LogBox-RHT

TEMPERATURE AND HUMIDITY LOGGER – INSTRUCTIONS V 1.1x A

1 INTRODUCTION

LogBox–RHT is an electronic logger of temperature and relative

humidity. There are sensors that measure such data and store them

in an electronic memory. Data can be later viewed and analyzed on a

PC where they can be opened in tabular and graphical forms.

The logger is supplied with Logchart-II software, which enables to set

up the logger operation mode. It is also used for data visualization.

Other parameters such as end of measurements, logging interval, etc.,

are easily selected through the LogChart-II software.

Measurements can be exported to and opened in other applications,

such as spreadsheet programs.

1.1 PACKAGE CONTENTS

Besides this manual, the user must check if the items below

accompany the product.

- The electronic logger LogBox-RHT;

- A CD-ROM with the Logchart-II software and a USB driver;

- A communication interface upon request.

1.2 Identification

The identification label is on the logger body. Check if the features

described are in accordance with your order. The RHT model is

designed to measure temperature and relative humidity.

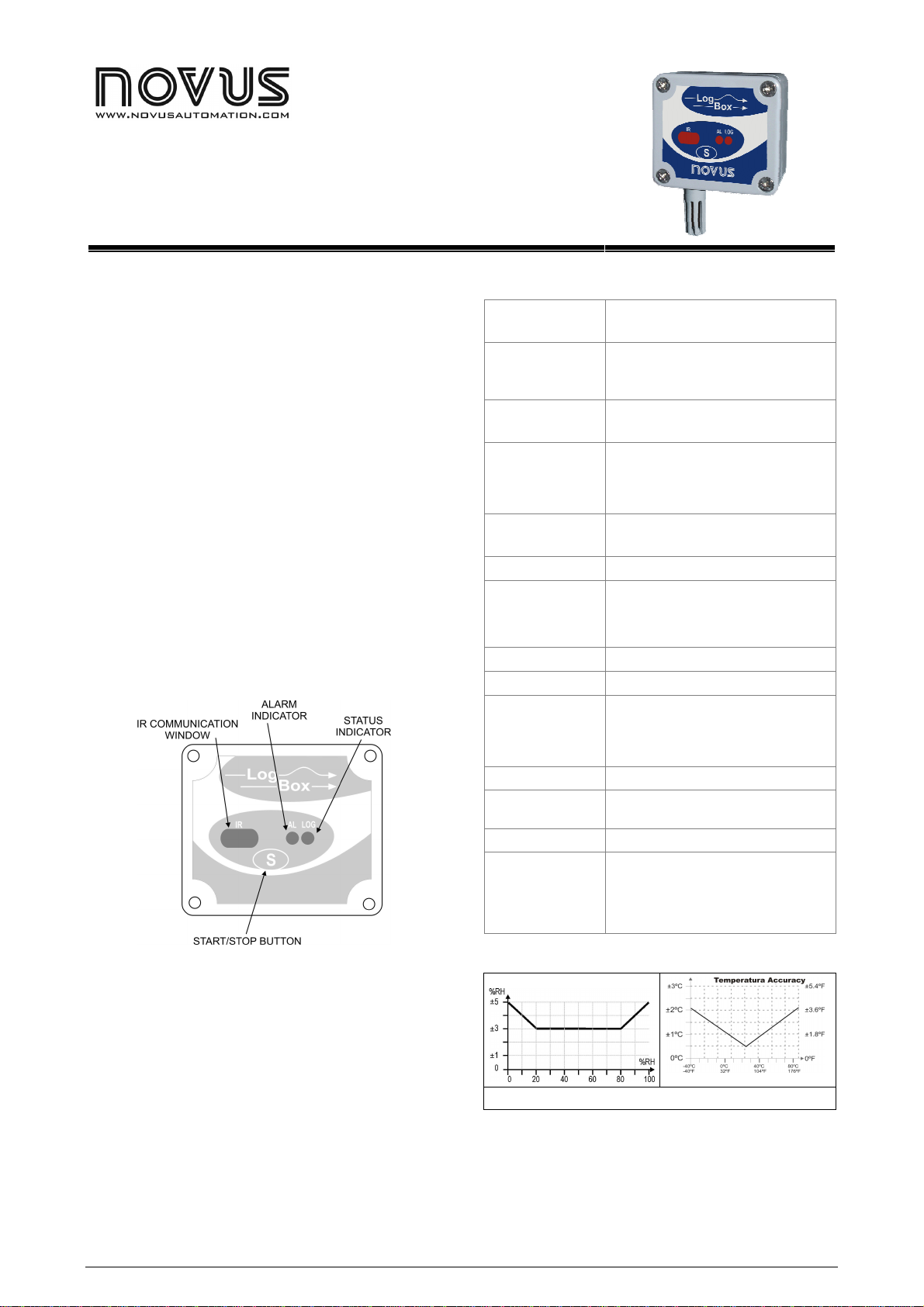

The following elements are shown in the logger front.

Figure 01 – Logger Front

START / STOP button: Can be configured to start or stop logging

when pressed.

IR Communication Window: PC-Logger communication area. The

communication interface should be pointed towards this window.

State indicator (LOG): While in stand-by (not logging) or after a

series of measurements is ended, it flashes once at every four

seconds. During logging it flashes twice at every four seconds.

Alarm Indicator (AL): Warns the user as to alarm conditions.

Whenever an alarm situation takes place it will flash once at every

four seconds, until a new configuration is applied to the logger.

2 TECHNICAL DATA

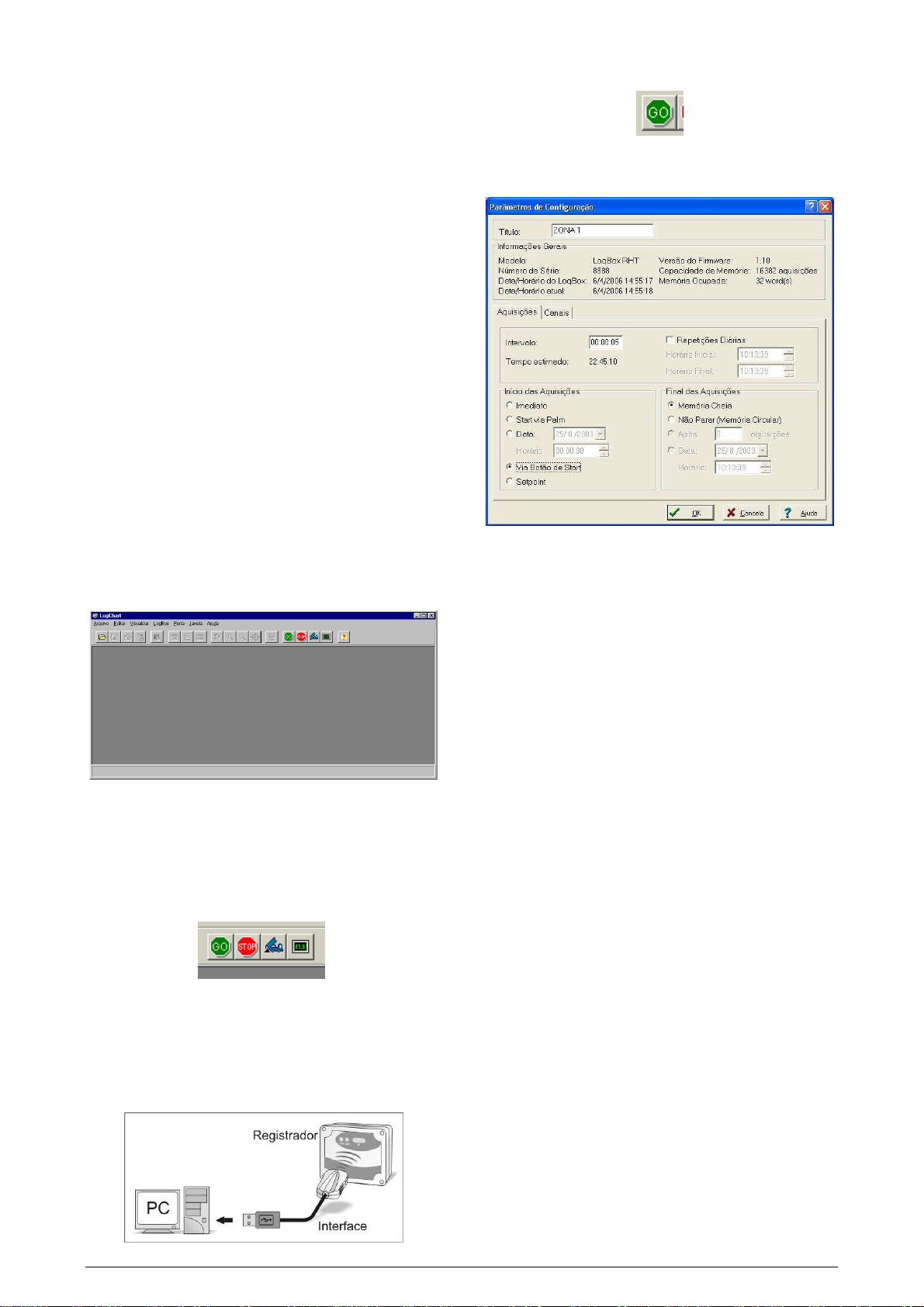

Measure Range

Accuracy

Measurement

Resolutions

Memory capacity

Measurement Interval 1 second min.

Power supply

Estimated autonomy Higher than 200 days with one weekly

Operating temperature From –40 °C to 80 °C

Case

Protection

Dimensions

Logger-PC data transfer

time

PC Interface

LogChart-ll software

operation environment

Temperature: -40 °C to 120 °C.

Relative Humidity (RH): 0 a 100 %.

See Figure 02.

Note: A measure error can be ruled out using the

OFFSET parameter in the Logchart-II software.

Temperature: 0.1 °C.

Relative Humidity (RH): 0,1 %.

32,000 (32 k) logs.

16,000 temperature and 16,000 humidity logs

or 32,000 temperature logs when relative

humidity is disabled.

18 hours max.

3.6 V lithium battery (1/2 AA), built-in

download and 5 minutes measuring interval.

Battery life depends heavily on data retrieval

frequency.

Polycarbonate

Suitable for products with protection level IP65.

See “Special Care” section.

Electronic circuit case: IP65; Sensors capsule:

IP40

60 x 70 x 35 mm

According to the number of logs. 40 seconds

for 16,000 logs.

Ir/USB or Ir/Serial

Set up Software for Windows 95, 98, NT, 2000

and XP.

Menus in Portuguese, English or Spanish.

Sets up, reads and displays data on the

screen.

2.1 Measurement Accuracy

RH Accuracy

Figure 02 – Measurement Accuracy

NOTE

The sensor from this device may be damaged or uncalibrated if

exposed to chemical agents-contaminated atmosphere. Chloridric

Acid, Nitric Acid, Sulphuric Acid and Ammonia in high concentrations

may damage the sensor. Acetone, Ethanol and Propylene Glycol

may cause a reversible measure error.

NOVUS AUTOMATION 1/6

LogBox-RHT

3 OPERATION

It is only possible to operate the logger after the Logchart-II software

is installed to a PC, according to the steps described at Logchart-II

Software section of this manual.

The communication between logger and PC is performed with the aid

of the IR-Link wand.

The logger operation mode set up is defined in advance by using the

LogChart-II software. Definitions are sent to the logger through the

IR-Link wand. The logger starts and stops logging as defined in the

setup.

4 INTERFACE INSTALLATION

In the Ir-Link3/RS232 model there is a RSR232/Ir communication

interface. It must be connected to the serial port at the PC.

In the Ir-Link3/USB model there is a USB/Ir communication

interface, which must be connected to the available USB port.

Windows will request the proper driver installation, which is found in

the CD-ROM that is provided with the logger.

5 LOGCHART-II SOFTWARE

5.1 Installing Logchart-II

LogChart II is the software provided with the logger to allow for

configuration and data offload. To install, run the LC_II_Setup.exe

file provided with the CD-ROM.

Note: Be sure your Windows date separator is configured as a slash:

dd/mm/yy or dd/mm/yyyy.

5.2 Running Logchart-II

When you open Logchart-II the main window is displayed.

When communication is established, select

The Configuration Parameters screen is displayed. In this screen

the user can define the logger operation mode and also obtain

general information about the device.

Figure 06 – Configuration window

Fields are:

1- Title: In this field, the user identifies the logger by assigning it a

name.

2- General information: Area with information about the logger,

such as Model, Serial Number, Logger Date/Time, PC Date/Time,

firmware version, memory capacity and number of acquisitions

stored in memory, etc.

In this field, time is constantly updated while the communication

between logger and computer is taking place.

Figure 03 – LogChart-II main window

Next, select the serial port that the communication interface will use

in the “Port” menu.

Check which is available. Usually COM2 is free, once the mouse

uses COM1. The selected COM port will be remembered next times

the LogChart II is run. When a valid port is selected, the icons below

are displayed.

Figure 04 – Icons enabled when the communication port selected is a valid port

5.3 CONFIGURING THE LOGGER

Make sure the communication interface is connected to the PC port

selected. The interface must be constantly directed towards the front

part of the logger (communication window) at a maximum distance of

1 m. (See Figure 05).

4- Readings: Presents a series of parameters that define how

measurements will be.

Interval between readings: Defines the interval between

readings: Minimum interval is 1 (one) second.

Note: When the type of value logged is mean, maximum and

minimum values, the minimum interval is 10 seconds.

In Daily repetitions the user defines the time that daily logs will

take place.

Estimated time: In this parameter, the logger informs the user

how long it will take to occupy the full memory, in the conditions

set up during configuration.

Start of Readings: Readings can be started in one of five

different modes:

•

Immediately: start as soon as programming is considered

to be ready, and is then sent (OK) to the logger.

•

Start via Palm: start with a command sent via Palmtop,

which runs the software Log Chart Palm-OS.

•

Date: readings start at predefined date and time.

•

Through Start Button: starts and interrupts readings by

pressuring the Start button, in the frontal part of the

logger, for two seconds. See Figure 01.

•

Setpoint: measurements start when a temperature

setpoint is reached. In this option, the setpoint value is

defined in the Channels field, where the Alarm parameter

is replaced by setpoint.

Figure 05 – Infrared communication interface position

NOVUS AUTOMATION 2/6

Loading...

Loading...