Page 1

000OM-E0799E

Page 2

English

Thank you for purchasing VIVA ace Motor Kit.

Please read this Operation Manual and the VIVA ace Basic Set Operation Manual carefully before use for

operating instructions and care and maintenance guidelines so that you can use it for many years to come

through a correct use.

Keep this Operation Manual within easy reach of users for future reference.

Table of Contents

English

1. User and Indications for Use .....................2

2. Precautions for handling and

operation ..................................................2

3. Package Contents.....................................6

4. Preparation for Use ...................................7

4-1 Connecting and Disconnecting

the Motor Cord and the Motor ...............................7

4-2 Connecting the Motor Cord and

VIVA ace Control Unit ...........................................8

4-3 Connecting and Disconnecting

the Handpiece (optional) ....................................... 9

4-4 Check before treatment ........................................9

5. Operation Procedure ...............................10

6. Post-use Maintenance ............................10

6-1 Preparation for Maintenance ............................... 10

6-2 Maintenance for Between Each Patient ..............12

6-3 Maintenance After Close .................................... 15

6-4 Sterilization ........................................................ 18

6-5 Maintenance of the Water Line for the Motor

and the Motor Cord ............................................ 20

7. Maintenance .......................................... 26

7-1 Replacing the O-ring ...........................................26

7-2 Periodical Maintenance Checks ...........................26

8. Troubleshooting ......................................27

8-1 Problems and Solutions ......................................27

9. Specifications .........................................28

9-1 Specifications .....................................................28

9-2 Classification of Equipment .................................28

9-3 Symbol ..............................................................28

10. After-sales Service ................................ 29

10-1 Warranty ..........................................................29

10-2 Disposing Product ............................................29

Operation procedure of this product is introduced in a movie.

Check the following URL or the QR code.

URL

http://www.nsk-dental.com/support/videos/

*This product is used connecting to VIVA ace Basic Set.

1

Page 3

1

User and Indications for Use

User : Dentist, Dental hygienist

Indications for use : The motor is intended for teeth and denture cutting, polishing and root canal treatment.

2

Precautions for handling and operation

Please read these precautions carefully and use only as intended or instructed.

Safety instructions are intended to avoid potential hazards that could result in personal injury or

damage to the device.

Safety instructions are classified as follows in accordance with the seriousness of the risk.

Class Degree of Risk

WARNING

CAUTION

NOTICE

Hazard that could result in serious injury or damage to the device if the

safety instructions are not correctly followed.

Hazard that could result in light or moderate injury or damage to the device if

the safety instructions are not correctly followed.

General product specification information highlighted to avoid product

malfunction and performance reduction.

2

Page 4

English

Precautions for handling and operation

WARNING

• Do not attempt to disassemble the product nor tamper with the mechanism except as recommended by NSK

in this Operation Manual.This may result in an injury, electric shock or fire.

• Do not touch the connection (terminal section) of the Motor and the Motor Cord. This could cause an electric

shock.

• Do not use the product when the patient or the operator is using cardiac pacemakers as there is a danger

that could affect the pacemaker.

• Keep away from explosive substances and flammable materials. Also, keep away from patients whom a

flammable anesthetic (laughing gas) is administered as this may cause fire.

• Electromagnetic waves may cause malfunction of the product. Keep away from devices that generate

electromagnetic waves. Turn off the product around ultrasonic generators (excluding the product) or electrode

knife. Keep away from communication equipment or elevators that generate electromagnetic waves.

3

Page 5

Precautions for handling and operation

CAUTION

• When operating the product always consider the safety of the patient.

• Use only as indicated.

• Users are responsible for the operational control, maintenance and periodical maintenance checks of this

product.

• Operators and all others in the area must wear eye protection, a mask, and gloves when operating this

product.

• Should the product functions abnormally, cease operation immediately and contact your Authorized NSK

Dealer.

• Do not turn the lighting of the motor directly to the eyes of the patients or the operators. There is a danger

that it may damage the eyes.

• Do not clean, immerse, or wipe with electrolyzed-oxidizing water (strong acidic water, super acidic water),

strong acidic and strong alkaline liquid medicine, solvent containing chlorine, benzene, or thinner.

(Reference : 6 Post-use Maintenance

)

• The motor is delivered in a non-sterile condition and must be autoclaved prior to use.

(Reference : 6-4 Sterilization

• Immediately wipe off any moisture, liquid medicine, solvent, or liquid disinfection on the Handpiece and Motor

Cord after use. Failure to do so may cause discoloration and deformation.

• Check for motor vibration, noise and overheating. If any abnormalities are found do not use the motor and

contact your Authorized NSK Dealer. (Reference : 4-4 Check before treatment

• Avoid excessive load and long-time use because it could cause overheating.

• Do not allow any impact on to the product. Do not drop the product. It could cause damage.

• Perform regular function and maintenance checks. (Reference : 7-2 Periodical Maintenance Checks

• If the product is not used for a long period, check for motor vibration, noise and overheating before using on

a patient.

• Portable and mobile RF communications equipment may affect Medical Electrical equipment. Do not use RF

equipment near the product.

• The temperature of the motor surface may reach up to 50 degrees depending on the condition of use. In that

case, leave the motor until it cools down before using it again.

)

)

)

4

Page 6

Precautions for handling and operation

NOTICE

• The motor and Motor Cord during operation could interfere with the computers, LAN cables in vicinity of use

or could cause noise in radio receivers nearby.

• To avoid clinical downtime, it is recommended that a spare is kept on hand in case of a breakdown during

surgery.

• Contact the Authorized NSK Dealer for repairing. The service staff of the company will take care of the

product in accordance with the service manual.

• No special training is required for this device.

• EMC (Electromagnetic compatibility) has been evaluated with the VIVA ace Control Unit and conforms to the

requirements.

English

5

Page 7

3

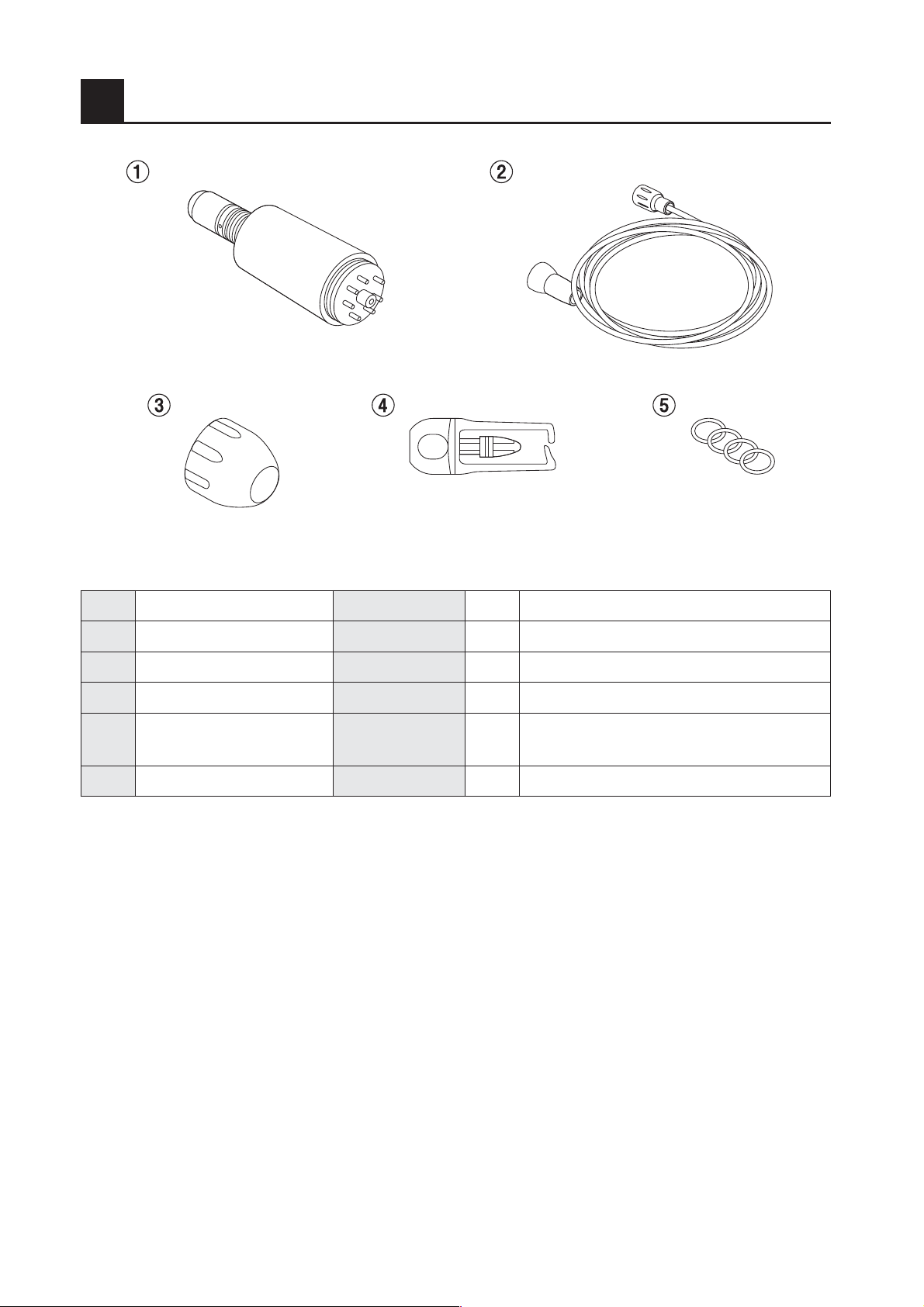

Package Contents

No. Part Name Order Code Quantity Remarks

1Motor E10400511

2Motor Cord E10400701

3 Motor Cap 20001300 1

4 Protection Plug 10001595 1

5O-ring Set Y10037281

6 Operation Manual - 1 *Not in the illustration.

Spare for replacement for Motor inserting part

(

Black 3 pieces, Blue 1 piece

-

-

-

-

Please specify the order code listed above when purchasing the spare parts.

)

6

Page 8

4

Preparation for Use

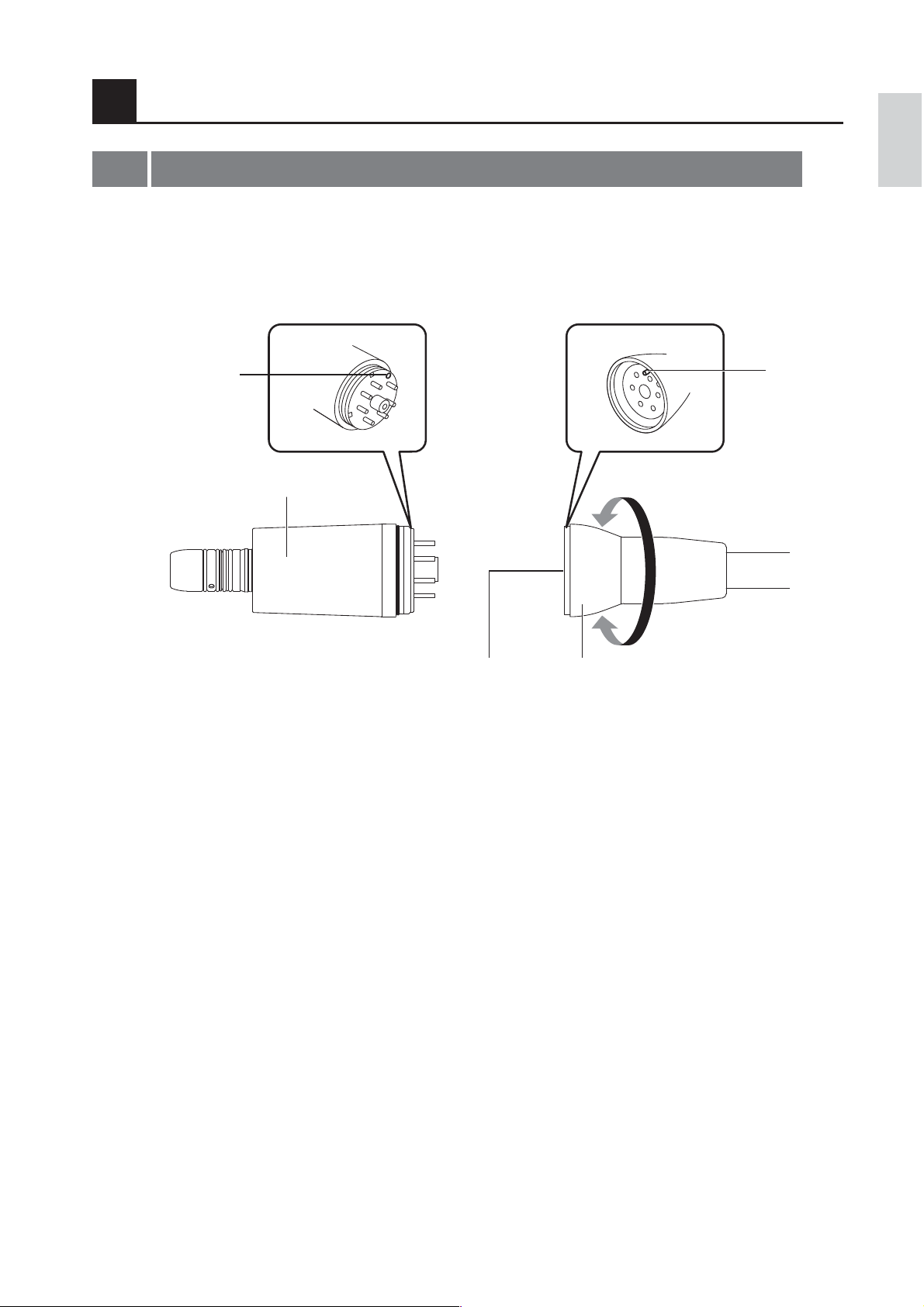

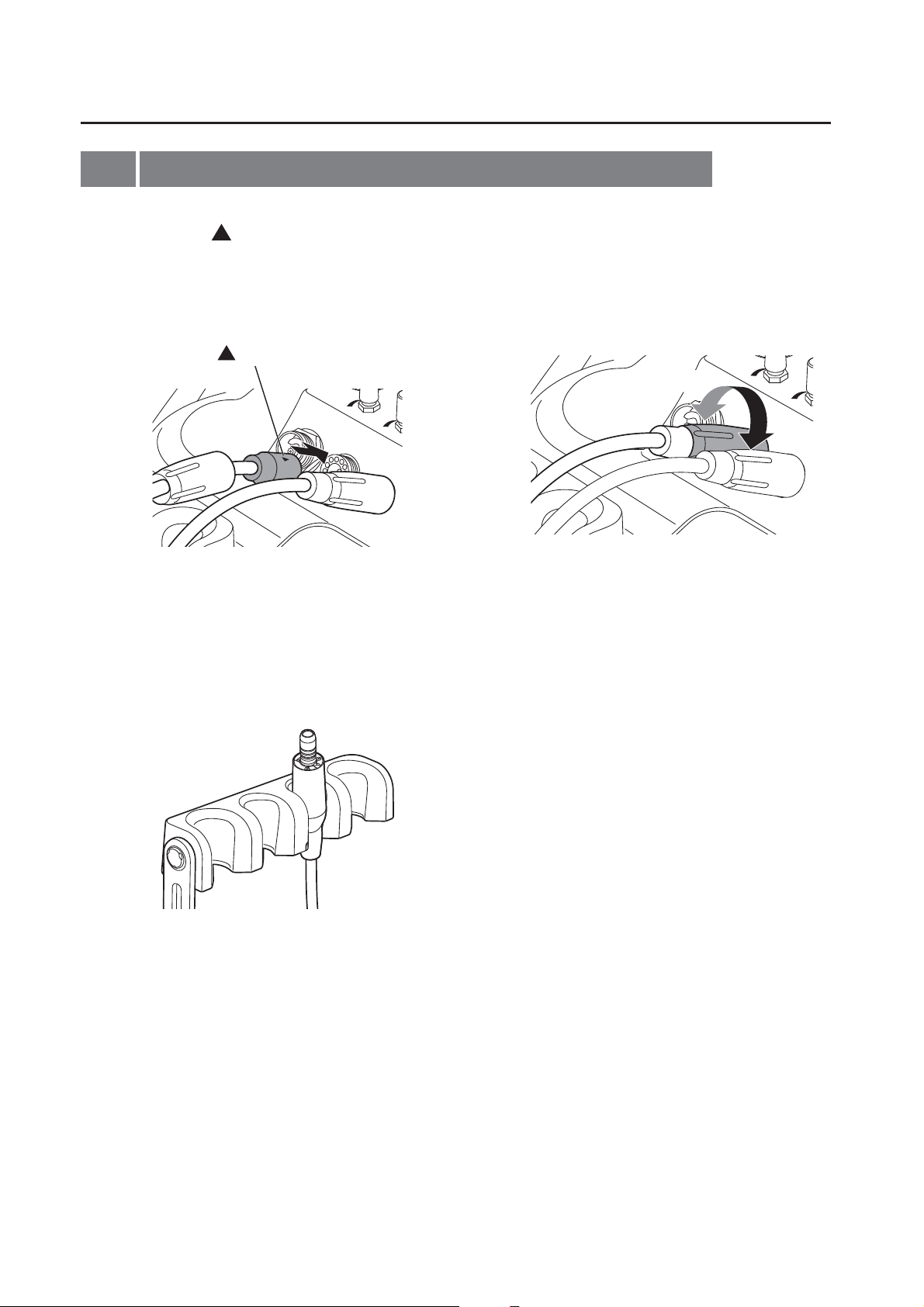

4-1 Connecting and Disconnecting the Motor Cord and the Motor

<Connection>

Aligning the hole on the back of the Motor and the pin on the Motor Cord Connector, insert the pin straight

into the hole and tighten the Motor Cord Nut firmly.

Hole

Motor

Tighten

Pin

English

Motor Cord Connector

<Disconnection>

Loosen the Motor Cord nut. Gently separate the motor from the cord.

Motor Cord Nut

Loosen

7

Page 9

Preparation for use

4-2 Connecting the Motor Cord and VIVA ace Control Unit

Aligning the mark of the Motor Cord plug

1

and the shape of the terminal as shown

below, insert the plug deep into the motor

connector.

mark

Put the Motor on the holder.

3

6&$/(5

02725

Turn the Plug Cover for tightening.

2

Loosen

6&$/(5

02725

Tighten

8

Page 10

Preparation for Use

4-3 Connecting and Disconnecting the Handpiece (optional)

Insert the Handpiece straight into the Motor.

1

When connecting an optic handpiece, turn

the Handpiece either to the right or left

until hearing a clicking sound securing the

position.

Positioning pin

Handpiece

(optional)

Motor

Confirm that the Handpiece is connected

2

firmly.

<Disconnecting>

Holding the front part of the Motor and the end

part of the Handpiece, gently pull straight apart.

English

CAUTION

• Use the following handpiece.

-ISO 3964 (EN 23964) compliant handpiece

-93/42/EEC compliant handpiece

• Connect/disconnect the Handpiece after the Motor has completely stopped.

• Adjust the speed within its allowable speed of the Handpiece (optional).

• Do not leave the lubricated Handpiece attached to the Motor. The oil may enter the Motor and cause a

malfunction.

• Keep the lubricated Handpiece in a different place in a standing condition and attach it to the Motor before

using it.

• Be careful not to get water into the Motor because it could cause a malfunction.

4-4 Check before treatment

Follow the Instruction manual for VIVA ace Basic Set. (Reference : 5-10 Check before treatment

)

9

Page 11

5

Operation Procedure

Follow the Operation Manual for VIVA ace Basic Set. (Reference : 6 Operation Procedure

6

Post-use Maintenance

6-1 Preparation for Maintenance

Wear eye protection, a mask, and gloves to

prevent infection.

1

Turn off the Power Switch of the Control

Unit.

2

Remove the Water Plug (IN) [Clear Tube]

while pulling the Slide Ring.

3

Remove the Water Plug (OUT) [Blue Tube]

pressing the Slide Ring.

4

Water Plug (IN)

[Clear Tube]

Slide Ring

)

Dispose of the water in the Water Bottle and

place the empty bottle again in the Control

5

Unit.

Turn on the Power Switch of the Control Unit.

6

Maximize Motor Water Adjuster, activate the Motor to let out the water remaining in the Motor Cord.

7

10

Page 12

Post-use Maintenance

CAUTION

• Do not clean, immerse, or wipe with electrolyzed-oxidizing water (strong acidic water, super acidic water),

strong acidic and strong alkaline liquid medicine, solvent containing chlorine, benzene, or thinner.

• Do not lubricate the Motor. It may cause overheating and a malfunction.

NOTICE

Be sure to remove the Water Plug (IN) [Clear Tube] first.

•

Note that if the Water Plug (OUT) [Blue Tube] is removed first, the water in the bottle may blow out for a

•

moment.

When the Water Bottle (IN) [Clear Tube] is removed, the air in the bottle bursts out and makes a noise.

•

However, this is not a failure.

English

11

Page 13

Post-use Maintenance

6-2 Maintenance for Between Each Patient

6-2-1

< Cleaning >

1

Cleaning and Disinfection of the outside of the

Motor and the Motor Cord, and Replacing the Motor

Remove the all debris on the surface of the Handpiece, Motor and the Motor Cord with a wipes

(Minuten Wipes: ALPRO).

Minuten Wipes (ALPRO)

Remove the bur form the Handpiece with tweezers.

2

* Maintenance of the bur should be done in accordance with the operation manual issued

manufacturer.

by

12

Page 14

Post-use Maintenance

Remove the Handpiece from the Motor

3

* Reference: "4-3 Connecting and Disconnecting the Handpiece (optional)".

* Maintenance of the Handpiece should be done in accordance with its operation manual.

Handpiece

(optional)

Wipe the debris on the surface of the Motor and the Motor cord using a cloth moistened with water.

Motor

4

English

Under appropriate lighting (500 lx or higher), inspect the Motor and the Motor cord for

5

contamination.

If any visible contamination remains, repeat the process until it is visually clean. Be sure to repeat

from the procedure No.4.

≥ 500 lx

13

Page 15

Post-use Maintenance

6-2-1

< Disinfection >

1

Cleaning and Disinfection of the outside of the Motor and

the Motor Cord, and Replacing the Motor (Continued)

Wipe the surface of the Motor, the Motor Cord and the Holder of the Control Unit with the

disinfectant wipes (Minuten Wipes: ALPRO).

Minuten Wipes (ALPRO)

Disconnect the Motor from the Motor Cord, then attach a sterilized Motor and place it on the Holder.

2

* Be sure to sterilize a used Motor. Reference: “6-4 Sterilization".

14

Page 16

Post-use Maintenance

6-3 Maintenance After Close

6-3-1

< Cleaning >

Remove the all debris on the surface of the Handpiece, Motor and the Motor Cord with a wipes

1

(Minuten Wipes: ALPRO).

Cleaning and Disinfection of the outside

of the Motor and the Motor Cord

English

2

Minuten Wipes (ALPRO)

Remove the bur form the Handpiece with tweezers.

* Maintenance of the bur should be done in accordance with the operation manual issued

manufacturer.

by

15

Page 17

Post-use Maintenance

6-3-1

< Cleaning (Continued) >

Remove the Handpiece from the Motor

3

* Reference: "4-3 Connecting and Disconnecting the Handpiece (optional)".

* Maintenance of the Handpiece should be done in accordance with its operation manual

Cleaning and Disinfection of the outside of

the Motor and the Motor Cord (Continued)

Handpiece

(optional)

Motor

Wipe the debris on the surface of the Motor and the Motor cord with a cloth moistened with water.

4

16

Page 18

Post-use Maintenance

Under appropriate lighting (500 lx or higher), inspect the Motor and the Motor cord for

5

contamination.

If any visible contamination remains, repeat the process until it is visually clean. Be sure to repeat

from the procedure No.4.

≥ 500 lx

< Disinfection >

Wipe the surface of the Motor, the Motor Cord and the Holder of the Control Unit with the

1

disinfectant wipes (Minuten Wipes: ALPRO).

English

Minuten Wipes (ALPRO)

Disconnect the Motor from the Motor Cord.

2

Motor Cord: Place the Holder of the Control Unit.

Motor: Proceed to section "6-4 Sterilization"

17

Page 19

Post-use Maintenance

6-4 Sterilization

CAUTION

Follow local rules, regulations, and guidelines regarding the reprocessing of devices.

•

Do not autoclave the product with other instruments even when it is in a pouch. This is to prevent possible

•

discoloration and damage to the product from chemical residue on other instruments.

Be sure to use sterilizers that can perform sterilization up to 135°C. In some sterilizers, the chamber

•

temperature may exceed 135°C. Do not use these sterilizers as failure of the product could occur. Contact

the sterilizer manufacturer for detailed information about cycle temperatures.

Keep the product in suitable atmospheric pressure, temperature, humidity, ventilation, and sunlight. The

•

air should be free from dust, salt and sulphur.

Do not touch the product immediately after autoclaving as it will be very hot and must remain in a sterile

•

condition.

Autoclave sterilization is recommended for the product. The validity of other sterilization methods (such as

•

plasma sterilization or EOG sterilization) is not confirmed.

Immediately after sterilization is complete (within 1 hour), remove the Motor from the sterilozer. Failure to

•

do so may cause corrotion.

NOTICE

NSK recommends Class B sterilizer as stated in EN 13060.

•

For details, confirm to the manufacturer's of the sterilizer operation manuals.

•

18

Page 20

Post-use Maintenance

Apply autoclave sterilization for the following products. After each patient treatment, sterilize the products

as follow.

Autoclavable equipment: Motor, Motor Cap, Protection Plug,

< Preparation before sterilization >

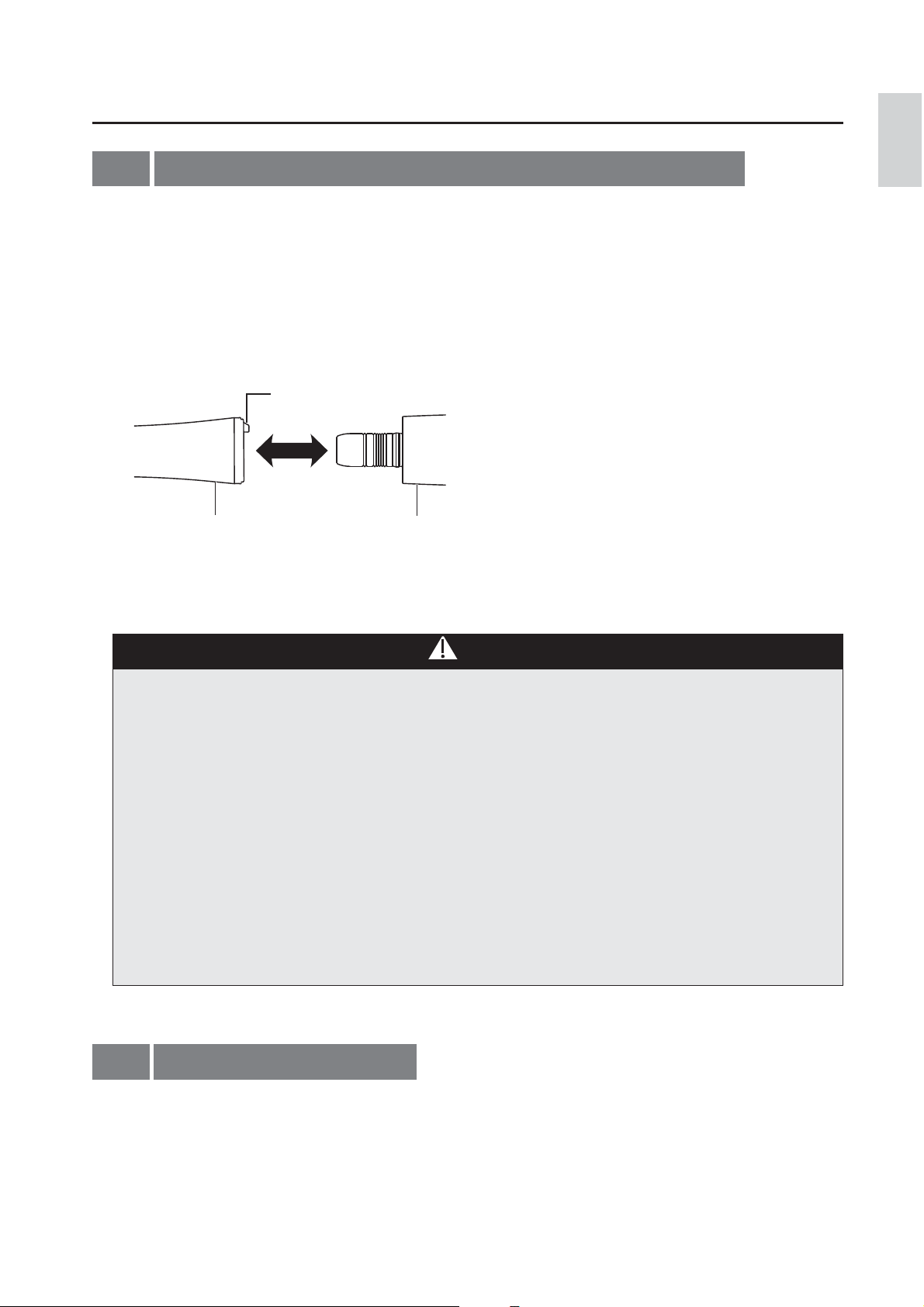

Tighten the Motor Cap to the connection

1

part of the Motor Cord and place the

Protection Plug in the insert part of the

Motor.

Prote ction Plug Motor Cap

Tighten

Insert the Motor with the Protection Plug

2

and the Motor Cap to the sterilization pouch

that conform to ISO 11607-1 and seal the

pouch.

English

< Sterilization >

Autoclave the Motor. Conduct autoclave sterilization as follow.

Type Gravity Displacement Pre-Vacuum (Dynamic Air Removal)

Temperature 121

Full Cycle Time 20 min. or longer 15 min or longer 3-18 min

Drying Time 30 min or longer 30 min or longer 30 min or longer

Store the product in a place where it is kept clean and keep it in a sterilization pouch until it is used next.

°C (

0 / +4

°C)

132

°C

(0 / +4

°C)

134

°C

(0 / +4

°C)

19

Page 21

Post-use Maintenance

6-5

Maintenance of the Water Line

for the Motor and the Motor Cord

Cleaning and Disinfection should be done in the cleaning tank.

CAUTION

Be sure to perform Cleaning and Disinfection the "6-3 Maintenance after Close (Cleaning and Disinfection

•

of the outside of the Motor and the Motor Cord)" before "6-5 Maintenance of the Water Line for the Motor

and the Motor Cord".

6-5-1 Preparation of the Water Line before Disinfection

Disinfect with Alpro Bilpron (ALPRO) (undiluted) is recommended as maintenance once or twice week.

Put 200 mL of disinfectant solution in the Water Bottle. Tightly close the Water Bottle lid and place

1

the Water Bottle in the Control Unit.

* For details, confirm the operation manual isseued by manufacturer.

Disinfectant Solution: Alpro

Disinfectant Solution

200

Bilpron (ALPRO) (undiluted)

mL

· When there is not enough disinfectant solution,

turn off the Power Switch of the Control Unit,

take out the Water Bottle, and add disinfectant

solution.

20

Page 22

Post-use Maintenance

Insert the Water Plug (OUT) [Blue Tube] and the Water Plug (IN) [Clear Tube] to the lid until hearing

2

a clicking sound.

English

Water Plug (OUT)

[Blue Tube]

Turn on the Power Switch of the Control

3

Unit.

Water Plug (IN)

[Clear Tube]

Maximize the Motor Water Adjuster.

4

21

Page 23

Post-use Maintenance

6-5-2

Push the MOTOR Key.

1

Turn ON the SPRAY Key to irrigation.

Press the ON/OFF Key for 2 seconds and

3

activate for

that the disinfectant solution comes out

from the tip of the Motor.

Disinfection of the Water Line of

the Motor and the Motor Cord

10 seconds or more to confirm

Hold the Motor and the Motor Cord in the

2

cleaning tank.

Place the Motor and the Motor Cord on the

4

Holder of the Control Unit state for a night (at

least 12 hours).

CAUTION

Disinfectant solution remains in the Water Line by letting the solution out from the tip of the Motor.

•

It takes 12 hours to complete the disinfection after disinfectant solution remain on the Water Line of the

•

Motor and the Motor Cord.

22

Page 24

Post-use Maintenance

6-5-3

Put 250 mL of drinking water in the Water Bottle. Tightly close the Water Bottle Lid and place the

1

Water Bottle in the Control Unit.

Rinsing of Water Line of the Motor

and the Motor Cord after Disinfection

Drinking water

250 mL

English

Insert the Water Plug (OUT) [Blue Tube] and the Water Plug (IN) [Clear Tube] to the lid until hearing

2

a clicking sound.

Water Plug (OUT)

[Blue Tube]

Water Plug (IN)

[Clear Tube]

23

Page 25

Post-use Maintenance

6-5-3

Turn on the Power Switch of the Control

3

Unit.

Rinsing of Water Line of the Motor and the

Motor Cord after Disinfection (Continued)

Maximize the Motor Water Adjuster

4

Push the MOTOR Key.

5

Turn ON the SPRAY Key to irrigation.

Hold the Motor and the Motor Cord in the

6

cleaning tank.

24

Page 26

Post-use Maintenance

English

Press the ON/OFF Key for 2 seconds and

7

activate for

that drinking water comes out from the tip

of the Motor.

· When there is not enough drinking water,

turn off the Power Switch of the Control

Unit, take out the Water Bottle, and add

drinking water.

Disconnect the Motor from the Motor Cord then attach the sterilized Motor to the Motor Cord and

9

place it on the Holder.

· Be sure to sterilize th

Reference: "6-4 Sterilization.

10 seconds or more to confirm

e rinsed Motor (Including Water Line) before use.

Wipe the surface of the Motor and the Motor

8

Cord with the disinfectant wipes (Minuten

Wipes: ALPRO).

Minuten Wipes: ALPRO

CAUTION

After rinsing, be sure to sterilize the Motor. Reference: "6-4 Sterilization".

•

25

Page 27

7

Maintenance

7-1 Replacing the O-ring

When the Handpiece does not come off easily or water or air leaks because of deterioration of the O-ring,

replace the O-ring.

Take off the O-ring at the insert part of the Motor with

a needle and fit a new O-ring in the O-ring groove.

* Refer to “3. Package Contents” to

identify the replacement O-ring.

CAUTION

• There are four O-rings in total. The size of the blue one is different

from the other ones. Refer to the illustration and place it in the correct

position.

• Problems below could occur due to deterioration of the O-ring.

•

Water leakage, No water supply.

•

Air leakage, No air supply.

•

Generates Vibration.

•

The Handpiece cannot be connected/disconnected easily.

7-2 Periodical Maintenance Checks

O-ring (Blue

O-ring (Black

)

)

Every 3 months perform periodical maintenance checks, referring to the check sheet below. If any

abnormalities are found, contact your Authorized NSK Dealer.

Points to check Details

Rotation Rotate the Motor and check if there is any abnormal vibration, noise, or generation of heat.

26

Page 28

8

Troubleshooting

8-1 Problems and Solutions

When a problem is detected, check the following again before requesting a repair. If none of these is

applicable or if the trouble is not remedied even after an action has been taken, a malfunction of this

product is suspected. Contact your Authorized NSK Dealer.

Problem Cause Remedy

No rotation of the Motor

No LED lighting Blowout of LED Contact your Authorized NSK Dealer.

Water leakage

Insufficient connection of the

Motor Cord

Insufficient connection of the

Motor Cord

Check the connection.

Check the connection.

English

27

Page 29

9

Specifications

9-1 Specifications

Model

Rotation Speed

Maximum Torque

Dimension

Use environment

Transportation and

storage environment

*No condensation.

Temperature Humidity Pressure

0 - 40ºC 30 - 75%*

-10 - 50 ºC 10 - 85%* 500 - 1060hPa

NLX Plus

100 - 40,000 min

4.0N · cm

DØ22 x H77 mm

-1

9-2 Classification of Equipment

• Method of sterilization or disinfection recommended by the manufacturer:

Reference : 6-4 Sterilization

• Degree of safety of application in the presence of a flammable anesthetic mixture with air or with

oxygen or nitrous oxide:

Equipment NOT suitable for use in the presence of a flammable anesthetic mixture with air or with oxygen or

nitrous oxide:

• Mode of operation:

Intermittent operation device

(

ON : 2 minutes, OFF : 3 minutes

)

28

Page 30

9-3 Symbol

This product is Autoclavable up to Max.135ºC.

Conforms to CE European Directive of “Medical device directive 93/42/EEC.”

Manufacturer.

Authorized representative in the European community.

Consult operation instructions.

Caution, Refer to attached instructions.

English

10

After-sales Service

10-1 Warranty

NSK products are warranted against manufacturing errors and defects in materials. NSK reserves the right

to analyze and determine the cause of any problem. Warranty is voided should the product be not used

correctly or for the intended purpose or has been tampered with by unqualified personnel or has had non

NSK parts installed. Replacement parts are available for seven years beyond discontinuation of the model.

10-2 Disposing Product

In order to avoid the health risks of operators handling the disposal of medical equipment, as well as the

risks of environmental contamination caused thereof, a surgeon or a dentist is required to confirm the

equipment is sterile. Ask specialist firms who are licensed to dispose of specially controlled industrial

wastes, to dispose the product for you.

29

Page 31

2018.08.10 002

Loading...

Loading...