

• After each use, remove all the disinfectant solution and perform "Auto Cleaning" procedure. If you have not

cleaned the system, it may become dirt disinfectant. And it is stuck in the tubing or some of the metal parts may

be rusted.

• During Auto Cleaning, water comes out from the handpiece. Perform cleaning after turning handpiece into a cup.

English

Fig.40

1) Remove the 2 Bottles from the Control Unit.

2) Clean inside of the Bottle.

3) Half fill the bottle with purified water (DO NOT USE SALINE)

CAUTION

Use only distilled water for cleaning.

4) Install the cap on the Bottle. Install the Bottle Joint into the Bottle Base Connector. Install it until clicks into place.

Improper connection may cause water leakage. Make sure the connection is tight.

CAUTION

• Perform Auto-Cleaning without tip.

• Make sure the handpiece and handpiece cord are firmly attached.

17

Page 19

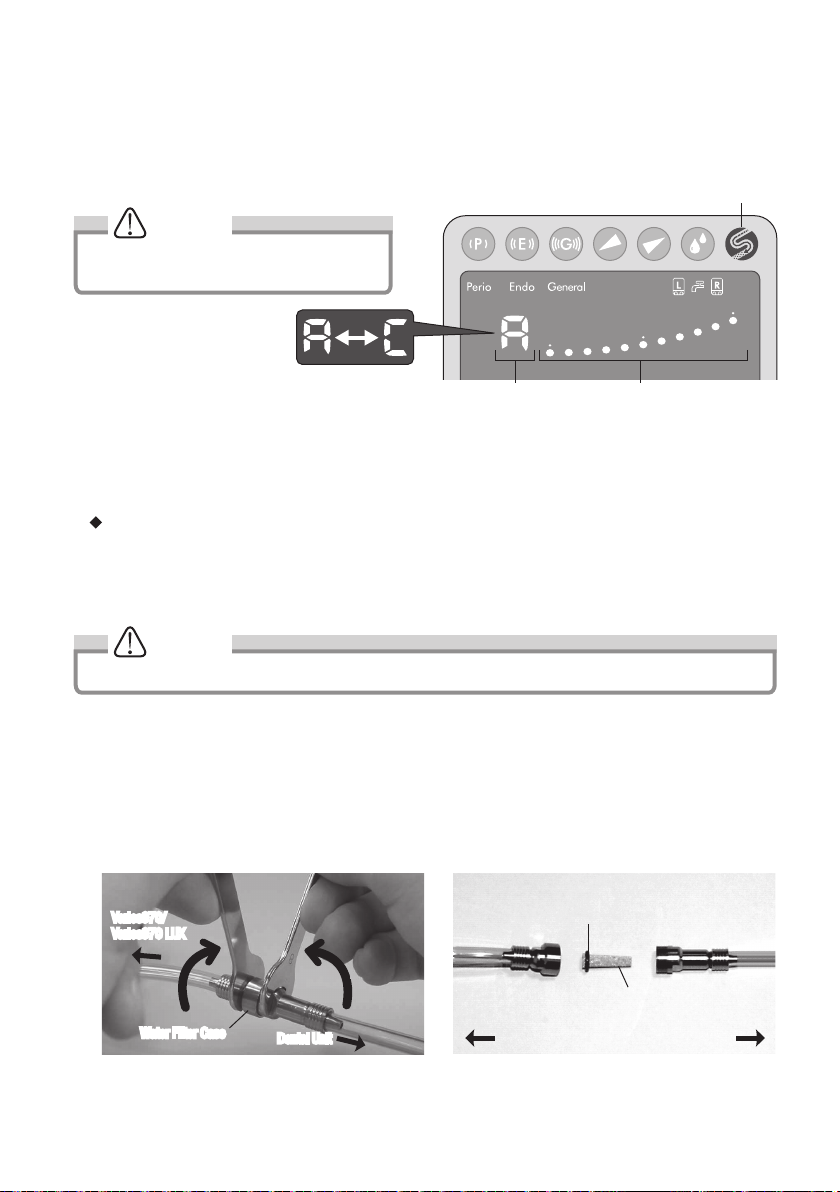

5) To perform the Auto-Cleaning, keep pressing the Auto-Cleaning Key (more than 1 second).It takes 30 seconds per

bottle to clean The Numerical Display will alternately displays “A” and “C”, the Bar Graph displays time remaining.

Single display (Bar Graph Display) is 6 second. When five displays of Bar Graph disappeared, Bottle will be changing

the other side.

To cancel the Auto-Cleaning, press Auto-Cleaning Key again.

Auto-Cleaning Key

NOTICE

During Auto-Cleaning, LED of the handpiece

does not illuminate. (Varios 970 LUX)

Numerical Display Bar Graph

6) When the Auto-Cleaning is finished, the Control Unit returns to the settings prior to cleaning. Remove the both bottles

from the Control Unit by pulling straight up. Clean thoroughly rinse and dry.

Following method is also available for cleaning. (Manual Cleaning)

1) Remove the Bottle from the Control Unit.

2) Open the cap of the cleaned Bottle and fill it with distilled water.

3) Close the cap firmly and insert the Bottle Joint into the Bottle Base Connector on the Control Unit until it clicks.

4) Operate the Control Unit about 30 seconds with water supply at maximum setting.

NOTICE

The Control Unit does not perform in Auto-Cleaning in Tap Water.

(6) Changing Water Filter (Option)

If you use Tap Water, change the Water Filter as it may necessary.

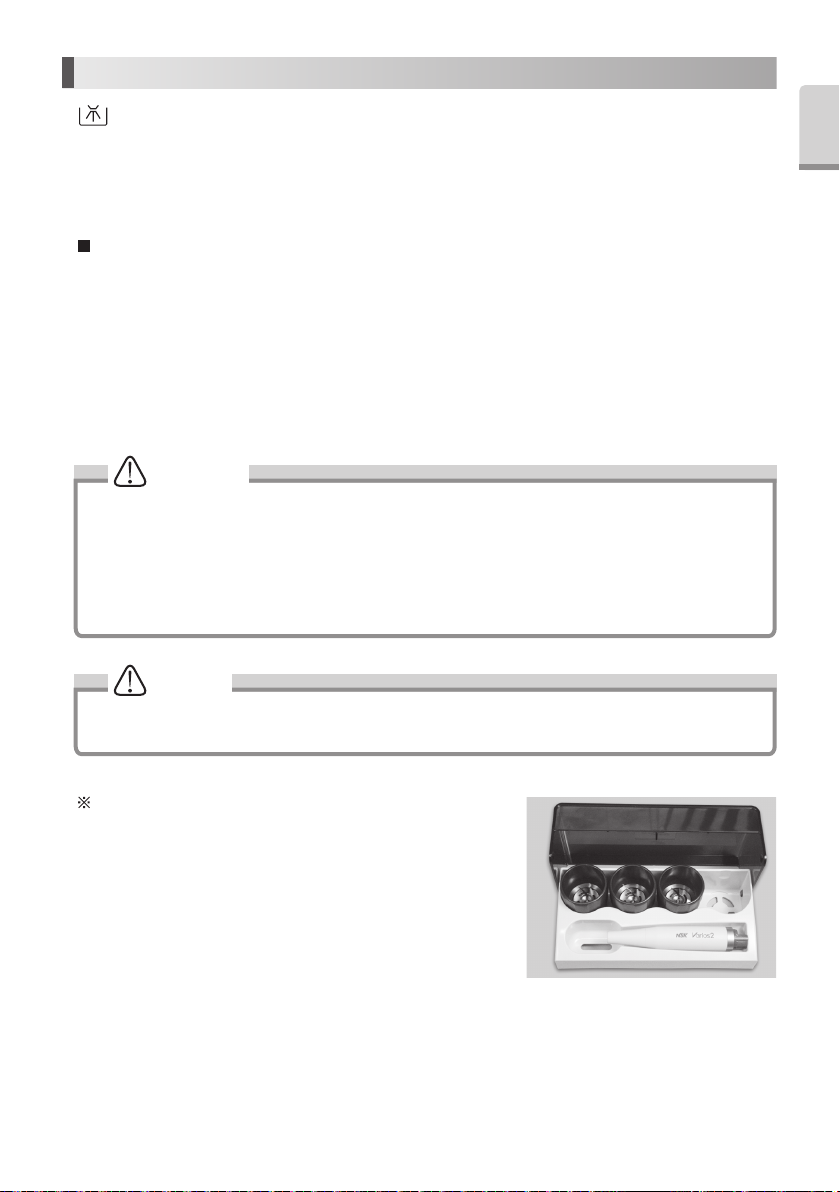

1) Close the water valve of the dental unit.

2) Mount two Spanner Wrenches (5x8) and turn those as shown in Fig.42.

3) When the Water Filter case is separated, the Water Filter can be removed as shown in Fig.43.

4) Replace with new ( Order Code U387042 ) and reassemble the filter in the reverse order.

Varios970/

Varios970 LUX

O-Ring

Fig.41

Water Filter Case

Dental Unit

Fig.42

Water Filter

Varios970/Varios970 LUX Dental Unit

Fig.43

18

Page 20

12. Sterilization

Only handpiece can be washed via Thermo Disinfector.

• Autoclave sterilization is recommended.

• Autoclave sterilization required first time you use and after each patient as noted below. Take handpiece out of the

packing bag before sterilization.

• ONLY the Tip, Handpiece and Tip Wrench can be autoclaved.

Autoclave Procedure

1) Remove the Tip after use. (Refer to 6. Mounting and Removing Tip)

2)

Wipe dirt and debris from the products, and wipe clean with alcohol-immersed cotton swab or cloth. For handpiece, use

MinutenWipes (ALPRO) to wipe. Do not use a wire brush.

3) Insert those into the Sterilization Case or an autoclave pouch. Seal the pouch.

4) Autoclavable up to max. 135˚C.

Ex.) Autoclave for 20 min. at 121˚C, or 15 min. at 132˚C.

5) Keep the products in the Sterilization Case or autoclave pouch to keep it clean until you use it.

* Sterilization at 121°C for more than 15 minutes is recommended by ISO17664 and EN ISO17665-1.

CAUTION

• Do not sterilize by ultraviolet ray. The handpiece could discolor.

• If autoclaved with other instruments stained with chemical solution, it could strip the plating and make the surface

black.

• Do not autoclave any parts (the Control Unit, Power Cord, Bottle, Foot Control, Handpiece Cord, O-Ring). Other

than those that can be subjected to autoclave sterilization. Perform alcohol disinfection to the Control Unit, Power

Cord, Foot Control, Handpiece Cord including after every patient.

• Do not wipe with, or clean or immerse in, high acid water or sterilizing solutions.

English

NOTICE

Repeated autoclaving may cause the handpiece to become discolored due to heat. However, this is due to

properties of the product and is not a problem in terms of quality.

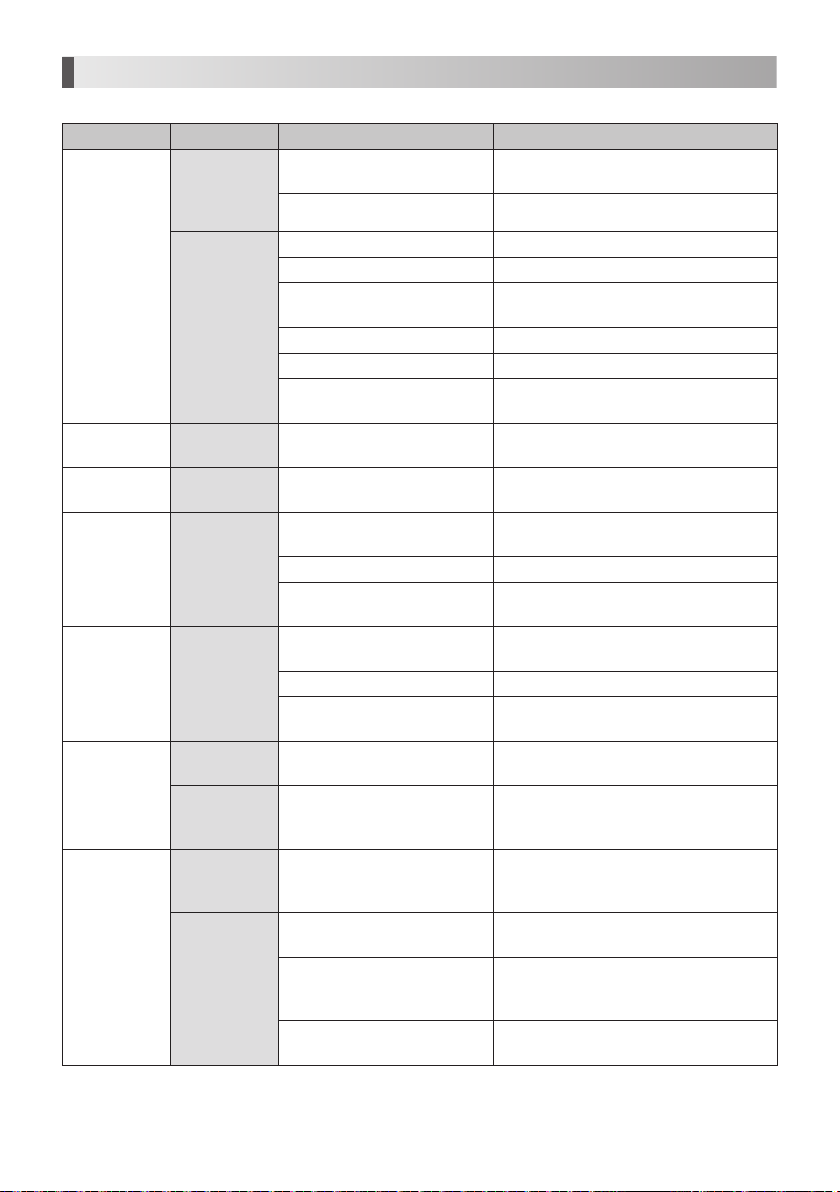

Sterilization Case

The Handpiece, Tip and Tip Wrench can be sterilized together using

Sterilization Case.

1) Remove the Tip after use. (Refer to 6. Mounting and Removing Tip)

2) Set the Tip Wrench with Tip into the Sterilization Case. (You can set four

Tip Wrenches and Tips at once).

3) Remove handpiece from the Handpiece Cord, and clean.

4) Set the handpiece into the Sterilization Case.

5) Autoclavable up to max. 135˚C.

ex.) Autoclave for 20 min. at 121˚C, or 15 min. at 132˚C.

6) Keep the products in the Sterilization Case or autoclave pouch to keep it clean until you use it.

19

Fig.44

Page 21

13. Troubleshooting

When trouble is found, please check the followings prior to consulting your dealer.

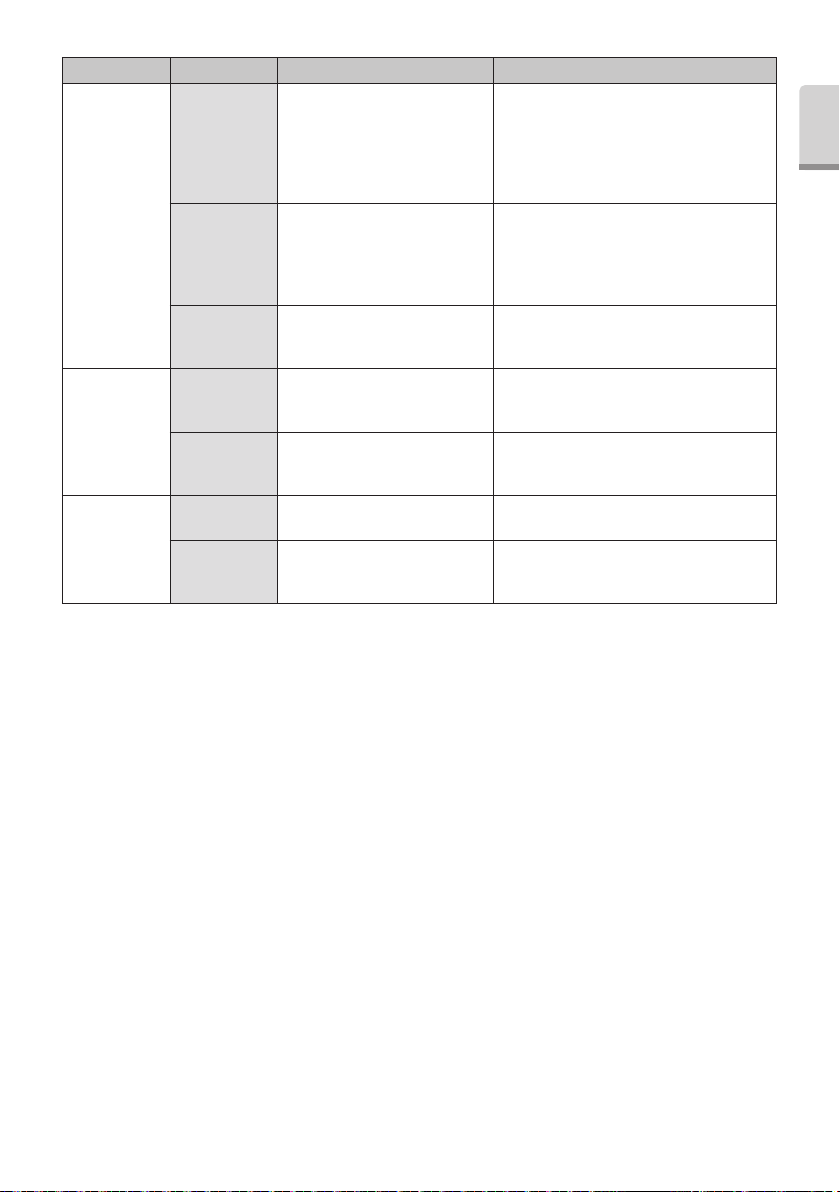

Problem Probable Cause Cause Solution

The Power Cord or the Jack is

disconnected.

The Fuse is burned out. Contact dealer.*

The Tip is not tightened firmly. Tighten the Tip until the Tip Wrench clicks.

Worn Tip. Replace the Tip.

Power has not been correctly

adjusted for the Tip.

The Foot Control is disconnected. Connect the Foot Control correctly.

Failure of vibrator in the handpiece. Contact dealer.*

Failure of internal components of

the Foot Control.

Power has not been properly

adjusted for the Tip.

Power has not been properly

adjusted for the Tip.

The Tip is not tightened firmly. Tighten the Tip until the Tip Wrench clicks.

Failure of vibration in the handpiece

or the Control Unit.

Power has not been properly

adjusted for the Tip.

The Tip is not tightened firmly. Tighten the Tip until the Tip Wrench clicks.

Failure of vibration in the handpiece

or the Control Unit.

The tube twisted. Straighten the twisted Irrigation Tube.

Time to replace Irrigation Pump.

(Approx. 500hours after used.)

—

The Water Adjustment Knob is

closed.

Disconnected Irrigation supply at

low volume range. (less than 10ml/

min.)

The Water Filter is clogged.

Correctly insert the Power Cord or the Jack.

Adjust the power on the Power Guide or Tip

case label. Do not exceed.

Contact dealer.*

Adjust the power level the Power Guide or Tip

case label. Do not exceed.

Adjust the power level on the Power Guide or

Tip case label. Do not exceed.

Contact dealer.*

Adjust the power level on the Power Guide or

Tip case label. Do not exceed.

Contact dealer.*

Replace with new Irrigation Pump (Refer to 11.

(4) Changing the Irrigation Pump).

Check the water circuitry and supply to the

Control Unit. Water pressure : 0.1-0.5MPa

(1-5kgf/cm

Turn the Water Adjustment Knob and adjust to

the appropriate volume.

No problem. Turn the Water Adjustment Knob

and increase the Irrigation volume.

Replace with new Water Filter (Refer to 11. (6)

Changing Water Filter (Option) ).

2

)

No / Poor

vibration.

The Tip is bent

or broken.

The Tip is flying

away.

Noise from the

handpiece.

The handpiece is

overheating.

No Irrigation

supply and/or

unstable

Irrigation supply

(Use of Bottle)

No / Poor water.

(Use of Tap

Water)

The Front Panel

does not light,

even if the Power

Switch is ON.

The Tip does

not generate

vibration, in spite

of depressing

the Foot Control.

—

— The Tip is not tightened firmly. Tighten the Tip until the Tip Wrench clicks.

—

—

The Irrigation

Pump is running.

The Irrigation

Pump is

stopping.

The water does

not reach to the

Control Unit.

Check to see if

water reaches

the Control Unit.

20

Page 22

Problem Probable Cause Cause Solution

Water is leaking

from the joint

between the

Irrigation Tube

The Irrigation Tube is not connected

correctly.

Firmly insert the Irrigation Tube into the Irrigation

Connector inmost.

and the Irrigation

Connector.

Water leakage.

Water is leaking

from the joint

between the

handpiece and

O-Ring at the handpiece cord is

worn or damaged.

Replace with new O-Ring (Refer to 11 (3)

Changing O-Ring •Handpiece Cord).

the cord.

Water is leaking

from the Control

Unit.

Tip oscillates, but

Handpiece

LED does not

illuminate.

(Varios 970 LUX)

Handpiece LED

turns on and off.

Tip oscillates, but

Handpiece LED

does not turn on.

Beeping while

power on.

Start Beeping

Beeping while

stopping

vibration of Tips.

* Repairs cannot be made by the customer.

The water circuitry in the Control

Unit is damaged.

The handpiece is not connected into

the Handpiece Cord correctly.

Disconnection in the Handpiece

Cord, or failure in the Control Unit.

Contact dealer.*

Firmly insert the handpiece into the Handpiece

Cord inmost.

Contact dealer.*

Depress Foot Control. Release the Foot Control.

Abnormal heating of the Control

Unit.

Stop the operation and leave until Control Unit

becomes cool.

English

21

Page 23

14. Specifications

Type NE255

Power Source

AC120V 50/60Hz

AC230V 50/60Hz

Vibration Frequency 28-32kHz

Maximum Output 11W

Rated Power 29VA

2

Water Pressure 0.1-0.5MPa (1-5kgf/cm

Lighting

Varios 970 : No

Varios 970 LUX : Yes

)

Bottle Volume 400mL (Per Bottle)

Dimensions W160 x D270 x H190mm (Including Bottle)

Weight 2.1kg (Except attachment)

Temperature 0 - 40 ˚C (The liquid must not freeze up)

Use Environment

Humidity 30 - 75 %

Atmospheric pressure 700 - 1060 hPa

Temperature -10 - 60 ˚C

Store Environment

Humidity 10 - 85 %

Atmospheric pressure 500 - 1060 hPa

15. Protection Circuit

It may overheat inside when you use this Control Unit in

more than Power 8 at G mode for long time.

In this case, Protection Circuit reduces the Power

automatically. (Power 7)

Bar Graph Indicator from 8 to 10 flashes. (Fig.45)

After Protection Circuit is released, the flashes stop.

However, Power Level can not automatically increase. If

needed, increase manually.

NOTICE

• During Protection Circuit function (during Bar Graph Indicator flash), the Control Unit can not increase the Power

Level.

• If Power Level decreases less than 7, Bar Graph Indicator stops flashing. However, it the Power increase more

than 8, flashes it again.

22

Fig.45

Page 24

16. Error Code

If an operational problem occurs numerical Display shows the error code to allow an immediate problem diagnosis.

Error Code Error Check / Remedy

E 0 Self-Check Error Contact dealer.

E 1 Circuit Failure Contact dealer.

E 7 Does not vibrate Contact dealer.

Confirm connection of the handpiece.

E 9 Handpiece Self Check Error

E 10 Circuit Failure Contact dealer.

*“E” and the number alternately display on the Display.

Power on the Control Unit again.

Leave the Control Unit until it become cool down and powers it again.

When an error can not be eliminated, Contact dealer.

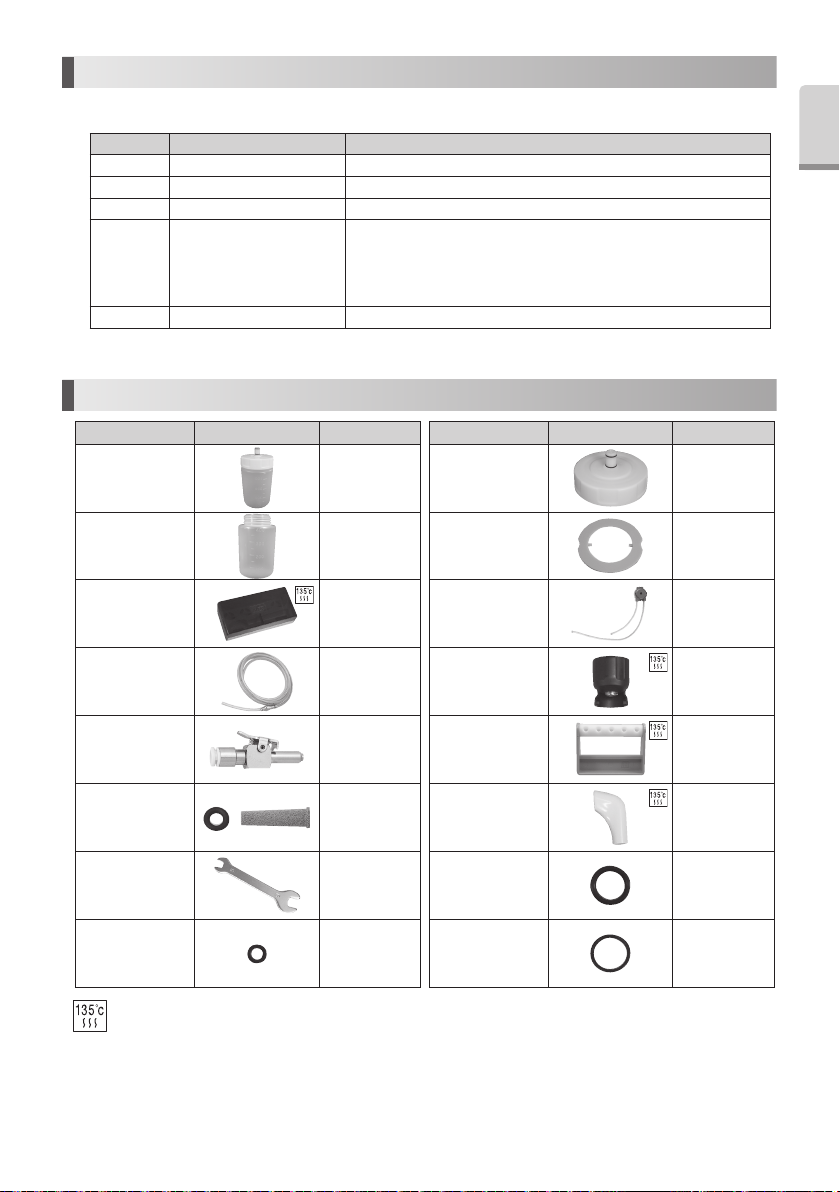

17. Spare Parts

Model Products Oeder Code Model Products Oeder Code

VA Bottle Set 400 Z1047002

VA Bottle 400 20000947

Sterilization Case Z1035001

Water Tube Set U387040

VA Bottle Cap 400 10000652

Gasket Z1047350

Irrigation Pump 10000643

Tip Wrench

(CR-10)

English

Z221076

Water Connector U387030

Water Filter U387042

Spanner Wrench

(5x8)

O-Ring

(for Handpiece

Cord)

Autoclavable at 135˚C max.

Y1001301

D0310020080

Tip Holder Z221A080

Tip Cover S Z217851

O-Ring

(Thick section)

(For VA Bottle)

O-Ring

(Thin section)

(For VA Bottle)

23

D0310075150

D0312090100

Page 25

18. Disposing product

Consult with dealer from whom you purchased it about waste disposal.

19. Warranty

Manufacturer warrants its products to the original purchaser against defects in material and workmanship under normal

practices of installation, use and servicing. Such expendable items as O-Rings and Irrigation Pump are not covered by this

warranty.

Symbols

TUV Rhineland of North America is a Nationally Recognized Testing Laboratory (NRTL) in the United States and is accredited by

the Standards Council of Canada to certify electro-medical products with Canadian National Standards.

Follow the waste of electric and electronic equipment (WEEE) Directive (2012/19/EU) to dispose of the product and

accessories.

Consult operation instructions.

Manufacturer.

This conforms to CE European Directive of “Medical equipment directive 93/42/EEC.”

Type BF applied part. Authorised representative in the European community.

Protected against vertically falling water drops. Autoclavable up to Max.135°C. *for detail see Sterilization.

This product can be cleaned and disinfected with a Thermo-Disinfector.

Marking on the outside of Equipment or Equipment parts that include RF transmitters or that apply RF electromagnetic energy

for diagnosis or treatment.

GS1 DataMatrix for Unique Device Identifier.

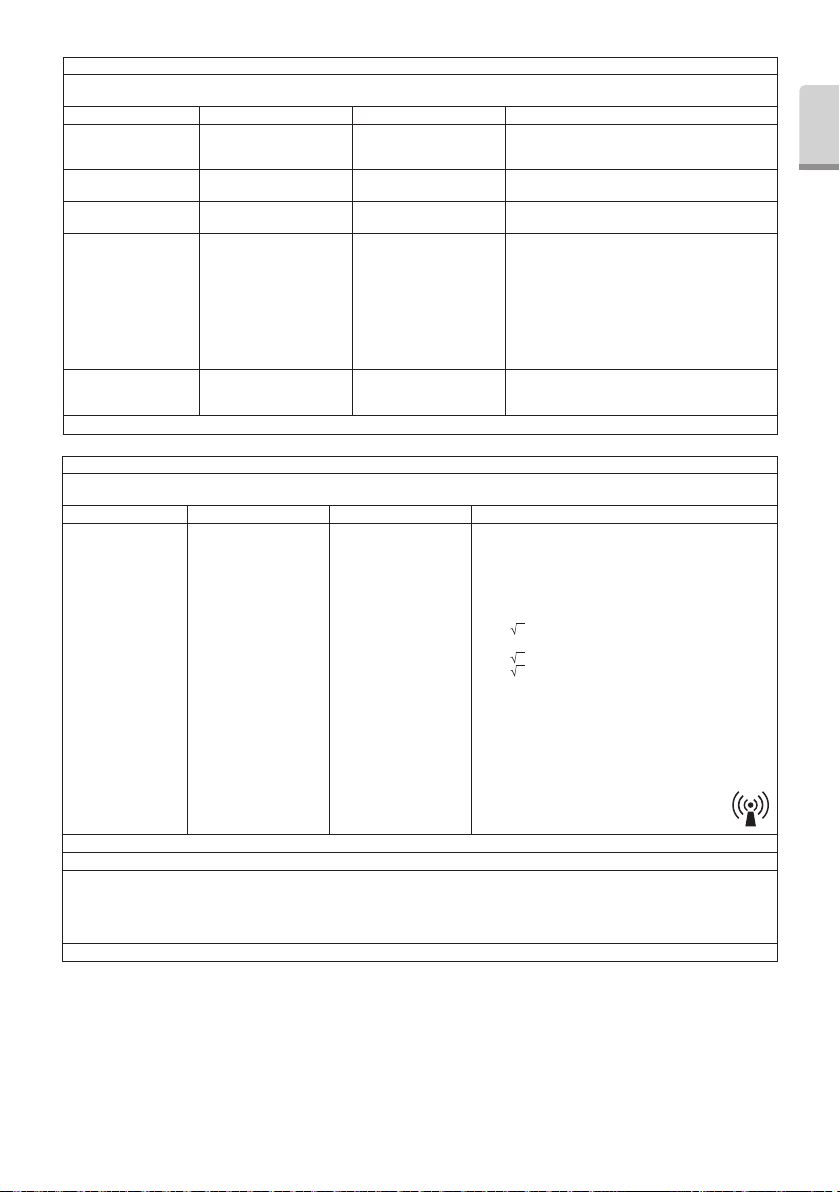

Guidance and manufacturer's declaration - electromagnetic emissions

The Varios 970 / Varios 970 LUX is intended for use in the electromagnetic environment specified below. The customer or the user of the Varios 970 / Varios 970 LUX

should assure that is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions

CISPR11/EN55011

RF emmissions

CISPR11/EN55011

Harmonic emissions

EN/IEC61000-3-2

Voltage fluctuations/flicker emissions

EN/IEC61000-3-3

Group 1

class B

class A

Complies

The Varios 970 / Varios 970 LUX uses RF energy only for its internal function. Therefore,

its RF emissions are very low and are not likely to cause any interference in nearby

electronic equipment.

The Varios 970 / Varios 970 LUX is suitable for use in all establishments, including

domestic establishments and those directly connected to the public low-voltage power

supply network that supply network that supplies buildings used for domestic purposes.

24

Page 26

Guidance and manufacturer's declaration - electromagnetic immunity

The Varios 970 / Varios 970 LUX is intended for use in the electromagnetic environment specified below. The customer or the user of the Varios 970 / Varios 970 LUX

should assure that it is used in such an environment.

Immunity test EN/IEC60601 test level Compliance level Electromagnetic environment - guidance

Electrostatic discharge (ESD)

EN/IEC61000-4-2

Electrical fast transient/burst

EN/IEC61000-4-4

Surge

EN/IEC61000-4-5

Voltage dips, short

interruptions and voltage

variations on power supply

input lines

EN/IEC61000-4-11

Power frequency (50/60Hz)

magnetic field

EN/IEC61000-4-8

NOTE: Ut is the a.c. mains voltage prior to application of the test level.

Guidance and manufacturer's declaration - electromagnetic immunity

The Varios 970 / Varios 970 LUX is intended for use in the electromagnetic environment specified below. The customer or the user of the Varios 970 / Varios 970 LUX

should assure that it is used in such an environment.

Immunity test EN/IEC60601 test level Compliance level Electromagnetic environment - guidance

Conducted RF

EN/IEC61000-4-6

Radiated RF

EN/IEC61000-4-3

NOTE 1 At 80MHz and 800MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects and people.

a Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobiles radios, amateur radio, AM and FM

radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an

electromagnetic site survey should be considered. If the measured field strength in the location in which the Varios 970 / Varios 970 LUX is used exceeds the

applicable RF compliance level above, the Varios 970 / Varios 970 LUX should be observed to verity normal operation. If abnormal performance is observed,

additional measures may be necessary, such as reorienting or relocating the Varios 970 / Varios 970 LUX.

b Over the frequency range 150kHz to 80MHz, field strengths should be less than 3 V/m.

±6kV contact

±8kV air

±2kV for power supply lines

±1kV for input/output

±1kV line(s) to line(s)

±2kV line(s) to earth

<5% Ut (>95% dip in Ut)

for 0.5 cycle

40% Ut (60% dip in Ut)

for 5 cycles

70% Ut (30% dip in Ut)

for 25 cycles

<5% Ut (>95% dip in Ut)

for 5 secs

3 A/m 3 A/m Power frequency magnetic fields should be at levels

3Vrms

150 kHz to 80MHz

3V/m

80MHz to 2.5 GHz

±6kV contact

±8kV air

±2kV for power supply lines

±1kV for input/output

±1kV line(s) to line(s)

±2kV line(s) to earth

<5% Ut(>95% dip in Ut)

for 0.5 cycle

40% Ut (60% dip in Ut)

for 5 cycles

70% Ut (30% dip in Ut)

for 25 cycles

<5% Ut (>95% dip in Ut)

for 5 sec

3Vrms

3V/m

Floors should be wood, concrete or ceramic tile. If floors are

covered with synthetic material, the relative humidity should

be at least 30%.

Mains power quality should be that of a typical commercial or

hospital environment.

Mains power quality should be that of a typical commercial or

hospital environment.

Mains power quality should be that of a typical commercial

or hospital environment. If the user of the Varios 970 / Varios

970 LUX requires continued operation during power mains

interruptions, it is recommended that the Varios 970 / Varios

970 LUX be powered from an uninterruptible power supply or

a battery.

characteristic of a typical location in a typical commercial or

hospital environment.

Portable and mobile RF communications equipment should be used

no closer to any part of the Varios 970 / Varios 970 LUX, including

cables, than the recommended separation distance calculated from

the equation applicable to the frequency of the transmitter.

Recommended separation distance

d = 1.2 P

d = 1.2 P 80MHz to 800MHz

d = 2.3 P 800MHz to 2.5GHz

Where P is the maximum output power rating of the transmitter in

watts (W) according to the transmitter manufacturer and d is the

recommended separation distance in meters (m).

Field strengths from fixed RF transmitters as determined by an

electromagnetic site survey, should be less than the compliance level

in each frequency range.

Interference may occur in the vicinity of equipment

marked with the following symbol:

English

25

Page 27

Cables and accessories Maximum length Complies with

Handpiece cord

Foot Control

AC Power Cord

Recommended separation distances between portable and mobile RF communications equipment and the Varios 970 / Varios 970 LUX.

The Varios 970 / Varios 970 LUX is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The customer or the user of

the Varios 970 / Varios 970 LUX can help prevent electromagnetic interference by maintaining a minimum distance between portable and mobile RF communications

equipment (transmitters) and the Varios 970 / Varios 970 LUX as recommended below, according to the maximum output power of the communications equipment.

Rated maximum output power of transmitter

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m) can be estimated using the equation

applicable to the frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1 At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects and people.

2 m

2 m

2 m

W

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

1 1.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

RF emissions, CISPR11, EN55011

Harmonic emissions,

Voltage fluctuations/ flicker emission,

Electrostatic discharge (ESD)

Electric fast transient / burst

Surge

Voltage dips, short interruptions and voltage variations on power supply input lines

Power frequency(50/60Hz) magnetic field

Conducted RF

Radiated RF

150kHz to 80MHz

d=1.2 P

Separation distance according to frequency of transmitter

m

80MHz to 800MHz

d=1.2 P

Class B/ Group 1

EN/IEC61000-3-2

EN/IEC61000-3-3

EN/IEC61000-4-2

EN/IEC61000-4-4

EN/IEC61000-4-5

EN/IEC61000-4-11

EN/IEC61000-4-8

EN/IEC61000-4-6

EN/IEC61000-4-3

800MHz to 2.5GHz

d=2.3 P

26

Page 28

Klassifizierung der Geräte

• Schutzart gegen Stromschlag :

– Geräteklasse I

• Schutzart gegen Stromschlag :

– Anwendungsteil Typ BF:

• Vom Hersteller empfohlenes Verfahren zum Sterilisieren oder Desinfizieren :

– Siehe 12. Sterilisation

• Schutzart gegen Eindringen von Wasser gemäß der Beschreibung in der aktuellen Ausgabe von IECD 60529:

– Fußschalter : IPX1 (gegen senkrecht herunterfallende Wassertropfen geschützt)

• Grad der Anwendungssicherheit bei Verwendung einer entflammbaren Betäubungsmittelmischung mit Luft oder mit

Sauerstoff oder Lachgas :

– GERÄT ist nicht zur Verwendung mit einer entflammbaren Betäubungsmittelmischung mit Luft oder mit Sauerstoff oder

Lachgas geeignet.

• Betriebsart :

– Dauerbetrieb

Deutsch

Bestimmungsgemäßer Gebrauch

Dieses Gerät ist nur zum Gebrauch in Zahnkliniken / Zahnarztpraxen bestimmt. Dieses Gerät erzeugt Ultraschallwellen, die

für Dentalanwendungen wie zum Beispiel Scaling, Wurzelkanalbehandlung, Paradontalbehandlung und Zahnpräparationen

bestimmt sind.

1. Vorsichtsmaßregeln für Handhabung und Bedienung

Lesen Sie diese Vorsichtsmaßregeln sorgfältig durch und verwenden Sie das Gerät nur bestimmungsgemäß bzw. gemäß

der Anleitung.

Die Sicherheitsvorschriften dienen zum Vermeiden möglicher Gefahren, die zu Verletzungen oder einer Beschädigung des

Geräts führen könnten. Die Sicherheitsvorschriften werden entsprechend des Risikogrades wie folgt eingestuft.

KLASSE RISIKOGRAD

WARNUNG

ACHTUNG

HINWEIS

Eine Gefahr, die zu Verletzungen oder zu einer Beschädigung des Geräts führen können, wenn die

Sicherheitsvorschriften nicht befolgt werden.

Eine Gefahr, die zu leichten oder mittelschweren Verletzungen oder einer Beschädigung des Geräts

führen können, wenn die Sicherheitsvorschriften nicht befolgt werden.

Allgemeine Informationen für den sicheren Betrieb des Geräts.

WARNUNG

• Stecken Sie das Anschlusskabel nicht mit nassen Händen aus, um einen Stromschlag zu vermeiden.

• Achten Sie darauf, dass die Steuereinheit nicht mit Wasser in Berührung kommt, da dies zu einem Kurzschluss und einem

Stromschlag führen kann.

• Berühren Sie das hintere Ende des Handstücks nicht, wo elektrische Anschlüsse mit dem Kabel verbunden sind. Dies

könnte zu einem Stromschlag führen.

• Wenn Sie vor oder während des Betriebs des Geräts eine Anormalität wie z.B. Vibrationen, Wärmeentwicklung, unnormale

Geräusche etc. feststellen, schalten Sie das Geärt sofort ab.

• Verwenden Sie eine geerdete Steckdose. Es kann zu einem Stromschlag kommen, wenn Sie eine andere verwenden.

• Betätigen Sie den Hauptschalter nicht grundlos, dies könnte eine Sicherung auslösen.

• Dieses Gerät ist ein medizinisches Elektrogerät. Die EMK (elektromagnetische Kompatibilität) wird in der

Begleitdokumentation beschrieben.

• Tragbare und mobile RF-Kommunikationsgeräte können das medizinische Elektrogerät beeinträchtigen. Verwenden Sie

keine RF-Geräte in der Umgebung des Geräts.

• Sehen Sie beim Installieren des Geräts Platz von circa 10 cm um die Steuereinheit herum vor, damit der Zulauf und das

Anschlusskabel einfach zugänglich sind.

27

Page 29

• Denken Sie beim Verwenden des Geräts stets an die Sicherheit des Patienten.

• Es ist zur Verwendung durch medizinisches Fachpersonal wie zum Beispiel durch einen Arzt/eine Ärztin oder einen

Dentalhygieniker /eine Dentalhygienikerin bestimmt.

• Überprüfen Sie vor dem Verwenden die Vibrationen außerhalb des Mundes des Patienten. Sollte Ihnen etwas unnormal

vorkommen, stellen Sie die Verwendung sofort ein und setzen Sie sich mit Ihrem Händler in Verbindung.

• Die Steuereinheit / das Handstück darf nicht fallen gelassen oder starken Erschütterungen ausgesetzt werden.

• Verwenden Sie nur echte NSK-Aufsätze für den NSK Varios Ultraschallscaler (Varios 970 oder Varios 970 LUX). Probleme

wie zum Beispiel eine Beschädigung, ein Ausfall oder eine Störung von Handstücken aufgrund der Verwendung von

anderen als NSK-Aufsätzen werden von der Garantie nicht abgedeckt. Im Folgenden finden Sie mögliche Fehler, die beim

Verwenden von anderen als NSK-Aufsätzen auftreten können.

– Schwingungsbruch, verursacht durch die Verwendung nicht konformer Schrauben.

– Patient verschluckt versehentlich beschädigte Aufsätze.

– Beschädigung des Gewindes am Handstück.

– Sie müssen den Aufsatz innerhalb des in der Leistungsrichtlinie für Aufsätze beschriebenen Leistungsbereichs

verwenden. Wenn Sie ihn außerhalb des Leistungsbereichs verwenden, könnte der Aufsatz abbrechen oder eine

Operationsstelle geschädigt werden.

• Verwenden Sie immer ausreichend Wasser (Kühlmittel), da es sonst zu einer Schädigung der Zahnoberfläche und einer

Überhitzung des Handstücks kommen kann.

• Sterilisieren Sie es nicht mit ultraviolettem Licht. Das Handstück könnte sich verfärben.

• Sterilisieren Sie den Aufsatz, das Handstück und den Drehmomentschlüssel mit dem Autoklaven. Wischen Sie die Steuereinheit,

das Wechselstrom-Anschlusskabel, den Fußschalter und das Handstückkabel mit DSH gelisteter Desinfektionslösung ab.

• Wenn chemische Lösungen, Lösungsmittel oder antiseptische Lösung an dieses Gerät gelangen, wischen Sie es sofort ab.

Sonst kann es zu einer Verfärbung oder Verformung kommen.

• Das Handstück/die Steuereinheit darf nicht auseinandergenommen oder verändert werden.

• Halten Sie das Gerät von Patienten mit einem Herzschrittmacher fern.

• Halten Sie das Gerät von explosiven Stoffen und entflammbarem Material fern. Verwenden Sie es nicht für Patienten, die

mit Lachgas betäubt werden.

• Verwenden Sie eine Sicherung mit entsprechender Bemessung (120 V: T630 mAL 250 V, 230 V: T315 mAL 250 V).

• Für dieses Gerät gelten besondere Vorsichtsmaßregeln bezüglich der EMK und es muss entsprechend den EMK-Daten

installiert und in Betrieb genommen werden.

• Die Verwendung von anderen ZUBEHÖRTEILEN, Wandlern und Kabeln als den hier angegebenen kann, mit Ausnahme

von Wandlern und Kabeln, die vom Gerätehersteller als Ersatzteile für Einbauteile verkauft werden, zu einer vermehrten

EMISSION oder einer verringerten STÖRFESTIGKEIT dieses Geräts führen.

• Dieses Gerät sollte nicht direkt neben, auf oder unter anderen Geräten aufgestellt werden, und wenn es direkt neben,

unter oder auf anderen Geräten verwendet werden muss, muss sichergestellt werden, dass das Gerät in der Konfiguration,

in der es verwendet werden soll, normal funktioniert.

• Wenn nach dem Autoklavieren noch Wassertropfen am Handstück, wischen

Sie sie ab. Wenn Sie sie nicht abwischen, können sich Flecken bilden.

• Dieses Gerät darf nicht vom Patienten benutzt werden.

• Eine zuverlässige Erdung kann nur erreicht werden, wenn die

Ausrüstung an einer Anschlussdose mit der Kennzeichnung "Nur

Krankenhaus" oder "Krankenhaus-Grad" angeschlossen wird.

• Wenden Sie keine zu hohe Leistung an der Spitze an, denn dies könnte

den Zahn beschädigen.

Netzstecker unten wird in Nordamerika verwendet.

Steckertyp NEMA 5-15P (Typ Krankenhaus-Grad)

ACHTUNG

• Während des Betriebes können das Handstück und das Handstückkabel Computer und LAB-Kabel beeinflussen. Es kann

zu einem Rauschen kommen, wenn es neben einem Rundfunkgerät betrieben wird.

• Stellen Sie sicher, dass der Hauptschalter am Gerät nach der Benutzung ausgeschaltet wird. Ziehen Sie den Netzstecker

und lassen Sie das Wasser aus dem Inneren der Steuereinheit ab, wenn sie für längere Zeit nicht verwendet wird.

• Der Benutzer ist für die Bedienung, Wartung und Inspektion verantwortlich.

• Reinigen/ sterilisieren Sie das Gerät direkt nach dem Verwenden. Dann lagern Sie es ein. Wenn Blut etc. darauf verbleibt,

kann dies zu einem Ausfall führen.

• Verwenden Sie zum Reinigen MinutenWipes (ALPRO) , um die Oberfläche des Handstücks abzuwischen. Die Verwendung

anderer Chemikalien als dieser kann dazu führen, dass sich das Handstück verfärbt, bricht usw.

28

Page 30

• Wenn Sie das Gerät längere Zeit nicht verwendet haben und es erneut einsetzen möchten, überprüfen Sie es vor dem

Einsatz auf seine Funktionstüchtigkeit.

• Schauen Sie nicht in die LED-Lampe und lassen Sie die Patienten nicht hineinschauen. Dies kann zu einer Schädigung der Augen führen.

• Dieses Gerät kann für Patienten jeden Alters (außer Kleinkinder), Geschlechts, Gewichts und jeder Staatsangehörigkeit

verwendet werden.

• Für dieses Gerät ist keine besondere Schulung erforderlich.

• Anwendungsteile, die mit dem Patienten bzw. Bediener in Berührung kommen, sind Aufsatz bzw. Handstück.

• Oberflächentemperatur der Spitze ist mehr als 50 Grad, ohne einen Leitungswaßer zu verwenden. Um dieses Ereignis zu

vermeiden, seien Sie sicher einen Leitungswaßer zu benutzen.

HINWEIS

• Das wiederholte Autoklavieren kann dazu führen, dass sich das Handstück durch die Hitze verfärbt. Dies ist jedoch auf die

Eigenschaften des Produkts zurückzuführen und stellt kein Qualitätsproblem dar.

Deutsch

29

Page 31

2. Bezeichnung der Komponenten

2

1

LICHTLEITFASER NICHT LICHTLEITFASER

LICHTLEITFASER NICHT LICHTLEITFASER

5

4

8

Optional

15

3

7

12 14

13

16

6

NR. BEZEICHNUNG DER TEILE ANZAHL

1 Steuereinheit 1

2 VA-Flasche 2

3 Wechselstrom-Anschlusskabel 1

4 Varios2 Handstück (Lichtleitfaser oder nicht) 1

Handstückkabel (Nicht abgeschirmter 2M)

5

119 10

17

18

6 Fußschalter 1

7 Sterilisierbox 1

8 Drehmomentschlüssel 3

9 Aufsatz G4 1

10 Aufsatz G8 1

11 Aufsatz G16 1

12 O-Ring (Dünner Abschnitt)(für VA-Flasche) 2

13 O-Ring (Dicker Abschnitt)(für VA-Flasche) 2

14 O-Ring (für Handstück) 2

15 Wasseranschluss (optional) 1

16 Wasserschlauch (optional) 1

17 Schraubenschlüssel (5 x 8) (optional) 2

18 Aufsatzabdeckung S (optional) 1

19 Leistungsrichtlinie für Aufsätze 1*

20 Aufsatzkarte 1*

21 Bedienungsanleitung 1*

* Diese sind im Foto oben nicht abgebildet.

(Lichtleitfaser oder nicht)

1

* Arbeitsprinzip

Der Generator erzeugt bei Ultraschallfrequenz ein sinusförmiges elektrisches Signal. Dieses Signal wird an die

Piezokeramik im Wandler angelegt. Die Piezokeramik wandelt dieses Signal in mechanische Schwingungen

um. Diese Schwingungen haben dieselbe Ultraschallfrequenz wie das elektrische Signal. Die mechanischen

Schwingungen breiten sich zum distalen Ende des Wandlers hin aus. Der Einsatz, der am distalen Ende des

Wandlers angebracht ist, vibriert mit Ultraschallfrequenz und ermöglicht das Erreichen des angestrebten Zieles.

30

Page 32

3. Bezeichnung und Funktion jedes Teils

Linke Flasche (L Flasche) Rechte Flasche (R Flasche)

Kühlmittelfluss Leitungswasser

Deutsch

Flaschenauswahlanzeiger L

Handstückkabelstecker

Kühlmittelfluss Leitungswasser

(links)

Flaschenauswahlanzeiger R

(rechts)

Kühlmittelfluss Flasche

(Boden)

Hauptschalter

Fußsteuerungsanschluss Leitungswasseranschluss

Anschluss Wechselstromkabel

31

Page 33

Bedienfeld und Anzeige

Betriebsartauswahltasten

ENDO-Taste

Perio-Taste

Betriebsartanzeige

(Numerische)

Leistungsanzeige

Wenn Sie optional erhältliche Teile wie den Wasserschlauch und den Wasseranschluss benutzen, können Sie

Leitungswasser verwenden.

General-Taste

Leistungsstufentasten

Ab-Taste

(verringern der Leistung)

Auf-Taste

(erhöhen der Leistung)

Kühlmittelauswahltaste

Auto Cleaning

Kühlmittelmodus

Leistungsanzeige

Betriebsartauswahltasten

Sie können mit dieser Taste die Betriebsart auswählen (Perio, Endo und General). Sie können in jeder Betriebsart individuell

die Wassermenge, die Art und die Leistung wählen.

Leistungsstufentasten

Sie können mit diesen Tasten die Leistungsstufen auswählen. Es gibt 11

Stufen (0 bis 10).

Keine Vibration bei Stufe 0 (null) (Abb. 1). Die Leistungsanzeige ändert sich

numerisch als auch grafisch.

Kühlmittelauswahl

Sie können mit dieser Taste die R Flasche oder die L Flasche auswählen. Die vordere Anzeige und die

Flaschenauswahlanzeige ändern sich gleichzeitig. Halten Sie die Kühlmittelwahltaste länger als eine Sekunde gedrückt, um

zur Leitungswasserkühlung zu wechseln.

Abb.1

Auto Cleaning/Selbstreinigungstaste

Sie können mit dieser Taste die Betriebsart Selbstreinigung

auswählen. Genauere Angaben finden Sie in 11. (5).

Flaschen-Wasserregler

Die Anpassung der Wassermenge kann vor der Vibration

des Aufsatzes vorgenommen werden. Sie können die

Wassermenge während des Spülens der Flasche oder der

Wartezeit vor dem Start der Aufsatzvibration anpassen. Wenn

die Einstellung für die Steuereinheit nicht anwendbar ist (zu

niedrig oder zu hoch), könnte es piepen.

Während der Bedienung zeigt die Fronttafel die aktuelle

Leistungsstufe an. Wenn Sie den Regler jedoch länger als

eine Sekunde; könnte es die Wassermenge verändern.

ACHTUNG

• Vermeiden Sie es, den Knopf schnell zu

zudrehen. Wenn er schnell gedreht wird, kann

die Einstellung möglicherweise nicht registriert

werden.

•

Die Wassermenge kann von 5 ml/min bis 45 ml/min

eingestellt werden.

• Die Geräusche können beim Betrieb der rechten

Flasche anders klingen als bei der linken Flasche.

• Während der Einstellung der Wassermenge

erscheint auf der numerischen Leistungsanzeige

„-“.

32

Page 34

Kühlmittelfluss Leitungswasser

Sie können die Leitungswasserzufuhr mit diesem Knopf einstellen.

4. Vor dem Benutzen des Systems

(1) Einrichten des Wassersystems

• VERWENDEN DER FLASCHE

1) Nehmen Sie den Staubschutz vom Anschluss am Flaschenboden (Abb. 2).

2) Öffnen Sie die VA-Flasche und füllen Sie sie bis zum gewünschten Füllstand.

3) Schließen Sie die VA-Flasche, Sie die Flaschenverbindung in den Anschluss am

Flaschenboden einrasten (Abb. 3).

Um die Flasche herauszunehmen, ziehen Sie sie nach oben.

Deutsch

ACHTUNG

•

Benutzen Sie das VA-Flaschen-Set 400 nur für Varios 970.

• Bitte prüfen Sie die Deckeldichtung auf Sauberkeit und Dichtheit, bevor Sie das

Kühlmittel einfüllen. (Abb. 4)

• Benutzen Sie keine scharfen Gegenstände für die Reinigung der Dichtung und

schützen Sie das Produkt vor Stößen. Diese können zu Störungen führen.

• Setzen Sie die Flasche gerade ein. Wenn sie nicht gerade eingesetzt wird,

kann der O-Ring des Verschlusses beschädigt werden.

• Halten Sie die Dichtung sauber. Verschmutzungen durch Wasser oder

antiseptische Lösungen sofort abwischen.

• Die Dichtung ist ein Verschleißteil. *Bestellnummer Z1047350

FLASCHENVERBINDUNG

Dichtung

Abb.2

Abb.3

HINWEIS

• Die Füllstandsanzeige ist auf beiden Seiten der Flasche aufgedruckt und

kann beim Auffüllen oder auf der Steuerungseinheit angebracht exakt

abgelesen werden.

• Bringen Sie den Staubschutz an, wenn Sie die Flaschen nicht verwenden.

Abb.4

• VERWENDUNG VON LEITUNGSWASSER (OPTIONAL)

1) Nehmen Sie die Abdeckung vom Leitungswasseranschluss (Abb. 5).

2) Schließen Sie die Filterseite des Wasserschlauchs tief im Leitungswasseranschluss an der Steuereinheit an (Abb. 6).

3) Verbinden Sie den Wasserschlauch mit dem Wasseranschluss an der Dentaleinheit.

ABDECKUNG

WASSERSCHLAUCH

Abb.5

33

LEITUNGSWASSERANSCHLUSS

WASSERFILTER

Abb.6

Page 35

ACHTUNG

Wenn über längere Zeit hinweg kein Wasser aus dem Wasserablass der Dentaleinheit abgelassen wurde, kann es

sein, dass bräunliches Wasser herauskommt; dann warten Sie bitte, bis sauberes Wasser kommt. Schließen Sie

erst dann das Gerät an.

HINWEIS

• Stecken Sie den Wasserschlauch fest in die Steuereinheit.

• Zum Entfernen des Schlauchs drücken Sie den weißen Ring

(den Schnellverbindungsring) am Leitungswasseranschluss

nach hinten und nehmen den Schlauch vorsichtig ab (Abb. 7).

• Wenn der Wasserschlauch nicht angeschlossen ist, bringen

Sie die Abdeckung am Leitungswasseranschluss an.

(2) Fußschalteranschluss

Stecken Sie den Fußschalterstecker mit der [ ] Markierung

auf der Oberseite des Steckers (Abb. 8) in die Steuereinheit.

(3) Handstückkabelanschluss

Stecken Sie den Anschluss des Handstückkabels in die

Steuereinheit. Die Seite mit der [

Stecken Sie ihn nicht verkehrt herum ein (Abb. 9).

] Markierung ist oben.

FUSSSCHALTERANSCHLUSS

FUSSSCHALTERSTECKER

[ ]

MARKIERUNG

weißen Ring

[ ]

MARKIERUNG

KABELANSCHLUSS

HANDSTÜCK

HANDSTÜCKKABEL

Abb.7

Abb.8

ACHTUNG

Stellen Sie vor dem Anschließen sicher, dass der Kabelstecker des

Handstücks sauber ist (Abb. 10).

34

Abb.9

Abb.10

Page 36

(4) Anbringen des Anschlusskabels

Stecken Sie das Anschlusskabel in die Buchse für das

Wechselstrom-Anschlusskabel an der Rückseite der

Steuereinheit (Abb. 11).

WECHSELSTROMANSCHLUSSKABEL

STECKER WECHSELSTROM

ACHTUNG

• Achten Sie darauf, dass die Stromversorgung an der Steuereinheit beim Einstecken des Anschlusskabels AUS ist.

Es kann zur Beschädigung der Sicherung kommen.

• Stellen Sie keine Verbindung mit der Steckdose her, bevor Sie nicht das Anschlusskabel an das Gerät angesteckt

haben.

• Ziehen Sie das Anschlusskabel nicht mit Gewalt heraus.

• Ziehen Sie das Anschlusskabel oder das Handstückkabel nicht heraus, während der Fußschalter betätigt wird.

5. Anbringen und Entfernen des Handstücks

Richten Sie die Punkte am Handstück und am Handstückkabel

zueinander aus. Drücken Sie beide geradlinig ineinander.

Zum Entfernen des Handstücks greifen Sie das Handstück und

das Handstückkabel und ziehen Sie sie gerade auseinander

(Abb. 12).

PUNKTE

Abb.11

Deutsch

WARNUNG

Berühren Sie das hintere Ende des Handstücks nicht

(dort, wo elektrische Anschlüsse mit dem Kabel

verbunden sind).

Dies könnte zu einem Stromschlag führen.

HANDSTÜCK HANDSTÜCKKABEL

ACHTUNG

• Stellen Sie stets sicher, dass das Handstück korrekt platziert und eingerastet ist.

• Stecken Sie kein anderes Handstück als das mitgelieferte (Varios2) Handstück an.

35

Hinteres Ende des

Handstücks

Abb.12

Page 37

6. Anbringen und Entfernen des Aufsatzes

1) Spitze leicht mit der Hand drehen und anschließend montieren (Abb. 13).

2) Die Spitze wird in das unterste Loch des Aufsatzschlüssels eingesetzt. Stecken Sie die viereckige Basis der Spitze in den

viereckigen Aufsatzschlüssel. Drehen Sie anschließend die Spitze bis sie einrastet (Abb. 14).

* Zur Vermeidung von Verletzungen sollten Sie die Oberseite der Spitze nicht berühren. (Es kann sein, dass sie länger ist

als die Länge des Spitzenschlüssels)

Zur Entfernung der Spitze, drehen Sie die Spitze mit dem Spitzenschlüssel gegen den Uhrzeigersinn.

DREHMOMENTSCHLÜSSEL

LÖSEN

ANZIEHEN

ANZIEHEN

Abb.13

LÖSEN

Abb.14

ACHTUNG beim Verwenden der Aufsätze

• Überprüfen Sie den Aufsatz, bevor Sie ihn verwenden (nicht sauber, beschädigt, verbogen, verrostet).

• Die maximale Leistungsstufe für die Aufsätze darf nicht überschritten werden. Es könnte zu einer Schädigung der

Zahnstruktur und der Aufsätze kommen.

• Vermeiden Sie, mit dem Aufsatz und dem keramischen Zahnersatz in Berührung zu kommen. Dadurch können

die Aufsätze beschädigt werden.

• Stoßen Sie nicht gegen Metall- oder Kunststoffkronen, außer wenn diese entfernt werden sollen. Die Aufsätze

könnten abbrechen und in den Mund fallen.

• Berühren Sie kein Zahnfleisch, keine Schleimhaut bzw. Haut. Es könnte zu Verletzungen und Verbrennungen

führen.

• Der Aufsatz darf nicht geschliffen bzw. verbogen werden. Das könnte die Aufsätze beschädigen, sodass beim

Scaling nicht genügend Schwingungen erzeugt werden.

• Während des Schleifens wird der Aufsatz nach und nach abgetragen. Wenn der Aufsatz abgenutzt ist, wird der

Hub kleiner und die Abtragleistung geringer. Wenn die Leistung geringer wird, wechseln Sie den Aufsatz aus.

• Bringen Sie den Aufsatz immer mit dem gelieferten Drehmomentschlüssel an, da der Aufsatz sonst nicht

ausreichend vibriert.

• Sehen Sie vor der Anwendung nach, ob Staub oder andere Verunreinigungen in der Aufsatzschraube sind. Wenn

die Aufsätze nicht sauber sind, kann die Schwingung nicht korrekt übertragen werden.

• Nehmen Sie den Aufsatz immer ab, bevor Sie das Handstück oder das Handstückkabel abnehmen.

Verletzungsgefahr!

• Wenn Sie spüren, dass der Aufsatz nicht vibriert, nehmen Sie ihn von der zu behandelnden Stelle und betätigen

Sie den Fußschalter erneut. Wenn das Problem dadurch nicht beseitigt wird, bringen Sie den Aufsatz erneut an

oder schalten Sie die Stromversorgung aus und wieder ein.

• Verwenden Sie zum Anbringen des Aufsatzes immer Handschuhe und den Drehmomentschlüssel.

• Stellen Sie sicher, dass die Wassermenge auf „0“ eingestellt ist, wenn ein Aufsatz zur Anwendung kommt, für den

kein Wasser benötigt wird.

• Der Drehmomentschlüssel ist ein Verbrauchsartikel. Er muss circa einmal pro Jahr ausgewechselt werden.

36

Page 38

7. Vorgehen beim Bedienen

(1) Einrichten der Kühlmittelversorgung

• VERWENDEN EINER FLASCHE

1) Stellen Sie sicher, dass die VA-Flasche bis zur entsprechenden Füllhöhe gefüllt ist.

2) Stellen Sie sicher, dass der Verschluss der Flasche dicht sitzt.

ACHTUNG

• Es darf keine Flüssigkeit verwendet werden, die wäremer als 35 °C ist.

• Es darf keine Flüssigkeit, wie zum Beispiel Wasser, mit einem hohen pH-Wert in die Flasche gefüllt werden.

• VERWENDEN VON LEITUNGSWASSER

1) Achten Sie darauf, dass der Schlauch fest angeschlossen ist.

2) Öffnen Sie das Wasserventil der Dentaleinheit (stellen Sie den Wasserdruck auf 0,1 bis 0,5 MPa (1–5 kgf/cm

(2) Strom an

Stecken Sie das Stromkabel in die Wandsteckdose. Betätigen

Sie den Hauptschalter an der Steuerungseinheit. Die Anzeige

an der Vorderseite leuchtet auf.

I AN AUS

HAUPTSCHALTER

2

) ein).

Deutsch

(3) Leistungsstufeneinstellung

Überschreiten Sie nicht die Leistungsstufe, die in der Aufsatz-Leistungsrichtlinie (im Paket enthalten) empfohlen wird.

1) Wählen Sie die Betriebsart mit den jeweiligen Tasten an der Vorderseite aus. Die Lampe über der ausgewählten

Betriebsart leuchtet auf (Abb. 16).

BETRIEBSARTAUSWAHLTASTEN

BETRIEBSART

Abb.16

Ausgabe für jede Betriebsart

37

Abb.15

Page 39

2) Stellen Sie die Leistungsstufe mit den jeweiligen

Tasten an der Vorderseite ein. Die grafische

und numerische Anzeige zeigen die gewählte

Leistungsstufe an (Abb. 17).