NSC CLC030VEC Datasheet

PRELIMINARY

February 2002

CLC030

SMPTE 292M/259M Digital Video Serializer with Video

and Ancilliary Data FIFOs and Integrated Cable Driver

General Description

The CLC030 SMPTE 292M/259M Digital Video Serializer

with Ancilliary Data FIFO and Integrated Cable Driver is a

monolithic integrated circuit that encodes, serializes and

transmits bit-parallel digital video data conforming to SMPTE

125M and 267M standard definition, 10-bit wide component

video and SMPTE 260M, 274M, 295M and 296M highdefinition, 20-bit wide component video standards. The

CLC030 operates at SMPTE 259M serial data rates of

270 Mbps, 360 Mbps, the SMPTE 344M (proposed) serial

data rate of 540 Mbps; and the SMPTE 292M serial data

rates of 1483.5 and 1.485 Gbps. The serial data clock frequency is internally generated and requires no external frequency setting, trimming or filtering components*.

Functions performed by the CLC030 include: parallel-toserial data conversion, SMPTE standard data encoding,

NRZ to NRZI data format conversion, serial data clock generation and encoding with the serial data, automatic video

rate and format detection, ancilliary data packet storage,

manipulation and insertion, and serial data output driving.

The CLC030 has circuitry for automatic EDH/CRC character

and flag generation and insertion per SMPTE RP-165 (standard definition) or SMPTE 292M (high definition). Optional

LSB dithering is implemented which prevents pathological

pattern generation. Unique to the CLC030 are its video and

ancilliary data FIFOs. The video FIFO allows from 0 to 4

parallel data clock delays to be inserted in the data path for

video timing purposes. The ancilliary data port and on-chip

FIFO and control circuitry offer elegant handling and insertion of ancilliary datapacketsandchecksumsin the ancilliary

data space. The CLC030 also has an exclusive built-in selftest (BIST) and video test pattern generator (TPG) with SD

and HD component video test patterns: reference black, PLL

and EQ pathologicals and colour bars in 4:3 and 16:9 raster

formats for NTSC and PAL standards*. The colour bar patterns feature optional bandwidth limiting coding in the

chroma and luma transitions.

The CLC030 has a unique multi-function I/O port which

provides access to control and configuration signals and

data. This port may be programmed to provide external

access to control functions and data for use as inputs and

outputs. This allows the designer greater flexibility in tailoring

the CLC030 to the desired application. At power-up or after a

reset command, the CLC030 is auto-configured to a default

operating condition. Separate power pins for the output

driver, PLL and the serializer improve power supply rejection, output jitter and noise performance.

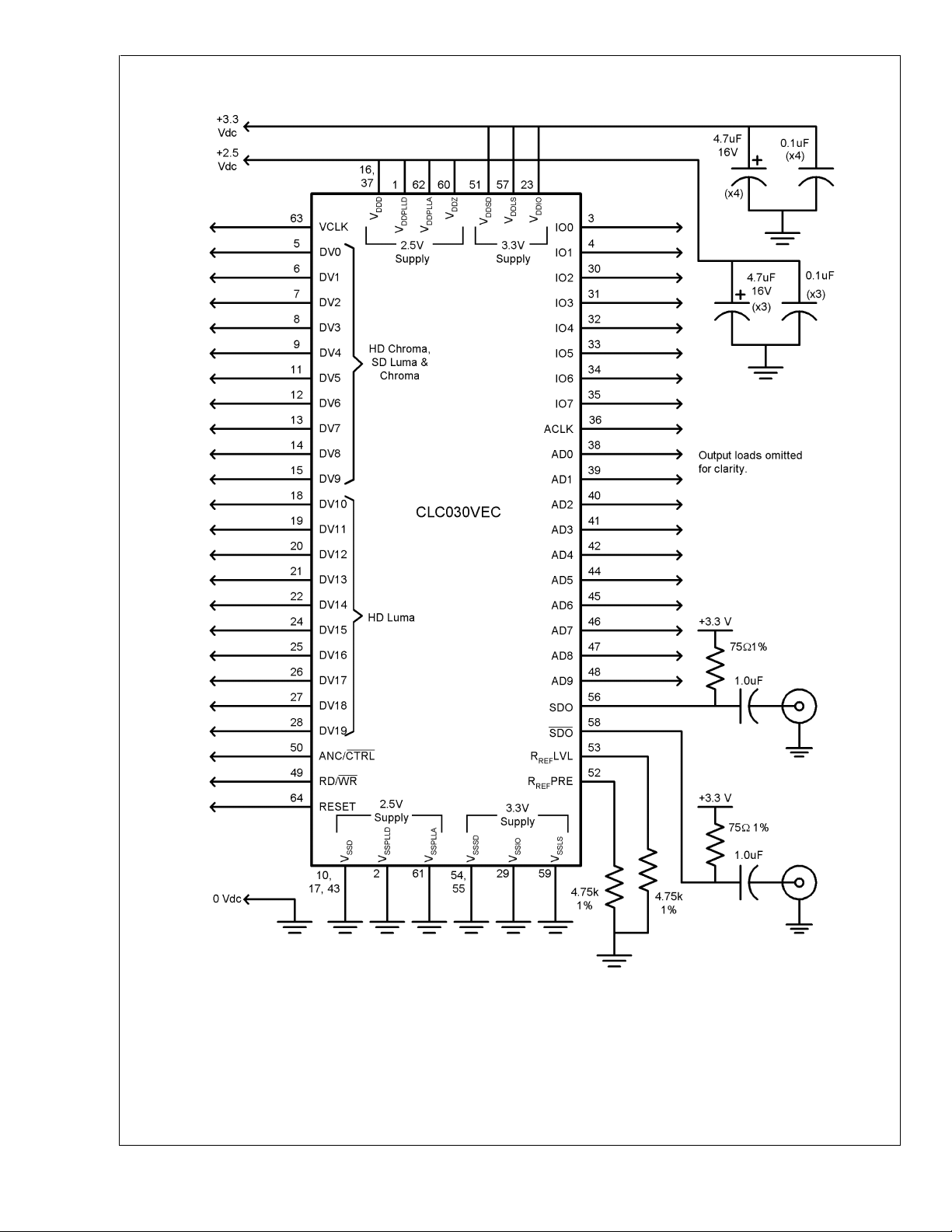

The CLC030’s internal circuitry is powered from +2.5V and

the I/O circuitry from a +3.3V supply. Power dissipation is

typically 430mW at 1.485Gbps including two 75Ω ACcoupled and back-matched output loads. The device is packaged in a 64-pin TQFP.

Features

n SDTV/HDTV serial digital video standard compliant

n Supports 270 Mbps, 360 Mbps, 540 Mbps, 1.4835Gbps

and 1.485 Gbps SDV data rates with auto-detection

n LSB dithering option

n No external serial data rate setting or VCO filtering

components required*

n Fast PLL lock time:

n Adjustable depth video FIFO for timing alignment

n Built-in self-test (BIST) and video test pattern generator

(TPG)*

n Automatic EDH/CRC word and flag generation and

insertion

n On-chip ancilliary data FIFO and insertion control

circuitry

n Flexible control and configuration I/O port

n LVCMOS compatible data and control inputs and

outputs

n 75Ω ECL-compatible, differential, serial cable-driver

outputs

n 3.3V I/O power supply, 2.5V logic power supply

operation

n Low power: typically 430mW

n 64-pin TQFP package

n Commercial temperature range 0˚C to +70˚C

*

Patent applications made or pending.

<

150µs typical at 1.485 Gbps

Applications

n SDTV/HDTV parallel-to-serial digital video interfaces for:

— Video cameras

— VTRs

— Telecines

— Digital video routers and switchers

— Digital video processing and editing equipment

— Video test pattern generators and digital video test

equipment

— Video signal generators

CLC030 SMPTE 292M/259M Digital Video Serializer with Video and Ancilliary Data FIFOs and

Integrated Cable Driver

Order Number CLC030VEC 64-Pin TQFP

© 2002 National Semiconductor Corporation DS200003 www.national.com

NS Package Number

VEC-64A

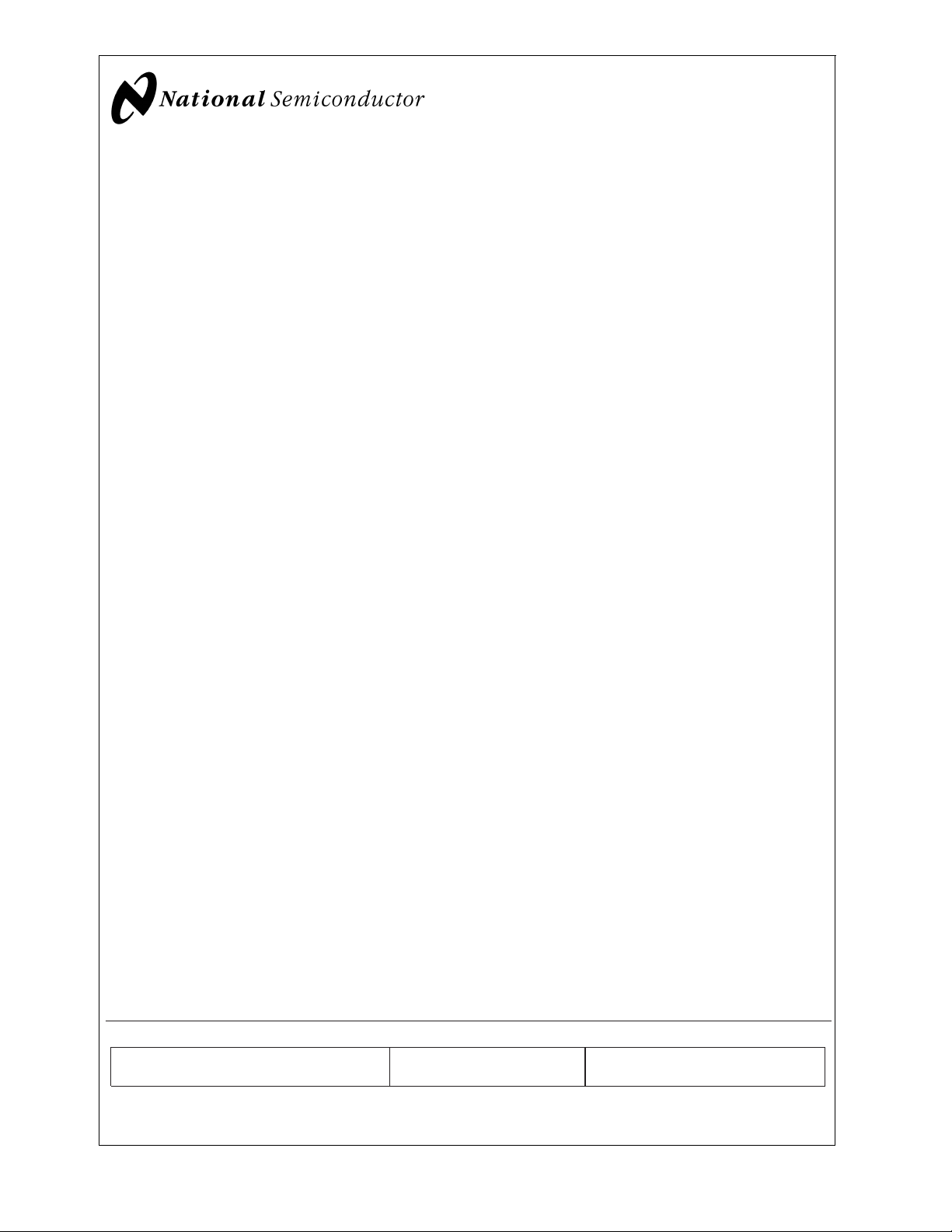

Typical Application

CLC030

DS200003-1

www.national.com 2

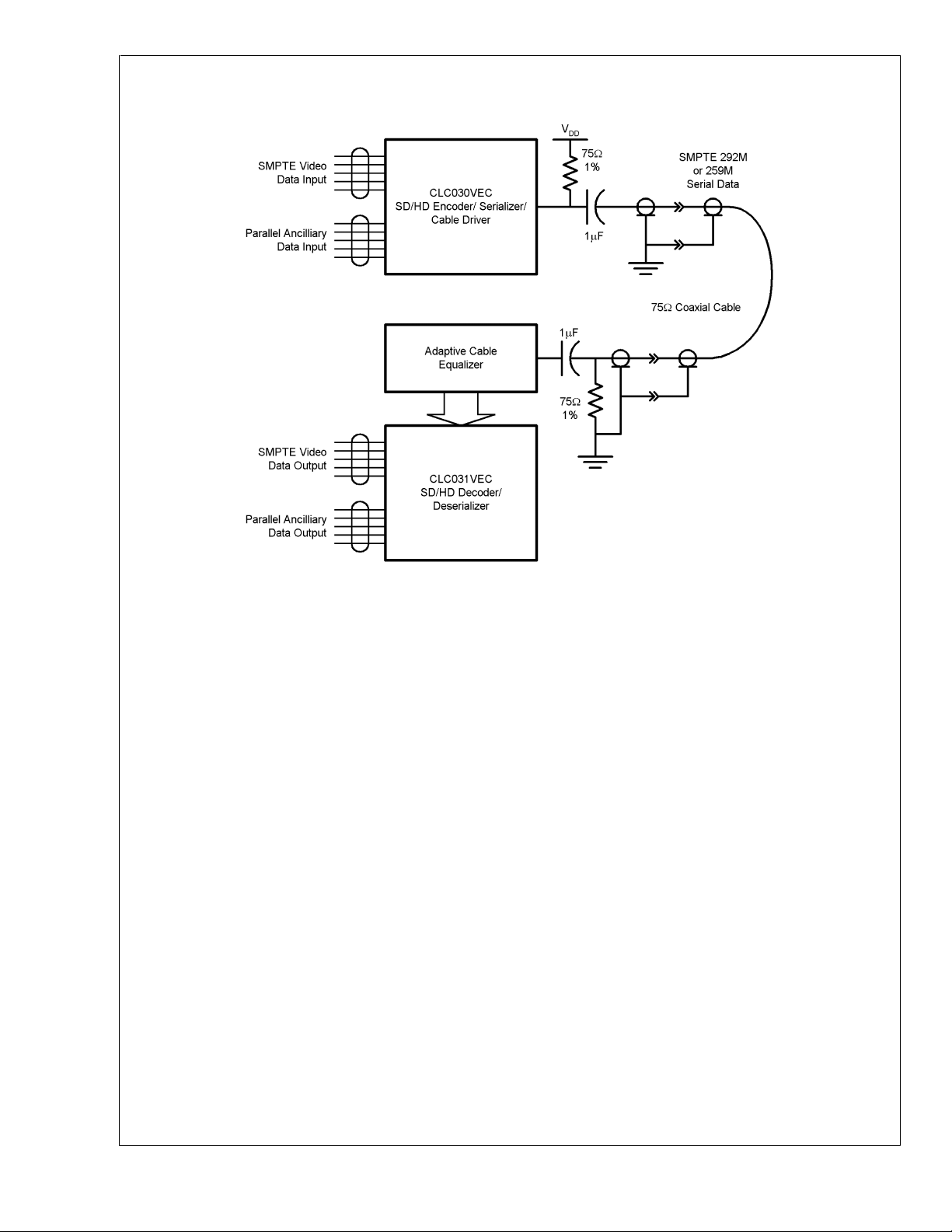

Block Diagram

CLC030

DS200003-2

www.national.com3

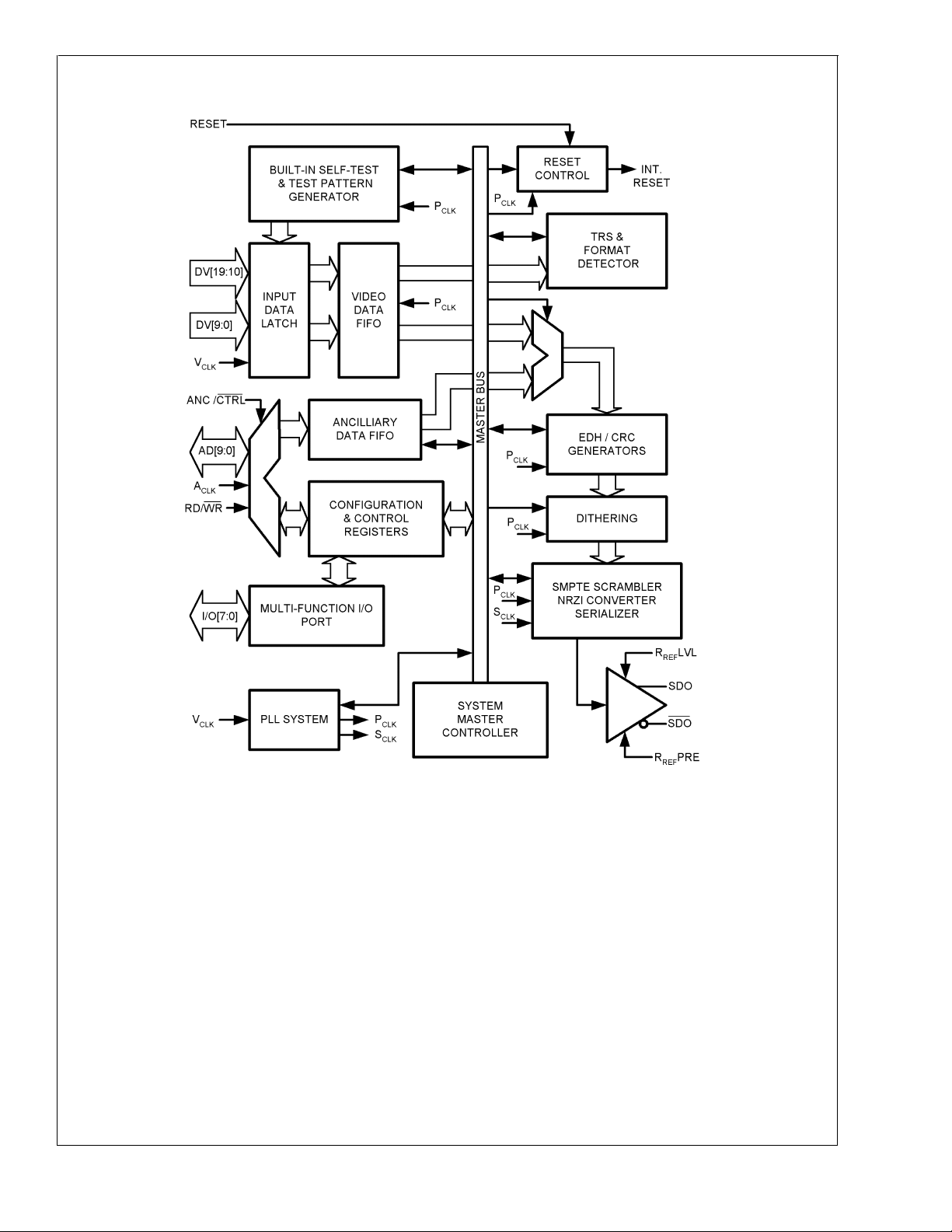

Connection Diagram

CLC030

64-Pin TQFP

Order Number CLC030VEC

See NS Package Number VEC-64A

DS200003-3

www.national.com 4

CLC030

Absolute Maximum Ratings (Note 1)

It is anticipated that this device will not be offered in

a military qualified version. If Military/Aerospace speci-

fied devices are required, please contact the National

Semiconductor Sales Office / Distributors for availability

and specifications.

CMOS Input Current (single input):

Vi=V

Vi=V

CMOS Output Source/Sink Current:

−0.15V: −5 mA

SSIO

+0.15V: +5 mA

DDIO

±

10 mA

SDO Output Sink Current: 40 mA

Package Thermal Resistance

CMOS I/O Supply Voltage

(V

DDIO–VSSIO

): 4.0V

SDO Supply Voltage

(V

DDSD–VSSSD

): 4.0V

Digital Logic Supply Voltage

(V

DDD–VSSD

): 3.0V

PLL Supply Voltage

(V

DDPLL–VSSPLL

): 3.0V

CMOS Input Voltage

(Vi):

CMOS Output Voltage

(Vo):

V

V

SSIO

V

SSIO

V

DDIO

DDIO

−0.15V to

+0.15V

−0.15V to

+0.15V

@

0 LFM Airflow 47˚C/W

θ

JA

@

500 LFM Airflow 27˚C/W

θ

JA

θ

JC

6.5˚C/W

Storage Temp. Range: −65˚C to +150˚C

Junction Temperature: +150˚C

Lead Temperature (Soldering 4 Sec): +260˚C

ESD Rating (HBM): 2 kV

ESD Rating (MM): 250V

Recommended Operating Conditions

Symbol Parameter Conditions Reference Min Typ Max Units

V

V

V

V

V

V

T

t

JIT

DDIO

DDSD

DDD

DDPLL

IL

IH

A

CMOS I/O Supply

V

DDIO−VSSIO

Voltage

SDO Supply Voltage V

Digital Logic Supply

DDSD−VSSSD

V

DDD–VSSD

Voltage

PLL Supply Voltage V

DDPLL–VSSPLL

CMOS Input Voltage,

Low Level

CMOS Input Voltage

High Level

Operating Free Air

Temperature

Video Clock Jitter V

CLK

3.150 3.300 3.450 V

3.150 3.300 3.450 V

2.375 2.500 2.625 V

2.375 2.500 2.625 V

V

SSIO

V

DDIO

0 +70 ˚C

100 ps

V

V

P-P

DC Electrical Characteristics

Over Supply Voltage and Operating Temperature ranges, unless otherwise specified (Notes 2, 3).

Symbol Parameter Conditions Reference Min Typ Max Units

V

IH

V

IL

I

IH

I

IL

V

OH

V

OL

V

SDO

I

DD

(3.3V)

I

DD

(3.3V)

Input Voltage High Level All LVCMOS

Input Voltage Low Level V

Input Current High Level VIH=V

Input Current Low Level VIL=V

CMOS Output Voltage

DDIO

SSIO

IOH= −6.6 mA All LVCMOS

High Level

CMOS Output Voltage

IOL= +6.6 mA

Inputs

Outputs

Low Level

Serial Driver Output

Voltage

Power Supply Current,

3.3V Supply, Total

Test Circuit, Test Loads

Shall Apply

V

= 27 MHz, NTSC

CLK

Colour Bar Pattern, Test

SDO, SDO

V

DDIO,VDDSD

Circuit, Test Loads Shall

Apply

Power Supply Current,

3.3V Supply, Total

V

= 74.25 MHz, NTSC

CLK

Colour Bar Pattern, Test

V

DDIO,VDDSD

Circuit, Test Loads Shall

Apply

2.0 V

SSIO

DDIO

0.8 V

+90 +150 µA

−1 −20 µA

2.4 2.7 V

V

V

SSIO

SSIO

+0.3

DDIO

V

SSIO

+0.5V

720 800 880 mV

48 65 mA

66 90 mA

www.national.com5

V

V

V

P-P

DC Electrical Characteristics (Continued)

Over Supply Voltage and Operating Temperature ranges, unless otherwise specified (Notes 2, 3).

CLC030

Symbol Parameter Conditions Reference Min Typ Max Units

I

DD

(2.5V)

Power Supply Current,

2.5V Supply, Total

V

= 27 MHz, NTSC

CLK

Colour Bar Pattern, Test

Circuit, Test Loads Shall

V

DDD,VDDZ

V

DDPLL

,

66 85 mA

Apply

I

DD

(2.5V)

Power Supply Current,

2.5V Supply, Total

V

= 74.25 MHz, NTSC

CLK

Colour Bar Pattern, Test

Circuit, Test Loads Shall

V

DDD,VDDZ

V

DDPLL

,

85 110 mA

Apply

AC Electrical Characteristics

Over Supply Voltage and Operating Temperature ranges, unless otherwise specified (Note 3).

Symbol Parameter Conditions Reference Min Typ Max Units

f

VCLK

DC

V

f

ACLK

DC

A

t

r,tf

BR

SDO

tr,t

f

t

r,tf

t

j

t

j

t

LOCK

t

LOCK

t

S

t

H

t

S

t

H

Note 1: “Absolute Maximum Ratings” are those parameter values beyond which the life and operation of the device cannot be guaranteed. The stating herein of

these maximums shall not be construed to imply that the device can or should be operated at or beyond these values. The table of “Electrical Characteristics”

specifies acceptable device operating conditions.

Note 2: Current flow into device pins is defined as positive. Current flow out of device pins is defined as negative. All voltages are referenced to V

Note 3: Typical values are stated for V

Note 4: Spec. is guaranteed by design.

Note 5: R

Note 6: R

Note 7: Measured from rising-edge of first DV

Note 8: Average value measured between rising edges computed over at least one video field.

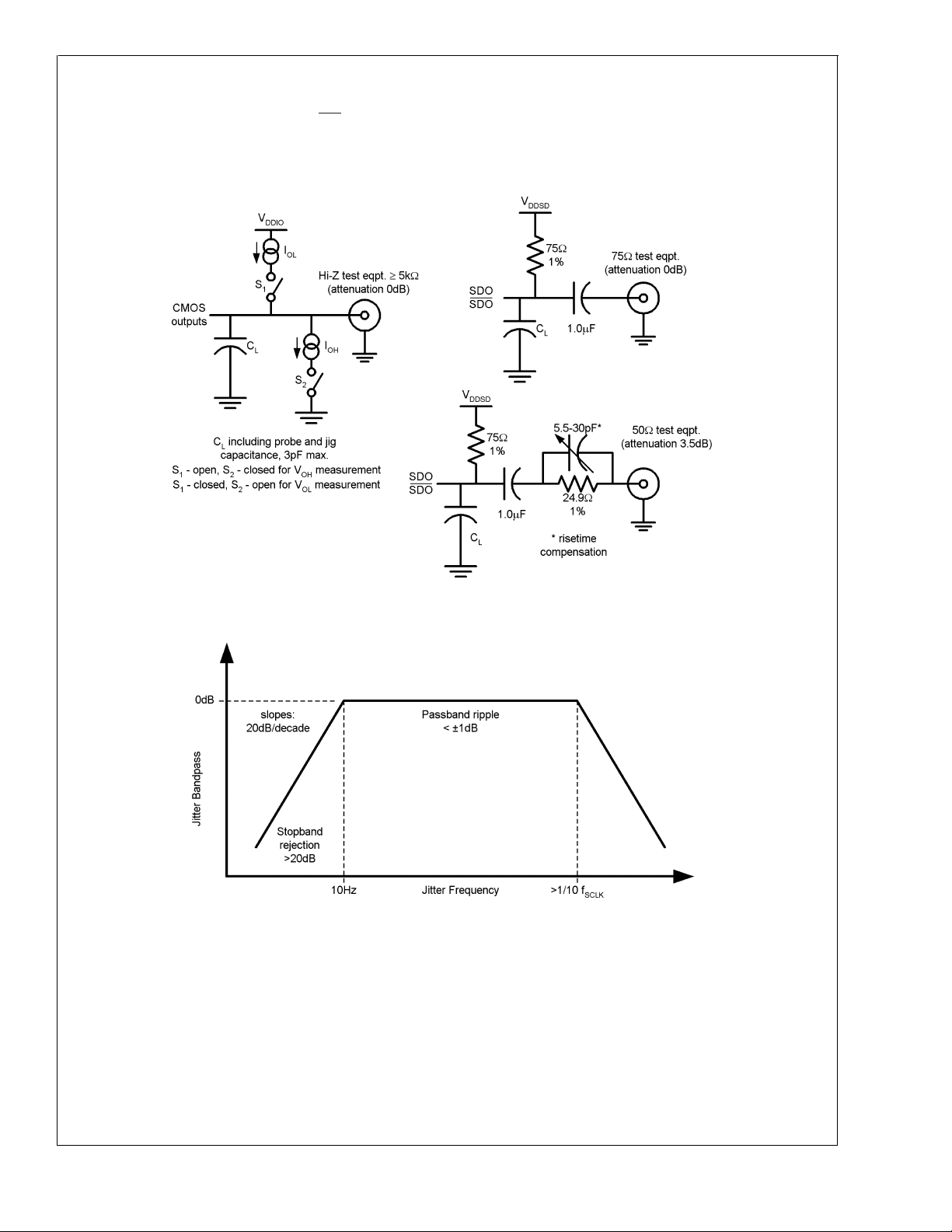

Note 9: Intrinsic timing jitter is measured in accordance with SMPTE RP 184-1996, SMPTE RP 192-1996 and the applicable serial data transmission standard,

SMPTE 259M-1997 or SMPTE 292M (proposed). A colour bar test pattern is used. The value of f

344M or 1,485 MHz for SMPTE 292M serial data rates. See Timing Jitter Bandpass section.

Parallel Video Clock

Frequency

Video Clock Duty

Cycle

Ancilliary Clock

Frequency

Ancilliary Clock Duty

Cycle

Input Clock and Data

Rise Time, Fall Time

10%–90% V

V

CLK

V

CLK

A

CLK

A

CLK

CLK,ACLK

,AD

DV

N

27 74.25 MHz

45 50 55 %

V

CLK

45 50 55 %

,

N

1.0 1.5 3.0 ns

Serial Data Rate (Notes 5, 6) SDO, SDO 270 1,485 M

Rise Time, Fall Time 20%–80%, (Note 6) SDO, SDO 270 ps

Rise Time, Fall Time 20%–80%, (Note 5) SDO, SDO 500 ps

Output Overshoot (Note 4) SDO, SDO

Serial Output Jitter,

270 M

, (Notes 5, 9, 10) SDO, SDO

bps

Intrinsic

Serial Output Jitter,

1,485 M

, (Notes 6, 9, 10) SDO, SDO

bps

Intrinsic

5%

200 ps

120 ps

Lock Time (Notes 5, 7) (SD Rates) 15 ms

Lock Time (Notes 6, 7) (HD Rates) 15 ms

Setup Time, Video

Data

Hold Time, Video

Data

Setup Time, Anc.

Data Port

Hold Time, Anc. Data

Port

=75Ω, AC-coupled@270 M

L

=75Ω, AC-coupled@1,485 M

L

Timing Diagram, (Note 4) DVNto V

Timing Diagram, (Note 4) V

Timing Diagram, (Note 4) ADNto A

Timing Diagram, (Note 4) A

DDIO=VDDSD

LVL = R

bps,RREF

bps,RREF

cycle until Lock Detect output goes high (true). Lock time includes format detection time plus PLL lock time.

CLK

= +3.3V, V

LVL = R

DDD=VDDPLL

PRE = 4.75 kΩ 1%, See Test Loads and Test Circuit.

REF

PRE = 4.75 kΩ 1%, See Test Loads and Test Circuit.

REF

= +2.5V and TA= +25˚C.

CLK

to DV

CLK

CLK

SCLK

N

CLK

to AD

N

is 270 MHz or 360 MHz for SMPTE 259M, 540MHz for SMPTE

1.5 2.0 ns

1.5 2.0 ns

1.5 2.0 ns

1.5 2.0 ns

SS

MHz

bps

P-P

P-P

=0V.

www.national.com 6

AC Electrical Characteristics (Continued)

Note 10: Intrinsic jitter is defined in accordance with SMPTE RP 184-1996 as: jitter at an equipment output in the absence of input jitter. As applied to this device,

the input port is V

and the output port is SDO or SDO.

CLK

Test Loads

CLC030

Timing Jitter Bandpass

DS200003-4

DS200003-6

www.national.com7

Test Circuit

CLC030

www.national.com 8

DS200003-7

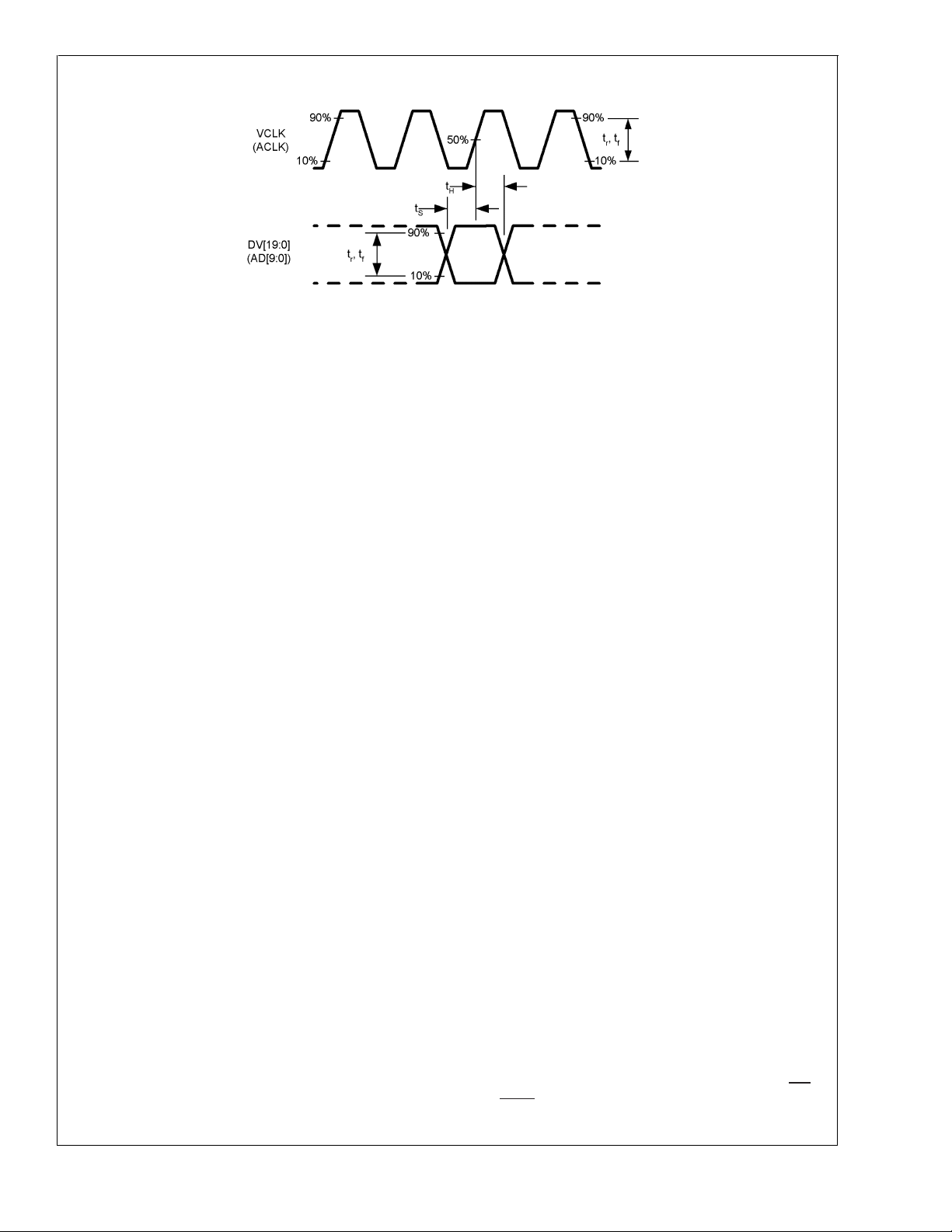

Timing Diagram

Device Operation

The CLC030 SDTV/HDTV Serializer is used in digital video

signal origination equipment: cameras, video tape recorders,

telecines and video test and other equipment. It converts

parallel SDTV or HDTV component digital video signals into

serial format. Logic levels within this equipment are normally

produced by LVCMOS logic devices. The encoder produces

serial digital video (SDV) signals conforming to SMPTE

259M, SMPTE 344M (proposed) or SMPTE 292M. The

CLC030 operates at parallel data rates of 27.0 MHz, 36.0

MHz, 54.0 MHz, 74.176MHz and 74.25 MHz. Corresponding

serial data rates are 270 Mbps, 360 Mbps, 540 Mbps,

1.4835Gbps and 1.485 Gbps. Segmented frame formats are

not supported.

VIDEO DATA PATH

The input data register accepts 10-bit standard definition or

20-bit high definition parallel data and associated clock signals having LVCMOS-compatible signal levels. All parallel

video data inputs, DV[19:0], have internal pull-down devices. VCLK does not have an internal pull-down device.

Parallel video data may conform to any of several SMPTE

standards: 125M, 267M, 260M, 274M, 295M or 296M. Segmented frame formats are not supported. For HDTV data,

the upper 10 bits of the DV input are luminance (luma)

information and the lower 10 bits are colour difference

(chrominance or chroma) information. For SDTV data, the

lower order 10 bits contain both luma and chroma information. Output from this register feeds the video FIFO, video

format detection circuit, TRS character detector, SMPTE

scrambler, EDH/CRC generators, serializer/NRZI converter

and the device control system.

Data from the input data register passes into a 4-register

deep video FIFO prior to encoding and other processing.

The depth of this FIFO is set by a word written into the

VIDEO FIFO Depth[2:0] bits in the ANC 0 control register.

The video format detector automatically determines the

raster characteristics (video data format) of the parallel input

data and configures the CLC030 to properly handle the data.

This assures that the data will be properly formatted, that the

correct data rate is selected and that ancilliary data, line

numbers (HD) and CRC/EDH data are correctly inserted.

Indication of the standard being processed is stored in the

FORMAT[4:0] bits in the FORMAT 1 control data register.

This format data can be programmed for output on the

multi-function I/O port.

The CLC030 may be configured to operate at a single video

format by writing the appropriate FORMAT SET[4:0] control

data into the FORMAT 0 control register. Also, the CLC030

may be configured to handle only the standard-definition

DS200003-8

data formats by setting the SD ONLY bit or only the highdefinition data formats by setting the HD ONLY bit in the

FORMAT 0 control register. When both of these bits are

reset the part automatically detects the data rate and range.

The TRS character detector processes the timing reference signals which control raster framing. The TRS detector

supplies control signals to the system controller to identify

the presence of the valid video data. The system controller

supplies necessary control signals to the EDH/CRC control

block. TRS character LSB-clipping as prescribed in ITU-R

BT.601 is used. LSB-clipping causes all TRS characters with

a value between 000h and 003h to be forced to 000h and all

TRS characters with a value between 3FCh and 3FFh to be

forced to 3FFh. Clipping is done prior to scrambling and

EDH/CRC character generation.

The CLC030 incorporates circuitry that implements the proposed SMPTE recommended practice and method for LSB

dithering. Control of this circuitry is via the Dither Enable bit

in the VIDEO INFO 0 control register. Dithering can be

selectively enabled during the vertical blanking interval by

use of the V Dither Enable bit in the VIDEO INFO 0 control

register. The initial condition of Dither Enable and V Dither

Enable is OFF.

The SMPTE scrambler accepts 10-bit standard definition or

20-bit high definition parallel video data and encodes it using

the polynomial X

standard in SMPTE 259M, SMPTE 344M (proposed) or

SMPTE 292M. The data is then serialized and sent to the

NRZ-to-NRZI converter before being output. The transmission bit order is LSB-first.

The NRZ-to-NRZI converter accepts NRZ serial data from

the SMPTE scrambler. The data is converted to NRZI format

using the polynomial (X + 1). The converter’s output goes to

the output cable driver amplifier.

ANCILLIARY/CONTROL DATA PATH

The Ancilliary and Control Data Port serves two functions

in the CLC030. It is used to selectively load ancilliary data

into the Ancilliary Data FIFO for insertion into the video data

stream. The utilization and flow of ancilliary data within the

device is managed by a system of control bits, masks and

IDs in the control data registers. This port also provides

read/write access to contents of the configuration and control registers. Configuration of the multi-function I/O Port is

also controlled by information stored in the control data

registers. Ancilliary and control data are input via the 10-bit

Ancilliary/Control Data Port, AD[9:0]. The signals RD/WR,

ANC/CTRL and ACLK control data flow through the port.

The operation and frequency of ACLK is completely inde-

9+X4

+ 1 as specified in the respective

CLC030

www.national.com9

Loading...

Loading...