Page 1

Micromotor for Laboratory Work

OPERATION MANUAL

Please read this Operation Manual carefully

before use, and file for future reference.

OM-E0387E 002

Page 2

OPERATION MANUAL

English

Micromotor for Laboratory Work

Page 3

Thank you very much for purchasing ULTIMATE XL.

Please read this Operation Manual carefully regarding the instructions for use, handling method,

and maintenance and inspection prior to use and store it in a place where users can review it

anytime.

Contents

English

IMPORTANT INSTRUCTIONS AND WARNING

1. Component Names

2. Set up of Control Unit

3. Operation Procedure

4. Speed limit mechanism

5. Protective Circuit for Motor

6. Memory Function

7. Error Code

8. Replacement of Fuse

9. Maintenance Mode

10. Vacuum-coupled Mode

11. Handling of Motor and Handpiece

12. Handpiece Stand

13. Handpiece Holder

14. Specification

15. Troubleshooting

16. Disposing Product

······································································································

·························································································

·····················································································

······················································································

···················································································

·············································································

····························································································

······················································································

·························································································

··················································································

··································································

····························································································

···························································································

···································································································

······························································································

··························································································

·············································

1

5

6

7

8

8

8

9

10

10

11

12

14

14

14

15

17

IMPORTANT INSTRUCTIONS AND WARNING -Electric Devices

WARNING!

When using electric tools, basic safety precautions should always be followed to reduce

the risk of fire, electrical shock and personal injury, including the following. Read all these

instructions before operating this product and save these instructions.

1

Page 4

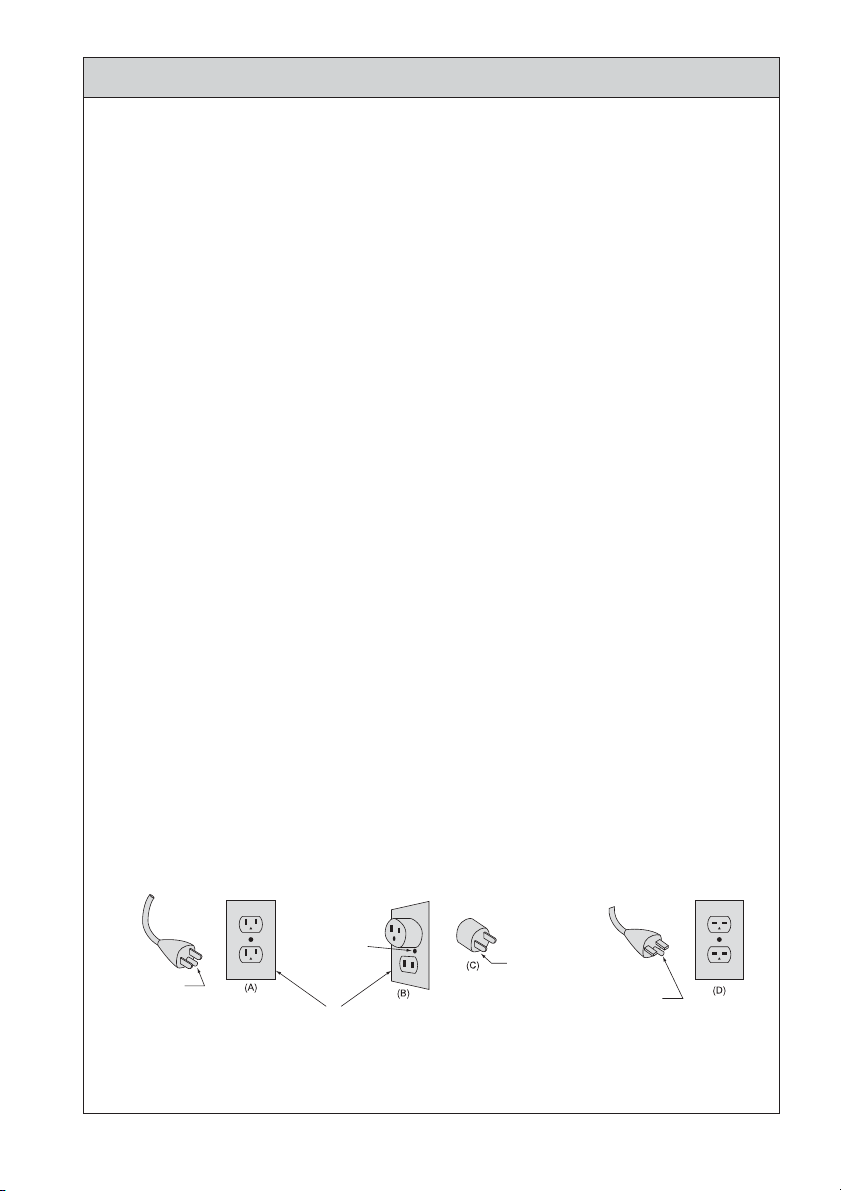

A. GROUNDING INSTRUCTIONS

1. In the event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and a grounding plug. The plug must be plugged

into a matching outlet that is properly installed and grounded in accordance with all local

codes and ordinances.

2. Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by

a qualified electrician.

3. Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment grounding conductor to a live

terminal.

4. Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

5. Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles

that accept the tool's plug.

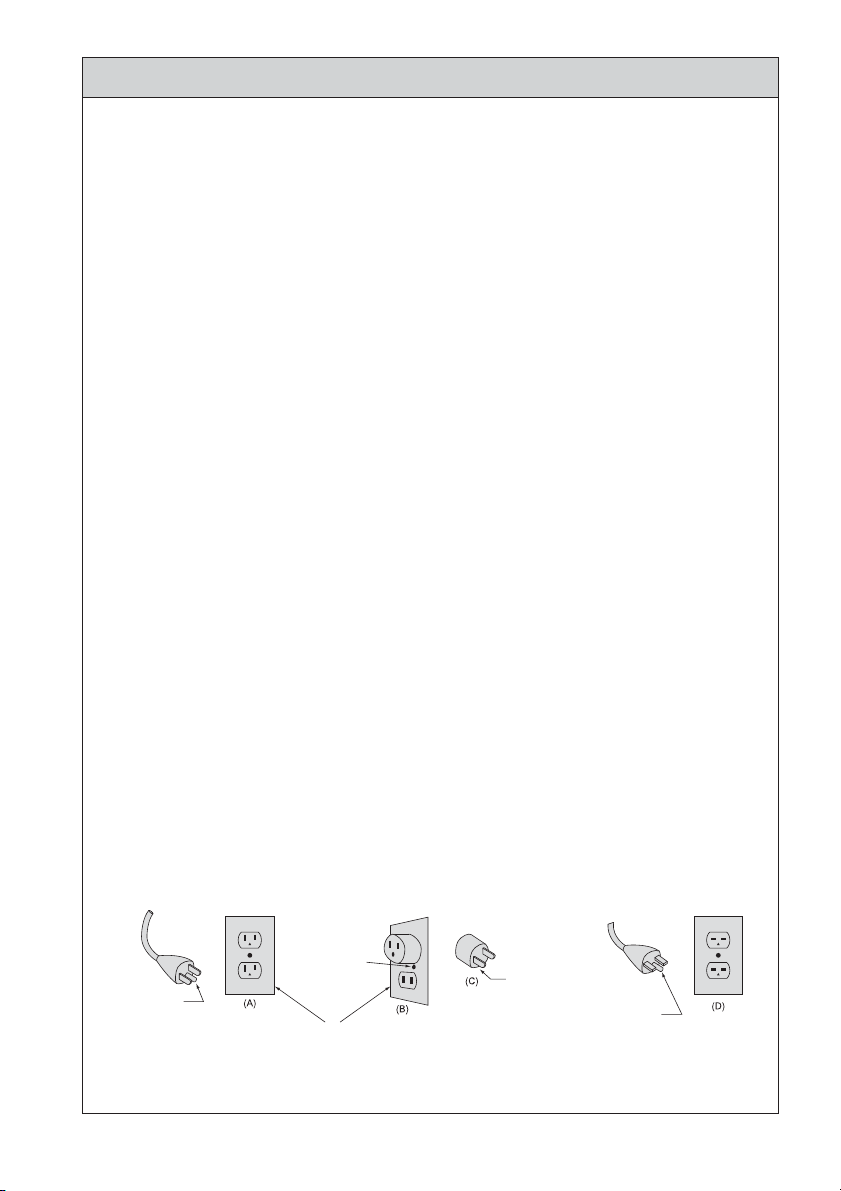

6. This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in

Sketch A in Figure (below) (120V). The tool has a grounding plug that looks like the plug

illustrated in Sketch A in Figure (below). A temporary adapter, which looks like the adapter

illustrated in Sketches B and C, may be used to connect this plug to a 2-pole receptacle as

shown in Sketch B if a properly grounded outlet is not available. The temporary adapter

should be used only until a properly grounded outlet can be installed by a qualified

electrician. The green-colored rigid ear, lug, and the like, extending from the adapter must be

connected to a permanent ground such as a properly grounded outlet box.

GROUNDING

PIN

Grounding Method

METAL SCREW

COVER OF GRIUNDING

OUTLET BOX

ADAPTER

GROUNDING MEANS

GROUNDING PIN

2

Page 5

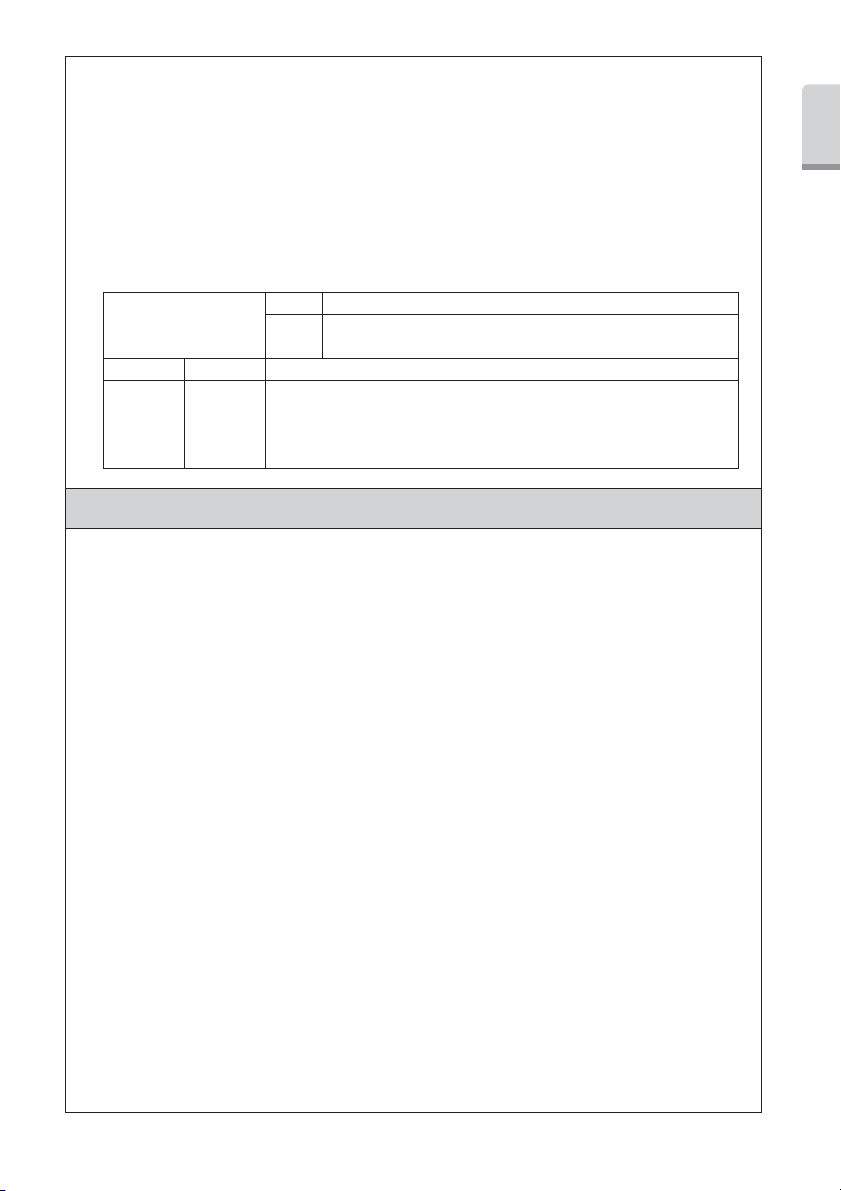

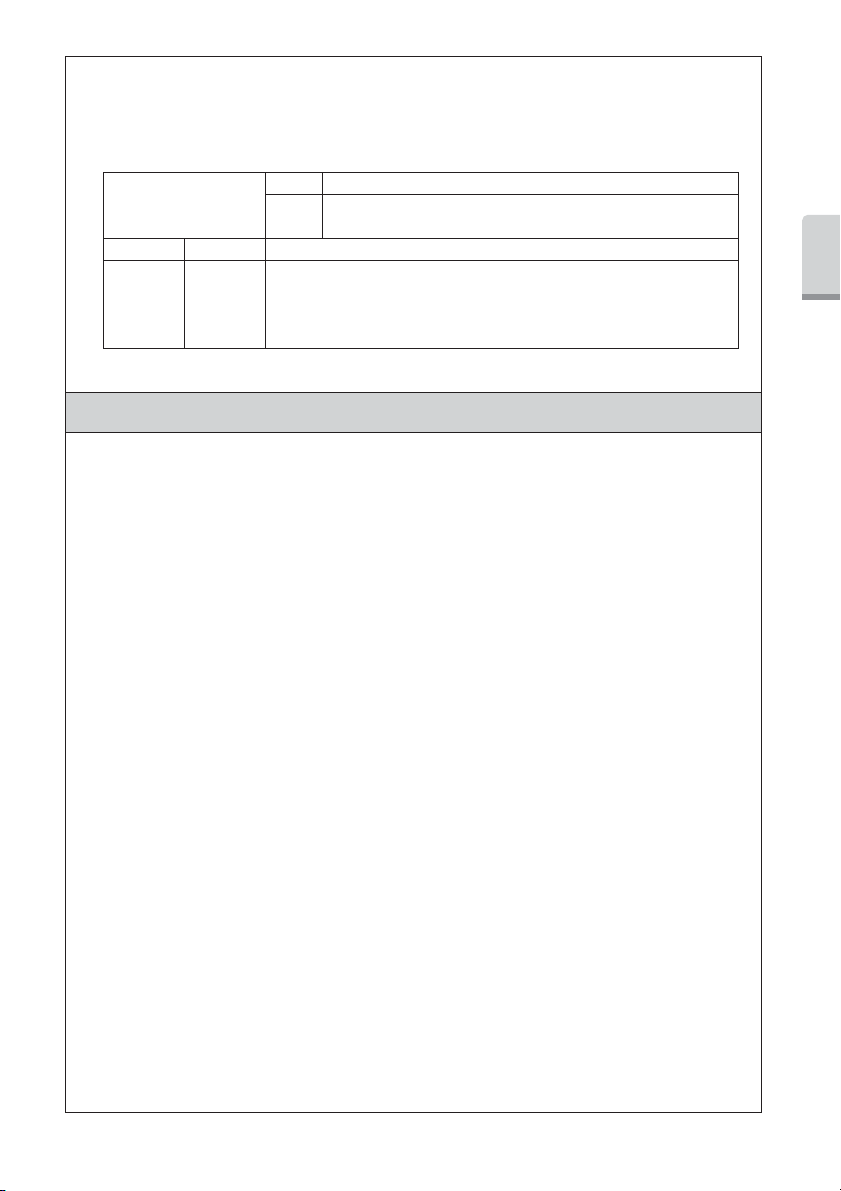

7. USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. Table (below) shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

8. Install equipment so that the power supply cord can be pulled out without hindrance in event

of emergency. Do not place anything within 10 centimeters around the unit.

Minimum gauge for cord

Total Length of cord

#16

#16

#16

#12

#16

#14

#14

Not Recommended

#14

#12

#12

More Than

0

6

10

12

Not More Than

6

10

12

16

Volts

7.5m (25ft.) 15m (50ft.) 30m (100ft.) 45m (150ft.)

120V

15m (50ft.) 30m (100ft.) 60m (200ft.) 90m (300ft.)Ampere Rating

240V

Code Number

#18

#18

#16

#14

B. OTHER WARNING INSTRUCTIONS

1. For your own safety read instruction manual before operating tool.

2. Wear eye protection.

3. Replace cracked wheel immediately.

4. Always use guards and eye shields.

5. Do not over tighten wheel nut.

6. Use only flanges furnished with the grinder.

7. REMOVE ADJUSTING KEYS AND WRENCHES. From habit of checking to see that keys and

adjusting wrenches are removed from tool before turning it on.

8. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

9. DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools in damp or wet

locations, or expose them to rain. Keep work area well lighted.

10. Risk of injury due accidental starting. Do not use in an area where children may be present.

11. DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

12. USE RIGHT TOOL. Don't force tool or attachment to do a job for which it was not designed.

13. WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or

other jewelry that might get caught in moving parts. Nonslip footwear is recommended. Wear

protective hair covering to contain long hair.

14. ALWAYS USE SAFETY GLASSES. Everyday eyeglasses only have impact resistant lenses,

they are NOT safety glasses. Also use face or dust mask if cutting operation is dusty.

15. SECURE WORK. Use clamps or a vise to hold work when practical. It's safer than using your

hand and it frees both hands to operate tool.

16. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best performance and to

reduce the risk of injury to persons. Follow instructions for lubricating and changing

accessories.

English

3

Page 6

17. DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits,

cutters, and like.

18. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position

before plugging in.

19. USE RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended

accessories. The use of improper accessories may cause risk of injury to persons.

20. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave tool until it

comes to a complete stop.

21. For recommended operating speed for various applications, please follow the instructions of

bur manufacturers.

22. The system functions normally in the environment where the temperature is at 0-40°C,

humidity at 10-85% RH and no moisture condensation in the Unit. Use at outside of these

limits may cause malfunction.

23. Store the system in the place where the temperature is at -10-60°C, humidity at 10-85% RH,

atmospheric pressure at 500-1060hPa, and the system is not subject to air with dust, sulfur,

or salinity.

24. Severe shock – Eg. Dropping Control Unit, or the Micromoto – may cause damage.

25. Do not turn the bur lock ring while the handpiece is rotating.

26. Do not rotate the motor when the bur lock ring is at OPEN position, or a bur is not mounted

in the chuck. It may cause the motor/handpiece disconnection or sudden heat generation.

27. Activation of Circuit Breaker means too much load is applied to the motor beyond the

capacity the motor takes. This circuit breaker is designed to protect the motor, but it is

desired to perform the grinding work without activating the circuit breaker.

28. Care should be taken not to drop micromotor handpiece on floor or hard work surface in

order to avoid damage caused by impact shock.

29. Do not disassemble or alter the product by yourself.

30. Be careful not to be injured by the grinder or bur.

31. Be sure to replace fuse with the correct type and rating.

C. Important Instructions and Warning on ULTIMATE XL.

1. No lubrication is required to either motor or handpiece because ball bearings impregnated

with grease in both motor and handpiece.

2. Only use with original power supply cord. In case of damage, contact NSK / Nakanishi

servicing center.

3. Equipment to be sent back to manufacturer for servicing / repair.

4

Page 7

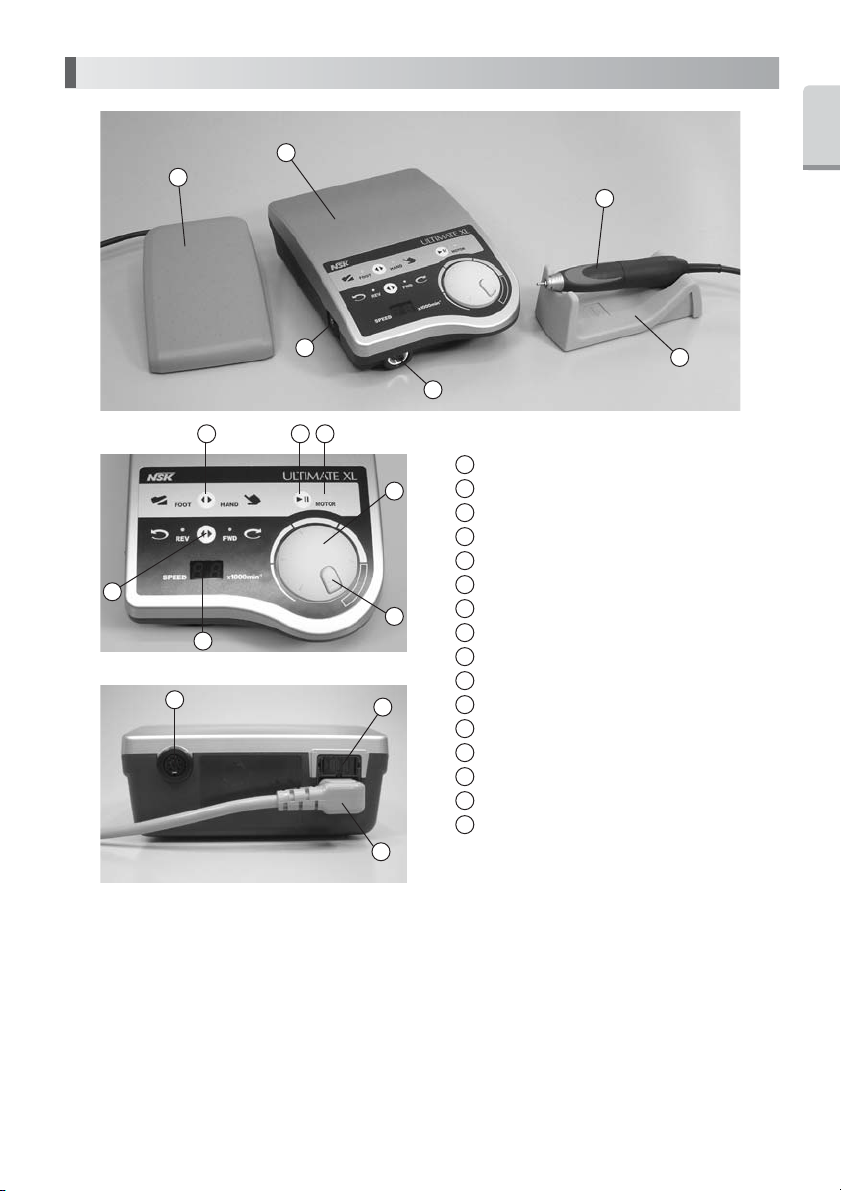

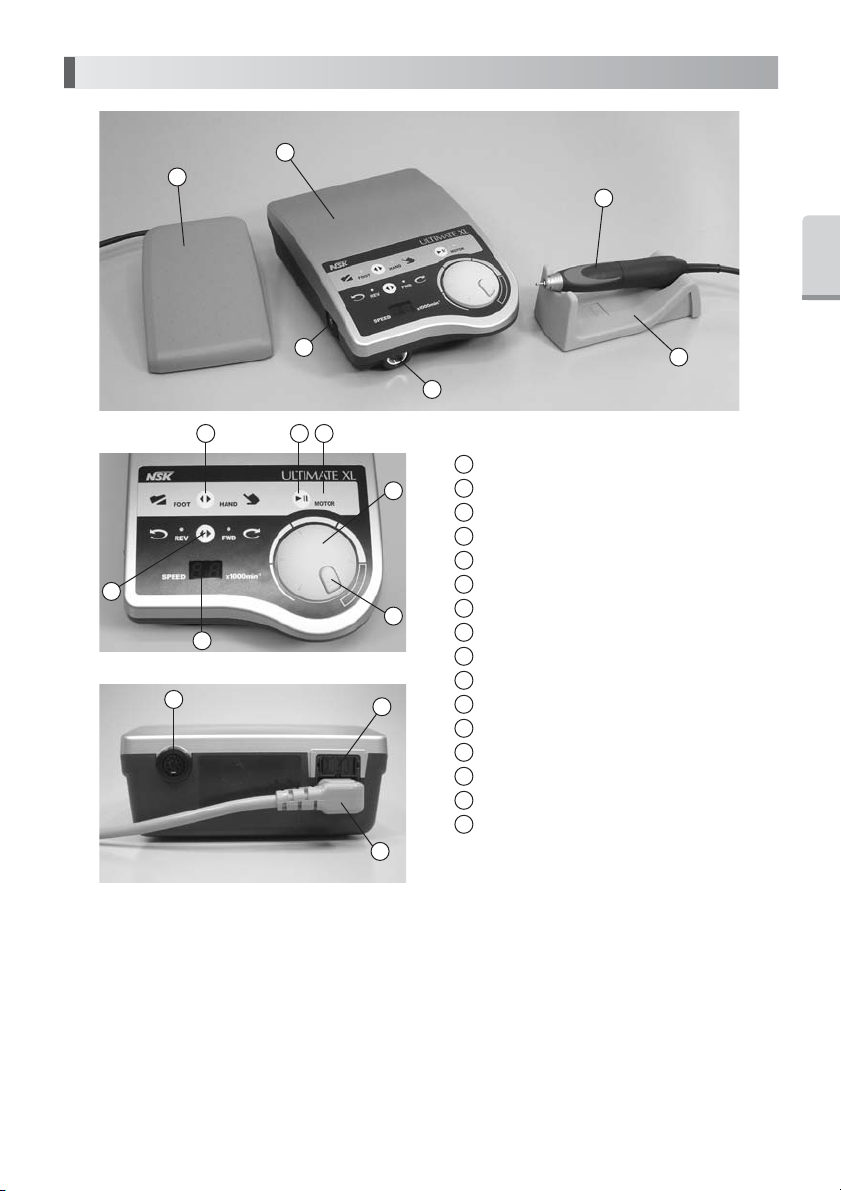

1. Component Names

1

3

2

4

5

8 9

7

11

14

10

15

16

12

13

1

Control Unit

2

Motor Handpiece

3

Foot Pedal (FC-64)

4

Power Switch

5

Motor Connector

6

Handpiece Stand

7

Forward/Reverse Selector Switch

8

Hand/Foot Selector Switch

9

Motor Switch

10

Motor LED

11

Indicator

12

Speed Control Knob

13

Speed Limit Release Button

14

Foot Pedal Connector

15

Fuse Box

16

Power supply cord

6

English

5

Page 8

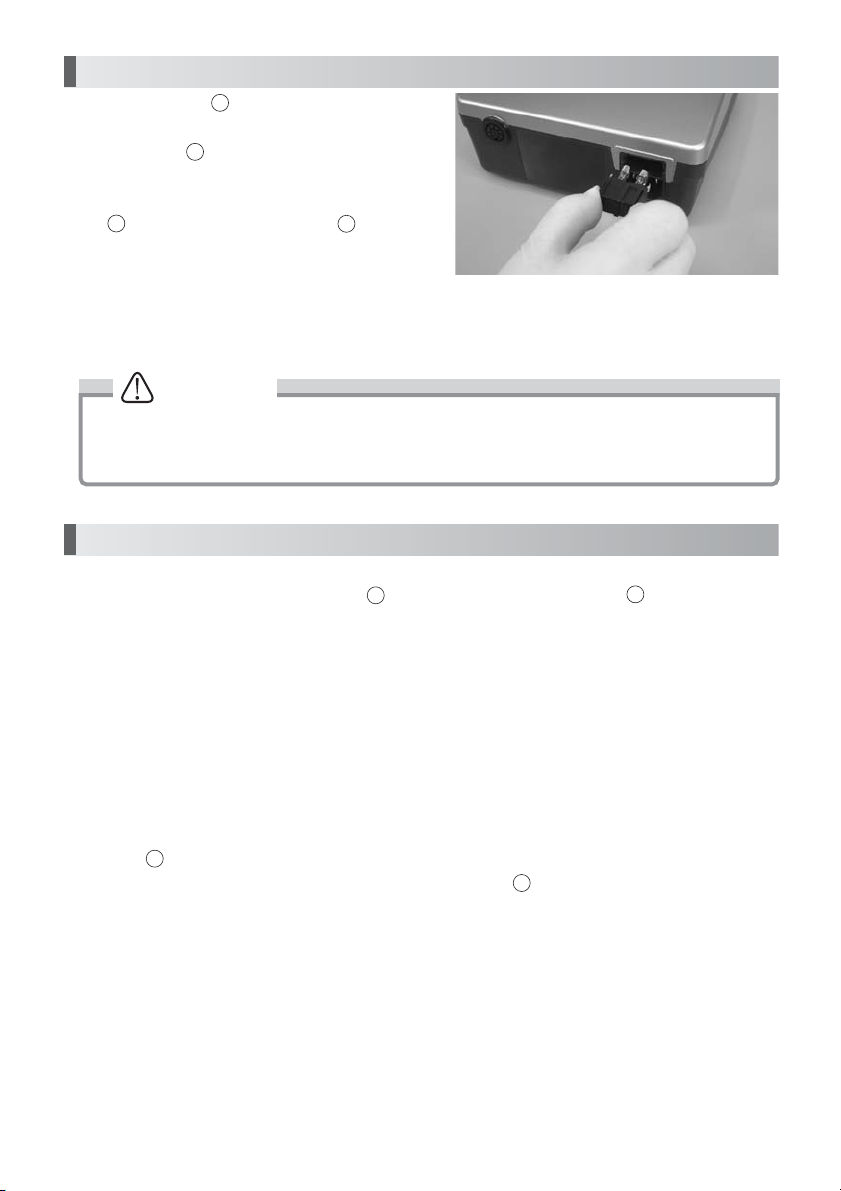

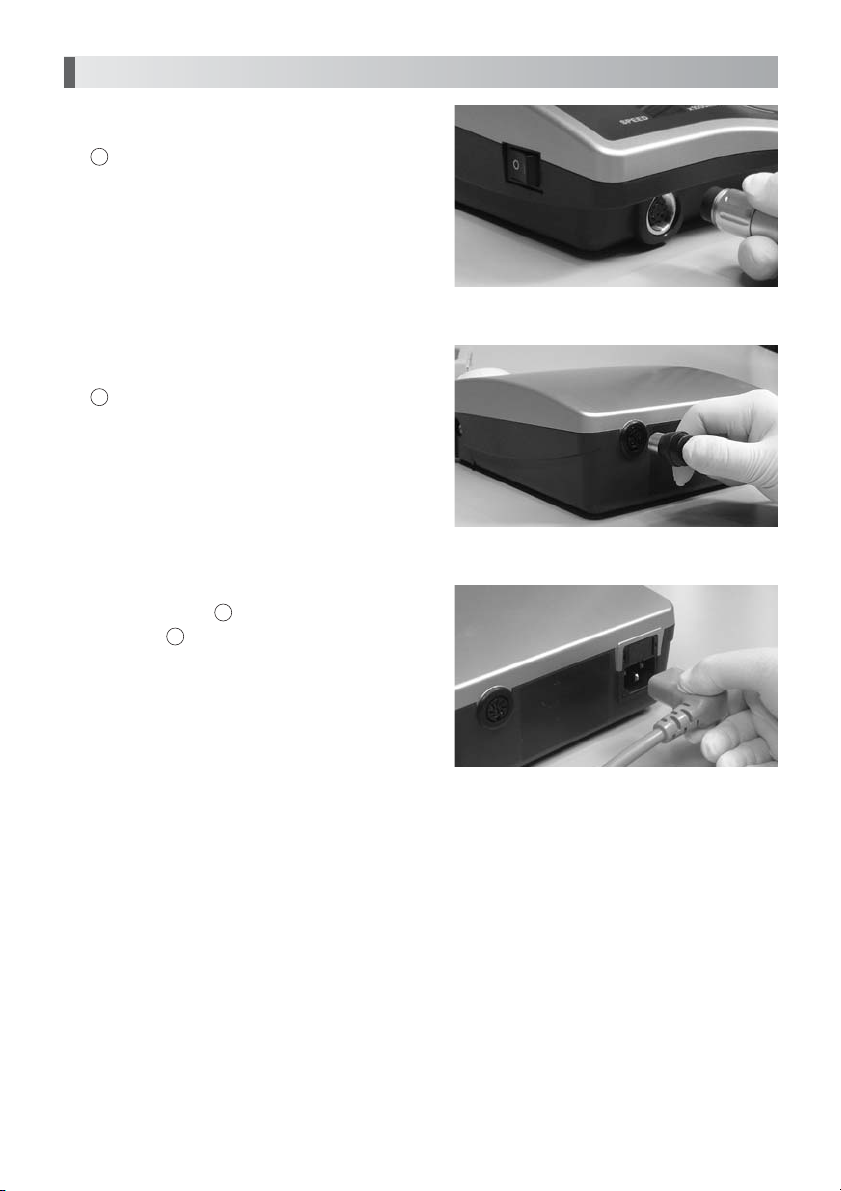

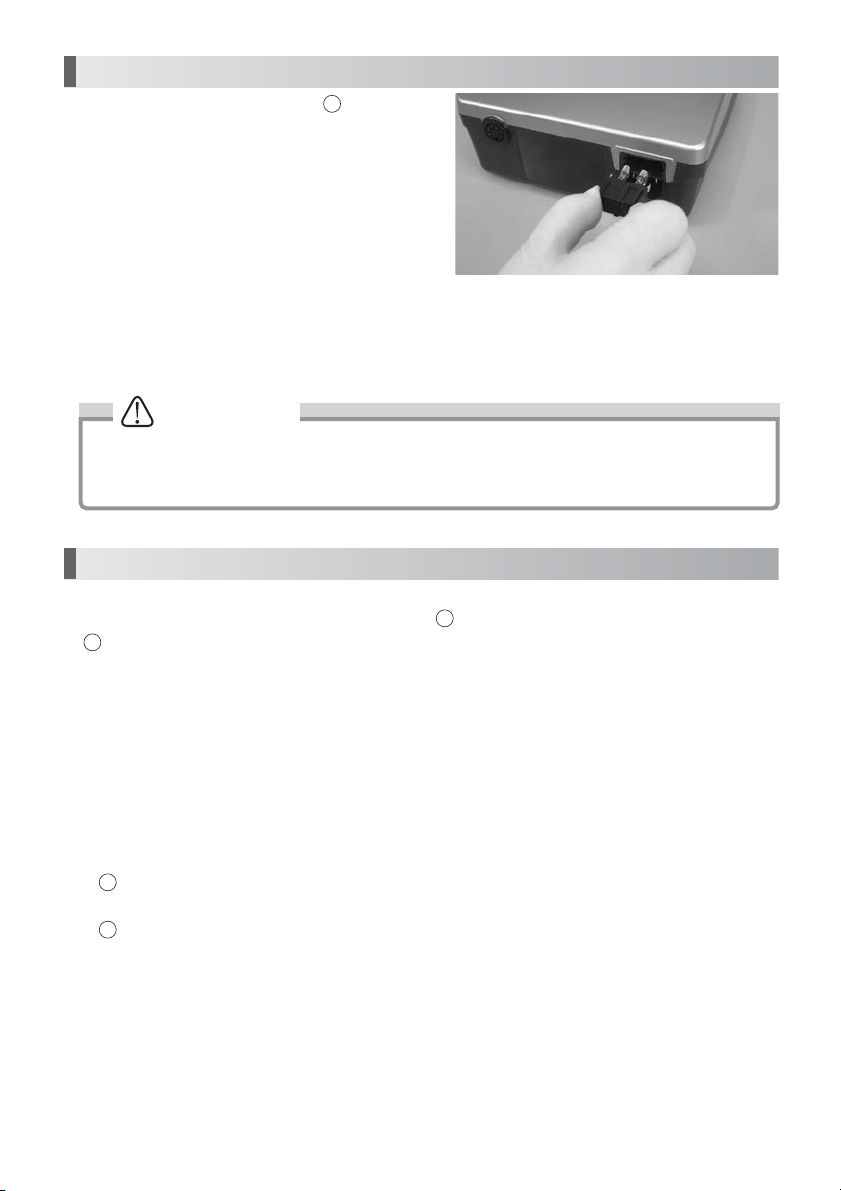

2. Set up of Control Unit

1. Mounting of Motor

Insert the motor cord plug locator into Motor

Connector aligning it with the groove of the

connector, and tighten the motor cord plug nut

to fix. (Fig. 1)

2. Mounting of Foot Pedal

Insert the Foot Pedal cord plug locator into

14

Foot Pedal Connector aligning it with the

groove of the connector. (Fig. 2)

3. Connecting of Power Cord

Securely insert the plug of Power Cord into

connector at the back of the unit aligning it with

the configuration. (Fig. 3)

16

5

Fig.1

Fig.2

Fig.3

6

Page 9

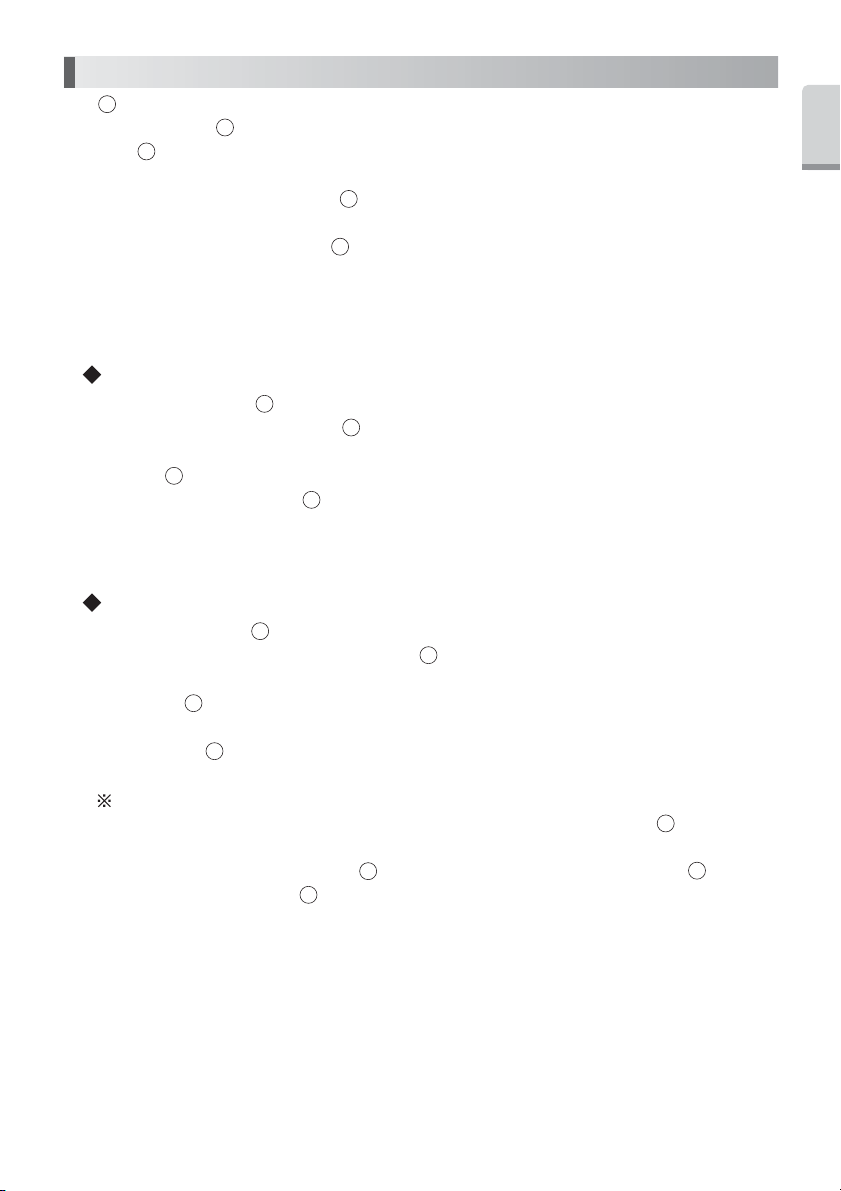

3. Operation Procedure

16

1. Connect Power Cord to a wall outlet.

2. Make sure that Speed Control Knob is at the lowest speed position.

3. Turn Power Switch ON (Green Power Lamp will light). The preset rotation speed will

4. Select the rotation direction with Forward/Reverse Selector Switch. Each time this switch

5. Select the control method with Hand/Foot Selector Switch. Each time this switch is

Operation - 1

4

appear on the Indicator.

is pressed, the direction changes between FORWARD and REVERSE.

pressed, the method changes between the HAND and FOOT.

HAND Operation

6. Select HAND with Hand/Foot Selector Switch.

7. Preset the rotation speed with Speed Control Knob with checking the speed on the

Speed Display.

8. Press Motor Switch, and the motor will run.

9. To stop the motor, press Motor Switch again.

Operation - 2

Operation by Foot Pedal

6. Select FOOT with Hand/Foot Selector Switch.

7. Preset the maximum rotation speed with Speed Control Knob with checking the speed

on the Speed Display.

8. Depress Foot Pedal, and the motor will run. The rotation speed can be variably

controlled within the preset maximum rotation speed range according to the amount of

depressing Foot Pedal.

Auto speed mechanism

To Fix the speed within the rotation speed range set by the volume, press Motor Switch

while the motor is running at the desired speed. The display lamp will flash and the rotation

speed can be maintained even if Foot Pedal is released. To cancel it, press Motor

Switch again or depress Foot Pedal again.

12

7

8

8

12

9

9

8

12

3

3

9

3

3

9

English

7

Page 10

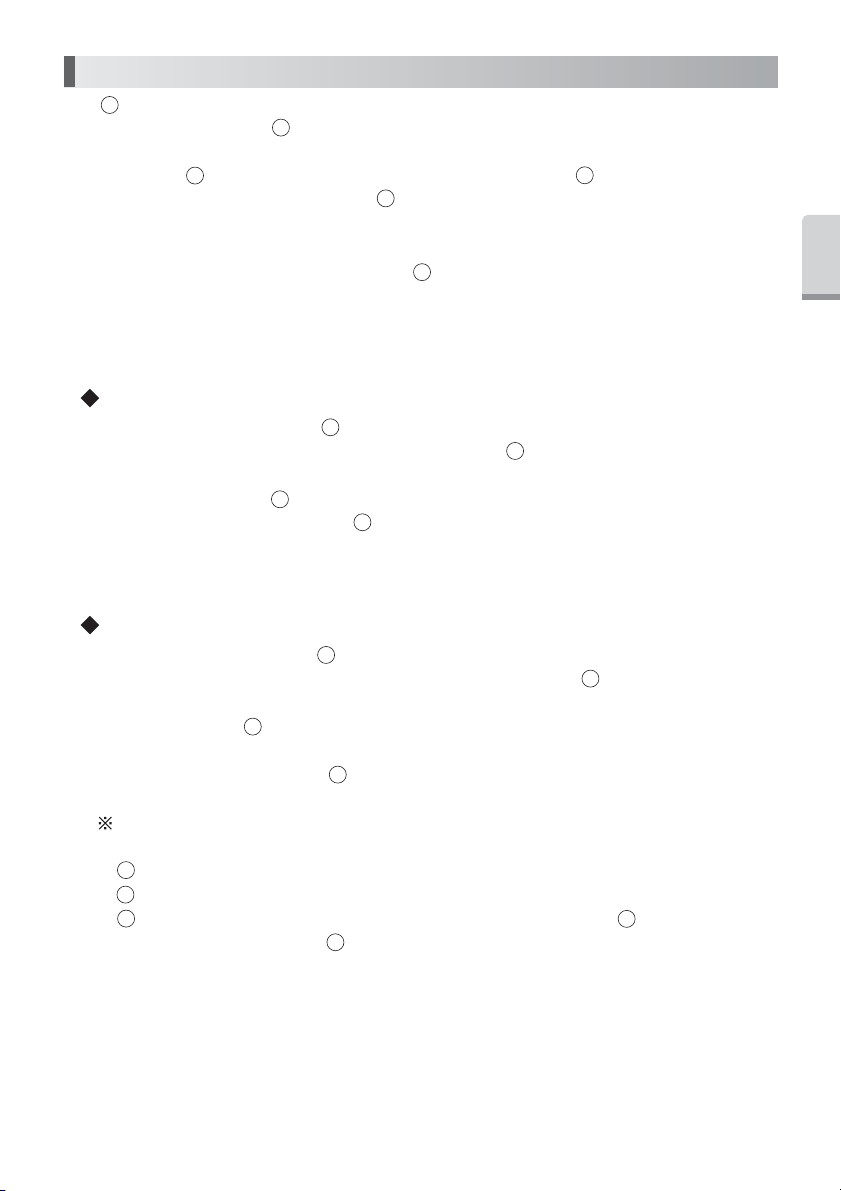

Speed Limit Release Button

Indicator

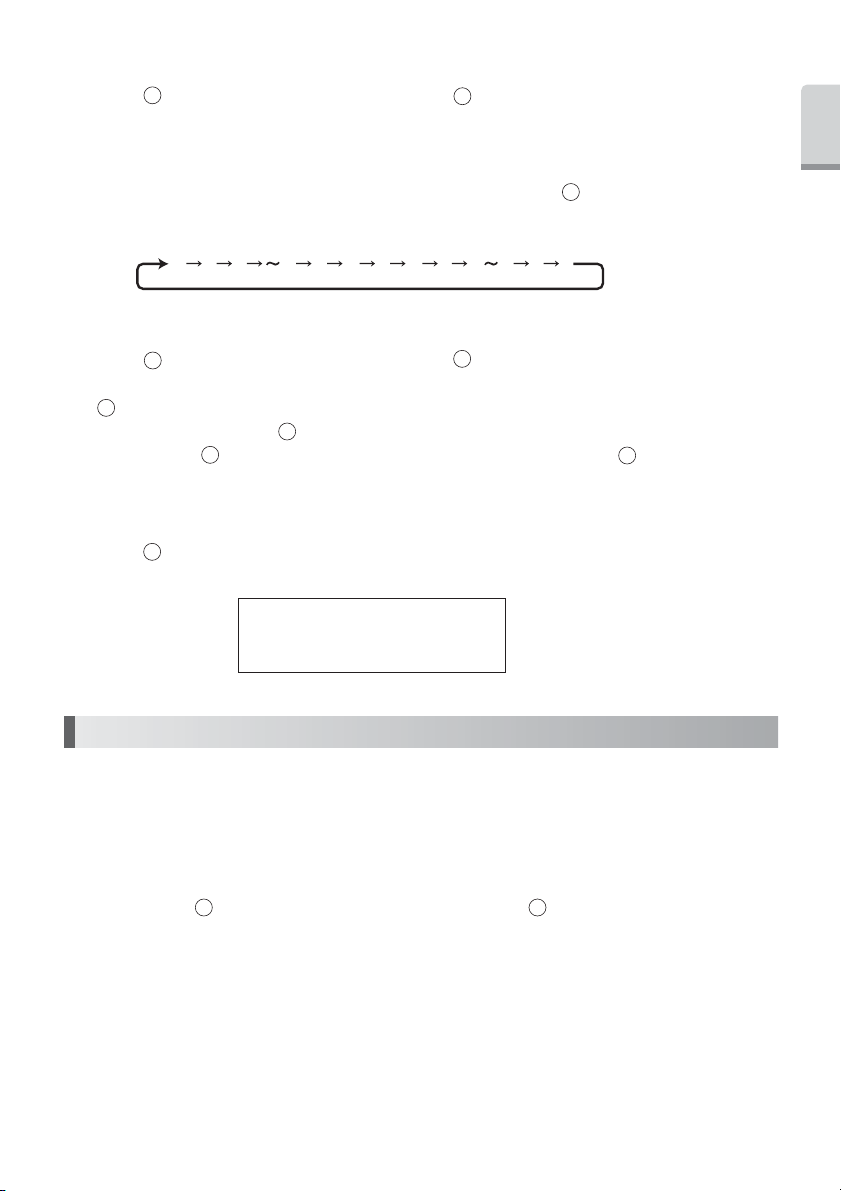

4. Speed limit mechanism

For the use of a small-diameter round bur or

fisher bur at 40,000min

13

the Speed Limit Release Button, which is

equipped with the Speed Control Knob, and

turning the Speed Control Knob allows a

12

setting of up to 50,000min

-1

(rpm) or more, pressing

12

-1

(rpm). (Fig.4)

Speed Limit Release Button

Speed Limit Release Button

CAUTION

Use of 40,000min-1(rpm) or more is allowable only when the bur manufacturer or dealer

specifies that the bur's acceptable rotation speed is 40,000 min

use of more than the acceptable rotation speed is made, the bur may be broken.

-1

(rpm) or more. If the

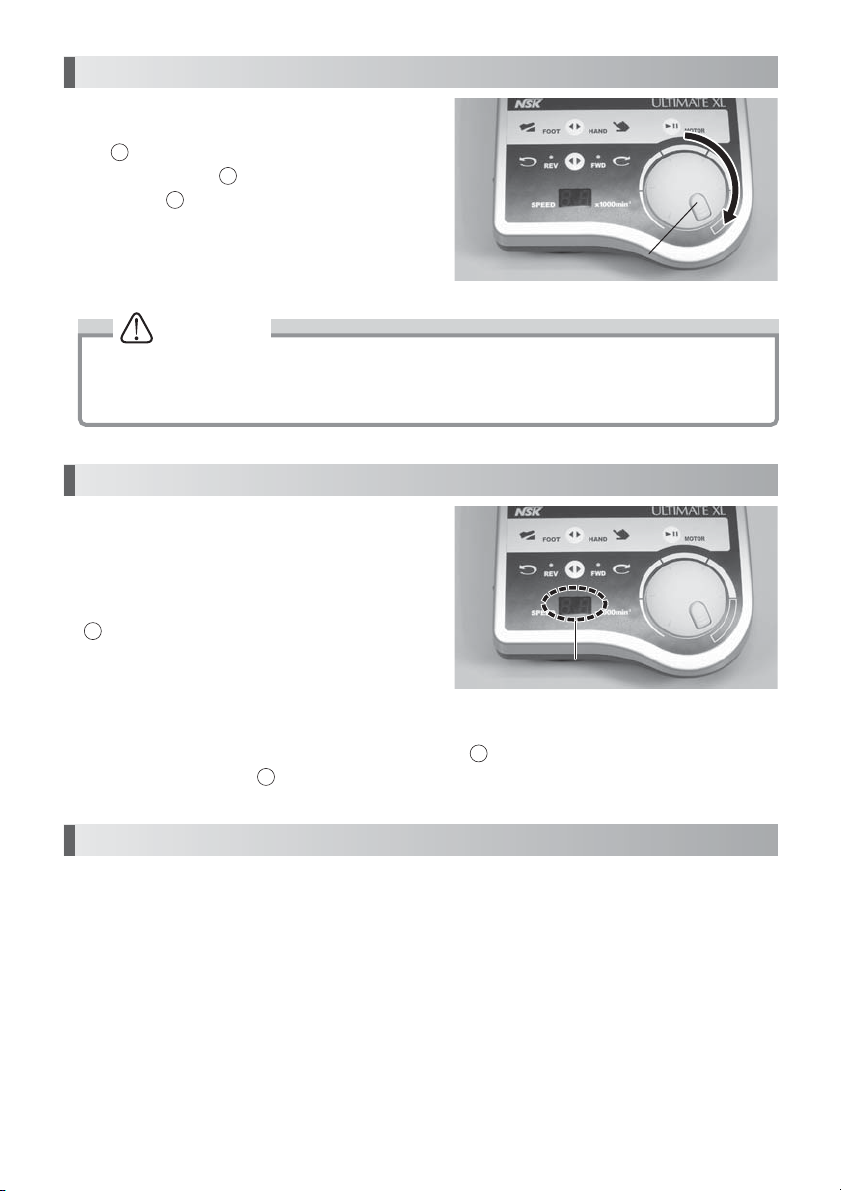

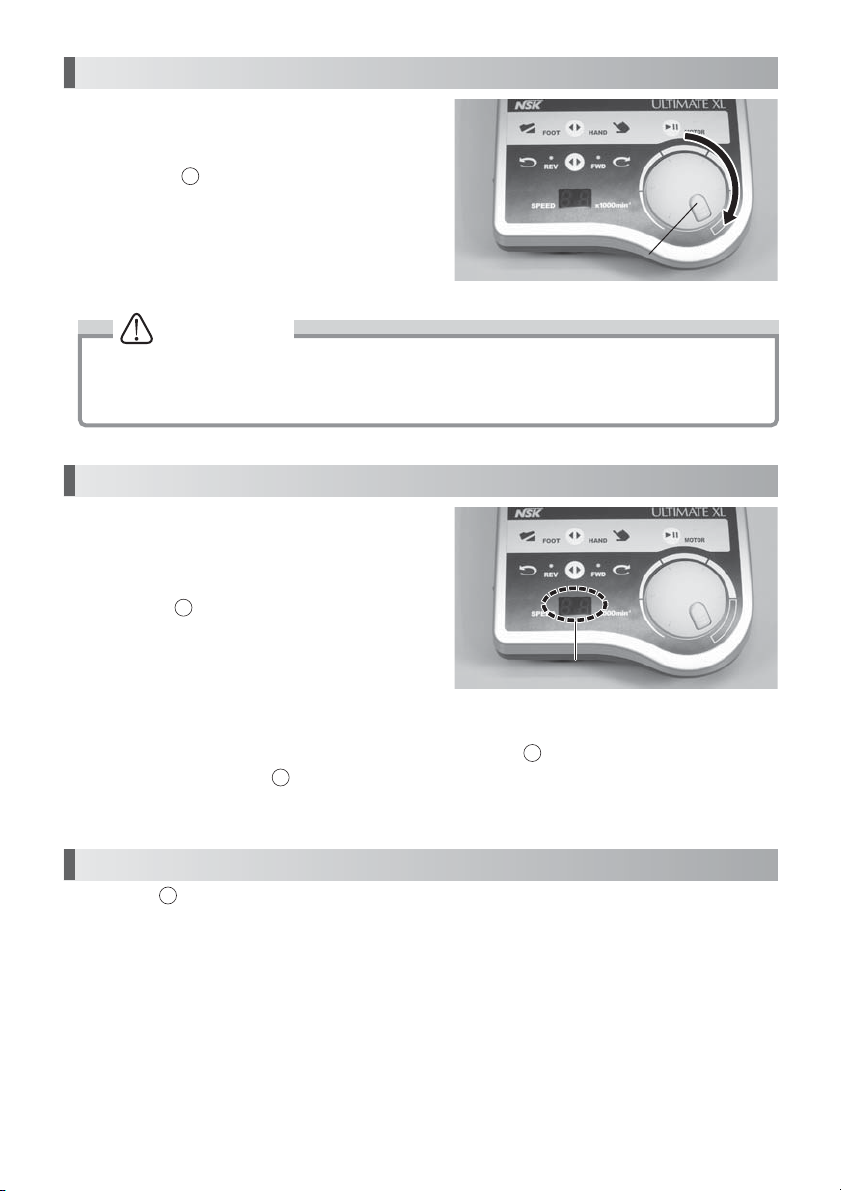

5. Protective Circuit for Motor

When the motor is operated with a load

exceeding the limit or the handpiece is in an

unrotational condition, the circuit to protect the

motor and unit works to stop the power supply

to the motor, an error code appears on

11

Indicator. (Fig.5)

Fig.4

Indicator

Indicator

Fig.5

How to reset the protective circuit

During manual operation, it can be reset by pressing Motor Switch again. During operation

by Foot Pedal, depress Foot Pedal back to stop, and the protective circuit will be reset.

3

9

6. Memory Function

When the Power Switch is turned on, the rotation direction and HAND/FOOT selections made

when the main switch was last turned off are restored. Special attention should be given to the

rotation direction.

8

Page 11

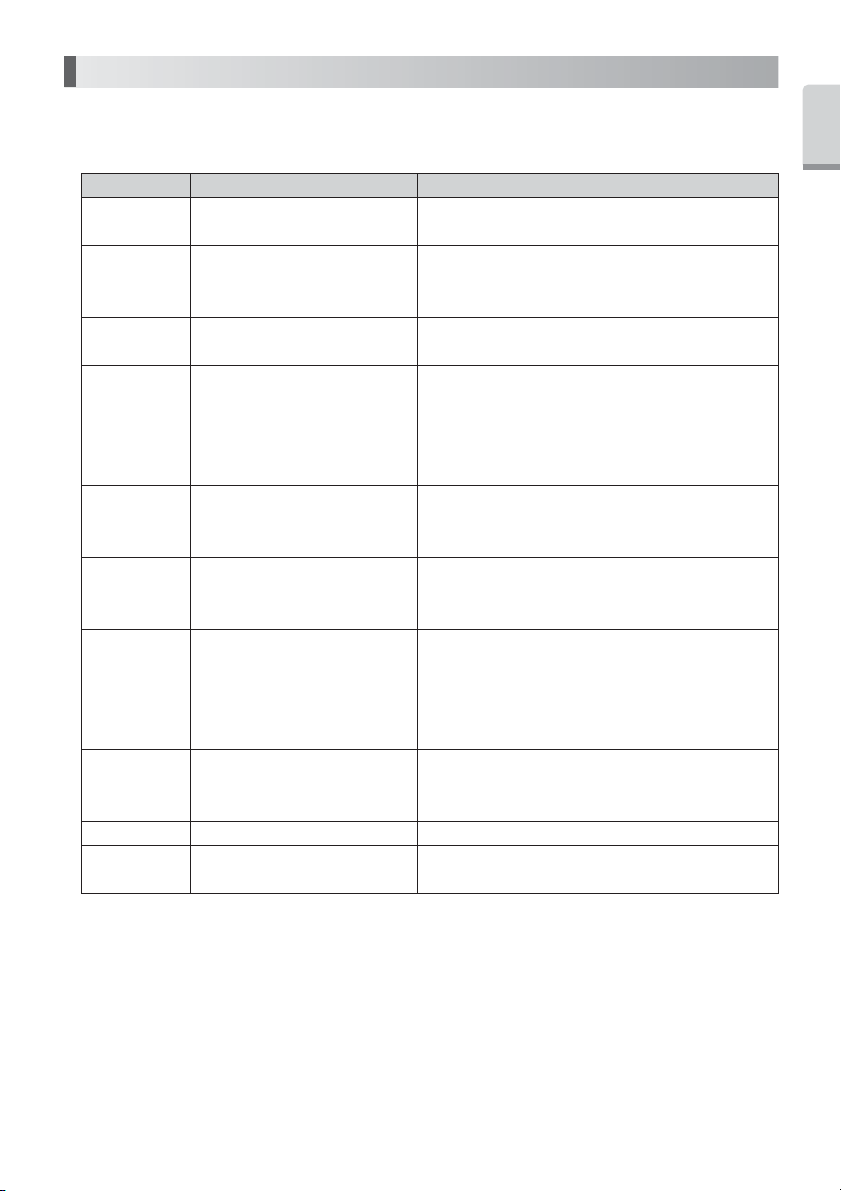

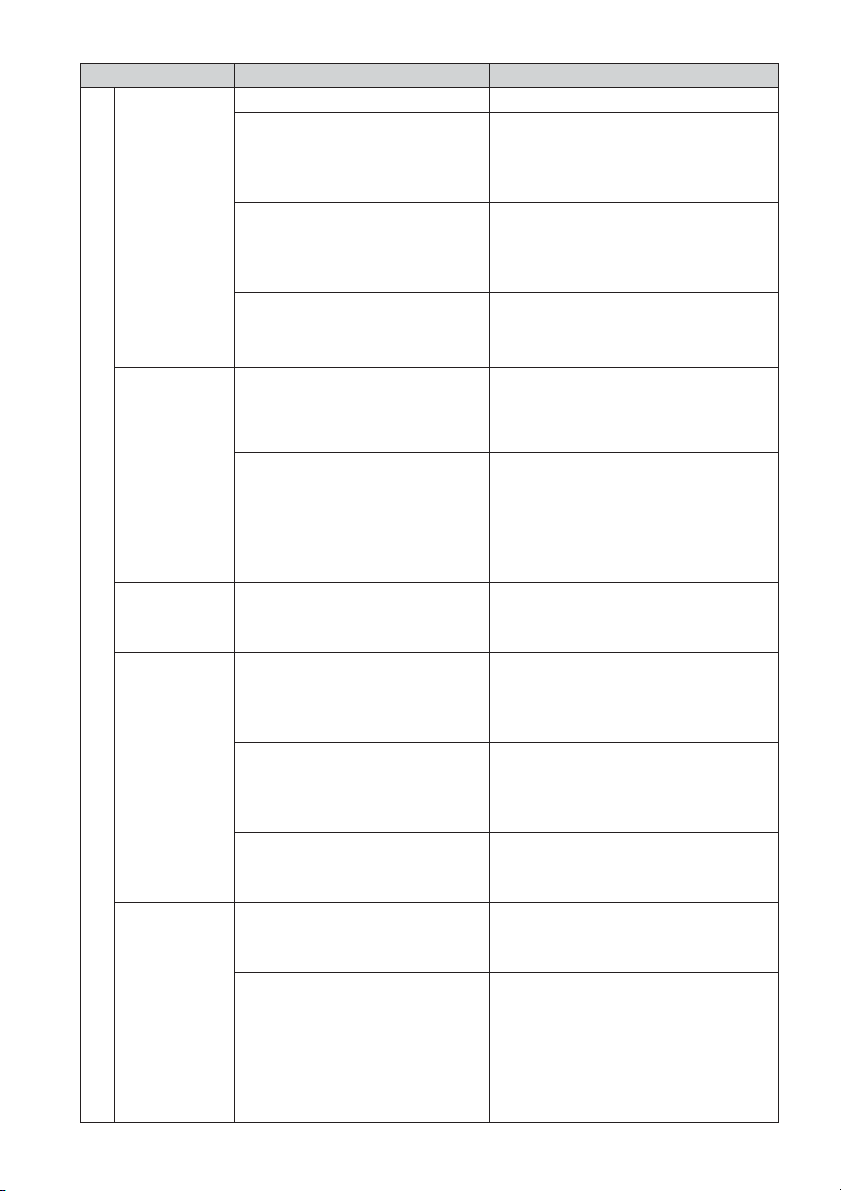

7. Error Code

When the motor is stopped due to some trouble such as a failure, overload, wire breakage or

misuse, Speed Display displays the error code for checking the status of the unit and

understanding the cause of the trouble easily.

Error code

E0

E1

E2

E3

E4

E5

E6

E8

E9

EF

For countermeasures against error displays, see the section on 15.Troubleshooting.

Self-check error

Overcurrent detection error

(Hard)

Overvoltage detection error

Motor sensor error

Unit overheat error

PAM circuit error

Rotor lock error

Overvoltage detection error

(Soft)

ITRIP error

Foot pedal error

Description

• Abnormal internal memory

• Broken internal memory

• Long-time use at a high load (overcorrect)

• Shorted cord (power line)

• Shorted motor winding

• Shorted cord (power line),damaged circuit

• Broken internal circuit

• Faulty sensor (Hall IC) in the motor

• Disconnected motor cord

• Severed cord (signal line)

• Open chuck

• Faulty handpiece

• Temperature rise in the unit due to longtime

use at a high load

• Unit placed under high temperature

• Abnormal voltage generated in start / stop

circuit

• Faulty start / stop circuit from PAM (L Slide)

• Open chuck

• Faulty handpiece

• Motor Faulty

• Faulty sensor (Hall IC) in the motor

• Severed cord (signal, power line)

• Long-time use at a high load (overcorrect)

• Shorted cord (power line)

• Shortstop of the motor winding

Faulty motor and circuit

• Faulty Foot Pedal or Shorted Foot Pedal cord

• Broken internal circuit

Cause

English

9

Page 12

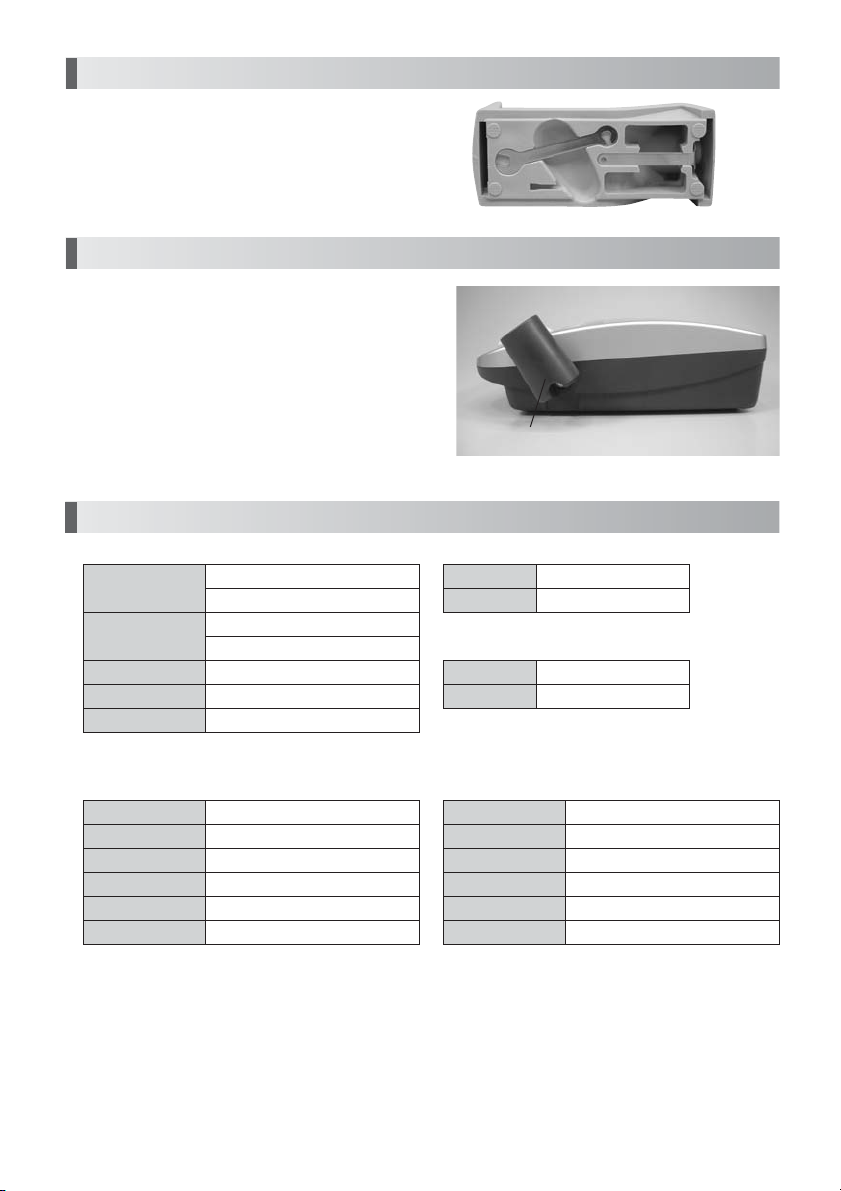

8. Replacement of Fuse

Fuse is located in Fuse Box. Release ratchet

clamp located on the right-and-left top and

bottom of the Fuse Box and pull it out to

change the fuse. (Fig. 6)

When the fuse come down, Insert new fuses into

15

the Fuse Box and then push the Fuse Box

into the original position until hearing a sound

click.(Fig.6)

- Fuse: Order Code (120V) : 1202225010 (T2.5AH 250V)

- Fuse: Order Code (230V) : 1202216010 (T1.6AH 250V)

15

15

15

CAUTION

Fuse is burned out when a short circuit occurs or when over-voltage is flowed into the

primary current source. If the cause is uncertain, return the product to an authorized

NSK's service shop for inspection.

9. Maintenance Mode

The unit is provided with a maintenance mode to check the function of the switches, display,

Foot Pedal, motor, etc. While pressing Hand/Foot Selector Switch and Motor Switch at

the same time, turn on the Power Switch and keep pressing the button until beeps are made

(for about 2 seconds). At this time, turning the volume from the minimum position in order

displays "oP", "dP", "HL", "Pd" and "in", allowing the following checks. To release Maintenance

Mode, turn Power Switch off and switch on again.

8

(1) "oP": Switch check (operation check)

Press the switches on the panel, and the right and/or left lamps will light to check to see if

the switches operate normally.

(2) "dP": Display check

7

Press Forward/Reverse Selector Switch, and the lamps will light one by one to check to

see if they operate normally. To cancel this check, press Forward/Reverse Selector Switch

again.

7

9

Fig.6

10

Page 13

(3)

"HL": Motor signal check (Hall IC check)

7

Press Forward/Reverse Selector Switch, and Indicator will indicate one or two

horizontal lines. Turn the motor slowly by hand, and this display will change to one line, two

lines, one line, two lines, smoothly from the top to bottom or from the bottom to top. If any

one of the three lines does not light, the sensor (Hall IC) in the motor is faulty or the cord is

severed, therefore repair is needed. To cancel this check, press Forward/Reverse Selector

Switch again.

Eg.

2 3 4 A b C d C b A 4 3 2

11

7

(4) "Pd": Foot Pedal check

Press Forward/Reverse Selector Switch, and Indicator will change. During normal time,

7

Indicator changes in hexadecimals ( 0~9, A~F ) according to the amount of depressing

Foot Pedal . Also, depressing the pedal slightly lights Reset Lamp, and depressing it fully

3

extinguishes the lamp. If Indicator does not change smoothly or Reset Lamp does not

light properly, Foot Pedal may be faulty. To cancel this check, press Forward/Reverse

Selector Switch again.

3

11

11

7

(5) "in": Initializing function

Press Forward/Reverse Selector Switch, and beeps will be made and rotation direction,

7

HAND/FOOT and other settings will return to the factory set condition.

Rotation direction: FWD (forward)

HAND/FOOT: HAND

Vacuum-coupled mode: OFF

English

10. Vacuum-coupled Mode

On some dental tables with vacuum dust collector, the motor may be used while being coupled

with a dust collector. When such a dust collector * is used, power consumption of ULTIMATE

XL can be regulated so that the vacuum-coupled function can work. If you need coupling with

a vacuum dust collector, select the mode as follows:

How to select the mode

While pressing Forward/Reverse Selector Switch, turn on Power Switch, and the mode

can be selected. A long beep indicates vacuum-coupled mode and 2 short beeps indicate

non-coupled (energy-saving) mode.

* Each time the switch selection is made, the mode changes between vacuum-coupled mode

and non-coupled mode.

* A currently known dust collector is KAVO EWL-560.

7

11

4

Page 14

11. Handling of Motor and Handpiece

Loosen

Loosen

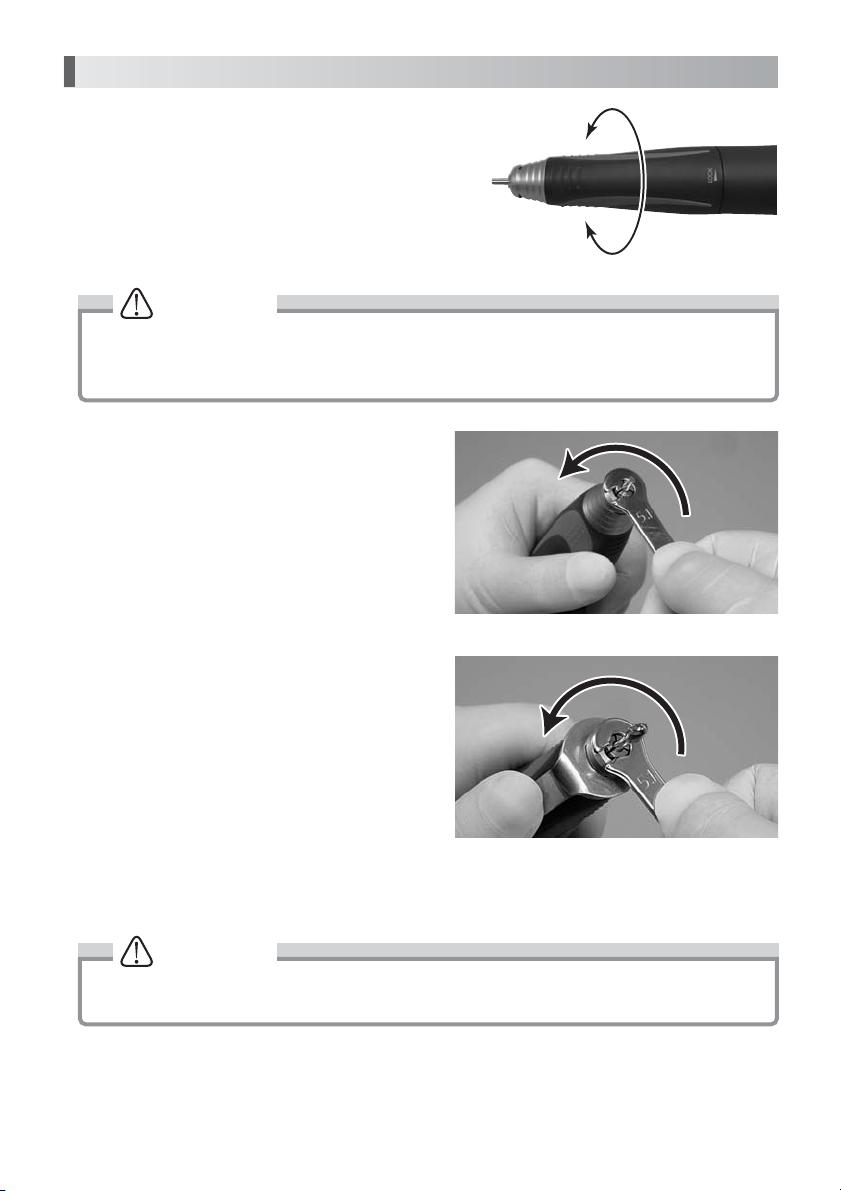

(1) Insertion or Removal of Bur

The chuck is opened by turning the Bur Lock Ring

to an open position. The chuck is loosened and the

bur can be removed. By turning the ring in the

LOCK direction, the chuck is closed and the bur

can be mounted. At this time, turn the ring until it

clicks. (Fig.7)

LOCK

OPEN

CAUTION

• Do not turn the Ring during rotation.

• Do not turn a motor, when it has not attached bur or the Ring Open position. It may be

reasons for the failure or overheating of the handpiece.

(2)

Cleaning and Replacement of Chuck

(1) Removal of Chuck

To remove the chuck, open the ring and turn

the chuck counterclockwise with the provided

spanner wrench. (Fig.8)

* If a bur having a large diameter of a cutting

part is used under a high torque, the chuck

may rotate in the close direction and the bur

may be stuck and cannot be removed. In

this case, align the nose's slit and spindle's

spanner position (flat part), and apply an L

spanner to fix the spindle. Open the ring and

turn the chuck counterclockwise with the

provided spanner wrench to remove it.

(Fig. 9)

(2) Cleaning of Chuck

Remove and clean the chuck as frequently as possible in the ultrasonic cleaner. Clean at

least once a week.

Loosen

Loosen

Loosen

Loosen

Fig.7

Fig.8

Fig.9

CAUTION

Neglecting to clean the chuck for a long time is very dangerous because wax, gypsum,

etc., accumulate in the chuck and the bur is caught insecurely, causing runout.

12

Page 15

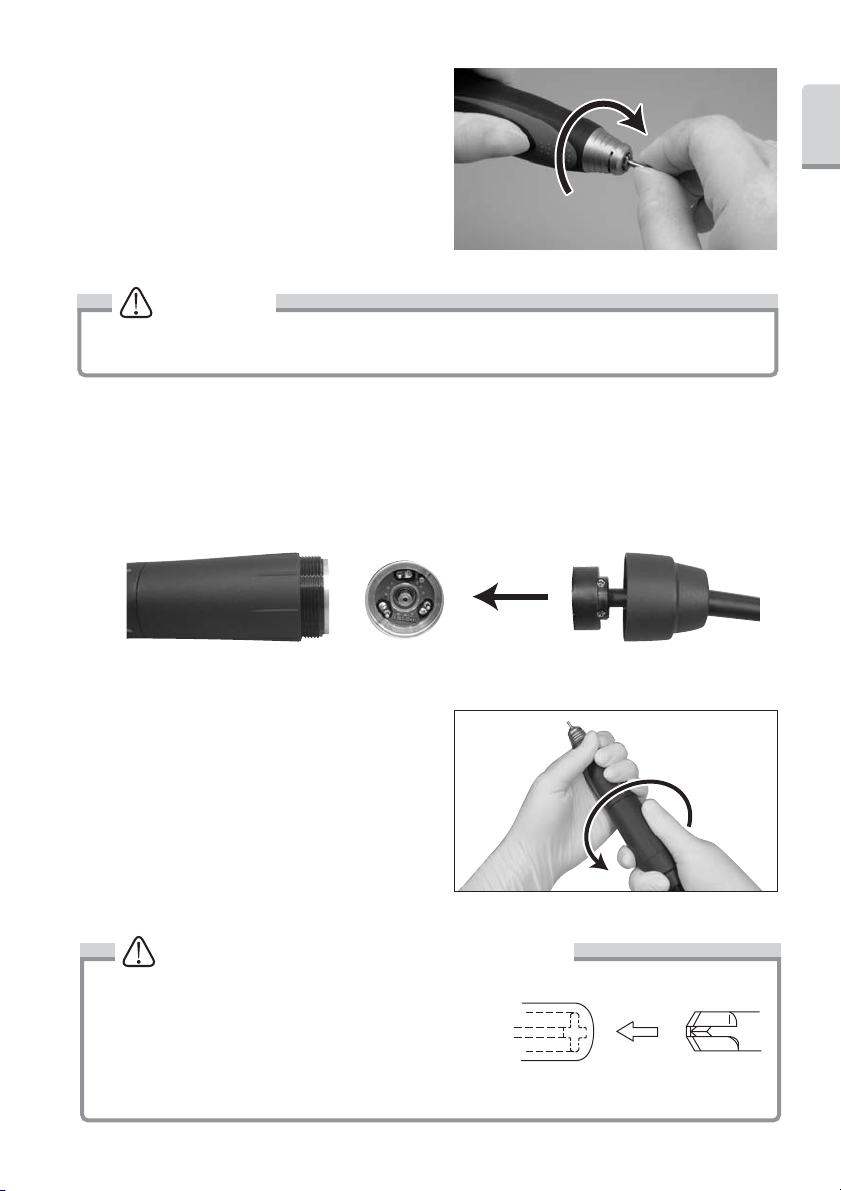

(3) Insertion of Chuck

Turn until finger-tight

Thinly apply oil before insertion. Open the ring,

insert the dummy bur or the bur in use into

the chuck, and turn the chuck clockwise by

hand until it stops. Then, lock the ring, and

the chuck could hold the bur securely.

(Fig. 10)

Turn until finger-tight

Turn until finger-tight

CAUTION

Before using the handpiece, make sure to pull the rotating instrument (bur, etc.) to check

that it is securely mounted.

3. Disconnecting and Connecting of Motor Cord to Motor

Remove the cord nut at the rear end of the motor, and the motor cord connector can be

pulled out. For connection, align the connector pin and the hole in the motor cord connector,

and insert the connector straight until it stops. Then, tighten the cord nut.

* When inserting the connector, do not turn or twist it.

English

Fig.10

4.

Disconnecting Handpiece from Motor

The handpiece and motor are screwed at the

midpoint. Firmly grasp the motor outer case

and the handpiece outer case and turn it

counterclockwise to disconnect. (Fig. 12)

CAUTION for Handpiece connection

When connecting the handpiece to the motor, turn

the handpiece clockwise and tighten firmly. If the

clutch is not engaged properly, the handpiece cannot

be tightened completely. In such case, Do Not Force.

Loosen the handpiece and turn the bur briefly to

re-position the drive dog. Reconnect the handpiece and tighten securely. (Fig. 13).

13

Torque Type/Compact Type

Fig.11

Fig.12

Fig.13

Page 16

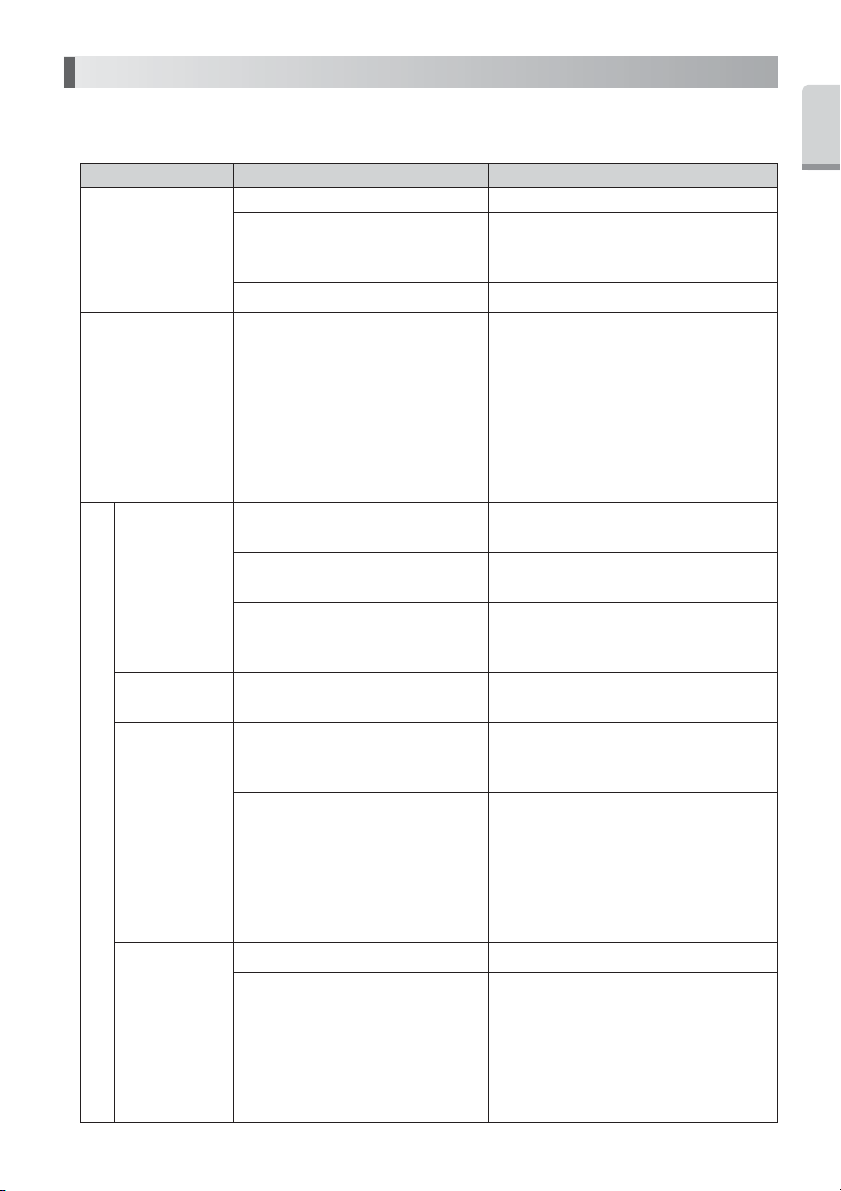

12. Handpiece Stand

At the bottom of the handpiece stand, tools

necessary for handpiece maintenance and a

spare chuck (optional) can be mounted.

(Fig. 14)

13. Handpiece Holder

The handpiece holder that can be mounted on

the right side of the control unit will widen a your

effective work area. Insert the holder into the slot

and fasten the screw. Adjust the holder angle to

your best position. (Fig. 15)

14. Specification

Control Unit

Model

Power supply

Rated Power

Weight

Dimensions

NE213-G (Gray)

NE213-W (White)

AC120V 50/60 Hz 46VA

AC230V 50/60 Hz 46VA

46VA

2.8kg

W167 x D247 x H77mm

Handpiece Holder

Food Pedal

Model

Weight

Handpiece

Model

Weight

Fig.14

Fig.15

FC-64

460g

Handpiece Stand

120g

Motor Handpiece

1 ) Torque Type

Model

Speed

Max. Torque

Weight

Dimensions

Cord Length

UMXL-T(P) / UMXL-T(P) 2M

1,000~50,000 min

8.7N · cm

215g ( exclude the cord)

L151 x ø 29mm

1.2m / 2.0m

-1

2 ) Compact Type

Model

Speed

Max. Torque

Weight

Dimensions

Cord Length

14

UMXL-C/ UMXL-C 2M

1,000~50,000 min

6 N · cm

181g ( exclude the cord)

L144 x ø 27mm

1.2m / 2.0m

-1

Page 17

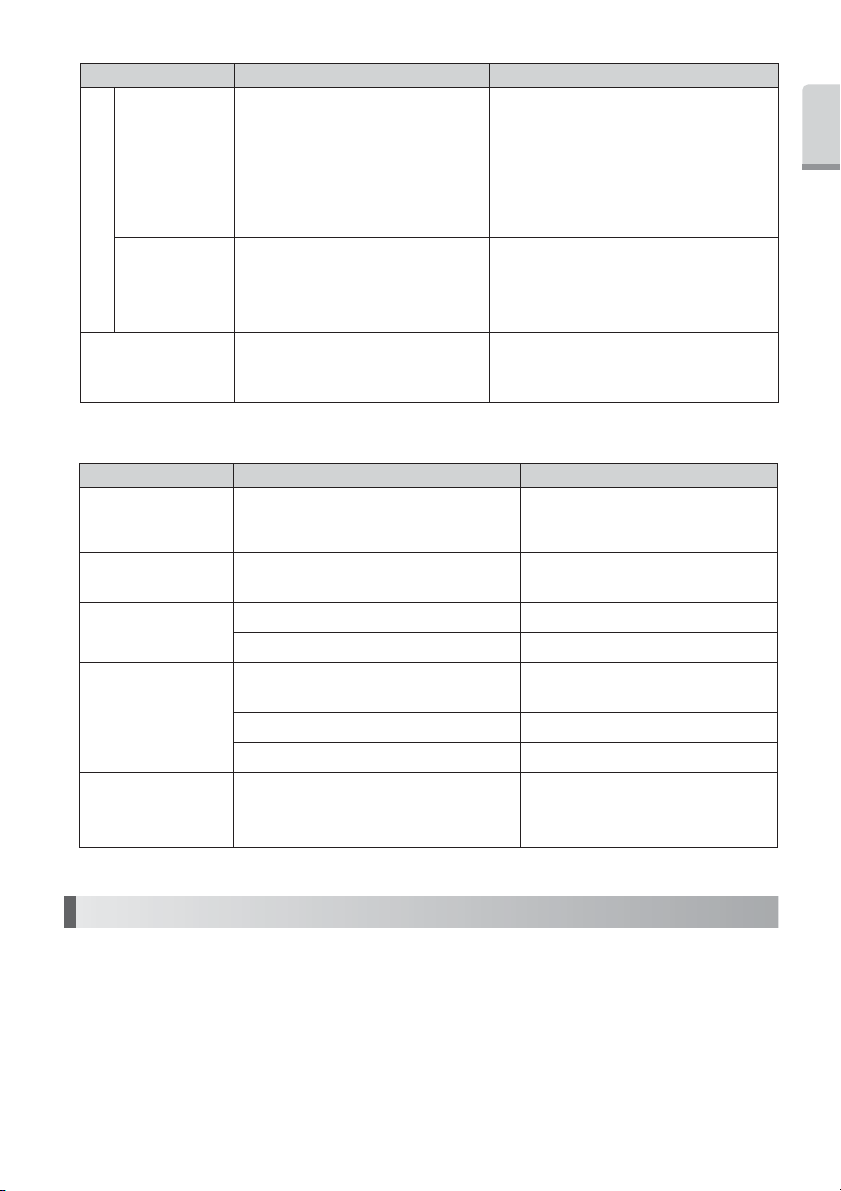

15. Troubleshooting

Please check the following points before sending back instruments for repair.

<Unit / Motor>

Trouble Cause / Check Remedy

The power plug is disconnected.

Pilot Lamp does not

light

Control Unit display

“—“and “Setting

Rotation Speed”

alternately.

Foot Pedal

dose not work.

Error code E0

appears.

Error code E1

appears.

The motor and handpiece do not run, or Reset Lamp lights.

Error code E2

appears.

The fuse is blown.

Power Switch is faulty.

Power on the Control Unit

within pressing the Foot Pedal.

The connection of the Foot Pedal

cord plug is loose.

Hand/Foot Selector Switch is set

by HAND.

Maintenance mode (4) “Pd”:

Check to see if the Foot Pedal

operates normally.

Turn on the power again.

Turn on the power again.

If you have two or more units,

replace the motor and the motor

cord and check the operation.

The motor cord is disconnected.

If you have two or more units,

replace the motor and the motor

cord and check the operation.

Insert the power plug correctly.

Replace it with a specified fuse. If the

reason the fuse has blown is unknown,

ask for an inspection.

Ask for repair.

Power on the Control Unit without

pressing the Foot Pedal. When it does

not work definitely, take off the Foot

Pedal cord plug from the Control Unit

and Power it on. If it does not operate

correctly, ask for your dealer.

Even after you tried above and the

Control Unit could not operate

normally, contact your dealer for repair.

Connect the Foot Pedal cord plug

correctly.

Set Hand/Foot Selector Switch to

FOOT.

If the Foot Pedal dose not operates

normally, ask for repair of the Foot

Pedal or replace it with a new one.

If the same error code appears, ask for

repair of the Control Unit.

If it operates normally, the error display

is temporarily due to overload, which is

not a problem.

If it operates normally after replacing

the motor and the motor cord, the

motor and/or the motor cord may be

shorted. Ask for repair of the motor

and/or the motor cord. If the same

error code still appears after replacing,

ask for repair of the Control Unit.

Connect the motor cord correctly.

If it operates normally after replacing

the motor and the motor cord, the

motor and/or the motor cord may be

severed. Ask for repair of the motor

and/or the motor cord. If the same

error code still appears after replacing,

ask for repair of the Control Unit.

English

15

Page 18

Trouble Cause / Check Remedy

The motor cord is disconnected.

Maintenance mode (3) “HL”:

Confirm whether you work by a

motor signal check normally.

Error code E3

appears.

Error code E4

appears.

Error code E5

appears.

Error code E6

The motor and handpiece do not run, or Reset Lamp lights.

appears.

Error code E8

appears.

The chuck is open.

Check turning a bur with a finger

lightly and turning around it

lightly.

Vacuum-coupled Mode is on,

while the dust collector is not

used.

After stopping to cool it down

place for about 10 minutes,

check the operation again.

Turn on the power again, and

repeat starting and stopping

several times.

The chuck is open.

Maintenance mode (3) “HL”:

Confirm whether you work by a

motor signal check normally.

Check turning a bur with a finger

lightly and turning around it

lightly.

Turn on the power again.

If you have two or more units,

replace the motor cord and

check the operation.

Connect the motor cord correctly.

If any problem is found during a check,

the motor cord may be severed or the

sensor in the motor may be faulty. Ask

for repair.

Lock the chuck. If any problem is

found during a check, the motor cord

may be severed or the sensor in the

motor may be faulty. Ask for repair.

If the rotation is abnormal, ask for

repair of the motor and handpiece.

Make the Vacuum-coupled Mode to

be off. See Vacuum-coupled Mode

section in the manual. (See *

Vacuum-coupled Mode)

If it operates normally, there is no

problem. Check the operating

environment, storage location, etc., for

high temperature. If the same error

code appears frequently, ask for repair

of the Control Unit.

If it operates normally, there is no

problem. If the same error code appears,

ask for repair of the Control Unit.

Lock the chuck. If any problem is

found during a check, the motor cord

may be severed or the sensor in the

motor may be faulty. Ask for repair.

If any problem is found during a check,

the motor cord may be severed or the

sensor in the motor may be faulty. Ask

for repair.

If the rotation is abnormal, ask for

repair of the motor and handpiece.

Error indication is a temporary thing by

the overload if it work normally. There

is not it abnormally.

If it operates normally after replacing

the motor cord, the motor and/or the

motor cord may be shorted. Ask for

repair of the motor and/or the motor

cord. If the same error code still

appears after replacing the motor

cord, ask for repair of the Control Unit.

16

Page 19

Trouble Cause / Check Remedy

Error code E9

appears.

Error code EF

appears.

The motor and handpiece do not run, or Reset Lamp lights.

The rotation speed

does not rise.

If you have two or more units,

replace the motor cord and

check the operation.

Maintenance Mode (4) “Pd”:

Check whether Foot Pedal

operates normally by Foot Pedal

Chuck.

The maximum rotation speed for

operation by foot pedal should be

set with the Speed Control Knob.

If it operates normally after replacing

the motor cord, the motor and/or the

motor cord may be shorted. Ask for

repair of the motor and/or the motor

cord. If the same error code still

appears after replacing the motor

cord, ask for repair of the Control Unit.

If it does not operate normally, change

the Foot Pedal for new or ask for

repair.

Set the maximum rotation speed with

the Speed Control Knob.

<Handpiece>

Trouble Cause / Check Remedy

The handpiece does

not run with the

chuck tightened.

Heat is generated

during rotation.

Vibration or noise

occurs during rotation.

Run out of the bur

is heavy.

The bur comes out

Entry of foreign matter in the ball

bearings or seizure.

Entry of foreign matter in the ball

bearings, causing wear of the bearings.

Same as the above.

A bent bur is used.

Dust may be stuck in the chuck or

spindle.

The chuck is worn.

The ball bearings are worn.

The chuck is loose.

Send it to your dealer. Ask for

repair.

Same as the above.

Same as the above.

Replace the bur

Clean the inside of the chuck and

spindle.

Replace the chuck.

Send it to your dealer.

Tighten the chuck securely. (See

*Handling of Motor and

Handpiece.)

English

16. Disposing Product

Please consult with dealer from whom you purchased it about waste disposal.

17

Page 20

BEDIENUNGSANLEITUNG

Deutsch

Labor-Mikromotor

Page 21

Vielen Dank, dass Sie sich fur den Kauf des ULTIMATE XL entschieden haben. Bitte lesen Sie

die Anweisungen zur Bedienung, Pflege und Wartung in diesem Handbuch vor der

Inbetriebnahme sorgfaltig durch. Bewahren Sie dieses Bedienungshandbuch fur spatere

Verwendung auf.

Inhalt

Deutsch

WICHTIGE ANWEISUNGEN UND WARNUNG

1. Namen der Komponenten

2. Einrichten der Kontrolleinheit

3. Betriebsverfahren

4. Geschwindigkeitsbegrenzung

5. Schutzschalter für Motor

6. Memory-Funktion

7. Fehlercode

8. Auswechseln der Sicherung

9. Wartungsmodus

10. Kupplung an Absaugung

11. Handhabung von Motor und Handstück

12. Handstückablage

13. Handstückhalter

14. Technische Daten

15. Fehlerbehebung

16. Entsorgung des Produktes

····························································································

····························································································

······································································································

······························································································

····························································································

·····························································································

····························································································

······························································································

···············································································

···········································································

··········································································

·················································································

············································································

················································································

·············································································

·············································

·························································

21

25

26

27

28

28

28

29

30

30

31

32

34

34

35

35

38

WICHTIGE ANWEISUNGEN UND WARNUNG -Elektronische Geräte

WARNUNG!

Bei der Verwendung elektrischer Geräte sollten stets einige grundsätzliche

Vorsichtsmaßnahmen befolgt werden, um die Gefahr von Feuer, Stromschlag und eigenen

Verletzungen zu reduzieren. Dazu gehören die nachfolgenden Maßnahmen. Lesen Sie alle

diese Anweisungen vor dem Betrieb dieses Produkts durch und bewahren Sie sie auf.

21

Page 22

A. ERDUNGSANWEISUNGEN

1. Im Falle einer Fehlfunktion oder eines Ausfalls bietet die Erdung einen Weg des

geringsten Widerstands für den elektrischen Strom, um die Gefahr eines Stromschlags

zu reduzieren. Dieses Gerät ist mit einem Stromkabel ausgestattet, das einen

Erdungsleiter und einen geerdeten Stecker besitzt. Der Stecker muss in eine passende

Steckdose gesteckt werden, die korrekt installiert und entsprechend aller geltenden

Vorschriften geerdet ist.

2. Den mitgelieferten Stecker nicht verändern – wenn er nicht in die Steckdose passt,

lassen Sie die richtige Steckdose von einem qualifizierten Elektriker installieren.

3. Unsachgemäßer Anschluss des Erdungsleiters kann zur Gefahr eines Stromschlags

führen. Der Leiter mit einer grünen oder grün-gelb gestreiften Isolierung ist der

Erdungsleiter. Wenn eine Reparatur oder ein Austausch von Stromkabel oder Stecker

erforderlich ist, den Erdungsleiter nicht an einen stromführenden Pol anschließen.

4. Überprüfen Sie die korrekte Erdung des Geräts zusammen mit einem qualifizierten

Techniker oder Kundendienstmonteur, wenn Sie die Erdungsanweisungen nicht

vollständig verstanden haben oder im Zweifel darüber sind.

5. Nur dreiadrige Verlängerungskabel verwenden, die dreizinkige Erdungsstecker und die

richtigen Buchsen für den Stecker des Geräts haben.

6. Dieses Gerät ist zur Verwendung an einem Stromkreis vorgesehen, der eine Steckdose

wie in Zeichnung A (unten) besitzt (120 V). Das Gerät besitzt einen Stecker wie in

Zeichnung A (unten). Ein provisorischer Adapter, wie unten in den Zeichnungen B und C

dargestellt, kann verwendet werden, um diesen Stecker mit einer zweipoligen Dose zu

verbinden, wie in Zeichnung B zu sehen, wenn keine korrekt geerdete Steckdose zur

Verfügung steht. Der provisorische Adapter sollte nur so lange verwendet werden, bis

eine korrekt geerdete Steckdose von einem qualifizierten Elektriker installiert werden

kann. Das grüne, starre Öhr, der Zapfen und andere Vorsprünge des Adapters müssen

an eine permanente Erdung wie beispielsweise eine korrekt geerdete Steckdose

angeschlossen werden.

ERDUNGSPIN

Erdungsmethode

METALL-

SCHRAUBE

ABDECKUNG DER

GEERDETEN

STECKDOSE

22

ADAPTER

ERDUNGSMITTEL

ERDUNGSPIN

Page 23

7. Platzieren Sie die Anlage so, das im Storfall, die Stromversorgung einfach zu Unterbrechen

ist. Mindenstens 10cm Platz um das Gerät herum frei lassen.

Mindeststärke für Kabel

Mehr als

0

6

10

12

Nicht mehr als

6

10

12

16

Volts

120V

7,5m (25ft.) 15m (50ft.) 30m (100ft.) 45m (150ft.)

240V

15m (50ft.) 30m (100ft.) 60m (200ft.) 90m (300ft.)Ampere-Einstufung

Kabels Zahl

#18

#18

#16

#14

Gesamtlänge des Kabels

#16

#16

#16

#12

#16

#14

#14

Nicht empfohlen

#14

#12

#12

B. WEITERE WARNHINWEISE

1. Lesen Sie zu Ihrer eigenen Sicherheit vor der Verwendung des Geräts die

Bedienungsanleitung durch.

2. Augenschutz tragen.

3. Gebrochenen Schleifkörper sofort ersetzen.

4. Immer Schutzvorrichtung und Augenschutz verwenden.

5. Schleifscheiben nicht zu stark anziehen.

6. Nur mit dem Schleifer mitgelieferte Scheiben verwenden.

7. SCHRAUBENSCHLÜSSEL UND EINSTELLWERKZEUGE ENTFERNEN. Überprüfen Sie

grundsätzlich immer, ob alle Einstellwerkzeuge und Schraubenschlüssel entfernt sind,

bevor Sie das Gerät einschalten.

8. ARBEITSBEREICH SAUBER HALTEN. Unaufgeräumte Arbeitsbereiche und Werkbänke

provozieren Unfälle.

9. NICHT IN GEFÄHRLICHER UMGEBUNG VERWENDEN. Elektrische Geräte nicht an

feuchten oder nassen Orten verwenden oder sie dem Regen aussetzen. Für eine gute

Beleuchtung des Arbeitsfeldes sorgen.

10. Verletzungsgefahr durch unbeabsichtigtes Starten. Nicht in Bereichen verwenden, in

denen sich Kinder aufhalten können.

11. GERÄT NICHT ÜBERBEANSPRUCHEN. Es macht seine Arbeit besser und sicherer bei

der Drehzahl, für die es entwickelt wurde.

12. RICHTIGES WERKZEUG VERWENDEN. Werkzeug oder Zubehörteil nicht zwingen,

etwas zu machen, wofür es nicht geeignet ist.

13. ZWECKMÄSSIGE KLEIDUNG TRAGEN. Keine losen Kleidungsstücke, Handschuhe,

Halstücher, Ringe, Armbänder oder anderen Schmuck tragen, der von beweglichen

Teilen erfasst werden könnte. Rutschfestes Schuhwerk wird empfohlen. Bei langen

Haaren schützende Abdeckung tragen.

14. IMMER SICHERHEITSBRILLEN VERWENDEN. Normale Brillen haben nur

schlagresistente Gläser und sind KEINE Sicherheitsbrillen. Auch Gesichts- oder

Staubmaske tragen, wenn das Schleifen mit Staubentwicklung verbunden ist.

Deutsch

23

Page 24

15. WERKSTÜCK SICHERN. Verwenden Sie Klemmen oder einen Schraubstock, um das

Werkstück zu halten, wann immer dies möglich ist. Das ist sicherer als Ihre Hand und

macht beide Hände frei für die Bedienung des Geräts.

16. WERKZEUGE SORGFÄLTIG PFLEGEN. Werkzeuge scharf und sauber halten, für

optimale Leistung und Verringerung des Verletzungsrisikos für Personen. Die

Anweisungen zum Schmieren und Auswechseln von Zubehörteilen befolgen.

17. WERKZEUGE vor Wartungsarbeiten und Austausch von Zubehörteilen

HERAUSNEHMEN, wie beispielsweise Klingen, Bohreinsätze, Schneider und ähnliches.

18. GEFAHR EINES UNBEABSICHTIGTEN STARTENS REDUZIEREN. Sicherstellen, dass

der Schalter aus ist, bevor Sie das Gerät einstecken.

19. EMPFOHLENE ZUBEHÖRTEILE VERWENDEN. Empfohlene Zubehörteile finden Sie im

Benutzerhandbuch. Die Verwendung ungeeigneter Zubehörteile kann ein

Verletzungsrisiko für Personen dastellen.

20. NIEMALS LAUFENDES GERÄT UNBEAUFSICHTIGT LASSEN. AUSSCHALTEN. Gerät

nicht verlassen, bevor es zu völligem Stillstand gekommen ist.

21. Hinsichtlich der empfohlenen Drehzahlen für verschiedene Anwendungen bitte die

Anweisungen des Bohrerherstellers befolgen.

22. Das System funktioniert normal bei Umgebungsbedingungen mit einer Temperatur von

10–40 °C (50–104 °F), einer Luftfeuchtigkeit von 10–85 % RH und ohne

Feuchtigkeitskondensation im Steuergerät. Eine Verwendung außerhalb dieser

Grenzwerte kann eine Fehlfunktion verursachen.

23. Die Aktivierung des Unterbrechers bedeutet, dass der Motor zu stark belastet wird, über

seine Kapazität hinaus.

24. Der Unterbrecher dient zum Schutz des Motors, doch sollte die Arbeit stets so

durchgeführt werden, dass der Unterbrecher nicht aktiviert wird.

25. Die Spannzangenverriegelung nicht drehen, während das Handstück sich dreht.

26. Den Motor nicht laufen lassen, wenn der Bohrerverschlussring in der Stellung OFFEN ist

oder wenn kein Bohrer in der Spannzange montiert ist. Dies könnte zum Lösen des

Handstücks vom Motor oder plötzlicher Hitzeentwicklung führen.

27. Darauf achten, das Mikro Motorhandstück nicht auf den Fußboden oder auf eine harte

Fläche fallen zu lassen, um eine Beschädigung durch den Aufprall zu vermeiden.

28. Versuchen Sie nicht, das Produkt auseinanderzubauen oder zu verändern.

29. Achten Sie darauf, sich nicht am Schleifer oder dem Bohrer zu verletzen.

30. Achten Sie auf das korrekte Modell und die korrekte Leistung, wenn Sie die Sicherung

ersetzen.

C. Wichtige Anweisungen und Warnhinweise für ULTIMATE XL.

1. Weder Motor noch Handstück erfordern eine Schmierung, da die Kugellager beider

Komponenten mit Schmierfett imprägniert sind.

2. Verwenden Sie ausschließlich das Original-Netzkabel. Falls dieses beschädigt ist,

nehmen Sie Kontakt auf mit dem NSK / Nakanishi Service Center.

3. Senden Sie das Gerät zur Wartung / Reparatur zurück zum Hersteller.

24

Page 25

1. Namen der Komponenten

1

3

2

Deutsch

4

5

8 9

7

11

14

10

16

15

12

13

1

Steuereinheit

2

Motorhandstück

3

Fußpedal (FC-40)

4

Netzschalter

5

Motoranschluss

6

Handstückablage

7

Wahlschalter Vorwärts/Rückwärts

8

Hand-/Fuß-Wahlschalter

9

Motorschalter

10

Netzlampe

11

Resetlampe

12

Motorschalter Drehzahlregler

13

Drehzahlgrenzen-Freigabeknopf

14

Fußpedal-Anschluss

15

Eingangsbox

16

Netzkabel

6

25

Page 26

2. Einrichten der Kontrolleinheit

1. Montage des Motorhandstücks

Stecken Sie das Motorkabel in den

5

Motoranschluss, wobei Sie es nach der Rille

des Steckers ausrichten, und fixieren Sie den

Stecker durch Anziehen der Überwurfmutter.

(Abb. 1)

2. Montage des Fußpedals

Stecken Sie das Fußpedalkabel in den

Fußpedal-Anschluss, wobei Sie es nach der

14

Rille des Steckers ausrichten. (Abb. 2)

* Der Anschluss des Fußpedals ist nicht

erforderlich, wenn die Einheit nur von Hand

betrieben wird.

3. Anschluss des Netzkabels

Stecken Sie das Eingangsbox richtig und

fest in die Netzkabel auf der Rückseite der

Einheit. (Abb. 3)

15

16

Abb.1

Abb.2

26

Abb.3

Page 27

3. Betriebsverfahren

1. Netzkabel in eine Steckdose einstecken.

16

2. Sicherstellen, dass der Drehzahlgrenzen-Freigabeknopf auf der niedrigsten Einstellung

steht.

3. Ich schalte Netzschalter an.Ich bestätige diese angeschaltete Netzlampe.

4. Wählen Sie die Drehrichtung mit dem Wahlschalter Vorwärts/Rückwärts. Bei jedem

Drücken dieses Schalters ändert sich die Drehrichtung zwischen RECHTSLAUF und

LINKSLAUF.

5. Wählen Sie die Art der Steuerung mit dem Hand-/Fuß-Wahlschalter. Bei jedem Drücken

dieses Schalters ändert sich die Steuerungsart zwischen HAND und FUSS.

Betrieb - 1

4

Manueller Betrieb

6. Wählen Sie HAND mit dem Hand-/Fuß-Wahlschalter.

7. Stellen Sie die Umdrehungsgeschwindigkeit mit dem Motorschalter Drehzahlregler ein

und üperprüfen Sie diese auf der Resetlampe.

8. Drücken Sie auf den Motorschalter, dann beginnt der Motor zu laufen.

9. Um den Motor zu stoppen, den Motorschalter nochmals drücken.

Betrieb - 2

Betrieb mit Fußpedal

6. Wählen Sie FUSS mit dem Hand-/Fuß-Wahlschalter.

7. Stellen Sie die maximale Umdrehungsgeschwindigkeit mit dem Motorschalter

Drehzahlregler ein und überprüfen Sie diese auf der Resetlampe.

8. Drücken Sie das Fußpedal, dann beginnt der Motor zu laufen. Die

Umdrehungsgeschwindigkeit kann variabel bis zur Maximaldrehzahl gesteuert werden, je

nachdem, wie stark Sie das Fußpedal drücken.

Drehzahlautomatik

Um die Drehzahl innerhalb des eingestellten Bereichs zu fixieren, drücken Sie den

5

Motorschalter, während der Motor mit der gewünschten Geschwindigkeit läuft.

11

Resetlampe blinkt, und die Drehzahl kann beibehalten werden, auch wenn das

3

Fußpedal losgelassen wird. Um die Automatik abzuschalten, den Motorschalter

nochmals drücken oder das Fußpedal erneut drücken.

13

10

7

8

8

12

9

9

8

12

3

3

9

3

Deutsch

27

Page 28

Drehzahlbegrenzungs -Freigabetaste

Resetlampe

4. Geschwindigkeitsbegrenzung

Zur Verwendung eines Rosenbohrers mit

kleinem Durchmesser oder eines Finierers bei

-1

40.000 Min.

Drücken des Drehzahlgrenzen-Freigabeknopf

(Upm) oder mehr erlaubt das

13

und Drehen des Drehzahlreglers eine Einstellung

-1

von bis zu 50.000 Min.

(Upm).(Abb. 4)

Drehzahlbegrenzungs -Freigabetaste

Drehzahlbegrenzungs -Freigabetaste

Abb.4

VORSICHT

Eine Drehzahl von 40.000 Min.-1 (Upm) oder mehr ist nur erlaubt, wenn der

Bohrerhersteller die zulässige Drehzahl für einen bestimmten Bohrer entsprechend

angibt.

5. Schutzschalter für Motor

Wenn der Motor mit einer zu hohen Belastung

betrieben wird oder das Handstück nicht mehr

rund läuft, stoppt der Schaltkreis zum Schutz

des Motors und der Einheit die Stromversorgung

des Motors, Resetlampe leuchtet und eine

Fehlermeldung auf der Resetlampe erscheint.

(Abb.5)

Schutzschalter zurücksetzen

Bei manuellem Betrieb kann er durch erneutes Drücken des Motorschalters zurückgesetzt

werden. Beim Betrieb mit Fußpedal das Fußpedal zurücknehmen, um zu stoppen; dann

wird der Schutzschalter zurückgesetzt.

11

Resetlampe

Resetlampe

Abb.5

5

3

6. Memory-Funktion

Wenn der Netzschalter eingeschaltet wird, werden die zuletzt verwendeten Einstellungen

von Laufrichtung und HAND-/FUSS-Auswahl wiederhergestellt. Sie sollten besonders auf die

richtige Laufrichtung achten.

4

28

Page 29

8. Auswechseln der Sicherung

Die Sicherung befindet sich in der Eingangsbox

Verriegelungsklemmen Verriegelungsklemmen

oben und unten an der Eingangsbox lösen und

herausziehen, um die Sicherung auszuwechseln

(Abb.6)

Wenn die Sicherung durchgebrannt ist,

wechseln Sie bitte die Sicherung aus und

drücken Sie den Sicherungshalter in die

ursprüngliche Position.

- Sicherung: Bestellnummer (120V): 1202225010 (T2,5AH 250V)

- Sicherung: Bestellnummer (230V): 1202216010 (T1,6AH 250V)

15

Abb.6

VORSICHT

Die Sicherung brennt durch, wenn ein Kurzschluss auftritt oder wenn eine

Überspannung in die primäre Stromversorgung fließt. Wenn die Ursache unklar ist, das

Produkt zur Inspektion an einen autorisierten NSK Kundendienst schicken.

9. Wartungsmodus

Die Einheit ist mit einem Wartungsmodus zur Funktionsprüfung von Schaltern, Anzeige,

Fußpedal, Motor usw. ausgestattet. Gleichzeitig Hand-/Fuß-Wahlschalter und

5

Motorschalter drücken, Netzschalter einschalten und gedrückt halten, bis ein Piepsignal

ertönt (etwa 2 Sekunden). Jetzt den Drehzahlregler von der Minimalstellung aus drehen, damit

im Display „oP“, „dP“, „HL“, „Pd“ und „in“ für die nachfolgenden Überprüfungen angezeigt wird.

Zum Verlassen des Wartungsmodus Netzschalter aus- und erneut einschalten.

8

(1) "oP": Schalterprüfung (Überprüfung Betrieb)

Die Schalter auf dem Bedienfeld drücken, damit die rechten und/oder linken Lampen

leuchten und überprüft werden kann, ob die Schalter normal funktionieren.

(2) "dP": Displayprüfung

7

Wahlschalter Vorwärts/Rückwärts drücken, und die Lampen leuchten nacheinander, damit

überprüft werden kann, ob sie normal funktionieren. Um diese Prüfung abzubrechen, den

7

Wahlschalter Vorwärts/Rückwärts erneut drücken.

30

Page 30

(3)

"HL": Motorsignal-Prüfung (Hall IC Prüfung)

7

Wahlschalter Vorwärts/Rückwärts drücken, und die Resetlampe zeigt eine oder zwei

horizontale Linien an. Den Motor langsam von Hand drehen, dann ändert sich diese Anzeige

abwechselnd zu einer Linie, zwei Linien, einer Linie, zwei Linien ... von oben nach unten und

von unten nach oben. Wenn eine der drei Linien nicht leuchtet, ist der Sensor (Hall IC) im

Motor defekt oder das Kabel überlastet und deshalb eine Reparatur erforderlich. Um diese

Prüfung abzubrechen, den Wahlschalter Vorwärts/Rückwärts erneut drücken.

Eg.

2 3 4 A b C d C b A 4 3 2

7

11

(4) "Pd": Fußpedalprüfung

7

Wahlschalter Vorwärts/Rückwärts erneut drücken, und die Resetlampe ändert sich. In

normaler Zeit ändert sich die Resetlampe zu Hexadezimalangaben (0~9, A~F), je

nachdem, wie weit das Fußpedal gedrückt wird. Beim Drücken des Pedals leuchtet auch die

10

Netzlampe leicht auf, und ein vollständiges Herunter-drücken des Pedals löscht die

Lampe. Wenn sich die Resetlampe nicht ändert oder die Resetlampe nicht korrekt

leuchtet, kann das Fußpedal defekt sein. Um diese Prüfung abzubrechen, den

7

Wahlschalter Vorwärts/Rückwärt erneut drücken.

3

11

11

11

(5) "in": Initialisierungsfunktion

7

Wahlschalter Vorwärts/Rückwärt drücken, dann ertönt ein Piepsignal und Laufrichtung,

HAND/FUSS und andere Einstellungen kehren zu den werkseitigen Voreinstellungen zurück.

Laufrichtung : FWD (Vorwärts; Rechtslauf)

HAND/FUSS : HAND

Kupplung an Absaugung : AUS

Deutsch

10. Kupplung an Absaugung

An einigen Zahntechnik-Arbeitstischen mit Absauganlage kann der Motor gekoppelt an die

Absaugung verwendet werden. Wenn eine solche Absauganlage* verwendet wird, kann der

Stromverbrauch des ULTIMATE XL reguliert werden, damit die Kopplung an die Absaugung

funktioniert. Wenn Sie eine Kopplung an die Absaugung verwenden möchten, wählen Sie den

Modus wie folgt:

Modus wählen

Bei gedrücktem Wahlschalter Vorwärts/Rückwärt den Netzkabel einschalten, dann kann

der Modus gewählt werden. Ein langer Piepton zeigt den Absaug-Modus an und zwei kurze

Pieptöne den nicht gekoppelten (energiesparenden) Modus an. Bei jeder Wahl mit dem

Schalter ändert sich der Modus von gekoppelt zu nicht gekoppelt.

* Eine derzeit bekannte Absauganlage ist KAVO EWL-560.

7

31

16

Page 31

11. Handhabung von Motor und Handstück

Lösen

Loosen

(1) Bohrer einsetzen oder herausnehmen

Das Spannfutter wird durch Drehen des

Verriegelungsrings in die Stellung OFFEN geöffnet.

Die Spannzange wird gelöst und der Bohrer kann

herausgenommen werden. Durch Drehen des

Rings in Richtung SCHLIESSEN wird das

Spannfutter geschlossen, und der Bohrer kann

montiert werden. Dann den Ring drehen, bis es

klickt. (Abb.7)

SCHLIESSEN

Öffnen

VORSICHT

• Die Spannzangenverriegelung nicht drehen, während das Motor sich dreht.

• Den Motor nicht laufen lassen, wenn der Bohrerverschlussring in der Stellung OFFEN

ist oder wenn kein Bohrer in der Spannzange montiert ist. Dies könnte zum Lösen des

Handstücks vom Motor oder plötzlicher Hitzeentwicklung führen.

(2) Reinigung und Austausch des

Spannfutters

(1) Spannfutter herausnehmen

Zum Herausnehmen des Spannfutters den

Ring öffnen und das Spannfutter mit dem

mitgelieferten Schraubenschlüssel gegen den

Uhrzeigersinn drehen. (Abb. 8)

* Wenn ein Bohrer mit großem Durchmesser

schneidender Teile bei hohem Drehmoment

verwendet wird, kann sich das Spannfutter in

Richtung Schließen drehen, sodass der

Bohrer festsitzt und sich nicht

herausnehmen lässt. In diesem Fall den

Schlitz der Nase entsprechend der

Schraubenschlüsselposition der Welle

ausrichten (flacher Teil) und die Welle mit

einem L-Schlüssel festhalten. Den Ring

öffnen und das Spannfutter mit dem

mitgelieferten Schraubenschlüssel gegen

den Uhrzeigersinn drehen, um es

herauszunehmen. (Abb. 9)

Lösen

Lösen

Loosen

Loosen

Abb.7

Abb.8

Abb.9

32

Page 32

(2) Spannfutter reinigen

Drehen Sie handfest an.

Spannfutter so oft wie möglich herausnehmen und im Ultraschallreiniger reinigen.

Mindestens ein Mal pro Woche reinigen.

VORSICHT

Eine Vernachlässigung der Reinigung über einen längeren Zeitraum ist sehr gefährlich,

da sich Wachs, Gips usw. Im Spannfutter ansammeln und der Bohrer nicht sicher

gehalten wird oder gar herausfällt.

(3) Spannfutter einsetzen und einstellen

Vor dem Einsetzen dünn Öl auftragen.

Den Ring öffenen, Testbohrer oder gerade

verwendeten Bohrer in das Spannfutter

setzen und dann das Spannfutter von Hand

im Uhrzeigersinn drehen, bis es stoppt. Dann

den Ring verriegeln; das Spannfutter kann

den Bohrer sicher festhalten. (Abb. 10)

Drehen Sie handfest an.

Drehen Sie handfest an.

VORSICHT

Bevor Sie das Handstück benützen, prüfen Sie bitte auf jeden Fall, daß das rotierende

Teil (Schleifkörper etc.) sicher montiert ist und sich nicht herausziehen lässt.

3. Motorkabel und Motor verbinden und trennen

Kabel-Überwurfmutter am hinteren Ende des Motors abnehmen, dann kann der

Motorkabelstecker herausgezogen werden. Zum Anschließen Steckerstift und Loch im

Motorkabel-Stecker ausrichten und den Stecker gerade bis zum Anschlag einstecken. Dann

die Überwurfmutter anziehen.

* Stecker beim Einsetzen nicht drehen oder verkanten.

Deutsch

Abb.10

4.

Handstück vom Motor abnehmen

Handstück und Motor sind in der Mitte

verschraubt. Jeweils Außengehäuse von

Handstück und Motor festhalten und gegen

den Uhrzeigersinn drehen, um beide zu trennen.

(Abb. 12) Beim Verbinden von Motor und

Handstück folgende VORSICHTSMASSNAHME

beachten.

Abb.11

Abb.12

33

Page 33

VORSICHT

Beim Verbinden von Handstück und Motor das

Handstück im Uhrzeigersinn drehen und fest

anziehen. Wenn der Mitnehmer nicht korrekt

einrastet, kann das Handstück nicht ganz angezogen

werden. In diesem Fall keine Gewalt anwenden.

Handstück lösen und den Bohrer kurz drehen, um die Antriebsklaue neu auszurichten.

Handstück wieder verbinden und fest anziehen. (Abb. 13)

Typ Torque / Typ Kompakt

12. Handstückablage

Im Boden der Handstückablage können für die

Wartung benötigte Werkzeuge und ein

Ersatz-Spannfutter (optional) aufbewahrt

werden. (Abb. 14)

13. Handstückhalter

Der Handstückhalter kann an der rechten Seite

der Einheit montiert werden und vergrößert so

Ihren effektiven Arbeitsbereich. Halter in den

Schlitz einsetzen und Schraube anziehen. Winkel

des Halters in der für Sie optimalen Position

einstellen. (Abb. 15)

Handstückhalter

Abb.13

Abb.14

Abb.15

34

Page 34

14. Technische Daten

Kontrolleinheit

Modell

Stromversorgung

Nennleistung

Gewicht

Abmessungen

NE213-G (Grau)

NE213-W (Weiß)

AC120V 50-60 Hz

AC230V 50-60 Hz

46VA

2,8kg

W167 x D247 x H77mm

Motorhandstück

1 ) Typ Drehmoment (Torque)

Modell

Drehzahl

Drehmoment

Gewicht

Abmessungen

Kabellänge

UMXL-T(P) / UMXL-T(P) 2M

1.000~50.000 min

8·7N · cm

215g (ohne Motorkabel)

L151 x ø 29mm

2,0m

-1

Fußpedal

Modell

Gewicht

FC-64

460g

Handstückablage

Modell

Gewicht

Handstückablage

120g

2 ) Typ Kompakt

Modell

Drehzahl

Max. Drehmoment

Gewicht

Abmessungen

Kabellänge

UMXL-C 2M

1.000~50.000 min

6 N · cm

181g (ohne Motorkabel)

L144 x ø 27mm

2,0m

15. Fehlerbehebung

Bitte folgende Punkte überprüfen, bevor Sie das Instrument zur Reparatur einschicken.

<Kontrolleinheit und Motor>

Problem Ursache / Überprüfen Abhilfe

Netzstecker richtig einstecken.

Durch angegebene Sicherung ersetzen.

Wenn die Ursache für das Durchbrennen

unbekannt ist, um Inspektion bitten.

Reparieren lassen.

Schalten Sie die Steuereinheit ohne

Drücken des Fußpedals ein. Wenn es

definitiv nicht funktioniert, ziehen Sie den

Fußpedalkabelstecker von der

Steuereinheit ab und schalten Sie diese

ein. Bei Fehlfunktion wenden Sie sich an

Ihren Händler.

Wenn die Steuereinheit auch nach

Ausführen der obigen Maßnahmen nicht

richtig arbeitet, wenden Sie sich an Ihren

Händler zur Reparatur.

Pilotlampe leuchtet

nicht.

Die Steuereinheit

zeigt abwechselnd

“—“ und “Setting

Rotation Speed” an.

Der Netzstecker ist ausgesteckt.

Die Sicherung ist durchgebrannt.

Netzschalter ist defekt.

Schalten Sie die Steuereinheit durch

Drücken des Fußpedals ein.

Deutsch

-1

35

Page 35

Problem Ursache / Überprüfen Abhilfe

Der Stecker desFußpedals ist

locker.

Hand-/Fuß-Wahlschalter ist auf

Fußpedal geht

nicht.

Fehlercode E0

erscheint.

Fehlercode E1

erscheint.

Fehlercode E2

erscheint.

Motor und Handstück laufen nicht oder Resetlampe leuchtet delete.

Fehlercode E3

erscheint.

HAND gestellt.

Im Wartungsmodus (4) “Pd”:

Fußpedal-Prüfung überprüfen, ob

das Fußpedal normal funktioniert.

Gerät nochmals einschalten.

Gerät nochmals einschalten.

Wenn Sie zwei oder mehrere

Einheiten haben, Motor und

Motorkabel austauschen und

Funktion prüfen.

Das Motorkabel ist nicht

angeschlossen.

Wenn Sie zwei oder mehrere

Einheiten haben, Motor und

Motorkabel austauschen und

Funktion prüfen.

Das Motorkabel ist nicht

angeschlossen.

Im Wartungsmodus (3) “HL”:

Motorsignal-Prüfung überprüfen, ob

das Gerät normal funktioniert.

Das Spannfutter ist offen.

Überprüfen, ob die Spitze leicht mit

der Hand gedreht werden kann.

Fußpedalstecker korrekt einstecken.

Hand-/Fuß-Wahlschalter auf FUSS

stellen.

Wenn das Fußpedal nicht normal

funktioniert, reparieren lassen oder durch

neues Pedal ersetzen.

Wenn der gleiche Fehlercode erneut

erscheint, die Einheit reparieren lassen.

Wenn es normal funktioniert, ist die

Fehleranzeige nur vorübergehend und

beruht auf einer Überlastung, was jedoch

kein echter Fehler ist.

Wenn das Gerät nach Austausch von

Motor und Kabel normal funktioniert,

können Motor und/oder Motorkabel

kurzgeschlossen sein. Motor und/oder

Kabel reparieren lassen. Wenn der

gleiche Fehlercode nach dem Austausch

erneut erscheint, die Einheit reparieren

lassen.

Schließen Sie das Motorkabel richtig an.

Wenn das Gerät nach Austausch von

Motor und Kabel normal funktioniert,

können Motor und/oder Motorkabel

kurzgeschlossen sein. Motor und/oder

Kabel reparieren lassen. Wenn der

gleiche Fehlercode nach dem Austausch

erneut erscheint, die Einheit reparieren

lassen.

Um die Genauigkeit der Spannzange zu

erhalten.

Wenn sich bei der Überprüfung irgendein

Problem ergibt, kann das Motorkabel

überlastet oder der Sensor im Motor

defekt sein. Reparieren lassen.

Spannfutter verriegeln.

Wenn die Drehung abnormal ist, Motor

und Handstück reparieren lassen.

36

Page 36

Problem Ursache / Überprüfen Abhilfe

Absaug-Modus ist an, während

Absaugung nicht verwendet wird.

Fehlercode E4

erscheint.

Fehlercode E5

erscheint.

Fehlercode E6

erscheint.

Fehlercode E8

erscheint.

Motor und Handstück laufen nicht oder Resetlampe leuchtet delete.

Fehlercode E9

erscheint.

Fehlercode EF

erscheint.

Nach Anhalten und 10 Minuten

Abkühlung Funktion nochmals

überprüfen.

Gerät nochmals einschalten und

mehrere Male starten/stoppen.

Das Spannfutter ist offen.

Im Wartungsmodus (3) „HL“:

Motorsignal-Prüfung überprüfen, ob

das Gerät normal funktioniert.

Überprüfen, ob die Spitze leicht mit

der Hand gedreht werden kann.

Gerät nochmals einschalten.

Wenn zwei oder mehrere Einheiten

zur Verfügung stehen, Motor und

Motorkabel austauschen und

Funktion prüfen.

Wenn zwei oder mehrere Einheiten

zur Verfügung stehen, Motor und

Motorkabel austauschen und

Funktion prüfen.

Wartungsmodus (4) “Pd” : Das

Fußpedal überprüfen, ob das

Fußpedal normal funktioniert.

Absaug-Modus ausschalten. Siehe

Abschnitt Absaug- Modus in dieser

Gebrauchsanleitung.

Wenn das Gerät normal funktioniert, liegt

kein Fehler vor. Betriebsumgebung,

Aufbewahrungsort usw. Auf hohe

Temperatur überprüfen. Wenn der gleiche

Fehlercode häufig erscheint, Einheit

reparieren lassen.

Wenn das Gerät normal funktioniert, liegt

kein Fehler vor. Wenn der gleiche

Fehlercode wieder erscheint, Einheit

reparieren lassen.

Spannfutter verriegeln.

Wenn sich bei der Überprüfung irgendein

Problem ergibt, kann das Motorkabel

überlastet oder der Sensor im Motor

defekt sein. Reparieren

lassen.

Wenn die Drehung abnormal ist, Motor

und Handstück reparieren lassen.

Bei normalem Betrieb, ist die

Fehleranzeige nur vorübergehend und

beruht auf einer Überlastung. Dies ist

jedoch kein echter Fehler.

Wenn bei der Überprüfung

Unregelmäßigkeiten entdeckt werden,

dann kann es möglich sein, dass das

Motorkabel unterbrochen oder der

Sensor im Motor defekt ist. Reparieren

lassen. Falls ein Turbinenadapter

verwendet wird, dann ist möglicherweise

das Turbinenadapterkabel unterbrochen

oder der Turbinenadapter defekt.

Reparieren lassen.

Wenn bei der Überprüfung

Unregelmäßigkeiten entdeckt werden,

dann kann es möglich sein, dass das

Motorkabel unterbrochen oder der

Sensor im Motor defekt ist. Reparieren

lassen. Falls ein Turbinenadapter

verwendet wird, dann ist möglicherweise

das Turbinenadapterkabel unterbrochen

oder der Turbinenadapter defekt.

Reparieren lassen.

Wenn das Fußpedal nicht normal

funktioniert, reparieren lassen oder durch

neues Pedal ersetzen.

37

Deutsch

Page 37

Problem Ursache / Überprüfen Abhilfe

Die Drehzahl steigt

nicht.

Die maximale Drehzahl für den

Betrieb mit Fußpedal muss mit dem

Drehzahlregler eingestellt werden.

Maximale Drehzahl mit dem

Drehzahlregler einstellen.

<Handstück>

Problem Ursache Abhilfe

Das Handstück läuft bei

angezogenem

Spannfutter nicht.

Während der Rotation

entsteht Hitze.

Vibration oder Geräusche

treten während der

Rotation auf.

Bohrer läuft sehr lange

nach.

Der Bohrer kommt

heraus.

Eindringen von Fremdmaterial in Kugellager

oder Blockieren.

Eindringen von Fremdmaterial in die

Kugellager verursacht Abnutzung der Lager.

Wie oben.

Es wird ein verbogener Bohrer verwendet.

Im Spannfutter oder in der Welle kann Staub

sitzen.

Das Spannfutter ist abgenutzt.

Die Kugellager sind abgenutzt.

Das Spannfutter ist lose.

An Ihren Händler schicken.

Reparieren lassen.

Wie oben.

Wie oben.

Bohrer ersetzen.

Spannfutter und Welle Innen

reinigen.

Spannfutter ersetzen.

An Ihren Händler schicken.

Spannfutter einstellen.

16. Entsorgung des Produktes

Bitte wenden Sie sich bezüglich Abfallentsorgung an den Händler, von dem Sie das Produkt

gekauft haben.

38

Page 38

Manuel Technique

Français

Moteur de laboratoire

Page 39

Nous vous remercions d’avoir acheté ULTIMATE XL.

Nous vous recommandons de lire attentivement ce manuel technique notamment les

instructions concernant l’utilisation, la méthode de manipulation, la maintenance ainsi que

l’inspection avant d’utiliser l’appareil et de ranger ce manuel dans un endroit où vous pourrez le

consulter à tout moment.

Table des matières

INSTRUCTIONS IMPORTANTES ET PRECAUTIONS POUR LES DISPOSITIFS

ELECTRIQUES

1. Désignation des éléments

2. Installation

3. Mise en route

4. Limiteur de Vitesse

5. Protection du circuit électronique

6. Mémoire

7. A propos du code d'erreur

8. Remplacement des fusibles

9. Mode de maintenance

10. Aspiration couplée à l’Ultimate XL

11. Manipulation du moteur et de la pièce à main

12. Support moteur

13. Support Pièce à main

14. Caractéristiques

15. Pannes et dispositions à prendre

16. Mis au rebut de l’instrument

······························································································

···············································································

·······································································································

··································································································

··························································································

····································································

·········································································································

··············································································

············································································

····················································································

··································································

·················································

······························································································

·····················································································

·····························································································

···································································

···········································································

41

45

46

47

48

48

48

49

50

50

52

52

55

55

55

56

58

Français

INSTRUCTIONS IMPORTANTES ET PRECAUTIONS POUR LES DISPOSITIFS ELECTRIQUES

PRECAUTIONS

Lors de l’utilisation d’appareils électriques, il faut toujours suivre les précautions de base de

sécurité afin de limiter les risques d’incendie, d’électrochoc et les blessures corporelles.

Lisez toutes ces instructions avant de faire fonctionner cet appareil et gardez-les près de

vous.

41

Page 40

A. INSTRUCTIONS POUR LA MISE A LA TERRE

1. En cas de mauvais fonctionnement ou de panne, la mise à la terre offre une voie de

résistance minime pour le courant électrique afin de réduire le risque d’électrochoc. Cet

appareil est fourni avec un cordon électrique équipé d’une prise de. Ce cordon électrique

doit être connecté à une prise adaptée qui sera correctement installée et mise à la terre

conformément à tous les codes et réglementations locales.

2. Ne modifiez pas la fiche fournie. Si elle ne convient pas à votre branchement, demandez à un

électricien qualifié d’installer une prise adéquate.

3. Une connexion incorrecte du conduteur de mise à la terre principale peut provoquer un

électrochoc. Le conducteur avec une isolation ayant une surface extérieure verte avec ou

sans raies jaunes est le conducteur de mise à la terre principale. S’il est nécessaire de

réparer ou de remplacer le cordon électrique ou la fiche, ne branchez pas le conducteur de

mise à la terre principale sur une phase ou un neutre.

4. Vérifiez avec un électricien qualifié ou une personne du service après-vente si les instructions

de la mise à la terre ne sont pas respectées, ou si un doute subsiste quant à la mise à la

terre correcte de cet appareil.

5. Utilisez uniquement des rallonges électriques avec des mises à la terre.

6. Cet outil a été conçu pour une utilisation sur un circuit qui ait une sortie comme celle indiquée

dans l’illustration A dans la figure (ci-dessous) (120V). Un adaptateur temporaire, semblable à

celui de l’illustration B et C, doit être utilisé pour brancher cette fiche à une prise femelle à 2

pôles comme indiqué dans l’illustration B si une sortie de mise à la terre correcte n’est pas

disponible. L’adaptateur temporaire ne doit être utilisé qu’en attendant qu’une sortie de mise

à la terre correcte puisse être installée par un électricien qualifié. L’oreille rigide verte, la cosse

pour câble ou autre pièce, allongeant l’adapteur doit être branchée à une mise à la terre

permanente notamment à une boîte de sortie de mise à la terre correcte.

GROUNDING

PIN

Méthode de mise à la terre

METAL SCREW

COVER IF GRIUNDING

OUTLET BOX

42

ADAPTER

GROUNDING MEANS

GROUNDING PIN

Page 41

7. UTILISEZ UNE RALLONGE CORRECTE. Assurez-vous du bon état de votre rallonge. Quand

vous l’utilisez, vérifiez bien qu’’elle est suffisamment puissante pour apporter le courant

nécessaire à votre appareil. Un cordon de dimension inférieure à la cote préconisée peut

provoquer une baisse dans la tension de ligne engendrant une perte de puissance et une

surchauffe. Le tableau (ci-dessous) indique la taille correcte à utiliser suivant la longueur du

cordon et la valeur nominale sur la plaque caractéristique. En cas de doute, utilisez la plus

haute cote suivante. Plus le numéro de cote est faible, plus le cordon est puissant.

8. Installez l’equipement de facon a pouvoir rapidement enlever la prise de courant en cas

d’urgence. Ne placez aucun objet dans un périmètre de 10 cm autour de l’unité.

Valeur minimale pour le cordon électrique

Longueur totale du cordon

#16

#16

#16

#12

#16

#14

#14

Non recommandée

#14

#12

#12

Supérieure à

0

6

10

12

Pas plus de

6

10

12

16

Volts

7,5m (25pieds) 15m (50pieds) 30m (100pieds) 45m (150pieds)

120V

15m (50pieds) 30m (100pieds) 60m (200pieds) 90m (300pieds)Valeur nominale

240V

Cordon Nombre

#18

#18

#16

#14

B. AUTRES INSTRUCTIONS DE PRECAUTIONS

1. Pour votre propre sécurité, lisez le manuel d’instructions avant de manipuler l’appareil.

2. Portez des lunettes de protection.

3. Remplacez immédiatement tout accessoire cassé.

4. Utilisez toujours des protections pour les yeux.

5. Ne serrez pas trop les écrous de fixation.

6. RETIREZ LES CLES ET LES BOULONS DE REGLAGE. Prenez l’habitude de vérifier que les

clés et les boulons de réglage sont retirés de l’outil avant de le mettre en marche.

7. GARDEZ TOUJOURS LE POSTE DE TRAVAIL PROPRE. Des postes de travail ou des bancs

encombrés peuvent provoquer des accidents.

8. N’UTILISEZ PAS CET APPAREIL DANS UN ENVIRONNEMENT DANGEUREUX. N’utililsez

pas d’outils électriques dans des lieux humides et mouillés. Gardez votre poste de travail

bien éclairé.

9. Risque de blessure en cas de démarrage accidentel. N’utilisez pas l’appareil dans un lieu où

il y a des enfants.

10. NE FORCEZ PAS L’APPAREIL. Il fera un meilleur travail s’il fonctionne à la vitesse pour

laquelle il a été conçu.

11. UTILISEZ LE BON OUTIL. Ne forcez pas l’outil ou sa fixation pour effectuer un travail pour

lequel l’appareil n’a pas été conçu.

12. PORTEZ UNE TENUE PROFESSIONNELLE ADAPTEE A VOTRE TRAVAIL. Ne portez pas de

vêtements amples, de gants, de cravate, de bagues, de bracelets ou autres bijoux qui

pourraient se coincer dans les pièces mobiles. Des chaussures non-glissantes sont

recommandées. Portez un bonnet de protection pour les cheveux longs.

Français

43

Page 42

13. UTILISEZ TOUJOURS DES LUNETTES DE PROTECTION. Les lunettes de vue ont des

verres résistants uniquement aux impacts, ce ne sont PAS des lunettes de protection. Utilisez

aussi un masque contre la poussière si nécessaire.

14. TRAVAILLEZ EN TOUTE SECURITE. Utilisez si nécessaire des crampons ou un étau pour

maintenir la pièce à usiner pendant le travail. Ceci est plus sûr que d’utiliser votre main et