TL/H/6750

LM1893/LM2893 Carrier-Current Transceiver

April 1995

LM1893/LM2893 Carrier-Current Transceiver

²

General Description

Carrier-current systems use the power mains to transfer information between remote locations. This bipolar carriercurrent chip performs as a power line interface for half-duplex (bi-directional) communication of serial bit streams of

virtually any coding. In transmission, a sinusoidal carrier is

FSK modulated and impressed on most any power line via a

rugged on-chip driver. In reception, a PLL-based demodulator and impulse noise filter combine to give maximum range.

A complete system may consist of the LM1893, a COPS

TM

controller, and discrete components.

Features

Y

Noise resistant FSK modulation

Y

User-selected impulse noise filtering

Y

Up to 4.8 kBaud data transmission rate

Y

Strings of 0’s or 1’s in data allowed

Y

Sinusoidal line drive for low RFI

Y

Output power easily boosted 10-fold

Y

50 to 300 kHz carrier frequency choice

Y

TTL and MOS compatible digital levels

Y

Regulated voltage to power logic

Y

Drives all conventional power lines

Applications

Y

Energy management systems

Y

Home convenience control

Y

Inter-office communication

Y

Appliance control

Y

Fire alarm systems

Y

Security systems

Y

Telemetry

Y

Computer terminal interface

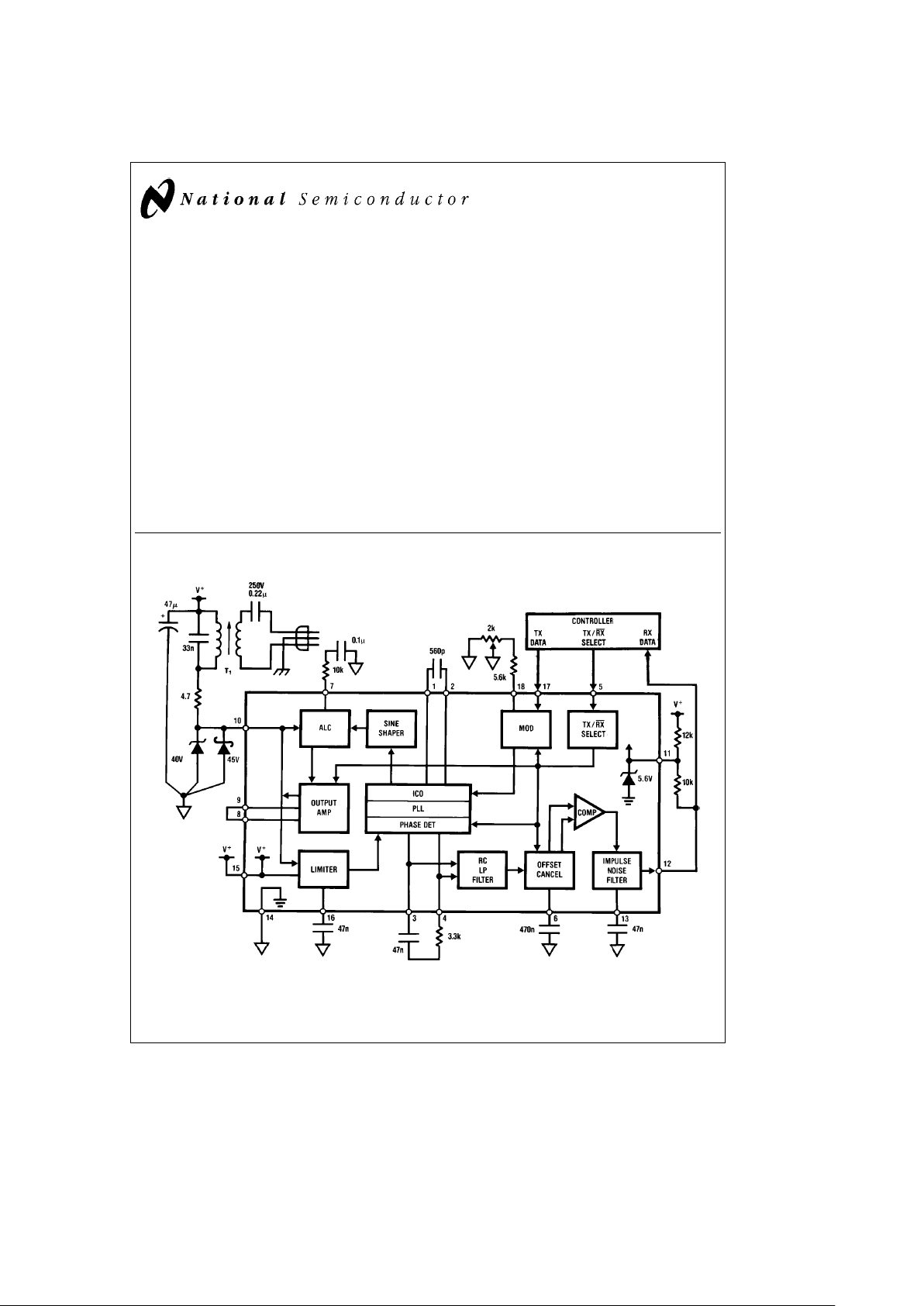

Typical Application

TL/H/6750– 1

FIGURE 1. Block diagram of carrierÐcurrent chip with a complement of discrete components making a complete

F

O

e

125 kHz, f

DATA

e

360 Baud transceiver. Use caution with this circuitÐdangerous line voltage is present.

BI-LINETMand COPSTMare trademarks of National Semiconductor Corp.

²

Carrier-Current Transceivers are also called Power Line Carrier (PLC) transceivers.

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply voltage 30 V

Voltage on pin 12 55 V

Voltage on pin 10 (Note 1) 41 V

Voltage on pins 5 and 17 40 V

5.6 V DC zener current 100 mA

Junction temperature: transmit mode 150

§

C

receive mode 125

§

C

Electro-Static Discharge (120 pF, 1500X) 1KV

Maximum continuous dissipation, T

A

e

25§C,

plastic DIP N (Note 2): transmit mode 1.66 W

receive mode 1.33 W

Operating ambient temp. range

b

40 to 85§C

Storage temperature range

b

65 to 150§C

Lead temp., soldering, 7 seconds 260

§

C

Note:

Absolute maximum ratings indicate limits beyond

which damage to the device may occur. Electrical specifications are not ensured when operating the device above

guaranteed limits but below absolute maximum limits, but

there will be no device degradation.

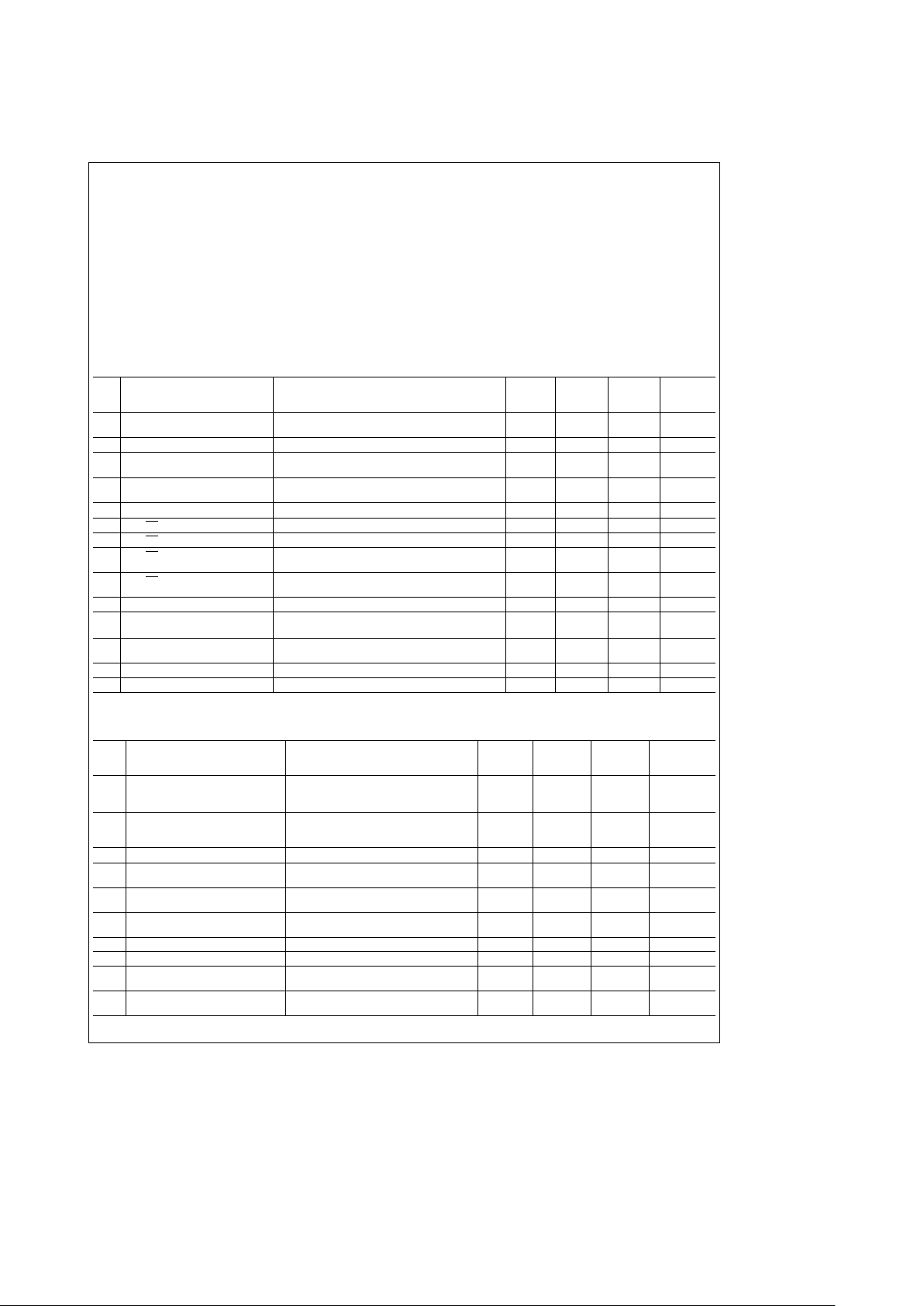

General Electrical Characteristics

(Note 3). The test conditions are: V

a

e

18V and F

O

e

125 kHz, unless otherwise noted.

Test Design

Limit

Ý

Parameter Conditions Typical Limit Limit

Units

(Note 4) (Note 5)

1 5.6 V Zener voltage, V

Z

Pin 11, I

Z

e

2 mA 5.6 5.2 V min.

5.9 V max.

2 5.6 V Zener resistance, R

Z

Pin 11, R

Z

e

(V

Z

@

10 mAbV

Z

@

1 mA)/(10 mAb1 mA) 5 X

3 Carrier I/O peak survivable Pin 10, discharge 1 mF cap. charged to V

OT

80 60 V max.

transient voltage, V

OT

thruk1X

4 Carrier I/O clamp voltage, V

OC

Pin 10, I

OC

e

10 mA, RX mode 44 41 V min.

2N2222 diode pin 8 to 9 50 V max.

5 Carrier I/O clamp resistance, R10Pin 10, I

OC

e

10 mA 20 X

6 TX/RX low input voltage, V

IL

Pin 5 1.8 0.8 V max.

7 TX/RX high input voltage, V

IH

Pin 5 (Note 9) 2.2 2.8 V min.

8 TX/RX low input current, I

IL

Pin 5 at 0.8 V

b

2

b

20 mA min.

1 mA max.

9 TX/RX high input current, I

IH

Pin5at40V

b

1 0 mA min.

10

b

4

10 mA max.

10 RXbTX switch-over time, T

RT

Time to develop 63% of full current drive thru pin 10 10 ms

11 TXbRX switch-over time, T

TR

1 bit time, T

B

e

1/(2F

DATA

). Time TTRis user 2 bit

controlled with C

M

, see Apps. Info.

12 ICO initial accuracy of F

O

TX mode, R

O

e

6.65 kX,C

O

e

560 pF 125 113 kHz min.

F

0

e

(F

1

a

F2)/2 137 kHz max.

13 ICO temperature coefficient of FOTX or RX mode, (F

OMAX

b

F

OMIN

)/(T

JMAX

b

T

JMIN

)

b

100 PPM/§C

14 Temperature drift of F

O

TX or RX mode,b40sT

J

s

T

JMAX

g

2.0

g

5.0 % max.

Transmitter Electrical Characteristics (Note 3). The test conditions are: V

a

e

18 V and F

O

e

125 kHz

unless otherwise noted. The transmit center frequency is F

O

, FSK low is F1, and FSK high is F2.

Test Design

Limit

Ý

Parameter Conditions Typical Limit Limit

Units

(Note 4) (Note 5)

15 Supply voltage, Va, range Meets test 17 spec. at T

J

e

25§C and: 13 14 15 V min.

l

(F

1

[

14V

]

b

F

1

[

18V])/F

1

[

18V

]

l

k

0.01 40 24 23 V max.

l

(F

1

[

24V

]

b

F

1

[

18V])/F

1

[

18V

]

l

k

0.01

16 Total supply current, I

QT

Pin 15. Pin 12 high. IQTis IQthrough 52 79 mA max.

pin 15 and the average current I

ODC

of the

Carrier I/O through pin 10

17 Carrier I/O output current, I

O

100X load on pin 10 70 45 mApp min.

18 Carrier I/O lower swing limit, V

ALC

Pin 10. Set internally be ALC. 4.7 4.0 V min.

2N2222 diode pin 8 to 9 5.7 V max.

19 THD of IO(Note 6) Q of 10 tank driving 10X line 0.6 5.0 % max.

100X load, no tank 5.5 9 % max.

20 FSK deviation, F

2

b

F

1

(F

2

b

F1)/([F

2

a

F

1

]

/2) 4.4 3.7 % min.

5.2 % max.

21 Data In. low input voltage, V

IL

Pin 17 1.7 0.8 V max.

22 Data In. high input voltage, V

IH

Pin 17 (Note 9) 2.1 2.8 V min.

23 Data In. low input current, I

IL

Pin 17 at 0.8 V

b

1

b

10 mA min.

1 mA max.

24 Data In. high input current, I

IH

Pin 17 at 40 V

b

1 0 mA min.

10

b

4

10 mA max.

2

Receiver Electrical Characteristics (Note 3). The test conditions are: V

a

e

18 V, F

O

e

125 kHz,g2.2%

deviation FSK, F

DATA

e

2.4 kHz, V

IN

e

100 mVpp, in the receive mode, unless otherwise noted.

Test Design

Limit

Ý

Parameter Conditions Typical Limit Limit

Units

(Note 4) (Note 5)

25 Supply voltage, Va, range Functional receiver (Note 7) 12 13 13.5 V min.

37 30 28 V max.

26 Supply current, I

QT

IQTis pin 15 (Va) plus pin 10 11 5 mA min.

(Carrier I/O) current. 2.4 kX Pin 13 to GND. 14 mA max.

27 Carrier I/O input resistance, R

10

Pin 10 19.5 14 kX min.

30 kX max.

28 Max. data rate, F

MD

Functional receiver (Note 7), C

F

e

100 pF, 10 4.8 2.4 kBaud

R

F

e

0X, no tank,

2.4 kHz

e

4.8 kBaud

29 PLL capture range, F

C

C

F

e

100 pF, R

F

e

0 X

g

40

g

15

g

10 % min.

30 PLL lock range, F

L

C

F

e

100 pF, R

F

e

0 X

g

45

g

15 % min.

31 Receiver input sensitivity, S

IN

For a functional receiver (Note 8)

Referred to chip side (pin 10) 1.8 10 12 mV

RMS

of the line-coupling XFMR: F

O

e

50 kHz 2.0 mV

RMS

F

O

e

300 kHz 1.4 mV

RMS

Referred to line side of XFMR: 0.26 mV

RMS

(assuming a 7.07:1 XFMR) F

O

e

50 kHz 0.29 mV

RMS

F

O

e

300 kHz 0.20 mV

RMS

32 Tolerable input dc voltage offset Pin 10 lower than pin 15 by V

INDC

2 0.1 V max.

range, V

INDC

33 Data Out. breakdown voltage Pin 12, leakage Is20 mA 70 55 V min.

34 Data Out. low output, V

OL

Pin 12, sat. voltage at I

OL

e

2 mA 0.15 0.4 V max.

35 Impulse noise filter current, I

I

Pin 13 charge and discharge current

g

55

g

45 mA min.

g

85 mA max.

36 Offset hold cap. bias voltage, V

CM

Pin 6 2.0 1.3 V min.

3.5 V max.

37 Offset hold capacitor max. drive Pin 6. V(pin 3)bV(pin 4)

e

g

250 mV

g

55

g

25 mA min.

current, I

MCM

g

80 mA max.

38 Offset hold bias current, I

OHB

Pin 6, TX mode. Bias pin 6 as it self-

b

0.5

b

20

b

40 nA min.

biased during test 31. 40 nA max.

39 Phase comparator current, I

PC

Bias pins 3 and 4 at 8.5 V 100 50 mA min.

I

PC

e

I(pin 3)aI(pin 4), TX mode 200 mA max.

40 Phase detector output resistance, Pins 3 and 4. 10 6 kX min.

R

PD

R

PD

e

(V@100mAbV@50mA)/(50mA) 18 kX max.

41 Phase detector demodulated output Pin 3 to 4, measured after filtering 100 60 mVpp min.

voltage, V

PD

out the 2FOcomponent 180 mVpp max.

42 Fast offset cancel voltage ‘‘window’’ V

PIN3

b

V

PIN4

e

g

V

WINDOW

a

DC offset 0.95 0.70 V/V min.

-to-V

PD

ratio, VW/V

PD

Drive forg1 mA pin 6 current 1.20 V/V max.

43 Power supply rejection, PSRR C

L

e

0.1 mF. PSRReCMRR. 120 Hz 80 dB min.

Note 1: More accurately, the maximum voltage allowed on pin 10 is VOC, and VOCranges from 41 to 50V. Also, transients may reach above 60V; see the transient

peak voltage characteristic curve.

Note 2: The maximum power dissipation rating should be derated for device operation above 25

§

C to insure that the junction temperature remains below the

maximum rating. Use a i

JA

of 75§C/W for the N package using a socket in still air (which is the worst case). Consult the Application Information section for more

detail.

Note 3: The boldface values apply over the full junction temperature range for the specified supply voltage range. All other numbers apply at T

A

e

T

J

e

25§C. Pin

numbers refer to LM1893. LM2893 tested by shorting Carrier In to Carrier Out and testing it as an LM1893.

Note 4: Guaranteed and 100% production tested.

Note 5: Guaranteed (but not 100% production tested) over the temperature and supply voltage ranges. These limits are not used to calculate outgoing quality

levels.

Note 6: Total harmonic distortion is measured using THD

e

[

I

RMS

(all components at or above 2FO)]/[I

RMS

(fundamental)].

Note 7: Receiver function is defined as the error-free passage of 1 cycle of 50% duty-cycle 2.4 kHz square-wave data (2 sequential 208 mS bits), with the first bit

being a ‘‘1.’’ All of the data transitions (edges) must fall within

g

10% (g20.8 ms) of their noise-free positions. RX time delay is minimized by using no impulse noise

filter cap. C

I

for this test.

Note 8: During the sensitivity check, note 7 requirements are followed with these exceptions: (1) data rate F

DATA

e

1.2 kHz, (2) all of the data transitions must fall

within

g

20% (g41.6 ms) of their noise-free positions, and (3), a time-domain filter capacitor (CI) is used. The time delay of CIis (/2 bit, or 208 ms. (CIis

approximately 6200 pF).

Note 9: For TTL compatibility use a pull-up resistor to increase min. V

OH

to above 2.8 V.

3

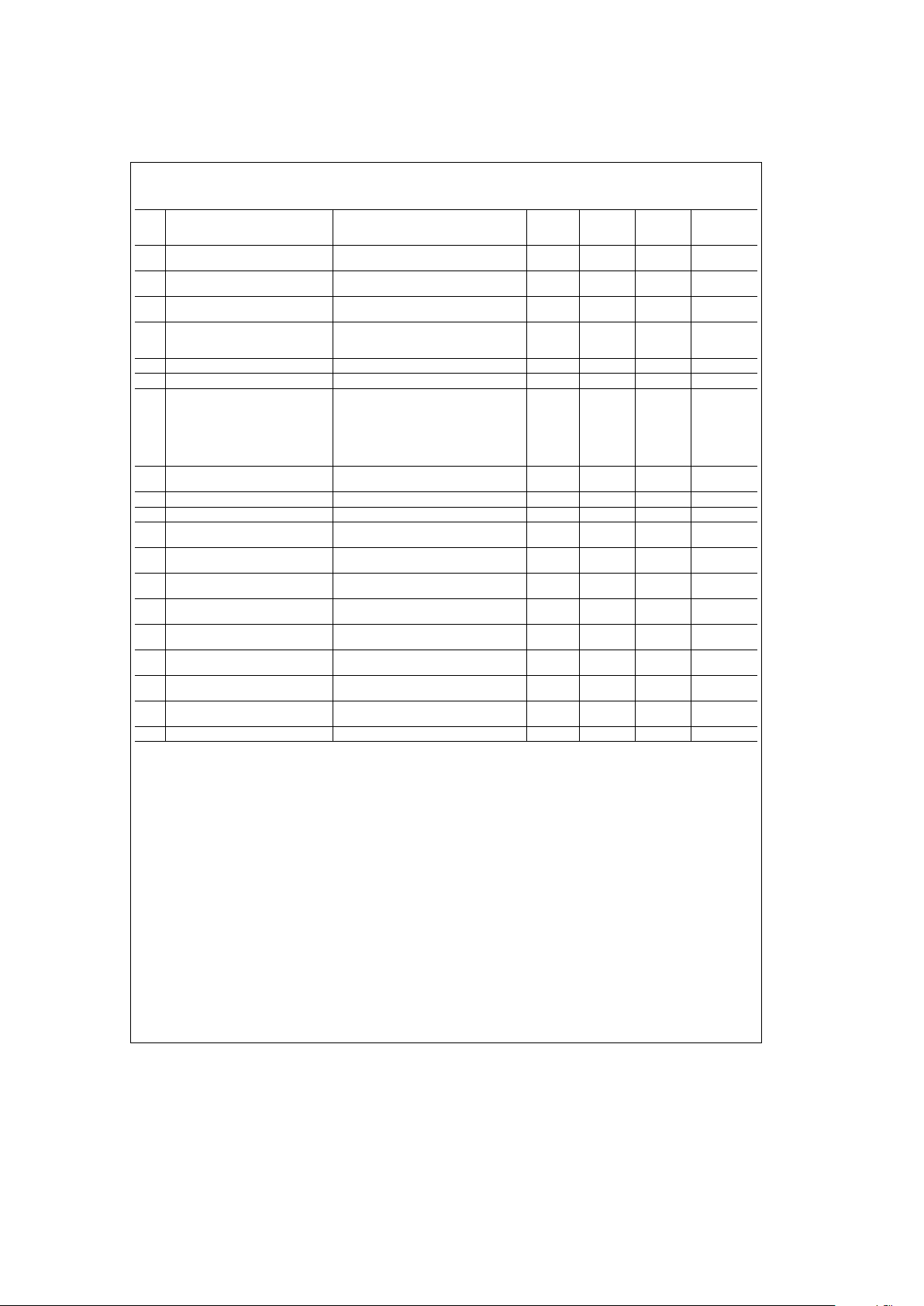

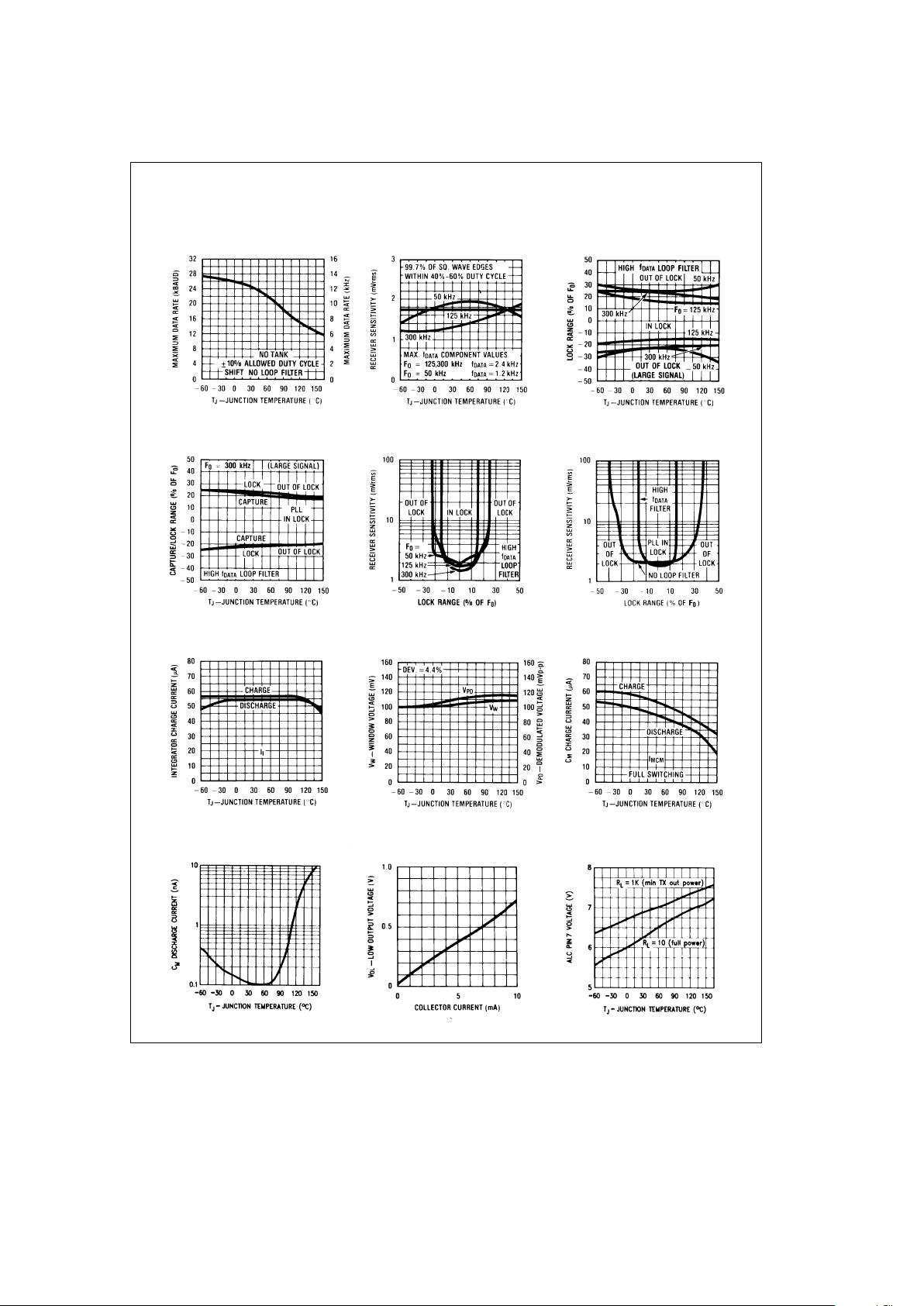

Typical Performance Characteristics (V

a

e

18V, F

O

e

125 kHz, circuit of

Figure 1

, pin numbers for

LM1893)

Total Current Consumption,

I

QT

, vs Supply Voltage

Total Current Consumption,

IQT, vs Junction Temperature

Chip Bias Current,

iQ, vs Supply Voltage

Chip Bias Current, I

Q

,

vs Junction Tempurature

Output Stage DC Current,

I

ODC

, vs Output Voltage

Output Stage DC Current,

I

ODC

,vs

Junction Temperature

Transient Voltage Survival

vs Pulse Time

Transmitter AC Output Current

vs Junction Temperature

Transmitter Sinusoid THD

vs Junction Temperature

ALC Voltage vs

Junction Temperature

ICO Frequency vs

Junction Temperature

Transmitter FSK Deviation

vs Junction Temperature

TL/H/6750– 38

4

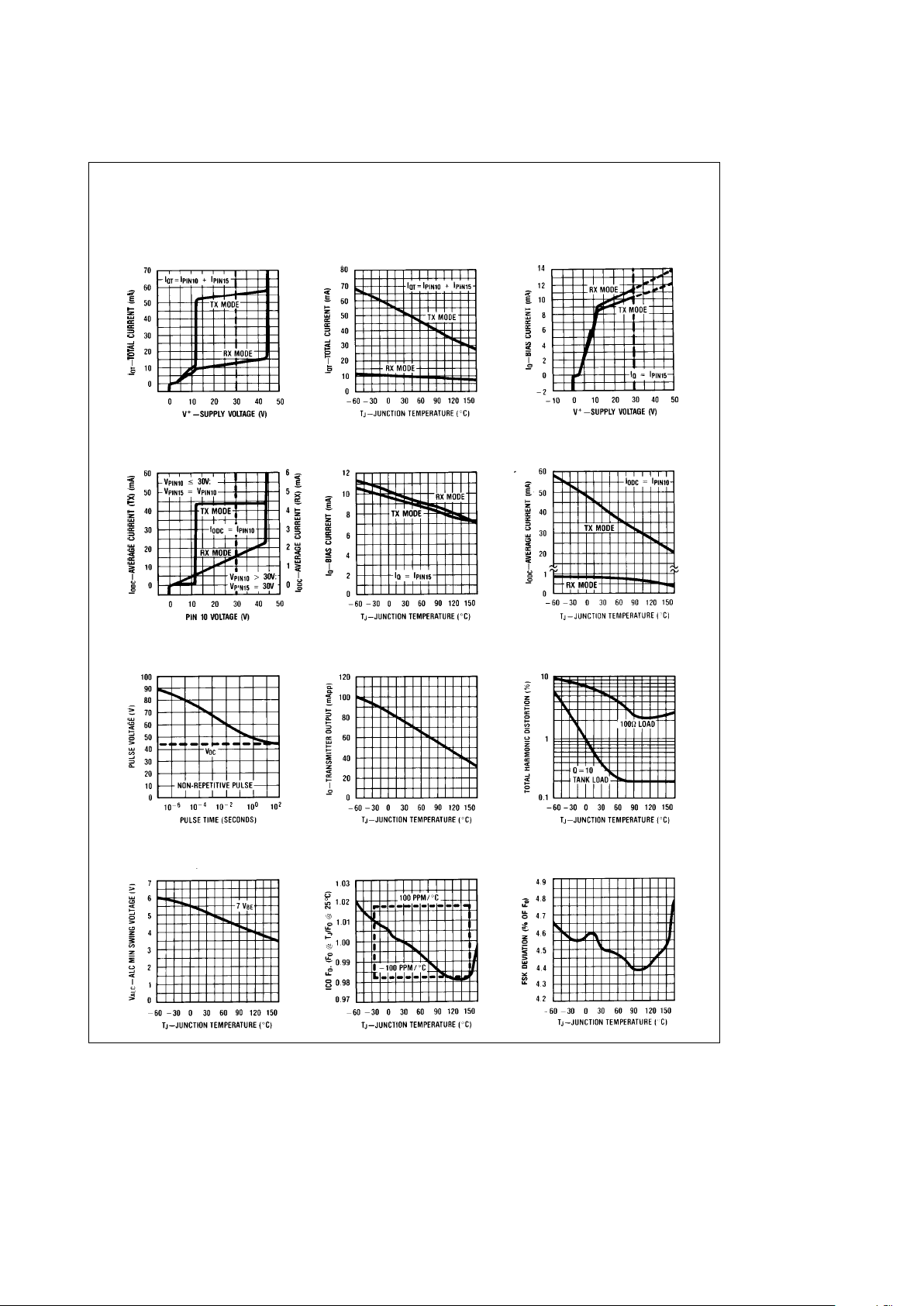

Typical Performance Characteristics (Continued)

Maximum Data Rate vs

Junction Temperature

Receiver Sensitivity vs

Junction Temperature

PLL Lock Range vs

Junction Temperature and F

O

PLL Capture & Lock Range vs

Junction Temperature

Receiver Sensitivity vs

PLL Lock Range and F

O

Receiver Sensitivity vs

PLL Lock Range and Loop Filter

Impulse Noise Filter

Current vs Junction

Temperature

Phase Detector Output

Voltage vs Junction

Temperature

Offset Hold Cap. Charge

Currents vs Junction

Temperature

Offset Hold Cap. Bias Current vs

Junction Temperature

Data Out. Low Voltage vs

Pull Down Current

Pin 7 Bias Voltage vs

Junction Temperature

TL/H/6750– 39

5

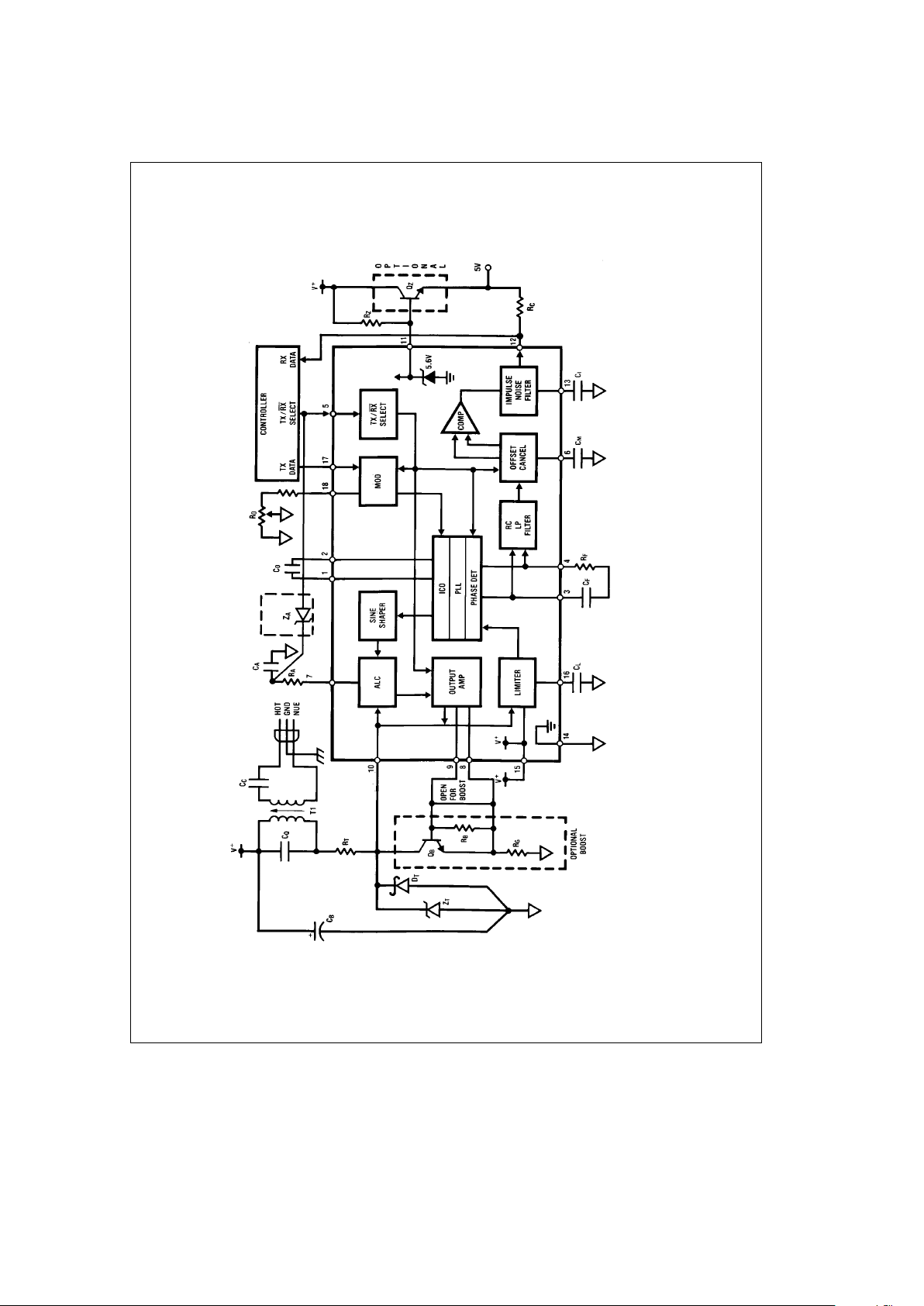

Application Information*

THE DATA PATH

The BI-LINETMchip serves as a power line interface in the

carrier-current transceiver (CCT) system of

Figure 3.Figure

4

shows the interface circuit now discussed. The controller

may select either the transmit (TX) or receive (RX) mode.

Serial data from the controller is used to generate a FSKmodulated 50 to 300 kHz carrier on the line in the TX mode.

In the RX mode line signal passes through the coupling

transformer into the PLL-based receiver. The recreated serial bit stream drives the controller.

With the IC in the TX mode (pin 5 a logic high), baseband

data to 5 kHz drive the modulator’s Data In pin to generate

a switched 0.978I/1.022I control current to drive the low TC,

triangle-wave, current-controlled oscillator to

g

2.2% deviation. The tri-wave passes through a differential attenuator

and sine shaper which deliver a current sinusoid through an

automatic level control (ALC) circuit to the gain of 200 current output amplifier. Drive current from the Carrier I/O develops a voltage swing on T

1

’s (

Figure 4

) resonant tank

proportional to line impedance, then passes through the

step-down transformer and coupling capacitor C

C

onto the

line. Progressively smaller line impedances cause reduced

signal swing, but never clipping-thus avoiding potential radio

frequency interference. When large line impedances threaten to allow excessive output swing on pin 10, the ALC

shunts current away from the output amplifier, holding the

voltage swing constant and within the amp’s compliance

limit. The amplifier is stable with a load of any magnitude or

phase angle.

In the RX mode (pin 5 a logic low), the TX sections on the

chip are disabled. Carrier signal, broad-band noise, transient

spikes, and power line component impinge of the receiver’s

input highpass filter, made up of C

C

and T1, and the tank

bandpass filter. In-band carrier signal, band-limited noise,

heavily attenuated line frequency component, and attenuated transient energy pass through to produce voltage swing

on the tank, swinging about the positive supply to drive the

Carrier I/O receiver input. The balanced Norton-input limiter

amplifier removes DC offsets, attenuates line frequency,

performs as a bandpass filter, and limits the signal to drive

the PLL phase detector differentially. The differential demodulated output signal from the phase detector, containing AC and DC data signal, noise, system DC offsets, and a

large twice-the-carrier-frequency component, passes

through a 3-stage RC lowpass filter to drive the offset cancel circuit differentially. The offset cancelling circuit works

by insuring that the (fixed)

g

50 mV signal delivered to the

data squaring (‘‘slicing’’) comparator is centered around the

0 mV comparator switch point. Whenever the comparator

signal plus DC offset and noise moves outside the carefully

matched

g

50 mV voltage ‘‘window’’ of the offset cancel

circuit, it adjusts its DC correction voltage in series with the

differential signal to force the signal back into the window.

While the signal is within the

g

50 mV window, the DC offset

is stored on capacitor C

M

. By grace of the highly non-linear

offset hold capacitor charging during offset cancelling, the

DC cancellation is done much more quickly than with an AC

coupling capacitor normally used in place of the offset cancel circuit. Since impulse noise spikes normally ring the signal symmetrically around 0 V, the fully bilateral offset cancel

topology affords excellent noise rejection. The switched current output of the comparator drives the impulse noise filter

integrator capacitor that rejects all data pulses of less than

the integrator charge time. Noise appears as duty-cycle jitter

at the open collector serial data output.

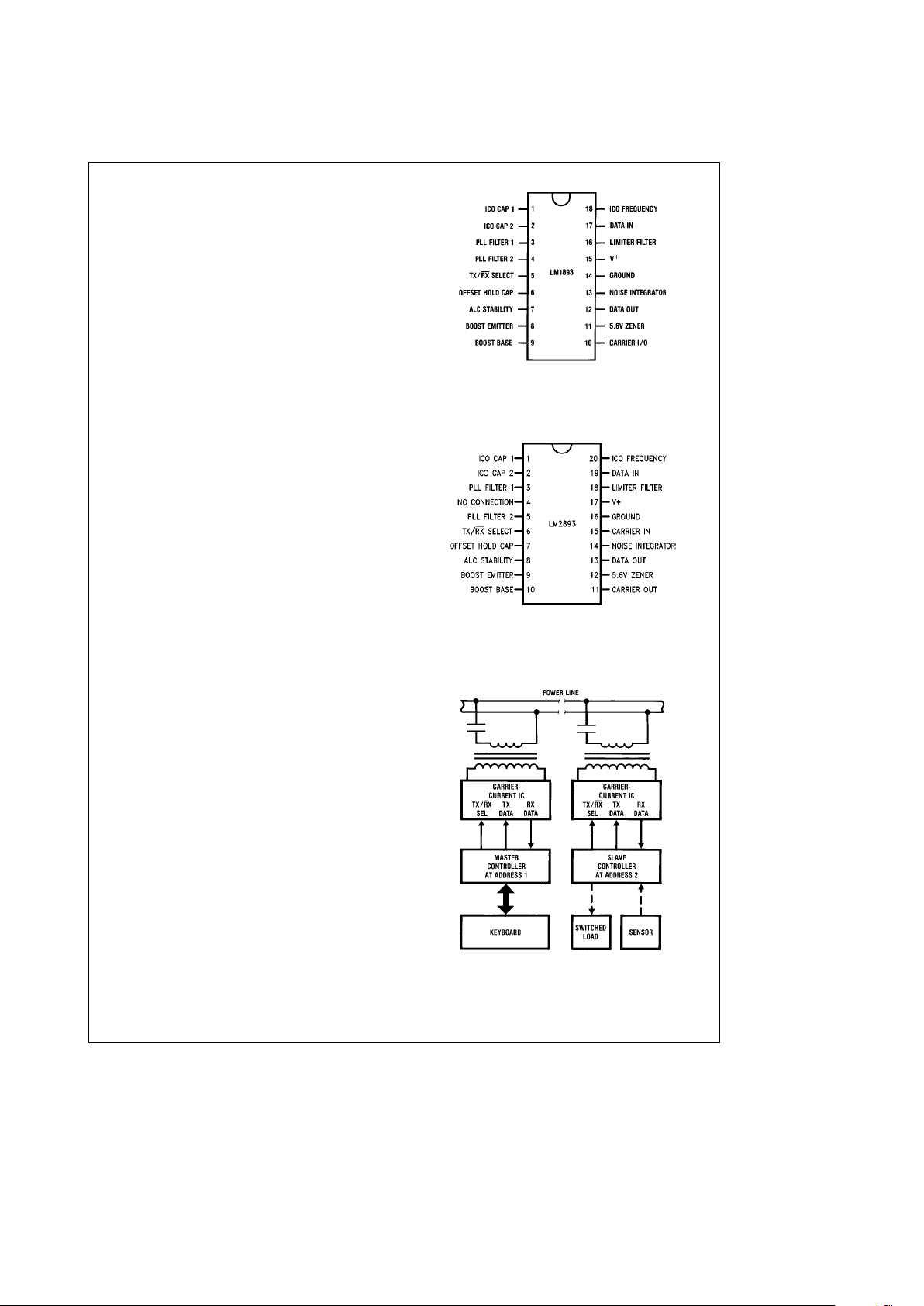

Dual-In-Line Package

TL/H/6750– 2

Top View

Order Number LM1893N

See NS Package Number N18A

Small Outline & Dual-In-Line Package

TL/H/6750– 41

Top View

Order Number LM2893M or LM2893N

See NS Package Number M20B or N20A

FIGURE 2. Connection Diagrams

TL/H/6750– 3

FIGURE 3. The block diagram of a carrier-current

system using the Bi-Line chip to interface digital

controllers via the power line

*Unless otherwise noted, all pin references refer to LM1893, but hold true

for equivalent LM2893 pin.

6

Application Information (Continued)

TL/H/6750– 4

FIGURE 4. Block diagram of a CCT system with the boost and 5V supply options shown in dashed boxes

7

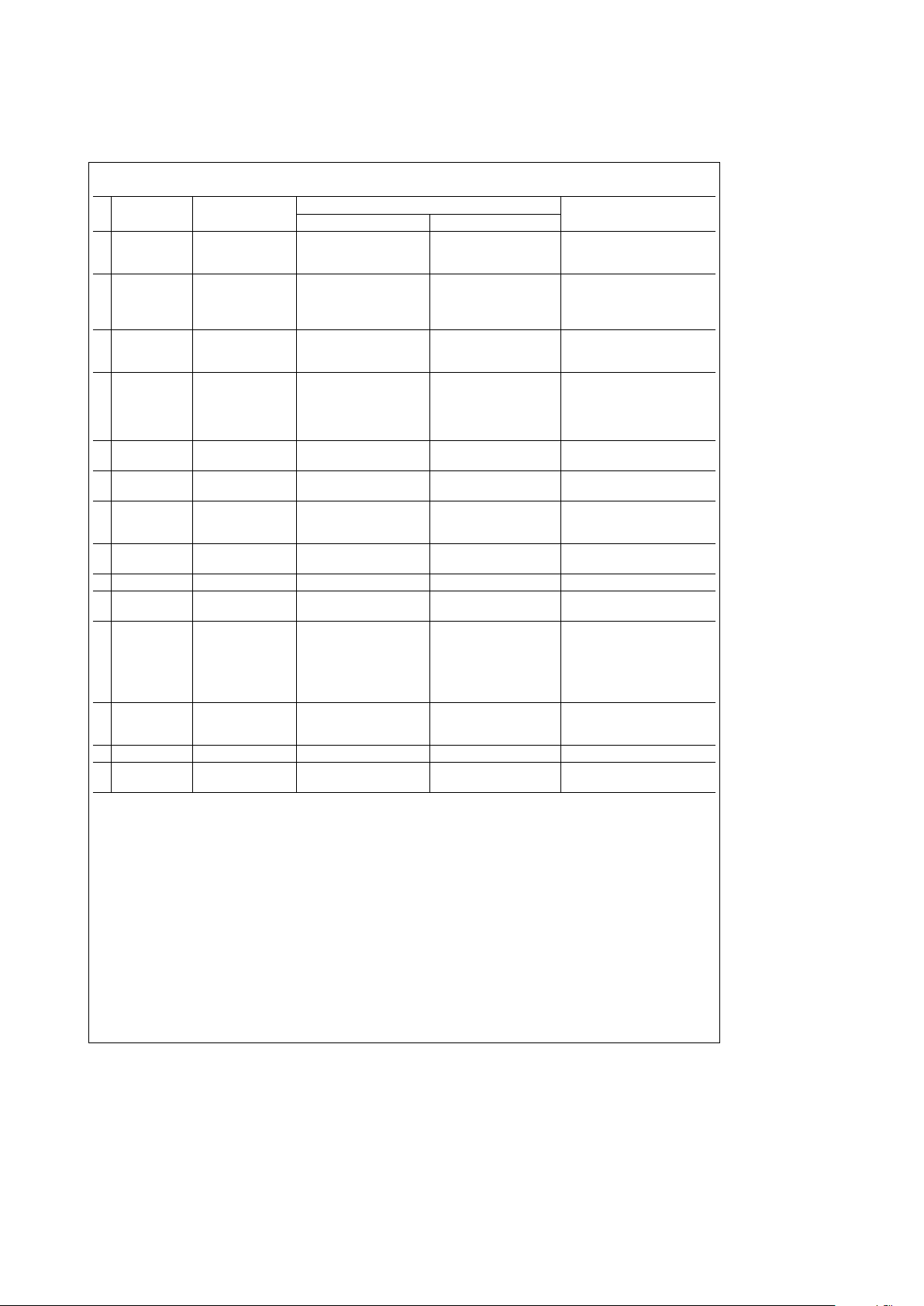

Application Information (Continued)

Ý

Recommended

Purpose

Effect of making the component value:

Notes

Value

Smaller Larger

CO560 pF Together, COand ROIncreases F

O

Decreases F

O

g

5% NPO ceramic. Use low TC

R

O

6.2 kX set ICO FO. Increases F

O

Decreases F

O

2 k pot and 5.6 k fixed R.

k

5.6 k not recommended.l7.6 k not recommended. Poor FOTC withk5.6kRO.

CF0.047 mF PLL loop filter pole Less noise immune, higher More noise immune, lower Depending on RFvalue and

f

DATA

, more PLL stability. f

DATA

, less PLL stability. FO, PLL unstable with large

RF3.3 kX PLL loop filter zero PLL less stable, allows PLL more stable, allows CF. See Apps. Info. C

F

less CF. Less ringing. more CF. More ringing. and RFvalues not critical.

CC0.22 mF Couples FOto line, Low TX line amplitude. Drives lower line Z.

t

250 V non-polar. Use 2C

C

CCand T1low-pass Less 60 Hz T1current. More 60 Hz T1current. on hot and neutral for max.

attenuates 60 Hz. Less stored charge. More stored charge. line isolation, safety.

CQ0.033 mF Tank matches line Z, Tank FOup or increase Tank FOdown or decrease 100 V nonpolar, low TC,g10%

bandpass filters, L of T

1

for constant FO. L of T1for constant FO. High large-signal Q needed.

T

1

Use isolates from line, Smaller L: higher FOor Larger L: lower FOor Optimize for low FOline

recommended and attenuates increase CC; decreased FOdecrease CC; increased FOpull with control of FOTC

XFMR transients. line pull. line pull. and Q.

CA0.1 mF ALC pole Noise spikes turn ALC off. Slower ALC response. RAoptional. ALC stable

R

A

10 kX ALC zero Less stable ALC. More stable ALC. for C

A

t

100 pF.

CL0.047 mF Limiter 50 kHz pole, Higher pole F, more 60 Hz Lower pole F, less 60 Hz Any reasonably low TC cap.

60 Hz rejection. reject. F

O

attenuation? reject, more noise BW. 300 pF guarantees stability.

CM0.47 mF Holds RX path VOSLess noise immune, shorter More noise immune, longer Low leakageg20% cap.

VOShold, faster VOSaqui- VOShold, slower VOSaqui- Scale with f

DATA

.

sition, shorter preamble. sition, longer preamble.

CI0.047 mF Rejects short pulses Less impulse reject, less More impulse reject, more CIcharge time (/2 bit nom.

like impulse noise. delay, more pulse jitter. delay, less pulse jitter. Must be

k

1 bit worst-case.

RC10 kX Open-col. pull-up Less available sink I. Less available source I. R

C

t

1.5 kX on 5.6 V

RZ12 kX 5.6 V Zener bias Larger shunt current, Smaller shunt current, 1kI

Z

k

30 mA recommended.

more chip dissipation. less V

a

current draw. (Chip power-up needs 5.6 V)

Z

T

t

44 V BV Transient clamp ZTfailure, higher series ZTcostly, lower series Recommend Zener rated

k

60 V peak R-excess peak V, Zener R gives enhanced fort500 W for 1 ms.

and chip damage, transient clamp,

less ruggedness. more ruggedness.

R

T

4.7 X Transient I limit Damage ZT, pull up Va. Excessive TX attenuation. Carbon comp. recommended.

D

T

t

44V BV Over-drive Clamp Failure on Transient Costly IRF 11DQ05 or 1N5819

RB180 X Base bleed Faster, lower THD IO. Inadequate turn-off speed. Boost optional. QBF(b3 dB)

Q

B

Power NPN Boost gain device Excessive TJand V

SAT

. More rugged, but costly. ofl200 MHz. R

B

l

24 Ohm.

RG1.1 X Current setting R More IO, need higher hfe. Less IO, lower min. hfe.I

O

e

70[(10aRG)/R

G

]

mApp.

C

B

t

47 mF Supply bypass Transients destroy chip. Less supply spike. Vanever over abs. max.

ZA5.1V Stop ALC charge Excess ALC ALC RX charging ZAoptional - 5.1V

in RX mode current flow not inhibited over T

J

g

20% low leakage type

FIGURE 5. A quick explanation of the external component function using the circuit of

Figure 4

. Values given are for V

a

e

18 V, F

O

e

125 kHz, f

DATA

e

360 Baud (180 Hz), using a 115 V 60 Hz power line

Component Selection

Assuming the circuit of

Figure 4

is used with something other than the nominal 125 kHz carrier frequency, 180 Hz data

rate, 18V supply voltage, etcetera, the component values

listed in

Figure 5

will need changing. This section will help

direct the CCT designer in finding the required component

values with emphasis placed on look-up tables and charts. It

is assumed that the designer has selected values for carrier

center frequency, F

O

; data rate, f

DATA

; supply voltage, Va;

power line voltage, V

L

; and power line frequency, FL.Ifone

or more of those parameters is not defined, one may read

the data sheet and make an educated guess.

Maxims to keep in mind, based on CCT electrical perform-

ance considerations only, are: 1) the higher the F

O

the better, 2) the lower the maximum data rate the better, and 3)

the more time and frequency filtering the better.

Use

Figure 5

as a quick reference to the external compo-

nent function.

THE TRANSMITTER

C

O

Central to chip operation is the low TC of FOemitter-coupled oscillator. With proper C

O

, the FOof the 2VBEamplitude triangle-wave oscillator output may vary from near DC

to above 300 kHz. While C

O

may have any value, COshould

8

Component Selection (Continued)

be made above 10 pF so that parasitic capacitance is not

dominant. Excessive or unbalanced common-mode-toground capacitance should be avoided. A low temperature

coefficient (TC) of capacitance (

k

100 PPM/§C), such as a

monolithic NPO ceramic multilayer type, preserves low TC

of F

O

.

Figure 6

finds a COvalue given FO.

R

O

Resistor ROis used by the IC to generate a VBE/R related

current that is multiplied by 2 to produce the 200 mA ICO

control current that sets F

O

. The control current TC ‘‘bucks’’

the V

BE

related tri-wave amplitude across COto effect a low

TC of F

O

. Vary ROto trim FO, within limits. Raising FOmore

than 20% above its untrimmed value by means of decreasing R

O

more than 20% is not recommended. Low RO, and

so high control current, risks ICO saturation and poor TC

under worst-case conditions. Raising R

O

reduces the demodulated signal amplitude from the phase detector; raising

R

O

by more than a factor of 2 (1 octave) is not recommended.

Since lower TC pots are relatively costly, it is recommended

that R

O

be made up of a 5.6 k fixed (k100 PPM/§C) resistor

witha2kX(

k

250 PPM/§C) series pot.

C

A

and R

A

Components CAand RAcontrol the dynamic characteristics

of the transmitter output envelope. Their values are not critical. Use the values given in

Figure 5

.CAand RAare func-

tions of loaded T

1

tank Q, RO,f

DATA

, and line impulse

noise. Any changes made in C

A

and RAshould be made

based on empirical measurements of a CCT on the line.

Roughly, C

A

acts as an ALC pole and RAan ALC zero.

T

1

At this point, the CCT system designer may choose to use

one of the recommended transformers or to design custom

T

1

. Consult ‘‘The Coupling Transformer’’ section to help

with the design of T

1

if a new or boost-capable transformer

is needed. The recommended 125 kHz transformer functions with an I

O

of up to 600 mApp.

It is recommended that CCT systems use the recommended

transformers, described in

Figure 7

, for T1. The 3 transformers are optimized for use in the ranges of 50 –100 kHz, 100 –

200 kHz, and 200 –400 kHz with unloaded Q’s (Q

U

) of about

35, and loaded Q’s (Q

L

) of about 12. Three secondary taps

are supplied with nominal 7.07, 10, and 14.1 turns ratios (N)

to drive industrial and residential power line impedances of

3.5, 7, and 14X respectively. All are inexpensive, all have

the same pin-outs for easy exchange in a PC board, and all

are small - on the order of 10 mm diameter at the base.

C

Q

Tank resonant frequency FQmust be correct to allow passage of transmitter signal to the line. Use

Figure 8

to find

C

Q

’s value. Trimming FQto equal FOis done with T1’s trim-

ming slug. The inductance of T

1

hasaTCofa150 PPM/§C

which may be cancelled by using a

b

150 PPM/§C cap such

as polystyrene. Since circulating current in the tank is (/4

A

RMS,CQ

should have a low series resistance (a 1 X series

resistance is too much). Polypropelene caps are excellent,

‘‘orange drop’’ mylars are adequate, while many other mylars are inadequate. A 100V rating is needed for transient

protection.

TL/H/6750– 5

FIGURE 6. Find CO’s value knowing F

O

TL/H/6750– 10

FIGURE 8. Find CO’s value given F

O

Bottom View

TL/H/6750– 6

TL/H/6750– 7

125 kHz

Toko 707VX-A042YUK

TL/H/6750– 8

50 kHz

Toko 707VX-A043YUK

TL/H/6750– 9

300 kHz

Toko 161XN-A207YUK

FIGURE 7. The recommended T1transformers, available through:

Toko America, 1250 Feehanville Drive, Mount Prospect, IL, 60056, (312) 297-0070

9

Component Selection (Continued)

C

C

Capacitor CC’s primary function is to block the power line

voltage from T

1

’s line-side winding. Also, CCand T1’s lineside winding comprise a LC highpass filter. The self-inductance of T

1

is far too low to support a direct line connection.

C

C

must have a low enough impedance at FOto allow T1to

drive transmitted energy onto the line. To drive a 14X power

line, the impedance of C

C

should be below 14X.

Use

Figure 9

to find the reactive impedance of CCto check

that it is less than the line impedance. Then check

Figure 10

to see that the power line current is small enough to keep

T

1

well out of saturation; the recommended transformers

can withstand a 10 Amp-turn magnetizing force (1 Amp

through the worst-case 10 turn line-side winding).

Caution is required when choosing C

C

to avoid series reso-

nance of the series combination of C

C

, the transformer inductance, and the reflected tank impedance. The low resistance of the network under series resonance will load the

line, possibly decreasing range. For your particular line coupling circuit, measure for series resonance using some expected line impedance load.

R

B

This base-bleed resistor turns QBoff quickly - important

since the amplifier output swing is about 200V/ms. An R

B

below about 24X will conduct excessive current and overload the chip amplifier and is not recommended.

TL/H/6750– 11

FIGURE 9. CC’s impedance should be,

as a rule-of-thumb, smaller than the lowest

expected line impedance

R

G

This resistor, in parallel with the internal 10X resistor, fixes

the current gain of the output amplifier, and so the output

current amplitude.

Figure 11

gives output current and mini-

mum AC current gain h

fe

for QBwhen RGis used to boost

output current.

Q

B

The boost gain transistor QBmust be fast. Double-diffused

devices with 50 MHz F

T

’s work, slower transistors (epi-base

types) do not preserve a sinusoidal waveform when F

O

is

high or will cause the output amp. to oscillate. Q

B

must have

a certain minimum h

fe

for given boost levels, as shown in

Figure 11.Figure 12

shows the power QBmust dissipate

continuously operating with a shorted output. BV

CER

(R

e

RB) must be 60V or greater and QBmust have adequate

SOA for transient survival.

Z

T

Unfortunately, potentially damaging transient energy passes

through transformer T

1

onto the Carrier I/O pin (instanta-

neous power of greater than 1 kW has been measured using the recommended transformers). For self protection, the

Carrier I/O has an internal 44V voltage clamp with a 20X

series resistance. A parallel low impedance 44V external

transient suppression diode will then conduct the lion’s

share of any current when transients force the Carrier I/O to

a high voltage.

TL/H/6750– 12

FIGURE 10. The AC line-induced current passed by C

C

TL/H/6750– 13

FIGURE 11. Output amplifier current and required min.

Q

Bhfe

versus gain-setting resistor R

G

TL/H/6750– 14

FIGURE 12. Boost transistor power dissipation versus

amplifier output current

Z

T

must be used unless some precaution is taken to protect

the Carrier I/O pin from line transients or transients caused

when stored line energy in C

C

is discharged by the random

phase of power line connection and disconnection. Worst

case, C

C

may discharge a full peak-to-peak line voltage into

the tuned circuit. Another way to reduce the need for Z

T

is

by placing another magnetic circuit in the signal path that

relies on a high, but easily saturated, permeability to couple

a primary and secondary winding - a toroidal transformer for

example. Toroids cost more than Z

T

.

Use an avalanche diode designed specifically for transient

suppression Ð they have orders of magnitude higher pulse

10

Component Selection (Continued)

power capability than standard avalanche diodes rated for

equal DC dissipation. Metal oxide varistors have not proven

useful because of their inferior clamping coefficient and are

not recommended. Specifications for an example minimum

diode are given in

Figure 13

.

Breakdown Voltage 44 –49V@1mA

Maximum Leakage 1mA@40V

Capacitance 300 pF@BV

Maximum Clamp Voltage 64.5V@7.8A

Peak Non-Repetitive Pulse Power 10 kW for 1 ms

(REA Standard Exponential Pulse)

Surge Current 70A for 1/120s

FIGURE 13. Key specifications for a recommended

transient suppressor Z

T

available from General

Semiconductor, 2001 West Tenth Place, Tempe, AZ

85281, 602–968-3101, part no. SA40A

R

T

RTacts as a voltage divider with ZT, absorbing transient

energy that attempts to pull the Carrier Input pin above 44V.

Make the resistor a carbon composition 1/4W. When experiments discharging C

C

charged to the peak-to-peak 620V

AC thru a 1X power line were carried out, film resistors blew

open-circuit.

D

T

This Schottky diode is placed in parallel with the CCT chip’s

substrate diode to pass the majority of the current drawn

from ground when the Carrier Input or Carrier Output is

pulled below ground by a larger-than-twice-the supply-swing

on the tank. Note that Z

T

is in parallel with the substrate

diode, but is ineffective due to its high forward voltage drop

and high diffusion capacitance caused by its low forward

speed. Tests proved that a 1N5818 kept a receive-path

functional with a 20X boost transmitter with a 7:1 transformer attempted to swing the receiver’s Carrier I/O to

g

100V

(300 mA peak ground current in the receiver). Without D

T

,

the receiver momentarily stops functioning at a 100 times

lower ground current.

This diode is not needed if the Carrier I/O never swings

below ground. If your CCT systems all run on the same

regulated voltage with all matched transformers and turns

ratios, it is not needed. Otherwise, it is.

THE RECEIVER

The receiver and transmitter share components C

C,T1,CQ

,

R

T,ZT,CO,RO

, and peripheral supply and bias components

that are not in need of change for RX mode operation. Values for the balance of the components are now found.

Line-Frequency Rejection

To use the ultimate sensitivity of the device, fully 110 dB of

115 V, 60 Hz attenuation is required between the line and

the limiter amplifier output. Using the circuit topology of

Fig-

ure 4

, the combined attenuation of the CC/T1highpass, the

tuned transformer, and the bandpass filter attenuation of

the limiter amplifier give far more line rejection than the

above-stated minimum. However, if some other CCT line

coupling circuit is used, line rejection will become important

to the system designer.

Receiver input power supply rejection (PSRR) and commonmode rejection (CMRR) are one-in-the-same using the supply-referenced signal input of

Figure 4

. Ripple swings both

differential inputs of the Norton amp. equally, while the single-ended input signal swings only the positive input. Overall

PSRR consists of the input CMRR (set by the input stage

component matching) and the ripple-frequency attenuation

of the input amplifier bandpass response that passes carrier

frequency but stops low frequencies. A typical 1% resistor

and 1 mV n-p-n mirror offsets give 26 dB of attenuation, the

bandpass gives 54 dB 120 Hz attenuation, for an overall 80

dB PSRR to allow tens of volts of ripple before impacting

ultimate sensitivity.

C

C

A value was chosen earlier. Knowing T1’s secondary inductance allows a check of LC line attenuation using

Figure 14

.

C

L

The Norton input limiter amplifier has a bandpass filter for

enhanced receiver selectivity, noise immunity, and line frequency rejection. The nominal response curve for F

O

e

50

kHz is shown in

Figure 15

. The 300 kHz pole is fixed. The 50

kHz pole is set by C

L

’s value. After CLis found, the resulting

line frequency attenuation is found for the bandpass filter.

Use

Figure 15

to find a CLvalue given for FO. The approximate line frequency attenuation of the bandpass filter may

then be found in

Figure 16.Figure 15

returns a value for C

L

33% larger than nominal, giving a low frequency pole 33%

low to allow for component tolerances.

TL/H/6750– 15

FIGURE 14. The 60 Hz line rejection of the highpass

filter made up of C

C

and T1’s line-side winding

(neglecting capacitive coupling)

TL/H/6750– 16

TL/H/6750– 17

FIGURE 15. Given FO,CLis found. Also shown is the

input amplifier’s small signal amplitude response

11

Component Selection (Continued)

C

F

and R

F

These phase-locked loop (PLL) loop filter components remove some of the noise and most of the 2F

O

components

present in the demodulated differential output voltage signal

from the phase detector. They affect the PLL capture range,

loop bandwidth, damping, and capture time. Because the

PLL has an inherent loop pole due to the integrator action of

the ICO (via C

O

), the loop pole set by CFand the zero set by

R

F

gives the loop filter a classical 2nd-order response.

TL/H/6750– 18

FIGURE 16. The Norton-input limiter amplifier bandpass

filter line-frequency signal attenuation given C

L

TL/H/6750– 19

FIGURE 17. Find CFgiven FO.

Figure 19

gives the maximum data rate

No C

F

and RFgive the most stable PLL with the fastest

response. Large C

F

’s with a too-small RFcause PLL loop

instability leading to poor capture range and poor step response or oscillation.

Calculation of C

F

and RFis quite difficult, involving not only

the 2nd-order loop step response, but also the PLL nondominant poles, the tuned transformer stepped-frequency

response, and the RC lowpass step response (for data rates

approaching 1 kHz). C

F

and RFvalues are best found empirically. Tolerance is not critical. Component values are selected to give the best possible impulse noise rejection

while preserving a

g

20% capture range and wide stability

margin.

Figures 17

and18give CFand RFvalues versus FO,

where ‘‘f

DATA

kk

MAX DATA RATE’’ means that f

DATA

should be less than the maximum data rate, in kHz, from

Figure 19

divided by 10.

Note that C

F

and RFare a function of data rate only for high

data rates and are not plotted against data rate - as one

might expect. The reason for this is important to understand

if the CCT system designer wishes to find C

F

and RFempirically. Data signal is, loosely speaking, passed through the

PLL loop and is therefore potentially attenuated if the loop

bandwidth is on the order of the 3rd harmonic of the data

rate, or less. Overall loop bandwidth is held as low as possible for maximum noise rejection while passing the data.

Loop bandwidth is roughly proportional to the geometric

mean of the unfiltered loop bandwidth and the filter pole set

by C

F

. Therefore, CFis related to data rate. Unfortunately,

the loop capture range falls to critically low values when

large enough values of C

F

are used to reduce loop band-

width down to the 100’s of Hz range, for low data rates. The

obvious way out is to then reduce the unfiltered loop bandwidth. That bandwidth is approximately proportional to the

value of C

O

. For a fixed FO, unfiltered loop bandwidth reduc-

tion requires a larger C

O

and larger control current. With this

chip, changing the control current is not allowed. So one is

forced to choose a C

F/RF

combination with some minimum

capture range, say

g

20%, that is within some guardband

from the point of loop instability. Happily, impulse noise

tends to last only fractions of a millisecond so that the lack

of low bandwidth loop response with low data rates is not a

heavy penalty. As long as there is adequate capture range,

the impulse noise filter performs admirably. Note that reducing F

O

will reduce the no-filter loop bandwidth, and indeed

the maximum data rate falls below the limit set by the RC

lowpass filter as F

O

falls below 100 kHz (

Figure 19

).

The tuned transformer characteristics will affect the demodulated data waveform more than C

F

and RFat low data

rates. Tank Q and off-tuning will affect overshoot during the

FSK frequency steps. This is a property of tuned circuits.

The maximum data rate of

Figure 19

is measured from the

receiver input to the Data Out and does not include the data

bandwidth reducing effects of T

I

.

C

M

Capacitor CMstores a voltage corresponding to a correction

factor required to cancel the phase detector differential output DC offsets. The stored voltage is ±/6 of the DC offset

plus some bias level of about 2.2 V. A large C

M

value increases the time required to bias-up the receive path at the

beginning of transmission. A large C

M

does filter well and

store its bias voltage long. Because of the initial random

charge of C

M

, the receiver must be given a data transition to

charge to the proper bias voltage. Therefore, reducing C

M

’s

value to one that may be charged in less than 2 bit-times will

not save biasing time and is not recommended.

TL/H/6750– 20

FIGURE 18. Find RFgiven FOwith F

DATA

a parameter

TL/H/6750– 21

FIGURE 19. The maximum data rate versus FOusing

loop filter components optimized for max. noise

performance while retaining a min.

g

20% capture

range (large signal)

Use

Figure 20

to find CM’s value knowing f

DATA

, assuming

the standard 2 bit receive charge time is desired. The cap.

value and TC are not critical, but the capacitor should have

low leakage.

12

Component Selection (Continued)

TL/H/6750– 22

FIGURE 20. Size CMassuming a 2 bit-time

receive bias time

C

I

The impulse noise filter integrator capacitor CIis used to

disallow the passage of any pulse shorter than the integrator charge time. That charge time, set to a nominal (/2 bit

time, is the time required for a

g

50 mA charge current to

swing C

I

overa2VBErange. Charge time under worst case

conditions must never be greater than a bit time since no

signal could then pass. Using a

g

10% capacitor, full junction temperature range, and full specified current range, a

maximum nominal charge time of (/2 bit is recommended.

Figure 21

gives CIversus data rate under those conditions.

R

C

The collector pull-up resistor is sized to supply adequate

pull-up current drive and speed while preserving adequate

output low current drive.

TL/H/6750– 24

FIGURE 21. Impulse noise filter cap. CIversus F

DATA

where the charge time is (/2 bit time

Z

A

The 5.1V silicon zener diode ZAis required when a short

RX-to-TX switch-over time is needed at the same time that

the chip is operating in the RX mode with a pin 10 input

signal swing approaching or exceeding twice the supply

voltage. Predominant causes of these large swings impinging on the RX input are: 1) a transmitter’s supply voltage

higher than the receiver’s supply voltage, 2) a TX and RX

pair that are electrically close, or, 3) a higher RX T

1

step-up

turns ratio than the TX T

1

step-down ratio.

Normally, when in the RX mode with small incoming signal

on pin 10, the ALC remains off with pin 7 at a 6V

(V

Z

b

2VBE) bias voltage. CAis then charged to 6V. TX

mode may then be selected with 6V on C

A

allowing 100%

TX power to pump T

1

’s tuned circuit, and so the AC line,

quickly for fast RX-to-TX switch time. As TX output swing

increases so that pin 10 swings below V

ALC

(4.7V typically),

that ALC activates to charge C

A

to about 6.6V to reduce TX

output drive. However, if in the RX mode pin 10 ever swings

below V

ALC,CA

will charge to above 6.6V. Now, when the

TX mode is selected with C

A

at 6.6V, somewhere from 0 to

100% TX output drive is available to pump T

1

’s tuned circuit

resulting in a slower rising line signal - effectively reducing

the RX-to-TX switch time.

Use a 5.1V Z

A

driven bya0to0.8V logic low signal to

guarantee over-temp. operation. R

A

must be in series with

Z

A

to limit current flow and should never fall below 1 kX.If

R

A

is less than 1 kX, then puta2kXresistor in series with

Z

A

. Logic high voltages above 10V will cause current flow

into pin 7 that must be limited to 1 mA (with R

A

or a

series R).

Breadboarding Tips

During CCT system evaluation, some techniques listed below will simplify certain measurements.

Ð Use caution when working on this circuit - dangerous

line voltages may be present.

Ð When evaluating PLL operation, offset cancel circuit op-

eration, and loop filter values, use the filter of

Figure 22

to view the demodulated signal minus the 2FOand noise

components. This filter models the RC lowpass filter on

chip.

TL/H/6750– 25

FIGURE 22. Circuit to view the differential demodulated data signal, minus the noise and 2FOcomponents,

conveniently with a single-ended gain-of-one output

13

Breadboarding Tips (Continued)

Ð When evaluating CCT system noise performance on a

real power line, it is desirable to vary the signal amplitude to the receiver. This is not easy. An in-line lineproof L-pad is fine except that the line impedance is unknown and variable and so the L-pad will rarely match.

Instead, the power output of a chip transmitter may be

controlled using the circuit of

Figure 23

. This circuit con-

trols the ALC.

Ð It is sometimes desirable to place impulse noise on the

line. A simple light dimmer with a 100 W light bulb load

produces representative impulse noise.

Ð Do not allow peak currents of over 1 A through the 5.6 V

Zener. In other words, don’t short charged capacitors

into this low-impedance device. Take care not to momentarily short pins 10 and 11 - chip damage may result.

Ð

Figure 24

shows some typical signals beginning with se-

rial data transmitted to received signal.

Tuning Procedure

This procedure applies to circuits similar to

Figure 4

LM1893

or LM2893 circuit.

First, trim F

O

by putting the chip in the TX mode, setting a

logical high data input, and measuring the TX high frequency, 1.022 F

O

, on the Carrier I/O using these steps:

1. Take pin 17 to a logic low.

2. Take pin 5 to a logic high.

3. Place a counter on pin 10.

4. Adjust R

O

on pin 18 for Fe1.022FO.

Second, the line transformer is tuned. The chip is placed in

the TX mode, a resistive line load is connected to disable

the ALC by reducing tank voltage swing below its limit. FSK

data is then passed through the tank so that the tank envelope may be adjusted for equal amplitude for high and low

data frequency.

1. Take pin 5 to a logic high.

2. Place a logic-level square wave at or below the receiver’s

maximum data rate on pin 17.

3. Temporarily place a 330 X resistor across the tank.

4. Place a scope on pin 10.

5. Adjust the transformer slug for the least envelope modu-

lation.

In lieu of the 330 X resistive load, T

1

may be coupled to the

power line to better simulate actual load and tank pull conditions during tank tuning. Alternatively, a passive network

representing an average line impedance may be connected

to the line side of T

1

. The circuit of

Figure 23

should then be

used to defeat the leveling effect of the ALC.

TL/H/6750– 26

FIGURE 23. A means of transmitter output amplitude

control is shown

Thermal Considerations

It is desirable to place the largest possible signal on the

power line for maximum range, limited only by the chip power dissipation and maximum junction temperature T

J

. The

falling output power at elevated T

J

allows a more optimal

power output - high power at low T

J

and lower power at high

T

J

for chip self-protection. However, it is still possible to

exceed the maximum T

J

within the specified ambient tem-

perature limit (T

A

e

85§C) under worst case conditions of

100% TX duty cyle, high supply, shorted load, poor PC

board layout (with small copper foil area), and an above

nominal current part. Under those conditions, a part may

dissipate 2140 mW, reaching a T

J

e

170§C worst-case (admittedly a rare occurrence). Proper system design includes

the measurement or calculation of T

J

max. to guarantee

function under worst-case operation. Like all devices with

failure modes modeled by the Arrhenius model, the high

chip reliability is further enhanced by keeping the die temperature mercifully below the absolute maximum rating.

A direct method of measuring operating junction temperature is to measure the V

BE

voltage on pin 18, which is al-

ways available under all operating modes. The graph of

Fig-

ure 25

may be used to find TJ, knowing VBEat the operating

point in question and V

BE

at T

A

e

T

J

e

25§C. VBEis found

by powering up a chip (in RX mode) that has been dissipating zero power at some T

A

for some time and measuring

V

BE

in less than 1 s (for better than 5§C accuracy).

Alternately, TJmay be calculated using:

T

J

e

T

A

a

iJAP

D

(1)

where iJAis 75§C/W for the plastic (N) package using a

socket. That i

JA

value is for a high confidence level; nomi-

TL/H/6750– 23

FIGURE 24. Oscillogram revealing signals at several important nodes under weak signal (0.5 mV

RMS

) conditions with

SCR spikes on an otherwise quiet 115 V, 60 Hz power line. The signals are: 1) transmitted data, 2) RX carrier on the

tuned transformer, 3) demodulated signal from the PLL after passing thru circuit of

Figure 22

, 4) signal after RC

lowpass, 5) data at impulse noise filter integrator, and 6) received data. Horizontal scale is 10 ms per div.

14

Thermal Considerations (Continued)

nal i

JA

for an N package is 60§C/W, lower with good PC

board layout. Since P

D

is a relatively strong function of TJ,

an iterative solution process starting with an initial guess for

T

J

is used. With the estimated TJ, find the total supply cur-

rent found in the typical performance characteristics.

TL/H/6750– 27

FIGURE 25. TJmay be found by using the temperature

coefficient of pin 18 V

BE

if VBEis known at 25§C

Transmit-To-Receive

Switch-Over Time

An important figure-of-merit for a half-duplex CCT link, affecting effective data rate, is the TX-to-RX switch time T

TR

.

Using the recommended component values gives this part a

nominal 2 bit-time (1 bit time

e

1/[2f

DATA

]

) over a wide

range of operating conditions, where the receiver requires 1

data transition. T

TR

cannot be decreased significantly but

does increase as noise filtering, especially via C

M

,isincreased. Impulse noise at switch, signals near the limiting

sensitivity, poor F

O

match between receiver and transmitter

because of poor trim or worst-case conditions, and the statistical nature of PLL signal acquisition may all contribute to

increase T

TR

to possibly 4 bit-times.

T

TR

is lower when a pair of LM1893’s handshake rapidly.

The receiver was designed to ‘‘remember’’ the RX-mode

DC operating points on C

M

and CFwhile in the TX mode.

Under noisy worst case conditions, C

M

will discharge to the

point of false operation after 35 bit-times in the TX mode

(1400 bit times with no noise and a nominal part, f

DATA

e

180 Hz). TTRis about 0.8 ms (proportional to the selected

F

O

) plus (/2 bit-time.

The major components of T

TR

are described below for a

nominal 125 kHz F

O

, 180 Hz f

DATA

, lightly-loaded tank with

a Q of 20, and the circuit of

Figure 4

. The remote CCT has

been operating in the TX mode with a 26.6 V

PP

tank swing

and is now selected as a receiver. An incoming signal requiring the ultimate receiver sensitivity immediately is placed

on the line.

First, the tank stored energy at the transmit frequency must

decay to a level below the 2.8 mV

PP

swing caused by the

0.14 mV

RMS

incoming line signal containing the information

to be received.

decay time

e

Q

qF

O

ln

#

V

1

V

O

J

e

20

q

c

125 000

ln

#

26.6

0.0028

J

e

0.466 ms (2)

That is 0.47 ms of delay (proportional to I/F

O

and Q).

Second, the PLL must acquire the signal; it must lock and

settle. Acquisition time is statistical and may take any length

of time, but average acquisition time depends on the loop

filter components C

F

and RFand the difference in center

frequencies, DF

O

, of the TX/RX pair. Using the recom-

mended C

F

and RF(47 nF and 6.2 kX) with ag4.4% DF

O

(ag100 mV DC offset on CFand RF), lock was measured

to take less than 50 cycles of F

O

. That is a 0.40 ms delay

(proportional to 1/F

O

).

Acquisition is incomplete until the second order PLL loop

settles. For the above-mentioned C

F

and RF, the loop natu-

ral frequency F

N

and damping factor are found to be

2.3 kHz and 1.0 respectively. Settling to within

g

25 mV of

the

g

100 mV DC offset change requires 2.7 periods of FN,

or 1.2 ms (a function of C

F

and RF).

Third, the RC lowpass filter introduces a 0.12 ms delay.

Fourth, C

M

must charge up tog(±/6)100e83 mV depend-

ing on the polarity of F

O

. Borderline data squaring with zero

noise immunity is possible with only

g

(±/6) 50 mV of charg-

ing. C

M

charge current is an asymptotic function approximated by assuming a 50 mA charge current and the full 83

mV charge voltage. C

M

charge time is then 1.7 ms (propor-

tional to 1/f

DATA

).

Fifth, the impulse noise filter adds a (/2 bit-time delay. Total

T

TR

is 3.9 ms plus (/2 bit-time for a total of 1.9 bit-times at

360 Baud.

Receive-To-Transmit

Switch-Over Time

Assume the chip has been in the RX mode and the TX

mode is now selected. In less than 10 ms, full output current

is exponentially building tank swing. 50% of full swing is

achieved in less than 10 cycles - or under 80 ms at 125 kHz.

In the same 10 ms that the output amp went on, the phase

detector and loop filter are disconnected and the modulator

input is enabled. FSK modulation is produced in 10 ms after

switching to TX mode.

Power Line Impedance

Irrespective of how wide the limits on power line impedance

Z

L

are placed, there are no guarantees. However, since the

CCT design requires an estimate of the lowest expected line

impedance Z

LN

encountered for the most efficient transmitter-to-line coupling, line impedance should be measured

and Z

L

limits fixed to a given confidence level. Reasonable

values for T

1

turns ratio, loaded Q, and tank resonant fre-

quency pull F

Q

may be found to enable a CCT system design that functions with the overwhelming majority of power

lines.

A limited sampling of Z

L

was made, during the LM1893 design, of residential and commercial 115V 60 Hz power line.

Data was also drawn from the research of Nicholson and

Malack (reference 1), among others, to produce

Figures 26

and27. All measured impedances are contained within the

shaded portions of

Figure 27

. A nominal 3.5, 7.0 and 14 X

Z

LN

is used throughout the application information with a

nominal 45

§

phase angle (0§is sometimes used for simplici-

ty).

TL/H/6750– 28

FIGURE 26. Measured line impedance range for

residential and commercial 115V, 60 Hz lines

15

Power Line Impedance (Continued)

TL/H/6750– 29 TL/H/6750 –30

TL/H/6750– 31

FIGURE 27. Complex-plane plots of measured 115V, 60 Hz line impedance where Z

L

e

R

L

a

jX

L

Power Line Attenuation

The wiring in most US buildings is a flat 3 conductor cable

called Amerflex, BX, or Romex. All referenced line impedances refer to hot-to-neutral impedances with a grounded

center conductor. The cable has a 100 X characteristic impedance, a 125 kHz quarter-wavelength of 600 m (250 m at

300 kHz), and a measured 7 dB attenuation for a 50 m run

with a 10 X termination. Generally, line loads may be treated as lumped impedances. Instrument line cords exhibit

about 0.7 mH and 30 pF per meter.

Limited tests of CCT link range using this chip show extensive coverage while remaining on one phase of a distribution transformer (100’s of m), with link failure often occuring

across transformer phases or through transformers unless

coupling networks are utilized. Total line attenuation allowed

from full signal to limiting sensitivity is more than 70 dB.

Typically, signal is coupled across transformer phases by

parasitic winding capacitance, typically giving 40 dB attenuation between phased 115 V windings. Coupling capacitors

may be installed for improved link operation across phases.

Power factor correcting capacitor banks on industrial lines

or filter capacitors across the power lines of some electronic

gear short carrier signal and should be isolated with inductors. Increasing range is sometimes accomplished by electing to install the isolating inductors (

Figure 28

) and coupling

capacitors, as well as by electing to use the boost option.

Frequency translating or time division multiplexed repeaters

will also increase range.

TL/H/6750– 40

FIGURE 28. An isolation network to prevent: 1) noise

from some device from polluting the AC line, and 2) to

stop some low impedance device (measured at F

o

)

from shorting carrier signal. Component values given

as an example for F

o

e

125 kHz on

residential power lines

The Coupling Transformer

The design arrived at for T1is the result of an unhappy

compromise - but a workable one. The goals of 1) building

T

1

with a stable resonant frequency, FQ, that is little affect-

ed by the de-tuning effect of the line impedance Z

L

, and of

2) building a tightly line-coupled transformer for transmitted

carrier with loose coupling for transients, are somewhat mutually exclusive. The tradeoffs are exposed in the following

example for the CCT designer attempting a new boost-capable, or different core, transformer design.

The compromises are eased by separating the TX output

and RX input in the LM2893. An untuned TX coupling transformer with only core coupling (not air-coupled solenoid

windings) would employ a high permeability, high magnetic

field, low loss, square saturating, toroidal core. The resonant RX path would be isolated from line-pull problems by a

unilateral amplifier that operates at line voltages with much

more than 110 dB of dynamic range, or by a capacitively

coupled pulse transformer driving a unilateral amplifier and

filter, for increased selectivity. See the LM2893-specific applications section.

For a LM1893-style transformer application, first, choose

the turns ratio N based on an estimated lowest Z

L

likely

encountered, Z

LN

.

Figure 29

shows graphically how N affects line signal. N should be as large as possible to drive

Z

LN

with full signal. If T1has an unloaded Q, QU, of well less

than 35, a guess of N somewhat high should be used and

later checked for accuracy. The recommended transformers

have secondary taps giving a choice of N

e

7.07, 10, and

14.1 (nominally) for driving Z

LN

’s of 14, 7.0, and 3.5 X re-

spectively (at T

J

e

25§C, Vae18V, and Q

U

e

35).

The resonating inductance of the tuned primary, L

1

,is

sought. Note that, while standard transformer design gives a

transformer self-inductance with an impedance at operating

frequency well above load impedance, the tuned transformer requires a low L

1

for adequate QUand minimum line pull.

Result: relatively poor mutual coupling.

L

1

e

R

2qFOQ

(3)

It is known that resonant frequency F

Q

e

FOand some

minimum bandwidth, or maximum Q, will be required to pass

signal under full load conditions.

L

1

e

R

Q

ll l

Z

LN

l

Ê

2q FOQ

L

(4)

l

Z

LN

l

Ê

is the reflected ZLN,QLis the loaded Q, and parallel

resistance R

Q

models all transformer losses and sets QO.

R

Q

ll l

Z

LN

l

Ê

is found knowing that it absorbs full rated power.

16

The Coupling Transformer (Continued)

TL/H/6750– 32

FIGURE 29. Impressed line voltage for a given Z

L

for each of the 3 taps available

on the recommended transformers

P

O

e

IOV

O

e

I

OPP

202

Ð

2(bV

ALC

a

Va)

202

(

e

(b4.7aVa)I

O

4

(5)

where I

O

is in amps peak-to-peak at an elevated T

J

P

O

e

(18b4.7) 0.06

4

e

0.200 W (6)

R

Q

ll l

Z

LN

l

Ê

e

V

O

2

P

O

e

(bV

ALC

a

Va)02

I

O

e

442 X (7)

R

Q

is found using ZLNand the value for N found when as-

suming Q

U

e

35.

l

Z

LN

l

Ê

e

N2Z

LN

e

(7.07)213.9e695 X (8)

R

Q

e

1

1

R

Q

ll l

Z

LN

l

Ê

b

1

l

Z

LN

l

Ê

e

1

1

442

b

1

695

e

1210 X (9)

R

QS

e

R

Q

1aQ

U

2

e

1210

1a35

2

e

1 X (10)

Only Q

L

remains to be found to calculate L1.QLis related to

the

b

3 dB (half-power) bandwidth by

Q

L

e

1

BW (% of FO)

(11)

An iterative solution is forced where line pull, DFQ, must be

guessed to find Q

L

and L1.L1is then used to check the line

pull guess; a large error requires a new guess. Try a BW of

8.7% - that is 4.4% for deviation, 1% for TC of F

O

, and

3.3% for DF

Q

- giving Q

L

e

11.5.

L

1

e

442

2qc125 000c11.5

e

49.0 mH (12)

Knowing the core inductance per turn, L, and L

1

, the num-

ber of turns is found.

T

1

e

0

L

1

L

e

0

49.0 mH

20 nH/T

e

49 (/2 turns (13)

T is normally an integer, but these transformers require so

few turns that half-turns are specified, remembering that the

remaining (/2 turn is completed on the P.C. board and is

loosely coupled. The secondary turns are calculated

T

2

e

T

1

N

e

49.5

7.07

e

7.00e7 turns (15)

giving an L

2

of 0.98 mH. Note that the recommended 125

kHz transformer mirrors these specifications. The resonating capacitor is

C

Q

e

1

(2qFQ)2L

1

e

33.1c10

b

9

e

33 nF (16)

Line pull DF

Q

was calculated (reference 3) for a ZLmagni-

tude of 14X and up with any phase angle from

b

90§to 90§.

DF

Q

was 6.4% - well above the 3.3% estimate. Referring to

(11), an 11.8% bandwidth is required, forcing L

1

to be reduced to reduce Q. That fix was not implemented; some

signal attenuation under worst-case drift and DF

Q

is al-

lowed. L

1

is already so small that the 31 gauge winding

conducts a (/4 A

RMS

circulating current.

Line Carrier Detection

While the addition of a carrier detection circuit (for a mute or

squelch function) will only decrease receiver ultimate sensitivity, there is sometimes good reason to employ it to free

the controller from watching for RX signal when no carrier is

incoming, or to employ it to reduce the probability of line

collisions (when multiple transmitters operate simultaneously to cause one or more transmissions to fail). Unless the

detector is heavily filtered or uses a high carrier amplitude

threshold, there will be false outputs that force the controller

to have Data Out data checking capability just as is required

when using no carrier detector. If false triggering is minimized, the probability of line collisions is increased due to

the inability to sense low carrier amplitudes and because of

sense delay. The property of the LM1893 to change output

state infrequently (although the polarity is undefined) when

in the RX mode, with no incoming carrier, reduces the desire

to implement carrier detection and preserves the full ultimate sensitivity. Also, many impulse-noise insensitive transmission schemes, like handshaking, are easily modified to

recover from line collisions.

Regarding this, it should be stated that for very complicated

industrial systems with long signal runs and high line noise

levels, it is probably wise to use a protocol which is inherently collision free so that no carrier detect hardware or software is needed. A token passing protocol is an example of

such a system.

Figure 30

shows a low cost carrier amplitude detection cir-

cuit.

Audio Transmission

The LM1893 is designed to allow analog data transmission

and reception. Base-band audio-bandwidth signals FM

modulate the carrier passing through the tuned transformer

(placing a limit on the usable percent modulation) onto the

power line to be linearly demodulated by the receiver PLL.

Because the receiver data path beyond the phase detector

will pass only digital signal, external audio filtering and amplification is required.

Figure 31

shows a simple audio transmitter and receiver circuit utilizing a carrier detection mute

circuit. A single LM339 quad. comparator may be used to

build the carrier detect and mute. Filter bandwidth is held to

a minimum to minimize noise, especially line-related correlated noise.

Communication and System

Protocols

The development of communication and system protocols

has historically been the single most time consuming element in design of carrier current systems. The protocols are

defined as the following:

1.

Communication protocol

: a software method of encoding

and decoding data that remains constant for every transmis-

17

TL/H/6750– 33

FIGURE 30. A simple carrier amplitude detector with output low when carrier is detected

TL/H/6750– 34

FIGURE 31. A simple linear analog audio transmitter and receiver are shown.

The carrier and 1.6V inputs are derived from the carrier detector of

Figure 30

.

The remaining 2 LM339 comparators may be used to build the carrier detector circuit.

Communication and System

Protocols

(Continued)

sion in a system. Its first purpose is to put data in a baseband digital form that is more easily recognized as a real

message at the receive end. Secondly, it incorporates encoding techniques to ensure that noise induced errors do

not easily occur; and when they do, they can always be

detected. Lastly, the software algorithms that are used on

the receive end to decode incoming data prevent the reception of noise induced ‘‘phantom’’ messages, and insure the

recovery of real messages from an incoming bit stream that

has been altered by noise.

2.

System protocol

: the manner in which messages are co-

ordinated between nodes in a system. Its first purpose is to

ensure message retransmission to correct errors (handshake). Secondly it coordinates messages for maximum utilization and efficiency on the network. Lastly, it ensures that

messages do not collide on the network. Common system

protocols include master-slave, carrier detect multiple access, and token passing. Token passing and master slave

have been found to be the most useful since they are inherently collision free.

Both protocols usually reside as software in a single microcontroller that is connected to the LM1893/2893 I/O. In any

case, some sort of intelligence is needed to process incoming and outgoing messages. UARTs have no usefulness in

18

Communication and System

Protocols

(Continued)

carrier current applications since they do not have the intelligence needed to distinguish between real messages and

noise induced phantoms.

The difficulty in designing special protocols arises out of the

special nature of the AC line, an environment laden with the

worst imaginable noise conditions. The relatively low data

rates possible over the AC line (typically less than 9600

baud) make it even more imperative that systems utilize the

most sophisticated means available to ensure network efficiency.

With these facts in mind, the designer is referred to a publication intended to aid in the development of carrier current

systems. This is literature

Ý

570075 The Bi-Line Carrier Current Networking System, a 200 pp. book that functions as

the ‘‘bible’’ of Bi-Line system design. It has sections on

LM1893 circuit optimization, protocol design, evaluation kit

usage, critical component selection, and the Datachecker/

DTS case study.

Basic Data Encoding (please refer to the pre-

viously mentioned publications for advanced techniques)

At the beginning of a received transmission, the first 0 to 2

bits may be lost while the chip’s receiver settles to the DC

bias point required for the given transmitter/receiver pair

carrier frequency offset. With proper data encoding,

dropped start bits can be tolerated and correct communication can take place. One simple data encoding scheme is

now discussed.

Generally, a CCT system consists of many transceivers that

normally listen to the line at all times (or during predetermined time windows), waiting for a transmission that directs

one or more of the receivers to operate. If any receiver finds

its address in the transmitted data packet, further action

such as handshaking with the transmitter is initiated. The

receiver might tell the transmitter, via retransmission, that it

received this data, waiting for acknowledgement before acting on the received command. Error detecting and correcting codes may be employed throughout. The transmitter

must have the capability to retransmit after a time if no response from the receiver is heard - under the assumption

that the receiver didn’t detect its address because of noise,

or that the response was missed because of noise or a line

collision. (A line collision happens when more than 1 transmitter operates at one time - causing one or more of the

communications to fail). After many re-transmissions the

transmitter might choose to give up. Collision recovery is

achieved by waiting some variable amount of time before re-

transmission, using a random number of bits delay or a delay based on each transmitter’s address, since each transceiver has a unique address.

An example of a simple transmission data packet is shown

in

Figure 32

. The 8 bit 50% duty-cycle preamble is long

enough to allow receiver biasing with enough bits left over

to allow the receiver controller to detect the square-wave

that signals the start of a transmission. If there had been no

transmission for some time, the receiver would simply need

to note that a data transition had occurred and begin its

watch for a square-wave. If the receive controller detected

the alternating-polarity data square-wave it would then use