NSC LM396K, LM196K Datasheet

TL/H/9059

LM196/LM396 10 Amp Adjustable Voltage Regulator

August 1992

LM196/LM396 10 Amp Adjustable Voltage Regulator

General Description

The LM196 is a 10 amp regulator, adjustable from 1.25V to

15V, which uses a revolutionary new IC fabrication structure

to combine high power discrete transistor technology with

modern monolithic linear IC processing. This combination

yields a high-performance single-chip regulator capable of

supplying in excess of 10 amps and operating at power levels up to 70 watts. The regulators feature on-chip trimming

of reference voltage to

g

0.8% and simultaneous trimming

of reference temperature drift to 30 ppm/

§

C typical. Thermal

interaction between control circuitry and the pass transistor

which affects the output voltage has been reduced to extremely low levels by strict attention to isothermal layout.

This interaction, called thermal regulation, is 100% tested.

These new regulators have all the protection features of

popular lower power adjustable regulators such as LM117

and LM138, including current limiting and thermal limiting.

The combination of these features makes the LM196 immune to blowout from output overloads or shorts, even if

the adjustment pin is accidentally disconnected. All devices

are ‘‘burned-in’’ in thermal shutdown to guarantee proper

operation of these protective features under actual overload

conditions.

Output voltage is continuously adjustable from 1.25V to

15V. Higher output voltages are possible if the maximum

input-output voltage differential specification is not exceeded. Full load current of 10A is available at all output voltages, subject only to the maximum power limit of 70W and

of course, maximum junction temperature.

The LM196 is exceptionally easy to use. Only two external

resistors are used to to set output voltage. On-chip adjustment of the reference voltage allows a much tighter specification of output voltage, eliminating any need for trimming in

most cases. The regulator will tolerate an extremely wide

range of reactive loads, and does not depend on external

capacitors for frequency stabilization. Heat sink requirements are much less stringent, because overload situations

do not have to be accounted forÐonly worst-case full load

conditions.

The LM196 is in a TO-3 package with oversized (0.060

×

)

leads to provide best possible load regulation. Operating

junction temperature range is

b

55§Ctoa150§C. The

LM396 is specified for a 0

§

Ctoa125§C junction tempera-

ture range.

Features

Y

Output pre-trimmed tog0.8%

Y

10A guaranteed output current

Y

PaProduct Enhancement tested

Y

70W maximum power dissipation

Y

Adjustable outputÐ1.25V to 15V

Y

Internal current and power limiting

Y

Guaranteed thermal resistance

Y

Output voltage guaranteed under worst-case conditions

Y

Output is short circuit protected

Typical Applications

V

OUT

e

(1.25V)

#

R1aR2

R1

J

a

I

ADJ

(R2)

TL/H/9059– 1

*For best TC of V

OUT

, R1 should be wirewound

or metal film, 1% or better.

**R2 should be same type as R1, with TC track-

ing of 30 ppm/

§

C or better.

²

C1 is necessary only if main filter capacitor is

more than 6

×

away, assumingÝ18 or larger

leads.

²²

C2 is not absolutely necessary, but is suggested to lower high frequency output impedance.

Output capacitors in the range of 1 mFto

1000 mF of aluminum or tantalum electrolytic

are commonly used to provide improved output impedance and rejection of transients.

Ê

C3 improves ripple rejection, output impedance, and noise. C2 should be 1 mF or larger

close to the regulator if C3 is used.

FIGURE 1. Basic 1.25V to 15V Regulator

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Power Dissipation Internally Limited

Input-Output Voltage Differential 20V

Operating Junction Temperature Range

LM196 Control Section

b

55§Ctoa150§C

Power Transistor

b

55§Ctoa200§C

LM396 Control Section 0§Ctoa125§C

Power Transistor 0

§

Ctoa175§C

Storage Temperature

b

65§Ctoa150§C

Lead Temperature (Soldering, 10 seconds) 300§C

ESD rating to be determined

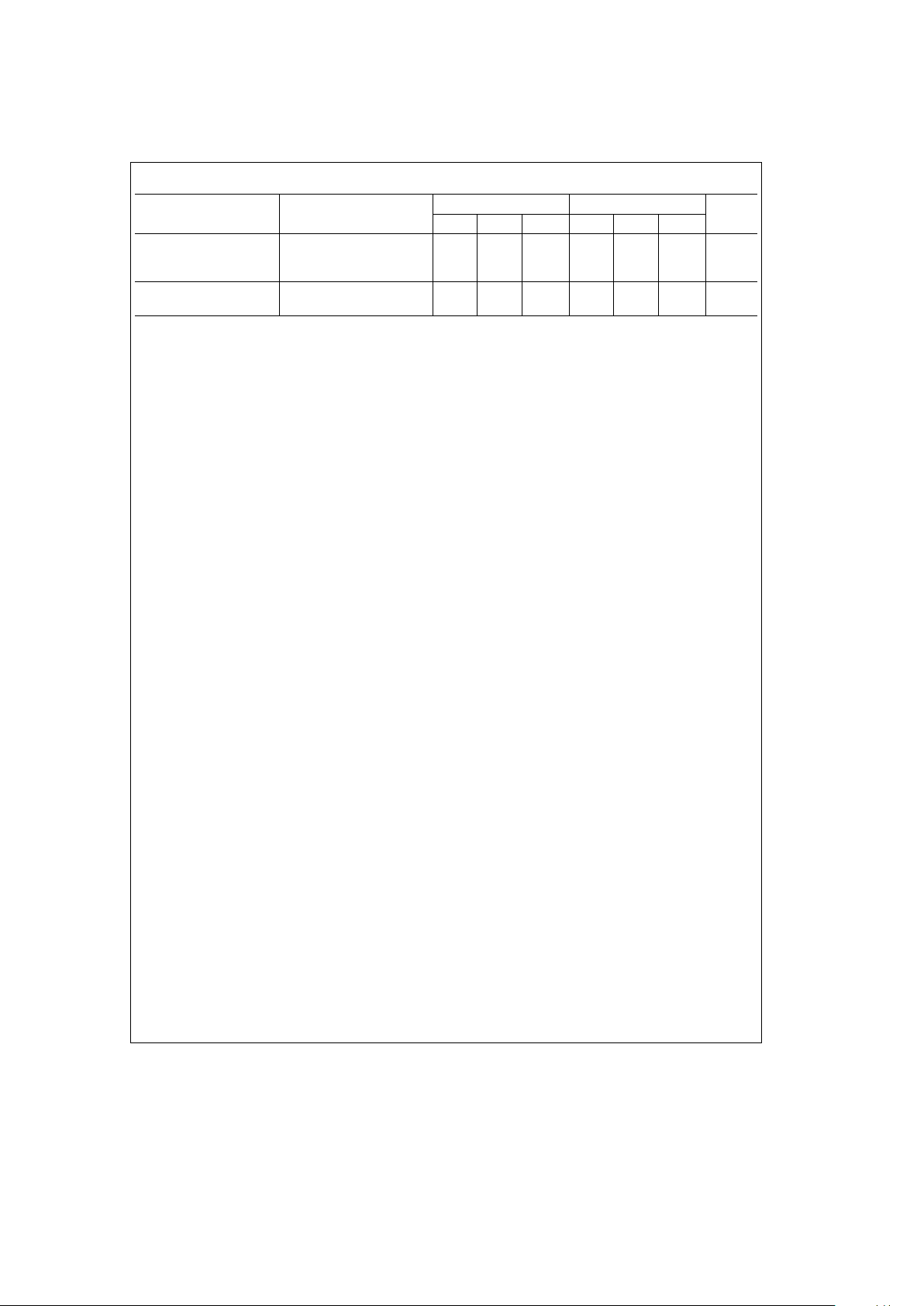

Electrical Characteristics (Note 1)

Parameter Conditions

LM196 LM396

Units

Min Typ Max Min Typ Max

Reference Voltage I

OUT

e

10 mA 1.24 1.25 1.26 1.23 1.25 1.27 V

Reference Voltage V

MIN

s

(V

IN

b

V

OUT

)s20V 1.22 1.25 1.28 1.21 1.25 1.29 V

(Note 2) 10 mA

s

I

OUT

10A, PsP

MAX

Full Temperature Range

Line Regulation V

MIN

s

(V

IN

b

V

OUT

)s20V 0.005 0.01 0.005 0.02 %/V

(Note 3) Full Temperature Range 0.05 0.05 %/V

Load Regulation 10 mAsI

OUT

s

10A 0.1 0.1 %/A

LM196/LM396 V

MIN

s

V

IN

b

V

OUT

s

10V, PsP

MAX

(Note 4) Full Temperature Range 0.15 0.15 %/A

Ripple Rejection C

ADJ

e

25 mF, fe120 Hz 60 74 66 74 dB

(Note 5) Full Temperature Range 54 54 dB

Thermal Regulation V

IN

b

V

OUT

e

5V, I

OUT

e

10A 0.003 0.005 0.003 0.015 %/W

(Note 6)

Average Output Voltage T

jMIN

s

T

j

s

T

jMAX

0.003 0.003 %/§C

Temperature Coefficient (See Curves for Limits)

Adjustment Pin Current 50 100 50 100 mA

Adjustment Pin Current 10 mAsI

OUT

s

10A 3 3 mA

Change (Note 7) 3V

s

V

IN

b

V

OUT

s

20V

PsP

MAX

, Full Temperature Range

Minimum Load Current 2.5Vs(V

IN

b

V

OUT

)s20V 10 10 mA

(Note 9) Full Temperature Range

Current Limit 2.5s(V

IN

b

V

OUT

s

7V 10 14 20 10 14 20 A

(Note 8) V

IN

b

V

OUT

e

20V 1.5 3 8 1.5 3 8 A

Rms Output Noise 10 Hzsfs10 kHz 0.001 0.001 %V

OUT

Long Term Stability T

j

e

125§C, te1000 Hours 0.3 1.0 0.3 1.0 %

Thermal Resistance Control Circuitry 0.3 0.5 0.3 0.5§C/W

Junction to Case Power Transistor 1.0 1.2 1.0 1.2

§

C/W

(Note 10)

2

Electrical Characteristics (Note 1) (Continued)

Parameter Conditions

LM196 LM396

Units

Min Typ Max Min Typ Max

Power Dissipation (P

MAX

) 7.0VsV

IN

b

V

OUT

s

12V 70 100 70 100 W

(Note 11) V

IN

b

V

OUT

e

15V 50 50 W

V

IN

b

V

OUT

e

18V 36 36 W

Drop-Out Voltage I

OUT

e

10A, 2.1 2.5 2.1 2.5 V

LM196/LM396 Full Temperature Range 2.75 2.75

Note 1: Unless otherwise stated, these specifications apply for T

j

e

25§C, V

IN

b

V

OUT

e

5V, I

OUT

e

10 mA to 10A.

Note 2: This is a worst-case specification which includes all effects due to input voltage, output current, temperature, and power dissipation. Maximum power

(P

MAX

) is specified under Electrical Characteristics.

Note 3: Line regulation is measured on a short-pulse, low-duty-cycle basis to maintain constant junction temperature. Changes in output voltage due to thermal

gradients or temperature changes must be taken into account separately. See discussion of Line Regulation under Application Hints.

Note 4: Load regulation on the 2-pin package is determined primarily by the voltage drop along the output pin. Specifications apply for an external Kelvin sense

connnection at a point on the output pin (/4

×

from the bottom of the package. Testing is done on a short-pulse-width, low-duty-cycle basis to maintain constant

junction temperature. Changes in output voltage due to thermal gradients or temperature changes must be taken into account separately. See discussion of Load

Regulation under Application Hints.

Note 5: Ripple rejection is measured with the adjustment pin bypassed with 25 mF capacitor, and is therefore independent of output voltage. With no load or

bypass capacitor, ripple rejection is determined by line regulation and may be calculated from; RR

e

20 log

10

[

100/(K

c

V

OUT

)]where K is line regulation

expressed in %/V. At frequencies below 100 Hz, ripple rejection may be limited by thermal effects, if load current is above 1A.

Note 6: Thermal regulation is defined as the change in output voltage during the time period of 0.2 ms to 20 ms after a change in power dissipation in the regulator,

due to either a change in input voltage or output current. See graphs and discussion of thermal effects under Application Hints.

Note 7: Adjustment pin current change is specified for the worst-case combination of input voltage, output current, and power dissipation. Changes due to

temperature must be taken into account separately. See graph of adjustment pin current vs temperature.

Note 8: Current limit is measured 10 ms after a short is applied to the output. DC measurements may differ slightly due to the rapidly changing junction temperature,

tending to drop slightly as temperature increases. A minimum available load current of 10A is guaranteed over the full temperature range as long as power

dissipation does not exceed 70W, and V

IN

b

V

OUT

is less than 7.0V.

Note 9: Minimum load current of 10 mA is normally satisfied by the resistor divider which sets up output voltage.

Note 10: Total thermal resistance, junction-to-ambient, will include junction-to-case thermal resistance plus interface resistance and heat sink resistance. See

discussion of Heat Sinking under Application Hints.

Note 11: Although power dissipation is internally limited, electrical specifications apply only for power dissipation up to the limits shown. Derating with temperature

is a function of both power transistor temperature and control area temperature, which are specified differently. See discussion of Heat Sinking under Application

Hints. For V

IN

b

V

OUT

less than 7V, power dissipation is limited by current limit of 10A.

Note 12: Dropout voltage is input-output voltage differential measured at a forced reference voltage of 1.15V, with a 10A load, and is a measurement of the

minimum input/output differential at full load.

Application Hints

Further improvements in efficiency can be obtained by using

Schottky diodes or high efficiency diodes with lower forward

voltage, combined with larger filter capacitors to reduce ripple. However, this reduces the voltage difference between

input and drive pins and may not allow sufficient voltage to

fully saturate the pass transistor. Special transformers are

available from Signal Transformer that have a 1V tap on the

output winding to provide the extra voltage for the drive pin.

The transformers are available as standard items for 5V applications at 5A, 10A and 20A. Other voltages are available

on special request.

Heat Sinking

Because of its extremely high power dissipation capability,

the

major limitation

in the load driving capability of the

LM196 is

heat sinking

. Previous regulators such as LM109,

LM340, LM117, etc., had internal power limiting circuitry

which limited power dissipation to about 30W. The LM196

is guaranteed to dissipate up to 70W continuously, as long

as the maximum junction temperature limit is not exceeded.

This requires careful attention to all sources of thermal resistance from junction-to-ambient, including junction-tocase resistance, case-to-heat sink interface resistance

(0.1–1.0

§

C/W), and heat sink resistance itself. A good thermal joint compound such as Wakefield type 120 or Thermalloy Thermocote must be used when mounting the LM196,

especially if an electrical insulator is used to isolate the regulator from the heat sink. Interface resistance without this

compound will be no better than 0.5

§

C/W, and probably

much worse. With the compound, and no insulator, interface

resistance will be 0.2

§

C/W or less, assuming 0.005×or less

combined flatness run-out of TO-3 and heat sink. Proper

torquing of the mounting bolts is important to achieve minimum thermal resistance. Four to six inch pounds is recommended. Keep in mind that good electrical, as well as thermal, contact must be made to the case.

3

Application Hints (Continued)

The actual heat sink chosen for the LM196 will be determined by the worst-case continuous full load current, input

voltage and maximum ambient temperature. Overload or

short circuit output conditions do not normally have to be

considered when selecting a heat sink because the thermal

shutdown built into the LM196 will protect it under these

conditions. An exception to this is in situations where the

regulator must recover very quickly from overload. The

LM196 may take some time to recover to within specified

output tolerance following an extended overload, if the regulator is cooling from thermal shutdown temperature (approximately 175

§

) to specified operating temperature (125§Cor

150

§

C). The procedure for heat sink selection is as follows:

Calculate worst-case

continuous

average power dissipa-

tion in the regulator from P

e

(V

IN

b

V

OUT

)c(I

OUT

). To

do this, you must know the raw power supply voltage/current characteristics fairly accurately. For example, consider a 10V output with 15V nominal input voltage. At full

load of 10A, the regulator will dissipate P

e

(15b10)

c

(10)e50W. If input voltage rises by 10%, power dissipation will increase to (16.5

b

10)c(10)e65W, a

30%

increase.

It is strongly suggested that a raw supply be

assembled and tested to determine its average DC output

voltage

under full load with maximum line voltage

.Donot

over-design by using unloaded voltage as a worst-case,

since the regulator will not be dissipating any power under

no load conditions. Worst-case regulator dissipation normally occurs under full load conditions except when the

effective DC resistance of the raw supply (DV/DI) is larger than (V

IN

*bV

OUT

)/2IfL, where VIN* is the lightly-load-

ed raw supply voltage and I

fL

is full load current. For (VIN*

b

V

OUT

)e5Vb8V, and I

fL

e

5A–10A, this gives a

resistance of 0.25X to 0.8X. If raw supply resistance is

higher than this, the regulator power dissipation may be

less

at full load current, then at some intermediate current, due to the large drop in input voltage. Fortunately,

most well designed raw supplies have low enough output

resistance that regulator dissipation does maximize at full

load current, or very close to it, so tedious testing is not

usually required to find worst-case power dissipation.

A very important consideration is the size of the filter capacitor in the raw supply. At these high current levels, capacitor

size is usually dictated by ripple current ratings rather than

just obtaining a certain ripple voltage. Capacitor ripple current (rms) is 2 – 3 times the DC output current of the filter. If

the capacitor has just 0.05X DC resistance, this can cause

30W internal power dissipation at 10A output current. Capacitor life is very sensitive to operating temperature, decreasing by a factor of two for each 15

§

C rise in internal

temperature. Since capacitor life is not all that great to start

with, it is obvious that a small capacitor with a large internal

temperature rise is inviting very short mean-time-to-failure.

A second consideration is the loss of usable input voltage to

the regulator. If the capacitor is small, the large dips in the

input voltage may cause the LM196 to drop out of regulation. 2000 mF per ampere of load current is the

minimum

recommended value, yielding about 2 Vp-p ripple of 120 Hz.

Larger values will have longer life and the reduced ripple will

allow lower DC input voltage to the regulator, with subse-

quent cost savings in the transformer and heat sink. Sometimes several capacitors in parallel are better to decrease

series resistance and increase heat dissipating area.

After the raw supply characteristics have been determined,

and worst-case power dissipation in the LM196 is known,

the heat sink thermal resistance can be found from the

graphs titled Maximum Heat Sink Thermal Resistance.

These curves indicate the minimim size heat sink required

as a function of ambient temperature. They are derived from

a case-to-control area thermal resistance of 0.5

§

C/W and a

case-to-power transistor thermal resistance of 1.2

§

C/W.

0.2

§

C/W is assumed for interface resistance. A maximum

control area temperature of 150

§

C is used for the LM196

and 125

§

C for the LM396. Maximum power transistor tem-

perature is 200

§

C for the LM196 and 175§C for the LM396.

For conservative designs, it is suggested that when using

these curves, you assume an ambient temperature 25

§

C–

50

§

C higher than is actually anticipated, to avoid running the

regulator right at its design limits of operating temperature.

A quick look at the curves show that heat sink resistance

(i

SA

) will normally fall into the range of 0.2§C/W–1.5§C/W.

These are

not

small heat sinks. A model 441, for instance,

which is sold by several manufacturers, has a i

SA

of

0.6

§

C/W with natural convection and is about five inches on

a side. Smaller sinks are more volumetrically efficient, and

larger sinks, less so. A rough formula for estimating the volume of heat sink required is: V

e

50/i

SA

1.5

CU. IN. This

holds for natural convection only. If the heat sink is inside a

small sealed enclosure, i

SA

will increase substantially because the air is not free to form natural convection currents.

Fan-forced convection can reduce i

SA

by a factor of two at

200 FPM air velocity, and by four at 1000 FPM.

Ripple Rejection

Ripple rejection at the normal ripple frequency of 120 Hz is

a function of both electrical and thermal effects in the

LM196. If the adjustment pin is not bypassed with a capacitor, it is also dependent on output voltage. A 25 mF capacitor from the adjustment pin to ground will make ripple rejection independent of output voltage for frequencies above

100 Hz. If lower ripple frequencies are encountered, the capacitor should be increased proportionally.

To keep in mind that the bypass capacitor on the adjustment pin will limit the turn-on time of the regulator. A 25 mF

capacitor, combined with the output divider resistance, will

give an extended output voltage settling time following the

application of input power.

Load Regulation (LM196/LM396)

Because the LM196 is a three-terminal device, it is not possible to provide true remote load sensing. Load regulation

will be limited by the resistance of the output pin and the

wire connecting the regulator to the load. For the data sheet

specification, regulation is measured 1/4

×

from the bottom

of the package on the output pin. Negative side sensing is a

true Kelvin connection, with the bottom of the output divider

returned to the negative side of the load.

4

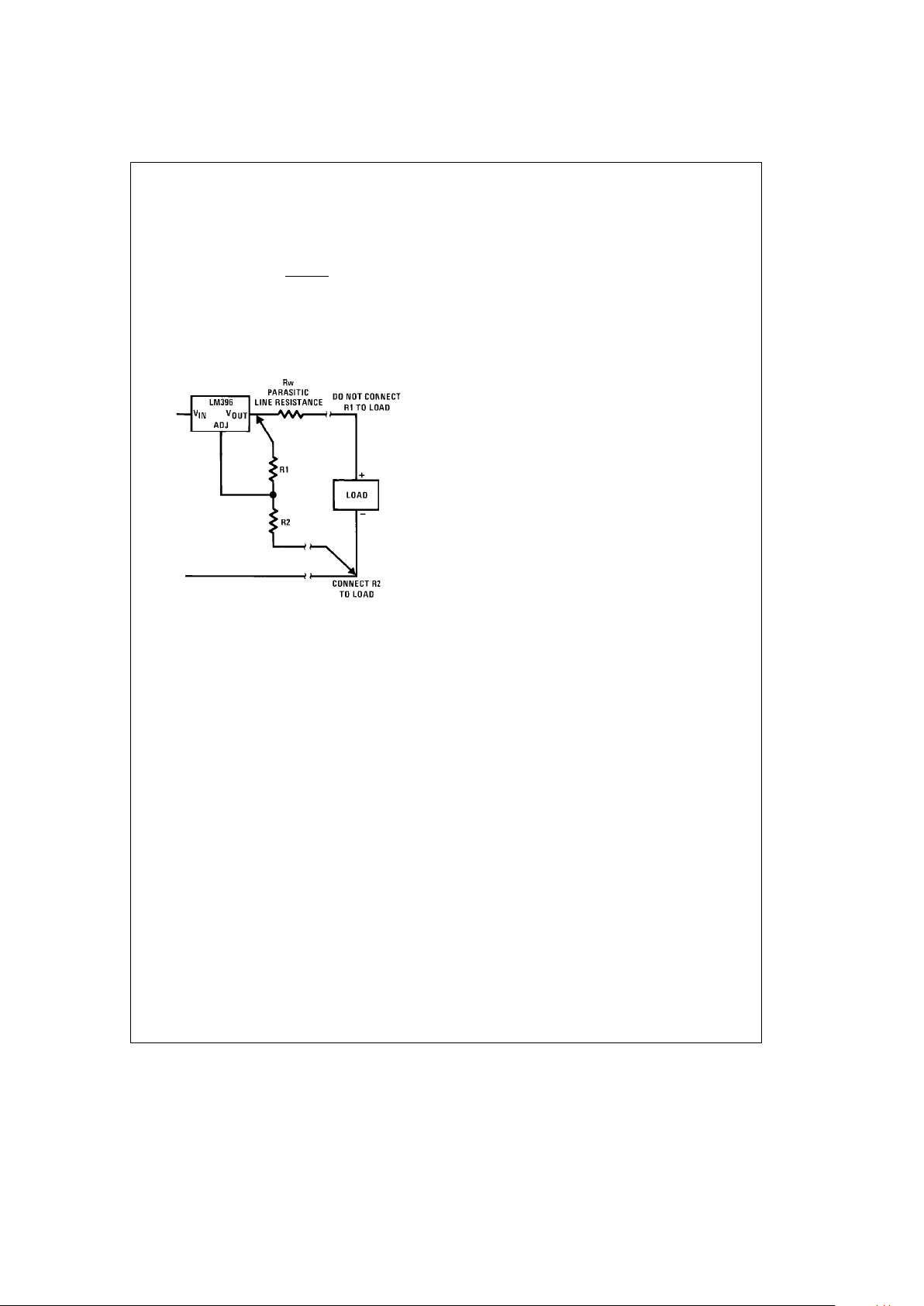

Application Hints (Continued)

Although it may not be immediately obvious, best load regulation is obtained when the top of the divider is connected

directly

to the output pin,

not to the load

. This is illustrated in

Figure 2

. If R1 were connected to the load, the effective

resistance between the regulator and the load would be

(Rw)

c

#

R2aR1

R1

J

RweLine Resistance

Connected as shown, Rw is not multiplied by the divider

ratio. Rw is about 0.004X per foot using 16 gauge wire. This

translates to 40 mV/ft at 10A load current, so it is important

to keep the positive lead between regulator and load as

short as possible.

TL/H/9059– 2

FIGURE 2. Proper Divider Connection

The input resistance of the sense pin is typically 6 kX, modeled as a resistor between the sense pin and the output pin.

Load regulation will start to degrade if a resistance higher

than 10X is inserted in series with the sense. This assumes

a worst-case condition of 0.5V between output and sense

pins. Lower differential voltage will allow higher sense series

resistance.

Thermal Load Regulation

Thermal, as well as electrical, load regulation must be considered with IC regulators. Electrical load regulation occurs

in microseconds, thermal regulation due to die thermal gradients occurs in the 0.2 ms-20 ms time frame, and regulation due to overall temperature changes in the die occurs

over a 20 ms to 20 minute period, depending on the time

constant of the heat sink used. Gradient induced load regulation is calculated from

DV

OUT

e

(V

IN

b

V

OUT

)c(DI

OUT

)c(b)

beThermal regulation specified on data sheet.

For V

IN

e

9V, V

OUT

e

5V, DI

OUT

e

10A, and b

e

0.005%/W, this yields a 0.2% change in output voltage.

Changes in output voltage due to overall temperature rise

are calculated from

V

OUT

e

(V

IN

b

V

OUT

)c(DI

OUT

)c(TC)c(ijA)

TC

e

Temperature coefficient of output voltage.

i

jA

e

Thermal resistance from junction to ambient. ijAis

approximately 0.5

§

C/Wai of heat sink.

For the same conditions as before, with TC

e

0.003%/§C,

and i

jA

e

1.5§C/W, the change in output voltage will be

0.18%. Because these two thermal terms can have either

polarity, they may subtract from, or add to, electrical load

regulation. For worst-case analysis, they must be assumed

to add. If the output of the regulator is trimmed under load,

only that portion of the load that changes need be used in

the previous calculations, significantly improving output accuracy.

Line Regulation

Electrical line regulation is very good on the LM196Ðtypically less than 0.005% change in output voltage for a 1V

change in input. This level of regulation is achieved only for

very low load currents, however, because of thermal effects. Even with a thermal regulation of 0.002%.W, and a

temperature coefficient of 0.003%/

§

C, DC line regulation

will be dominated by thermal effects as shown by the following example:

Assume V

OUT

e

5V, V

IN

e

9V, I

OUT

e

8A

Following a 10% change in input voltage (0.9), the output

will change quickly (

s

100 ms), due to electrical effects, by

(0.005%V)

c

(0.9V)e0.0045%. In the next 20 ms, the

output will change an additional (0.002%/W)

c

(8A)

c

(0.9V)e0.0144% due to thermal gradients across the die.

After a much longer time, determined by the time constant

of the heat sink, the output will change an additional

(0.003%/

§

C)c(8A)c(0.9V)c(2§C/W)e0.043% due to

the temperature coefficient of output voltage and the thermal resistance from die to ambient. (2

§

C/W was chosen for

this calculation). The sign of these last two terms varies

from part to part, so no assumptions can be made about any

cancelling effects. All three terms must be added for a proper analysis. This yields 0.0045

a

0.0144a0.043

e

0.062% using

typical

values for thermal regulation and temperature coefficient. For worst-case analysis, the maximum

data sheet specifications for thermal regulation and temperature coefficient should be used, along with the

actual

ther-

mal resistance of the heat sink being used.

Paralleling Regulators

Direct paralleling of regulators is not normally recommended because they do not share currents equally. The regulator with the highest reference voltage will supply all the current to the load until it current limits. With an 18A load, for

instance, one regulator might be operating in current limit at

16A while the second device is only carrying 2A. Power dissipation in the high current regulator is extremely high with

attendant high junction temperatures. Long term reliability

cannot be guaranteed under these conditions.

Quasi-paralleling may be accomplished if load regulation is

not critical. The connection shown in

Figure 5a

will typically

share to within 1A, with a worst-case of about 3A. Load

regulation is degraded by 150 mV at 20A loads. An external

op amp may be used as in

Figure 5b

to improve load regula-

tion and provide remote sensing.

5

Loading...

Loading...