NSI LUMA-NET 400CP Installation And Operation Manual

LUMA-NET

400CP REMOTE CONTROL PANEL

INSTALLATION AND OPERATION GUIDE

Software Revision 3.00, Version C

INTRODUCTION

The NSI 400CP represents a key part of a state of the art, total lighting control system. Combined with NSI

dimmers and optionally, an NSI memory control console, a totally integrated system is achieved.

The 400CP can automatically take control of up to 512 dimmer channels. Control is automatically passed between

400CP’s and the memory control console as desired. The 400CP is exceptionally easy to operate and features 4

zone control with programmable fade times. Remote lockout capability is also included. Installation is a snap

with the simple 4 wire digital connection required.

IMPORTANT

• Programming differs from older 400CP panels (prior to release 3.00), please read instructions.

• 400CP control panels with software release 3.00 and higher are not directly compatible and will not

operate with older 400CP panels with software prior to release 3.00. Contact dealer or factory for

modifications if necessary.

• NSI dimming systems used with these release 3.00 panels require the following software releases:

2408CD, 2408CR, 2404CD release 2.30 and above.

DDS 8600/8800/9600/9800 release 1.30 and above. *

DDS 6000 release 1.30 and above. *

DDS 5300/5500/5600 release 1.30 and above. *

* Optional interface kit required for these units.

400CP REMOTE CONTROL PANEL

Software Revision 3.00, Version C

WIRING

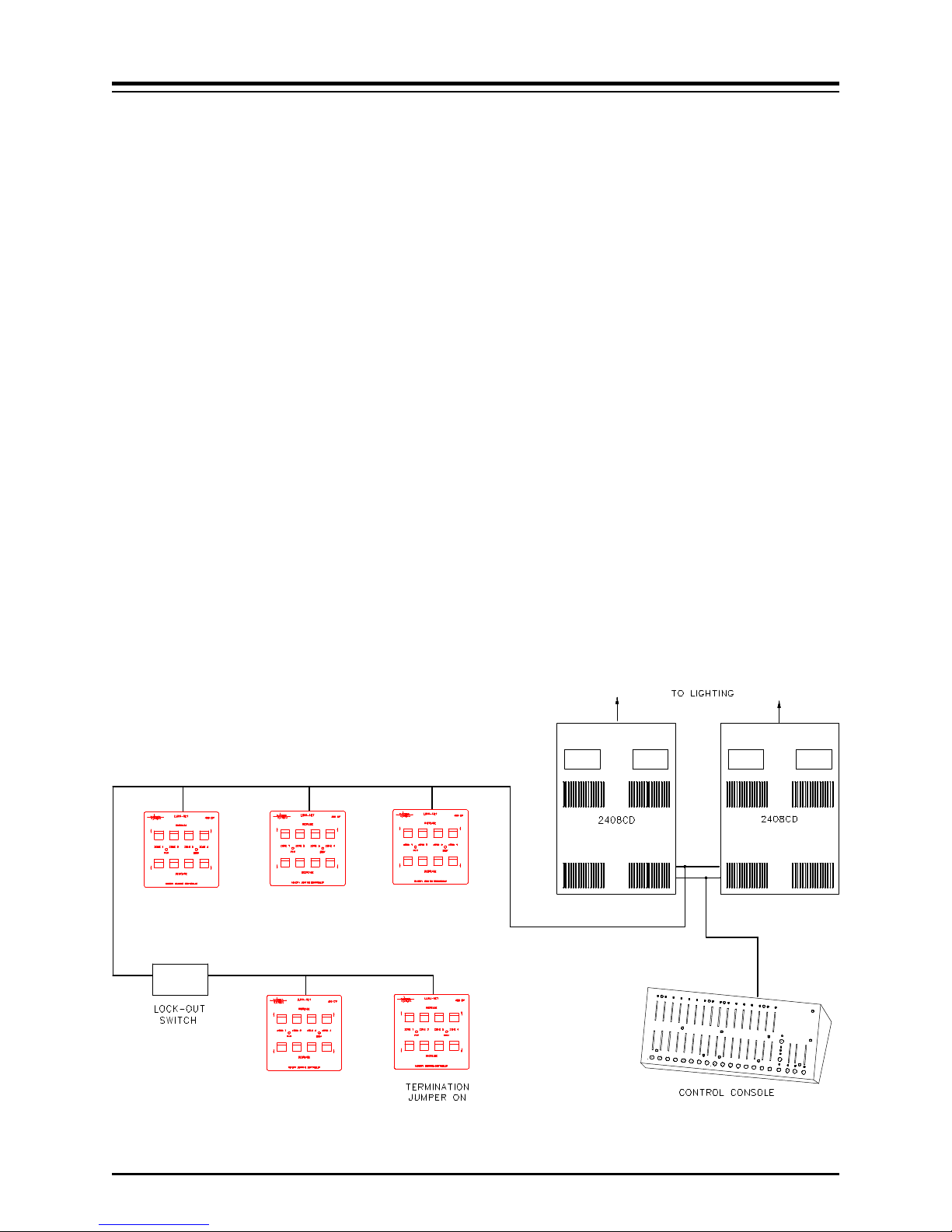

The 400CP will only operate with NSI dimming and control systems explicitly designed for interfacing with it.

Communication between the 400CP and the dimming system is via a 4 wire interface. Three wires carry the RS

422/485 bi-directional data. A fourth wire carries the DC voltage necessary for powering the unit.

Wiring cable between the 400CP and the dimming system is class 2 and should be at least 22 AWG, 4 conductor

shielded, twisted pairs. (BELDEN 8302, 8723; 22 AWG.)

The 400CP may be connected to the dimming system via parallel or daisy-chained wiring. Due to power supply

current demands, 400CP’s must be limited to 5 units per daisy chain run with 22 awg wire, or 10 units with 20

AWG wire.

The Luma-net panels feature plug on wiring terminals. The terminals may be unplugged from the panel to facilitate

ease of wiring and testing. Connect the terminals marked remote+, remote-, common, and +15 VDC to the same

respective terminals on the dimming system and other 400CPs. Use one twisted pair for remote+ and remote- and

the other pair for common and +15 VDC.

The wiring to the remote lockout switch, if used, can be simple 2 conductor 22 AWG. Connect the wires from

the switch to the lockout+ and lockout- terminals. Any panel or group of panels may be locked-out remotely by

interrupting the +15V supply to the panels. This should not affect any other panels still powered, or affect lighting

levels currently set.

IMPORTANT: Verify wiring is correct before powering system! Make sure nothing conductive may touch

pc board or components!

MOUNTING

The 400CP will mount in any standard double-gang electrical box with the 4 screws provided. See below paragraph

on system turn-on before final mounting of panels.

SYSTEM TURN-ON

It is very important that the system operation be verified one panel at a time. Else, an improper connection at

one panel would cause the entire system to not operate properly and may be difficult to diagnose.

After all terminal plugs have been wired and the dimmer system has been installed and tested, the installer is ready

to connect each panel to the system. Panels may be plugged-in while system is live, but the installer must take

care not to touch PC board or connections with fingers or metal objects. On daisy-chain runs, the panels closest

to the dimming system should be connected first.

400CP panels without dip switches must have their network ID programmed after the power is connected. The

panels that are provided with dipswitches should have the ID set before the system is powered. It is recommended

that the installer review the programming procedures for network ID before proceding. A duplicate network ID

number will cause the entire network to malfunction.

Connect the first panel and immediately notice whether the POWER LED comes on, indicating power to the

panel. The BUSY LED should come on momentarily and then go out and stay out. This indicates a successful

reconfiguration of the network. If the BUSY LED flashes slowly, this indicates a duplicate ID number or wiring

problem. Program the ID number, if not already, and observe the BUSY LED. (Note, the busy LED also flashes

quickly when the program jumper is removed).

NSI CORPORATION 2

400CP REMOTE CONTROL PANEL

Software Revision 3.00, Version C LEDS

Now test the dimmer function by programming one scene or zone and operating the panel. If the dimmer responds,

then mount the panel and procede to the next panel in the system and follow the same procedure .

LEDS

The PWR LED indicates the presence of +15VDC to the panel.

The BUSY LED indicates the following:

Off Normal state when there is no activity.

Short Blinks A message is being sent on the network.

Steady on or Slow flashing Network trying to reconfigure (bad ID?)

While programming, the following actions are normal.

Quickly flashing Programming mode, no mode selected.

Off Programming mode, mode selected.

LOCKOUT

Any 400CP may be disabled from operation with a remote key switch or other contact closure. Several Luma-net

panels of the same version may be connected to the same contacts in parallel as long as polarity is maintained.

Closing the contact will prevent connected panels from operating, regardless of button presses.

Luma-net panels may also be locked out by causing a switch to disconnect the +15V supply to the panels.

NSI CORPORATION 3

400CP REMOTE CONTROL PANEL PROGRAMMING

Software Revision 3.00, Version C Factory Default Setting:

PROGRAMMING

Several parameters must be programmed into the 400CP for it to operate properly:

Maximum number of dimmers channels.

Dimmer channel assignments for each zone.

Fade time for each zone.

Master / Slave Mode.

Network ID number (IMPORTANT).

Optionally, the unit may be ordered preprogrammed from the factory. Any field modifications can be made if

necessary.

Factory Default Setting:

The 400CP is programmed at the factory for zone 1-4 to be set for channel 1-4 respectively. The fade rate ant

other parameters are also set to factory defaults. This may be acceptable for initial testing. If necessary to return

the 400CP panel to it’s factory default settings (except network ID), follow this procedure:

1. Remove program jumper block and disconnect plug-in terminal block.

2. Hold down all ZONE 1-4 LOWER buttons while connecting terminal block.

Full Memory Clear:

Normally, the 400CP will not require memory clearing. Once the memory is cleared, all parameters, including

fade rate, must be reprogrammed. Unless it is necessary to clear memory to remove a large or unknown programming,

skip these steps.

1. Remove program jumper block and disconnect terminal block.

2. Hold down all ZONE 1-4 RAISE buttons while connecting the terminal block.

Prepare the 400CP for reprogramming:

In order to program the 400CP, a jumper block must be removed from the program jumper pins (See diagram).

This will allow data to be stored in the eeprom memory. At this point the BUSY LED will start flashing, indicating

that you are in the program select mode.

IMPORTANT: After programming it is important to replace the programming jumper block so memory

will be protected.

NSI CORPORATION 4

Loading...

Loading...