NOVUS RHT-Air User Manual

RHT

-Air

WIRELESS EQUIPMENT F

1

246

Dew point: -40.0 °C and 100.0 °C

measurement errors can be discarded

through the soft ware’ s OFFSET parameter.

levels)

80 % RH).

A minimum of 15 seconds. No more than 30

minutes (1800 s)

B) for

ve RP SMA (Plug) connector for

Direct Sequence

Offset Quadrature

128 (Advanced Encryption

Standard).

Storage

Polycarbonate

The product is suitable for applications that

IP40.

60 x 70 x 35 mm + antenna 105 mm + sensor

37.2 mm

configuration environme nt

It configures, reads and displays data on the

screen.

OR TEMPERATURE AND HUMIDITY – INSTRUCTIONS MANUAL V1.0x A

1 INTRODUCTION

RHT-Air comes with a high precision and stability sensor to measure both

temperature and relative humidity. Because it operates with a

microprocessor, it can be fully configured through it s USB and IEEE 8 02.15.4

interfaces, using Modbus RTU commands. The software DigiConfig enables

for all the eq uipment’s res ources to be configured.

RHT-Air can be configured to display the temperature and Relative Humidity

measured or even, the temp erature and the Dew Point

RHT-Air should be connected (via wireless) to an AirGate-Modbus so that

its registers can be read whenever it is in operation.

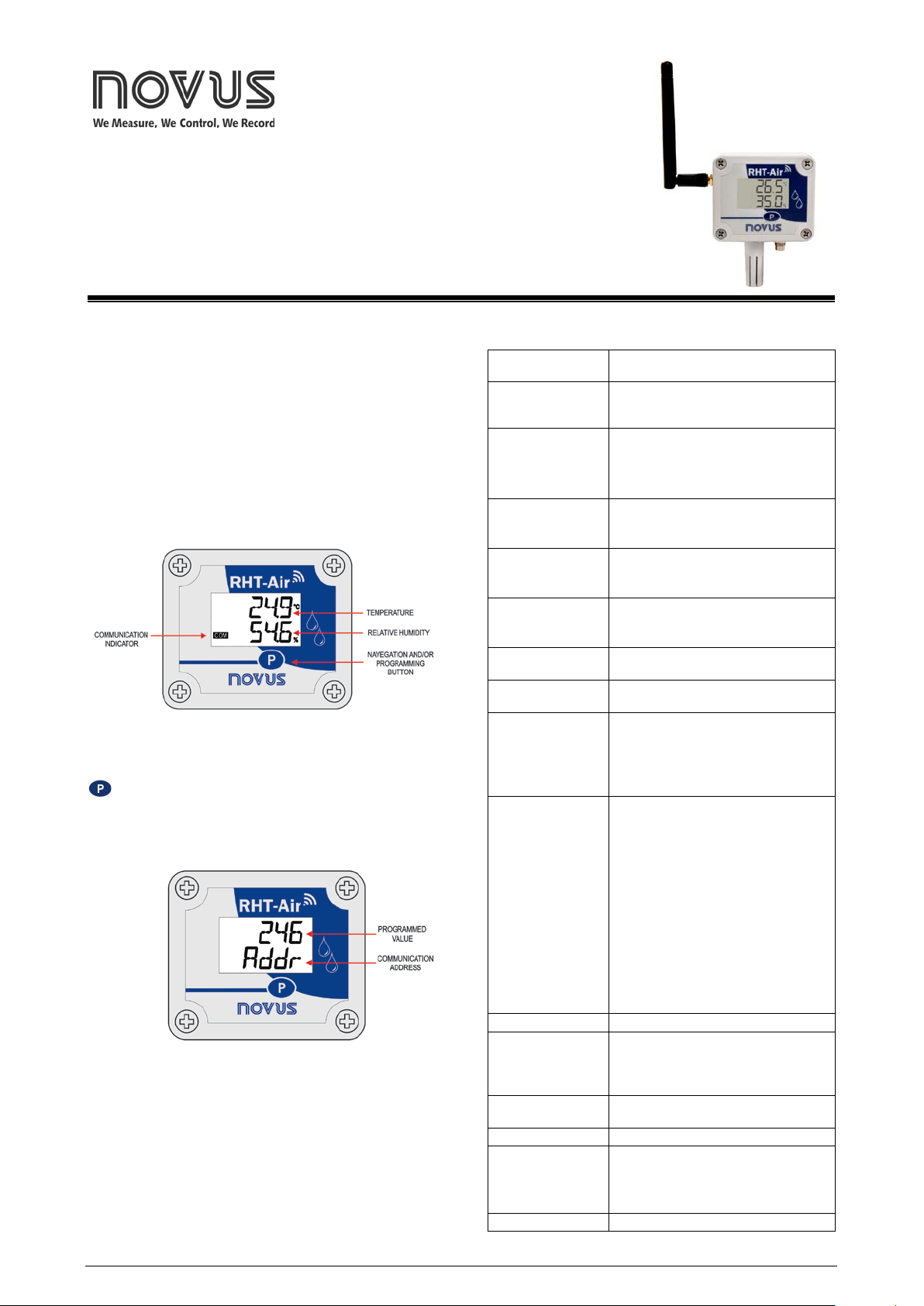

1.1 IDENTIFICATION

The following elements appear in the front part of the equipment:

Fig. 1 – RHT-Air main screen

Communication Indicator (COM): It signals that the device is receiving data

from the Modb us network.

Button (Programming): This button is used to configure the Modbus

address, the Update Interv al and screen changes.

Temperature: Room temperature measured by the equipment.

Relative Humidity: Relative Humidity measur e me nt.

2 SPECIFICATIONS

Equipment’s operat ing

temperature

Electromagnetic

compatibility

Sensor’s me asurement

range

Precision of

measurements

Resolution of

measurements:

Response time

(Sensor)

Interval bet ween updates

Power supply

Connections

Wireless

RTH-Air = from -10 °C to 70 °C

EMC: EN61326-1:2006 CISPR11/EN55011,

EN61000-4-2, EN61000-4-3, EN61000-4-4,

EN61000-4-6, EN61000-4-8

Temperature: -40.0 °C to 100.0 °C.

Relative Humidity (RH): 0.0 to 100.0 % RH.

(No Condensat ion)

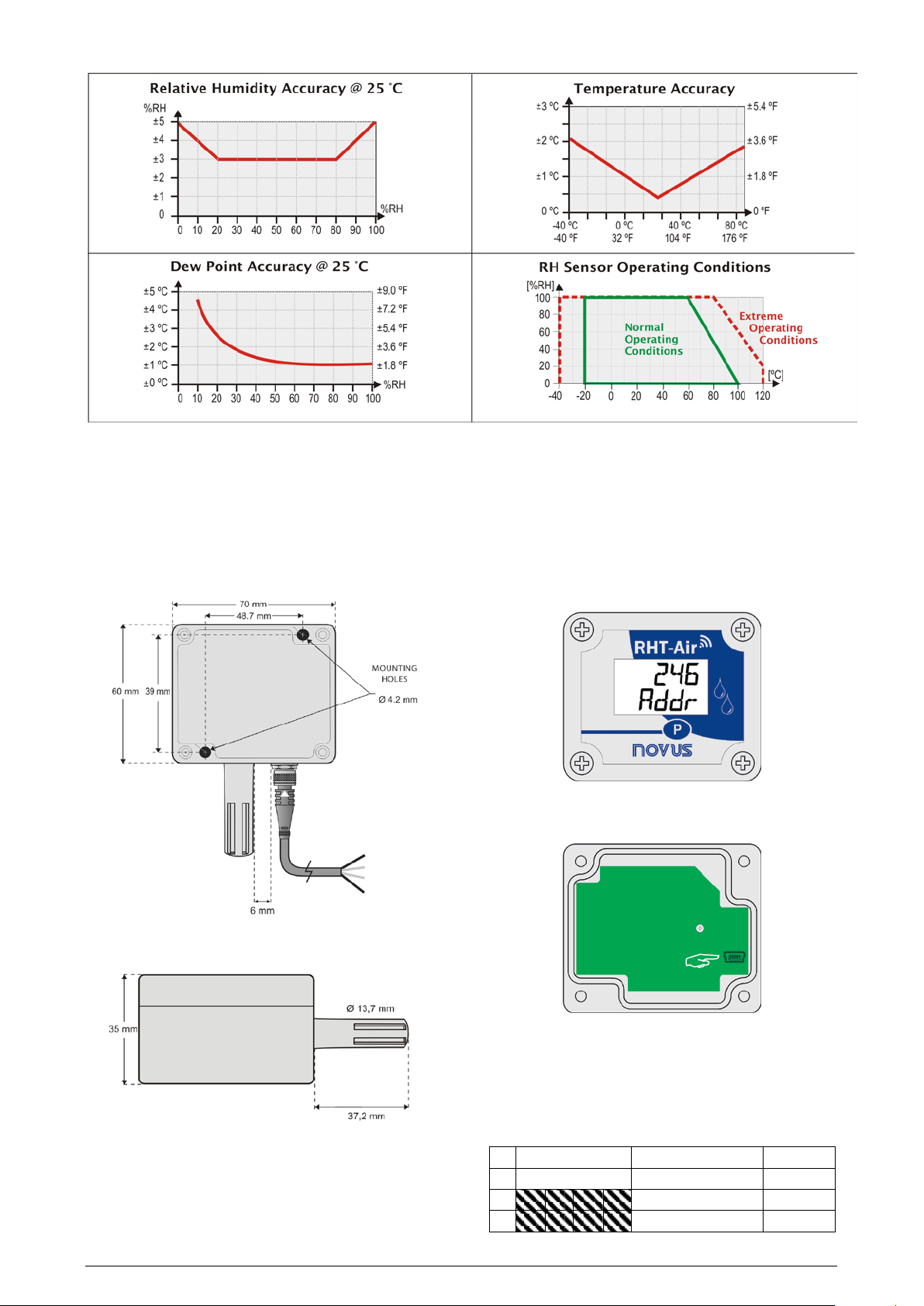

See Fig. 3.

Note:

Temperature: 0.1 °C. 14 bits (16383 levels)

Relative Humidity (RH): 0.1 %. 12 bits (4095

Temperature: Up to 30 s in slow moving air.

Humidity: Up to 8 s in softly moving air (20 to

12 Vdc to 30 Vdc, consumption < 100 mA or

Lithium batt ery of 3.6 Vcc (1/2 AA), internal.

• Internal USB Device (Miniconfiguration and firmware update.

• Groo

antenna.

•

Power supply connector.

• Maximum transmission power of 25,11

mW (14 dBm).

• Maximum Range: 500 meters line-of-sight

in open field.

• Receptor sensibility - 92 dBm.

• Operation band ISM 2.4 GHz.

• DSSS Technology -

Spread Spect rum.

• OQPSK Modulation -

Phase Shift Keying.

• 15 operation channels .

• AES-CBC-

Fig. 2 – RHT-Air’s second screen

Communication Address: Programmed value to identify the Modbus

network equipment. Programmable betw een

NOVUS AUTOMATION 1/8

require a level of protection of up to IP65.

Electronic module box: IP65; Sensor capsule:

Configurati on Software Windows®.

Menus in Portuguese, English or Spanish.

and

Level of protecti on

.

Dimensions

Weight 171 grams / 40 grams (cable)

DigiConfig software

Certifications CE, ANATEL (0172-13-7089)

2.1 PRECISION OF MEASUREMENTS AND OPERATIONAL LIMITS OF SENSORS:

Fig. 3 - Precision of the humidity and temperature measurement

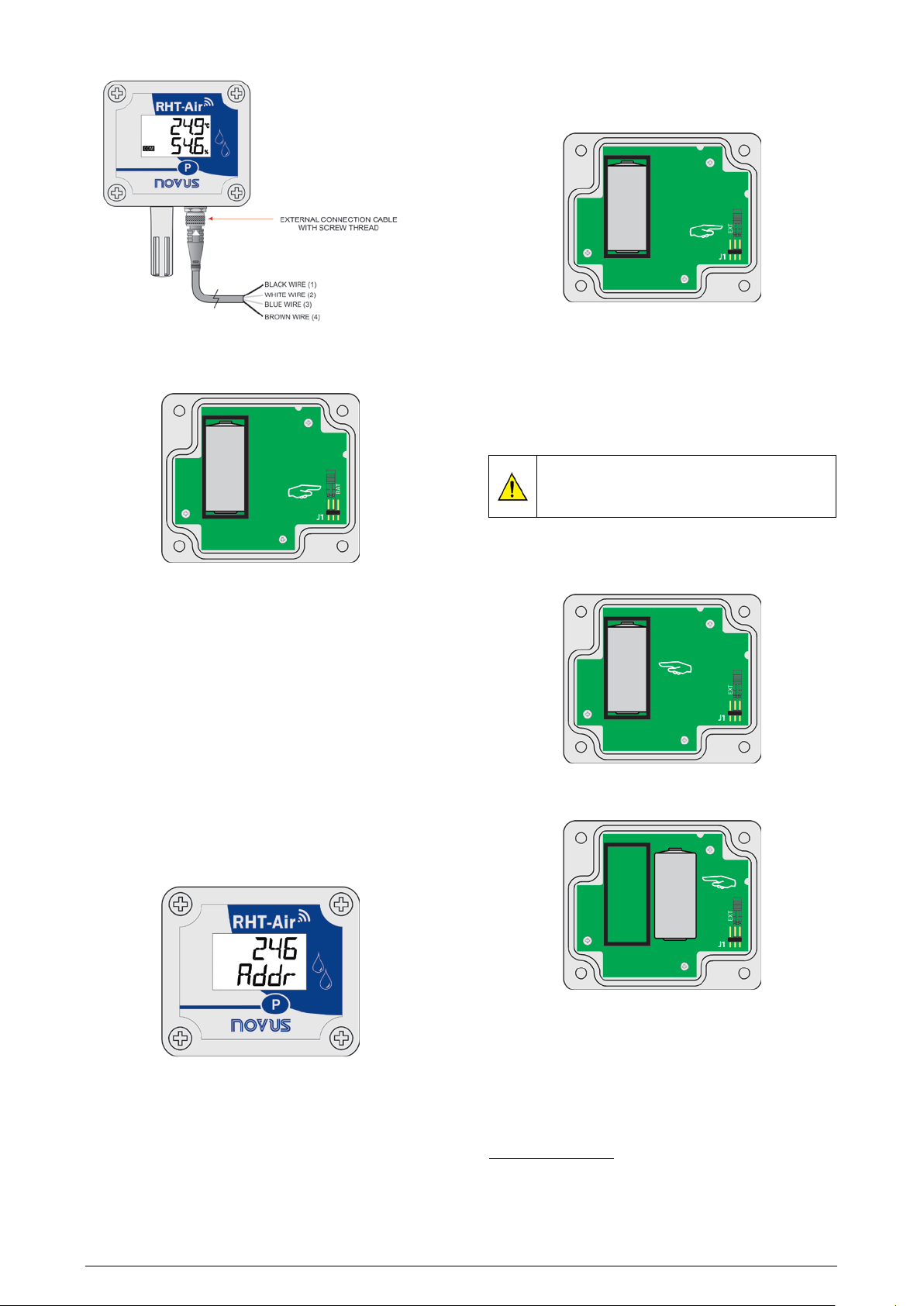

3 MECHANICAL INSTALATION

RHT-Air was designed to be attached to walls. By removing the equipment’s

cover, users will have access to two molding holes of the base, as shown in

Fig. 4. The equipment should be attached with the sensor capsule

facing downwards in order to ensure precision and the specified level

or protection.

Fig. 4 - RHT-Air mounting holes and measures

4 CONFIGURATION

4.1 CONFIGURATION VIA USB INTERFACE

Initially, the first conf iguration must be done through USB interface.

• Remove the four set screws of the front panel of the equipment RHT-Air,

taking the necessary precaution not to apply force on the internal connector

of the electronic circ ui t.

• In order to configure it through a USB interface, connect the cable as

shown below. The external power cord should not be used during the

configuration.

5 ELECTRICAL INSTALLATION

5.1 EXTERNAL POWER SUPPLYING

Fig. 6 below shows RHT-Air’s necessary electrical connection. Terminals

1 and 2 are to be used in the electrical connection and terminals 3 and 4

Fig. 5 - RHT-Air Measurements

NOVUS AUTOMATION 2/8

are not used.

1 - VDC Power Supply Black wire

2 + VDC Power Supply White Wire

3 Not used Blue wire

4 Not used Brown Wire

RHT-Air

Addr

• After removing the front panel, change the position of the jumper (J1) to

“BAT” so that it can be supplied through the battery. Replace the front

panel, by placing the four set screws, taking the necessary precaution

not to apply force on the internal connector of the electronic circuit.

Fig. 6 - Electrical wiring

• RHT-Air is manufactured with the jumper (J1) set in the position “EXT”

for external power supply .

5.1.1 RECOMENDATIONS FOR INSTALLATION

• Conductors of small electric signals must be separated from activation

conductors or higher current or power in the system’s plan, if possible in

grounded electroducts.

• The instrument’s supply must come from a network proper for

instrumentation.

• In control and monitoring applications, it is essential to consider what

may happen when any part of t he system fails.

• The use of RC FILTERS (47 Ω and 100 nF, series) in parallel with

contactor and solenoid coi ls, etc. is recommended.

5.2 BATTERY POWER SUPPLY

RHT-Air can be supplied by an internal battery whenever the equipment is

not energized by the electrical grid. Below are guidelines on how to proceed

for supplyin g power with a battery:

• Remove the four set screws of the front panel of the equipment RHT-Air,

taking the necessary precaution not to apply force on the internal connector

of the electronic circ ui t.

5.2.1 REPLACING THE INTERNAL BATTERY

It is possible to check the battery’s charge through register “29”. A full y charged

battery typically has a power above 3.6 V. As you use the RHT-Air, the power

of the battery will gradually decrease. It is recommended that you check the

value of registry “29" regularly so that when it reaches below 3.3 V, the battery

can be replaced.

Note: Even when the power is below 100 %, the equipment will operate

normally.

Only suitable replacement battery for this product is:

• Remove the four set screws of the front panel, taking the necessary

precaution not to apply force on the internal connector of the electronic

circuit. After removing the front panel, replace the battery, taking the

necessary precaution not to to uch the electronic circuit.

MANUFACTURER: OMNICELL

MODEL: ER14250HD

• Insert a new battery and replace the front panel carefully, placing the

four molding screws.

6 CONFIGURATION / OPERATION

NOVUS AUTOMATION 3/8

The application DigiConfig is a Windows® software used for configuring

RHT-Air. In order to install it, please run the file “DigiConfigSetup.exe” from

the CD that comes with the equipment and follow the inst ructions therein.

DigiConfig comes with an unabridged help tutorial, containing all the

necessary information for you to use it. If you want to use help tutorial, start

the applicat ion and select t he "Help” menu or press "F1".

If you do not have the CD that comes with the equipment, go to

www.novusautomation.com

manual guides.

Users will receive the fully calibrated adjustment-free equipment. The original

configuration is s hown below :

(Communication address) = 246

Time (Update interval) = 60

to get the DigiConfig installer and the additional

Loading...

Loading...