Page 1

USER MANUAL

SUBSCRIBE TO NSK NEWSLETTER

SUBSCRIBE TO NSK NEWSLETTER

INDUCTION HEATER IHN080/120

Page 2

Table of Contents

Chapter ����������������������������������������������������������������������������������������������������������������������������������������������� Page

Safety Recommendations ������������������������������������������������������������������������������������������������������������������������3

1 Introduction ��������������������������������������������������������������������������������������������������������������������������������������3

1�1 Intended Use ������������������������������������������������������������������������������������������������������������������������������������3

1�2 Principle of Operation ����������������������������������������������������������������������������������������������������������������������4

1�3 Distinguishing Feature ���������������������������������������������������������������������������������������������������������������������4

2 Description ���������������������������������������������������������������������������������������������������������������������������������������4

2�1 Components �������������������������������������������������������������������������������������������������������������������������������������4

2�2 Technical Data ����������������������������������������������������������������������������������������������������������������������������������5

3 Installation of Mains Plug ���������������������������������������������������������������������������������������������������������������5

4 Preparation for Use ��������������������������������������������������������������������������������������������������������������������������6

5 Operation ������������������������������������������������������������������������������������������������������������������������������������������7

5�1 Function of Displays ������������������������������������������������������������������������������������������������������������������������7

5�2 Function of Buttons �������������������������������������������������������������������������������������������������������������������������8

5�3 Temp Mode ��������������������������������������������������������������������������������������������������������������������������������������8

5�4 Time Mode ���������������������������������������������������������������������������������������������������������������������������������������9

5�5 Temperature Measurement ������������������������������������������������������������������������������������������������������������9

5�6 Change of Temperature Unit �����������������������������������������������������������������������������������������������������������9

5�7 Demagnetisation �����������������������������������������������������������������������������������������������������������������������������9

5�8 Power Level Selection ������������������������������������������������������������������������������������������������������������������ 10

6 Safety Features ����������������������������������������������������������������������������������������������������������������������������� 10

7 Troubleshooting ���������������������������������������������������������������������������������������������������������������������������� 11

8 Spare Parts ������������������������������������������������������������������������������������������������������������������������������������ 11

2

Page 3

Safety Recommendations

› Because the IHN080/120 generates a magnetic field,

people wearing a pacemaker must not be within 5 m

(16 ft) of the IHN080/120 during operation� Electronic

equipment, such as wrist watches, may also be affected�

› Follow the operating instructions at all times�

› Be certain that the voltage supply is correct�

› Electrical arcing may occur when a potential difference

exists between the IHN080/120 and the workpiece� This

is not dangerous to human beings and will not cause

damage to the IHN080/120 or the workpiece� However,

the IHN080/120 must never be used in areas where

there is a risk of explosion�

› Do not expose the heater to high humidity�

› Never operate the IHN080/120 without a yoke in

position�

› Do not modify the IHN080/120�

› Use proper handling equipment when lifting heavy

workpieces�

› Avoid contact with hot workpieces� Wear the supplied

heat-resistant gloves to handle hot workpieces�

1 Introduction

The IHN080/120 induction heater is designed to heat bearings that are mounted with an interference fit onto a shaft� The

heat causes the bearing to expand, which eliminates the need to use force during installation� A 90°C (194°F) temperature

difference between the bearing and shaft is generally sufficient to enable installation� At an ambient temperature of 20°C

(68°F), the bearing must therefore be heated to 110°C (230°F)�

1.1 Intended Use

The IHN080/120 has been designed to heat rolling bearings� However, other metal workpieces that form a closed circuit can

also be heated� Examples of acceptable workpieces include bushings, shrink rings, pulleys, and gears� All bearings that fit

over the inductive coil and between the vertical supports with the top yoke in place can be heated using the IHN080/120�

In addition, smaller bearings can be placed over either of the three standard yokes�

3

Page 4

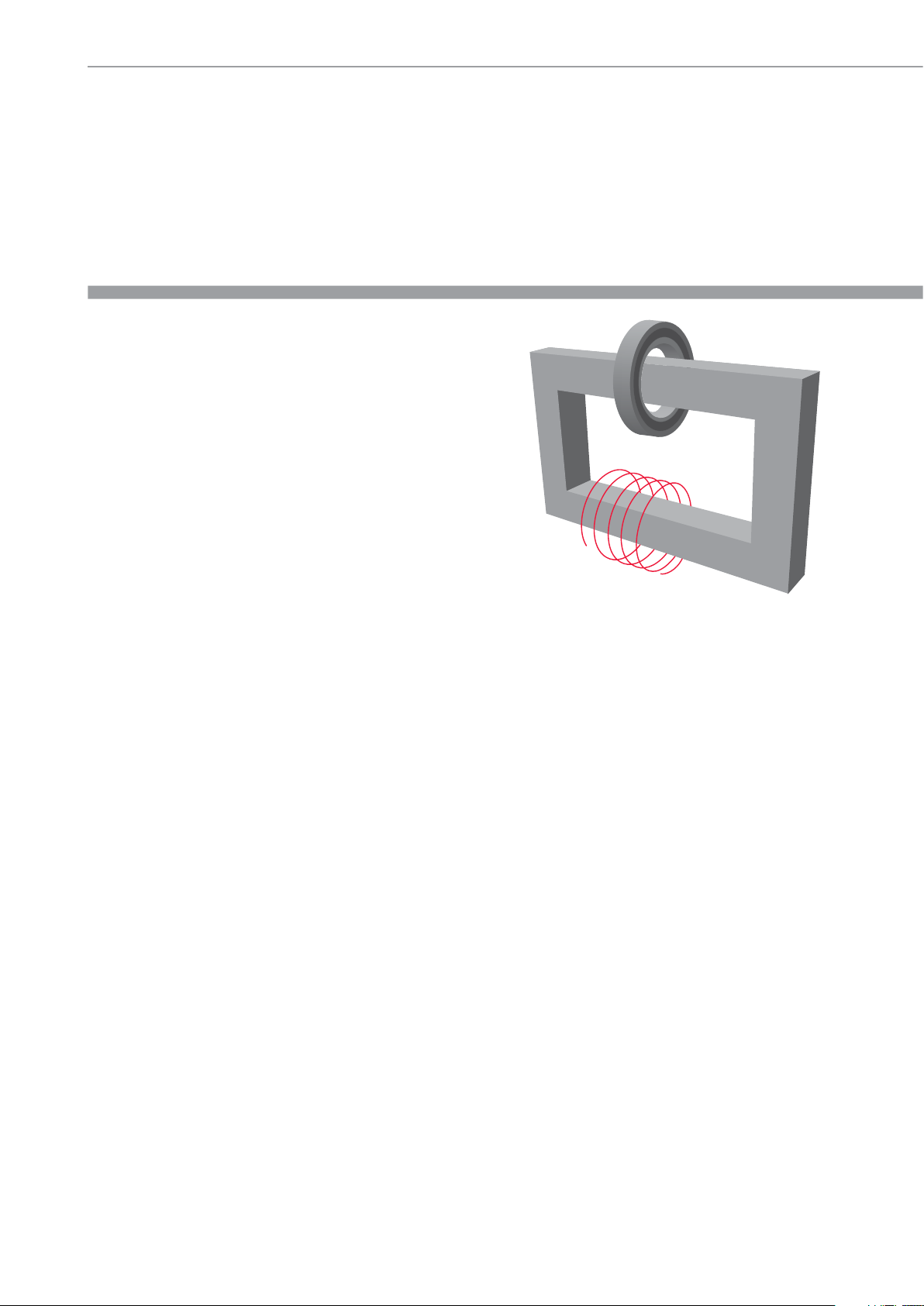

1.2 Principle of Operation

The IHN080/120 generates heat by means of a large electrical

current that is magnetically induced in the workpiece by a

coil within the heater� The high voltage, low current electricity

flowing through the large number of windings in the inductive

coil induces low voltage, high current electricity in the workpiece�

Because the workpiece has the electrical characteristics of a coil

with a single, short-circuited winding, the high current generates

heat within the workpiece� Because the heat is generated within

the workpiece, all of the heater components remain cool�

1.3 Distinguishing Feature

The distinguishing feature of the IHN080/120 induction heater is the location of the workpiece at the same position on the

core as the inductive coil� This design improves efficiency, resulting in less power consumption and faster heating, which

reduces the cost to heat each bearing�

2 Description

The operation of the heater is controlled by the internal electronics in either of two modes� The operator can either select the

desired temperature of the bearing in TEMP MODE or set the length of time that the bearing will be heated in TIME MODE� The

power level can be adjusted in steps of 20% for slower heating of sensitive workpieces (for example, bearings with C1 or C2

clearance)�

2.1 Components

The IHN080/120 induction heater contains a U-shaped iron core with an inductive coil surrounding one of the vertical supports� Internal electronics control the operation of the heater� A removable yoke on the top of the vertical supports allows

the workpiece to be placed onto the heater� The top yoke of the IHN120 is mounted on a swivel� To accommodate smaller

workpieces, two smaller yokes are also provided� A temperature probe is included with the heater� Heat-resistant gloves are

also included�

4

Page 5

2.2 Technical Data

IHN080 IHN0120

Voltage (± 9%): 1 ~ 100 – 240 V / 50-60 Hz* 3 ~ 400 – 575 V / 50-60 Hz*

Recommended circuit protection 20 A circuit breaker 20 A circuit breaker

Power consumption (maximum) 3�7 kVA 9�2 kVA

Temperature control

Probe maximum temperature 250 °C (482 °F) 250 °C (482 °F)

Time mode 0 – 60 minutes in steps of 0�1 minute 0 – 60 minutes in steps of 0�1 minute

Power range 20 – 100% in steps of 20% 20 – 100% in steps of 20%

Demagnetisation, automatic Residual magnetism < 2 A/cm Residual magnetism < 2 A/cm

Overall dimensions 420 x 280 x 345 mm 420 x 280 x 420 mm

Area between supports (wxh) 145 x 205 mm 145 x 205 mm

Coil diameter 115 mm 115 mm

Weight (with yokes) 35 kg 38 kg

Workpiece maximum weight Bearing 80 kg, solid component 40 kg Bearing 120 kg, solid component 60 kg

Maximum heating temperature Approx� 400°C (752°F) Approx� 400 °C (752 °F)

Standard yoke dimensions

0 – 250 °C (32 – 482 °F)

in steps of 1 °C (2 °F)

55 x 55 x 275 mm (for Ø of 80 mm)

28 x 28 x 275 mm (for Ø of 40 mm)

14 x 14 x 275 mm (for Ø of 20 mm)

0 – 250 °C (32 – 482 °F)

in steps of 1 °C (2 °F)

55 x 55 x 275 mm (for Ø of 80 mm)

28 x 28 x 275 mm (for Ø of 40 mm)

14 x 14 x 275 mm (for Ø of 20 mm)

* Each bearing heater family has several voltage options. Please refer to the type plate on the heater body to determine the actual operating voltage.

3 Installation of Mains Plug

Due to the many types of mains plugs, no mains plug is supplied with the IHN080/120� A qualified electrician must install a

suitable mains plug� The correct supply voltage is shown on the type plate / underside of the heater�

The wires should be connected as follows:

IHN080

Color of IHN080 Wire Mains Supply Terminal

Yellow/green Protection earth (PE)

Brown Phase 1 (L1)

Blue Neutral (N)

5

Page 6

IHN120

Color of IHN120 Wire Mains Supply Terminal

Yellow/green Protection earth (PE)

Brown Phase 1 (L1)

Blue Phase 2 (L2)

Connect the IHN120 to only two of the three phases� Verify that the correct circuit breaker is installed� See section 2�2 for

circuit breaker specifications�

4 Preparation for Use

› Place the IHN080/120 in the horizontal position on a stable surface�

› Connect the mains plug to a suitable mains supply�

› For the IHN120 only, follow these steps to install the swivel arm:

› Attach the protection plate (4) to the side post to prevent damage�

› Install the swivel head (1) and the swivel body (2) on the lefthand

side post of the heater�

› Install the large top yoke (55 x 55mm) in the swivel head� Adjust

the swivel body so that there is no visible gap (A) between the

side post and the yoke�

› Tighten the four screws (3) of the swivel body (maximum torque 5Nm)�

› Turn the screw (5) on top of the swivel head to position the top

yoke� The top yoke must contact as much of the upper surface of

the right-hand side post (B) as possible� Noise during

operation could indicate that the top yoke is not positioned properly�

› Special notes for the IHN120:

› The yoke support is required when either of the smaller yokes

(28 x 28mm or 14 x 14mm) is installed� Install the yoke support and

the yoke together in the swivel head� If necessary, rotate the swivel

head to provide better access�

› Heavy workpieces (≥10kg / 22lbs) that must be installed on the top

yoke should be supported until the yoke is in the correct position on

the right-hand side post� The heater may tip over if the workpiece is not supported�

› The swivel body (2) can remain on the heater at all times�

› Turn the screw (5) on top of the swivel head to position the top yoke� The top yoke must contact as much of the upper

surface of the right-hand side post (B) as possible� Noise during operation could indicate that the top yoke is not positioned

properly�

6

Page 7

› For workpieces with an internal diameter large enough to fit over the inductive coil, follow these steps:

› Place the workpiece over the inductive coil using appropriate lifting equipment�

› For best performance, adjust the position of the workpiece so that the inductive coil is in the center�

› Remove the protective film from the bright underside of the top yoke before the first use�

› Position the top yoke so that it completely covers the top of both vertical supports�

› If you will use TEMP MODE, plug the temperature probe into the connector on the left side of the heater� Place the magnetic

end of the probe on the inner ring of the bearing or on the innermost surface of the workpiece�

› Use the power switch on the left side to switch on the IHN080/120�

› Observe the self-test of the display and signal tone�

5 Operation

5.1 Function of Displays

A

B

A) The main display shows the selected time or temperature for heating:

Display Indication

t Time in minutes

°C Temperature in degrees Celsuis

°F Temperature in degrees Fahrenheit

B) The power display shows the selected power setting:

Display Indication

•

••

•••

••••

•••••

20% power

40% power

60% power

80% power

100% power

7

Page 8

5.2 Function of Buttons

Button Function

POWER Press to adjust the power in steps of 20%� The selected power is indicated on the power display�

MODE Press to switch between TIME MODE and TEMP MODE�

UP (+) Press to increase the value shown on the main display�

DOWN (-) Press to decrease the value shown on the main display�

START/STOP

Press to start or stop the heater� The LED on the START/STOP button is lit when the heater is heating and

flashes during temperature measurement�

5.3 Temp Mode

› If the main display shows “t”, press MODE to select TEMP MODE� The main display shows °C or °F in TEMP MODE�

› The selected temperature is shown on the main display� The default temperature for bearings is 110°C (230°F)� If a different

temperature is desired, press UP or DOWN to adjust the temperature in steps of 1°C (2°F)�

› It may be desirable to heat bearings to temperatures above 110°C (230°F) for increased mounting time� Consult the bearing

specifications to determine the maximum permitted temperature� Always ensure the bearing does not lock due to an

excessive expansion of the inner ring compared to outer ring� See section 5�8�

› All Spherical Roller Bearings (SRBs) are subjected to a special heat treatment� These bearings can be operated at temperatures

as high as 200°C (392°F)� Heating these bearings above 110°C (230°F) will not cause any damage as long as the bearing is

still able to rotate� For other bearings, a temperature of 125°C (257°F) must not be exceeded unless otherwise specified�

› Press POWER to select the power level� Use the guidelines in section 5�8 to determine the correct power setting�

› Make sure the temperature probe is mounted on the bearing inner ring�

› Press START/STOP to start the heater� The main display shows the current temperature of the workpiece�

› When the selected temperature has been reached, the heater demagnetises the workpiece, switches off and generates an

acoustic signal for 10 seconds or until START/STOP is pressed�

› Press START/STOP to stop the heater�

› Remove the workpiece with proper handling equipment�

8

Page 9

› If the workpiece remains on the heater, the heater will start again when the temperature of the workpiece drops 10°C (18°F)�

Press START/STOP to stop the heater and demagnetise the workpiece�

› The IHN080/120 is now ready to heat another workpiece with the same settings�

5.4 Time Mode

› If the main display shows °C or °F, press MODE to select TIME MODE� The main display shows “t” in TIME MODE�

› Press UP or DOWN to adjust the time in steps of 0�1 minute�

› Press POWER to select the power level� Use the guidelines in section 5�8 to determine the correct power setting�

› Press START/STOP to start the heater� The main display shows the time that remains�

› When the time has elapsed, the heater demagnetises the workpiece, switches off and generates an acoustic signal for 10 seconds�

› Press START/STOP to cancel the acoustic signal and stop the heater�

› Remove the workpiece with proper handling equipment�

› The IHN080/120 is now ready to heat another workpiece with the same settings�

5.5 Temperature Measurement

When the heater is not operating, the temperature of the workpiece can be measured by pressing MODE and START/STOP

at the same time� The LED on the START/STOP button flashes during temperature measurement� Press START/STOP to cancel

temperature measurement�

5.6 Change of Temperature Units

Press MODE and UP at the same time to switch between °C and °F� The temperature unit setting remains the same even after

disconnection from mains power�

5.7 Demagnetisation

The workpiece is automatically demagnetised when heating is complete� Demagnetisation will not occur if the power is

interrupted or the main switch is switched off� To use the IHN080/120 for demagnetisation only, select TIME MODE and set

the time to 0�1 minute (6 seconds)�

9

Page 10

5.8 Power Level Selection

When heating bearings with an induction heater, most of the heat will be generated in the inner bearing race� The heat

will then be transferred through the bearing� It is therefore important that bearings with small internal clearance or slight

preload are heated slowly� Slow heating ensures that the bearing expands evenly, thereby preventing damage to the bearing�

The shape, weight, size, and internal clearances all affect the amount of time required to heat a bearing� The large

variety of bearing types prevents the possibility of providing a specific power level setting for each type� Instead, the

following guidelines are provided:

› For sensitive bearings (including bearings with C1 or C2 internal clearance) or bearings with brass cages, do not exceed

20% power when using the small yoke, 40% power when using the medium yoke, or 60% power when using the

large yoke�

› When using the small yoke, never exceed 40% power�

› When using the medium yoke, never exceed 60% power�

6 Safety Features

The IHN080/120 is equipped with the following safety features:

› Automatic overheating protection�

› Automatic current control�

› In the TEMP MODE the heater will switch off if the temperature probe does not register a temperature increase of 1°C (2°F)

every 15 seconds� To increase the interval to 30 seconds, press MODE and DOWN at the same time�

› Additionally, the IHN120 is equipped with a main switch with over-current circuit breaker�

10

Page 11

7 Troubleshooting

A system fault will be indicated by an acoustic signal and one of the following fault codes on the main display:

Display Fault Action

E01 E General system failure Return heater for repair

E02 E Memory failure Return heater for repair

E03 E Overheated coil Wait until the inductive coil cools

E04 E Not in use

E05 E

E06 E Temperature probe not connected (or defective) Check the temperature probe

E07 E Failure during current measurement Return heater for repair

E08 E

E09 E Overheated printed circuit board Wait until the printed circuit board cools�

Temperature increase of less than 1°C (2°F) every

15 seconds (or 1°C (2°F) every 30 seconds)

Failure during communication with power printed

circuit board

Check the temperature probe connection� If the connection

is OK, select the 30 second interval as described in section 6

or operate the heater in TIME MODE�

Return heater for repair

8 Spare Parts

Description Part Number

Spare temperature probe IHNP2SENSOR

Spare protective gloves IHNGLOVES

Spare set support yoke 55 x 55 x 100 mm for IHN080/120 IHN080/120-YS

Spare yoke 10 x 10 x 275 mm for IHN080/120 IHN080/120-Y1

Spare yoke 14 x 14 x 275 mm for IHN080/120 IHN080/120-Y2

Spare yoke 20 x 20 x 275 mm for IHN080/120 IHN080/120-Y3

Spare yoke 28 x 28 x 275 mm for IHN080/120 IHN080/120-Y4

Spare yoke 40 x 40 x 275 mm for IHN080/120 IHN080/120-Y6

Spare yoke 55 x 55 x 275 mm for IHN080/120 IHN080/120-Y8

Spare swivel arm complete for IHN080/120 IHN080/120-SA

11

Page 12

NSK SALES OFFICES WORLDWIDE

HEADQUARTER

Japan

NSK Ltd�-Headquarters

Nissei Bldg�, 1-6-3 Ohsaki

Shinagawa-ku

Tokyo 141-8560

Industrial machinery business

Division-Headquarters

Tel� +81 (3) 3779 7227

Fax +81 (3) 3779 7644

Automotive business

Division-Headquarters

Tel� +81 (3) 3779 7189

Fax +81 (3) 3779 7917

AFRICA

South Africa

NSK South Africa (Pty) Ltd�

27 Galaxy Avenue

Linbro Business Park

Sandton 2146

Tel� +27 (011) 458 3600

Fax +27 (011) 458 3608

nsk-sa@nsk�com

ASIA AND OCEANIA

Australia

NSK Australia Pty� Ltd�

11 Dalmore Drive

Scoresby

Victoria 3179

Tel� +61 3 9765 4400

Fax +61 3 9764 8304

aus-nskenquiries@nsk�com

New Zealand

NSK New Zealand Ltd�

3 Te Apunga Place

Mt� Wellington

Auckland

Tel� +64 9 276 4992

Fax +64 9 276 4082

nz-info@nsk�com

China

NSK Hong Kong Ltd�

Suite 705, 7th FloorSouth Tower

World Finance Centre

Harbour City, T�S�T

Kowloon, Hong Kong

Tel� +852 2739 9933

Fax +852 2739 9323

NSK China Sales Co�, Ltd�

No�8 NSK Rd�, Huaqiao Economic

Development Zone, Kunshan

Jiangsu, China (215332)

Tel� +86 512 5796 3000

Fax +86 512 5796 3300

lndia

NSK in diasales Co�Pvt�Ltd�

6th Floor, Bannari Amman Towers

No�29 Dr� Radhakrishnan Salai

Mylapore, Chennai-600 004 Tamil Nadu

Tel� +91 44 2847 9600

Fax +91 44 2847 9601

lndonesia

Pt� NSK Indonesia

Summitmas II, 6th Floor

Jl� Jend Sudirman Kav� 61-62

Jakarta 12190

Tel� +62 21 252 3458

Fax +62 21 252 3223

Korea

NSK Korea Co�, Ltd�

Posco Center (West Wing) 9F

892, Daechi-4Dong

Kangnam-Ku

Seoul, 135-777

Tel� +82 2 3287 0300

Fax +82 2 3287 0345

Malaysia

NSK Bearings (Malaysia) Sdn� Bhd�

No� 2, Jalan Pemaju, U1/15, Seksyen U1

Hicom Gienmarie lndustrial Park

40150 Shah Alam

Selangor

Tel� +60 3 7803 8859

Fax +60 3 7806 5982

Philippines

NSK Representative Office

8th Floor The Salcedo Towers

169 H�V� dela Costa St�

Salcedo Viilage Makati City

Philippines 1227

Tel� +63 2 893 9543

Fax +63 2 893 9173

Taiwan

Taiwan NSK Precision Co�, Ltd�

11 F�, No�87, Song Jiang Rd�

Jhongshan District

Taipei City 104

Tel� +886 2 2509 3305

Fax +886 2 2509 1393

Thailand

NSK Bearings (Thailand) Co�, Ltd�

26 Soi Onnuch 55/1 Pravet Subdistrict

Pravet District

Bangkok 10250

Tel� +66 2320 2555

Fax +66 2320 2826

Vietnam

NSK Vietnam Co�, Ltd�

Techno Center, Room 204-205

Thang Lang lndustrial Park

Dang Anh District

Hanoi

Tel� +84 4 3955 0159

Fax +84 4 3955 0158

EUROPE

UK

NSK UK Ltd�

Northern Road, Newark

Nottinghamshire NG24 2JF

Tel� +44 (0) 1636 605123

Fax +44 (0) 1636 643276

info-uk@nsk�com

France & Benelux

NSK France S�A�S�

Quartier de l’Europe

2, rue Georges Guynemer

78283 Guyancourt Cedex

Tel� +33 (0) 1 30573939

Fax +33 (0) 1 30570001

info-fr@nsk�com

Germany, Austria,

Switzerland, Nordic

NSK Deutschland GmbH

Harkortstraße 15

40880 Ratingen

Tel� +49 (0) 2102 4810

Fax +49 (0) 2102 4812290

info-de@nsk�com

Italy

NSK Italia S�p�A�

Via Garibaldi, 215

20024 Garbagnate

Milanese (MI)

Tel� +39 02 995 191

Fax +39 02 990 25 778

info-it@nsk�com

Poland & CEE

NSK Polska Sp� z o�o�

Warsaw Branch

Ul� Migdałowa 4/73

02-796 Warszawa

Tel� +48 22 645 15 25

Fax +48 22 645 15 29

info-pl@nsk�com

Russia

NSK Polska Sp� z o�o�

Russian Branch

Office I 703, Bldg 29,

th

18

Line of Vasilievskiy Ostrov,

Saint-Petersburg, 199178

Tel� +7 812 3325071

Fax +7 812 3325072

info-ru@nsk�com

Spain

NSK Spain, S�A�

C/ Tarragona, 161 Cuerpo Bajo

a

2

Planta, 08014 Barcelona

Tel� +34 93 2892763

Fax +34 93 4335776

info-es@nsk�com

Turkey

NSK Rulmanları Orta Doğu Tic� Ltd� Şti

19 Mayıs Mah� Atatürk Cad�

Ulya Engin İş Merkezi No: 68/3 Kat� 6

P�K�: 34736 - Kozyatağı - İstanbul

Tel� +90 216 4777111

Fax +90 216 4777174

turkey@nsk�com

MIDDLE EAST

Dubai

NSK Bearings Gulf Trading Co�

JAFZA View 19, Floor 24 Office 2/3

Jebel Ali Downtown,

PO Box 262163

Dubai, UAE

Tel� +971 (0) 4 804 8205

Fax +971 (0) 4 884 7227

info-me@nsk�com

NORTH AND SOUTH AMERICA

United States of America

NSK Americas, Inc�

4200 Goss Road

Ann Arbor, Michigan 48105

Tel� +1 734 913 7500

Fax +1 734 913 7511

NSK Latin America, Inc�

2500 NW 1 07th Avenue, Suite 300

Miami, Florida 33172

Tel� + 1 305 4 77 0605

Fax + 1 305 4 77 0377

Canada

NSK Canada Inc�

5585 McAdam Road

Mississauga, Ontario

Canada L4Z 1 N4

Tel� + 1 905 890 07 40

Fax + 1 800 800 2788

Argentina

NSK Argentina SRL

Garcia del Rio 2477

Piso 7 Oficina „A“ (1429)

Buenos Aires

Tel� +54 11 4704 51 00

Fax +54 11 4704 0033

Brazil

NSK BRASIL LTDA�

Rua 13 de Maio

1633-14th Andar-Bela Vista-CEP

01327-905 Sao Paulo, SP

Tel� +55 11 3269 4786

Fax +55 11 3269 4720

Peru

NSK PERU S�A�C�

Av� Caminos del lnca 670

Ofic: #402

Santiago del Surco

Lima

Tel� +51 1 652 3372

Fax +51 1 638 0555

Mexico

NSK Rodamientos Mexicana

S�A� DE C�V�

Av� Presidente Juarez No�2007 Lote 5

Col� San Jeronimo Tepetlacalco

Tlalnepantla, Estado de Mexico

C�P �54090

Tel� +52 (55) 3682 2900

Fax +52 (55) 3682 2937

Please also visit our websites:

www.nsk.com | www.au.nsk.com | www.nskeurope.com | www.nskamericas.com

Every care has been taken to ensure the infor mation in this publication is accurate but no liability can be accepted for any errors or omissions�

© Copyright NSK 2015� The contents of this publication are the copyright of the publishers� Printed in Switzerland� Ref: H080/A/E/01�16

Loading...

Loading...