Page 1

DATA SHEET

Thermal Cutoff SEFUSE

SM/G SERIES

FUSIBLE ALLOY THERMAL SENSITIVE TYPE,

0.5 AMPERES (250 Va.c.) and 3 and 5 AMPERES (50 Vd.c.) Rated Current

The NEC's SEFUSE (SM/G series) is a small, solid and reliable thermal cutoff that can be used under 0.5 A / 250

Vac. 3 and 5 ampere / 50 Vdc. electrical rating type, added to the product line-up lately, is also available. It

protects home appliances and industrial equipment from fire and accident by opening of electrical circuit if it

senses an abnormal temperature rise.

FEATURES

™ Approved by UL (USA), CSA (Canada), VDE (Germany), BEAB (UK) and MITI (Japan)

™ Very small

™ Conpact, durable and veliable by hermetic seal structure.

™ Excellent sensitive to abnormal temperature rise and high accuracy in operation.

™ Stable characteristics in a long-term.

™ Capable of opening at a cutoff current of AC 0.5 amperes and DC 3 and 5 amperes.

™ One shot operation.

TM

APPLICATIONS

Transformers

Motors

Battery packs

Electric home appliances

Electric Industrial equipments,

Office automation equipments, etc.

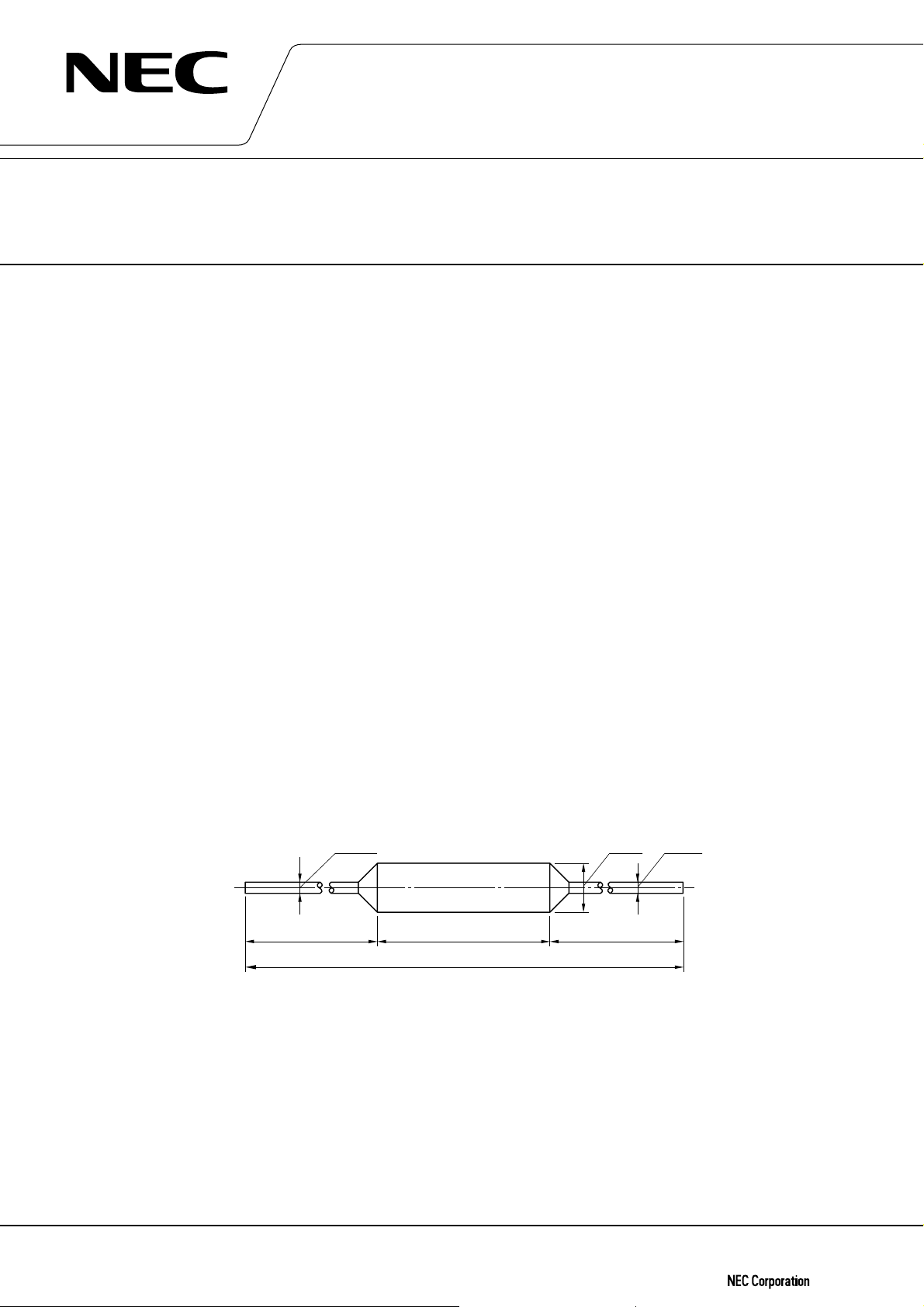

OUTLINE DIMENSIONS (Unit : mm)

φ

40(70) 40(70)5.0

0.53

85(145)

Note: Dimensions in parentheses are for long lead devices.

φ

1.6

φ

0.53

The information in this document is subject to change without notice.

Document No. EM0255EJ5V0DS00 (5th edition)

Date Published March 1998 M

Printed in Japan

©

1992 (1997

)

Page 2

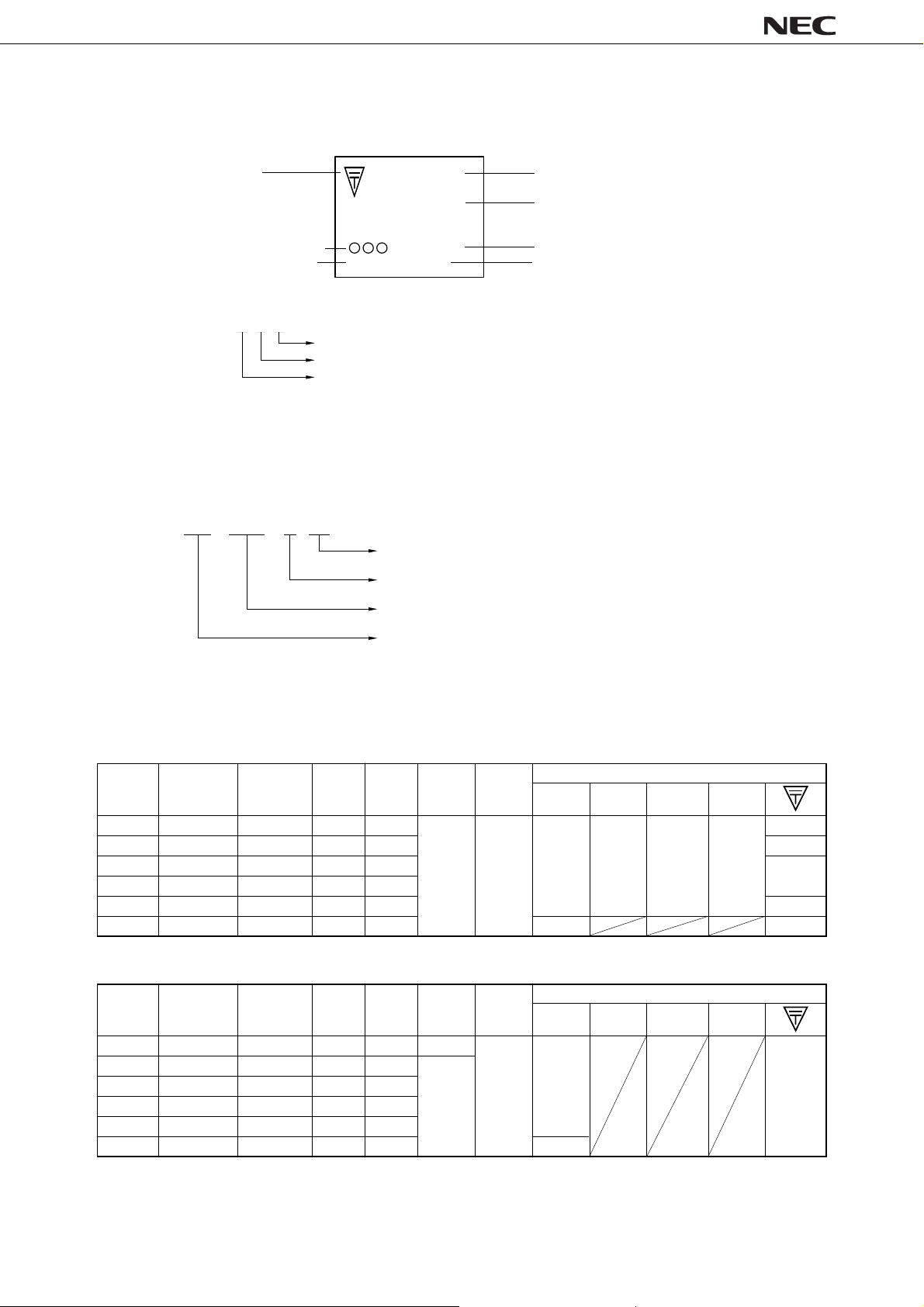

SM/G SERIES

MARKING

SM/G SERIES

MITI

approved mark

Production control No.

Rated current

∗ Designation of Production Control No.

8 1 0

∗∗ The marking of electrical ratinga is only the AC ratings and the DC ratings is not indicated.

TYPE NAME DESIGNATION

SM 110 G 0

SEFUSE

110 GO

∗

∗∗ ∗∗

Sub-Lot No.

Production month (1 to 9 as Jan. to Sep. and X, Y, Z as Oct., Nov. and Dec.)

Production year (last figure of A. D.)

Tf 115˚C

0.5 A 250V

(example)

~

Brand name

Part number

(First two letters “SM” are omitted)

Rated functioning temperature

Rated voltage

Lead Length (0 : standard lead type, 1 : long lead type)

Series Name (SM/G series)

Operating Temperature

Type Name (SM type)

STANDARD RATINGS

(AC Electrical Ratings)

1)

Part

Number

SM095G0

SM110G0

SM126G0

SM130G0

SM145G0

SM134G0

Rated

Functioning

T emperature

100 ˚C

115 ˚C

131 ˚C

135 ˚C

150 ˚C

139 ˚C

Operating

Temperature

+5

95 ˚C

–0

110±2 ˚C

126±2 ˚C

130±2 ˚C

145±2 ˚C

+3

134 ˚C

–2

TH

Th

TC

65 ˚C

80 ˚C

96 ˚C

100 ˚C

115 ˚C

104 ˚C

TM

Tm

115 ˚C

125 ˚C

140 ˚C

145 ˚C

155 ˚C

200 ˚C

Rated

Current

0.5 Aac

(res.)

Rated

Voltage

250 Vac

(res.)

UL CSA BEAB

2)

(DC Electrical Ratings)

1)

Part

Number

SM095G0

SM110G0

SM126G0

SM130G0

SM145G0

SM134G0

Notes 1) : The type names are for standard lead. When long lead type is required, change the last number “0” to “1”.

2

Rated

Functioning

T emperature

100 ˚C

115 ˚C

131 ˚C

135 ˚C

150 ˚C

139 ˚C

2) : Under application

3) : There is no regulation about d.c. electrical ratings in the Electrical Appliance and Material Control Low of Japan.

4) : The VDE recognized file number had been changed in February 1998. The number in parentheses are previous

file number.

Operating

Temperature

+5

95 ˚C

–0

110±2 ˚C

126±2 ˚C

130±2 ˚C

145±2 ˚C

+3

134 ˚C

–2

TH

Th

TC

65 ˚C

80 ˚C

96 ˚C

100 ˚C

115 ˚C

104 ˚C

TM

Tm

115 ˚C

125 ˚C

140 ˚C

145 ˚C

155 ˚C

200 ˚C

Rated

Current

3 Adc

5 Adc 50 Vdc

Rated

Voltage

UL CSA BEABVDE

E71747

2)

Safety Standard

VDE

6778.2

–1171

–0003

4)

6778.2

–4510

( )

–1005

Safety Standard

33–466

33–472

C0743LR52330E71747

33–467

33–468

33–467

3)

Page 3

SM/G SERIES

Definition of Terms

●

Rated Functioning Temperature

Rated functioning temperature is the operating temperature of the thermal cutoff, measured using the method

specified in the safety standard. In Electrical Appliance and Material Control Law of Japan, case operation

should be within the specified operating temperature range of ± 7 ˚C. In standards that comply with the IEC

standard (such as UL, CSA, VDE, BEAB), it is called the rated functioning temperature, and should operate

within the prescribed temperature range of +0/–10 ˚C.

It is represented by the symbol T

standards.

In SEFUSE, a temperature that complies with both standards is set as the rated functioning temperature, and

is indicated on the body of the thermal cutoff.

●

Operating Temperature

Operating temperature is the operating temperature range when the thermal cutoff is made to operate inside

a constant temperature oven whose temperature is raised at the rate of 1 ˚C/min. while a detection current of

100 mA or lower is applied.

The operating temperature is a standard set by NEC and is not specified by a safety standard.

F in the UL standard, and by the symbol Tf in the CSA, VDE and BEAB

●

TH, Th. Tc (Holding Temperature)

Holding temperature is the maximum temperature at which, when applying a rated current to the thermal

cutoff, the state of conductivity is not changed during 168 hours.

It is represented by the symbol TH in the UL standard, Th in the CSA standard, and Tc in the VDE and BEAB

standards.

●

TM, Tm (Maximum Temperature Limit)

Maximum temperature limit is the maximum temperature for which conductivity does not occur again after

thermal cutoffs operation.

It is represented by the symbol T

●

Rated Current

M in the UL standard and by Tm in the CSA, VDE and BEAB standards.

Maximum alternating current that can pass through the thermal cutoff and that the thermal cutoffs can cut off

the circuit in safety and reliability.

●

Rated Voltage

Maximum circuit voltage that the thermal cutoffs can cut off the circuit in safety and reliability.

3

Page 4

SM/G SERIES

,

,,

,

,,,

,

,,

,

,,

,,,,

,

Performance Data

SM/G Series

SM095G0

SM110G0

SM126G0

10

5

Temperature Rise (˚C)

SM130G0

SM134G0

Temperature Rise Response Time

30

20

10

SM095G0

SM110G0

SM126G0

SM130G0

SM134G0

SM145G0

0

146

SM145G0

145

144

135

134

133

131

SM130G0

130

129

127

SM126G0

126

125

112

SM110G0

111

110

SM095G0

Part

Number

4

99

98

97

Operating

Temperature

(˚C)

Pass-through Current (A)

6

10

5

10

4

10

6

10

5

10

4

10

6

10

5

10

4

10

6

10

5

10

4

10

6

10

5

10

4

10

6

10

5

10

4

10

Insulation

Resistance after

Operation

(MΩ)

3.0

2.0

1.0

3.0

2.0

1.0

3.0

2.0

1.0

3.0

2.0

1.0

3.0

2.0

1.0

3.0

2.0

1.0

Withstand Voltage

after Operation

(kV)

SM145G0

5.0

4.0

3.0

6.0

5.0

4.0

6.0

5.0

4.0

6.0

5.0

4.0

6.0

5.0

4.0

13.0

11.0

9.0

Internal

Resistance

(mΩ/25 mm)

Time for opening after immersion

into oil (seconds)

10 20 300

54321

Temperature Difference (˚C)

(oil temp. minus operating temp.)

High Temperature Storage TestInitial Characteristics

SM145G0

SM134G0SM134G0

SM130G0

SM126G0

SM110G0

SM095G0

Part

Number

+

+

+

+

+

+

Change of

Operating

Temperature

(˚C)

5

0

–

5

5

0

–

5

5

0

–

5

5

0

–

5

5

0

–

5

5

0

–

5

0 10 100 1,000 10,000

Time (Hours)

@125˚C

@115˚C

@110˚C

@106˚C

@90˚C

@75˚C

Page 5

SM/G SERIES

Cautions

This section describes cautions designed to protect the performance of the thermal cutoff, Be sure to read and

fully understand these cautions.

To obtain full performance from the thermal cutoff, it is necessary for the customer to appropriately store

the thermal cutoff, design appropriate circuits for the application, and perform evaluations, mounting and

testing as necessary. Problems arising from the inappropriate execution of the above are the responsibility

of the customer, and NEC declines any and all responsibility.

Design Cautions

●

Do not use this device for any purpose other than as a thermal cutoff.

The thermal cutoff is designed to detect abnormal rises in temperature and break circuits if needed. It is not

a current fuse that cuts excess current. If used as a current fuse, the SEFUSE may malfunction.

●

Do not use this device in aerospace equipment, aeronautical equipment, nuclear reactor control systems, Iife

support equipment or systems, transportation machinery engine control or safety-related equipment.

This device is designed for use in household electric appliance, office automation equipment, audio and video

equipment, computer and communications equipment, test and measurement equipment, personal electronic

equipment and transportation equipment (excluding engine control).

●

The customer should select the proper thermal cutoff device, mounting location, and mounting method as

appropriate for each application.

Verify whether the chosen selections are appropriate by repeatedly testing the final design for thermal cutoff

under normal conditions as well as under predicted maximum abnormal conditions.

●

Make designs so that the temperature of the body of the thermal cutoff does not exceed the temperatures

shown in Table 1.

If, these temperatures are exceeded on a regular basis, the thermal cutoff may start operating only at temperatures lower than the normal operating temperature. Malfunctions may also occur. Even if the thermal

cutoff's operating temperature is exceeded, it may malfunction.

Table 1. Recommended maximum body temperature on a reqular basis

Part Number

SM095G

SM110G

SM126G

SM130G

SM134G

SM145G

to 1 A to 2 A to 3 A to 4 A to 5 A

75˚C 70˚C 65˚C — —

90˚C 85˚C 85˚C 80˚C 75˚C

106˚C 106˚C 100˚C 95˚C 90˚C

110˚C 110˚C 105˚C 100˚C 95˚C

114˚C 114˚C 110˚C 105˚C 100˚C

125˚C 125˚C 120˚C 120˚C 115˚C

Pass-through Current

∗1) : The temperature does not means ambient temperature but surface temperature on

thermal cutoff.

∗2) : When a large current flows through a thermal cutoff, temperature difference occurs

between the case and the lead. Therefore, it is recommended to measure some points

on the thermal cutoff, and make design so that the highest temperature does not exceed

the temperature shown in Table 1.

5

Page 6

SM/G SERIES

,,

,

,,,

,,

,

,

,,

,

,

●

The body temperature of the thermal cutoff becomes higher as current passes through and might rise higher

than the ambient operating temperature (see test data). The temperature may rise even higher depending on

the mounting method and other conditions. Therefore, after mounting the thermal cutoff under the same

conditions you would use for the actual application, work the final product and measure the body temperature

of the thermal cutoff.

●

Use the thermal cutoff with a voltage and current level lower than the rated level.

If the thermal cutoff is used with a voltage or current level higher than the rated level, the body of the thermal

cutoff may be destroyed.

●

Do not use the thermal cutoff in water, organic solvents or other liquids, or envir onments containing sulfurous

acid gas, nitrous acid gas, or high humidity. Doing so will cause deterioration of the sealing resin, the thermal

cutoff may operate at lower than operating temperatures, or any other malfunctions may occur. Also, the

thermal cutoff may not operate even if its operating temperature is exceeded.

Lead wire process

●

When bending the lead wire, in order to protect the resin seal from excessive pressure, secure the lead wire

cIose to the case and bend the part beyond the secured section,

3 mm or more

SecuredSecured

The lead wire should be bent at a distance 3 mm or more from the body of the fuse, and should not be twisted.

●

The tensile strength applied to the lead wire should be 1kg or less for the SM type thermal cutoff.

●

The strength applied to the body of the thermal cutoff should be 5 kg or less for the SM type thermal cutoff.

5 kgf max.

0.8 steel wire

φ

Mounting

●

6

SEFUSE can be mounted by soldering, caulking, or welding.

If soldering, note that the thermal cutoff may not function because of excessive solder temperature.

To prevent such malfunctions, for example, holding the lead near the case by a tool is effective for allowing

the heat to escape, and the soldering should be done in short interval.

Another effective method is to use a lower solder temperature and to solder at a location that is distant from

the case.

Page 7

SM/G SERIES

●

If caulking or welding, be careful to keep the resistance value of the connecting section low.

If the connecting section has a high resistance value, the passing current may generate an abnormally high

temperature that will cause the thermal cutoff to operate (break the circuit).

●

It is recommended that the connecting position at the lead of resign-sealed side should be 5 mm or more from

the body of the thermal cutoff.

5 mm or more 5 mm or more

●

After mounting the thermal cutoff, be careful not to apply force that may pull, push or twist the lead wires.

Position of installation

Recommendation

●

Be careful when mounting the thermal cutoff because external force, heat, or a harmful atmosphere (containing excessive humidity or sulfurous acid gas) may damage the characteristics of the thermal cutoff. If applicable, it is recommended to warn general consumers who are not aware of the usage cautions for the thermal

cutoff not to mount, remove or replace the thermal cutoff through a note to this effect in the user's manual and

other related material.

If you desire any clarifications or explanations regarding these cautions, please call an NEC sales

representative.

The values contained in this document were obtained under certain testing conditions at NEC. They are not

guaranteed and are for reference only.

7

Page 8

SM/G SERIES

No part of this document may be copied or reproduced in any form or by any means without the prior

written consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which

may appear in this document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property rights of third parties by or arising from use of a device described herein or any other

liability arising from use of such device. No license, either express, implied or otherwise, is granted

under any patents, copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its electronic

components, the possibility of defects cannot be eliminated entirely. To minimize risks of damage or

injury to persons or property arising from a defect in an NEC electronic component, customers must

incorporate sufficient safety measures in its design, such as redundancy, fire-containment, and antifailure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based

on a customer designated "quality assurance program" for a specific application. The recommended

applications of a device depend on its quality grade, as indicated below. Customers must check the

quality grade of each device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment, au-

dio and visual equipment, home electronic appliances, machine tools, personal electronic equipment and industrial robots

Special: T ransportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

Loading...

Loading...