Page 1

Caution

Caution

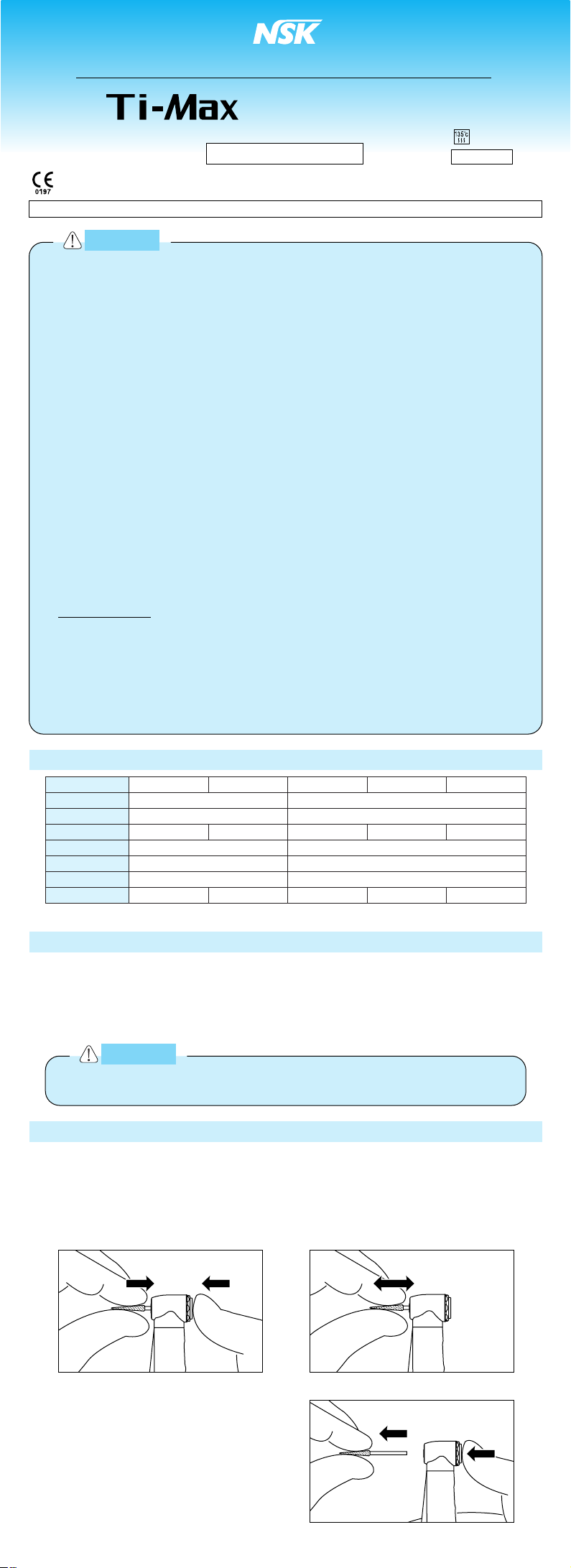

Fig. 1 Fig. 2

Fig. 3

・When operating the handpiece always consider the safety of the patient.

・The handpiece is designed only for dental clinical use.

・

Check the vibration, noise and overheating outside the patient's oral cavity

before use. If any abnormalities are found, stop using and contact your dealer.

・If any abnormalities are found in use, stop using immediately and contact

your dealer.

・Do not allow any impact on the shank. Do not drop the handpiece.

・

Do not attempt to disassemble the handpiece nor tamper with the mechanism.

・Do not connect or disconnect the handpiece until the drive motor has

completely stopped.

・Do not exceed a speed of 200,000min

-1

(rpm) at the head.

・Do not use eccentric, worn or damaged burs.

・Use short shank bur for miniature head speed increasing handpiece. (Ti85L,

Ti85LA,Ti85) Using long burs could result in bur spin-out while using, or

premature bearing failure.

・Do not use a long surgical bur on speed increasing handpiece, which runs

to 200,000min

-1

(rpm). Such long bur as 25mm in length shall not be used. Its

shank may warp under load at a high speed and spin out of the handpiece

when the load is released.

・Before use always confirm that the bur is correctly seated and locked into

place.

・Depressing the push-button while handpiece bur is in rotation will result in

OVERHEATING of the handpiece head. Special caution must be exercised

during use to keep cheek tissue AWAY from the push-button of the handpiece. Contact with cheek tissue may cause the push-button to depress and

injury to the patient may occur.

・Always operate with spray. Without cooling spray, the handpiece may build

up heat.

・Supply PANA SPRAY after each use.

・Use only the genuine NSK-manufactured oil. (PANA SPRAY)

1. Specifications

3. Insertion and Removal of the bur

a Bur Insertion

Insert the bur into the chuck until it stops (4-6mm depth).

Depress the push-button and insert further into the chuck until the bur stops. (Fig. 1)

After the bur is inserted, push and pull the bur to make sure that it is held firmly in

place. (Fig. 2)

This action will further increase the bur retention force.

2. Connecting / Disconnecting the motor and the handpiece

To connect the motor and the handpiece, align the positioning marks on the motor

and the handpiece, and insert straight. This procedure will also align the light

receptacle and allow you to use illumination if your handpiece and motor are

equipped for illumination. (Ti85L, Ti85LA, Ti95L, Ti95LA) To disconnect, hold the

front part of the motor and the back part of the handpiece, and pull straight out.

# Only use burs capable of 200,000min-1(rpm).

s Bur Removal

Depress the push-button and Pull out

the bur. (Fig. 3)

Note : The push-button chuck has a

double action. The button stops

when it touches the rotor

Depress further and pull out the

bur.

The EU directive 93/42/EEC was applied in the design and production of this medical device.

Please read this Operation Manual carefully and file for future reference.

OPERATION MANUAL

Do not connect or disconnect the handpiece until the motor has

completely stopped.

1 : 5 Speed Increasing Contra Angle Handpiece FG bur

Ti85L / Ti85LA / Ti85

Ti95L

/

Ti95LA / Ti95 / Ti95EX

OM-C0179E Rev.B

Model

Gear Ratio

Allowable Max. Speed

Coolant Delivery

Spray Type

Chuck Type

Burs (#)

Optics

Ti95EX

External

−

Ti95

1 : 5 Increasing

40,000min

-1

(rpm)

Internal

Quadruple Spray

Ultra Push

ø1.59-1.60mm Standard Bur

−

Ti95L/Ti95LA

Internal

Glass Rod optic

Ti85

Internal

−

1 : 5 Increasing

40,000min

-1

(rpm)

Single Spray

Ultra Push

ø1.59-1.60mm Short Shank Bur

Ti85L/Ti85LA

Internal

Glass Rod optic

: AUTOCLAVABLE

Page 2

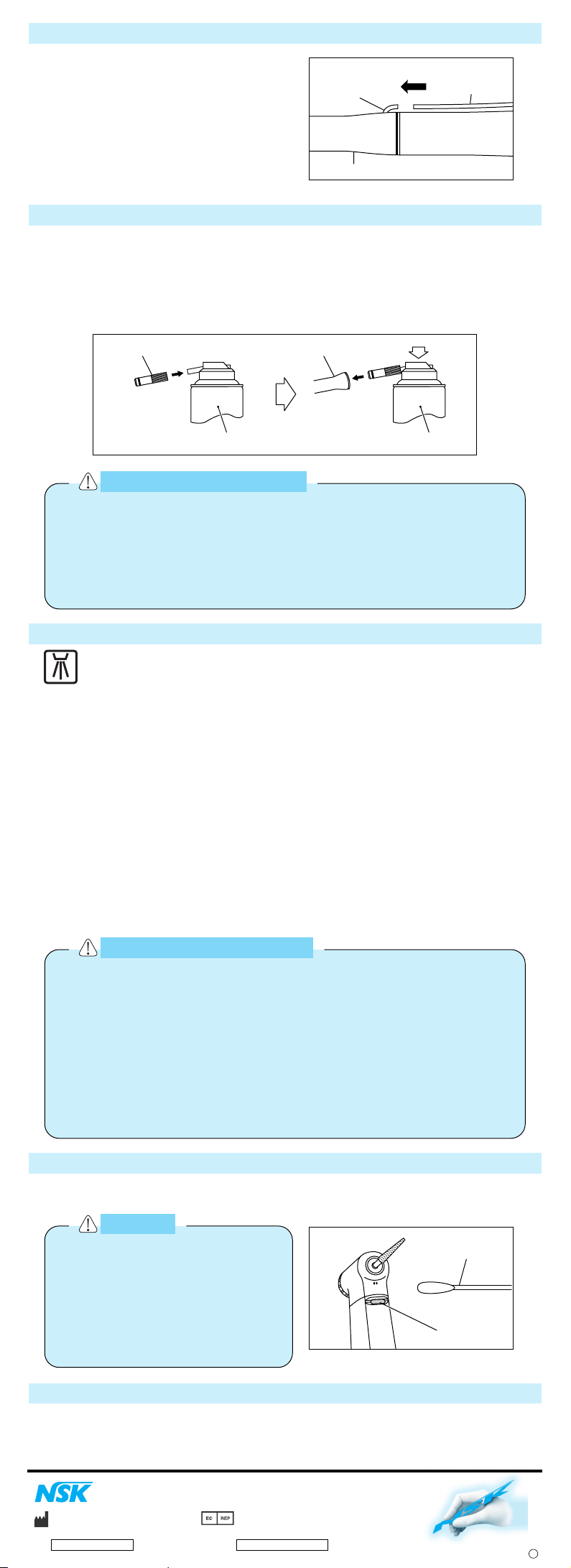

Fig. 5

PANA SPRAYPANA SPRAY

E-type Spray Nozzle

Handpiece

Cotton Swab

Glass Rod Optic End

Handpiece

Cautions on Lubrication

Cautions on Sterilization

Fig. 6

Fig. 4

Caution

4. Irrigation Nozzle (Ti95EX)

When irrigation is required please connect

the irrigation tube to the irrigation nozzle.

5. Lubrication

Supply PANA SPRAY after each use and/or before autoclaving.

q Push E-type spray nozzle attachment over the PANA SPRAY nozzle until it

firmly seats.

w Shake the can 3-4 times to well mix lubricant and propellant.

e Insert the E-type spray nozzle in the rear of the handpiece and spray for

approximately 2-3 seconds until the oil comes out of the handpiece head.

6. Cleaning and Sterilization

NSK recommends heat sterilization by autoclave.

Sterilization required after each patient as noted below.

Autoclave Procedure

q

Scrub dirt and debris from the handpiece, and wipe clean with alcohol-

immersed

cotton swab or cloth. Do not use a wire brush.

w Lubricate with PANA SPRAY. Refer to 5. Lubrication.

e Insert into an autoclave pouch. Seal the pouch.

r Autoclavable up to a max. 135˚C.

ex.) Autoclave for 20 min. at 121℃, or 15 min. at 132℃.

t Keep the handpiece in the autoclave pouch to keep it clean until you use it.

✻ Sterilization at 121˚C for more than 15 minutes is recommended by EN13060

or EN554.

✻ Performing sterilization according to our instruction has minimal effect on the

instruments. Life span is generally determined by wear and damage due to

use.

7. Cleaning Glass Rod Optic End (Ti85L, Ti85LA, Ti95L, Ti95LA)

In case the light had become dim, clean the glass rod optic end with an alcoholsoaked cotton swab. (Fig.6)

・Be sure to hold the handpiece firmly to prevent the handpiece from

slipping out by the spray pressure when lubricating.

・Supply lubricant until it comes out of the handpiece head (for approx.

2 seconds).

・Keep the PANA SPRAY can upright.

・Use of lubricants other than NSK’s PANA SPRAY can cause excessive

heat generation and possible handpiece damage.

・In case the sterilizer chamber temperature could exceed 135℃ during

the dry cycle. Skip the dry cycle.

・Always place the handpiece in the center or upper shelf of the

chamber, as the local temperature at the chamber bottom could rise

beyond the set value.

・Do not autoclave the handpiece, even when it is bagged, together with

other instruments, from which chemicals are not sufficiently cleaned.

This is to avoid discoloration and / or damage to the plating of the

handpiece.

・Do not heat or cool the handpiece quickly. Rapid change in tempera-

ture could break the glass rod give abnormal strain to other metals.

8. Repair Service

For genuine NSK service and parts always return the handpiece to your NSK dealer.

Irrigation Nozzle

Irrigation Tube

Do not use a pointed tool or sharp

edges to clean the glass rod optic

end. They may damage the mirror

finish and reduce the light transmission efficiency. If the glass rod

optic end has become damaged,

send the handpiece to the NSK

dealer for repair.

Powerful Partners

®

’07.06.02 M

※ Specifications may be changed without notice.

www.nsk-inc.com

NAKANISHI INC.

700 Shimohinata, Kanuma, Tochigi

322-8666, Japan

www.nsk-europe.de

NSK EUROPE GmbH

Westerbachstraße 58 60489 Frankfurt,

Germany

This handpiece can be washed via Thermo Disinfector.

Loading...

Loading...