NSC LV8573AV Datasheet

LV8573A Low Voltage Real Time Clock (RTC)

LV8573A Real Time Clock (RTC)

PRELIMINARY

December 1993

General Description

The LV8573A is intended for use in microprocessor based

systems where information is required for multi-tasking, data

logging or general time of day/date information. This device

is implemented in low voltage silicon gate microCMOS technology to provide low standby power in battery back-up environments. The circuit’s architecture is such that it looks

like a contiguous block of memory or I/O ports organized as

one block of 32 bytes. This includes the Control Registers,

the Clock Counters, the Alarm Compare RAM, and the Time

Save RAM.

Time and date are maintained from 1/100 of a second to

year and leap year in a BCD format, 12 or 24 hour modes.

Day of week and day of month counters are provided. Time

is controlled by an on-chip crystal oscillator requiring only

the addition of the 32.768 kHz crystal and two capacitors.

Power failure logic and control functions have been integrated on chip. This logic is used by the RTC to issue a power

fail interrupt, and lock out the mP interface. The time power

fails may be logged into RAM automatically when V

VCC. Additionally, two supply pins are provided. When V

BB

BB

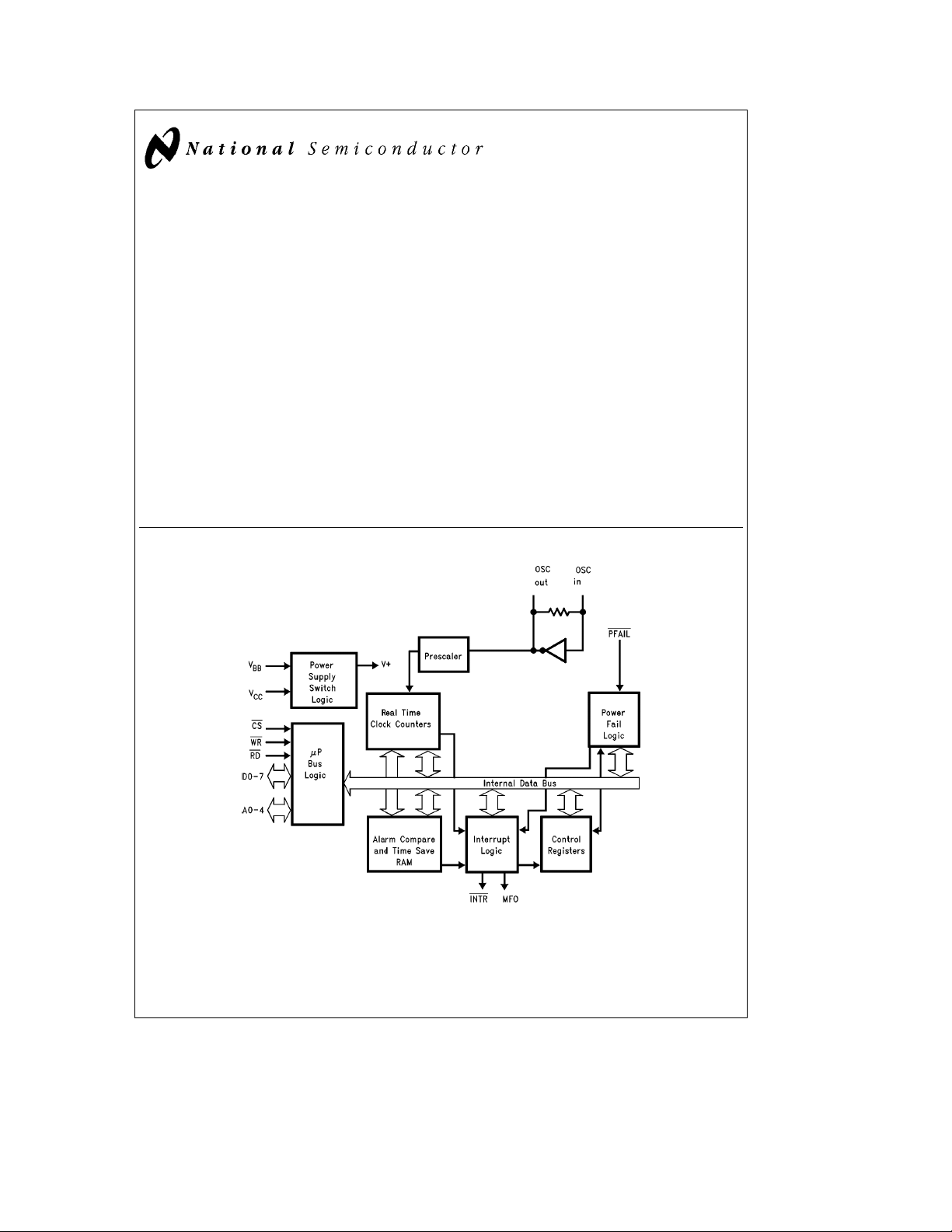

Block Diagram

l

VCC, internal circuitry will automatically switch from the

main supply to the battery supply.

The LV8573A’s interrupt structure provides three basic

types of interrupts: Periodic, Alarm/Compare, and Power

Fail. Interrupt mask and status registers enable the masking

and easy determination of each interrupt.

Features

Y

3.3Vg10% supply

Y

Full function real time clock/calendar

Ð 12/24 hour mode timekeeping

Ð Day of week counter

Ð Parallel resonant oscillator

Y

Power fail features

Ð Internal power supply switch to external battery

Ð Power Supply Bus glitch protection

Ð Automatic log of time into RAM at power failure

Y

On-chip interrupt structure

l

Ð Periodic, alarm, and power fail interrupts

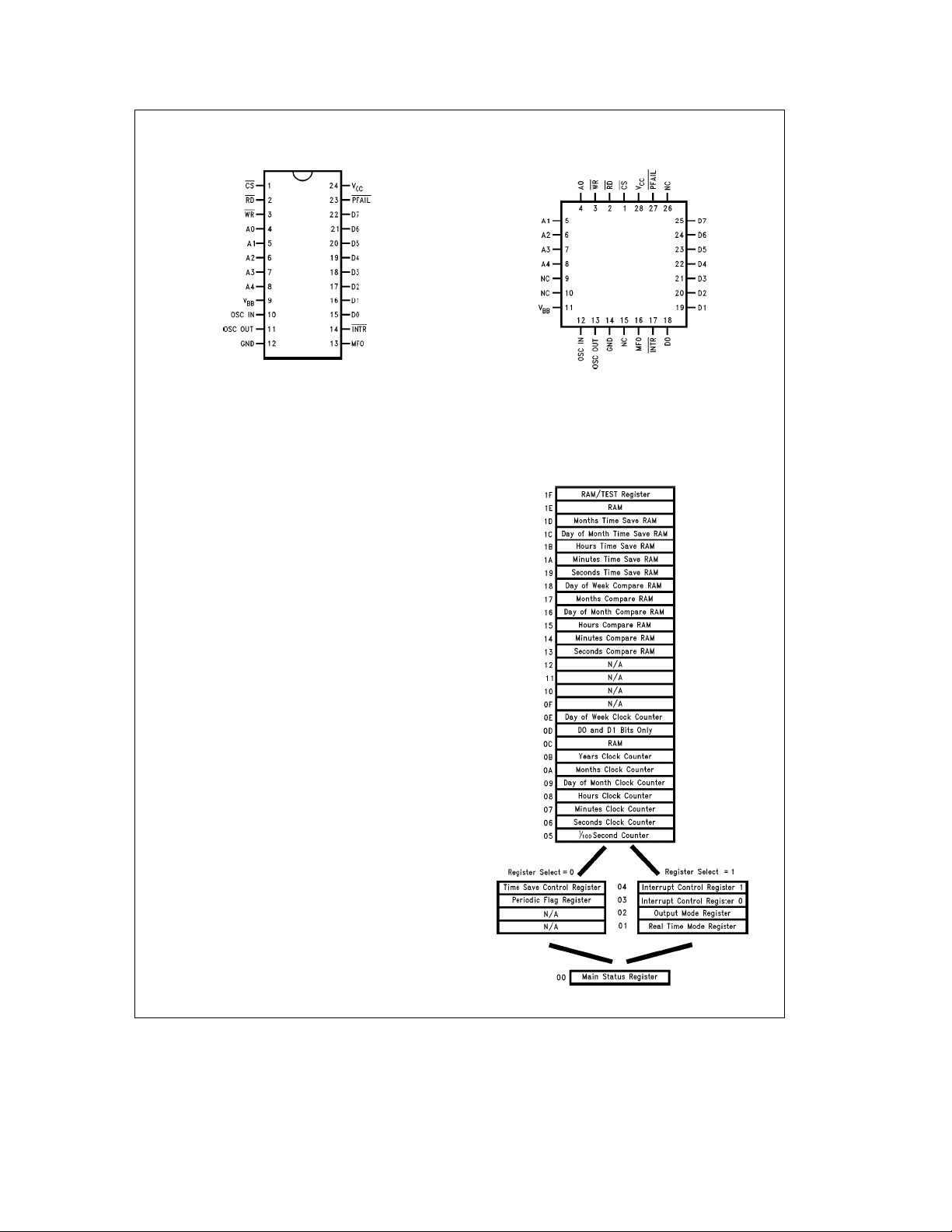

FIGURE 1

TRI-STATEÉis a registered trademark of National Semiconductor Corporation.

C

1995 National Semiconductor Corporation RRD-B30M105/Printed in U. S. A.

TL/F/11418

TL/F/11418– 1

Absolute Maximum Ratings (Notes1&2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage (V

CC

)

DC Input Voltage (VIN)

DC Output Voltage (V

OUT

)

Storage Temperature Range

Power Dissipation (PD) 500 mW

Lead Temperature (Soldering, 10 sec.) 260§C

b

0.5V toa7.0V

b

0.5V to V

b

0.5V to V

b

65§Ctoa150§C

CC

CC

a

0.5V

a

0.5V

Operation Conditions

Supply Voltage (V

) (Note 3) 3.0 3.6 V

CC

Supply Voltage (VBB) (Note 3) 2.2 V

DC Input or Output Voltage

(V

IN,VOUT

)

Operation Temperature (T

Electr-Static Discharge Rating 1 kV

Typical Values

i

DIP Board 61§C/W

JA

Socket 67

iJAPLCC Board 80§C/W

Socket 88

Min Max Unit

0.0 V

b

)

A

40

CC

a

§

§

b

0.4 V

CC

85

C/W

C/W

V

C

§

DC Electrical Characteristics

V

CC

e

3.3Vg10%, V

BB

e

2.5V, V

PFAIL

l

VIH,C

e

100 pF unless otherwise specified

L

Symbol Parameter Conditions Min Max Units

V

IH

V

IL

V

OH

V

OL

I

IN

I

OZ

I

LKG

I

CC

I

CC

I

BB

I

BLK

Note 1: Absolute Maximum Ratings are those values beyond which damage to the device may occur.

Note 2: Unless otherwise specified all voltages are referenced to ground.

Note 3: In battery backed mode, V

Note 4: This parameter (V

Note 5: This specification tests I

Note 6: This specification tests I

Note 7: OSC IN is driven by a signal generator. Contents of the Test Register

High Level Input Voltage Any Inputs Except OSC IN, 2.0 V

(Note 4) OSC IN with External Clock V

Low Level Input Voltage All Inputs Except OSC IN

OSC IN with External Clock

High Level Output Voltage I

(Excluding OSC OUT, INTR)I

Low Level Output Voltage I

(Excluding OSC OUT) I

Input Current (Except OSC IN) V

Output TRI-STATEÉCurrent V

Output High Leakage Current V

MFO, INTR Pins Outputs Open Drain

Quiescent Supply Current F

(Note 6) V

Quiescent Supply Current V

(Single Supply Mode) V

(Note 7) F

Standby Mode Battery V

Supply Current OSC OUT

(Note 7) other pins

Battery Leakage 2.2VsV

s

b

V

Single Supply Mode: Data retention voltage is 2.2V min.

In single Supply Mode (Power connected to V

BB

) is not tested on all pins at the same time.

IH

with all power fail circuitry disabled, by setting D7 of Interrupt Control Register 1 to 0.

CC

with all power fail circuitry enabled, by setting D7 of Interrupt Control Register 1 to 1.

CC

0.4V.

CC

pin) 3.0VsV

CC

eb

20 mAV

OUT

eb

2.0 mA 2.4 V

OUT

eb

20 mA 0.2 V

OUT

e

2.0 mA 0.3 V

OUT

e

VCCor GND

IN

e

VCCor GND

OUT

e

VCCor GND

OUT

e

32.768 kHz

OSC

e

VCCor GND (Note 5) 220 mA

IN

e

V

VCCor GND (Note 6) 700 mA

IN

e

V

VIHor VIL(Note 6) 5 mA

IN

e

GND

BB

e

VCCor GND 30 mA

IN

e

32.768 kHz

OSC

e

GND

CC

e

open circuit,

e

GND

e

F

32.768 kHz

OSC

s

2.6V

BB

other pins at GND

e

V

GND, V

CC

e

V

3.6V, V

CC

s

CC

e

2.6V 0.8 mA

BB

e

2.2V

BB

3.6V.

e

00(H) and the MFO pin is not configured as buffered oscillator out.

b

0.2 V

BB

b

0.3 0.8 V

b

0.3 0.2 V

b

0.2 V

CC

b

0.8 mA

a

0.3 V

CC

g

0.7 mA

g

1 mA

g

1 mA

8 mA

2

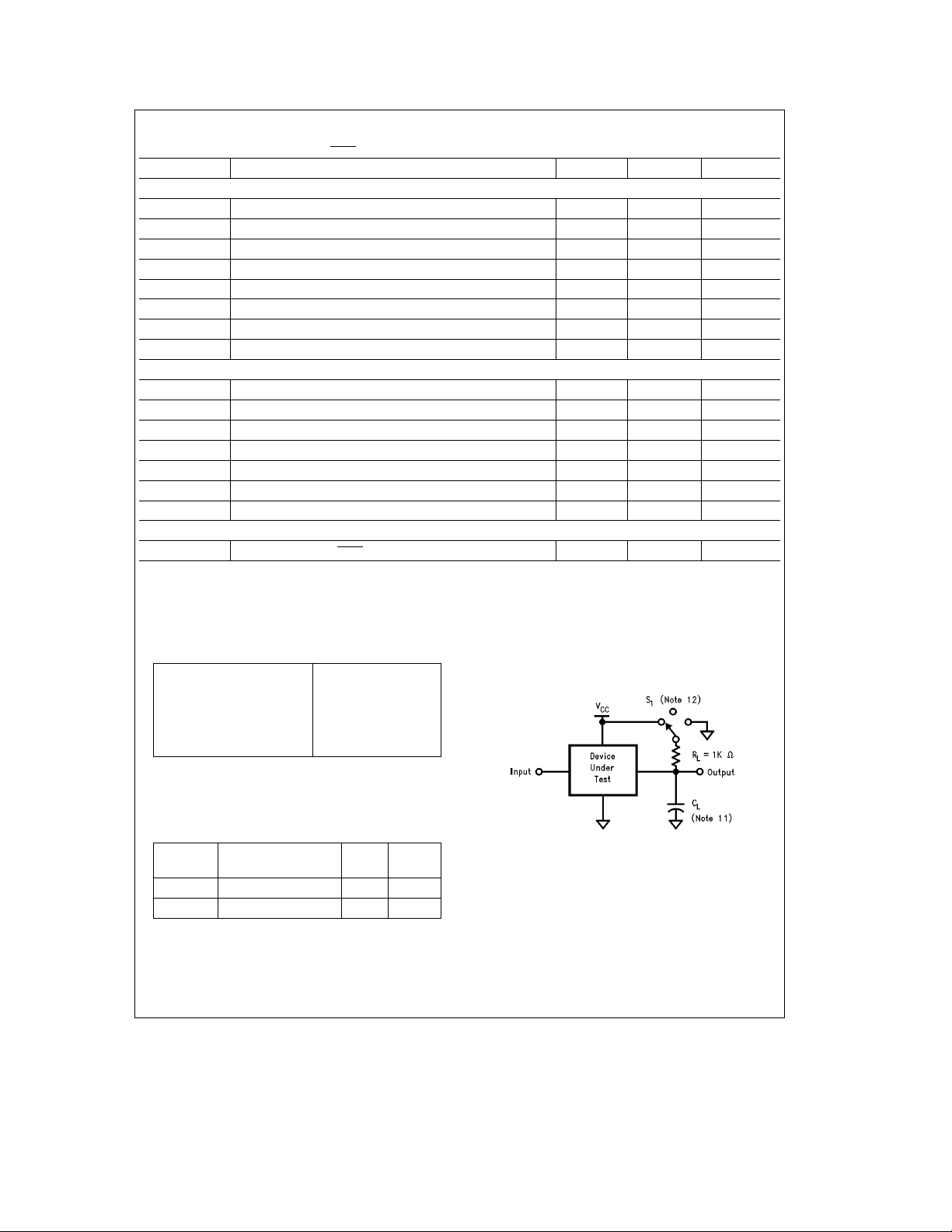

AC Electrical Characteristics

V

CC

e

3.3Vg10%, V

BB

e

2.5V, V

PFAIL

l

VIH,C

e

100 pF unless otherwise specified

L

Symbol Parameter Min Max Units

READ TIMING

t

AR

t

RW

t

CD

t

RAH

t

RD

t

DZ

t

RCH

t

DS

Address Valid Prior to Read Strobe 10 ns

Read Strobe Width (Note 8) 100 ns

Chip Select to Data Valid Time 100 ns

Address Hold after Read (Note 9) 2 ns

Read Strobe to Valid Data 90 ns

Read or Chip Select to TRI-STATE 80 ns

Chip Select Hold after Read Strobe (Note 9) 0 ns

Minimum Inactive Time between Read or Write Accesses 70 ns

WRITE TIMING

t

AW

t

WAH

t

CW

t

WW

t

DW

t

WDH

t

WCH

Address Valid before Write Strobe 10 ns

Address Hold after Write Strobe (Note 9) 2 ns

Chip Select to End of Write Strobe 110 ns

Write Strobe Width (Note 10) 100 ns

Data Valid to End of Write Strobe 70 ns

Data Hold after Write Strobe (Note 9) 2 ns

Chip Select Hold after Write Strobe (Note 9) 0 ns

INTERRUPT TIMING

t

ROLL

Note 8: Read Strobe width as used in the read timing table is defined as the period when both chip select and read inputs are low. Hence read commences when

both signals are low and terminates when either signal returns high.

Note 9: Hold time is guaranteed by design but not production tested. This limit is not used to calculate outgoing quality levels.

Note 10: Write Strobe width as used in the write timing table is defined as the period when both chip select and write inputs are low. Hence write commences when

both signals are low and terminates when either signal returns high.

Clock rollover to INTR out typically 20 ms

AC Test Conditions

Input Pulse Levels GND to 3.0V

Input Rise and Fall Times 6 ns (10% –90%)

Input and Output

Reference Levels

TRI-STATE Reference Active High

Levels (Note 12) Active Low

S1

S1

Symbol

C

IN

C

OUT

e

100 pF, includes jig and scope capacitance.

L

e

VCCfor active low to high impedance measurements.

e

GND for active high to high impedance measurements.

e

open for all other timing measurements.

e

25§C, fe1 MHz)

A

Parameter

(Note 13)

Input Capacitance 5 pF

Output Capacitance 7 pF

Note 11: C

Note 12: S1

Capacitance (T

Note 13: This parameter is not 100% tested.

Note 14: Output rise and fall times 25 ns max (10%– 90%) with 100 pF load.

1.3V

a

0.5V

b

0.5V

Typ Units

TL/F/11418– 2

3

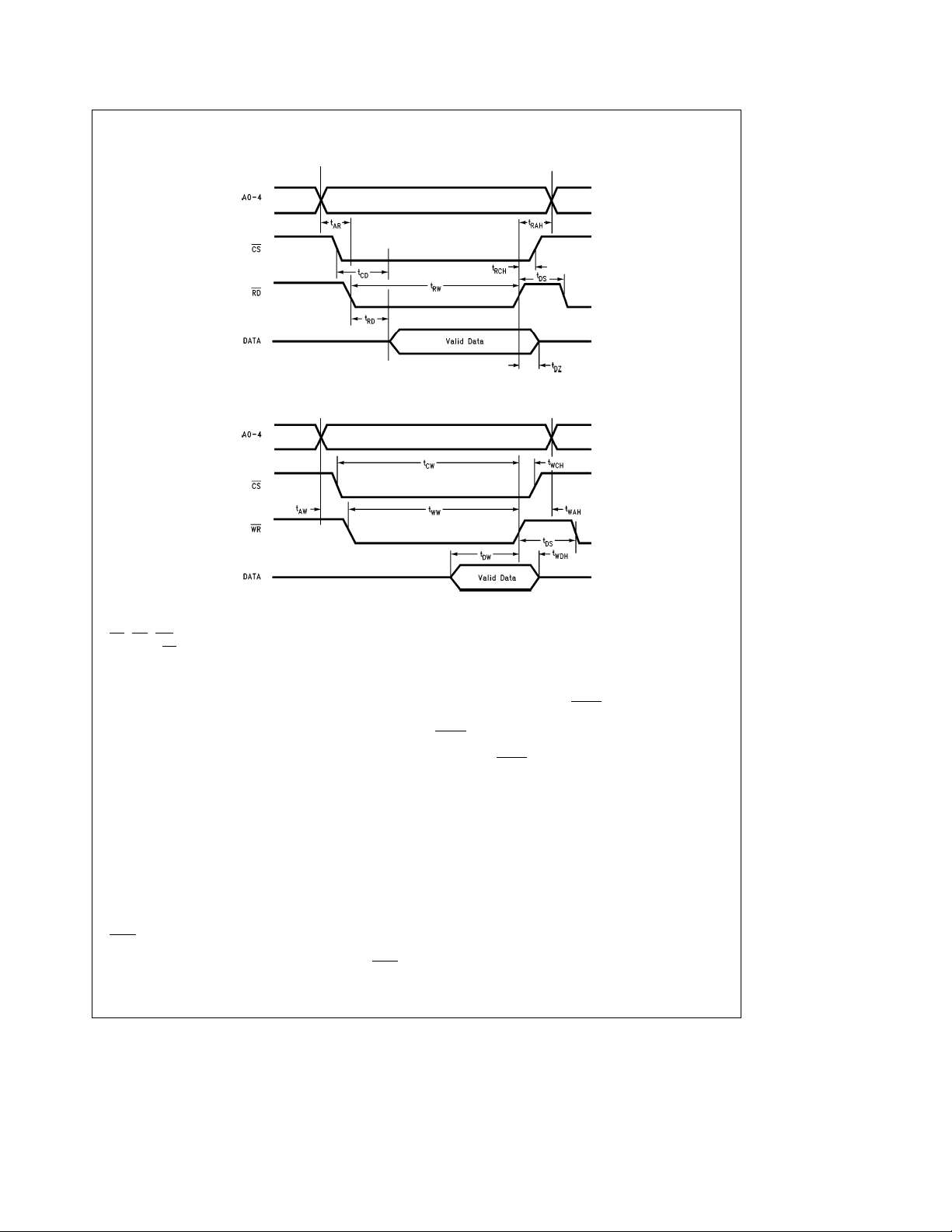

Timing Waveforms

Read Timing Diagram

TL/F/11418– 3

Write Timing Diagram

Pin Description

CS,RD,WR(Inputs): These pins interface to mP control

lines. The CS

write operations. Read and Write pins are also active low

and enable reading or writing to the RTC. All three pins are

disabled when power failure is detected. However, if a read

or write is in progress at this time, it will be allowed to complete its cycle.

A0–A4 (Inputs): These 5 pins are for register selection.

They individually control which location is to be accessed.

These inputs are disabled when power failure is detected.

OSC IN (Input): OSC OUT (Output): These two pins are

used to connect the crystal to the internal parallel resonant

oscillator. The oscillator is always running when power is

applied to V

MFO (Output): The multi-function output can be used as a

second interrupt (Power fail) output for interrupting the mP.

This pin can also provide an output for the oscillator. The

MFO output is configured as push-pull, active high for normal or single power supply operation and as an open drain

during standby mode (V

mode and a pull-up resistor is attached, it should be connected to a voltage no greater than V

INTR (Output): The interrupt output is used to interrupt the

processor when a timing event or power fail has occurred

and the respective interrupt has been enabled. The INTR

pin is an active low enable for the read and

and VCC.

BB

l

VCC). If in battery backed

BB

.

BB

TL/F/11418– 4

output is permanently configured active low, open drain. If in

battery backed mode and a pull-up resistor is attached, it

should be connected to a voltage no greater than V

D0–D7 (Input/Output): These 8 bidirectional pins connect

to the host mP’s data bus and are used to read from and

write to the RTC. When the PFAIL

pin goes low and a write

is not in progress, these pins are at TRI-STATE.

PFAIL

(Input): In battery backed mode, this pin can have a

digital signal applied to it via some external power detection

logic. When PFAIL

e

logic 0 the RTC goes into a lockout

mode, in a minimum of 30 ms or a maximum of 63 ms unless

lockout delay is programmed. In the single power supply

mode, this pin is not useable as an input and should be tied

to V

. Refer to section on Power Fail Functional Descrip-

CC

tion.

V

(Battery Power Pin): This pin is connected to a back-

BB

up power supply. This power supply is switched to the internal circuitry when the V

ing this pin eliminates the need for external logic to switch in

becomes lower than VBB. Utiliz-

CC

and out the back-up power supply. If this feature is not to be

used then this pin must be tied to ground, the RTC programmed for single power supply only, and power applied to

the V

pin.

CC

VCC: This is the main system power pin.

GND: This is the common ground power pin for both V

and VCC.

4

BB

.

BB

Connection Diagrams

In-Line Packages

Plastic Chip Carrier

Top View

TL/F/11418– 5

DIP: Order Number LV8573AN

See NS Package Number N24C

SOIC: Order Number LV8573AM

See NS Package Number M24B

Functional Description

The LV8573A contains a fast access real time clock, interrupt control logic, and power fail detect logic. All functions of

the RTC are controlled by a set of seven registers. A simplified block diagram that shows the major functional blocks is

given in

Figure 1

.

The blocks are described in the following sections:

1. Real Time Clock

2. Oscillator Prescaler

3. Interrupt Logic

4. Power Failure Logic

5. Additional Supply Management

The memory map of the RTC is shown in the memory addressing table

Register is used to select either control register block.

INITIAL POWER-ON of BOTH V

VBBand VCCmay be applied in any sequence. In order for

the power fail circuitry to function correctly, whenever power

is off, the V

maximum of 1 MX. The user should be aware that the control registers will contain random data. The user should ensure that the RTC is not in test mode (see register descriptions).

REAL TIME CLOCK FUNCTIONAL DESCRIPTION

As shown in

which count from 1/100 of a second to years. Each counter

counts in BCD and is synchronously clocked. The count sequence of the individual byte counters within the clock is

shown later in Table VII. Note that the day of week, day of

month, and month counters all roll over to 1. The hours

counter in 12 hour mode rolls over to 1 and the AM/PM bit

toggles when the hours rolls over to 12 (AM

The AM/PM bit is bit D7 in the hours counter.

All other counters roll over to 0. Upon initial application of

power the counters will contain random information.

(Figure 2).

pin must see a path to ground through a

CC

Figure 2

A control bit in the Main Status

and V

BB

CC

, the clock has 8 bytes of counters,

e

0, PMe1).

Top View

TL/F/11418– 6

Order Number LV8573AV

See NS Package Number V28A

TL/F/11418– 7

FIGURE 2. LV8573A Internal Memory Map

5

Functional Description (Continued)

READING THE CLOCK: VALIDATED READ

Since clocking of the counter occurs asynchronously to

reading of the counter, it is possible to read the counter

while it is being incremented (rollover). This may result in an

incorrect time reading. Thus to ensure a correct reading of

the entire contents of the clock (or that part of interest), it

must be read without a clock rollover occurring. In general

this can be done by checking a rollover bit. On this chip the

periodic interrupt status bits can serve this function. The

following program steps can be used to accomplish this.

1. Initialize program for reading clock.

2. Dummy read of periodic status bit to clear it.

3. Read counter bytes and store.

4. Read rollover bit, and test it.

5. If rollover occured go to 3.

6. If no rollover, done.

To detect the rollover, individual periodic status bits can be

polled. The periodic bit chosen should be equal to the highest frequency counter register to be read. That is if only

SECONDS through HOURS counters are read, then the

SECONDS periodic bit should be used.

READING THE CLOCK: INTERRUPT DRIVEN

Enabling the periodic interrupt mask bits cause interrupts

just as the clock rolls over. Enabling the desired update rate

and providing an interrupt service routine that executes in

less than 10 ms enables clock reading without checking for

a rollover.

READING THE CLOCK: LATCHED READ

Another method to read the clock that does not require

checking the rollover bit is to write a one into the Time Save

Enable bit (D7) of the Time Save Control Register, and then

to write a zero. Writing a one into this bit will enable the

clock contents to be duplicated in the Time Save RAM.

Changing the bit from a one to a zero will freeze and store

the contents of the clock in Time Save RAM. The time then

can be read without concern for clock rollover, since internal logic takes care of synchronization of the clock. Because only the bits used by the clock counters will be

latched, the Time Save RAM should be cleared prior to use

to ensure that random data stored in the unused bits do not

confuse the host microprocessor. This bit can also provide

time save at power failure, see the Additional Supply Management Functions section. With the Time Save Enable bit

at a logical 0, the Time Save RAM may be used as RAM if

the latched read function is not necessary.

INITIALIZING AND WRITING TO THE

CALENDAR-CLOCK

Upon initial application of power to the TCP or when making

time corrections, the time must be written into the clock. To

correctly write the time to the counters, the clock would

normally be stopped by writing the Start/Stop

Time Mode Register to a zero. This stops the clock from

counting and disables the carry circuitry. When initializing

the clock’s Real Time Mode Register, it is recommended

that first the various mode bits be written while maintaining

the Start/Stop

second time with the Start/Stop

bit reset, and then writing to the register a

bit set.

bit in the Real

The above method is useful when the entire clock is being

corrected. If one location is being updated the clock need

not be stopped since this will reset the prescaler, and time

will be lost. An ideal example of this is correcting the hours

for daylight savings time. To write to the clock ‘‘on the fly’’

the best method is to wait for the 1/100 of a second periodic interrupt. Then wait an additional 16 ms, and then write

the data to the clock.

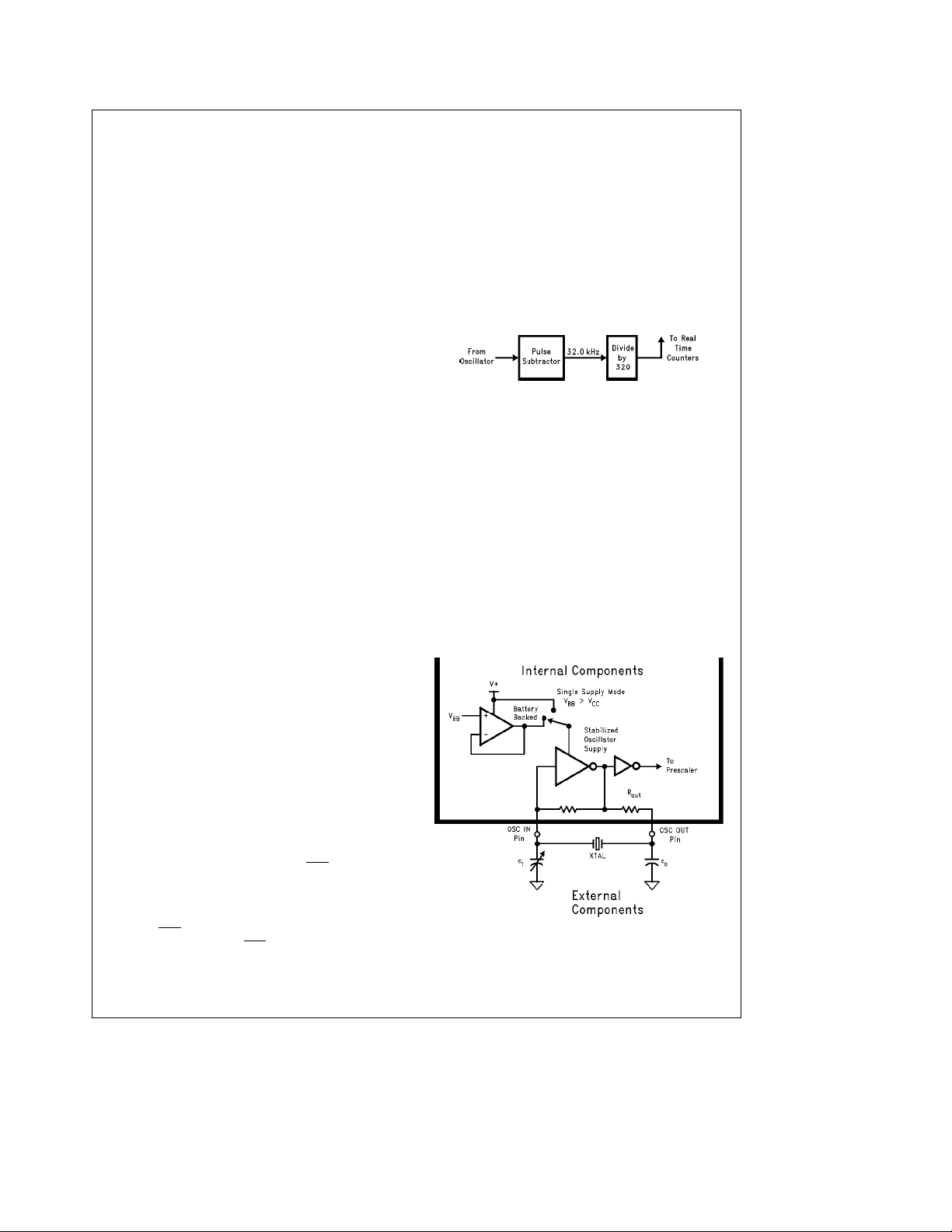

PRESCALER/OSCILLATOR FUNCTIONAL

DESCRIPTION

Feeding the counter chain is a programmable prescaler

which divides the crystal oscillator frequency to 32 kHz and

further to 100 Hz for the counter chain (see

FIGURE 3. Programmable Clock Prescaler Block

In addition to the inverter, the oscillator feedback bias resistor is included on chip, as shown in

input may be driven from an external source if desired. Refer to test mode application note for details. The oscillator

stability is enhanced through the use of an on chip regulated

power supply.

The typical range of trimmer capacitor (as shown in Oscillator Circuit Diagram

the oscillator input pin is suggested only to allow accurate

tuning of the oscillator. This range is based on a typical

printed circuit board layout and may have to be changed

depending on the parasitic capacitance of the printed circuit

board or fixture being used. In all cases, the load capaci-

tance specified by the crystal manufacturer (nominal value

11 pF for the 32.768 crystal) is what determines proper oscillation. This load capcitance is the series combination of

capacitance on each side of the crystal (with respect to

ground).

Figure 4

, and in the typical application) at

FIGURE 4. Oscillator Circuit Diagram

Figure 4

Figure 3

).

TL/F/11418– 8

. The oscillator

TL/F/11418– 9

6

Loading...

Loading...