Page 1

InstructionInstruction

Instruction

InstructionInstruction

ManualManual

Manual

ManualManual

Series HH

Electronic Metering Pumps

Carefully read and understand all precautions

!

CAUTION

For file reference, please record the following data:

before installing or

servicing any metering pump.

!

CAUTION

Model Number:______________________________

Serial Number:_____________________________

Installation Date:____________________________

Installation Location:_________________________

When ordering replacement parts for your LMI Series HH

Metering Pump or Accessory, please include complete Model

Number and Serial Number of your unit.

201 Ivyland Road

Ivyland, PA 18974 USA

TEL: (215) 293-0401

FAX: (215) 293-0445

http://www.lmipumps.com

ISO 9001 Certified

1983.A 03/04

Page 2

Contents

1.0 Introduction ................................................................ 4

1.1 Spare Parts ........................................................... 4

2.0 Unpacking ................................................................ 5

3.0 HH9 Features ................................................................ 6

4.0 How to Interpret the Model Number ............................... 7

5.0 Pre-Installation Instructions ............................................ 8

6.0 Installation Instructions................................................... 9

6.1 Pump Location ...................................................... 9

6.2 Pump Mounting ................................................... 10

6.3 Plumbing ............................................................. 10

6.4 External Control Connections.............................. 11

6.5 Priming & Operation ............................................ 12

7.0 Output Adjustment Controls ......................................... 13

7.1 Pressure Control Adjustment............................... 13

7.2 Speed Adjustment ............................................... 13

7.3 Stroke Adjustment ............................................... 14

7.4 Calibration ........................................................... 14

8.0 Accessories .............................................................. 15

8.1 8-pin Cable.......................................................... 15

8.2 Optional 4-pin Cable HH9.................................... 16

8.3 Optional 4-pin Cable HH7.................................... 16

8.4 Optional "Hall Effect" Cable................................. 17

9.0 Checking Pump for Proper Zero Position ..................... 18

9.1 Push On Knob..................................................... 18

10.0 Keypad / Display HH9 .................................................. 20

10.1 LCD Screen......................................................... 20

10.2 Start / Stop .......................................................... 21

10.3 Up & Down Key................................................... 21

10.4 Mode Key............................................................ 21

11.0 Operation of the Series HH9 ........................................ 22

11.1 Pump Start/Stop.................................................. 22

11.2 Speed .............................................................. 23

11.3 Pressure Level Control........................................ 24

11.4 Keypad Lock ....................................................... 24

11.5 Low-Level Switch ................................................ 25

2

Page 3

12.0 External Control Modes HH9........................................ 25

12.1 Programming Pulse Divide.................................. 26

12.2 Programming Pulse Multiply................................ 27

12.3 Programming mA Response ............................... 28

12.4 Programming Points 1&2 (SPM) ......................... 29

12.5 Programming Points 1&2 (SPH).......................... 31

13.0 Advanced Features and the Setup Menu HH9 ............. 33

13.1 Accessing the Setup Menu.................................. 34

13.2 Menu Items ......................................................... 34

13.2.1 Batch Accumulate.................................. 34

13.2.2 Automatic Voltage Compensation.......... 35

13.2.3 Flow Monitoring ..................................... 35

13.2.4 Input Signal Pulse Width (Debounce) .... 35

13.2.5 Activate the Intergral Blowdown Feature . 36

14.0 Troubleshooting ........................................................... 38

Appendix A:Input/Output Descriptions .................................... 42

Appendix B:Summary of Error Messages............................... 47

3

Page 4

1.0 Introduction

LMI is the world’s most versatile manufacturer of economical and

efficient metering pumps. This manual addresses the installation,

maintenance and troubleshooting procedures for the HH Series

manually and externally controlled pumps. LMI has a worldwide

network of stocking representatives and authorized repair centers to

give you prompt and efficient service.

The Series HH9 electronic metering pump offers an extensive range of

features, including microprocessor control for accurate and flexible

automation in response to instrument signals. The microprocessor

design employs a customized liquid crystal display (LCD) and tactile

response keypad. The "state-of-the-art" surface mount electronics are

fully encapsulated to ensure protection in its working environment. All

external inputs and outputs are opto-isolated from the microprocessor.

Please review this manual carefully. Pay particular attention

to warnings and precautions. Always follow good safety

procedures, including the use of protective clothing, eye and

face protection.

1.1 Spare Parts

LMI recommends replacing all components subject to wear and tear

on an annual basis. RPM Pro Pacs™ and spare part kits are available

from your local LMI Master Stocking Distributor. The spare parts

kit for the HH pump is SP-987.

Figure 1:

LMI Series

HH9 Electronic

Metering Pump

4

Page 5

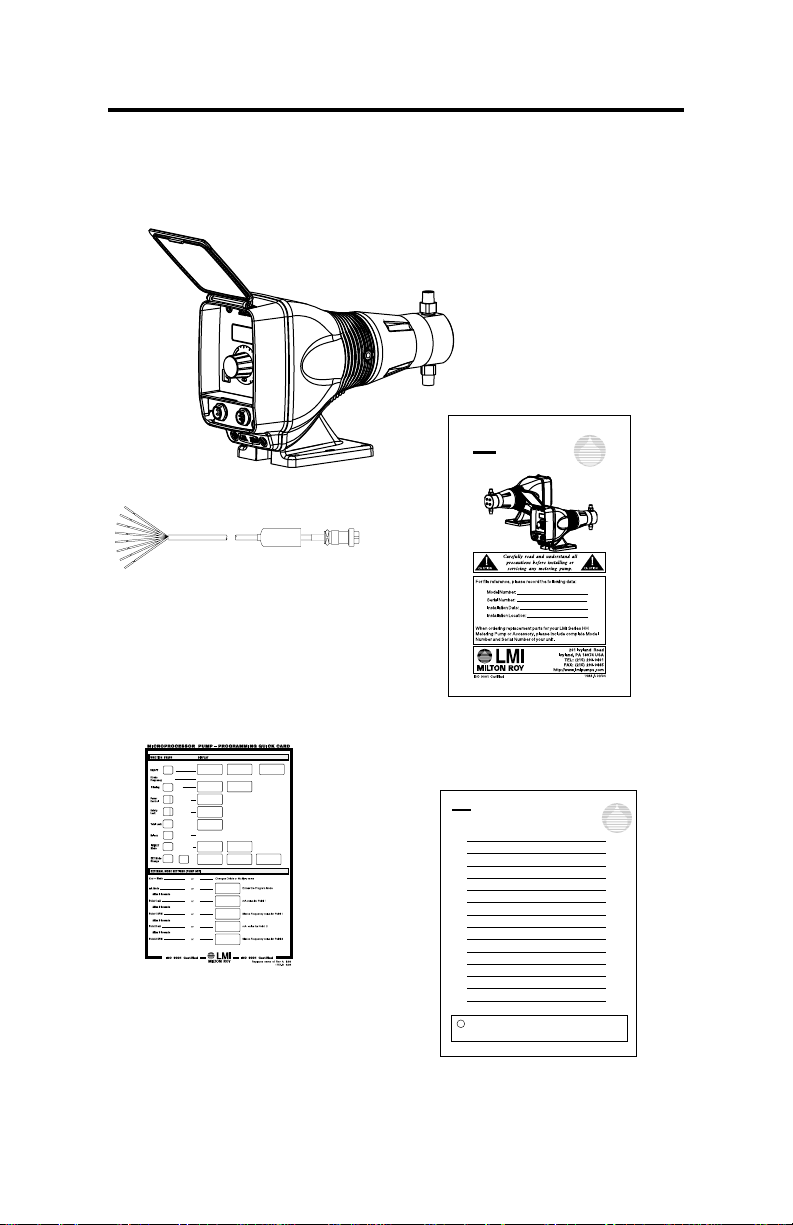

2.0 Unpacking

You should find the following items in the box:

Electronic

Metering Pump

InstructionInstruction

Instruction

InstructionInstruction

Electronic Metering Pumps

8 Pin Cable

(Series HH9 Only

P/N 33738)

ManualManual

Manual

ManualManual

Series HH

Quick

Card

(Series HH9 Only

P/N 1757)

Series HH

Instruction

Manual

(P/N 1983)

Instruction Supplement

LMI

MILTONROY

Instruction

Supplement

Figure 2: Unpacking Items

5

Page 6

3.0 HH9 Features

Stroke frequency adjustment from 0 SPH (strokes per hour) to

100 SPM (strokes per minute).

Internal (manual) or external mode select.

Flexible slope adjustable response to mA input signals.

Divide or multiply (batch) incoming pulses (1 to 999).

Batch accumulate option.

Integral blowdown controller feature.

Keypad locking.

Low-level shutoff with alarm output.

6-level pressure control.

Continuous non-volatile memory (EEPROM)--no battery

required.

Remote ON/OFF control.

Pulse (pacing) output.

Automatic line voltage compensation and over voltage

protection.

Programmable menu for optional features/parameters.

6

Page 7

4.0 How to Interpret the Model Number

The silver data plate (located on the front of the pump) tells you how

your pump is configured.

PSI

1.4 A

1000

115 V.A.C.

MODEL # HH931-987

SERIAL #

MAX/

GPH

50/60 HZ.

0.07

Figure 3a : Data Plate

Included on the data plate is the model number of the pump. Each

number in the model number represents the following in Figure 3b.

HHXXX-987

Series

or Model

Control Code

1 = Manual

7 = Instrument

Responsive Manual

9 = Microprocessor/

Instrument

Responsive

Output Codes

1 = 0.14 GPH at 300 PSI

2 = 0.10 GPH at 600 PSI

3 = 0.07 GPH at 1000 PSI

Cord & Voltage Codes

Liquid End

1 = 120 V US plug, UL

2 = 240 V US plug, UL

3 = 230 V DIN plug, CE

5 = 240 V UK plug, CE

6 = 250 V Aust/ NZ plug

7 = 230 V Swiss plug

8 = 120 V No plug, CE

Figure 3b : Model Number Representation

7

Page 8

5.0 Pre-Installation Instructions

Specific precautions should be taken when working

!

CAUTION

Protective Clothing

!

CAUTION

Water Pre-Prime

!

CAUTION

with all LMI metering pumps. Please read this section

carefully prior to installation.

ALWAYS wear protective clothing, face shield, safety

glasses and gloves when working on or near your

metering pump. Additional precautions should be taken

depending on the solution being pumped. Refer to

MSDS precautions from your solution supplier.

All LMI pumps are pre-primed with water when shipped

from the factory. If your solution is not compatible with

water, disassemble the Pump Head Assembly.

Thoroughly dry the pump head, plunger, and check

valve components. Reassemble head assembly

tightening screws in a crisscross pattern. Refill the

pump head with the solution to be pumped before

priming the pump. (This will aid in priming.)

8

Page 9

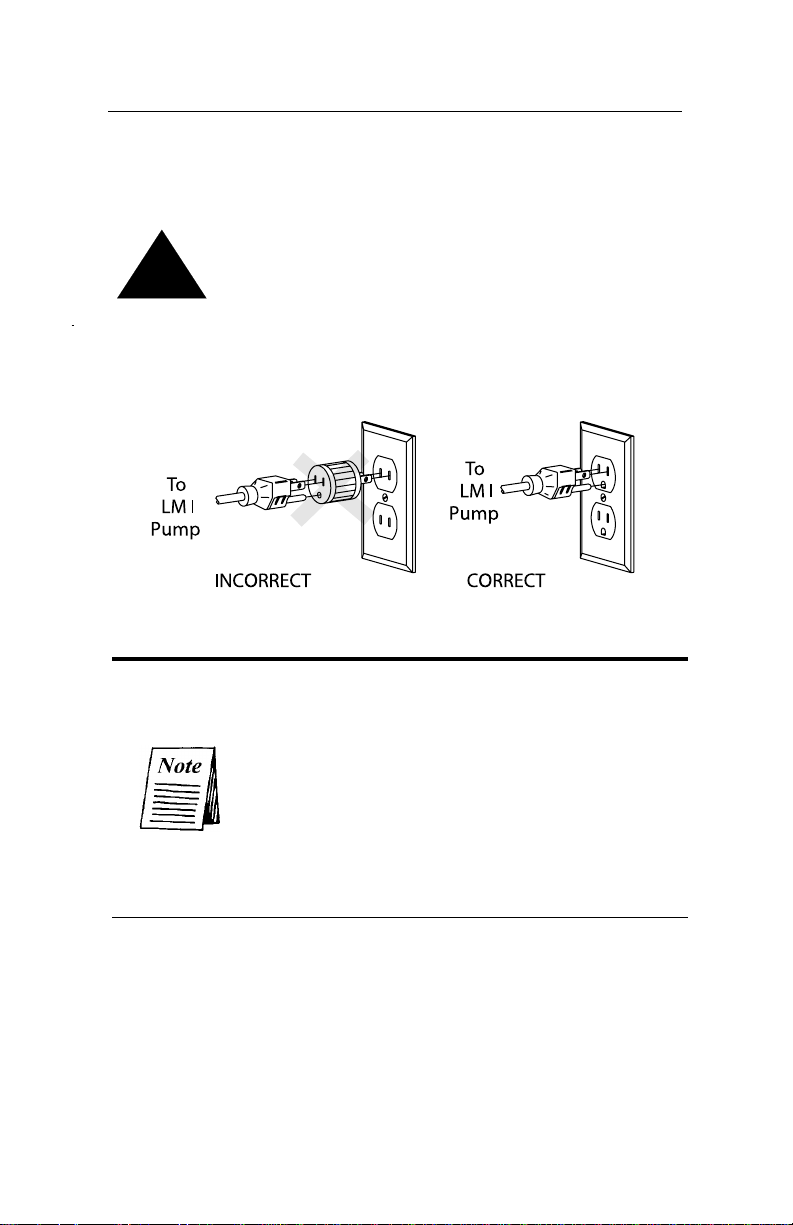

Electrical Connections

WARNING: to reduce the risk of electrical shock, the

metering pump must be plugged into a grounded outlet

!

CAUTION

with ratings conforming to the data on the pump

control panel. The pump must be connected to a good

ground. DO NOT USE ADAPTERS! All wiring must

conform to local electrical codes.

6.0 Installation Instructions

The minimum allowable system pressure for the

HH pump is 200 psi. If your system operates at

a lower pressure, a back pressure valve must be

installed.

6.1 Pump Location

Locate the pump in an area convenient to the solution tank and

electrical supply. The pump should be accessible for routine

maintenance, and should not be subjected to ambient temperatures

above 122°F (50°C).

9

Page 10

6.2 Pump Mounting

The HH pump requires a Flooded Suction installation. The pump

should be securely mounted at the base of the storage tank with the

suction piping sloping downward to the pump.

All piping should be cleaned and blown-out

prior to connection to the HH pump.

6.3 Plumbing

Always adhere to local plumbing codes and

requirements. Be sure the installation does not

!

CAUTION

The HH high pressure metering pump utilizes 1/4" N.P.T.

connections. These connections require the use of Teflon Tape.

When applying the Teflon Tape, make sure it does not extend over

the fitting. This would restrict the flow of chemical.

All piping being attached to the HH must be cleaned and blown out

to prevent debris from entering the Liquid End. A 100 micron

strainer or filter should be installed to prevent any debris in the

chemical from entering the pump.

constitute a cross connection. Check your local

plumbing codes for guidelines. LMI is not

responsible for improper installations.

10

Both the discharge and suction check valves

should be supported while tightening the mating

pipe connections. This is done by placing a

wrench on the check valve flat, to prevent it

from turning and becoming over tightened,

when connecting the pipe.

Page 11

The discharge piping must be installed and supported so that it does

not place a supportive load on the liquid end.

Series HH pumps are capable of developing 1000

!

CAUTION

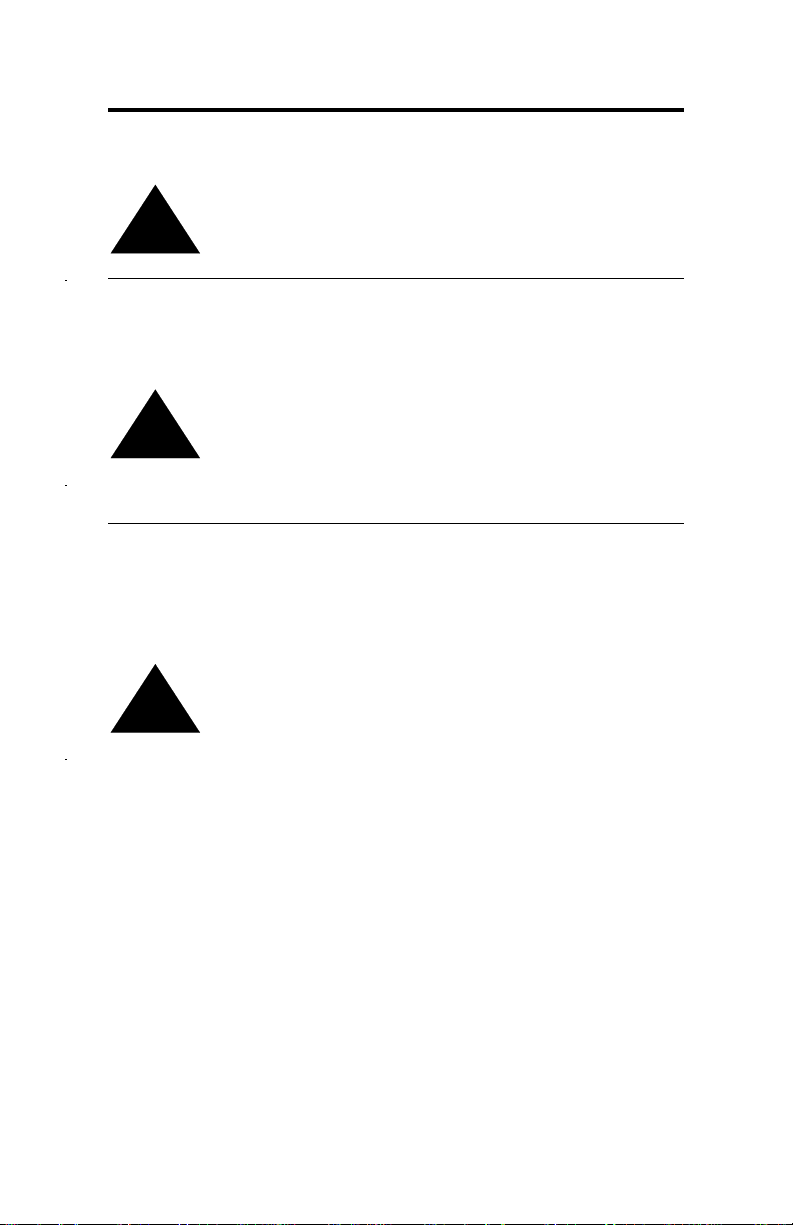

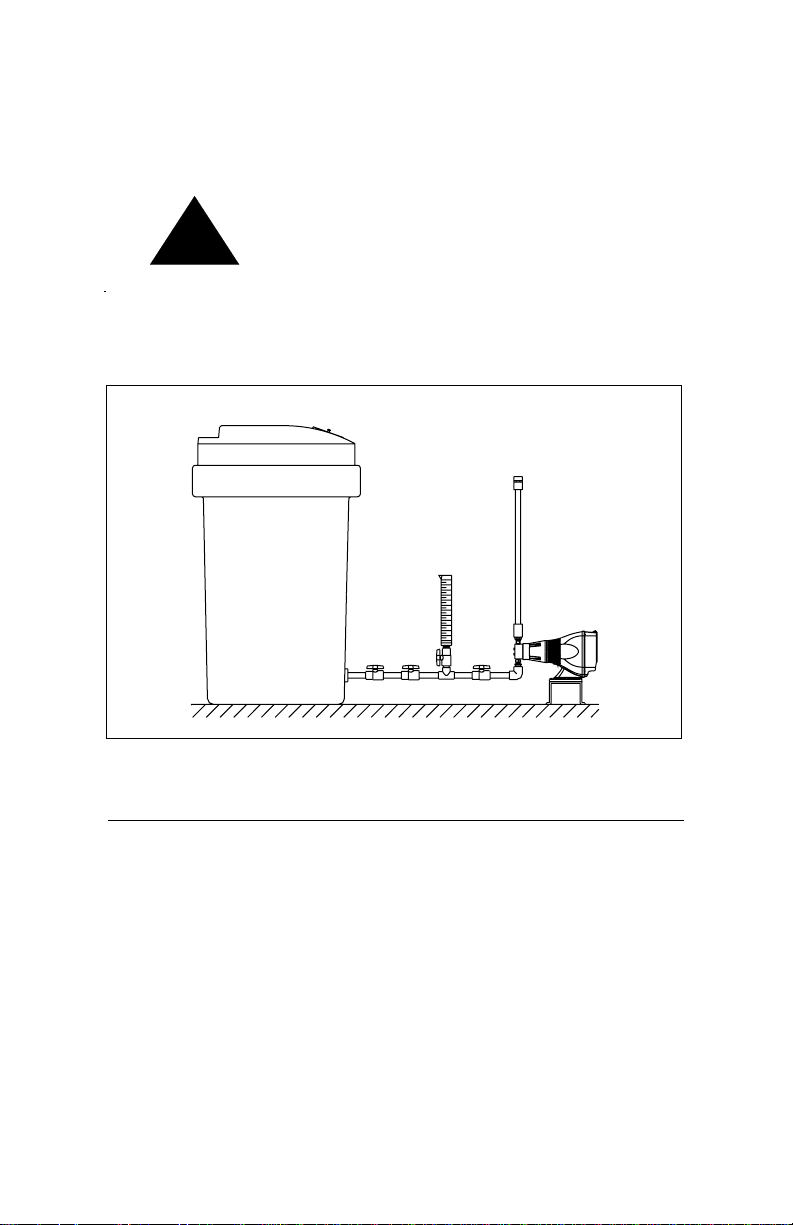

For calibration purposes, it is recommended that a 200 mL graduated

cylinder be piped in-line, on the suction side of the pump (see

Figure 4).

psi of discharge pressure. All piping must have

sufficient rating to withstand maximum pressure.

TANK

Figure 4: Series HH Recommended Installation.

6.4 External Control Connections

The HH7 and HH9 come standard with various electrical connectors.

These are located on the front of the pump. The functions and

appropriate connections are covered in greater detail later in this

manual.

The HH pump comes equipped with a 1/8" NPT port on the bottom

of the liquid end spacer. This port is provided for draining in the

event that the seal stack leaks. Use a 1/8" NPT, Teflon taped

connector to safely route any leakage to a suitable container.

25ml

Cylinder

11

Page 12

6.5 Priming and Operation

LMI performance tests every pump prior to shipping to insure that

it meets the design parameters. This test is performed using water.

Please be advised that the pumps are shipped with water in the

Liquid End. If it is incompatible with the chemical that is being

injected, the head must be dried.

When all of the previously mentioned precautions and safety

regulations required by your facility or local ordinances have been

considered, you may start priming your pump.

The HH precisely injects small amounts of

chemical. Due to this characteristic, the HH will

take a considerable amount of time to prime.

System design may also affect the priming time

The HH9 Control Panel has a Start/Stop button

labeled "Hold for Prime". This key has a timer that

shuts off after one minute of operation. The

lengthy priming time of the HH renders this

function unusable. The priming procedure should

be done with the pump running in the internal

mode.

12

Step 1- Plug in or switch on your pump

Step 2- While the pump is running, turn the stroke dial

knob to 100% and the speed adjustment knob (if equipped)

to 80%.

Step 3- Make sure that any valves are open to allow

chemical to enter the pump head.

Page 13

7.0 Output Adjustment Controls

Once the pump is primed, the output must be adjusted to meet the

requirements of the system. This adjustment is made by varying

both the stroke and speed of the pump.

7.1 Pressure Control Adjustment (HH9 Only):

The pressure control adjustment, unique to LMI, allows for the fine

tuning of your HH9 Pump. This reduces over pumping of chemical

and power consumption while increasing the accuracy and life of

your pump.(See Section 11.3)

7.2 Speed Adjustment:

The HH9 speed control can be adjusted manually, using the keypad

or externally as described in section 11. In either case, the speed

adjustment controls the frequency or rate at which the chemical is

being injected.

The HH1 and HH7 come equipped with a manual speed adjustment

knob. Turning the knob clockwise to the maximum setting increases

the stroke rate up to 100 strokes per minute.

HH7 Only:

When operating the pump in external mode, the

speed control knob should be turned fully counter

clockwise.

13

Page 14

7.3 Stroke Adjustment:

The Stroke Adjustment dial controls the volume of chemical being

injected with each stroke. The 100% setting indicates the maximum

volume per stroke.

The maximum rated output of your pump is

indicated on the data plate. The HH output

control features have been designed to make it

easy for the user to determine the appropriate

speed and stroke settings.

7.4 Calibration

The HH has been designed to inject a precise, repeatable amount of

chemical against system pressure. Because every system is different,

it is necessary to calibrate the pump once it is installed. The

calibration will enable you to fine tune the HH to provide the desired

injection amount.

The HH calibration is done after the pump is fully primed. The

discharge or injection point must be at normal operating pressure

for an accurate calibration to be done.

The suction line should be valved to run off the in-line calibration

cylinder. This cylinder must reproduce the suction pressure applied

by the tank (see Figure 4).

14

Page 15

8.0 Accessories

8.1 8-Pin Cable ( P/N 33738 HH9 Only)

The 8-pin external cable assembly can be used to control stroke

frequency in response to a 0 to 20 mA or 4 to 20 mA instrument

signal. This cable assembly also provides output signals for

pacing (pulse output), alarm (general) and computer alarm.

Figure 5: 8-Pin Cable (P/N 33738)

PIN WIRE SIGNAL

1 Red +15V Output

2 Black -15V Ground

3 V iolet +0-20 or 4-20 mA (+) Input

4 Green -0-20 or 4-20 mA (-) Input

5 Orange Pulse Output

6 Y ellow Alarm Output

7 Brown Flow Input

8 Blue Computer Alarm Output

& Computer Output

Table 1: Pin Out Table - 8-Pin Cable (P/N 33738)

15

Page 16

8.2 Optional 4-Pin Cable (P/N 33796 HH9 Only)

The optional 4-pin external cable is used for connecting incoming

pulse or pacing signals such as those triggered by a manual

switch, reed switch, opto-coupler or by NPN or PNP transistors.

The remote ON/OFF input is also accessed through the

standard 4-pin connector.

Figure 6: 4-Pin Cable (P/N 33796)

PIN WIRE SIGNAL

1 White +15V Output

2 Black Pacing input

3 Green +15V Ground

4 Red Remote ON/OFF

& Computer Input

Table 2: Pin Out Table - 4-Pin Cable (P/N 33796)

8.3 Optional 4-Pin Cable (P/N 28368 HH7 Only)

The optional 4-pin external cable is used for connecting incoming

pulse or pacing signals such as those triggered by a manual

switch, reed switch, opto-coupler or by NPN or PNP transistors.

Figure 7: 4-Pin Cable (P/N 28368)

PIN WIRE SIGNAL

1 White Pacing Input

2 Black Pacing input

3 None None

4 None None

Table 3: Pin Out Table - 4-Pin Cable (P/N 28368)

16

Page 17

8.4 Optional "Hall Effect" Cable (P/N 33833)

An optional cable assembly is available for pacing your pump

directly from an LMI Flowmeter fitted with a Hall Effect

sensor. This cable connects to the Flowmeter as shown in

Figure 8 (There is no need for a Programmable Divider; its

function is built into the pump).

Figure 8: Optional "Hall Effect" Cable (P/N 33833)

17

Page 18

9.0 Checking Pump for Proper Zero Position (Stroke Knob)

1.With pump running, turn stroke knob counter-clockwise

toward zero or end of black or red band on dial.

2. LISTEN to the clicking as the pump is running. The pump

should operate quietly at the zero position (no clicking).

3. If the pump continues to click at zero or stops clicking before

zero is reached, the pump zero must be reset.

9.1 Push on Knob

Re-Zeroing and Stroke Knob Disassembly and Assembly

1.Remove stroke knob from the pump by grasping the knob

firmly and pulling it toward you.

2.Pry off the yellow cap.

3.Place the knob on a flat surface.

4.Using needle-nose pliers, squeeze the inner section together

while lifting the outer section up.

5.Push the inner section back onto the “D” shaped stroke shaft.

6.With the pump running, zero the pump by turning the inner

section of the knob counter-clockwise

clicking.

7. Position the outer section of the knob so that the pointer aligns

with zero on the nameplate or end of the black or red band.

8. Push down on the outer section (a snap sound indicates parts

are locked together).

9. Replace the yellow cap over the outer section of the knob,

aligning the tabs on the cap with the slots inside the knob.

18

until the pump stops

Page 19

Figure 9: Stroke Knob Assembly

19

Page 20

10.0 Keypad/Display: Description and

Function (HH9 Only)

mA EXT

X INT

Figure 10: HH9 Keypad

10.1 LCD Screen

MIN

P12:FLOW

The LCD screen is the window in which all values and menu choices

are displayed (see Figure 11).

FLOW

Figure 11: Liquid Crystal Display

20

Page 21

10.2 Start/Stop

STOP

The (Start/Stop) key turns the pump on or off. If the pump

START

STOP

START

is not running, pressing this key will cause the pump to start

running. The symbol appears on the display while the pump

is running. Each time the pump strokes, the symbol clears. If

the pump is running, pressing the (Start/Stop) key will stop

STOP

START

the pump.

10.3 Up and Down Key

Use the (Up) and (Down) keys when: changing the stroke

frequency; altering the pressure level; activating and deactivating

the keypad lock; programming the divide and multiply values;

accessing the setup menu; and changing certain parameters included

in the setup menu. All of these functions are covered in greater detail

later in this manual.

MODE

E

10.4 Mode Key

MODE

I

Use the (Mode) key when: changing to or from external or

N

T

I

N

N

T

T

E

N

T

internal mode; accessing the pressure level; activating and

deactivating the keypad lock; and accessing specific advanced

features in the setup menu.

21

Page 22

11.0 Operation of the Series HH9

These pumps feature EEPROM nonvolatile memory. The pump will

always power up in the last used mode. When shipped from the

factory the pump will power up in the "Internal" (manual) mode,

with the pump OFF and a speed setting of 100 SPM.

If the power to the pump is cut less than 15 seconds after the

last programmed values have been set, the latest changes

will NOT be stored in nonvolatile memory. Allow at least 15

seconds before disconnecting from power to ensure that the

latest changes are stored.

11.1 Pump Start/Stop

Press the

STOP

(Start/Stop) key to start or stop the pump. When the

START

pump is OFF, the LCD screen will alternate between

INT

every 16 seconds. When you start the pump, the

MIN

symbol appears on the LCD

the symbol disappears. Press the

INT

. Each time the pump strokes,

MIN

STOP

(Start/Stop) key again

START

to stop the pump.

"INT" signifies that the pump is in the "Internal" (Manual)

mode.

INT

and

22

Page 23

11.2 Speed

The speed may be changed with the pump ON or OFF. To increase

or decrease the speed, press or hold the

(Up) or (Down)

key. The range runs from 0 SPH to 100 SPM. While normally the

speed will be set in SPM, if settings of SPH are desired, hold the

(Down) key until the display reads 0, then continue to hold it for an

additional three (3) seconds. The display will then show H60, which

is 60 SPH. The speed can be further reduced to 0 SPH with the

(Down) key.

For example:

INT

MIN

INT

MIN

+3 sec

INT

23

Page 24

11.3 Pressure Level Control

The maximum pressure rating of your pump can be adjusted to

reduce pulsation shock in your discharge line. The pumps have a 6point pressure control scale. The minimum setting is 0 and the

maximum is 5. To access the pressure setting, press the

MODE

I

N

TT

(Mode) key and (Up) key at the same time and hold for two (2)

seconds. The current pressure setting

may be altered

MIN

using the (Up) or (Down) keys.

The pressure may be changed with the pump ON or OFF and in

either Internal or External mode.

11.4 Keypad Lock

The pump has two (2) lock modes to prevent casual tampering. The

small "LOC" de-activates all key functions except

Stop) and Prime. To activate this "LOC" mode, press the

STOP

START

(Start/

MODE

I

N

TT

(Mode) key and (Down) key at the same time and hold for two

(2) seconds. The LCD will read for five (5) seconds and

then return to the previous display. This display reappears when any key except the

STOP

(Start/Stop) key is pressed.

START

E

X

E

X

The large "LOC" disables all keypad entries, including Start/Stop.

Activate this by pressing the Mode, Down, and Up keys at the same

time and holding for two (2) seconds. The LCD will read

for five (5) seconds and then return to the previous display. This

display re-appears whenever any key is pressed.

MODE

I

E

X

To de-activate either lock mode, press the

N

(Mode) key and

TT

(Down) key at the same time, and hold for two (2) seconds. The

or will disappear.

24

Page 25

11.5 Low-Level Switch (P/N 29190)

When the Low-Level Switch is fitted to the pump and a fault

condition exists, the "E1" error code will flash on the LCD screen

INT

.

MIN

For more information on the Low-Level Switch, see the LowLevel Switch Assembly information sheet (P/N 1368).

When a fault condition exists, the pump is stopped and the alarm

and computer alarm lines are activated to allow remote monitoring.

After clearing the fault (by filling the tank), the pump will

automatically restart.

12.0 External Control Modes for HH9

To access the pulse divide, pulse multiply or milliamp response, the

pump must be changed from Internal (manual) mode to External

mode. To do this, first be sure the pump is stopped. Press the

(Mode) key and hold it for three (3) seconds. The LCD screen

displays the last External mode that was programmed. If this is the

first time the pump has been put in the External mode, the factory

default will be displayed on the LCD screen. The factory default

mode is "External Pulse Divide" with a divide value of one (1)

EXT

:

. The display will alternate between SPM and OFF.

MODE

I

N

TT

E

X

25

Page 26

External Mode Select: Pulse Divide, Pulse Multiply, and

mA Response

Any of three external modes may be selected when the pump is

stopped by pressing and holding the

MODE

I

E

X

N

(Mode) key and

TT

STOP

START

(Start/Stop) key for five (5) seconds, then releasing. As noted

above, the default is Pulse Divide. Pressing and releasing these

EXT

keys brings you to the Pulse Multiply mode

X

. In this mode,

the LCD screen alternates between the pulse multiply value and

OFF. Pressing and releasing these keys one more time brings you

to the third external mode, mA response

mA EXT

. In this mode the

MIN

LCD screen alternates between SPM and the mA value.

Summary of External Mode Select

MODE

I

E

X

N

STOP

+

TT

START

For 5 Seconds

mA EXT

MIN

EXT

:

MODE

I

E

X

N

For 5 Seconds

+

TT

STOP

START

MODE

I

E

X

N

STOP

+

TT

For 5 Seconds

START

EXT

X

12.1 Programming the Pulse Divide Value

The divide value is altered by using the

( Up) and (Down)

keys. To do this, the pump must be in the External Divide mode and

be OFF. The valid range for the divide value runs from 1 to 999. With

the pump running in the Divide mode, the speed in SPM is calculated

based on the rate of incoming pulses and the divide value, and

EXT

displayed on the LCD screen

If the calculated speed is less than one (1) SPM, the LCD screen

will display 0 SPM. If the calculated speed is GREATER THAN

100 SPM, the E3 error code will be displayed periodically until

the fault condition is corrected

NOT activate the alarm outputs or stop the pump.

26

:

.

MIN

EXT

:

. This error does

MIN

Page 27

12.2 Programming the Pulse Multiply (Batch) Value

The multiply value is altered by using the

(Up) and (Down)

keys to change the value. The pump must be OFF and in the External

Multiply mode. Like the divide value, the valid range for the multiply

value runs from 0 to 999 pulses. When the pump is ON, a single

external pulse will initiate a batch of pump strokes. The number of

EXT

remaining pulses are displayed on the LCD screen

X

. When

0 is reached, the display resets to the multiply value. The pump is

now ready for another pulse input.

If a pulse is received before the countdown to 0 is complete, the E4

error code is displayed, and the pump batch count resets to the

programmed multiply value. The batch countdown then continues

from its programmed value. As the countdown continues, the E4

error code

X

will be displayed intermittently until the fault is

EXT

corrected. The strokes that remained from the first batch are NOT

accounted for. To clear the fault display, the pump must be stopped

and restarted.

To allow true flow proportioning, the speed in the Multiply mode

is equal to the speed set in the Internal (manual) mode. That

is, if the Internal mode speed is set at 60 SPM, in the External

Multiply mode the pump counts down at 60 SPM.

27

Page 28

Batch Accumulate

The Batch Accumulate function allows you to opt to have any

extra input pulses received in the multiply mode accumulate up to

a maximum batch of 999. If Batch Accumulate is enabled and

a pulse is received during the countdown, the programmed

multiply value will be added to the current displayed value. Pulses

causing the maximum batch of 999 to be exceeded will result in

an E4 error message. When Batch Accumulate is enabled, the

LCD screen alternates between the current multiply value and

EXT

"ACC"

X

. The Batch Accumulate function is activated

in the Setup Menu (see Section 13).

12.3 Programming the mA Response

The HH9 pump accepts a 0-20 mA or 4-20 mA signal directly. The

response to this signal is fully programmable. In the mA mode, the

pump speed is determined by the programmed response curve, as

defined by points "P1" and "P2." The factory default set values for

P1 and P2 are (4 mA, 0 SPM) and (20 mA, 100 SPM) respectively.

This is illustrated in Figure 12.

While in the mA mode, the pump speed

mA

are displayed alternately every four (4) seconds while the

mA EXT

and the mA value

MIN

pump is running.

28

Page 29

12.4 Programming Points 1 and 2 (SPM)

To program points P1 and P2, first ensure the pump is in the mA

mode and OFF. If you wish to program the response in "SPM",

switch to the internal mode. The speed must be set to a SPM value

INT

. Return to the External mA mode.

MIN

mA

MIN

P1P1

100

SPM

50

P1

.

0

4

and

12

mA

P2

.

P2

20

P2

MIN

mA

Figure 12

Press either the (Up) or (Down) key. The LCD screen

will display . After five (5) seconds, the display will show

the mA value for P1

mA

. This value may be altered using the

P1

(Up) or (Down) key within five (5) seconds (i.e. )

. Five (5) seconds following the last key press, the stroke rate for

P1 will be displayed

. This value may be altered within five

MIN

P1

(5) seconds using the Up or Down key (i.e. ).

Five (5) seconds after the last key press, the mA value for P2 is

displayed

mA

). Likewise, five (5) seconds after the last key press the

P2

mA

. Edit as described in the above paragraph (i.e.

P2

stroke rate for P2 is displayed. Edit as described above (i.e. ).

The above examples would result in the inverse control profile

shown in Figure 13 on the following page.

29

Page 30

Figure 13

If the mA input goes below the value programmed for P1 or above

the P2 value, the response will "plateau," as indicated by the dotted

lines above.

The valid input range is from 0.5 to 21 mA. Below 0.5 mA, the

pump will be off. Above 21 mA, the E5 error code will be

displayed intermittently .

30

Page 31

12.5 Programming Points 1 and 2 (SPH)

If you wish to program the response in strokes per hour, start by

being in the External mA mode. Next, switch to the Internal mode.

If the Internal setting is in strokes per minute, change to strokes per

hour by holding the

(Down) key until the display reads 0 SPM.

Continue to hold it for another three (3) seconds. The display will

now read SPH

INT

. Set the speed to any SPH value (the actual

setting has no bearing on mA response). Return to the External mA

mode.

In the External mA mode, pressing the

(Down) key or (Up)

key will change the display to . After five (5) seconds, the

display will show the mA value for P1

mA

. This value may be

P1

altered by using the (Up) key or (Down) key within five

(5) seconds (i.e. ). Five (5) seconds following the last key

press, the stroke rate for P1 will be displayed . This value

may be altered within five (5) seconds using the (Up) or

(Down) key (i.e. ).

Five (5) seconds after the last key press, the mA value for P2 will

be displayed

mA

. Edit as described above (i.e.

P2

mA

).

P2

Likewise, five (5) seconds after the last keypress, the stroke rate for

P2 is displayed and may be altered as above (i.e.

).

P2

The above example would result in the inverse control profile shown

in Figure 14 on the following page.

31

Page 32

Figure 14

The valid input range is from 0.5 to 21 mA. Below 0.5 mA, the

pump will be off. Above 21 mA, the E5 error code will be

displayed intermittently .

When programming strokes per hour, the maximum rate is 60.

P1 and P2 must BOTH BE SPM or BOTH BE SPH.

32

Page 33

13.0 Advanced Features and the Setup

Menu for HH9

Advanced features such as Batch Accumulate, Computer Interfacing,

and Automatic Voltage Compensation, may be selected and altered

in the Setup Menu of the Series HH9. The following configuration

chart describes each menu item, its description, and available

settings.

Menu Description/

Item Function Setting Notes

Software Revision Read Only

1 Batch Accumulate 0 = Disable Applies to External Multiply mode

1 =Enable

3 Automatic Voltage 0 = Disable Becomes active two (2) minutes after

Compensation 1 = Enable power up.

6 Input Pulse Width 0-60 Allows pulse widths of 1 to 60 mSec to be

set. Setting of 0 gives a debounce time of

approximately 1 mSec.

7 Integral Blowdown 0 =Disable Allows Activation of the integral blowdown

8 Integral Blowdown 0 to 255 Set solenoid ON time in seconds.

Solenoid ON Time

(Seconds)

9 Integral Blowdown 0 to 255 Set pump ON time in seconds.

Pump ON Time

(Seconds)

1 =Enable feature.

Note:

Allow 15 seconds after programming before disconnecting from power

to ensure latest changes are stored in nonvolatile memory.

33

Page 34

13.1 Accessing the Setup Menu

To access the Setup Menu, ensure that the pump is OFF and in the

Internal mode. Using the

(Up) key, bring the stroke rate to 100

SPM. At this point, keep the (Up) key pressed for five (5)

seconds. The LCD screen then displays the current software

revision, indicating that you have entered the Menu mode .

Press the

MODE

I

E

X

N

(Mode) key to scroll through the Menu Items. Use

TT

the (Up) or (Down) key to enable or disable menu

functions and program values.

To exit the Menu mode, press the

keys are pressed for 13 seconds, the display reverts to

STOP

(Start/Stop) key. Or, if no

START

INT

.

MIN

13.2 Menu Items

13.2.1 Menu Item 1: Batch Accumulate Enable/Disable

Batch Accumulate may be enabled (1) or disabled (0)

. Use the (Up) or (Down) key to change the

selection.

34

Page 35

13.2.2 Menu Item 3: Automatic Voltage Compensation

Menu item 3 enables (1) or disables (0) automatic voltage compensation. This unique feature allows a constant power level to be

delivered to the EPU of the pump, even when the voltage of the

external power source is fluctuating. This results in smooth pump

output in spite of fluctuating voltage and prevents overheating.

Automatic voltage compensation becomes active two minutes

after power up.

13.2.3 Menu Items 4 and 5: Flow Monitoring

These menu items are not applicable to the Series HH9 metering

pump. Menu item 4 must be disabled (0).

13.2.4 Menu Item 6: Input Signal Pulse Width (Debounce)

Menu Item 6 determines the "debounce" period (pulse width) to be

applied to incoming pulse (pacing) signals. The default value is 15,

which corresponds to a debounce value of 60 mSec . Each

unit corresponds to approximately 4 mSec. This means that in order

to be recognized, an input signal must be at least 60 mSec in duration.

This setting may need to be reduced from its maximum setting for

high frequency input pulse signals such as those from a Hall Effect

flowmeter.

35

Page 36

13.2.5 Menu Items 7, 8 and 9 Activate the Integral

Blowdown Feature

These Menu Items will require additional accessories and customer

supplied components.

This Integral Blowdown feature provides cooling tower control from

your LMI microprocessor pump when used in conjunction with a

pulse output type flowmeter (batch mode) or 4-20 mA signal

(milliamp mode). These signals can then be input into the pump to

provide activation of both the pump and a customer supplied solenoid

valve.

LMI's Relay Pack, Model RP-100A, must be ordered separately

to provide power to the customer supplied solenoid.

36

Page 37

A. Batch Mode

Programming Menu

Menu Item 1 Batch Accumulate Select: 0 = (Disable) or

1= (Enable)

Menu Item 7 Integral Blowdown: Select 1 = (Enable)

Menu Item 8 Solenoid ON time: Select 0 to 255 (Seconds)

Select "INT" mode and set the manual strokes per minute.

Select "EXT X" (multiply) mode (batch mode) and program

stroke count.

On receipt of a pulse from the flowmeter, the pump strokes the

programmed number of pulses. The batch value (multiply [X]

value) and manual SPM determines the length of time the pump

will be on.

On receipt of a pulse from the flowmeter, the solenoid valve is

opened. The solenoid remains open for the length of time

programmed in Menu Item 8. If another flowmeter pulse is

received before the above is completed the solenoid ON time

is extended by the time programmed in Menu Item 8.

37

Page 38

14.0 Troubleshooting

PROBLEM POSSIBLE CAUSE

Pump Will Not Prime 1. Pump not turned on or plugged in.

2. Output dials not set properly.

3. Pump suction not flooded.

4. Air trap in suction piping.

5. Too much pressure at discharge.

Pump Loses Prime 1. Solution container ran dry.

2. Pump suction not flooded.

3. Air trap in suction piping.

SOLUTION

1. Turn on pump/plug in pump.

2. Always prime pump with speed at 80% and stroke at 100%.

3. The HH pump requires a flooded suction. Reposition the pump

accordingly.

4. Be sure the suction piping is installed so that there are no air traps

(see section 6.2).

5. Depressurize discharge piping and verify that system pressure is

within the operating pressure of your pump.

1. Refill container with solution and reprime (see Section 6.0).

2. The HH pump requires a flooded suction. Reposition the pump

accordingly.

3. Be sure the suction piping is installed so that there are no air traps

(see section 6.2).

3938

Page 39

Troubleshooting (continued)

PROBLEM POSSIBLE CAUSE

Leakage at

Piping Connection

Low Output or Failure 1. Pump’s maximum pressure rating

to Pump Against is exceeded by injection pressure.

Pressure

Failure to Run 1. Pump not turned on or plugged in.

1. Piping not sealed.

2. Worn seal rings.

3. Solution attacking Liquid Handling

Assembly material.

2. Worn Check Valves.

3. Worn Plunger Seal.

4. Incorrect stroke length.

5. Piping run on discharge may be too

long.

2. EPU failure.

3. Pulser failure.

SOLUTION

1. Apply Teflon tape to NPT threads and tighten piping (see section 6.3).

2. Replace o-rings. Spare Parts (SP-987).

3. Consult your local distributor for alternate materials.

1. Injection pressure cannot exceed pump’s maximum pressure. See

pump data plate.

2. Replace check valve components. Spare Parts (SP- 987).

3. Replace plunger seal. Spare Parts (SP- 987).

4. Check zero on pump/Re-zero pump (see Section 9.0).

5. Longer piping runs may create frictional losses sufficient to reduce

pump’s pressure rating. Consult factory for more information.

1. Turn on or plug in pump.

2. Disassemble pump and measure the resistance of the EPU across the

EPU wires (yellow). For 120v HH pump the coil resistance should be

82 ohm. For 240v HH pump resistance should be should be 330 ohm.

3. The pulser should be replaced if EPU checks out OK. Consult supplier

or factory.

Excessive Pump Output 1. Syphoning. (Pumping downhill).

2. Little or no pressure at injection point.

3. Excessive strokes per minute.

1. Move injection point to a pressurized location or install a back

pressure valve.

2. If pressure at injection point is less than 200 psi (13.8 Bar)a back

pressure valve must be installed.

3. Replace pulser or resistor. Consult factory.

4140

Page 40

Appendix A: Input/Output Description

Pin 1

Pin 2

Black

Black

Black

Black

White

White

White

White

Pin 1

Pin 2

+

-

Pin 1

Pin 2

+

-

Pin 1

Pin 2

+

-

NPN Transistor

Switch

PNP Transistor

Opto Isolator

4-Pin Connector

Pacing (Pulse) Input / Opto-Isolated Input (HH7 and HH9 Only)

Methods of Triggering Pump.

Reference: 4-Pin Cable (P/N 33796) (HH9 Only)

4-Pin Cable (P/N 28368) (HH7 Only)

42

Appendix A

HH9 Only

Switch or transistor must be capable of switching 2mA at

15 VDC. When in the Divide mode, the switch must close then

open to trigger.

Minimum time in low impedance state (i.e. switch closed) is

60 mSec. by default.

Setup Menu Item 6 sets this value in multiples of 4mSec.

Example: Default = 4 X 15 = 60 mSec

Page 41

HH7 Only

Switch or transistor must be capable of switching 2mA at

15 VDC. Minimum time in low impedance state (on) is 50 mSec.

Minimum time in high impedance state (off) is 100 mSec.

Remote On/Off (Opto-isolated Input) (HH9 Only)

Switching this line to ground starts the pump. Releasing this line,

stops the pump. The

STOP

(Start/Stop) key will always override the

START

Remote Start/Stop.

Reference: 4-Pin Cable (P/N 33796)

Pin 4 Red Remote ON/OFF

Pin 3 Green Ground

Switch Closed = Start Pumping

Switch Open = Stop Pumping

Switch must be capable of switching 2 mA at +15 VDC.

Minimum time in low impedance state (i.e. Switch closed) is

approximately one (1) second.

Low-Level Input (P/N 29190) (HH7 and HH9 Only)

Opening the float switch (i.e. breaking the line from ground) stops the

pump and activates the alarm output.

Float Switch Closed - Pump Running

Float Switch Open - Pump Stopped - Alarm Activated

Switch must be capable of switching 2 mA at +15 VDC.

Minimum time in low impedance state (i.e. switch closed) is

approximately 1 second. (For use with LMI Float Switches [P/

N 29190.]

Low-level input can be used as a remote start/stop in the HH7.

Appendix A

43

Page 42

8-Pin Connector (HH9 Only)

Analog 0-20 mA Input

+0 to 20 mA Violet

-0 to 20 mA Green

8-Pin Cable (P/N 33738)

This is reverse polarity protected with a 22 Ohm impedance, a

resolution or 0.1 mA and an accuracy of +/- 0.2 mA typically.

15 v Output

The +15V Output (pin 1 Red) is regulated and capable of delivering

30 mA current.

Alarm Output

This is an opto-isolated open collector Darlington pair capable of

switching 25 mA at +24 VDC to within 1V of ground typically.

Reference: 8-Pin Cable (P/N 33738)

Pin 6 Yellow

GND Pin 2 Black

The output pair turns ON when an alarm condition occurs (i.e. low

level) and remains ON until the alarm condition is cleared.

Appendix A

44

Page 43

Application: Relay Switching

+15V

Pin 1

Red

Alarm Output

Pin 6

Yellow

Load

GND Pin 2 Black

Computer Alarm Output

This is an opto isolated, open collector output capable of switching

2 mA at +24 VDC to within 0.4V of ground typically.

Reference: 8-Pin Cable (P/N 33738)

Pin 8 Blue

GND Pin 2 Black

This output tracks the alarm output (i.e. the conditions for activating

and de-activating this output are the same as for the alarm output).

This output may be used to directly switch small loads such as

computer inputs and low current LEDs. It may also be used to

initiate switching of larger loads if suitable buffer circuitry is

provided.

Appendix A

45

Page 44

Application: Low Current LED Switching

+15V

Pin 1

Red

10K Ohms

Pin 8 Blue

*Low Current LED

1.0 mA = 10 mcd

GND Pin 2 Black

This is an opto-isolated, open collector output capable of switching

2 mA at +24 VDC to within 0.4V of ground typically.

Pacing Output (Opto-isolated Output)

Reference: 8-Pin Cable (P/N 33738)

Pin 5 Orange

GND Pin 2 Black

The output transistor turns ON at the start of a stroke and remains

ON for approximately 100 mSec.

This is an opto-isolated, open collector output capable of switching

2 mA at +24 VDC to within 0.4V of ground typically.

Appendix A

46

Page 45

Appendix B: Summary of Error Messages

(HH9 Only)

E1

E2

FLOW

E3

:

E4

X

E5

FLOW P12

INT

MIN

INT

EXT

MIN

EXT

EXT

is caused by a Low-Level fault with a Low-Level

Switch connected to the pump. The pump is stopped

and the alarm outputs are activated. This operates in all

Internal and External modes. The pump automatically

restarts when the fault is cleared.

indicates that the pump has lost prime. Again, the pump

is stopped and output alarms activated. Item 4 in the

Advanced Menu must be disabled (set to 0), it is not

usable with the HH9 pump.

is displayed in the External mode if the stroke rate

exceeds 100 SPM. The pump is NOT stopped and NO

alarm outputs are activated with this fault. To stop E3

flashing, clear the fault condition, then stop and restart

the pump.

is displayed in the External X (Batch) mode in two

situations. 1) If "Batch Accumulate" is disabled and a

pulse signal is received while the pump is counting

down. The pump is not stopped, and the alarms are not

activated. To clear the E4 message, the pump must be

stopped and restarted. 2) If "Batch Accumulate" is

enabled and the cumulative batch value exceeds 999, E4

will be displayed. The E4 message can only be cleared

if the pump is stopped and restarted.

is displayed in the mA External mode if the mA input

value exceeds 21.0 mA, whether the pump is running or

stopped. Again, the alarms are NOT activated. Once

the mA signal goes below 21.0 mA, the E5 error

message is cleared.

Appendix B

48

Page 46

ISO 9001 Certified

201 Ivyland Road

Ivyland, PA 18974 USA

TEL: (215) 293-0401

FAX: (215) 293-0445

http://www.lmipumps.com

© 2004 LMI Milton Roy - All Rights Reserved

Printed in USA

Specifications subject to change without notice.

49

Loading...

Loading...