Page 1

Page 2

English

Contents

1. Introduction ..................................................2

1-1 Outline .......................................................................2

1-2 User and Indication for Use .........................................2

1-3 Precautions for handling and operation ........................3

1-4 Classification of Equipment .........................................6

2. Components .................................................7

2-1 List of components .....................................................7

2-2 Part Names of Control Unit and Main Unit ....................8

3. Preparations for Use ...................................12

3-1 Installing the Main Unit and the Control Unit ...............12

3-2 Connecting the Tubing ..............................................13

3-3 Connecting the Motor Cord .......................................14

3-4 Connecting the AC Adapter .......................................14

3-5 Connecting the AC Power Cord ..................................15

3-6 Connecting / disconnecting the motor ........................15

and motor cord

3-7 Connecting / disconnecting the motor ........................16

and the handpiece (option)

3-8 Changing the settings for various functions ................17

3-9 Check before treatment ............................................21

4. Operation Procedure ...................................22

4-1 General Application Mode .........................................23

4-2 Rotary Endo Mode (NLZ E only) .................................24

4-3 Reciprocating Endo Mode (NLZ E only) .......................27

4-4 Contra-Check Function .............................................28

4-5 Sound Volume ..........................................................33

(When the load exceeds the set torque limit value,

Error etc.)

4-6 Last Memory Function ..............................................34

4-7 Initializing Program ................................................... 34

(Restoring the Factory Setting)

4-8 Overheat Prevention .................................................36

English

5. Post-use Maintenance ................................38

5-1 Cleaning at point-of use (Motor) ................................38

5-2 Cleaning, Disinfecting (Motor) .................................... 40

5-3 Packaging, Sterilizing, ...............................................41

Drying and Storage (Motor)

5-4 Cleaning, Disinfecting ............................................... 42

(Control unit, motor cord)

6. Maintenance ............................................... 43

6-1 Replacing the O-rings (Motor insert) ..........................43

6-2 Replacing the O-rings (Motor rear side) ......................44

6-3 Periodical Maintenance Checks .................................45

7. Troubleshooting ..........................................46

7-1 Error Code ...............................................................46

7-2 Troubles and Actions ................................................. 47

8. Specifications .............................................48

8-1 Specifications ...........................................................48

8-2 Symbol ....................................................................49

9. After-sales Service ......................................50

9-1 Warranty ..................................................................50

9-2 Spare Parts List ........................................................50

9-3 Option Parts List .......................................................51

9-4 Disposing product .....................................................51

10. EMC Information .........................................52

(Electromagnetic Compatibility Information)

1

Page 3

Introduction

1

CAUTION

U.S. Federal law restricts this device to be used by or on the order of a licensed dental professional.

Thank you for purchasing the NSK NLZ E / NLZ motor system.

This product can be connected to a dental unit (air unit), which is currently in use, to equip it with a

brushless electric micromotor with LED light.

Please read this Operation Manual carefully before use for operation instructions and maintenance

guidelines to increase overall product life span. Keep this Operation Manual in a handy place for future

reference.

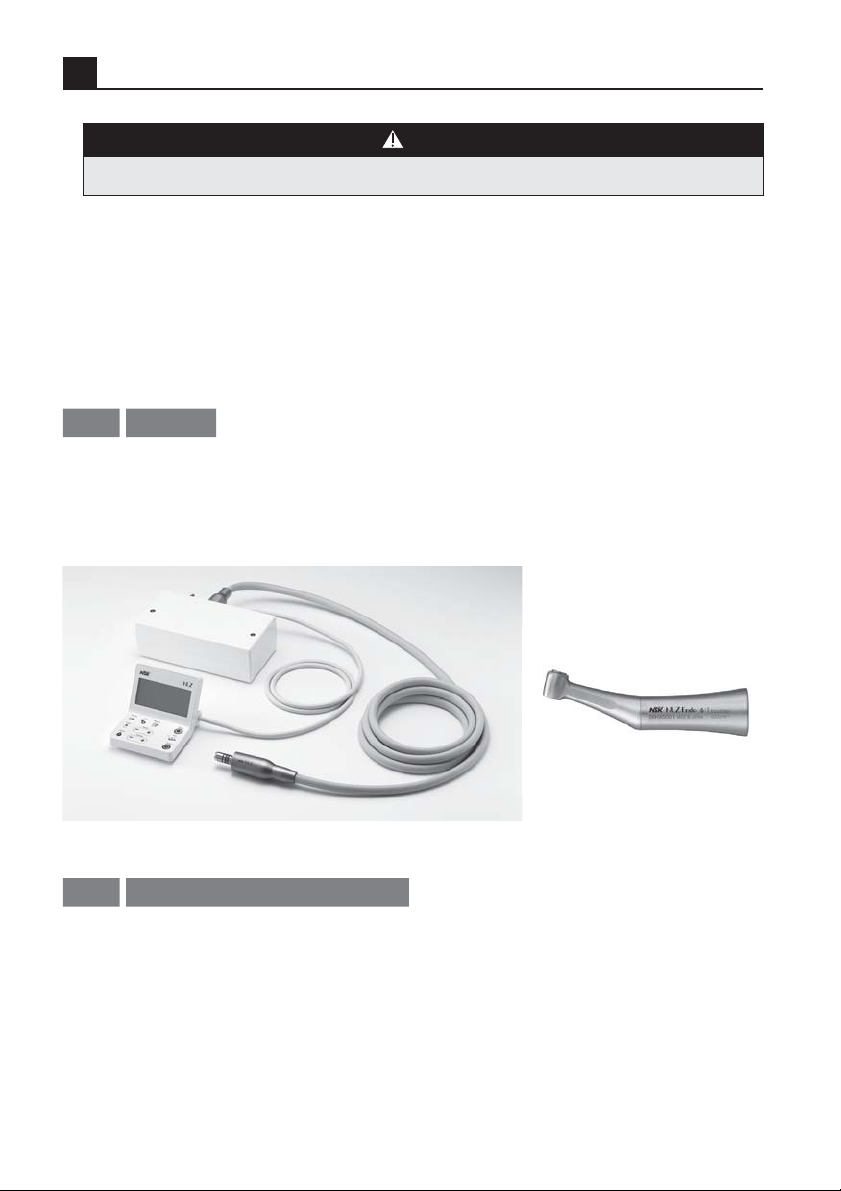

Outline

1-1

NLZ Motor Systems are available in two models.

NLZ Motor Set, which consists of the main unit, the control unit (Endo function not available) and the

Motor.

NLZ E Motor Set, which consists of the main unit, the control unit (Endo function available) and the Motor.

Optional

User and Indications for Use

1-2

User:

U.S. Federal law restricts this device to be used by or on the order of a licensed dental professional.

Indications for Use:

The NLZ Motor System is intended for use by dental professionals in the performance of dental restoration,

prophylaxis and endodontic procedures.

The NLZ Endo is intended for use by dental professionals in the performance of dental endodontic

procedures.

2

Page 4

Introduction

1-3

Precautions for handling and operation

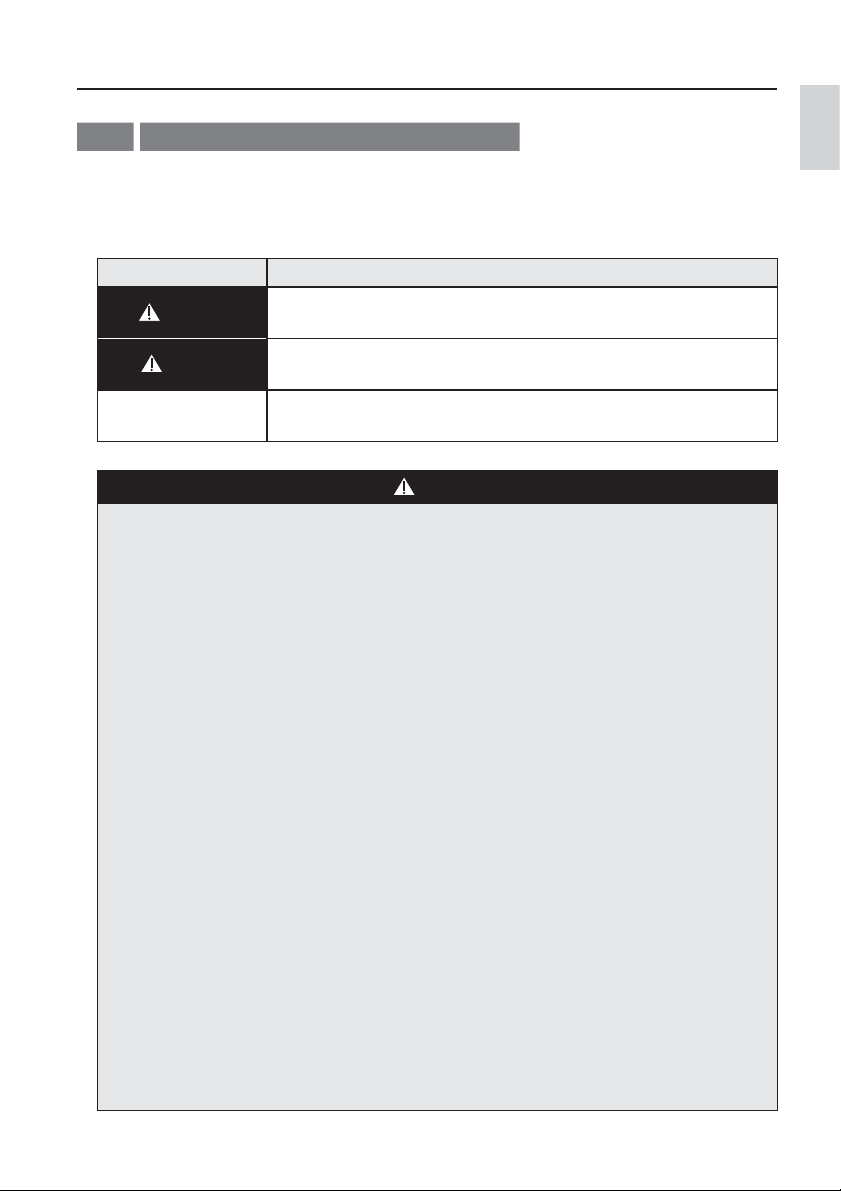

ŘPlease read these precautions carefully and use only as intended or instructed.

ŘSafety instructions are intended to avoid potential hazards that could result in personal injury or damage

to the device. Safety instructions are classified as follows in accordance with the seriousness of the risk.

Class Degree of Risk

WARNING

CAUTION

NOTICE

ŘDo not disassemble, adjust or alter the motor or handpiece except as recommended by NSK in this Operation

Manual.

ŘDo not handle the AC power cord or any other components of this system with wet hands. Touching electrical

devices with wet hands may result in electric shock.

ŘAvoid splashing water into or near the control unit. Otherwise it could cause short circuits and lead to fire and/or

electric shock.

ŘDo not allow any impact on to the product. Do not drop the product. Doing so might cause electric shock or

malfunction.

ŘDo not operate this product close to patients with cardiac pacemakers. It may affect the function of pacemaker.

ŘKeep this product away from explosive substances and flammable materials. Also, do not use this product on or

near patients who have been administered flammable anesthesia, such as dinitrogen monoxide.

ŘIf the product overheats or smells like burning, immediately turn OFF the power switch, disconnect the power

plug (by pulling the plug, not the cable) and contact your Authorized NSK Dealer.

ŘWhen using of this equipment adjacent to or stacked with other equipment, this equipment and the other

equipment should be observed to verify that they are operating normally.

ŘConnect the handpiece to the motor, rotate before using to check for motor/handpiece vibration, noise or

overheating. If any abnormalities occur, stop using the product immediately and contact your Authorized NSK

Dealer. (Refer to "3-9 Check before treatment")

ŘShould the product function abnormally during use, stop using the product immediately and contact your

Authorized NSK Dealer.

ŘIf the product has not been used for a long period, rotate the motor/handpiece and check for noise, vibration or

overheating before use.

<Motor, Handpiece (Option)>

ŘImmediately after a treatment (within 1 hour), perform maintenance and then store the motor and the handpiece.

Failure to properly maintain the motor and the handpiece may lead to overheating, causing infection, burn

injuries or product failure. Follow maintenance procedures as instructed in this manual and operation manual of

the handpiece.

Hazard that could result in serious injury or damage to the device if the

safety instructions are not correctly followed.

Hazard that could result in light or moderate injury or damage to the device

if the safety instructions are not correctly followed.

General product specification information highlighted to avoid product

malfunction and performance reduction.

WARNING

English

3

Page 5

Introduction

CAUTION

ŘPlace the most priority on patient safety.

ŘThe product is designed only for clinical dental use by qualified personnel. This product must not be used for oral

surgery, implants or dental laboratory work.

ŘThis product may be used only by Dental Professionals, such as Dentists in dental clinics or other medical

premises including hospitals.

ŘThe product must be used in a dental clinic, hospital or other dental institution.

ŘThe user shall be responsible for any judgment that relates to the application of this product to a patient.

ŘThe user is responsible for the operational control, maintenance and continual inspection of this product.

ŘDo not use the product outside the specified use environment. It may cause malfunction. (Refer to “8-1

Specifications”)

ŘOperators and all others in the area must wear eye protection and a mask when operating this handpiece.

ŘUse only the AC adapter, AC power cord provided with the product. Never use other AC adapters. Doing so might

cause a malfunction.

ŘThe AC power cord is the means to cut off commercial power supply. Make sure that the AC power cord can be

pulled out from the power outlet without delay in an emergency. Do not place any articles within 15cm of the AC

power cord.

ŘWhen dirt adheres to the control unit, main unit or AC Adaptor, turn OFF the power, wipe off the dirt with a firmly

wrung moist cloth, and then wipe thoroughly with a soft, dry cloth.

ŘDo not use the following fluids to wipe, immerse or clean the product; strong / super acid water, strong acid /

alkaline chemicals, chlorine-containing solutions, solvents such as benzene or thinner. (Refer to “5. Post-use

Maintenance”)

ŘPerform regular function and maintenance checks. (Refer to “6-3 Periodical Maintenance Checks”)

ŘThis product is rated Medical Electrical equipment. EMC (Electromagnetic compatibility) is described in the

documentation included. Installation and use of this product requires special precautions regarding EMC

according to the EMC information. (Refer to “10. EMC Information (Electromagnetic Compatibility Information”))

ŘPortable and mobile RF communications equipment can affect Medical Electrical equipment. Do not use RF

equipment near the product.

ŘUse only authorized components. Use of other components might impair the EMC performance of the product.

ŘMake sure that each part is properly connected. Improper connections might cause faulty operation, LED lighting

failure and water or air leakage.

ŘThe AC power cord included with the product has the length of 2 meters. Bundle and fix the extra cord to prevent

the operator or the patient from inadvertently stepping on it.

<Control Unit, Main Unit>

ŘWhen disconnecting the AC power cord, motor cord or other cords, hold the cords by their plug and pull the plug

out. Holding and pulling the cord might snap the wiring in the cord and cause a malfunction.

ŘWhen installing the control unit, motor and other components, provide enough room to avoid bending or twisting

the tubing or the cord.

ŘDo not sterilize the control unit, main unit, AC adapter, AC power cord, motor cord.

4

Page 6

Introduction

<Motor, Handpiece (Option)>

ŘThe output torque changes according to the type of handpiece connected to the motor, operating conditions

and other factors. Be sure to use a handpiece made by NSK. (Refer to “4-4 Contra-Check Function”) Use of a

handpiece made by a different manufacturer might cause trouble such as disparity between the preset and the

output torque.

ŘEnsure that the motor has completely stopped rotating before handling. Connecting or disconnecting the

handpiece while the motor is rotating may result in injuries or damage the handpiece.

ŘDo not point the light illuminated from the motor and handpiece directly into patient's or operator's eyes. Doing

so might damage the eyes.

ŘThe motor is delivered in a non-sterile condition and must be performed steam sterilization prior to use.

ŘDo not lubricate the motor. It may cause overheating and product failure.

ŘUse moisture- and dust-free air as the supply air. Mixing in of moisture might cause malfunction or heat

generation.

ŘConnect only ISO 9168-compliant, Type 2 (Midwest 4 holes), or Type 3 (ISO-compliant standard 4 holes with

light) tubing.

ŘMake sure to supply coolant air. Otherwise, the motor/handpiece surface might reach a temperature of 51°C or

higher.

NOTICE

Ř

During operation, the motor and motor cord may affect computers, LAN cables in the vicinity of use.

Noise could be heard during operation near a radio receiver.

Ř

Use the "Power Key" to turn ON/OFF the power on a daily basis. If the system is not used for a long

period of time or if the system malfunctions, turn OFF the power of the main unit, disconnect the

power cord, and drain water from main unit, tubing and motor cord.

Ř

For details on handling the handpiece, refer to the Operation Manual of the handpiece.

Ř

Only authorized service personnel should inspect inside the product by following the instructions in

the service manual. Leave the product with your Authorized NSK Dealer, if necessary.

Ř

No special training is required to operate this device.

Ř

Drain water from the main unit, turbing and motor cord, if the main unit is not to be used for a long

time.

English

5

Page 7

Introduction

Classification of Equipment

1-4

ŘType of protection against electric shock:

- Class ll equipment

ŘDegree of protection against electric shock:

- Type B applied part:

ŘMethod of sterilization or disinfection recommended by the manufacturer:

- Refer to ”5-3 Packaging, Sterilizing, Drying and Storage (Motor)”

ŘDegree of protection against ingress of water as detailed in the current edition of IEC 60529:

- Control Unit: IPX0 (Not protected)

ŘDegree of safety of application in the presence of a flammable anesthetic mixture with air or with oxygen

or nitrous oxide:

- Equipment NOT suitable for use in the presence of a flammable anesthetic mixture with air or with oxygen

or nitrous oxide.

ŘMode of operation:

- Intermittent operation ( ON:3 min, OFF:10min.)

(Applied parts: Motor, Handpiece)

6

Page 8

Components

2

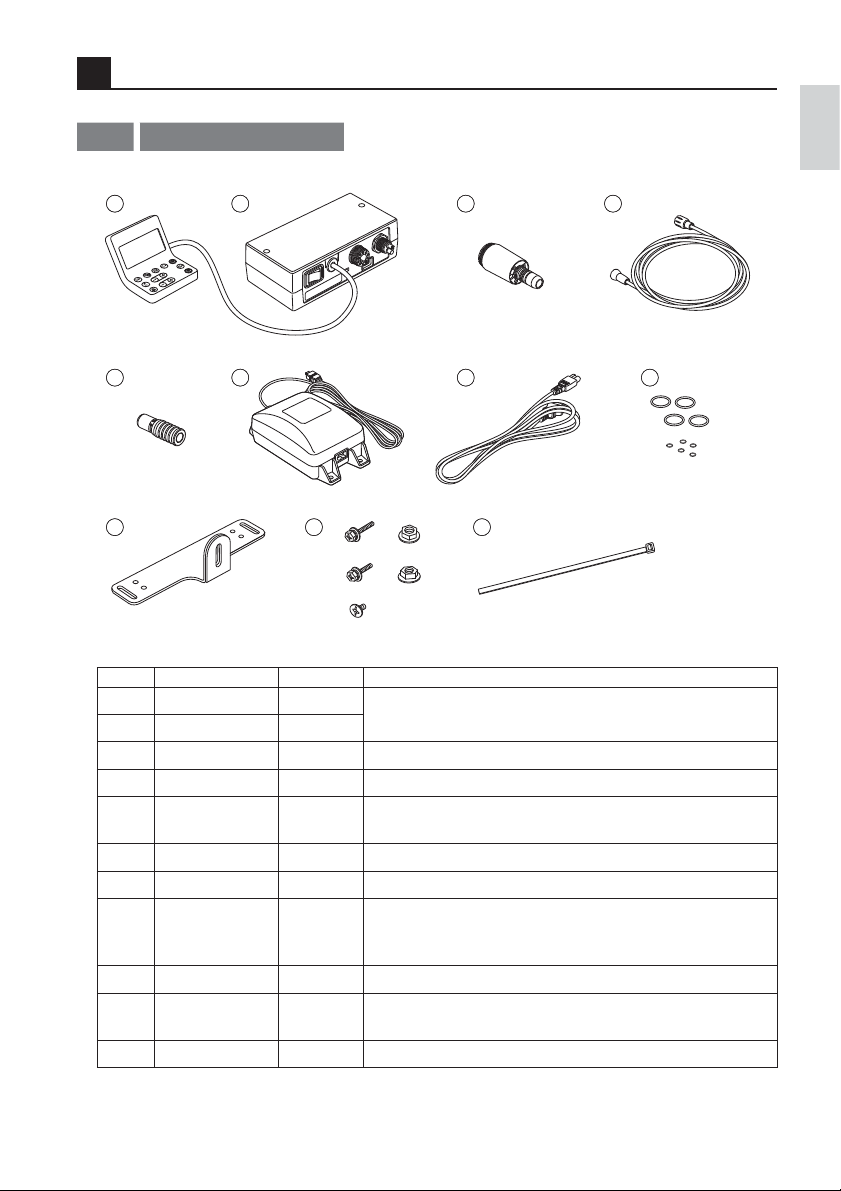

2-1

List of components

1

5

9

No. Part Name Quantity Remark

1 Control unit 1

2 Main unit 1

3 Motor 1 4 Motor cord 1 Cord length: 1.8m

5 Purge nozzle 1

6 AC adapter 1 Cord length: 5m

7 AC power cord 1 Cord length: 2m

8 O-ring set 1set

9 Mounting bracket 1 For the main unit

Mounting screws

10

and nuts

11 Cable tie 2 For fixing the link cable

2

6

10 11

The control unit and the main unit are connected via the link cable.

For purging excess oil (compatible with ISO 3964-compliant

handpieces)

Spare parts

For the motor insert joint (Black: 3pcs., Blue: 1 pc.)

For the pipes at the rear side of the motor (Black: 5 small pcs.)

1set

M5x30 screw (2 pcs.), M4x30 screw (2 pcs.), M4 flat head screw (2

pcs.), M5 nut (2 pcs.), M4 nut (2 pcs.)

3

7

English

4

8

7

Page 9

Components

Part Names of Control Unit and Main Unit

2-2

Link cable

(cable length: 1m)

LCD Display

Control panel AC power cord connector

< Control Unit > < Main Unit >

Power switch

Motor cord connector

Tubing connector

8

Page 10

Components

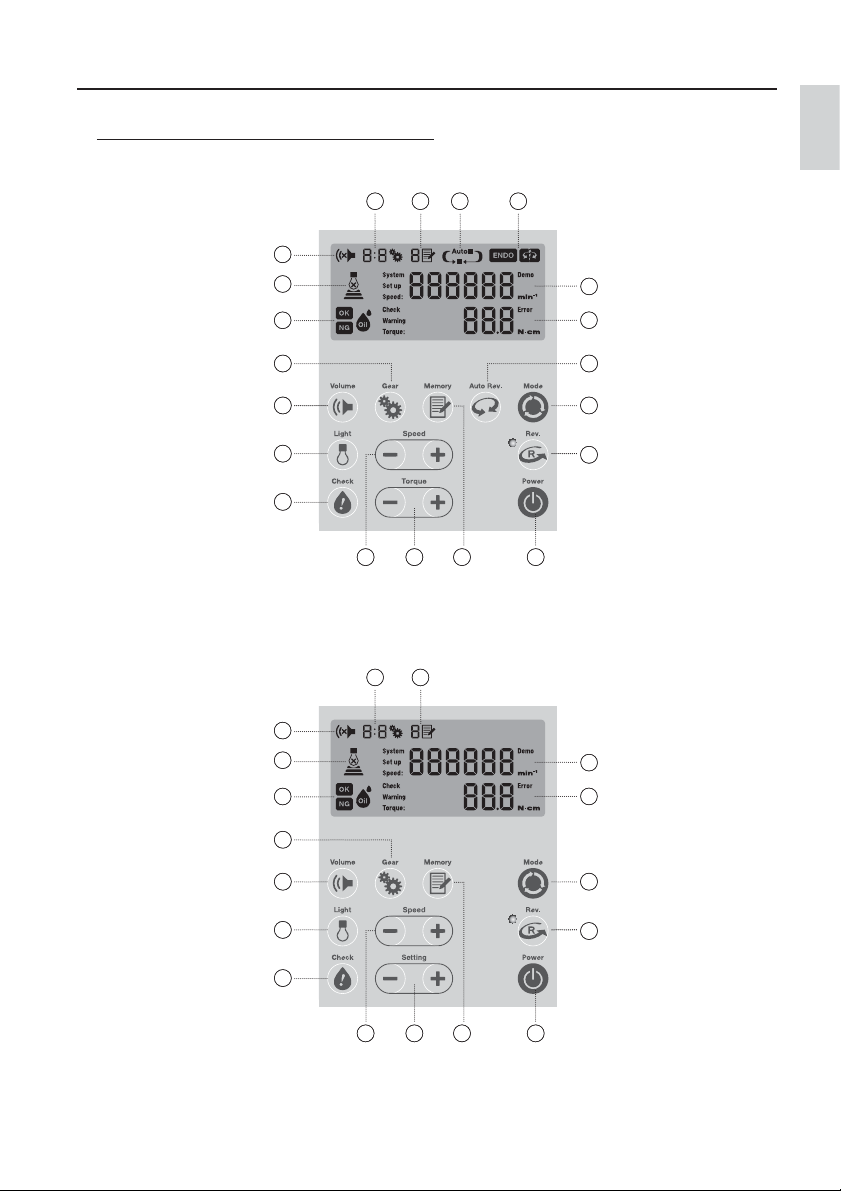

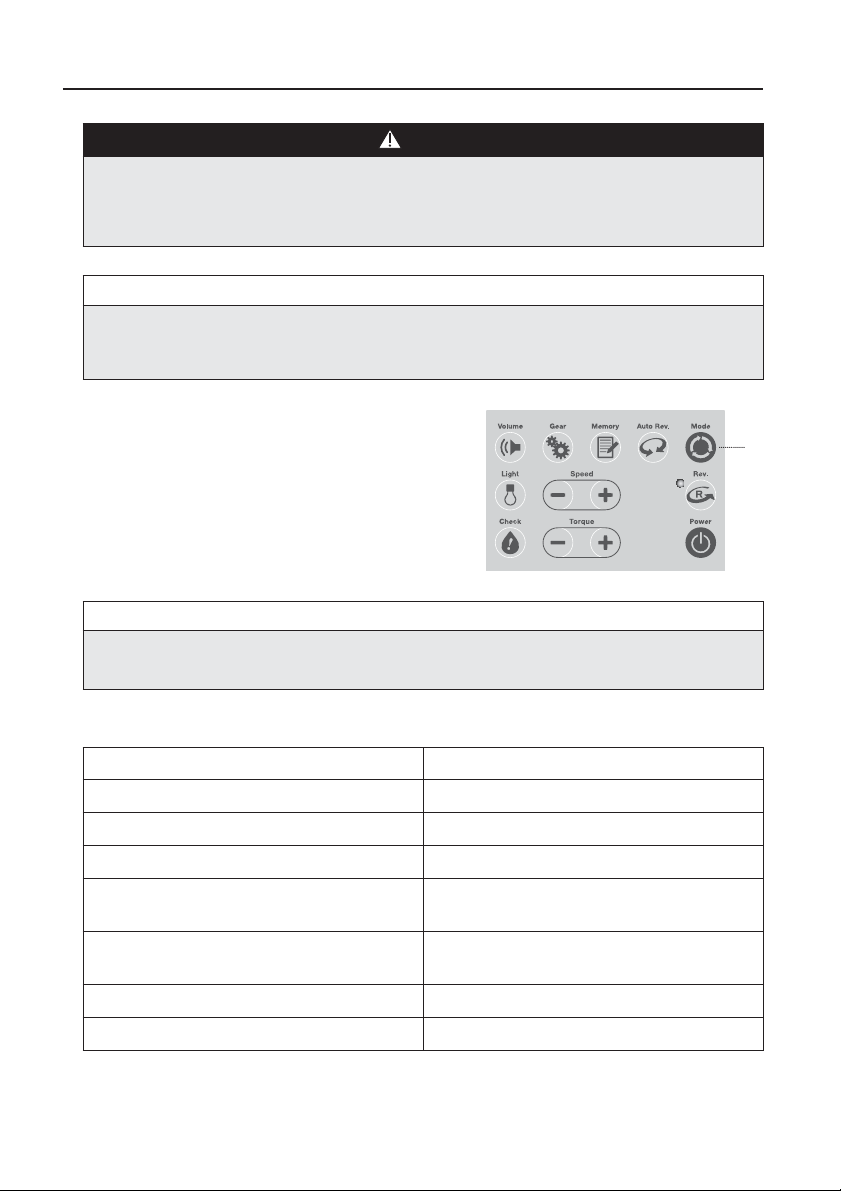

LCD Display and the Control Panel of the Control Unit

< NLZ E >

F3G2H

E

D

C

8

7

6

5

4

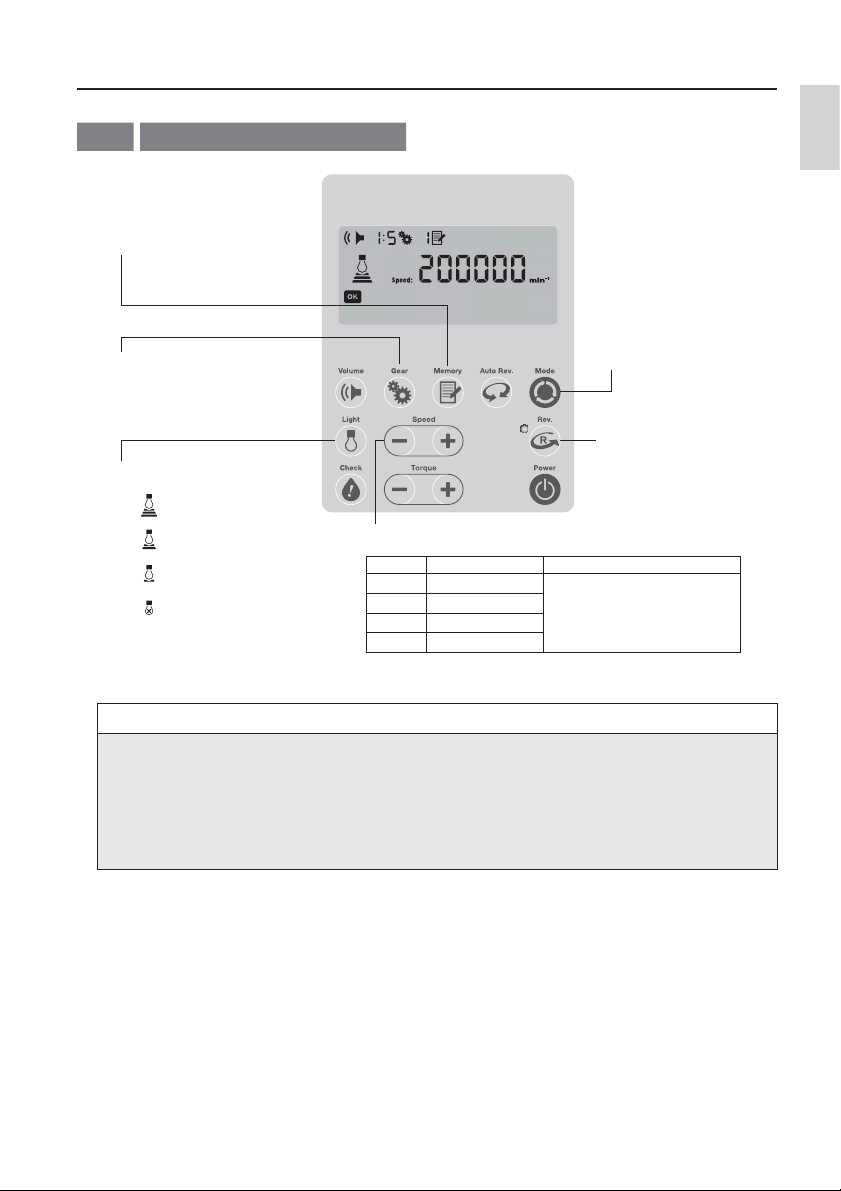

< NLZ >

F3G

English

I

A

B

9

10

11

1

E

D

C

8

7

6

5

4

2

A

B

10

11

1

9

Page 11

Components

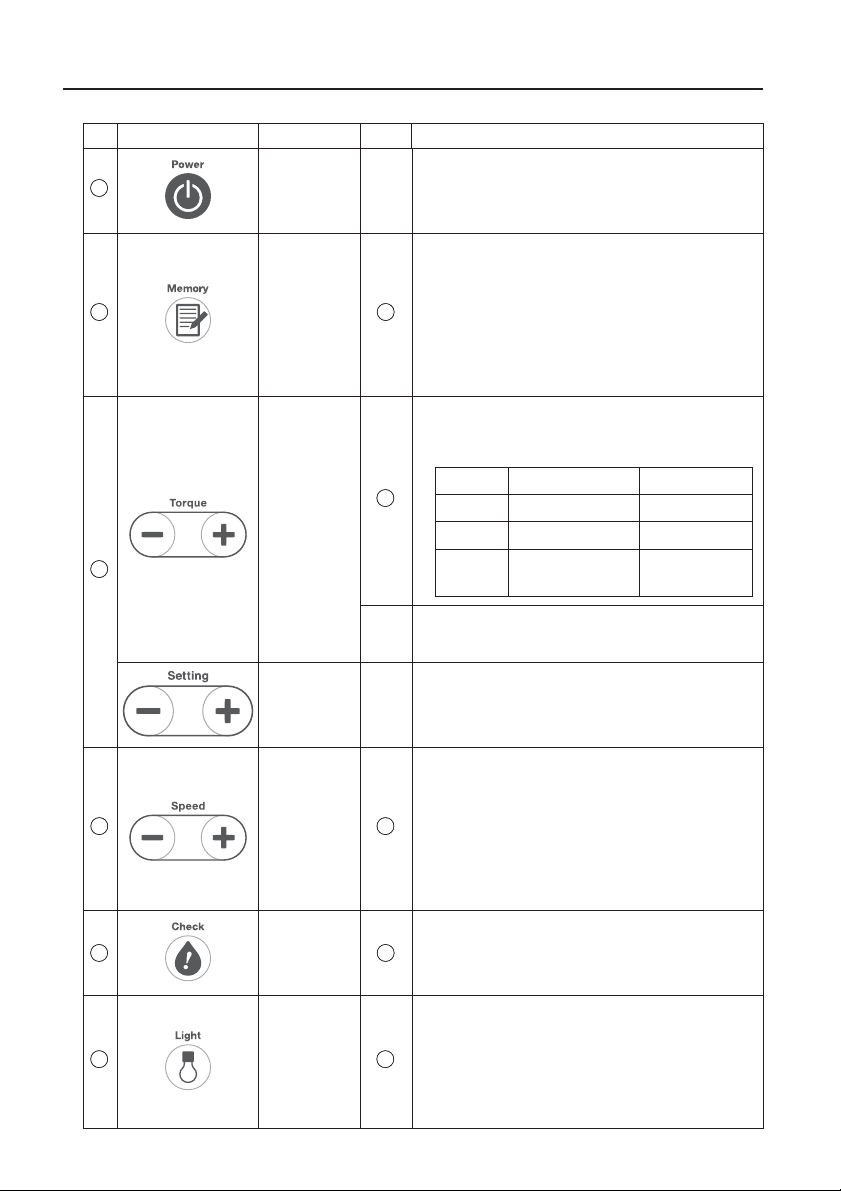

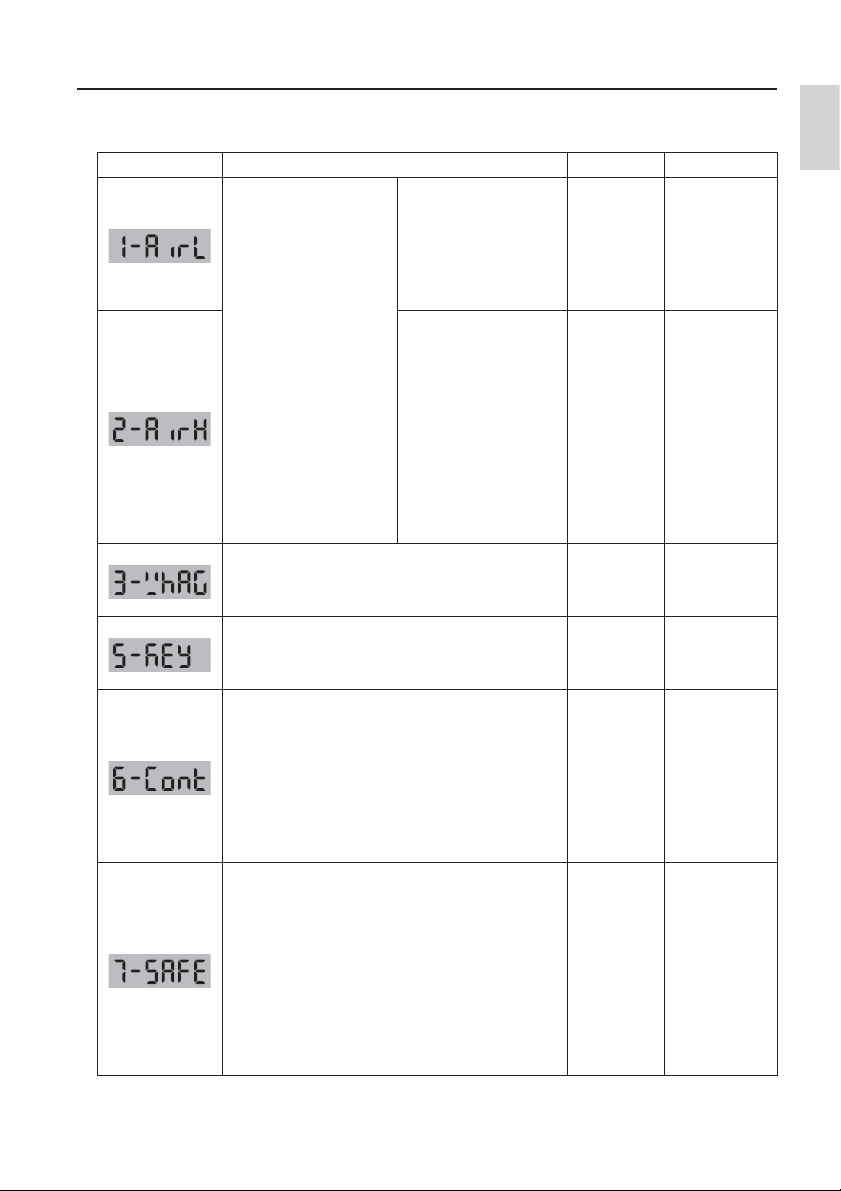

No. Key Name Display Function

1

2

3

Power Key -

Memory Key

Torque Key

(NLZ E)

Setting Key

(NLZ)

Press once to turn ON the power. When the power is ON,

hold it down for more than two seconds to turn OFF the

power

In General Application Mode:

Motor speed can be adjusted between 100 and

40,000 min-1.

G

In Rotary Endo Mode:

Motor speed can be adjusted between 100 and

6,000 min-1.

*Display value changes interlocked with the gear ratio.

When gear ratio is set by each time pressing this key you

can adjust the torque.

Rotary Endo Mode

B

Gear Ratio Torque Range (N·cm) Increment (N·cm)

1:1 0.3 - 3.0 0.1

4:1 0.8 - 6.0 0.4

6:1 1.0 - 6.0 1.0 - 1.2:0.2

Change the setting as described in “3-8 Changing the

settings for various functions”

Change the setting as described in “3-8 Changing the

settings for various functions”

1.2 - 6.0:0.6

In General Application Mode:

Motor speed can be adjusted between 100 and

40,000 min-1.

4

5

6

Speed Key

Check Key

Light Key

A

In Rotary Endo Mode:

Motor speed can be adjusted between 100 and

6,000 min-1.

*Display value changes interlocked with the gear ratio.

Check the status of the handpiece as described in “4-4

C

Contra-Check Function”

Set light intensity (Strong·Moderate·Weak·OFF)

By each time pressing this key you can change the

volume from OFF -> intensity 1 -> intensity 2 -> intensity

D

3 and then back to OFF again

* The light can be turned on for 5 seconds by pressing the

key while the motor is stopped.

10

Page 12

Components

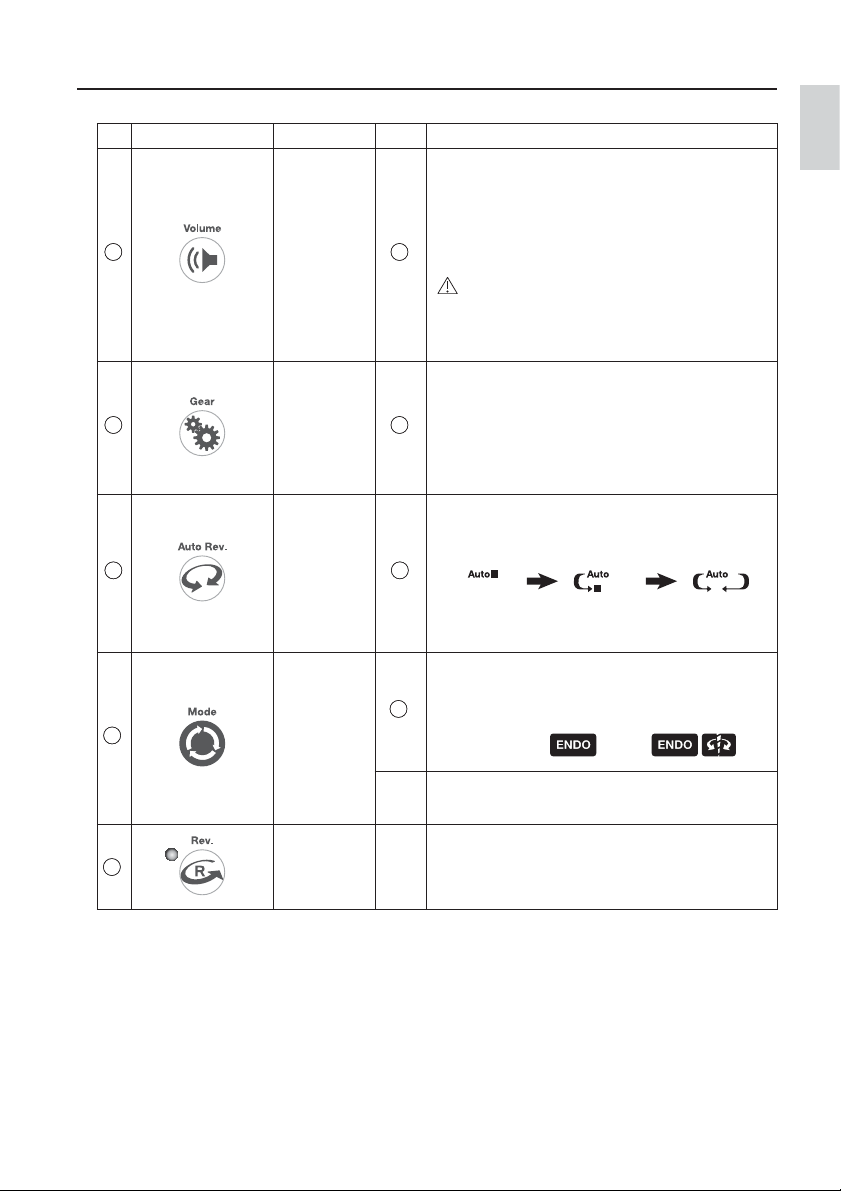

No. Key Name Display Function

Set the volume of the notifying sound generated when

reaching a set torque limit value or when errors occur

(High·Low·OFF)

By each time pressing this key you can change the

7

Volume Key

volume from OFF -> volume 1 -> volume 2 and then

E

back to OFF again

CAUTION

When the volume is set to OFF, there will be no alarm

sound. Care should be taken when using the system with

the volume set to OFF.

By each time pressing this key you can switch the gear

ratio

8

Gear Key

from 1:5 -> 1:1 -> 4:1 -> 6:1 -> and then back to 1:5

F

again – in General Application Mode

from 1:1 -> 4:1 -> 6:1 -> and then back to 1:1 again –

in Rotary Endo Mode

By each time pressing this key you can switch the mode

Auto Rev. Key

9

(NLZ E)

*Rotary Endo

Mode Only

between AUTO STOP -> AUTO REVERSE STOP -> AUTO

REVERSE FORWARD and then back to AUTO STOP again

H

AUTO STOP

AUTO REVERSE

STOP

Toggles between 3 application modes as below

Mode Key

(NLZ E)

10

Setting Mode

I

General

Application Mode:

No display

Rotary Endo

Mode:

Key

(NLZ)

Change the setting as described in “3-8 Changing the

settings for various functions”

English

AUTO REVERSE

FORWARD

Reciprocating Endo Mode:

11

Rev. Key -

The rotation direction can be changed by this key. The

LED lights up during reverse rotation.

11

Page 13

Preparations for Use

3

CAUTION

Make sure that each part is properly connected. Improper connections might cause faulty operation, LED lighting

failure and water or air leakage.

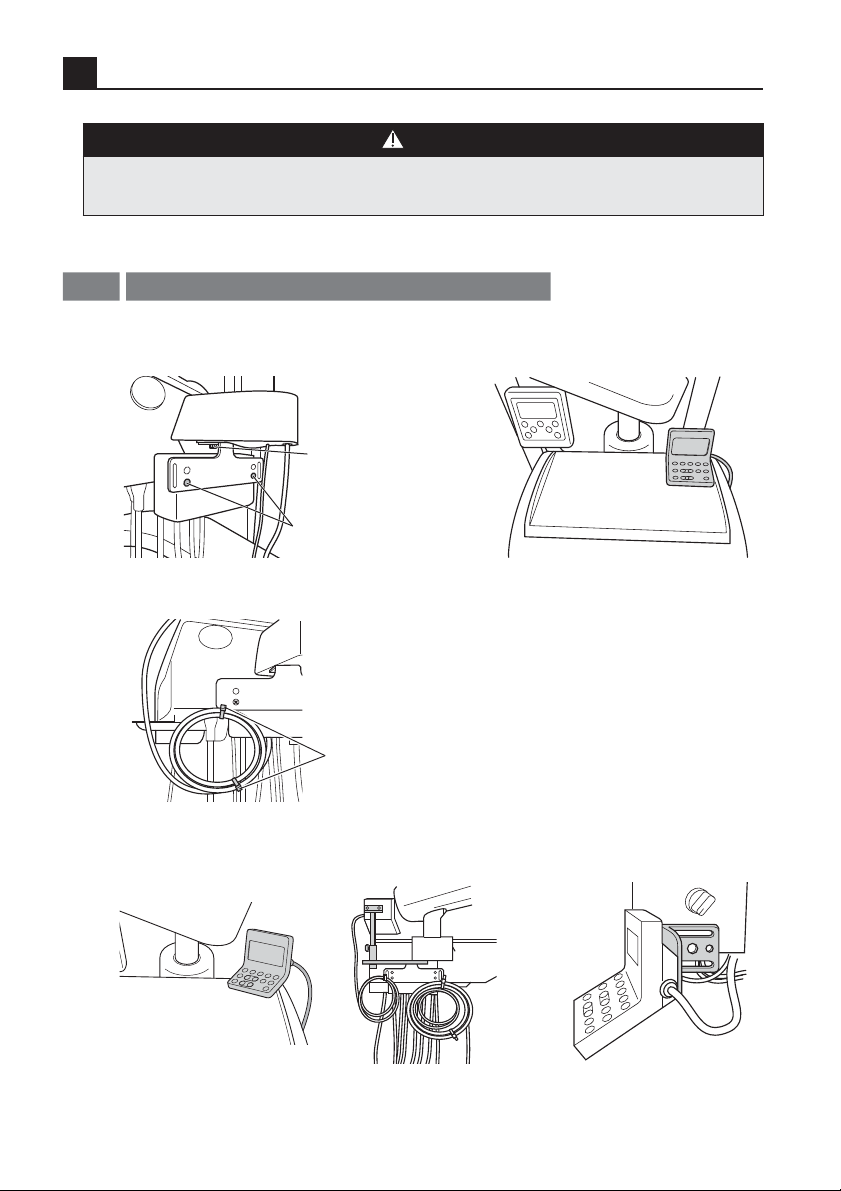

Installing the Main Unit and the Control Unit

3-1

Fix the main unit to the dental unit using the

1

screws. As shown below:

M4x30, M5x30

with the nut

( included)

M4 flat head screw

( included )

Bundle the link cable appropriately and fix it by cable tie.

3

Cable tie

(included)

If you wish to install as shown below, optional parts are available for purchase.

4

( Refer to “ 9-3 Optional Parts List ” )

2

Place the control unit on the tray of the dental

unit.

Installation example using

NLZ STAY

Installation example using

NLZ MOUNTING PLATE

12

Page 14

Preparations for Use

CAUTION

ŘKeep the main unit away from water.

ŘThe control unit incorporates a LCD panel. Place the unit where the operator can see the display.

ŘDo not bend the tubing forcibly when putting the main unit in place. Allow some extra space for tubing to avoid

pinching or bending it.

3-2

Connecting the Tubing

Align the tubing from the dental unit and the tubing connector at the

back of the main unit (1). Insert it firmly and tighten it completely

(2).

①

IN

OUT

AC28V

POWER

CAUTION

ŘBe sure that there is no air or water coming from tubing when attaching it to the main unit.

ŘUse moisture- and dust-free air as the supply air. Mixing in of moisture might cause malfunction or heat

generation.

ŘScrew the nut properly without unnatural force, when you plug in tubing connector and motor cord connector.

Avoid cross threading.

ŘConnect only ISO 9168-compliant, Type 2 (Midwest 4 holes), or Type 3 (ISO-compliant standard 4 holes with

light) tubing.

ŘAir requirement: dry, free from contamination and oil. Use a compressor with a dry air system. Install an air filter

if necessary. Blow out the lines before installation.

ŘDo not pull the tubing using more than necessary force.

ŘMake sure to supply coolant air. Otherwise, the motor/handpiece surface might reach a temperature of 51°C or

higher.

English

②

13

Page 15

Preparations for Use

C

Connecting the Motor Cord

3-3

Align the motor cord plug and the motor connector at the back of the

main unit (

1

). Insert it firmly and tighten it completely (2).

CAUTION

ŘGently screw in the nut of the motor cord plug when tightening it.

ŘDo not pull the motor cord using more than necessary force.

Connecting the AC Adapter

3-4

Check that main power switch is off. ( side)

1

OUT

A

POWER

IN

OUT

AC28V

POWER

Insert the AC adapter plug, with the arrow facing

2

up, into the AC power cord connector at the back

①

of the main unit firmly.

IN

OUT

AC28V

POWER

②

14

Page 16

Preparations for Use

3-5

Connecting the AC Power Cord

Insert the AC power cord into the inlet of the AC

1

adapter.

Insert the AC power cord plug to commercial

2

power supply outlet.

CAUTION

ŘDuring this procedure the power switch of the main unit should remain OFF.

ŘThe AC power cord included with the product has the length of 2 meters. Bundle and fix the extra cord to prevent

the operator or the patient from inadvertently stepping on it.

ŘUse only the AC adapter, AC power cord provided with the product. Never use other AC adapters. Doing so might

cause a malfunction.

ŘWhen disconnecting the AC power cord, motor cord or other cords, hold the cords by their plug and pull the plug

out. Holding and pulling the cord might snap the wiring in the cord and cause a malfunction.

3-6

Connecting / disconnecting the motor and motor Cord

English

<Connecting> <Disconnecting>

Align and insert the pins of the connector carefully and

firmly into the pin holes of the motor, and fasten the

motor nut securely.

Pin

Motor

Motor Cord NutMotor Cord Connector

Hole

Tighten

Loosen

Unscrew and detach the motor cord nut, and gently

pull out the motor cord.

15

Page 17

Preparations for Use

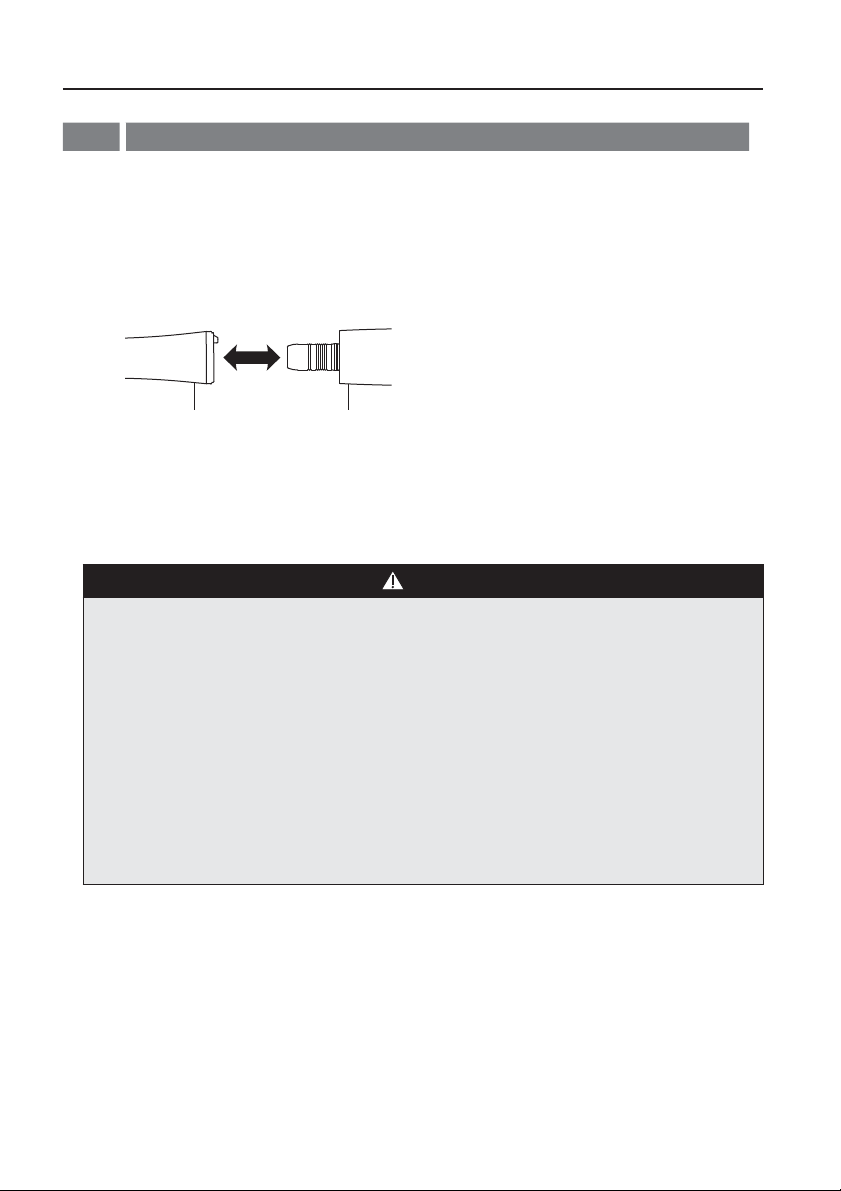

Connecting / disconnecting the motor and the handpiece (option)

3-7

<Connecting>

Insert the E-type handpiece into the motor insert,

1

and turn until it clicks as the positioning pin on

the handpiece falls into positioning hole on the

motor.

<Disconnecting>

Simply pull out the handpiece from the motor.

MotorHandpiece (option)

Confirm that the handpiece is securely connected

2

to the motor.

CAUTION

ŘEnsure that the motor has completely stopped rotating before handling. Connecting or disconnecting the

handpiece while the motor is rotating may result in injuries or damage the handpiece.

ŘBe sure to adjust the rotation speed of the motor within the allowable rotation speed of the handpiece (option).

ŘLubricated handpiece should stand and allow oil to drain prior to steam sterilization cycle. Attach to the motor

after the excess oil has been completely drained. If the oil enters the motor, it may cause malfunction of the

motor.

ŘAfter lubrication, keep the handpiece standing apart from the motor. Connect the handpiece to the motor when

using.

ŘDo not allow water to enter the motor. It may cause malfunction of the motor.

ŘBefore each use, operate the motor outside the patient's oral cavity. If any abnormality, such as vibration, noise

or overheating occurs, stop using the product immediately and contact your Authorized NSK Dealer. (Refer to

"3-9 Check before treatment")

16

Page 18

Preparations for Use

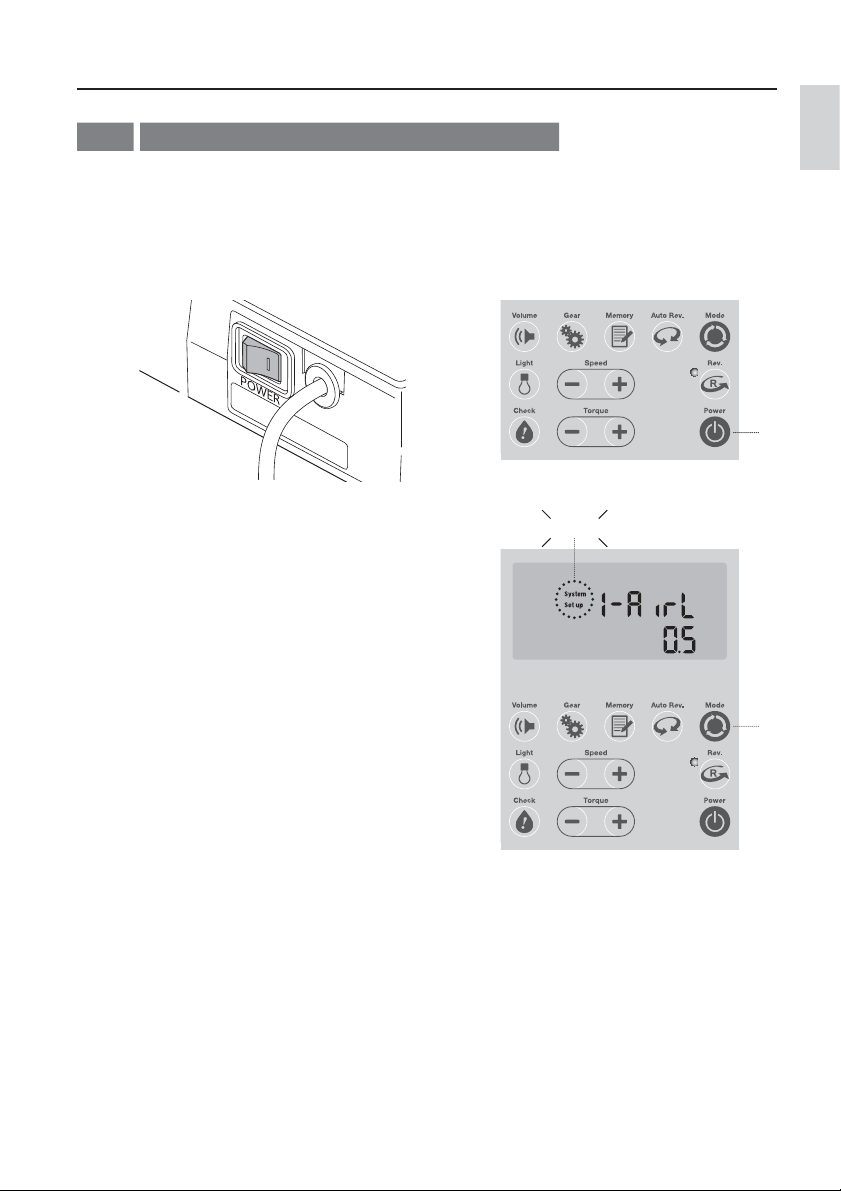

3-8

Changing the settings for various functions

Settings for various functions can be changed from their default values. This is to make the system easier

to use, when it is used for the first time after purchase. You will need to enter into the setup mode, change

the settings and save the new ones as below:

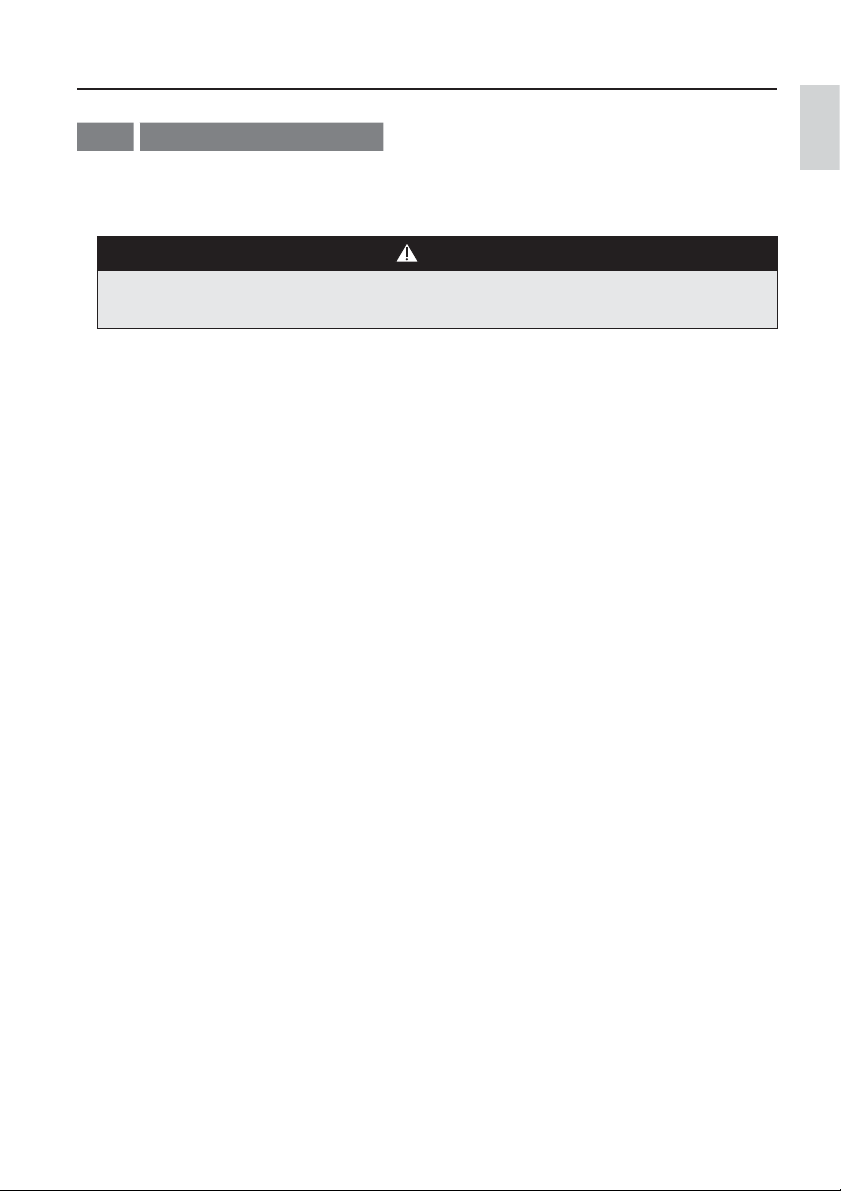

Turn ON ( I side ) the power switch on the main

1

unit.

Hold down the Mode Key* for more than two

3

seconds. With an alarm sound, "System" and

"Setup" on the LCD display will start blinking and

the system will enter into the setup mode.

* The Setting Mode Key in case of NLZ

Press the Power Key on the control unit.

2

Blinking

English

2

17

3

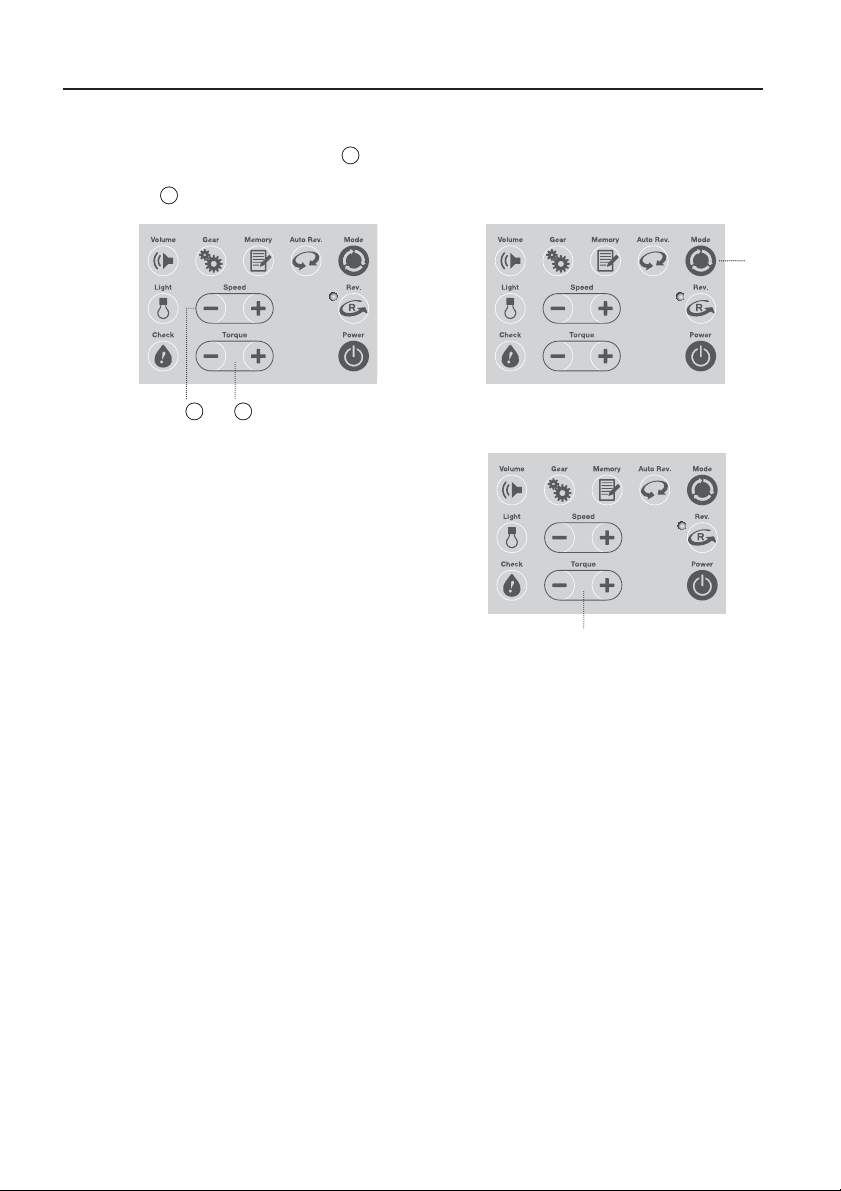

Page 19

Preparations for Use

In the setup mode, the function item can be

4

selected using the Speed Key (+/-) (

the value can be changed using the Torque Key

(+/-)* (2).

* The Setting Key (+/-) in case of NLZ

1

2

4-

4-

Change the settings by pressing the Torque Key

6

(+/-). * The Setting Key (+/-) in case of NLZ

1

), and

Once a value is changed, the new value will

5

blink. Press the Mode Key quickly to save the

new value. Once saved, this new value will stop

blinking.

6

5

18

Page 20

Preparations for Use

<Setting each function item>

Display Function item Factory Setting Setting Range

Air pressure for motor

startup speed:

This is the lower limit

Foot Air Calibration:

This function enables

you to use the maximum

speed 40,000 min-1, even

though the air pressure

of the dental unit is not

high enough, by setting

air pressures for “motor

startup speed” and

“maximum motor speed”.

Delay time for the light:

This function sets the delay time for the white illumination

lamp going off after the motor stops.

The notifying sound :

This function sets the volume for the operation tone

when a key is pressed.

Contra-Restriction:

This function automatically slows down and stops the

rotation of the motor when the checking result through

Contra-Check is either “OIL” or “NG”. The motor cannot

be activated when the checking result is “NG” blinking

which shows the status of handpiece defect. (Refer

to “4-4 Contra-Check Function” and “4-8 Overheat

Prevention”)

Contra-SAFE:

This is a function to stop the rotation of the motor when

continuous motor high-load current is detected with a 1:5

increasing handpiece.*

In this mode, there are selectable three sensitivity levels:

Fast, standard and Slow and the “Fast” setting offers

the most sensitive response. (Refer to “4-8 Overheat

Prevention”)

*Use NSK handpieces : the model of Z95L, Z85L, X95EX,

X95L, X95, M95L, M95, X85L, X85 of 1:5 Gear Ratio.

of the air pressure at

which the motor starts to

operate.

Air pressure for maximum

motor speed:

This is the upper limit of

the air pressure at which

the motor will run at its

maximum speed.

This value can be set

only when there is an

air supply at a pressure

of equal or higher than

1.5bar.

0.5bar

(0.05MPa)

1.8bar

(0.18MPa)

3 seconds

High=2

ON=1

Standard=2

English

0.3 – 3.0bar

(0.03 - 0.3MPa)

(@ 0.1bar

increments)

1.5 - 3.0bar

(0.15 - 0.3MPa)

(@ 0.1bar

increments)

0 - 10 seconds

(@ 1sec.

increments)

High=2

Low=1

OFF=0

ON=1

OFF=0

Fast=3

Standard=2

Slow=1

No stop=0

19

Page 21

Preparations for Use

WARNING

NSK recommends to always activate both functions of " Contra-Restriction" and "Contra-SAFE" because using

these functions under “Off” or “No stop” may increase the probability or severity of overheating of defective or

poorly maintained handpieces.

NOTICE

Set the lower air pressure limit at motor start-up, lower than the upper air pressure limit at maximum

rotation of the motor.

After you are finished making changes, hold down the

7

Mode Key again for more than two seconds to return to

the regular screen.

NOTICE

Notifying sound will not be generated when the sound volume is set to OFF. Be aware of this while using the

system when the sound volume setting is OFF.

7

<Notifying sound during key operation>

Items Notifying sound

When turning on the power 1 short beep

When turning off the power 1 short beep followed by 1 long beep

When pressing the keys 1 short beep

When pressing and holding the Speed Key/Torque Key

When reaching upper/ lower setting limit, when

becoming inoperable

When switching to the function setting mode 1 long beep

When storing into the memory 2 short beeps

1 short beep followed by successive short beeps while

the key is being pressed.

3 short beeps

20

Page 22

Preparations for Use

3-9

Check before treatment

ŘBefore each use, operate the motor outside the patient's oral cavity.

ŘMake sure the light is working properly and there is enough water spray.

CAUTION

If any abnormality, such as vibration, noise or overheating occurs, stop using the product immediately and contact

your Authorized NSK Dealer.

English

21

Page 23

Operation Procedure

4

Refer to “2-2 Part Names of Control Unit and Main Unit”, which explains the functions of the system in

detail.To start operation, insert the power cord plug into an outlet and turn ON the equipment. The LCD

Display will light. This product has two power control functions. The "Power Key" on the control panel and

the "Power Switch" on the main unit. Use the "Power Key" to turn ON/OFF the power on a daily basis. Use

the "Power Switch" to turn OFF the power when the equipment is not being used for a long period of time

or when the equipment is malfunctioning.

<Mode explanation>

Both NLZ Motor Set and NLZ E Motor Set provide general application mode which is used for dental

restoration and prophylaxis. In this mode, the rotation speed can be adjusted.

The “Rotary Endo Mode” and “Reciprocating Endo Mode” are used for the endodontic procedure, which

are provided only under NLZ E Motor Set.

Rotary endo mode provides low rotation speed for use with gear ratio 1:1, 4:1, and 6:1 handpieces.The

value of rotation speed and torque can be adjusted.

(Refer to “4-2 Rotary Endo Mode (NLZ E Only) <Auto Reverse Function>)

Pressing the “Check” key to perform “Contra-Check” Function before use, the status of a handpiece can

be evaluated as “OK”, “OIL”, “NG” or “NG Blinking”. When the handpiece is evaluated “OK”, the ContraCheck Function works as a torque calibration. (Refer to “4-4 Contra-Check Function)

Under the reciprocating endo mode, automatic unequal bidirectional rotation is provided. The user can not

alter the preset parameters.

<Mode selection>

System General Mode Rotary Endo Mode Reciprocating Endo Mode

NLZ Motor Set

NLZ E Motor Set

ݲ

ݲݲݲ*

Not Available Not Available

*The “Reciprocating Endo Mode” can be operated only with the NLZ Endo Contra Angle handpiece and WaveOne file.

(Refer to “4-3 Reciprocating Endo Mode (NLZ E only)”)

22

Page 24

Operation Procedure

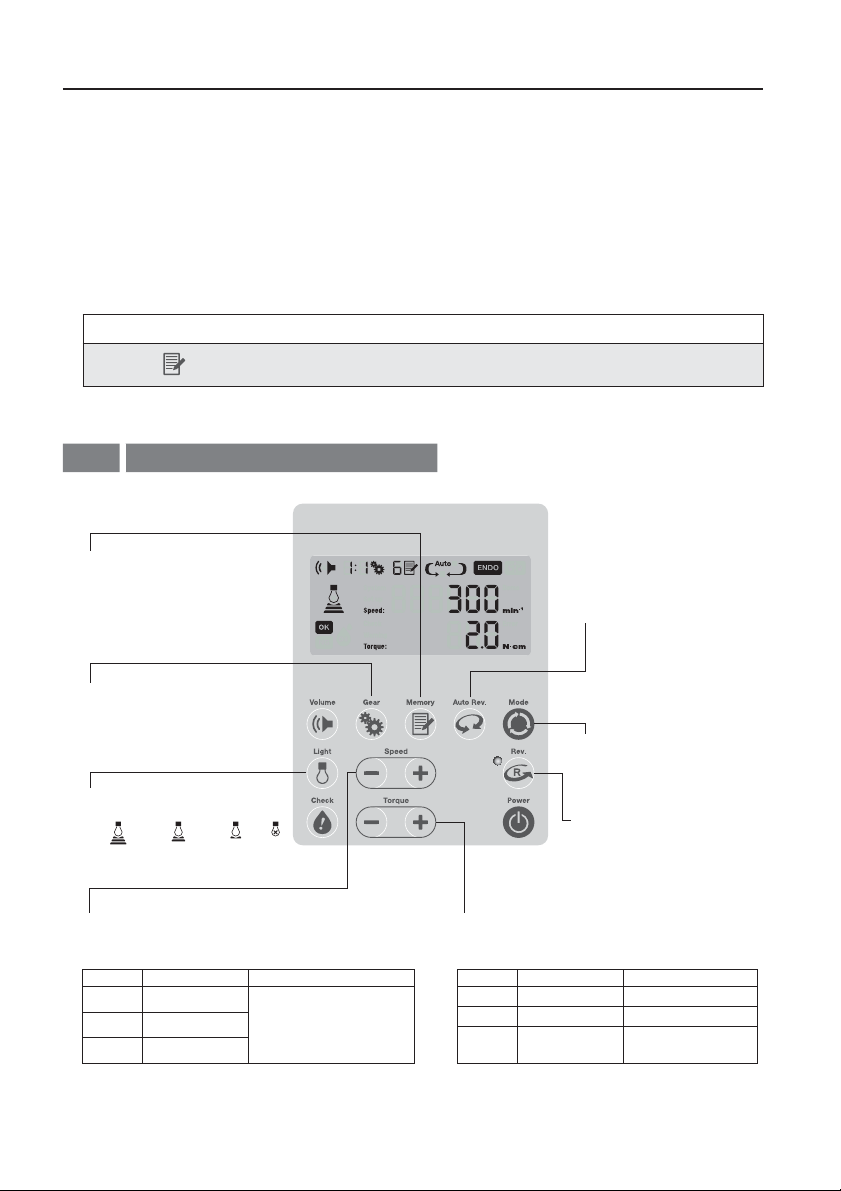

4-1

General Application Mode

Select the program # - 6

2

programs can be selected

Select the gear ratio

3

according to the handpiece

1:5, 1:1, 4:1, 6:1

Set the light intensity

6

Strong

Moderate

Weak

OFF

Select the General

1

Application Mode

(NLZ E only)

Select the rotation

5

direction, FWD / REV

Select the proper speed required for the application

4

Gear Ratio Rotation Speed (min-1) Setting range (min-1)

1:5 500 – 200,000 20 – 100:10 Increment

1:1 100 – 40,000

4:1 30 – 10,000

6:1 20 – 6,600 50,000 – 200,000:5,000 Increment

100 – 1,000:100 Increment

1,000 – 5,000:500 Increment

5,000 – 50,000:1,000 Increment

English

NOTICE

ŘSince the NLZ Endo contra angle handpiece is only for endodontic treatment, it cannot be used for General

Application Mode.

ŘThe rotation speed of the bur, mounted to the handpiece, depends on the gear ratio of the handpiece.

ŘThe actual rotation speed is displayed during operation. The Max set speed is displayed when stopped.

ŘThe max set speed can be adjusted even during rotation by pressing the Speed Keys on the control panel.

Adjust the water spray of the handpiece at the dental unit

7

Contra-Check

8

Perform Contra-Check before treatment. (Refer to “4-4 Contra-Check Function”)

23

Page 25

Operation Procedure

The motor operation will be controlled by the foot pedal of the dental unit (also called Rheostat). Pressing the

9

pedal all the way down will run the motor up to the Max speed set at step 4

Memory setting

10

Press and hold the Memory Key for more than 2 seconds. After 2 short beeps the memory sign will stop blinking

and gear ratio and speed will be memorized in the selected program number (M1 through M6 is shown, so that

up to 6 programs can be stored in memory).

NOTICE

A blinking indicates that the program is not stored in the memory yet.

Rotary Endo Mode (NLX E only)

4-2

Select the program # - 6

2

programs can be selected

Select the gear ratio

3

according to the handpiece

1:1, 4:1, 6:1

Set the light intensity

Set the light intensity

8

OFFStrong Moderate Weak

Select the Auto-Reverse

6

Mode: AUTO STOP /

AUTO REVERSE STOP /

AUTO REVERSE

FORWARD

Select the Rotary Endo

1

Mode

Select the rotation

7

direction, FWD / REV

Select the proper speed recommended by

4

file manufacturers

Gear Ratio Rotation Speed (min-1) Setting range (min-1)

1:1 100 – 6,000

4:1 30 – 1,500

6:1 20 – 1,000

20 – 500:10 Increment

500 – 1,000:50 Increment

1,000 – 6,000:100 Increment

24

Select the proper torque recommended

5

by file manufacturers

Torque Setting Range (N・cm)

Gear Ratio

1:1 0.3 – 3.0 0.1 Increment

4:1 0.8 – 6.0 0.4 Increment

6:1 1.0 – 6.0

Setting range (N・cm)

1.0 – 1.2:0.2 Increment

1.2 – 6.0:0.6 Increment

Page 26

Operation Procedure

NOTICE

ŘThe rotation speed of the file, mounted to the handpiece, depends on the gear ratio of the handpiece.

ŘThe actual rotation speed is displayed during operation. The Max set speed is displayed when stopped.

ŘThe max set speed can be adjusted even during rotation by pressing the Speed Keys on the control panel.

Adjust the water spray of the handpiece at the dental unit

9

Turn off the water flow of the dental unit due to lack of water flow circuit inside the NLZ Endo contra angle

handpiece.

Contra-Check

10

Perform Contra-Check before treatment. (Refer to “4-4 Contra-Check Function”)

NOTICE

Depends on the connected contra-angle handpiece, a short beep sound may occur when the rotation

starts, which is not a malfunction.

The motor operation will be controlled by the foot pedal of the dental unit (also called Rheostat). Pressing the

11

pedal all the way down will run the motor up to the Max speed set at step 4

CAUTION

ŘThe torque displayed in the Rotary Endo Mode varies according to the type of the handpiece or using condition.

Make sure to use an NSK-manufactured handpiece and perform the Contra-Check before use. The Contra-Check

will carry out torque calibration. (Refer to “4-4 Contra-Check Function”)

ŘUsing handpieces not manufactured by NSK may cause malfunction including discrepancy between set torque

limit value and the actual output torque.

English

Memory Setting

12

Press and hold the Memory Key for more than 2 seconds. After 2 short beeps the memory sign

stop blinking and gear ratio, rotation speed, torque and auto-reverse mode will be memorized in the selected

program number (M1 through M6 is shown, so that up to 6 programs can be stored in memory).

NOTICE

A blinking

indicates that the program is not stored in the memory yet.

25

will

Page 27

Operation Procedure

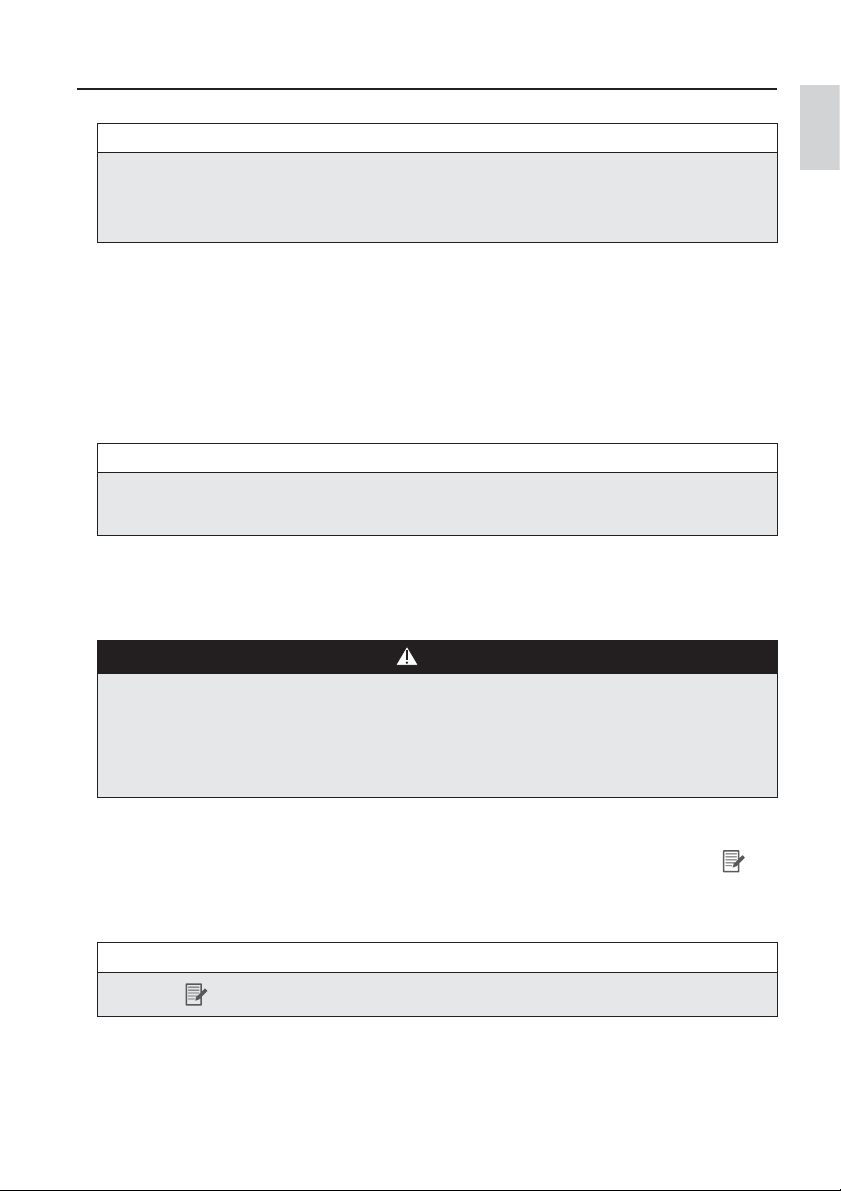

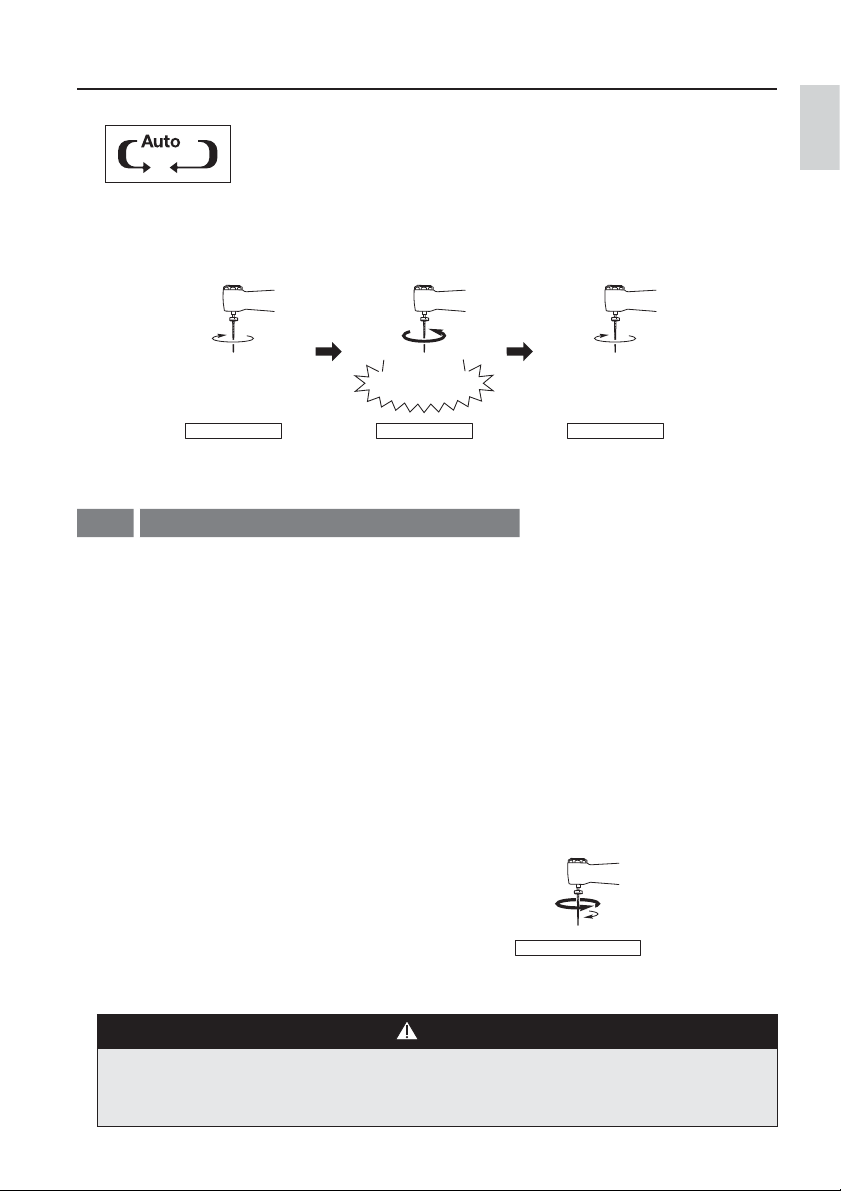

<Auto Reverse Function>

By each time pressing the Auto Rev. Key you can switch the mode between AUTO STOP -> AUTO

REVERSE STOP -> AUTO REVERSE FORWARD and then back to AUTO STOP again

AUTO STOP AUTO REVERSE STOP AUTO REVERSE FORWARD

Explaining the above 3 Modes:

AUTO STOP

The handpiece starts in forward rotation. When a load reaches the set torque limit value, the motor rotation

stops with a beep sound. If the load continues, the set speed on the LCD Display starts blinking until the

foot pedal is released.

Load lower than

the set torque limit value

Forward rotation Stop

When load reaches

the set torque limit value

AUTO REVERSE STOP

The handpiece starts in forward rotation. When a load higher than the torque limit is applied, the file will

rotate in reverse with a beep sound. When the load is removed, the motor rotation stops and the set speed

on the LCD Display starts blinking until the foot pedal is released. If you want the motor to rotate again, repress the foot pedal.

Load lower than

the set torque limit value

Forward rotation Reverse rotation Stop

Load higher than

the set torque limit value

Reverse rotation when load continues,

stop when load is removed

26

Page 28

Operation Procedure

AUTO REVERSE FORWARD

The handpiece starts in forward rotation. When a load higher than the torque limit is applied,

the file will rotate in reverse with a beep sound. When the load is removed, the file will return to normal

rotation (forward) automatically.

Load higher than

the set torque limit value

Reverse rotation when load continues,

return to forward rotation

when load is removed

4-3

Load lower than

the set torque limit value

Forward rotation Return to forwardReverse rotation

Reciprocating Endo Mode (NLZ E only)

The Reciprocating Endo Mode is preset for the NLZ Endo (6:1 reduction Endodontic Contra Angle

Handpiece) using with the WaveOne

®

reciprocating file made by DENTSPLY SIRONA Group. In this mode,

automatic unequal bidirectional rotation is provided and the user can not alter the preset parameters.

Please use the WaveOne

(WaveOne

®

is a registered trademark of DENTSPLY SIRONA Inc.)

Select the Reciprocating Endo Mode.

1

®

Reciprocating file to operate in this mode.

Turn off the water flow of the dental unit due to

2

lack of water flow circuit inside the NLZ Endo

contra angle handpiece.

English

Contra-Check

3

Perform Contra-Check before treatment. (Refer

to “4-4 Contra-Check Function”)

The motor operation will be controlled by the foot

4

pedal of the dental unit (also called Rheostat).

Unequal bidirectional rotation

CAUTION

The Reciprocating Endo Mode has been designed and verified exclusively for the NLZ Endo contra angle handpiece

and WaveOne® reciprocating file manufactured by DENTSPLY SIRONA Group. Using other contra angle handpieces

or files may result in gear’s premature wear, overheating, or file breakage.

27

Page 29

Operation Procedure

Contra-Check Function

4-4

This function evaluates the state of the Contra Angle / Straight Handpiece as:

“OK” : The check result is acceptable

“OIL” : Needs a maintenance such as lubricating with oil

“NG” : There is a serious malfunction

WARNING

ŘDamaged handpiece, Foreign materials in the handpiece, Inadequate Maintenance, and Water Entrance are

risks for overheating/burn event. Those abnormalities appear as vibration, noise or overheating.Check handpiece

for those abnormalities before treatment, or it may cause overheating of handpiece and cause burn in patients.

ŘContra-Check function niether measures the temperature of overheating handpiece directly nor assures to

maintain handpiece safe temperature. As possible risk of overheating still remains even after Contra-Check,

make sure to always check for above abnormalities before treatment.

ŘIf any abnormality, such as vibration, noise or overheating occurs, stop using the handpiece immediately and

contact your authorized NSK dealer.

ŘThis function is only available for NSK Contra Angle /Straight Handpiece : models of Z95L, Z85L, X95EX, X95L,

X95, M95L, M95, X85L, X85 of Gear Ratio 1:5, Z25L, X25L, X25, X65L, X65, M25L, M25, M65 of Gear Ratio

1:1, Z15L, X15L, X15, M15L, M15 of Gear Ratio 4:1 and the NLZ Endo Contra Angle Handpiece of Gear Ratio 6:1.

ŘUse of incorrect handpieces may cause overheating.

NOTICE

ŘPerform this function before treatment to check the handpiece status.

ŘContra-Check function includes torque calibration under the Rotary Endo Mode.

Torque displayed in the Rotary Endo Mode varies according to the type of handpiece or it’s using condition. This

is a function to recognize the rotation torque of the attached handpiece and to adjust the generated torque into

the set torque limit value.

ŘAfter the Handpiece is evaluated as “NG” or “OIL” through the Contra-Check, the motor rotation is automatically

slowed down and stopped if the risk of overheating is detected. (Refer to “3-8 Changing the settings for various

functions”)

28

Page 30

Operation Procedure

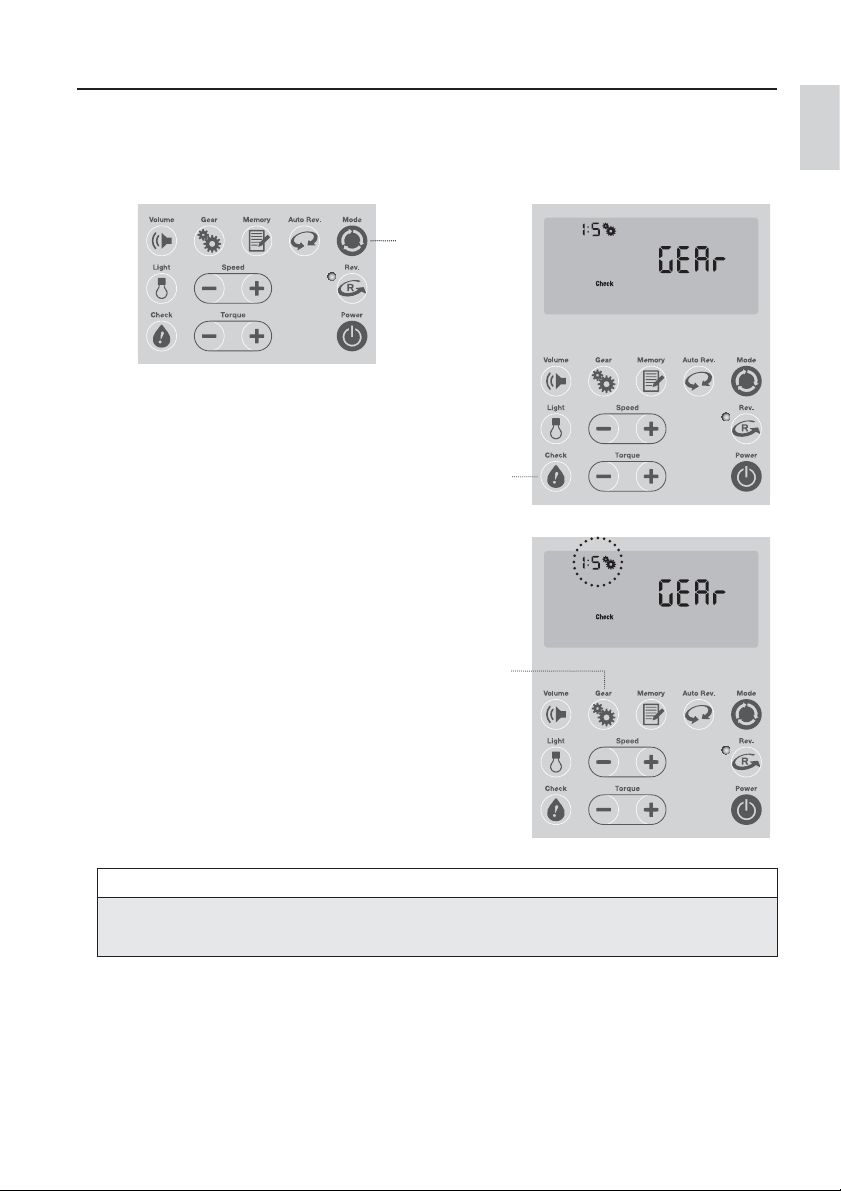

Select the Mode (NLZ E only)

1

Select the gear ratio of the attached handpiece

3

General Application Mode 1:5, 1:1, 4:1, 6:1

Rotary Endo Mode 1:1, 4:1, 6:1

Reciprocating Endo Mode 6:1 (Fixed)

Hold down the Check Key for more than 2

2

seconds to start up the Contra-Check. The “GEAr”

and the gear icon will start blinking after a short

beep sound.

1

2

3

English

NOTICE

Make sure that the correct gear ratio of the handpiece is selected before checking process, otherwise it will lead to

wrong results.

29

Page 31

Operation Procedure

After selecting the correct gear ratio, press the

4

Check Key again to start the checking process.

4

The motor automatically starts to operate at low speed and then accelerates to high speed to automatically

5

measure the state of the handpiece.

CAUTION

ŘStart the checking process while holding the handpiece. Checking, while leaving the handpiece on the handpiece

stand, may cause drop and damage of the handpiece and injury to user or patient.

ŘTo avoid any problems, care should be taken as the motor operates and rotates automatically.

ŘDuring the checking process, the system is designed to stop in an emergency by pressing any key on the control

panel. So, if you sense any danger, press any key on the control panel for an emergency stop.

NOTICE

Checking is possible with or without a bur/file.

Refrain from using burs which are not specified in the instruction of handpiece, otherwise it will lead to wrong

results.

Once the process is completed, "Fin" will be

6

displayed on the screen after a beep sound along

with the <Checking Result> displayed on the

screen as one of these cases:

30

Page 32

Operation Procedure

<Checking Result>

The check result is acceptable. After use, follow maintenance procedures as instructed in the

operation manual of the handpiece.

WARNING

If any abnormality, such as vibration, noise or overheating occurs, stop using the handpiece immediately even the

display shows the check result of "OK". We recommend repair or use new handpiece. Contact your Authorized

NSK Dealer.

The handpiece needs maintenance such as lubricating with oil.

WARNING

If you get the same result even after performing maintenance, the handpiece condition might have deteriorated.

We recommend repair or use new handpiece. Contact your Authorized NSK Dealer.

The handpiece is not functional.

WARNING

English

ŘIf you get the same result even after performing maintenance, the handpiece may be broken. We recommend

repair or use new handpiece. Contact your Authorized NSK Dealer.

ŘContinuing to use this handpiece should cause serious injuries due to abnormal heat generation.

The handpiece is damaged and motor cannot be activated in this situation!

Blinking

WARNING

ŘWhen you get this result, the handpiece is broken. Stop using the handpiece and change it to other handpiece.

We recommend repair or use new handpiece. Contact your Authorized NSK Dealer.

ŘContinuing to use this handpiece causes serious injuries due to abnormal heat generation.

31

Page 33

Operation Procedure

Press the Check Key again to return to the regular

7

screen.

7

CAUTION

ŘThere are cases where the motor works and the checking result is “OK” even though the bur or the file does not

rotate. In such case, the gears of the handpiece are worn out and damaged. Please contact your Authorized NSK

Dealer.

ŘContra-Check does not guarantee safety of handpieces in any environment.

Perform pre-use inspections ("3-9 Check before treatment") together with Contra-Check to ensure safety before

use.

NOTICE

Depending on the type of lubricator and maintenance unit, oil may build up inside the handpiece and have bad

impact on the checking process. If "OIL" or "NG" is displayed:

(1) Insert the purge nozzle (Refer to “2-1 List of

components”) into the rear of the handpiece, until

it clicks of a secure insertion and then insert the

tip of the air gun / syringe into the purge nozzle.

Purge nozzleAir gun / Syringe

(3) Perform the checking again.

(2) Run air with air gun / syringe for 30 seconds to

purge oil from inside the handpiece.

32

Page 34

Operation Procedure

4-5

Sound Volume (When the load exceeds the set torque limit value, Error etc.)

Press the Volume key.

1

Volume: High

Volume: Low

Volume: OFF

1

<List of Notifying Sound>

Type Notifying Sound

Rotary Endo Mode

Alarm sound for when the motor or a handpiece is overheating. Melody 3

When the motor/ handpiece is not functional, meaning the checking result of

the handpiece is “NG (blinking)”

Turning ON the power while pressing the foot pedal of the dental unit

When an error is generated: 1 short beep followed by 1 long beep.

When reaching 75% of the torque setting Melody 1

When reverse rotating Melody 2

A set of 3 short beeps continues to

sound.

English

CAUTION

Notifying sound will not be generated when the sound volume is set to OFF. Be aware of this while using the

system with the sound volume set to OFF.

33

Page 35

Operation Procedure

Last Memory Function

4-6

This function memorizes the last settings of each mode just before the power is turned OFF using the

Power key.

When the power is turned back ON, this function retains those settings of each mode.

The settings stored in this memory includes:

In <General Application Mode>

Gear ratio, rotation speed, light intensity, notifying sound volume, and memory number

In <Rotary Endo Mode>

Gear ratio, rotation speed, torque, auto reverse mode, light intensity, notifying sound volume, and

memory number

In <Reciprocating Endo Mode>

Notifying sound volume

Initializing Program (Restoring the Factory Setting)

4-7

This function allows to reset the programs of various settings (gear ratio, rotation speed, torque, auto

reverse mode) stored in the memory to the default factory setting.

By carrying out this function, various functional settings (such as air pressure for motor startup speed) as

described in “3-8 Changing the settings for various functions” will be reset to the default factory setting.

Turn OFF the power of the control unit.

1

While pressing down the Torque Key* (press +/-

2

keys simultaneously) (

Power Key (2) to turn ON the power. *Setting

key in case of NLZ.

1

1

), press and hold the

1

2-

2

2-

34

Page 36

Operation Procedure

With a short beep sound “rESEt” will be displayed

3

on the LCD Display. Press the Mode Key.

3

Press the Memory Key in the General Application Mode or Rotary Endo Mode.

5

When the memory sign stops blinking, initializing is completed.

blinking

With a long beep sound followed by a short beep

4

sound “Fin” will be displayed on the LCD Display.

With another short beep sound the display will

return to the last screen before the control unit

was turned OFF.

English

5

35

Page 37

Operation Procedure

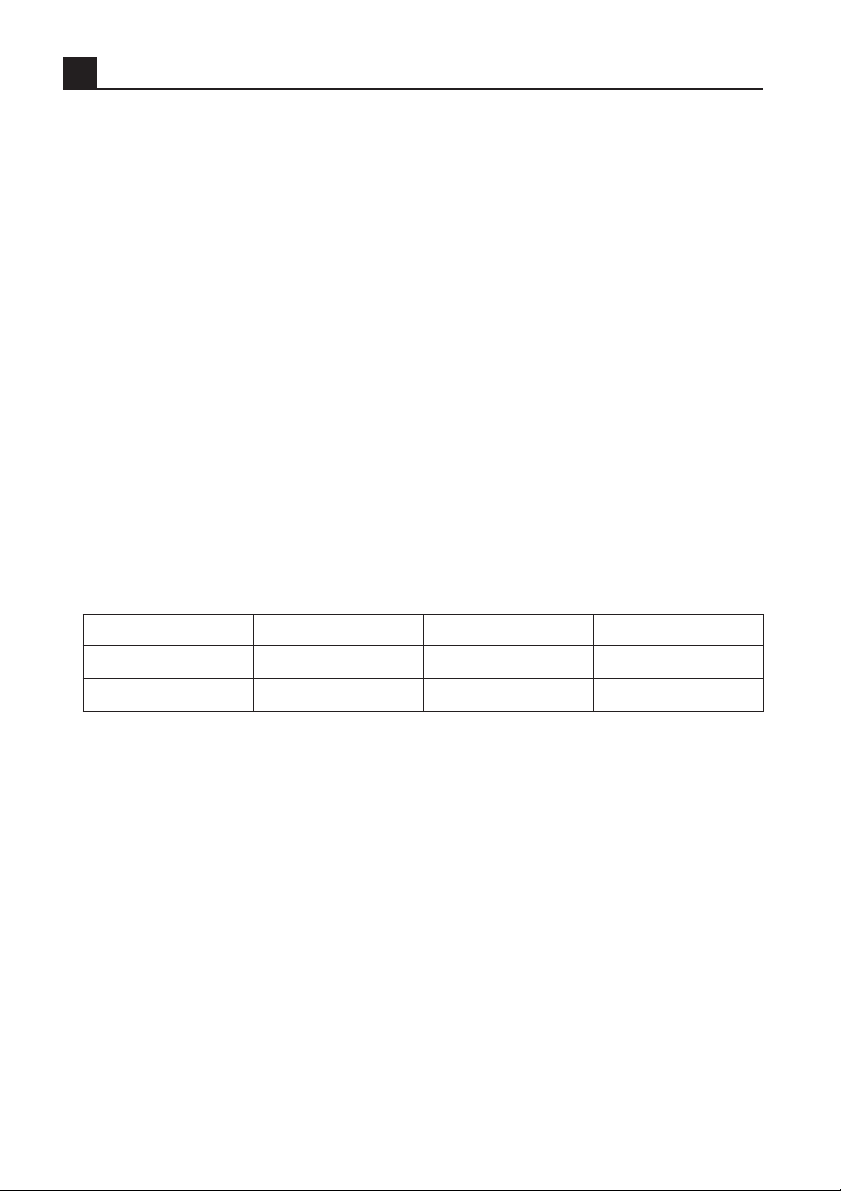

<Default Factory Setting>

Mode Memory No. Gear ratio Rotation speed (min-1) Torque (N・cm) Auto reverse mode

1 1:5 200,000

2 1:1 40,000

General

Application

Mode

Rotary Endo

Mode

3 1:1 30,000

4 1:1 20,000

5 1:1 10,000

6 4:1 3,000

1 1:1 250 1.0 AUTO REVERSE FORWARD

2 1:1 250 1.5 AUTO REVERSE FORWARD

3 1:1 250 2.0 AUTO REVERSE FORWARD

4 1:1 250 3.0 AUTO REVERSE FORWARD

5 1:1 300 2.0 AUTO REVERSE FORWARD

6 1:1 1,000 3.0 AUTO STOP

NOTICE

If necessary, take a memo of the latest settings before initializing.

Overheat Prevention

4-8

Following functions detect a risk of overheating from motor current and rotation speed and then slows

down and stops motor rotation by activating the protection circuit to prevent incidents or failure due to the

overheat of the handpiece or the motor.

<Motor Overheat Prevention Function>

This function stops the rotation of the motor when detecting

overload or a risk of abnormal heating of the motor.

”Warning” and ”HE0” will be displayed along with alarm

sound and rotation of the motor will be slowed down.

Continued use will result in motor stop and Error Code “E8” will be displayed. (Refer to “7-1 Error Code”)

36

36

Page 38

Operation Procedure

<Contra-Restriction>

This function automatically slows down and stops the rotation

of the motor when the checking result through Contra-Check

is either “OIL” or “NG”.

”Warning” and ”HE1” will be displayed along with an alarm

sound and rotation of the motor will stop after approximately

2 seconds.

Error Code “E8” will be displayed once the motor stops. (Refer to “7-1 Error Code”)

NOTICE

Refer to “3-8 Changing the settings for various functions, Contra-Restriction”. Be aware that changing the setting

to “OFF” will deactivate this function.

<Contra-SAFE>

This is a function to stop the rotation of the motor when possible risk of overheat is detected with a 1:5

increasing handpiece. Error Code “EE” will be displayed once the motor stops. (Refer to “7-1 Error Code”)

NOTICE

Refer to “3-8 Changing the settings for various functions, Contra-SAFE”. Be aware that changing the setting to “No

stop” will deactivate this function.

WARNING

English

ŘNSK recommends to always activate both functions of " Contra-Restriction" and "Contra-SAFE" because using

these functions under “Off” or “No stop” may increase the probability or severity of overheating of defective or

poorly maintained handpieces.

Ř“Contra-Restriction” and “Contra-SAFE” functions are additional features for reducing the risk of handpiece

overheat but may not assure to maintain handpiece safe temperature.

ŘIf any abnormality, such as vibration, noise or overheating occurs, stop using the handpiece immediately and

contact your authorized NSK dealer.

37

37

Page 39

Post-use Maintenance

5

CAUTION

ŘFollow local rules, regulations, and guidelines regarding the reprocessing of devices.

ŘPerform the following cleaning and disinfection quickly after treatment (within 1 hour) to remove any residue.

ŘDo not perform steam sterilization the control unit, motor cord and AC adapter, AC power cord.

ŘDo not lubricate the motor. It may cause overheating and product failure.

ŘDo not use the following fluids to wipe, immerse or clean the product; strong/super acid water, strong acid/

alkaline chemicals, chlorine containing solutions, solvents such as benzine or thinner. It may cause color change

of resin part, or corrosion of the metal part of the NLZ Motor System.

ŘSteam sterilization is recommended for the product. The validity of other sterilization methods (such as plasma

sterilization or EOG sterilization) is not confirmed.

ŘFor details on maintenance of the handpiece, check the Operation Manual of the handpiece.

ŘDo not immerse the product in disinfectant or perform cleaning with an ultrasonic washer. Doing so may cause

product failure.

After each patient, maintain the product as follows.

Cleaning at point-of use (Motor)

5-1

Always wear protective gloves, a mask, and

1

protective goggles for safety purposes and to

minimize the risk of infection.

Remove the bur/file.

3

38

Turn off power by pressing the Power Key

2

2

Page 40

Wipe the exterior of the motor attached with the

4

handpiece clean using a cloth moistened with

disinfectant or ethanol with a concentration of 60-90%.

When using disinfectant, follow the instructions given by

the manufacturer of the disinfectant.

Use a state-sanctioned disinfectant with proven

bactericidal, fungicidal, and virucidal properties.

The following disinfectants can be used in the United

States and Canada.

Example) CaviCide

Metrex)

CaviCide® and CaviWipes® are registered trademarks of

Metrex Research, LLC.

®

, CaviWipes® (manufactured by

Post-use Maintenance

English

Remove the handpiece from the motor.

5

Carry the motor to the decontamination area.

7

Remove the motor from the motor cord.

6

39

Page 41

Post-use Maintenance

Cleaning, Disinfecting (Motor)

5-2

Wipe the exterior of the motor clean using a cloth moistened with disinfectant or ethanol with a

concentration of 60-90%.

ŘWhen using disinfectant, follow the instructions given by the

manufacturer of the disinfectant.

Use a state-sanctioned disinfectant with proven bactericidal,

fungicidal, and virucidal properties.

The following disinfectants can be used in the United States

and Canada.

Example) CaviCide

CaviCide

Metrex Research, LLC.

®

, CaviWipes® (manufactured by Metrex)

®

and CaviWipes® are registered trademarks of

40

Page 42

Post-use Maintenance

5-3

Packaging, Sterilizing, Drying and Storage (Motor)

Insert the motor into an FDA-approved sterilization pouch that conforms to ISO 11607-1, and seal

1

the pouch.

Perform steam sterilization with the following conditions.

2

Type Gravity Displacement Pre-Vacuum (Dynamic Air Removal)

Temperature 132°C 132°C

Full Cycle Time 15 min. or longer 4 min. or longer

Drying Time 30 min. or longer 30 min. or longer

Store the motor in a clean location without humidity.

3

CAUTION

ŘUse an FDA-approved steam sterilizer to perform sterilization.

ŘFollow local rules, regulations, and guidelines regarding the reprocessing of devices.

ŘImmediately after sterilization is complete (within 1 hour), remove the motor from the sterilizer. Failure to do so

may cause corrosion.

ŘDo not sterilize the control unit, main unit, AC adapter, AC power cord, motor cord.

ŘDo not lubricate the motor. It may cause overheating and product failure.

ŘDo not perform steam sterilization the product with other instruments even when it is in a pouch. This is to

prevent possible discoloration and damage to the product from chemical residue on other instruments.

ŘDo not heat or cool the product too quickly. Rapid change in temperature could cause damage to the motor.

ŘTo avoid product failure, do not use a sterilizer that exceeds a cycle temperature of 136°C, including the dry

cycle. In some sterilizers, the chamber temperature may exceed 136°C. Contact the sterilizer manufacturer for

detailed information about cycle temperatures.

ŘDo not touch the product immediately after steam sterilization as it will be very hot and must remain in a sterile

condition.

ŘSteam sterilization is recommended for the product. The validity of other sterilization methods (such as plasma

sterilization or EOG sterilization) is not confirmed.

ŘKeep the product in suitable atmospheric pressure, temperature, humidity, ventilation, and sunlight. The air

should be free from dust, salt and sulphur.

ŘSterility is not guaranteed after the sterility retention period specified by the manufacturer and seller of the

sterilization pouch has elapsed. If the sterility retention period has elapsed, perform sterilization again with a new

sterilization pouch.

English

NOTICE

NSK recommends Class B sterilizers as stated in EN 13060.

41

Page 43

Post-use Maintenance

C

Cleaning, Disinfecting (Control unit, motor cord)

5-4

Turn off the power switch of the main unit.

1

POWER

Wipe the exterior of the control unit and the motor

2

cord clean using a cloth moistened with disinfectant or

ethanol with a concentration of 60-90%.

When using disinfectant, follow the instructions given by the manufacturer of the disinfectant.

Use a state-sanctioned disinfectant with proven bactericidal, fungicidal, and virucidal properties.

The following disinfectants can be used in the United States and Canada.

Example) CaviCide

®

CaviCide

®

, CaviWipes® (manufactured by Metrex)

and CaviWipes® are registered trademarks of Metrex Research, LLC.

OUT

A

42

Page 44

Maintenance

6

6-1

Replacing the O-rings (Motor insert)

If a deteriorated O-ring makes it difficult to attach the

handpiece or causes water or air to leak, replace the

O-ring.

Using a needle or other pointed tool, remove defective

O-rings from the motor insert section, and fit new O-rings

into the O-ring grooves.

CAUTION

The blue O-ring is thinner than the other three O-rings.

When inserting new O-rings, make sure that they are

inserted in the correct grooves as shown in the figure.

English

O-ring (Blue)

O-ring (Black)

43

Page 45

Maintenance

Replacing the O-rings (Motor rear side)

6-2

If water or air leaks from the motor and motor cord

connection, replace the O-ring(s).

Using a needle or other pointed tool, remove the defective

O-ring(s) from the pipe at the motor rear section, and fit

new O-ring(s) into the O-ring groove(s).

(Air circuit: 2 pcs., water circuit: 2 pcs., coolant air

circuit: 1 pc.)

If an O-ring deteriorates, the following phenomena might occur:

-Water leakage, no water discharge

-Air leakage, no air discharge

-Generation of vibration

-Handpiece becomes difficult to attach or remove

NOTICE

Refer to “9-2 Spare Parts List” to identify the correct parts.

CAUTION

44

Page 46

Maintenance

6-3

Periodical Maintenance Checks

Every 3 months, perform periodical maintenance checks, referring to the check sheet below. If any

abnormalities are found, contact your Authorized NSK Dealer.

Points to check Details

Rotation

Rotate the motor/handpiece and check for abnormalities such as abnormal vibration, noise, and

overheating.

English

45

Page 47

Troubleshooting

7

Error Code

7-1

If the motor stops due to an abnormality such as a malfunction, overload, overheat, etc. it automatically

checks the state of all components, detects the cause of the abnormality and displays a warning and error

code on the LCD panel of the control unit.

Warning Description of Warning Action (Check / Remedy)

The handpiece has been used after the

HE1

HE0

* If you continue using the product, the motor will stop and error code “E8” will be displayed.

Error Code Description of error Action (Check / Remedy)

checking result through Contra-Check was

either “OIL” or “NG”.<Contra-Restriction> *

Overload or a risk of abnormal heating of the

motor detected. <Motor overheat prevention

function> *

E0 The motor shaft is locked. Check if the handpiece is connected properly.

E1 Detected over current in the circuit.

Detected a higher motor speed than the rated

E2

value.

E3 The motor drive IC generated an error signal.

E4 Detected high temperature of FET. Allow the unit to cool down and try again

E5 Detected an overvoltage input to the unit.

E6 Detected an overvoltage of an LED light. Check the LED light connection.

Detected a residual overvoltage when the

E7

motor was started.

A handpiece heat generation error was

detected.

E8

A motor heat generation error was detected. Leave the motor until it cools down.

E9 The motor does not start up. Check the motor connection.

EC Data cannot be saved to EPROM (Memory). Turn the power OFF and then ON again.

ED Signals from the sensor cannot be read. Check the connection of the motor to motor cord.

An increasing handpiece heat generation error

EE

was detected.

EF Detected an under-voltage input to the unit.

Perform maintenance of the handpiece and then

check the handpiece by <Contra-Check>.

Avoid overloading the handpiece with heavy cutting,

etc. and wait for the warning to disappear.

Avoid overloading the handpiece with continuous

heavy cutting, etc.

Press the foot pedal again to remove the error.

Check proper connection of AC adaptor and AC

power cord.

Wait for approx. 5 sec., then press the foot pedal

again.

If the error does not disappear, check if the motor

and motor cord are connected properly.

Perform maintenance of the handpiece, and then

check the handpiece by the Contra- Check.

Perform maintenance of the handpiece, and then

check the handpiece by the Contra- Check.

Check proper connection of AC adaptor and AC

power cord.

When an error code is displayed, stop operation of all devices immediately and perform the remedy

indicated in the table above. If the error code appears again, turn the power OFF and then ON again

and check if the error code disappears. If the error persists, the product may be broken. Contact your

Authorized NSK Dealer.

46

Page 48

Troubleshoting

7-2

Troubles and Actions

When trouble is found, check the following again before contacting your Authorized NSK Dealer. If none of

these is applicable or the trouble is not remedied even after action has been taken, a failure of this product

is suspected.

Troubles Cause Actions

The power Switch is OFF. Turn ON the power.

The AC adapter or AC power cord is

The LCD Display does not light.

The motor does not run.

The rotation speed of the motor

does not rise.

Beeps continue to sound when

turning ON the switch.

The LED does not light. Reached the end of life expectancy.

The motor heats up abnormally

during rotation.

Water leakage

Settings when the power is

turned ON are different from the

previous ones when turning off

the power.

not connected correctly.

Internal Fuse is blown, due to some

reason

The tubing, motor cord, AC adapter

or AC power cord is not connected

correctly.

The air pressure is not given, or not

proper from the dental unit.

The LCD Display shows an error

code.

The air pressure of the dental unit

is lower than the “Upper limit of the

air pressure”

You are stepping on the foot pedal

when turning on the power switch.

(Safety function)

Coolant air is not given, or not

proper from the dental unit.

The tubing, motor cord is not

connected correctly.

The power is turned OFF using the

main unit’s power switch.

Check the connection.

Contact your Authorized NSK

Dealer.

Check the connection.

Check the air pressure of the dental

unit.

Refer to the error code.

(Refer to “7-1 Error Code”)

Set the Upper limit of the air

pressure below the air pressure of

the dental unit.

(Refer to “3-8 Changing the settings

for various functions”)

Do not step the foot pedal, and turn

on the power switch.

Contact your Authorized NSK

Dealer.

Check the air pressure on the side

of the dental unit.

Check the connection. If it is

happening inside the control unit,

contact your Authorized NSK Dealer.

Previous settings will not be

retained when turning OFF the main

unit’s power switch. Turn OFF using

the control unit’s Power Key.

English

47

Page 49

Specifications

8

Specifications

8-1

Control Unit, Main Unit

Model NLZ E U (NE319): Endo function available

NLZ U (NE318): Endo function not available

Rated Input AC28V 50/60 Hz

Air Pressure 4bar (0.4MPa)

Dimensions Control Unit : W75.3 x D86.2 x H63.8 mm

Main Unit: W146 x D94.2 x H48 mm

Link Cable:1.0 m

Motor

Model NLZ

Rotation Speed 100 - 40,000 min

Max. Torque 4.2N・cm

Dimensions DØ22 x H68.8 mm

Optic White LED

Water Supply 65 mL/min or more

Chip Air Supply 1.5 L/min or more

Coolant Air Supply 6.5 NL/min or more

Use Environment 10 - 40

Transportation and Store Environment -10 - 50

-1

Temperature Humidity Pressure

℃

℃

AC Adaptor

Model NE180

Rated Input AC120V 50/60Hz 41VA

Rated Output AC28V 1.3A

Fuse Rating T1.6A/250V

Dimensions W100 x D178 x H64 mm

30 - 75%*

10 - 85%* 500 – 1,060hPa

*No Condensation

48

Page 50

Specifications

8-2

Symbol

This product can be sterilized in a steam sterilizer up to Max. 135°C.

Conforms to CE European Directive of "Medical device directive 93/42/EEC."

Manufacturer.

TUV Rhineland of North America is a Nationally Recognized Testing Laboratory (NRTL) in the United States

and is accredited by the Standards Council of Canada to certify electro-medical products with Canadian

National Standards

Consult operation instructions Class ll equipment Type B applied par

Caution, consult accompanying documents

Follow the waste of electric and electronic equipment (WEEE) Directive (2012/19/EU) for product and

accessory disposal

Marking on the outside of Equipment or Equipment parts that include RF transmitters or that apply RF

electromagnetic energy for diagnosis or treatment.

Serial number

English

Caution: U.S. Federal law restricts this device to be used by or on the order of a licensed dental professional.

GS1 DataMatrix for Unique Device ldentifier.

49

Page 51

After-sales Service

9

Warranty

9-1

NSK products are warranted against defects in manufacturing, workmanship and materials. NSK reserves the

right to analyze and determine the cause of any problem. Warranty is voided should the product not be used

in accordance with this manual or has been tampered with by unqualified personnel or has had non NSK parts

installed. Replacement parts are available for seven years beyond discontinuation of the model.

Spare Parts List

9-2

Model Order Code Remarks

O-ring Set Y1003728 For the motor insert section (Black: 3pcs., Blue:1 pc.)

O-ring D0312010050 For the motor rear side

NLZ E1152051 Motor (without a motor cord)

NLZ CD E1152061 Motor cord (1.8m)

Purge Nozzle Z1259080 NLAC (120V) Y141133 AC adapter (common with NLX nano)

AC Power Cord U438550 NLZ U BRACKET Z1322 A bracket used for mounting to the main unit.

NLZ E U U1142002 NLZ E control unit, main unit

NLZ U U1141002 NLZ control unit, main unit

50

Page 52

Afrter-sales Service

9-3

9-4

Option Parts List

Model Order Code Remarks

NLZ Endo C1130 6:1 Reduction Endodontic Contra Angle Handpiece

NLZ STAY Z1321 A stay used for mounting to the control unit.

NLZ MOUNTING PLATE Z1323 A plate used for mounting to the control unit.

NLZ CDL E1152062 Motor cord (2.2m)

Disposing product

In order to avoid the health risks of operators handling the disposal of medical equipment, as well as the

risks of environmental contamination caused thereof, a surgeon or a dentist is required to confirm the

equipment is sterile. Ask specialist firms who are licensed to dispose of specially controlled industrial

wastes, to dispose the product for you.

English

51

Page 53

EMC Information

10

Guidance and manufacturer’s declaration - Electromagnetic Emissions

The product is intended for use in the electromagnetic environment specified below. The customer or the user of the product should

assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment – guidance

RF emissions

CISPR11/EN55011

RF emissions

CISPR11/EN55011

Harmonic emissions

EN/IEC61000-3-2

Voltage fluctuations/flicker

emissions

EN/IEC61000-3-3

Guidance and manufacturer’s declaration - Electromagnetic Immunity

The product is intended for use in the electromagnetic environment specified below. The customer or the user of the product should

assure that it is used in such an environment.

Immunity test IEC/EN60601 test level Compliance level Electromagnetic environment - guidance

Electrostatic discharge(ESD)

EN/IEC61000-4-2

Electrical fast transient/burst

EN/IEC61000-4-4

Surge

EN/IEC61000-4-5

Voltage dips, short

interruptions and voltage

variations on power supply

input lines

EN/IEC61000-4-11

Power frequency

(50/60Hz) magnetic field

EN/IEC61000-4-8

NOTE: ‘Ut’ is the AC mains voltage prior to application of the test level.

Group 1 The product uses RF energy only for its internal function. Therefore, its

Class B The product is suitable for use in all establishments, including domestic

No applicable

No applicable

±(2,4)6kV contact

±(2,4)8kV air

±2kV for power supply lines

±1kV for input/output lines

±1kV line(s) to line(s)

±2kV line(s) to earth

<5% Ut

(>95% dip in Ut)

for 0.5 cycles

40% Ut

(60% dip in Ut)

for 5 cycles

70% Ut

(30% dip in Ut)

for 0.5 cycles

<5% Ut

(<95% dip in Ut)

for 5 sec

3 A/m 3 A/m Power frequency magnetic fields should

(Electromagnetic Compatibility Information)

RF emissions are very low and are not likely to cause any interference in

nearby electronic equipment.

establishments and those directly connected to the public low-voltage

power supply network that supplies buildings used for domestic

purposes.

±(2,4)6kV contact

±(2,4)8kV air

±2kV for power supply lines

±1kV for input/output lines

±1kV line(s) to line(s)

±2kV line(s) to earth

<5% Ut

(>95% dip in Ut)

for 0.5 cycles

40% Ut

(60% dip in Ut)

for 5 cycles

70% Ut

(30% dip in Ut)

for 0.5 cycles

<5% Ut

(<95% dip in Ut)

for 5 sec

Floors should be wood, concrete or

ceramic tile. If floors are covered with

synthetic material, the relative humidity

should be at least 30%.

Mains power quality should be that

of a typical commercial or hospital

environment.

Mains power quality should be that

of a typical commercial or hospital

environment.

Mains power quality should be that

of a typical commercial or hospital

environment. If the user of the product

requires continued operation during power

mains interruptions, it is recommended

that the product be powered from an

uninterruptible power supply or a battery.

be at levels characteristic of a typical

location in a typical commercial or hospital

environment.

52

Page 54

EMC Information

(Electromagnetic Compatibility Information)

Guidance and manufacturer’s declaration - Electromagnetic Immunity

The product is intended for use in the electromagnetic environment specified below. The customer or the user of the product should

assure that it is used in such an environment.

Immunity test IEC/EN60601 test level Compliance level Electromagnetic environment – guidance

Conducted RF

EN/IEC61000-4-6

Radiated RF

EN/IEC61000-4-3

NOTE 1: At 80MHz and 800MHz, the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from

structures, objects and people.

a: Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur